Duct SUBARU TRIBECA 2009 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1886 of 2453

ME(H6DO)-20

General Description

MECHANICAL

2. GENERAL TOOL

E: PROCEDURE

It is possible to conduct the following service procedures with engine on vehicle, however, the procedures

described in this section are based on the condition that the engine is removed from vehicle.

•Camshaft

•Cylinder head

18471AA000 FUEL PIPE

ADAPTER

Used for measuring fuel pressure.

42075AG690 FUEL HOSE Used for measuring fuel pressure.

This is a genuine Subaru part.

TOOL NAME REMARKS

Compression gauge Used for measuring compression.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

Page 1893 of 2453

ME(H6DO)-27

Valve Clearance

MECHANICAL

8. Valve Clearance

A: INSPECTION

Inspection and adjustment of valve clearance

should be performed while engine is cold.

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Remove the under cover.

6) Lower the vehicle.

7) When inspecting RH side cylinders:

(1) Remove the air intake duct and air cleaner

case.

(2) Remove the fuel tank protector (RH).

(3) Disconnect the connector of oil pressure

switch.

(4) Remove the ignition coil.

Assembly.>

(5) Remove the rocker cover (RH).

8) When inspecting LH side cylinders:

(1) Disconnect the battery cable, and then re-

move the battery and battery carrier.

(2) Disconnect the PCV hose and blow-by hose

from rocker cover (LH).

(3) Remove the fuel pipe protector (LH).

(4) Remove the ignition coil.

Assembly.>

(5) Remove the rocker cover (LH).

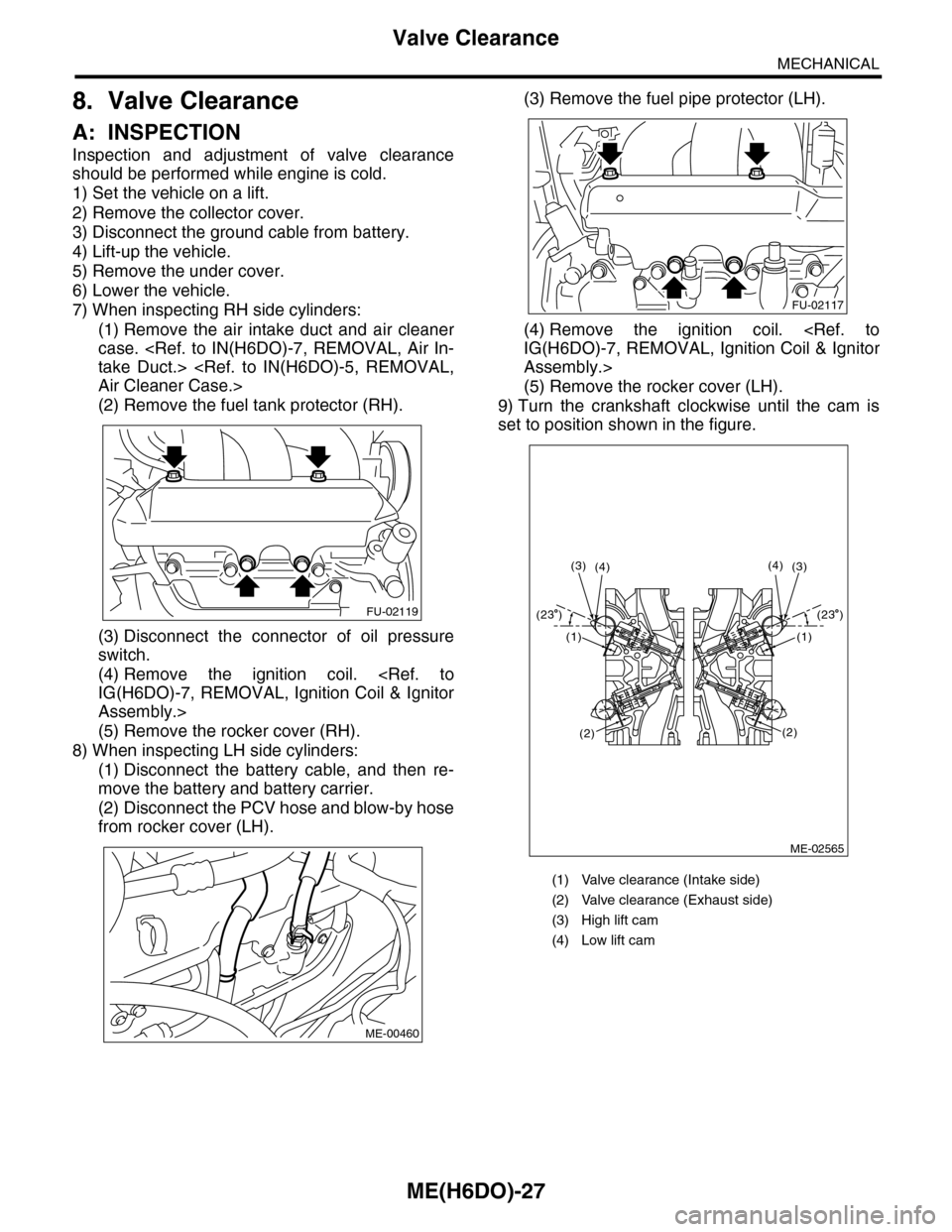

9) Turn the crankshaft clockwise until the cam is

set to position shown in the figure.

FU-02119

ME-00460

(1) Valve clearance (Intake side)

(2) Valve clearance (Exhaust side)

(3) High lift cam

(4) Low lift cam

FU-02117

ME-02565

(4)(3)(3)(4)

(1)

(2)

(1)

(2)

(23 )(23 )

Page 1898 of 2453

ME(H6DO)-32

Engine Assembly

MECHANICAL

10.Engine Assembly

A: REMOVAL

1) Set the vehicle on a lift.

2) Change the bolt mounting position from (A) to

(B), then completely open the front hood.

3) Remove the collector cover.

4) Collect the refrigerant from A/C system.

cedure.>

5) Release the fuel pressure.

6) Remove the battery from vehicle.

7) Remove the air intake duct, air cleaner case and

air intake chamber.

8) Remove the engine front cover.

9) Remove the radiator from the vehicle.

NOTE:

Protect the condenser so that it will not be dam-

aged.

10) Remove the fuel hose bracket.

11) Remove the V-belts.

12) Disconnect the A/C pressure hoses from A/C

compressor.

13) Remove the engine ground terminal.

14) Disconnect the following connector.

(1) Engine harness connectors

(2) Generator connector, terminal and A/C

compressor connector

(3) Power steering switch connector

ME-02652

(A)

(B)

CO-02176

ME-02653

ME-00476

ME-02654

Page 1904 of 2453

ME(H6DO)-38

Engine Assembly

MECHANICAL

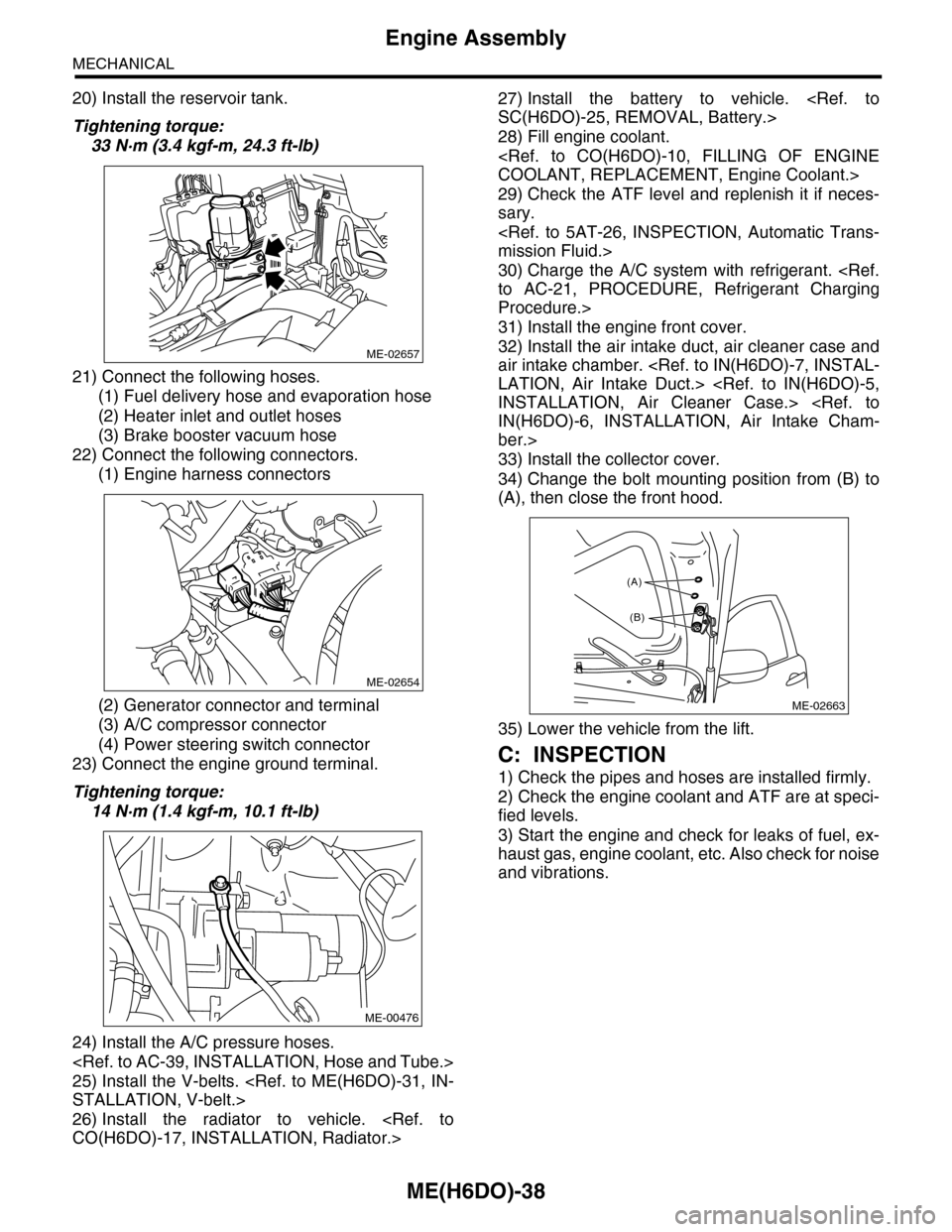

20) Install the reservoir tank.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

21) Connect the following hoses.

(1) Fuel delivery hose and evaporation hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

22) Connect the following connectors.

(1) Engine harness connectors

(2) Generator connector and terminal

(3) A/C compressor connector

(4) Power steering switch connector

23) Connect the engine ground terminal.

Tightening torque:

14 N·m (1.4 kgf-m, 10.1 ft-lb)

24) Install the A/C pressure hoses.

25) Install the V-belts.

26) Install the radiator to vehicle.

27) Install the battery to vehicle.

28) Fill engine coolant.

29) Check the ATF level and replenish it if neces-

sary.

30) Charge the A/C system with refrigerant.

Procedure.>

31) Install the engine front cover.

32) Install the air intake duct, air cleaner case and

air intake chamber.

ber.>

33) Install the collector cover.

34) Change the bolt mounting position from (B) to

(A), then close the front hood.

35) Lower the vehicle from the lift.

C: INSPECTION

1) Check the pipes and hoses are installed firmly.

2) Check the engine coolant and ATF are at speci-

fied levels.

3) Start the engine and check for leaks of fuel, ex-

haust gas, engine coolant, etc. Also check for noise

and vibrations.

ME-02657

ME-02654

ME-00476

ME-02663

(A)

(B)

Page 1928 of 2453

ME(H6DO)-62

Cylinder Block

MECHANICAL

21.Cylinder Block

A: REMOVAL

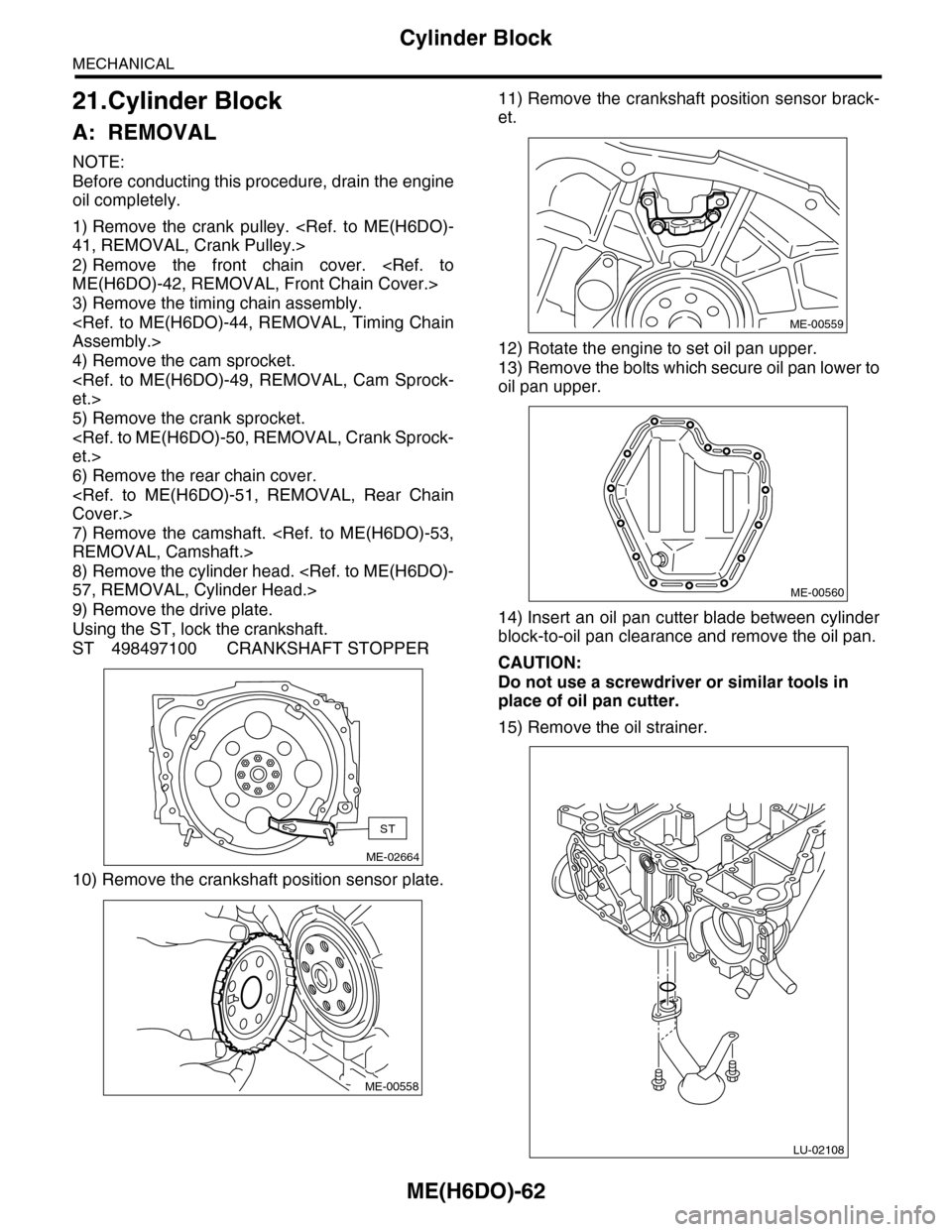

NOTE:

Before conducting this procedure, drain the engine

oil completely.

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain assembly.

4) Remove the cam sprocket.

5) Remove the crank sprocket.

6) Remove the rear chain cover.

7) Remove the camshaft.

8) Remove the cylinder head.

9) Remove the drive plate.

Using the ST, lock the crankshaft.

ST 498497100 CRANKSHAFT STOPPER

10) Remove the crankshaft position sensor plate.

11) Remove the crankshaft position sensor brack-

et.

12) Rotate the engine to set oil pan upper.

13) Remove the bolts which secure oil pan lower to

oil pan upper.

14) Insert an oil pan cutter blade between cylinder

block-to-oil pan clearance and remove the oil pan.

CAUTION:

Do not use a screwdriver or similar tools in

place of oil pan cutter.

15) Remove the oil strainer.

ME-02664

ST

ME-00558

ME-00559

ME-00560

LU-02108

Page 1950 of 2453

ME(H6DO)-84

Engine Trouble in General

MECHANICAL

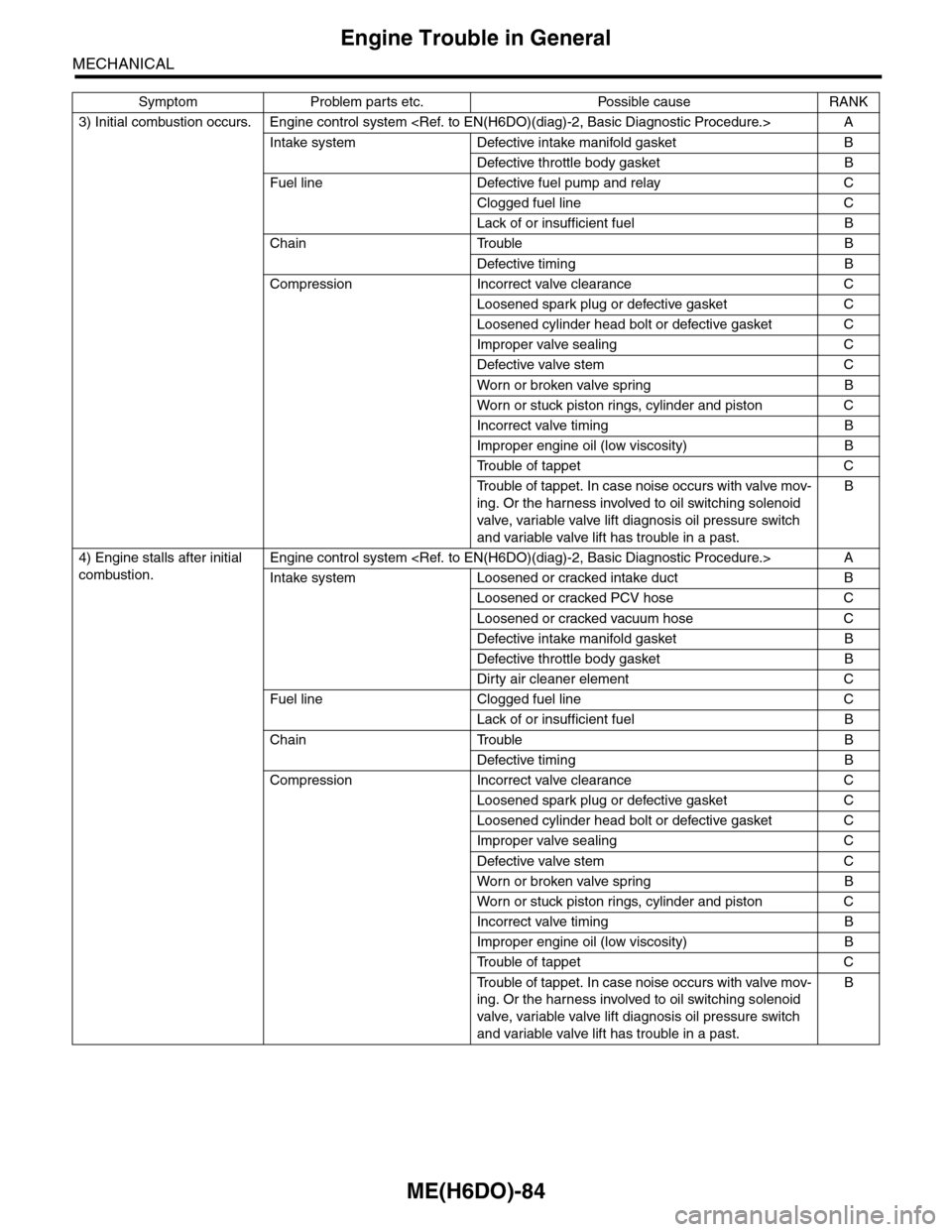

3) Initial combustion occurs. Engine control system

Intake system Defective intake manifold gasket B

Defective throttle body gasket B

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

4) Engine stalls after initial

combustion.

Engine control system

Intake system Loosened or cracked intake duct B

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose C

Defective intake manifold gasket B

Defective throttle body gasket B

Dirty air cleaner element C

Fuel line Clogged fuel line C

Lack of or insufficient fuel B

Chain Trouble B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Symptom Problem parts etc. Possible cause RANK

Page 1951 of 2453

ME(H6DO)-85

Engine Trouble in General

MECHANICAL

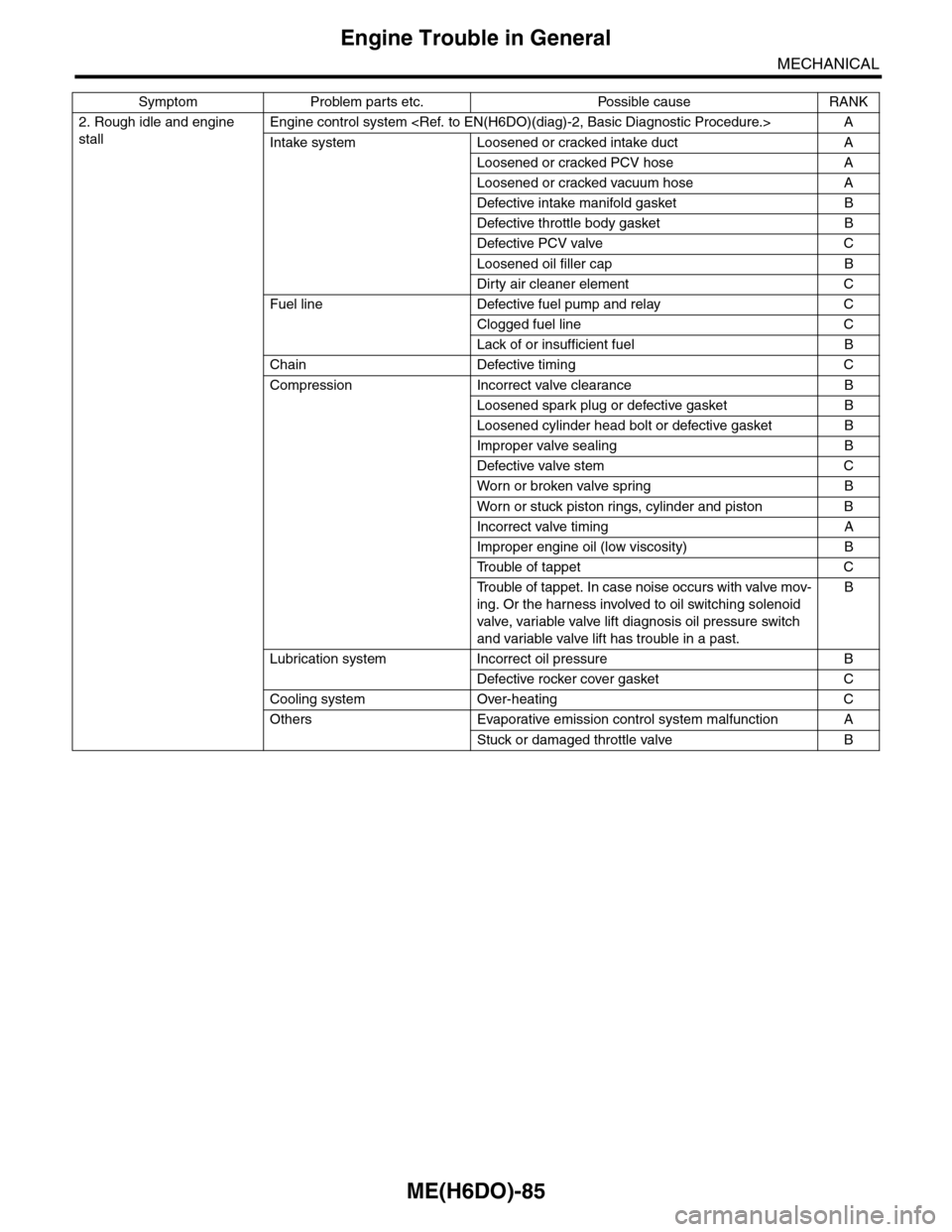

2. Rough idle and engine

stall

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Defective timing C

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Over-heating C

Others Evaporative emission control system malfunction A

Stuck or damaged throttle valve B

Symptom Problem parts etc. Possible cause RANK

Page 1952 of 2453

ME(H6DO)-86

Engine Trouble in General

MECHANICAL

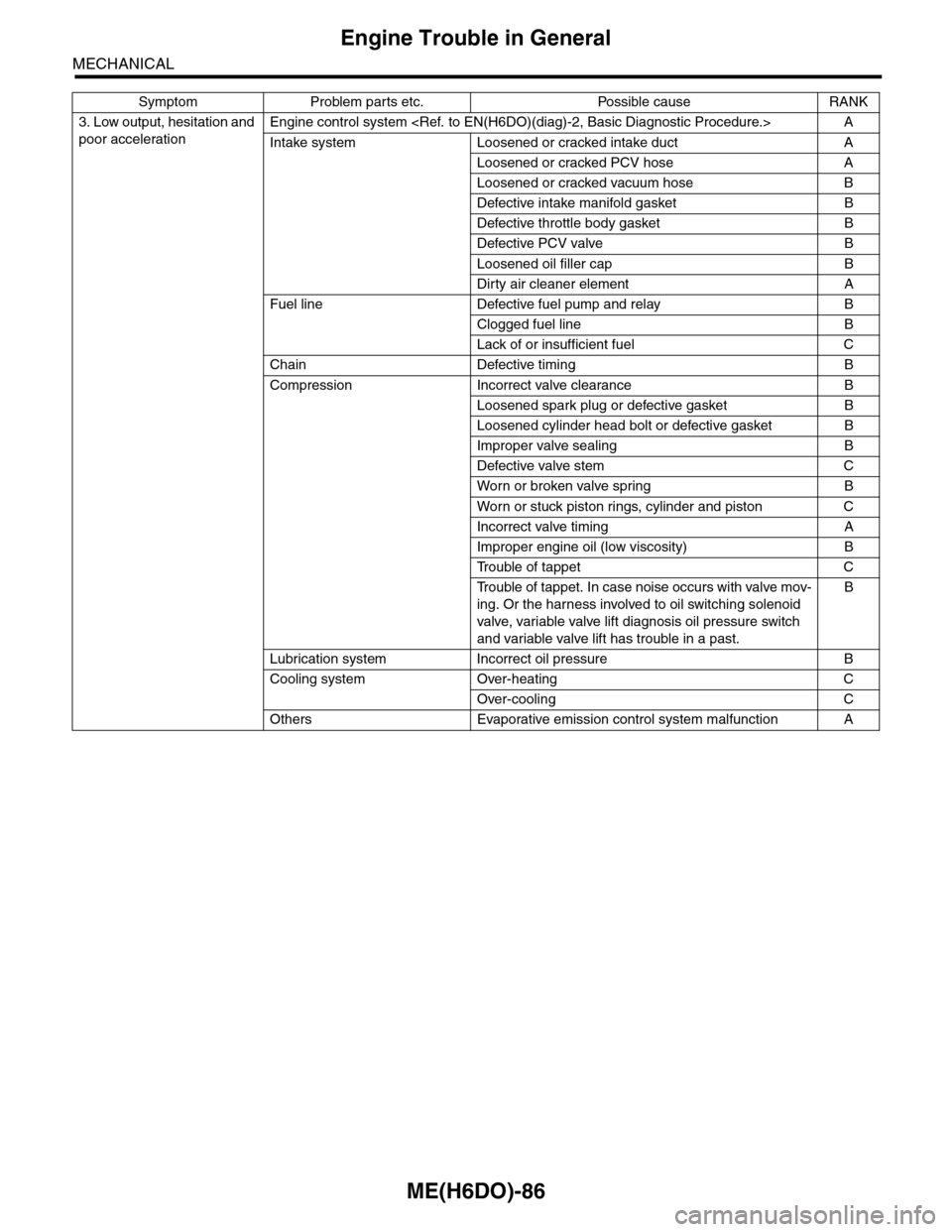

3. Low output, hesitation and

poor acceleration

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Cooling system Over-heating C

Over-cooling C

Others Evaporative emission control system malfunction A

Symptom Problem parts etc. Possible cause RANK

Page 1953 of 2453

ME(H6DO)-87

Engine Trouble in General

MECHANICAL

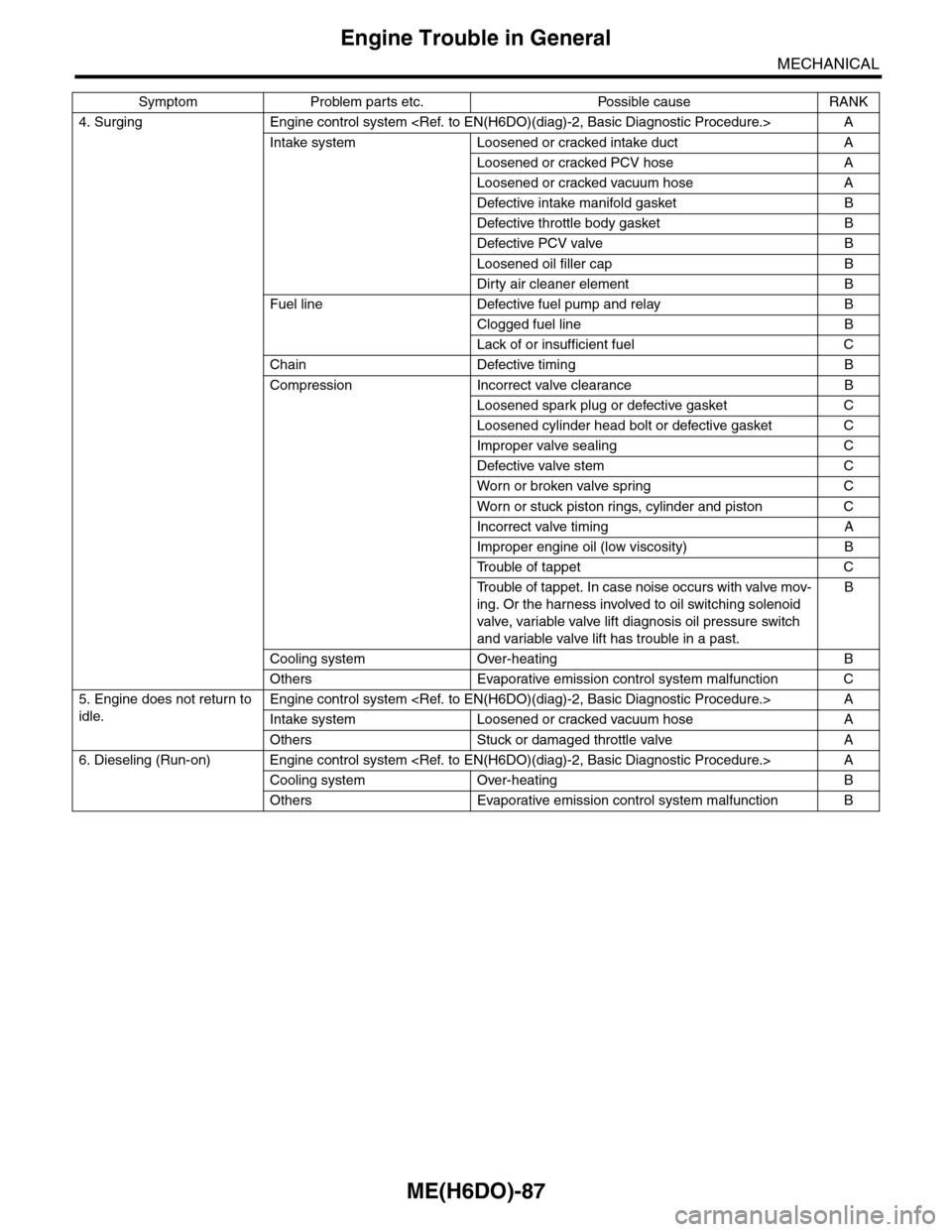

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating B

Others Evaporative emission control system malfunction C

5. Engine does not return to

idle.

Engine control system

Intake system Loosened or cracked vacuum hose A

Others Stuck or damaged throttle valve A

6. Dieseling (Run-on) Engine control system

Cooling system Over-heating B

Others Evaporative emission control system malfunction B

Symptom Problem parts etc. Possible cause RANK

Page 1954 of 2453

ME(H6DO)-88

Engine Trouble in General

MECHANICAL

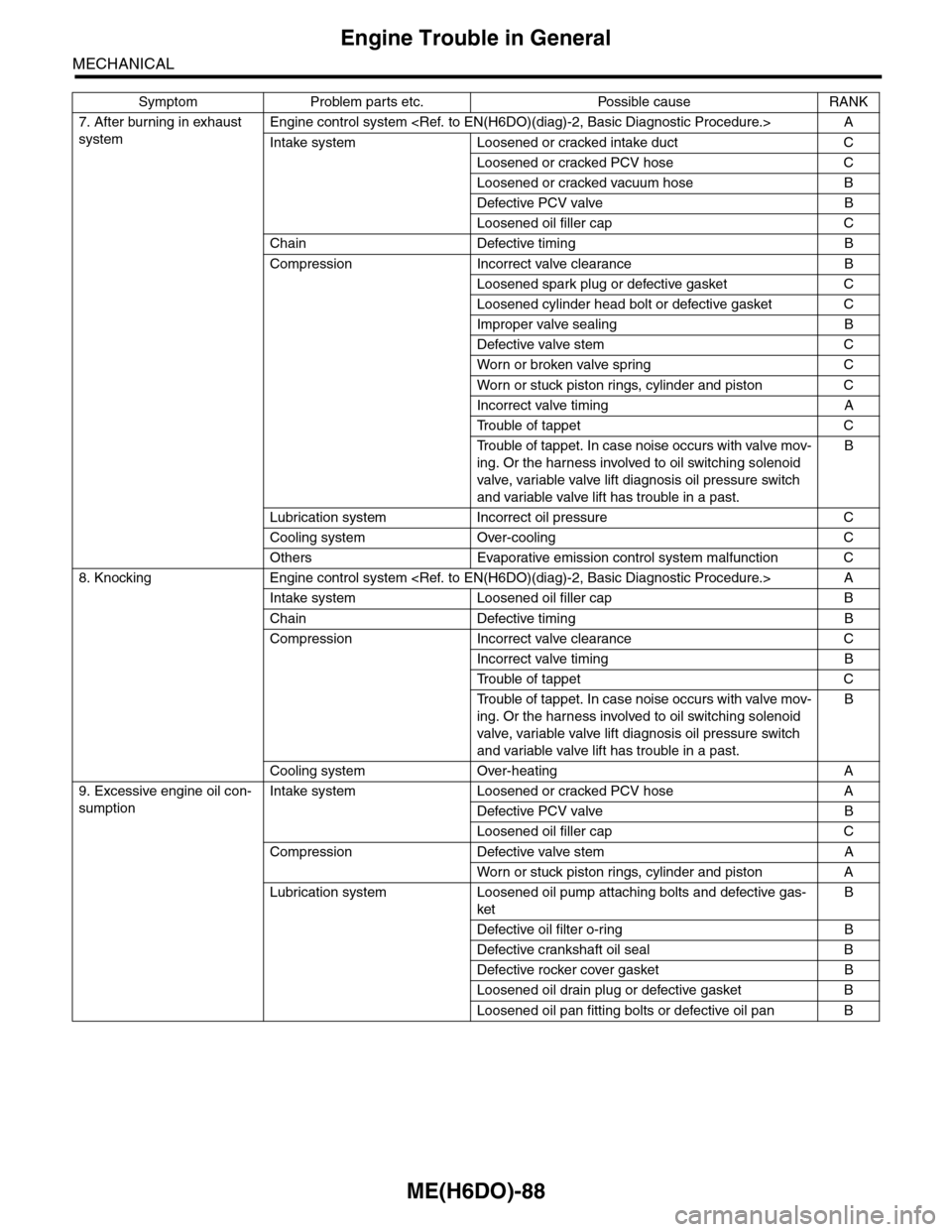

7. After burning in exhaust

system

Engine control system

Intake system Loosened or cracked intake duct C

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose B

Defective PCV valve B

Loosened oil filler cap C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure C

Cooling system Over-cooling C

Others Evaporative emission control system malfunction C

8. Knocking Engine control system

Intake system Loosened oil filler cap B

Chain Defective timing B

Compression Incorrect valve clearance C

Incorrect valve timing B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating A

9. Excessive engine oil con-

sumption

Intake system Loosened or cracked PCV hose A

Defective PCV valve B

Loosened oil filler cap C

Compression Defective valve stem A

Wor n or stuck piston r ings, cylinder and piston A

Lubrication system Loosened oil pump attaching bolts and defective gas-

ket

B

Defective oil filter o-ring B

Defective crankshaft oil seal B

Defective rocker cover gasket B

Loosened oil drain plug or defective gasket B

Loosened oil pan fitting bolts or defective oil pan B

Symptom Problem parts etc. Possible cause RANK