Duct SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 339 of 2453

AC-13

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

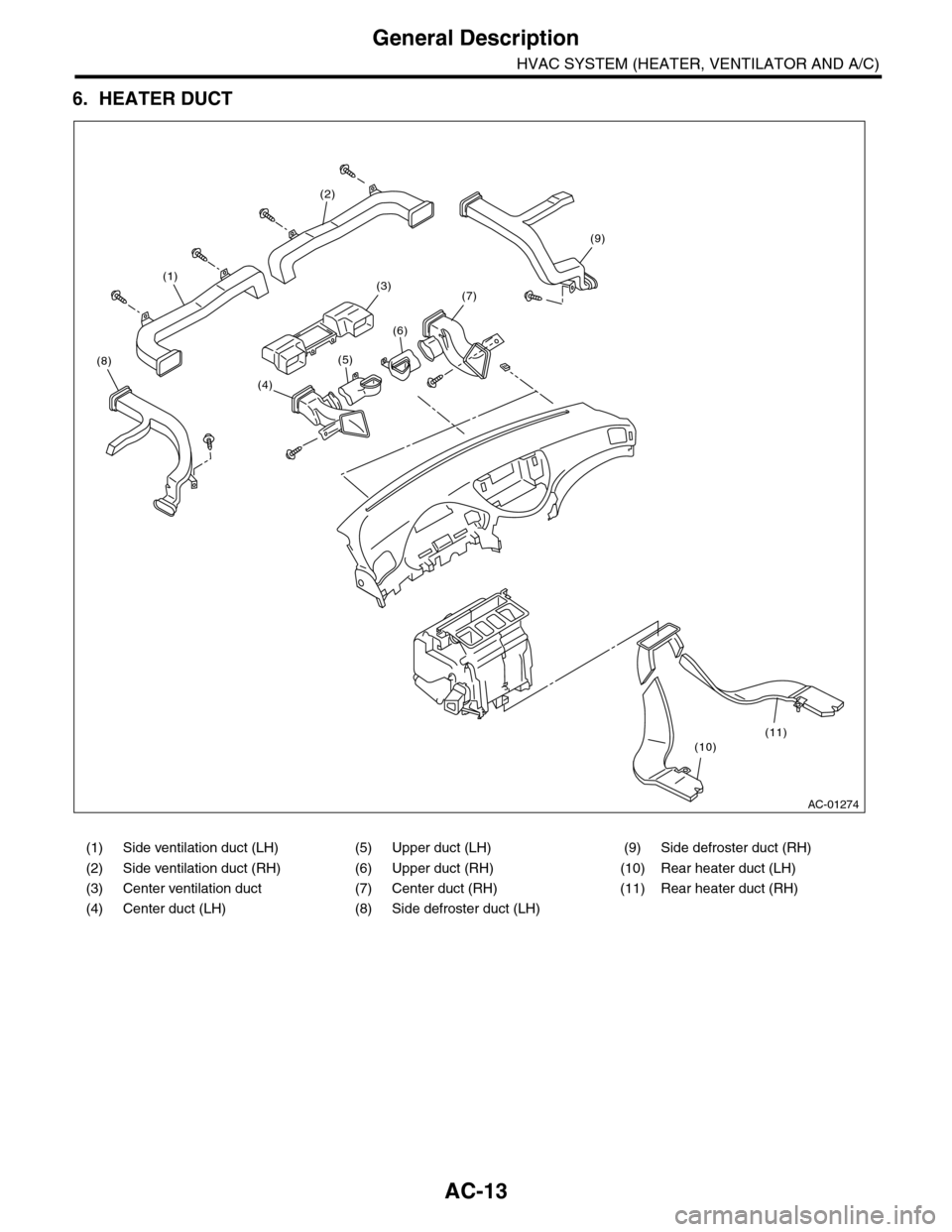

6. HEATER DUCT

(1) Side ventilation duct (LH) (5) Upper duct (LH) (9) Side defroster duct (RH)

(2) Side ventilation duct (RH) (6) Upper duct (RH) (10) Rear heater duct (LH)

(3) Center ventilation duct (7) Center duct (RH) (11) Rear heater duct (RH)

(4) Center duct (LH) (8) Side defroster duct (LH)

AC-01274

(7)

(5)

(6)

(10)(11)

(1)

(2)

(9)

(4)

(3)

(8)

Page 373 of 2453

AC-47

Heater Duct

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

26.Heater Duct

A: REMOVAL

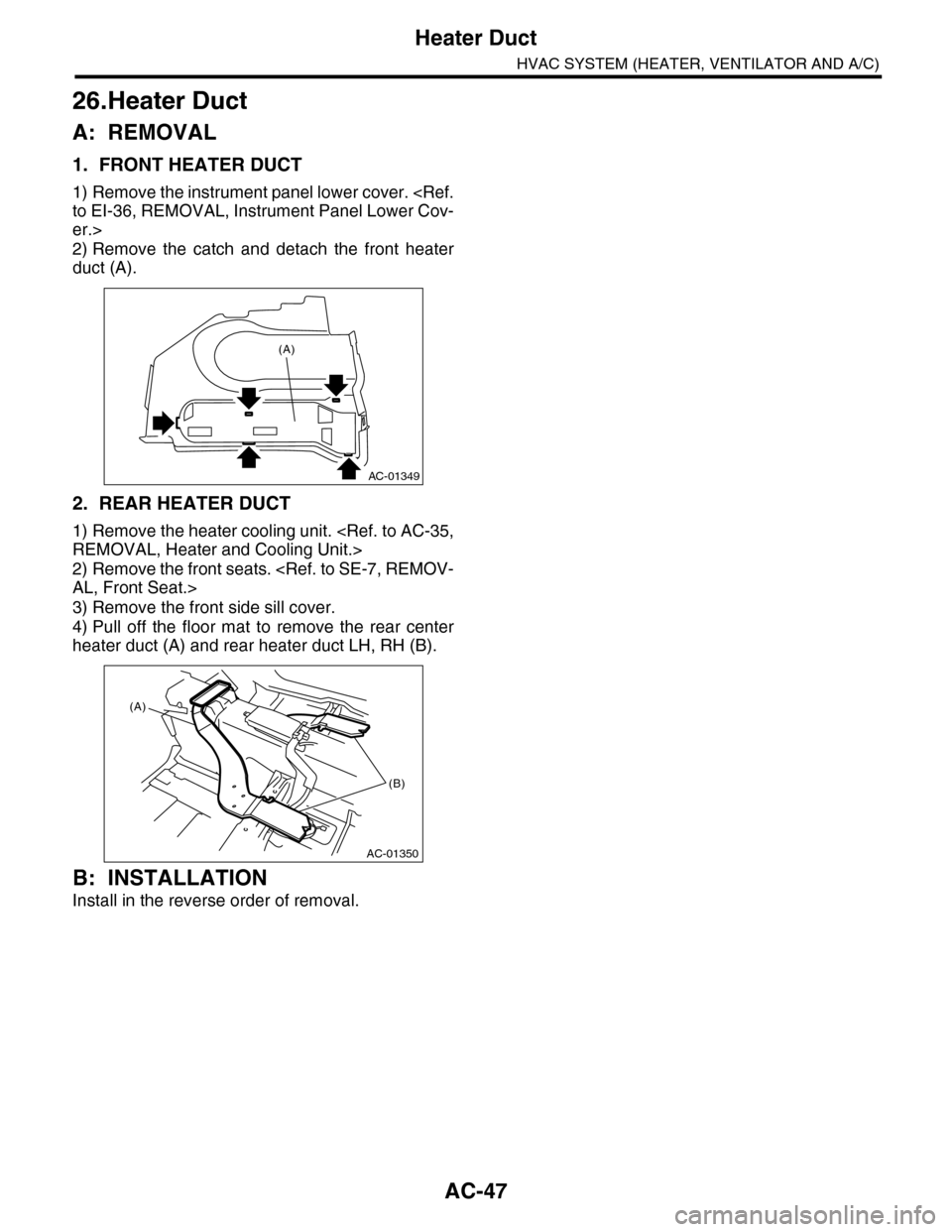

1. FRONT HEATER DUCT

1) Remove the instrument panel lower cover.

er.>

2) Remove the catch and detach the front heater

duct (A).

2. REAR HEATER DUCT

1) Remove the heater cooling unit.

2) Remove the front seats.

3) Remove the front side sill cover.

4) Pull off the floor mat to remove the rear center

heater duct (A) and rear heater duct LH, RH (B).

B: INSTALLATION

Install in the reverse order of removal.

AC-01349

(A)

AC-01350

(A)

(B)

Page 374 of 2453

AC-48

Heater Vent Duct

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

27.Heater Vent Duct

A: REMOVAL

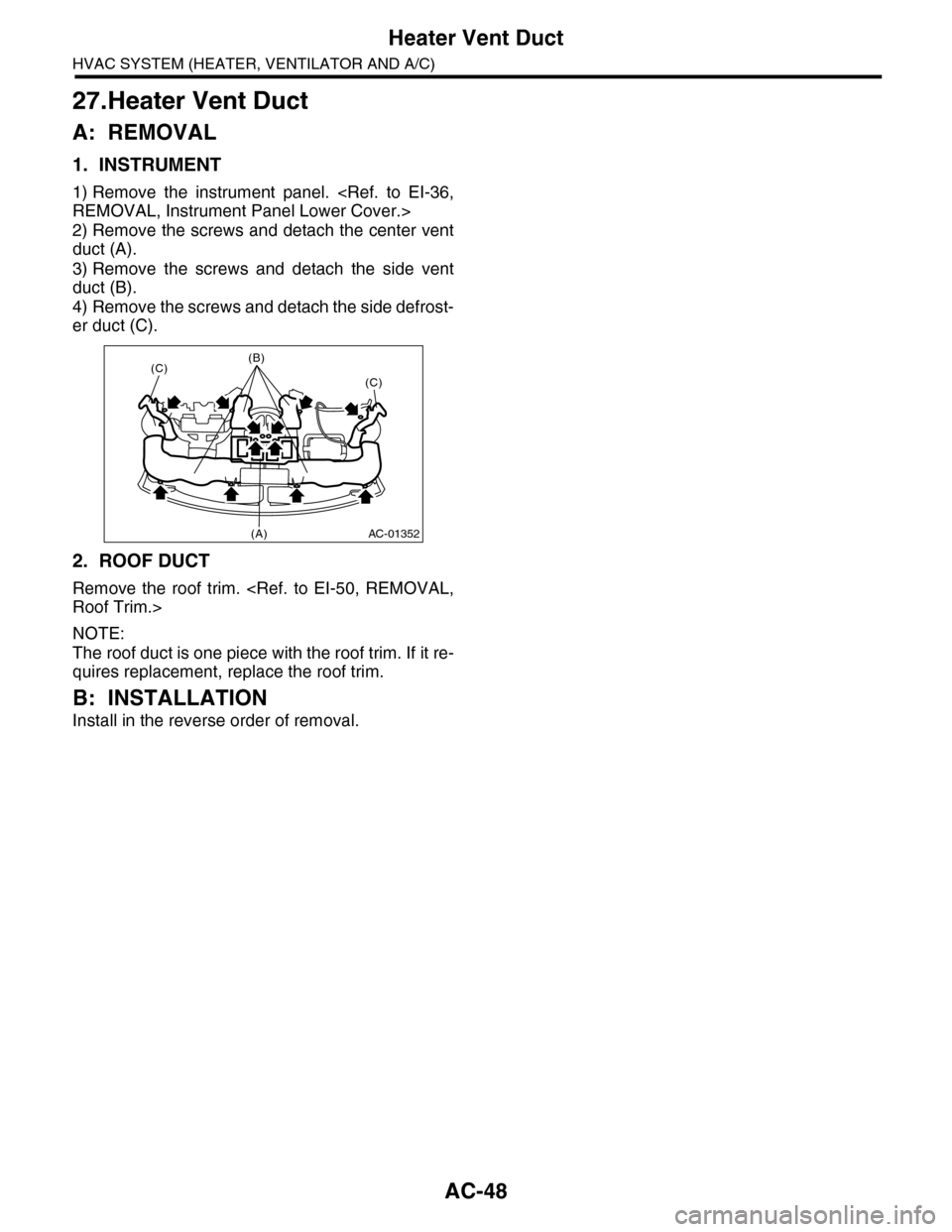

1. INSTRUMENT

1) Remove the instrument panel.

2) Remove the screws and detach the center vent

duct (A).

3) Remove the screws and detach the side vent

duct (B).

4) Remove the screws and detach the side defrost-

er duct (C).

2. ROOF DUCT

Remove the roof trim.

NOTE:

The roof duct is one piece with the roof trim. If it re-

quires replacement, replace the roof trim.

B: INSTALLATION

Install in the reverse order of removal.

AC-01352

(C)(B)

(C)

(A)

Page 376 of 2453

AC-50

General Diagnostic Table

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

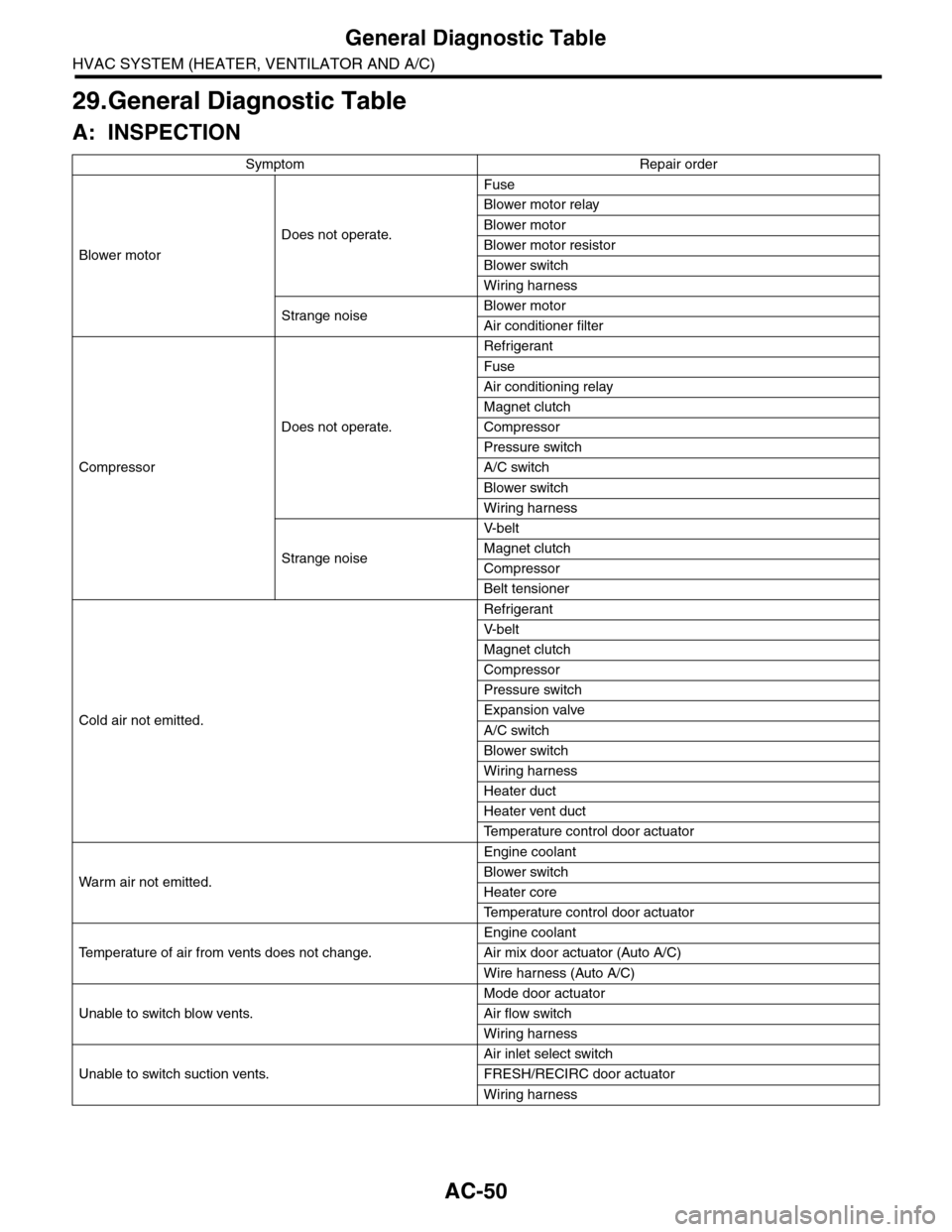

29.General Diagnostic Table

A: INSPECTION

Symptom Repair order

Blower motor

Does not operate.

Fuse

Blower motor relay

Blower motor

Blower motor resistor

Blower switch

Wiring harness

Strange noiseBlower motor

Air conditioner filter

Compressor

Does not operate.

Refrigerant

Fuse

Air conditioning relay

Magnet clutch

Compressor

Pressure switch

A/C switch

Blower switch

Wiring harness

Strange noise

V- b e l t

Magnet clutch

Compressor

Belt tensioner

Cold air not emitted.

Refrigerant

V- b e l t

Magnet clutch

Compressor

Pressure switch

Expansion valve

A/C switch

Blower switch

Wiring harness

Heater duct

Heater vent duct

Te m p e r a t u r e c o n t r o l d o o r a c t u a t o r

Wa r m a ir n ot e mi t te d .

Engine coolant

Blower switch

Heater core

Te m p e r a t u r e c o n t r o l d o o r a c t u a t o r

Te m p e r a t u r e o f a i r f r o m v e n t s d o e s n o t c h a n g e .

Engine coolant

Air mix door actuator (Auto A/C)

Wire harness (Auto A/C)

Unable to switch blow vents.

Mode door actuator

Air flow switch

Wiring harness

Unable to switch suction vents.

Air inlet select switch

FRESH/RECIRC door actuator

Wiring harness

Page 544 of 2453

LI-11

Headlight Assembly

LIGHTING SYSTEM

10.Headlight Assembly

A: REMOVAL

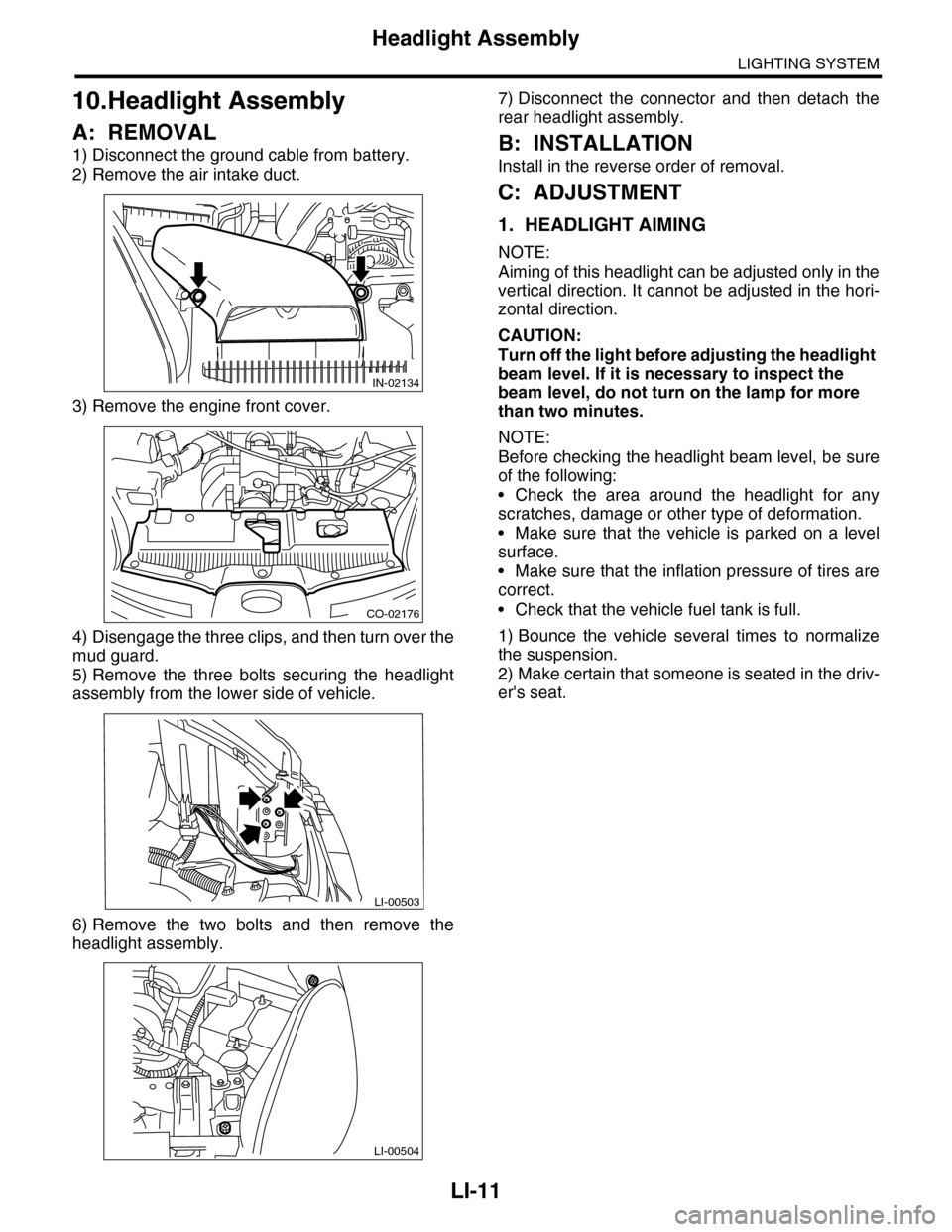

1) Disconnect the ground cable from battery.

2) Remove the air intake duct.

3) Remove the engine front cover.

4) Disengage the three clips, and then turn over the

mud guard.

5) Remove the three bolts securing the headlight

assembly from the lower side of vehicle.

6) Remove the two bolts and then remove the

headlight assembly.

7) Disconnect the connector and then detach the

rear headlight assembly.

B: INSTALLATION

Install in the reverse order of removal.

C: ADJUSTMENT

1. HEADLIGHT AIMING

NOTE:

Aiming of this headlight can be adjusted only in the

vertical direction. It cannot be adjusted in the hori-

zontal direction.

CAUTION:

Turn off the light before adjusting the headlight

beam level. If it is necessary to inspect the

beam level, do not turn on the lamp for more

than two minutes.

NOTE:

Before checking the headlight beam level, be sure

of the following:

•Check the area around the headlight for any

scratches, damage or other type of deformation.

•Make sure that the vehicle is parked on a level

surface.

•Make sure that the inflation pressure of tires are

correct.

•Check that the vehicle fuel tank is full.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er's seat.

IN-02134

CO-02176

LI-00503

LI-00504

Page 546 of 2453

LI-13

Headlight Bulb

LIGHTING SYSTEM

11.Headlight Bulb

A: REMOVAL

1. HIGH BEAM AND LOW BEAM

CAUTION:

•Because the halogen bulb operates at a high

temperature, dirt and oil on the bulb surface re-

duces the bulb's service life. Hold the flange

portion when replacing the bulb. Never touch

the glass portion.

•Do not leave the headlight without a bulb for

a long time. Dust, moisture, etc. entering the

headlight may affect its performance.

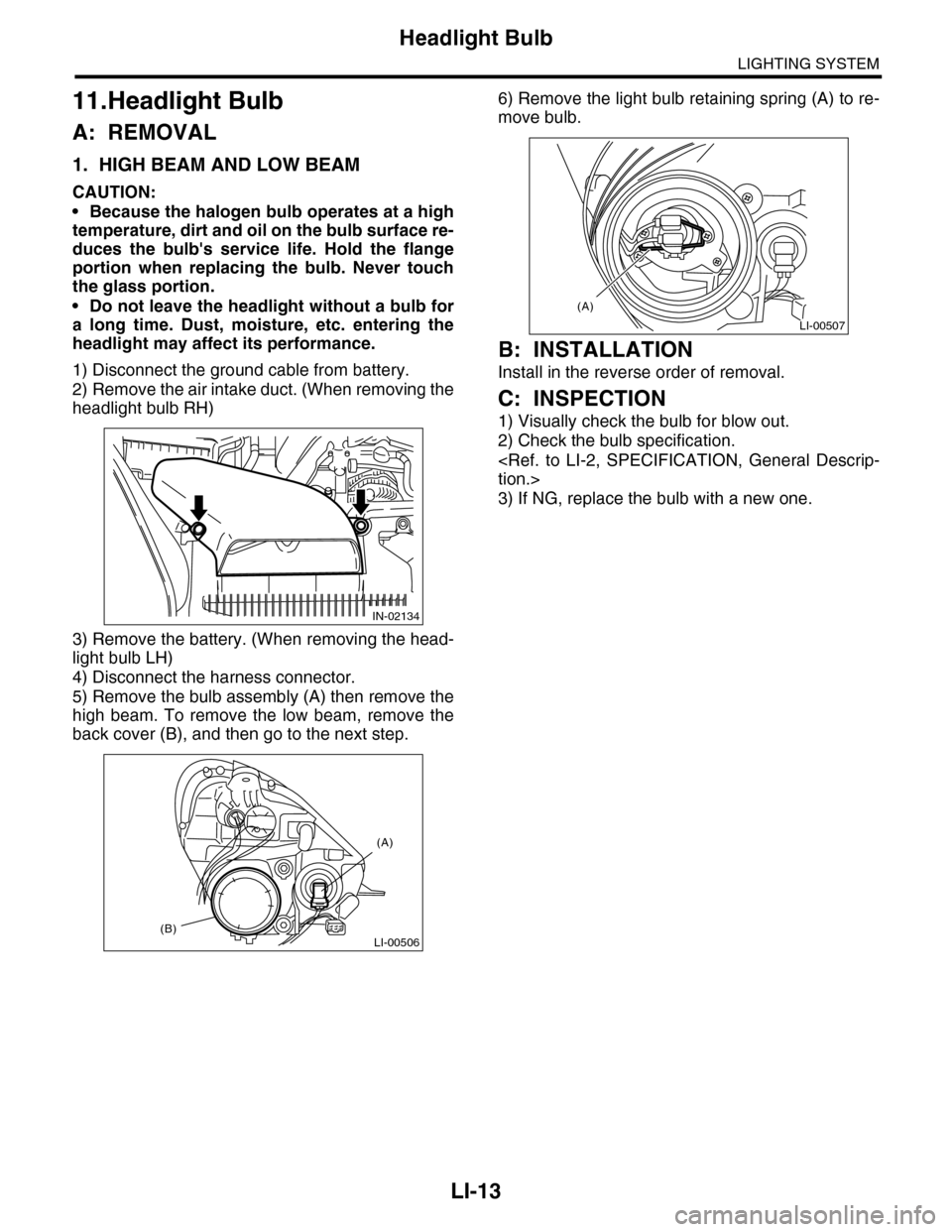

1) Disconnect the ground cable from battery.

2) Remove the air intake duct. (When removing the

headlight bulb RH)

3) Remove the battery. (When removing the head-

light bulb LH)

4) Disconnect the harness connector.

5) Remove the bulb assembly (A) then remove the

high beam. To remove the low beam, remove the

back cover (B), and then go to the next step.

6) Remove the light bulb retaining spring (A) to re-

move bulb.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1) Visually check the bulb for blow out.

2) Check the bulb specification.

3) If NG, replace the bulb with a new one.

IN-02134

LI-00506(B)

(A)

LI-00507

(A)

Page 684 of 2453

SL-55

Immobilizer Antenna

SECURITY AND LOCKS

26.Immobilizer Antenna

A: REMOVAL

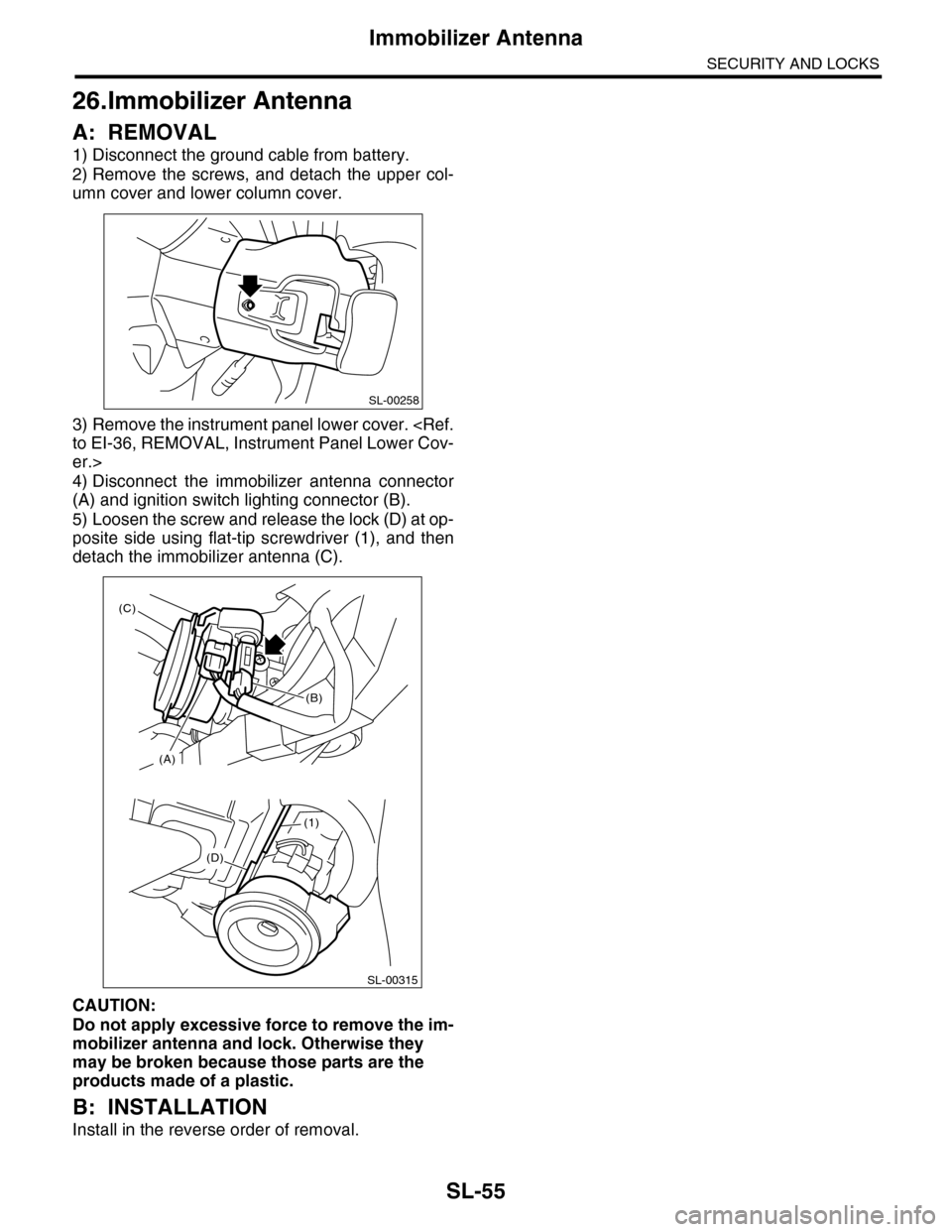

1) Disconnect the ground cable from battery.

2) Remove the screws, and detach the upper col-

umn cover and lower column cover.

3) Remove the instrument panel lower cover.

er.>

4) Disconnect the immobilizer antenna connector

(A) and ignition switch lighting connector (B).

5) Loosen the screw and release the lock (D) at op-

posite side using flat-tip screwdriver (1), and then

detach the immobilizer antenna (C).

CAUTION:

Do not apply excessive force to remove the im-

mobilizer antenna and lock. Otherwise they

may be broken because those parts are the

products made of a plastic.

B: INSTALLATION

Install in the reverse order of removal.

SL-00258

(D)

(1)

SL-00315

(A)

(C)

(B)

Page 917 of 2453

PS-37

Pipe Assembly

POWER ASSISTED SYSTEM (POWER STEERING)

6. Pipe Assembly

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and then remove the front

crossmember support plate and jack-up plate.

3) Remove the one pipe joint at the center of the

gearbox, and connect the vinyl hose to the pipe and

the joint. Discharge the fluid by turning the steering

wheel fully clockwise and counterclockwise. Dis-

charge the fluid similarly from other pipes.

4) Remove the clamp E from return hose and pres-

sure hose.

5) Disconnect the pipe D from return hose and pipe

C from pressure hose.

6) Remove the air intake duct.

(1) Front crossmember support plate

(2) Jack–up plate

(1) Pipe A

(2) Pipe B

(2)(1)

(1)

FS-00200

(2)

PS-00553

(1)

(1) Return hose

(2) Pressure hose

(3) Clamp E

(1) Pipe C

(2) Pipe D

(3) Pressure hose

(4) Return hose

PS-00537

(3)

(1)

(2)

PS-00538

(4)

(3)

(2)

(1)

Page 921 of 2453

PS-41

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

7. Oil Pump

A: REMOVAL

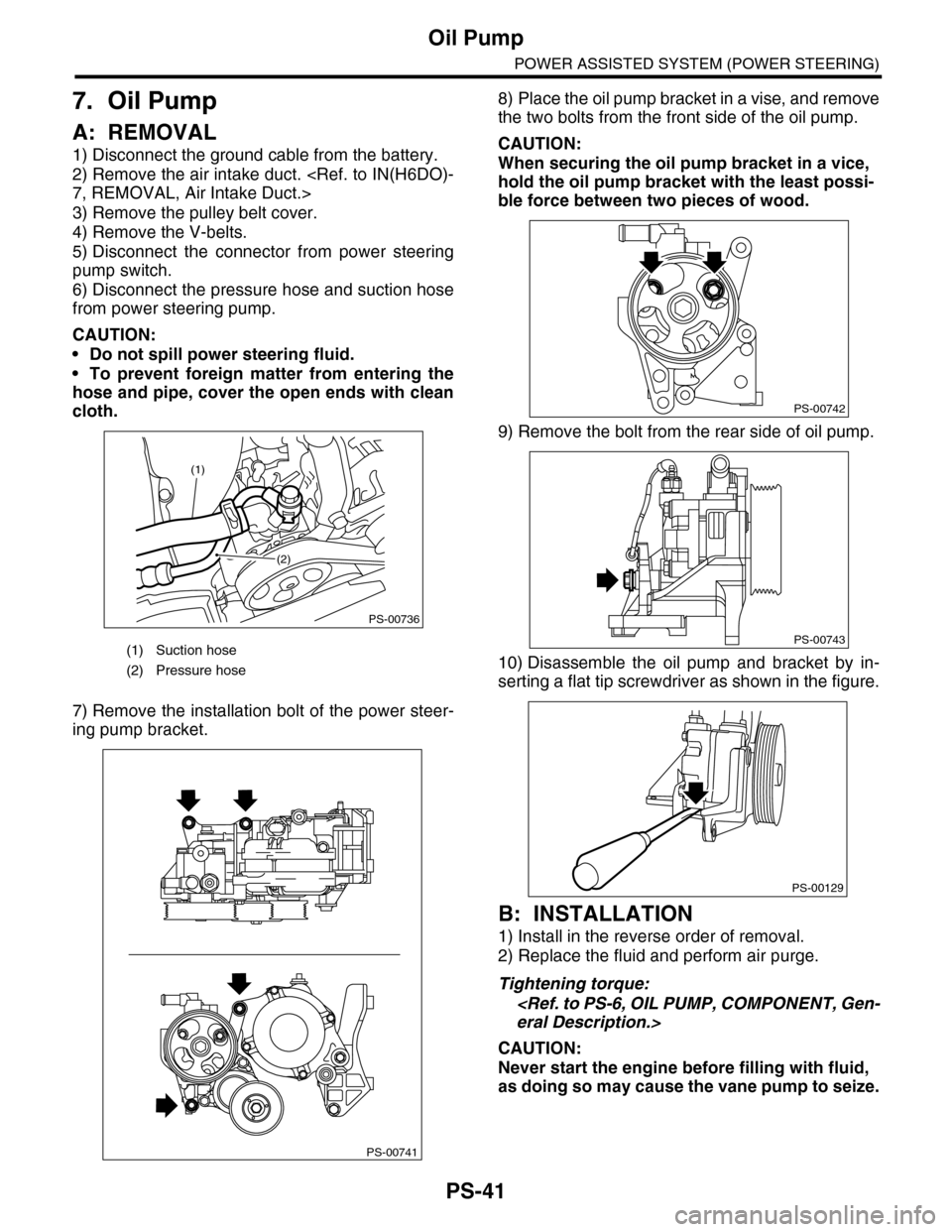

1) Disconnect the ground cable from the battery.

2) Remove the air intake duct.

3) Remove the pulley belt cover.

4) Remove the V-belts.

5) Disconnect the connector from power steering

pump switch.

6) Disconnect the pressure hose and suction hose

from power steering pump.

CAUTION:

•Do not spill power steering fluid.

•To prevent foreign matter from entering the

hose and pipe, cover the open ends with clean

cloth.

7) Remove the installation bolt of the power steer-

ing pump bracket.

8) Place the oil pump bracket in a vise, and remove

the two bolts from the front side of the oil pump.

CAUTION:

When securing the oil pump bracket in a vice,

hold the oil pump bracket with the least possi-

ble force between two pieces of wood.

9) Remove the bolt from the rear side of oil pump.

10) Disassemble the oil pump and bracket by in-

serting a flat tip screwdriver as shown in the figure.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the fluid and perform air purge.

Tightening torque:

CAUTION:

Never start the engine before filling with fluid,

as doing so may cause the vane pump to seize.

(1) Suction hose

(2) Pressure hose

PS-00736

(1)

(2)

PS-00741

PS-00742

PS-00743

PS-00129

Page 925 of 2453

PS-45

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

3) Rotating resistance of pulley

Service limit:

Maximum load: 9.22 N (0.94 kgf, 2.07 lb) or

less

NOTE:

•A rather higher value may be indicated when pul-

ley starts turning.

•Measure the load during rotation to make a judg-

ment.

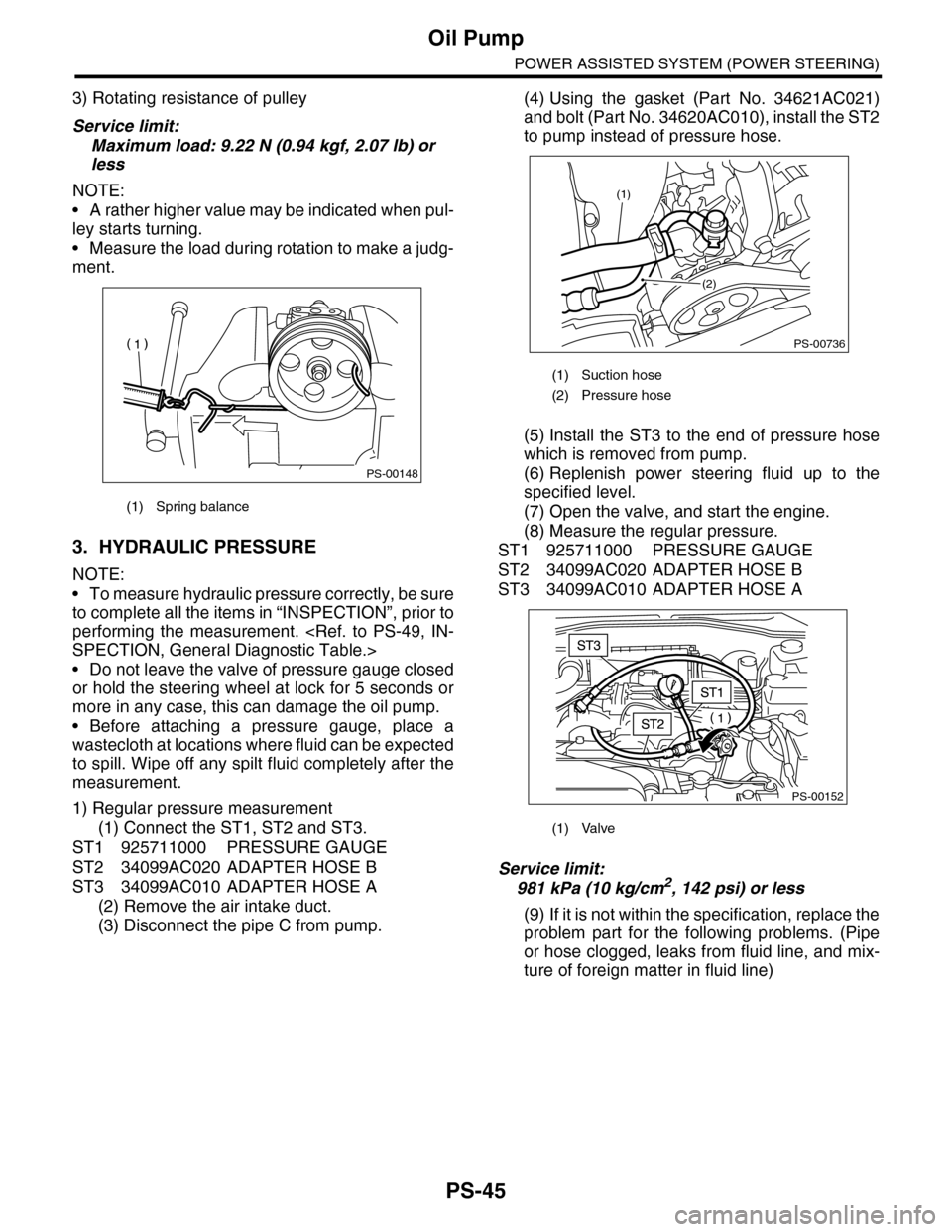

3. HYDRAULIC PRESSURE

NOTE:

•To measure hydraulic pressure correctly, be sure

to complete all the items in “INSPECTION”, prior to

performing the measurement.

•Do not leave the valve of pressure gauge closed

or hold the steering wheel at lock for 5 seconds or

more in any case, this can damage the oil pump.

•Before attaching a pressure gauge, place a

wastecloth at locations where fluid can be expected

to spill. Wipe off any spilt fluid completely after the

measurement.

1) Regular pressure measurement

(1) Connect the ST1, ST2 and ST3.

ST1 925711000 PRESSURE GAUGE

ST2 34099AC020 ADAPTER HOSE B

ST3 34099AC010 ADAPTER HOSE A

(2) Remove the air intake duct.

(3) Disconnect the pipe C from pump.

(4) Using the gasket (Part No. 34621AC021)

and bolt (Part No. 34620AC010), install the ST2

to pump instead of pressure hose.

(5) Install the ST3 to the end of pressure hose

which is removed from pump.

(6) Replenish power steering fluid up to the

specified level.

(7) Open the valve, and start the engine.

(8) Measure the regular pressure.

ST1 925711000 PRESSURE GAUGE

ST2 34099AC020 ADAPTER HOSE B

ST3 34099AC010 ADAPTER HOSE A

Service limit:

981 kPa (10 kg/cm2, 142 psi) or less

(9) If it is not within the specification, replace the

problem part for the following problems. (Pipe

or hose clogged, leaks from fluid line, and mix-

ture of foreign matter in fluid line)

(1) Spring balance

PS-00148

(1) Suction hose

(2) Pressure hose

(1) Valve

PS-00736

(1)

(2)

PS-00152