fuse SUBARU TRIBECA 2009 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 402 of 2453

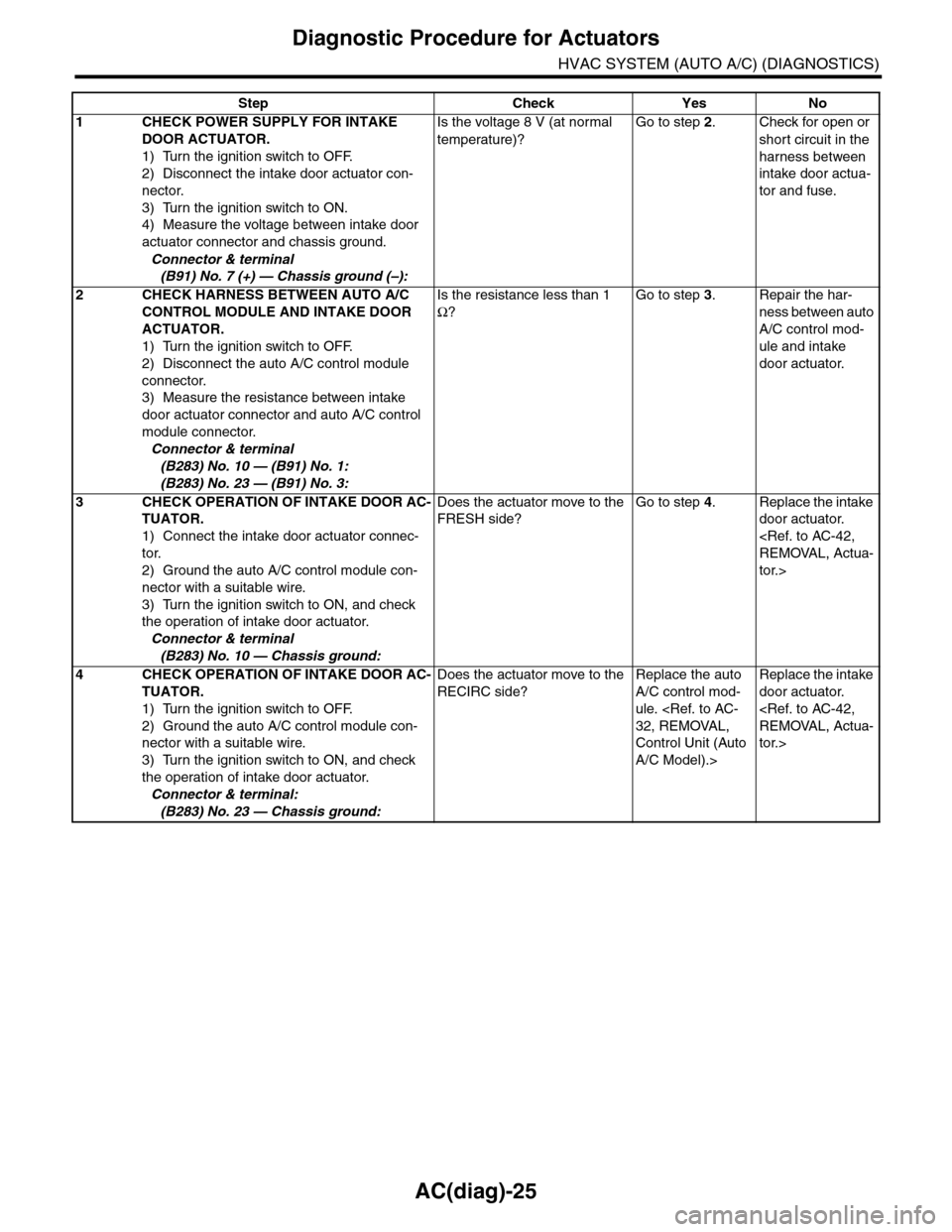

AC(diag)-25

Diagnostic Procedure for Actuators

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

Step Check Yes No

1CHECK POWER SUPPLY FOR INTAKE

DOOR ACTUATOR.

1) Turn the ignition switch to OFF.

2) Disconnect the intake door actuator con-

nector.

3) Turn the ignition switch to ON.

4) Measure the voltage between intake door

actuator connector and chassis ground.

Connector & terminal

(B91) No. 7 (+) — Chassis ground (–):

Is the voltage 8 V (at normal

temperature)?

Go to step 2.Check for open or

short circuit in the

harness between

intake door actua-

tor and fuse.

2CHECK HARNESS BETWEEN AUTO A/C

CONTROL MODULE AND INTAKE DOOR

ACTUATOR.

1) Turn the ignition switch to OFF.

2) Disconnect the auto A/C control module

connector.

3) Measure the resistance between intake

door actuator connector and auto A/C control

module connector.

Connector & terminal

(B283) No. 10 — (B91) No. 1:

(B283) No. 23 — (B91) No. 3:

Is the resistance less than 1

Ω?

Go to step 3.Repair the har-

ness between auto

A/C control mod-

ule and intake

door actuator.

3CHECK OPERATION OF INTAKE DOOR AC-

TUATOR.

1) Connect the intake door actuator connec-

tor.

2) Ground the auto A/C control module con-

nector with a suitable wire.

3) Turn the ignition switch to ON, and check

the operation of intake door actuator.

Connector & terminal

(B283) No. 10 — Chassis ground:

Does the actuator move to the

FRESH side?

Go to step 4.Replace the intake

door actuator.

tor.>

4CHECK OPERATION OF INTAKE DOOR AC-

TUATOR.

1) Turn the ignition switch to OFF.

2) Ground the auto A/C control module con-

nector with a suitable wire.

3) Turn the ignition switch to ON, and check

the operation of intake door actuator.

Connector & terminal:

(B283) No. 23 — Chassis ground:

Does the actuator move to the

RECIRC side?

Replace the auto

A/C control mod-

ule.

Control Unit (Auto

A/C Model).>

Replace the intake

door actuator.

tor.>

Page 416 of 2453

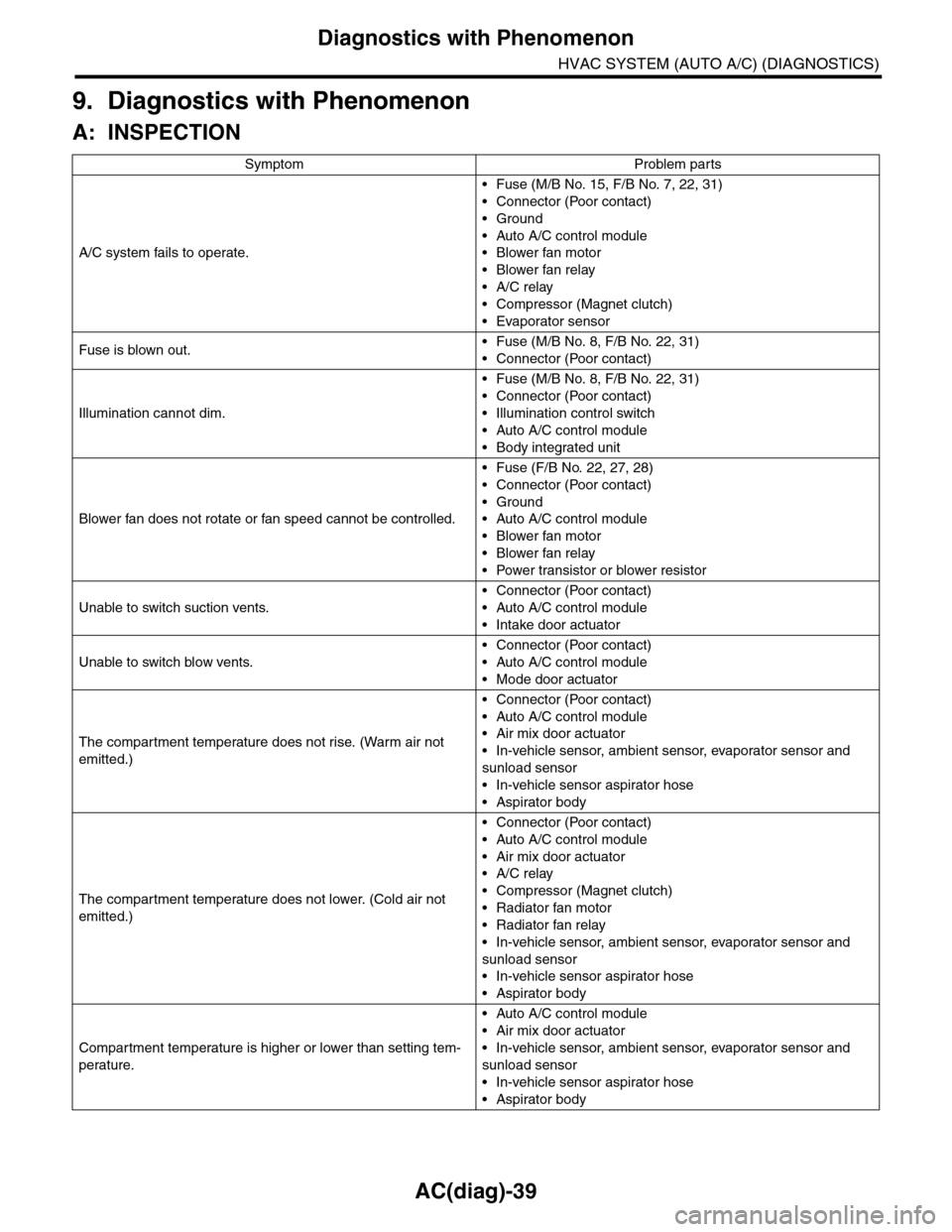

AC(diag)-39

Diagnostics with Phenomenon

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

9. Diagnostics with Phenomenon

A: INSPECTION

Symptom Problem parts

A/C system fails to operate.

•Fuse (M/B No. 15, F/B No. 7, 22, 31)

•Connector (Poor contact)

•Ground

•Auto A/C control module

•Blower fan motor

•Blower fan relay

•A/C relay

•Compressor (Magnet clutch)

•Evaporator sensor

Fuse is blown out.•Fuse (M/B No. 8, F/B No. 22, 31)

•Connector (Poor contact)

Illumination cannot dim.

•Fuse (M/B No. 8, F/B No. 22, 31)

•Connector (Poor contact)

•Illumination control switch

•Auto A/C control module

•Body integrated unit

Blower fan does not rotate or fan speed cannot be controlled.

•Fuse (F/B No. 22, 27, 28)

•Connector (Poor contact)

•Ground

•Auto A/C control module

•Blower fan motor

•Blower fan relay

•Power transistor or blower resistor

Unable to switch suction vents.

•Connector (Poor contact)

•Auto A/C control module

•Intake door actuator

Unable to switch blow vents.

•Connector (Poor contact)

•Auto A/C control module

•Mode door actuator

The compar tment temperature does not rise. (Warm air not

emitted.)

•Connector (Poor contact)

•Auto A/C control module

•Air mix door actuator

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

The compar tment temperature does not lower. (Cold air not

emitted.)

•Connector (Poor contact)

•Auto A/C control module

•Air mix door actuator

•A/C relay

•Compressor (Magnet clutch)

•Radiator fan motor

•Radiator fan relay

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

Compartment temperature is higher or lower than setting tem-

perature.

•Auto A/C control module

•Air mix door actuator

•In-vehicle sensor, ambient sensor, evaporator sensor and

sunload sensor

•In-vehicle sensor aspirator hose

•Aspirator body

Page 427 of 2453

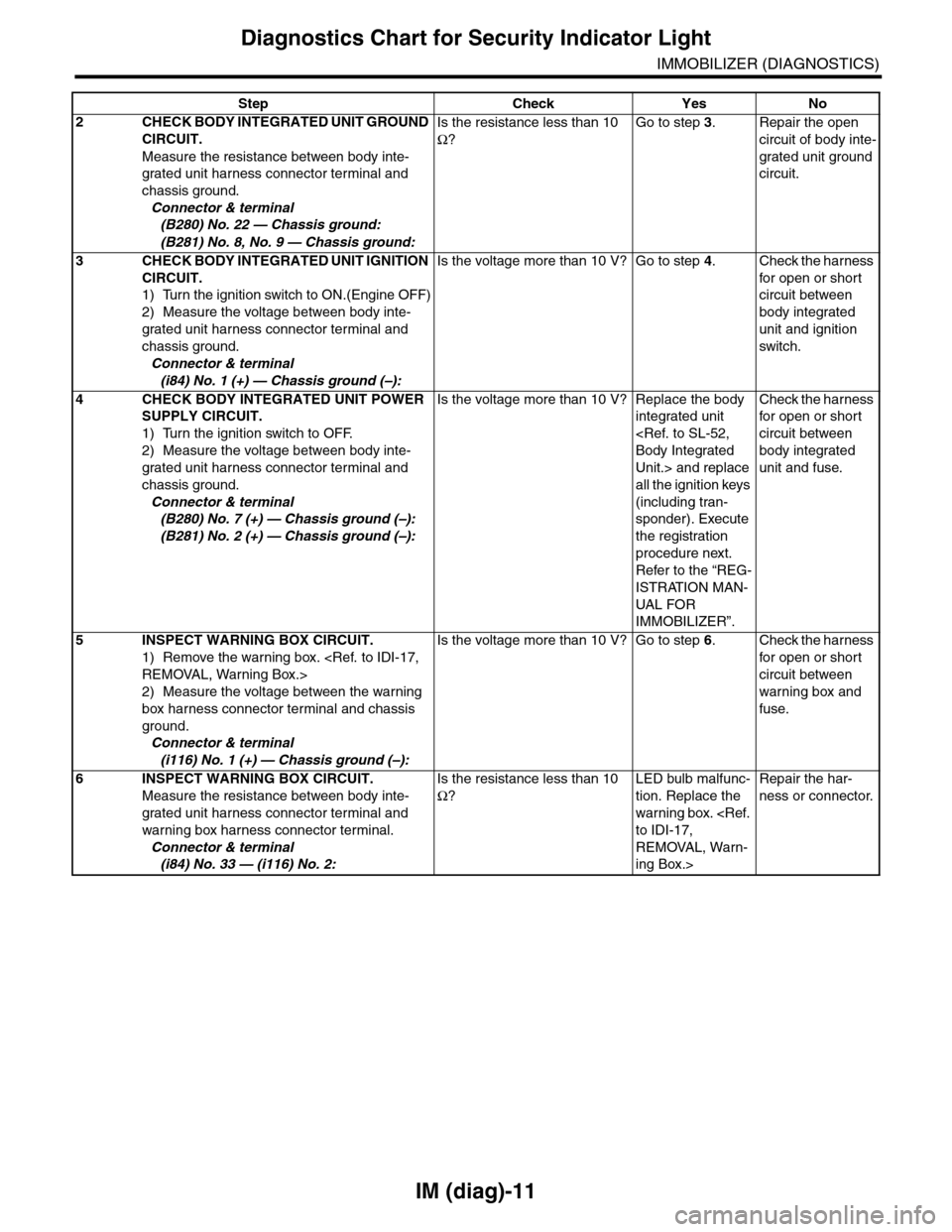

IM (diag)-11

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

2CHECK BODY INTEGRATED UNIT GROUND

CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 22 — Chassis ground:

(B281) No. 8, No. 9 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 3.Repair the open

circuit of body inte-

grated unit ground

circuit.

3CHECK BODY INTEGRATED UNIT IGNITION

CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Check the harness

for open or shor t

circuit between

body integrated

unit and ignition

switch.

4CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

5INSPECT WARNING BOX CIRCUIT.

1) Remove the warning box.

2) Measure the voltage between the warning

box harness connector terminal and chassis

ground.

Connector & terminal

(i116) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Check the harness

for open or shor t

circuit between

warning box and

fuse.

6INSPECT WARNING BOX CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

warning box harness connector terminal.

Connector & terminal

(i84) No. 33 — (i116) No. 2:

Is the resistance less than 10

Ω?

LED bulb malfunc-

tion. Replace the

warning box.

REMOVAL, Warn-

ing Box.>

Repair the har-

ness or connector.

Step Check Yes No

Page 429 of 2453

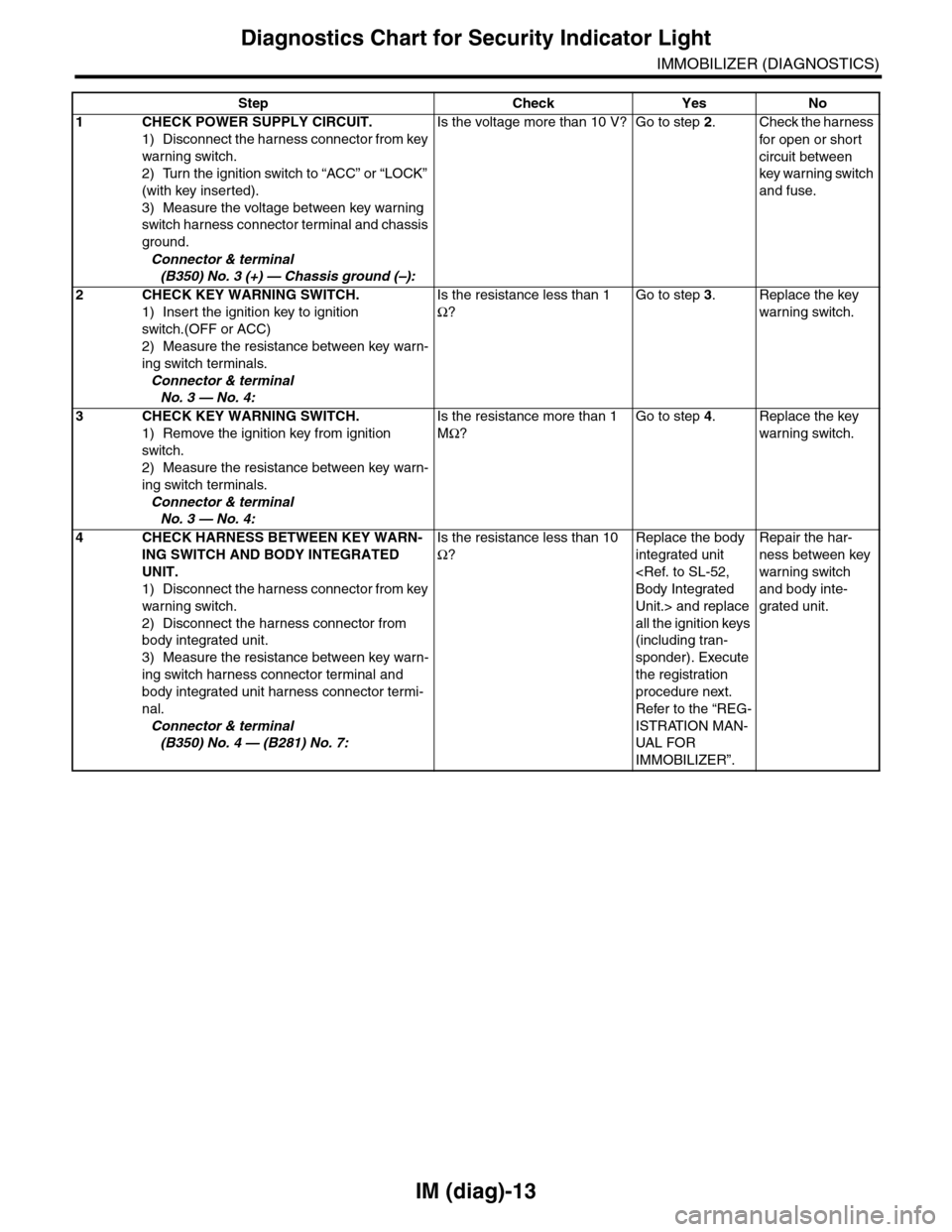

IM (diag)-13

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

Step Check Yes No

1CHECK POWER SUPPLY CIRCUIT.

1) Disconnect the harness connector from key

warning switch.

2) Turn the ignition switch to “ACC” or “LOCK”

(with key inserted).

3) Measure the voltage between key warning

switch harness connector terminal and chassis

ground.

Connector & terminal

(B350) No. 3 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

circuit between

key warning switch

and fuse.

2 CHECK KEY WARNING SWITCH.

1) Insert the ignition key to ignition

switch.(OFF or ACC)

2) Measure the resistance between key warn-

ing switch terminals.

Connector & terminal

No. 3 — No. 4:

Is the resistance less than 1

Ω?

Go to step 3.Replace the key

warning switch.

3 CHECK KEY WARNING SWITCH.

1) Remove the ignition key from ignition

switch.

2) Measure the resistance between key warn-

ing switch terminals.

Connector & terminal

No. 3 — No. 4:

Is the resistance more than 1

MΩ?

Go to step 4.Replace the key

warning switch.

4CHECK HARNESS BETWEEN KEY WARN-

ING SWITCH AND BODY INTEGRATED

UNIT.

1) Disconnect the harness connector from key

warning switch.

2) Disconnect the harness connector from

body integrated unit.

3) Measure the resistance between key warn-

ing switch harness connector terminal and

body integrated unit harness connector termi-

nal.

Connector & terminal

(B350) No. 4 — (B281) No. 7:

Is the resistance less than 10

Ω?

Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Repair the har-

ness between key

warning switch

and body inte-

grated unit.

Page 436 of 2453

IM (diag)-20

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

IMMOBILIZER (DIAGNOSTICS)

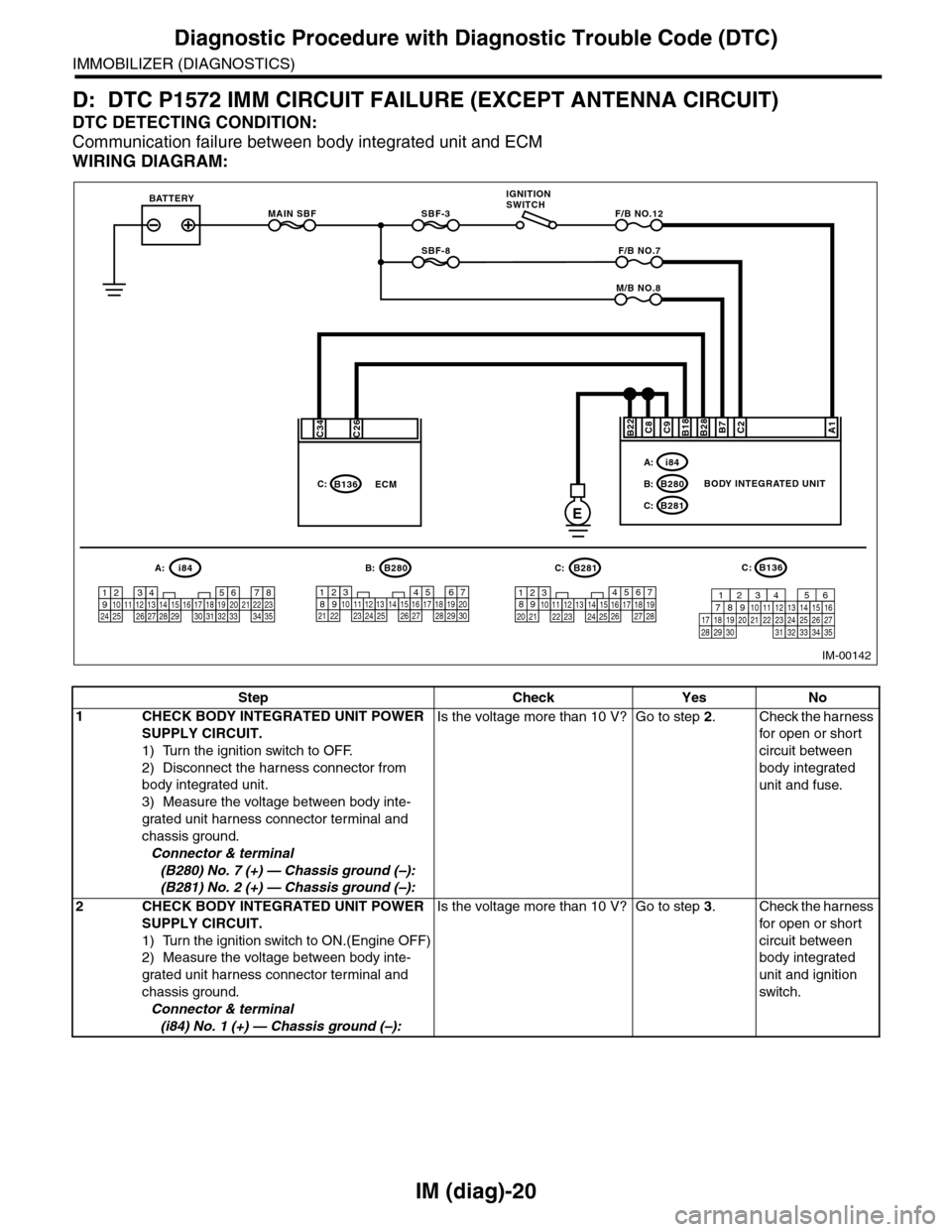

D: DTC P1572 IMM CIRCUIT FAILURE (EXCEPT ANTENNA CIRCUIT)

DTC DETECTING CONDITION:

Communication failure between body integrated unit and ECM

WIRING DIAGRAM:

MAIN SBF

SBF-8

SBF-3BATTERYF/B NO.12

IGNITIONSWITCH

A1B28B18C9C2B7C8

E

F/B NO.7

M/B NO.8

BODY INTEGRATED UNIT

i84A:

B280B:

B281C:

B22

567821943102422 23 25111213141526 27281617181920 21

B281i84

1234567891011121314151617181920212223242526272829303132333435

5467821931022 231112131415242526 2716171828 29192021 30

B280A:C:B:B136C:

C26C34

B136C:ECM

IM-00142

16101112131415252430

9871718192028212223293231

123456

2726333435

Step Check Yes No

1CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

body integrated unit.

3) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

2CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

circuit between

body integrated

unit and ignition

switch.

Page 446 of 2453

IDI-7

Combination Meter System

INSTRUMENTATION/DRIVER INFO

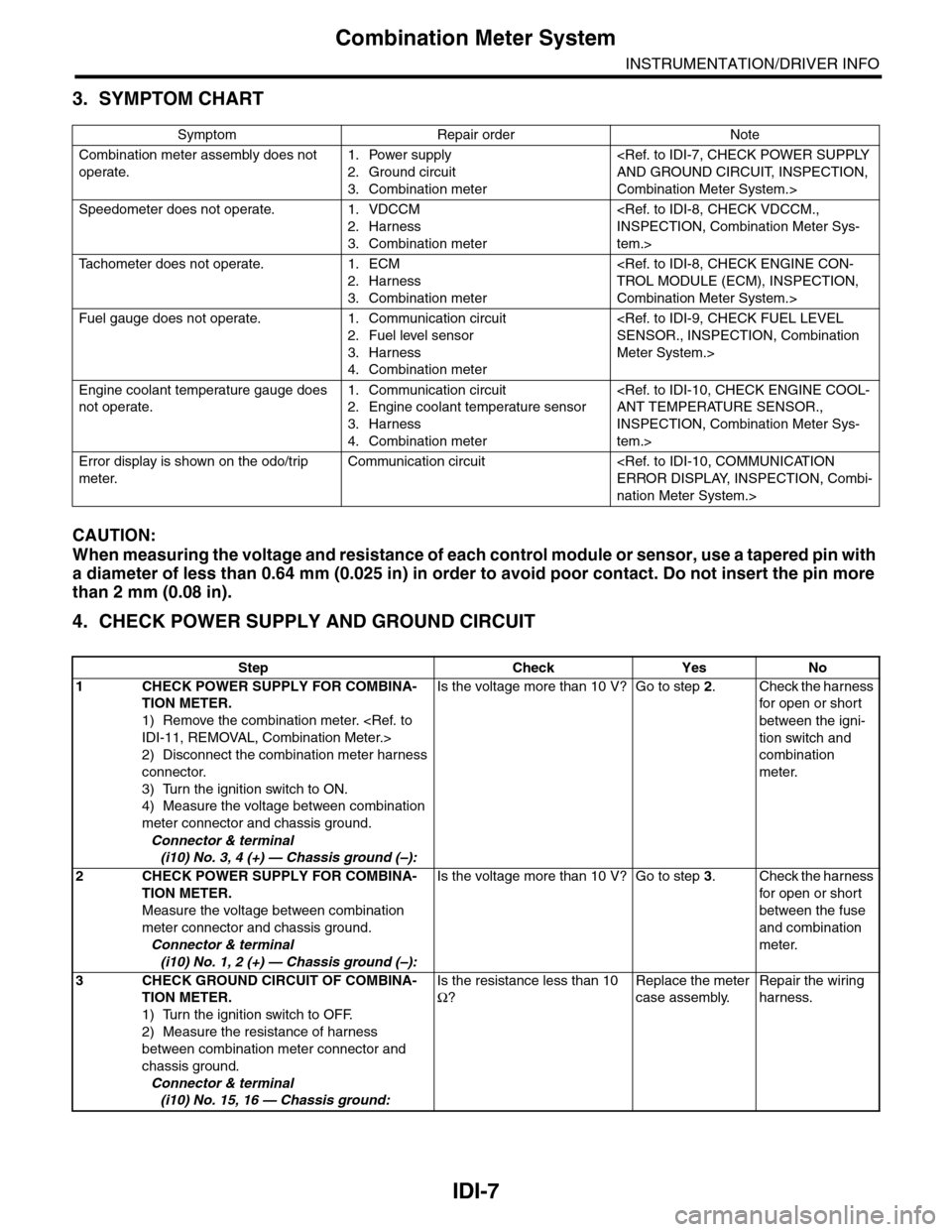

3. SYMPTOM CHART

CAUTION:

When measuring the voltage and resistance of each control module or sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

4. CHECK POWER SUPPLY AND GROUND CIRCUIT

Symptom Repair order Note

Combination meter assembly does not

operate.

1. Power supply

2. Ground circuit

3. Combination meter

Combination Meter System.>

Speedometer does not operate. 1. VDCCM

2. Harness

3. Combination meter

tem.>

Ta c h o m e t e r d o e s n o t o p e r a t e . 1 . E C M

2. Harness

3. Combination meter

Combination Meter System.>

Fuel gauge does not operate. 1. Communication circuit

2. Fuel level sensor

3. Harness

4. Combination meter

Meter System.>

Engine coolant temperature gauge does

not operate.

1. Communication circuit

2. Engine coolant temperature sensor

3. Harness

4. Combination meter

INSPECTION, Combination Meter Sys-

tem.>

Error display is shown on the odo/trip

meter.

Communication circuit

nation Meter System.>

Step Check Yes No

1CHECK POWER SUPPLY FOR COMBINA-

TION METER.

1) Remove the combination meter.

2) Disconnect the combination meter harness

connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 3, 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

between the igni-

tion switch and

combination

meter.

2CHECK POWER SUPPLY FOR COMBINA-

TION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 1, 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

between the fuse

and combination

meter.

3CHECK GROUND CIRCUIT OF COMBINA-

TION METER.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between combination meter connector and

chassis ground.

Connector & terminal

(i10) No. 15, 16 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 461 of 2453

LAN(diag)-5

General Description

LAN SYSTEM (DIAGNOSTICS)

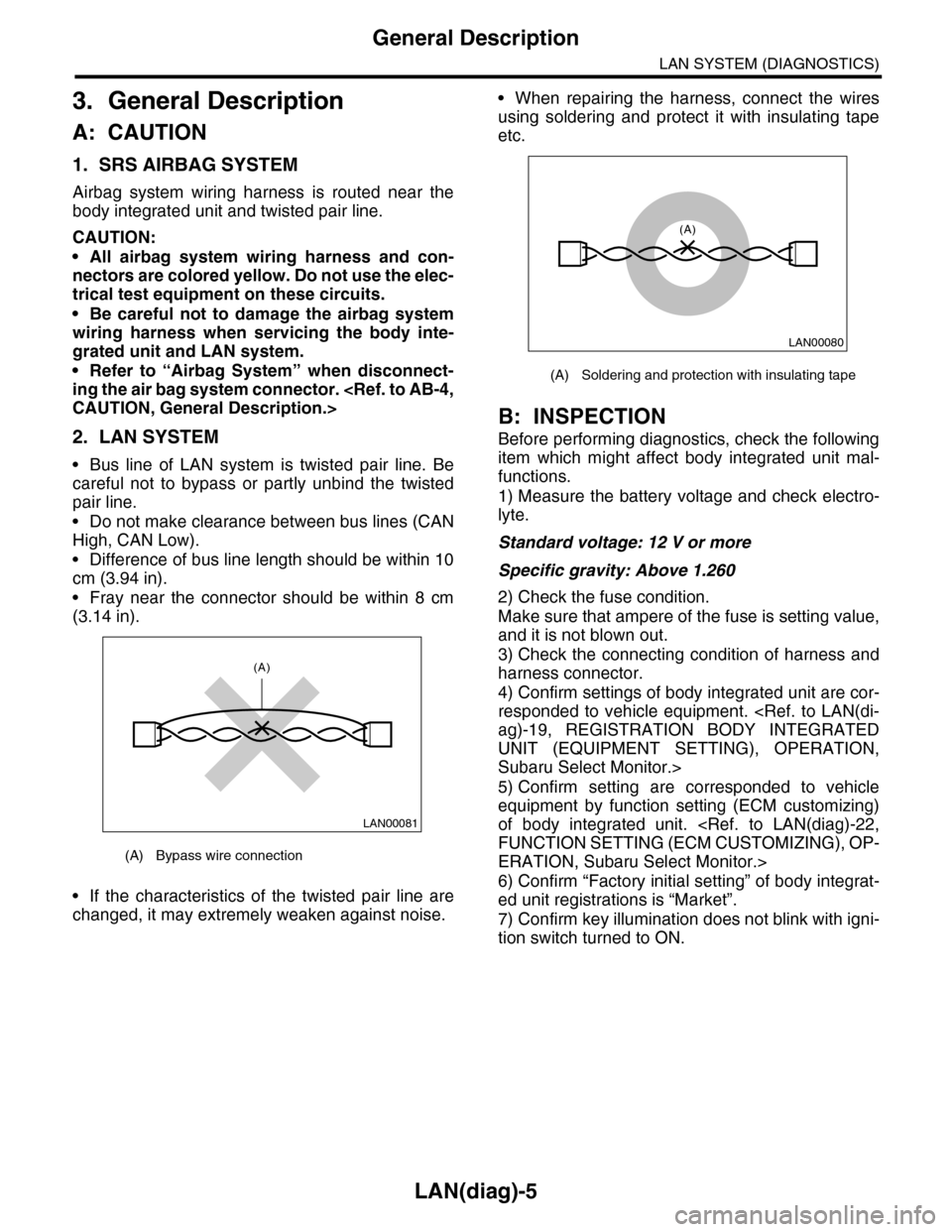

3. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

body integrated unit and twisted pair line.

CAUTION:

•All airbag system wiring harness and con-

nectors are colored yellow. Do not use the elec-

trical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the body inte-

grated unit and LAN system.

•Refer to “Airbag System” when disconnect-

ing the air bag system connector.

2. LAN SYSTEM

•Bus line of LAN system is twisted pair line. Be

careful not to bypass or partly unbind the twisted

pair line.

•Do not make clearance between bus lines (CAN

High, CAN Low).

•Difference of bus line length should be within 10

cm (3.94 in).

•Fray near the connector should be within 8 cm

(3.14 in).

•If the characteristics of the twisted pair line are

changed, it may extremely weaken against noise.

•When repairing the harness, connect the wires

using soldering and protect it with insulating tape

etc.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect body integrated unit mal-

functions.

1) Measure the battery voltage and check electro-

lyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2) Check the fuse condition.

Make sure that ampere of the fuse is setting value,

and it is not blown out.

3) Check the connecting condition of harness and

harness connector.

4) Confirm settings of body integrated unit are cor-

responded to vehicle equipment.

UNIT (EQUIPMENT SETTING), OPERATION,

Subaru Select Monitor.>

5) Confirm setting are corresponded to vehicle

equipment by function setting (ECM customizing)

of body integrated unit.

ERATION, Subaru Select Monitor.>

6) Confirm “Factory initial setting” of body integrat-

ed unit registrations is “Market”.

7) Confirm key illumination does not blink with igni-

tion switch turned to ON.

(A) Bypass wire connection

LAN00081

(A)

(A) Soldering and protection with insulating tape

LAN00080

(A)

Page 493 of 2453

LAN(diag)-37

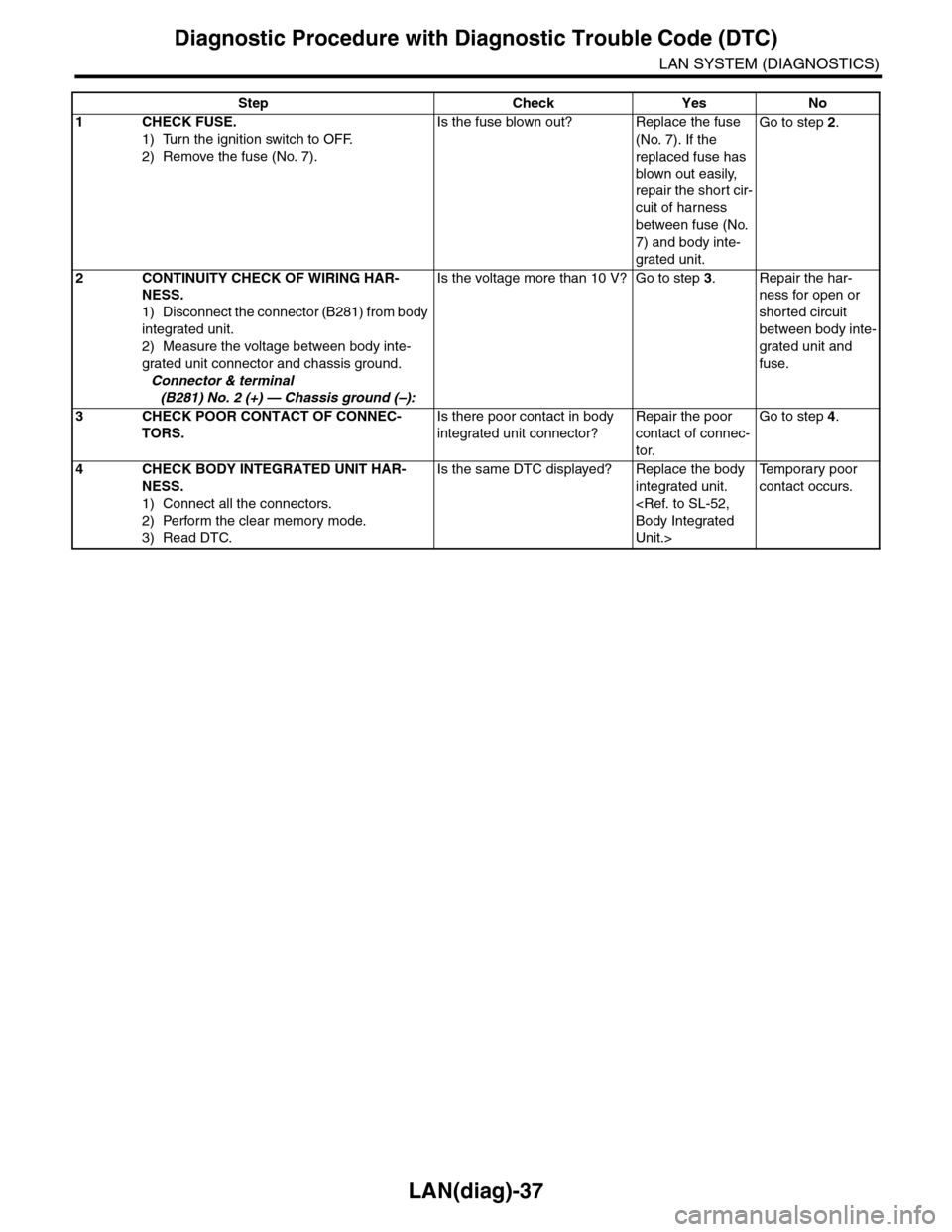

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

Step Check Yes No

1CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 7).

Is the fuse blown out? Replace the fuse

(No. 7). If the

replaced fuse has

blown out easily,

repair the short cir-

cuit of harness

between fuse (No.

7) and body inte-

grated unit.

Go to step 2.

2CONTINUITY CHECK OF WIRING HAR-

NESS.

1) Disconnect the connector (B281) from body

integrated unit.

2) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for open or

shorted circuit

between body inte-

grated unit and

fuse.

3CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in body

integrated unit connector?

Repair the poor

contact of connec-

tor.

Go to step 4.

4CHECK BODY INTEGRATED UNIT HAR-

NESS.

1) Connect all the connectors.

2) Perform the clear memory mode.

3) Read DTC.

Is the same DTC displayed? Replace the body

integrated unit.

Unit.>

Te m p o r a r y p o o r

contact occurs.

Page 495 of 2453

LAN(diag)-39

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

Step Check Yes No

1CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 8).

Is the fuse blown out? Replace the fuse

(No. 8). If the

replaced fuse has

blown out easily,

repair the short cir-

cuit of harness

between fuse (No.

8) and body inte-

grated unit.

Go to step 2.

2CONTINUITY CHECK OF WIRING HAR-

NESS.

1) Disconnect the connector (B280) from body

integrated unit.

2) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for open or

shorted circuit

between body inte-

grated unit and

fuse.

3CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in body

integrated unit connector?

Repair the poor

contact of connec-

tor.

Go to step 4.

4CHECK BODY INTEGRATED UNIT HAR-

NESS.

1) Connect all the connectors.

2) Perform the clear memory mode.

3) Read DTC.

Is the same DTC displayed? Replace the body

integrated unit.

Unit.>

Te m p o r a r y p o o r

contact occurs.

Page 496 of 2453

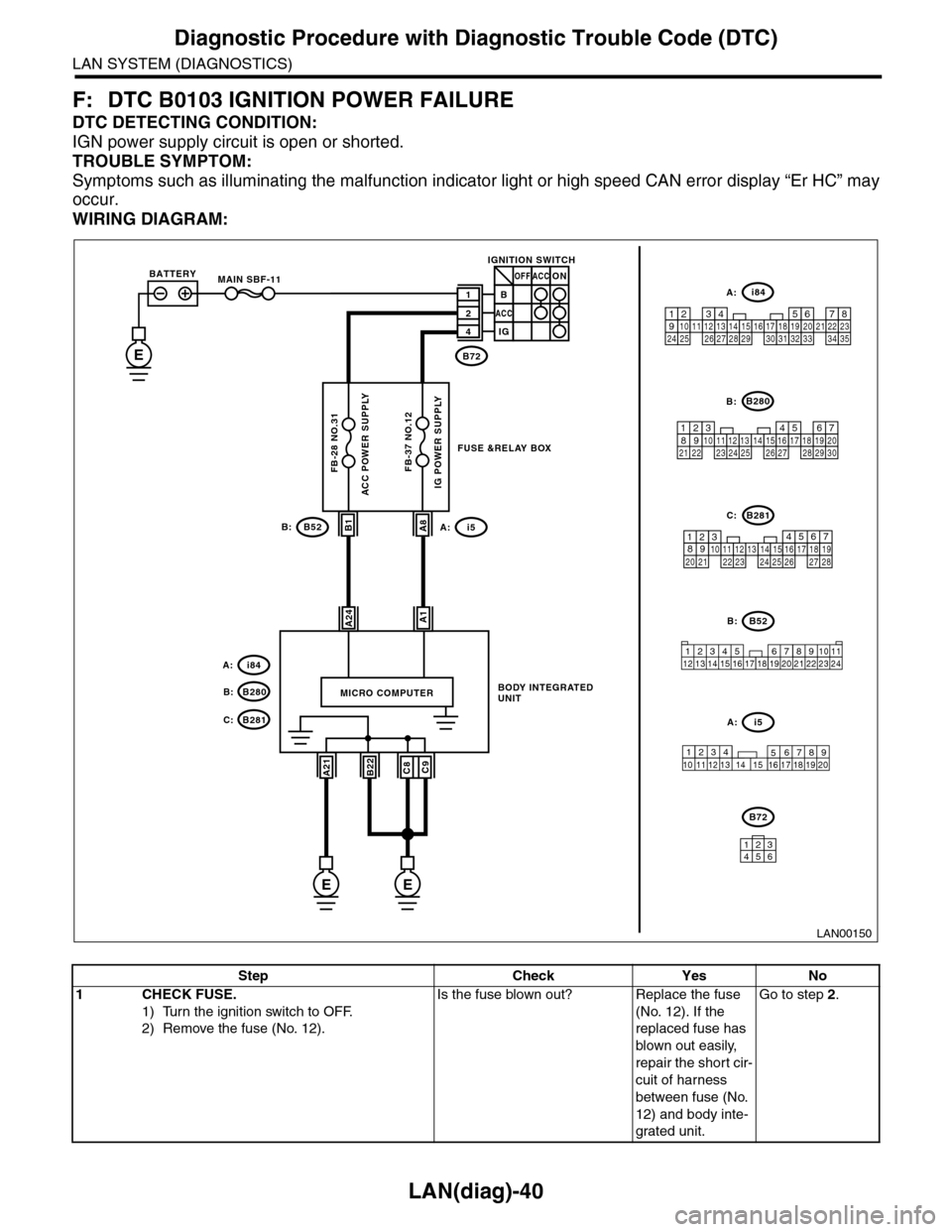

LAN(diag)-40

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

F: DTC B0103 IGNITION POWER FAILURE

DTC DETECTING CONDITION:

IGN power supply circuit is open or shorted.

TROUBLE SYMPTOM:

Symptoms such as illuminating the malfunction indicator light or high speed CAN error display “Er HC” may

occur.

WIRING DIAGRAM:

LAN00150

BODY INTEGRATED UNIT

A1A24

MICRO COMPUTER

B1A8

B72

IGNITION SWITCH

1B

2

4

ACC

ACCOFF

IG

ON

B52B:

34128910 1112 13 14 15 16 17 18 19 20 21 22 23 24567

B280B:

B281C:

567821943102422 2325111213141526 27281617181920 21

5467821931022 23111213141524 25 26 2716171828 29192021 30

i84A:

1234567891011121314151617181920212223242526272829303132333435

12345678910 11 12 19 2013 14 15 16 17 18

i5A:

ACC POWER SUPPLY

B52i5A:B:

E

MAIN SBF-11

FB-28 NO.31

BATTERY

IG POWER SUPPLY

i84

B280B:

A:

B281C:

A21C9B22C8

EE

FB-37 NO.12

B72

134562

FUSE &RELAY BOX

Step Check Yes No

1CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 12).

Is the fuse blown out? Replace the fuse

(No. 12). If the

replaced fuse has

blown out easily,

repair the short cir-

cuit of harness

between fuse (No.

12) and body inte-

grated unit.

Go to step 2.