fuse SUBARU TRIBECA 2009 1.G Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1166 of 2453

EN(H6DO)(diag)-5

General Description

ENGINE (DIAGNOSTICS)

3. General Description

A: CAUTION

1) Airbag system wiring harness is routed near the

ECM, main relay and fuel pump relay.

CAUTION:

•All airbag system wiring harnesses and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ECM, TCM,

main relay and fuel pump relay.

2) Never connect the battery in reverse polarity.

•The ECM will be destroyed instantly.

•The fuel injector and other parts will be dam-

aged.

3) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as ECM etc.

4) Before disconnecting the connectors of each

sensor and ECM, be sure to turn the ignition switch

to OFF. Perform the clear memory mode after con-

necting the connectors.

5) Poor contact has been identified as a primary

cause of this problem. Measure the voltage or re-

sistance of individual sensor or all electrical control

modules using a tapered pin with a diameter of less

than 0.64 mm (0.025 in). Do not insert the pin more

than 5 mm (0.20 in) into the part.

6) Remove the ECM from the located position after

disconnecting two cables on battery.

Otherwise, the ECM may be damaged.

CAUTION:

When replacing the ECM, be careful not to use

the wrong spec. ECM to avoid any damage on

the fuel injection system.

7) Connectors of each sensor in the engine com-

partment and the harness connectors on the en-

gine side and body side are all designed to be

waterproof. Even if the connectors are waterproof,

take care not to allow water to get into them when

washing the vehicle, or when servicing the vehicle

in rainy weather.

8) Use ECM mounting stud bolts as the grounding

point to chassis when measuring voltage and resis-

tance in the passenger compartment.

9) Use the engine ground terminal or engine as-

sembly as the grounding point to chassis when

measuring the voltage and resistance in engine

compartment.

10) Every MFI-related part is a precision part. Do

not drop them.

11) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

•The antenna must be kept as far apart as pos-

sible from control unit. (The ECM is located un-

der the steering column, inside of the

instrument panel lower trim panel.)

•The antenna feeder must be placed as far apart

as possible from the ECM and MFI harness.

•Carefully adjust the antenna for correct

matching.

•When mounting a large power type radio, pay

special attention to the three items mentioned

above.

•Incorrect installation of the radio may affect

the operation of ECM.

12) Release the pressure in the fuel system before

disconnecting the fuel hose. If engine starts during

this operation, run it until it stops.

13) For the model with ABS, the ABS warning light

may illuminate when performing driving test with

jacked-up or lifted-up condition, but this is not a

system malfunction. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clear procedure of self-

diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect engine problems.

1. BATTERY

1) Measure the battery voltage and specific gravity

of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

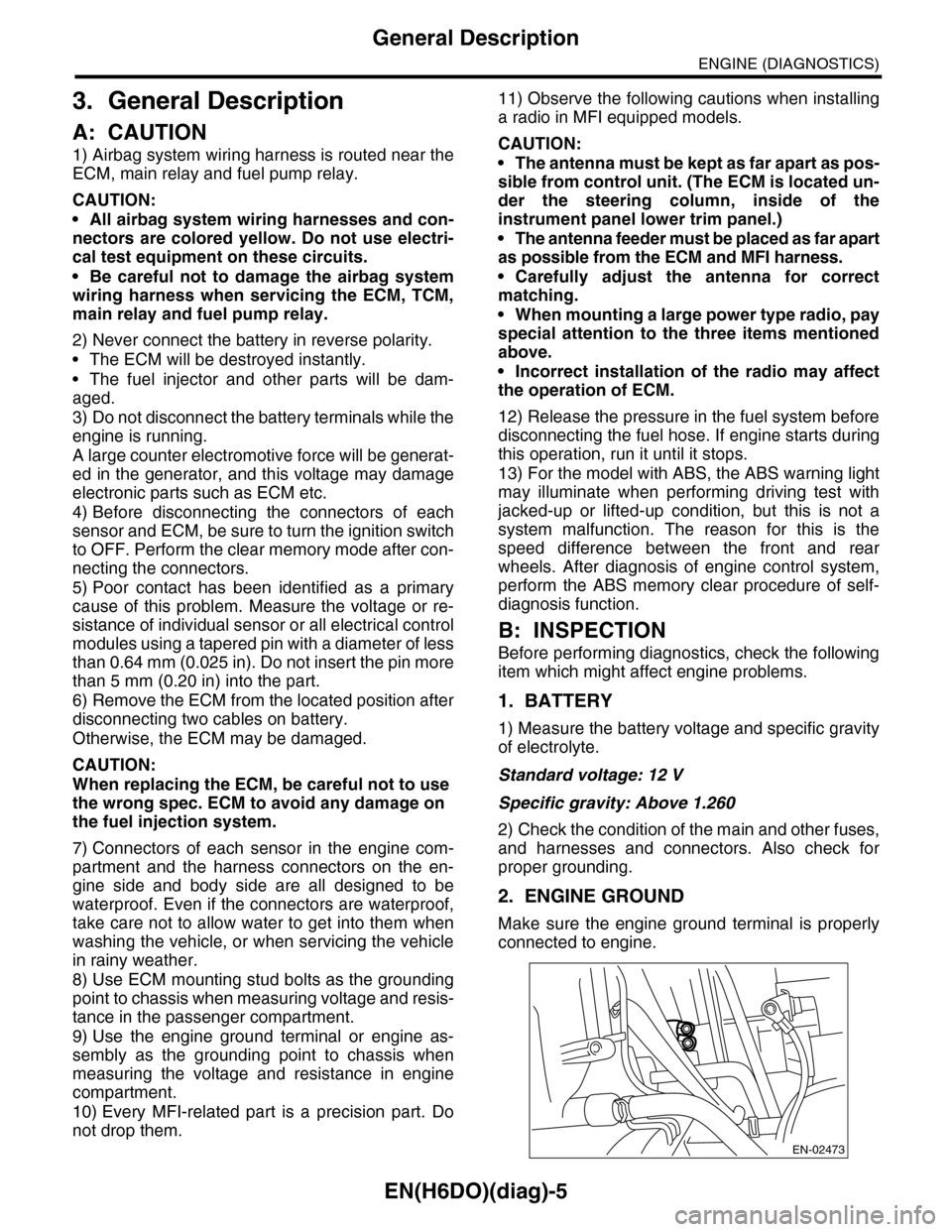

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to engine.

EN-02473

Page 1212 of 2453

EN(H6DO)(diag)-51

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

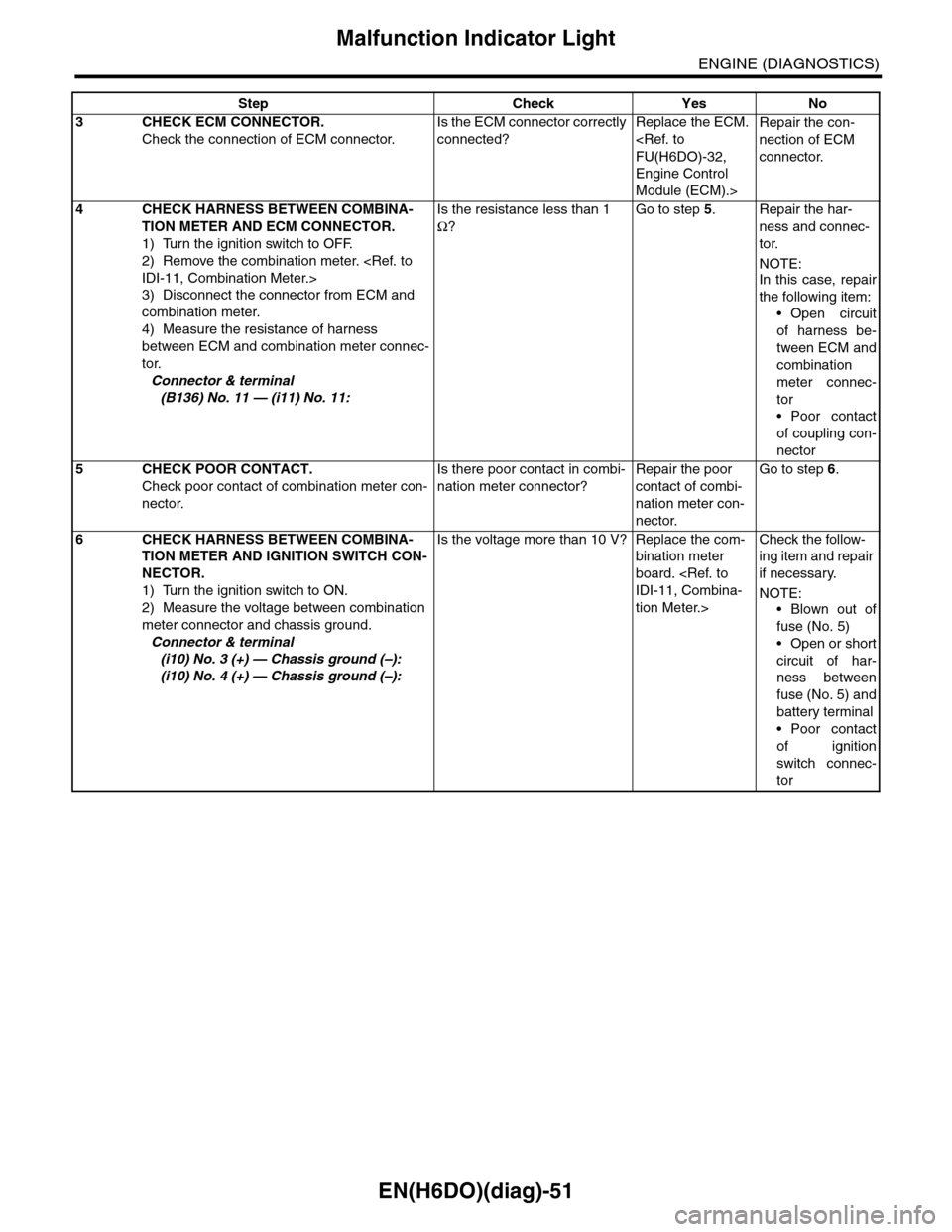

3CHECK ECM CONNECTOR.

Check the connection of ECM connector.

Is the ECM connector correctly

connected?

Replace the ECM.

Engine Control

Module (ECM).>

Repair the con-

nection of ECM

connector.

4CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Disconnect the connector from ECM and

combination meter.

4) Measure the resistance of harness

between ECM and combination meter connec-

tor.

Connector & terminal

(B136) No. 11 — (i11) No. 11:

Is the resistance less than 1

Ω?

Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

combination

meter connec-

tor

•Poor contact

of coupling con-

nector

5CHECK POOR CONTACT.

Check poor contact of combination meter con-

nector.

Is there poor contact in combi-

nation meter connector?

Repair the poor

contact of combi-

nation meter con-

nector.

Go to step 6.

6CHECK HARNESS BETWEEN COMBINA-

TION METER AND IGNITION SWITCH CON-

NECTOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 3 (+) — Chassis ground (–):

(i10) No. 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the com-

bination meter

board.

tion Meter.>

Check the follow-

ing item and repair

if necessary.

NOTE:

•Blown out of

fuse (No. 5)

•Open or short

circuit of har-

ness between

fuse (No. 5) and

battery terminal

•Poor contact

of ignition

switch connec-

tor

Step Check Yes No

Page 1220 of 2453

EN(H6DO)(diag)-59

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

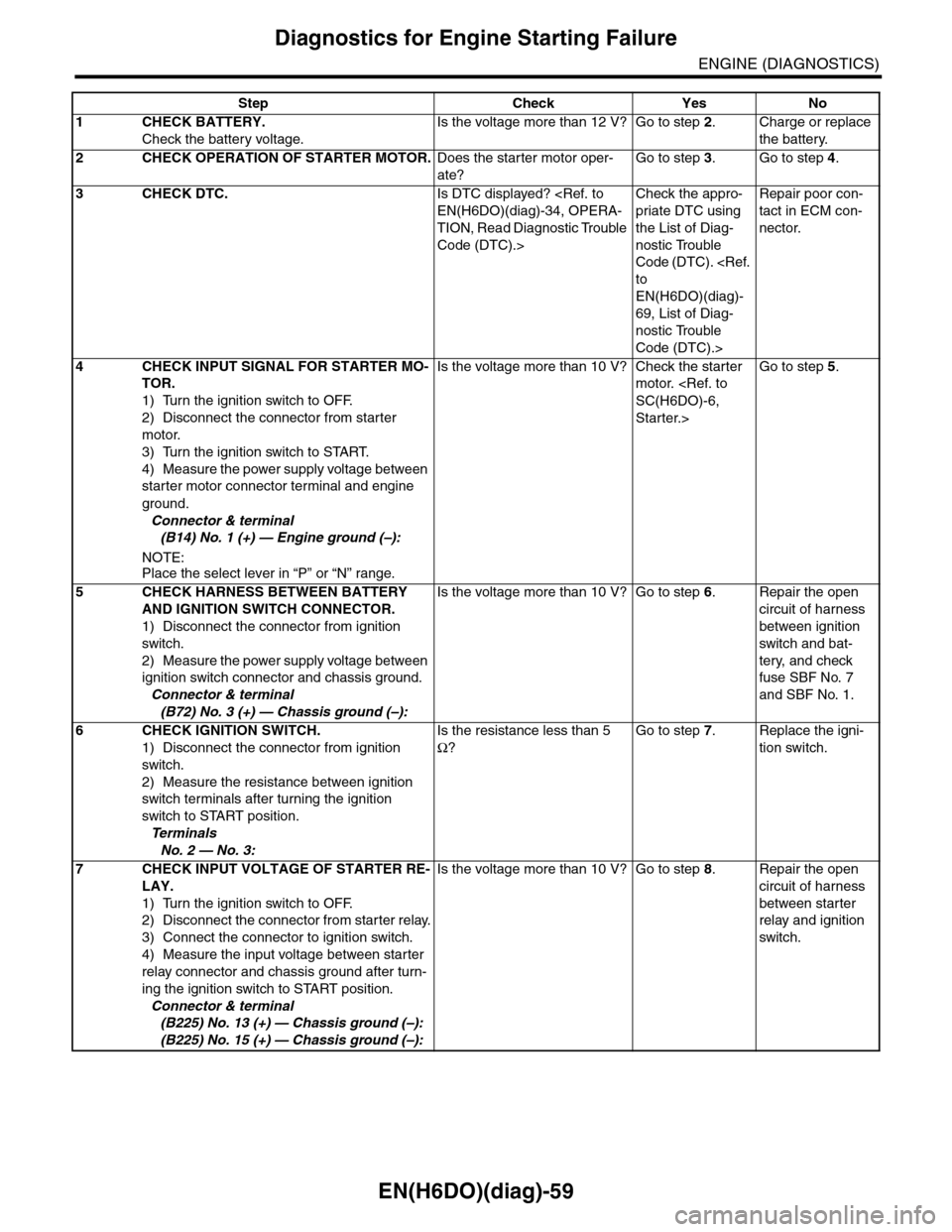

Step Check Yes No

1CHECK BATTERY.

Check the battery voltage.

Is the voltage more than 12 V? Go to step 2.Charge or replace

the battery.

2CHECK OPERATION OF STARTER MOTOR.Does the starter motor oper-

ate?

Go to step 3.Go to step 4.

3CHECK DTC.Is DTC displayed?

TION, Read Diagnostic Trouble

Code (DTC).>

Check the appro-

priate DTC using

the List of Diag-

nostic Trouble

Code (DTC).

EN(H6DO)(diag)-

69, List of Diag-

nostic Trouble

Code (DTC).>

Repair poor con-

tact in ECM con-

nector.

4CHECK INPUT SIGNAL FOR STARTER MO-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from starter

motor.

3) Turn the ignition switch to START.

4) Measure the power supply voltage between

starter motor connector terminal and engine

ground.

Connector & terminal

(B14) No. 1 (+) — Engine ground (–):

NOTE:Place the select lever in “P” or “N” range.

Is the voltage more than 10 V? Check the starter

motor.

Starter.>

Go to step 5.

5CHECK HARNESS BETWEEN BATTERY

AND IGNITION SWITCH CONNECTOR.

1) Disconnect the connector from ignition

switch.

2) Measure the power supply voltage between

ignition switch connector and chassis ground.

Connector & terminal

(B72) No. 3 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Repair the open

circuit of harness

between ignition

switch and bat-

tery, and check

fuse SBF No. 7

and SBF No. 1.

6CHECK IGNITION SWITCH.

1) Disconnect the connector from ignition

switch.

2) Measure the resistance between ignition

switch terminals after turning the ignition

switch to START position.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance less than 5

Ω?

Go to step 7.Replace the igni-

tion switch.

7CHECK INPUT VOLTAGE OF STARTER RE-

LAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from starter relay.

3) Connect the connector to ignition switch.

4) Measure the input voltage between starter

relay connector and chassis ground after turn-

ing the ignition switch to START position.

Connector & terminal

(B225) No. 13 (+) — Chassis ground (–):

(B225) No. 15 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 8.Repair the open

circuit of harness

between starter

relay and ignition

switch.

Page 1480 of 2453

EN(H6DO)(diag)-319

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

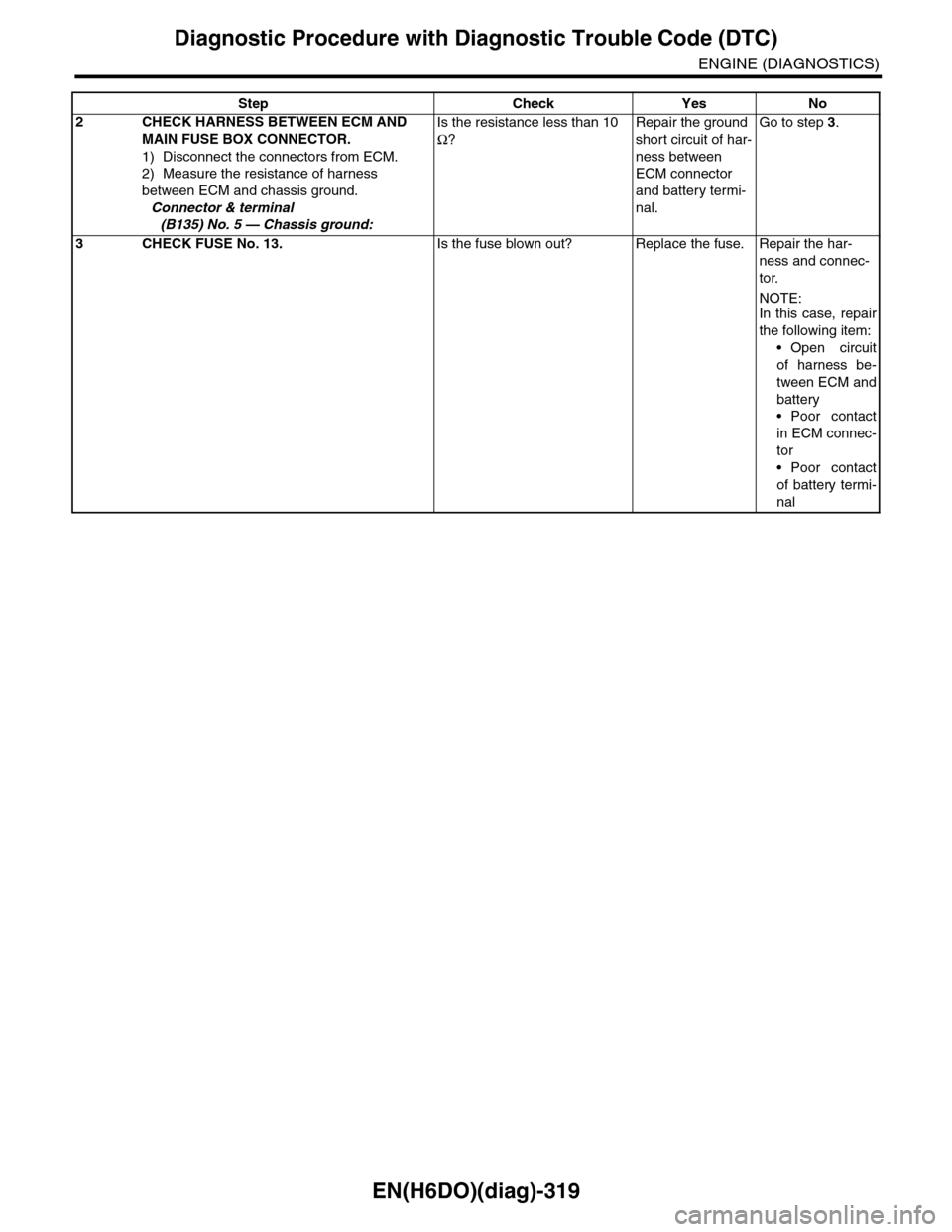

2CHECK HARNESS BETWEEN ECM AND

MAIN FUSE BOX CONNECTOR.

1) Disconnect the connectors from ECM.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B135) No. 5 — Chassis ground:

Is the resistance less than 10

Ω?

Repair the ground

short circuit of har-

ness between

ECM connector

and battery termi-

nal.

Go to step 3.

3CHECK FUSE No. 13.Is the fuse blown out? Replace the fuse. Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

battery

•Poor contact

in ECM connec-

tor

•Poor contact

of battery termi-

nal

Step Check Yes No

Page 1576 of 2453

FU(H6DO)-15

Intake Manifold

FUEL INJECTION (FUEL SYSTEMS)

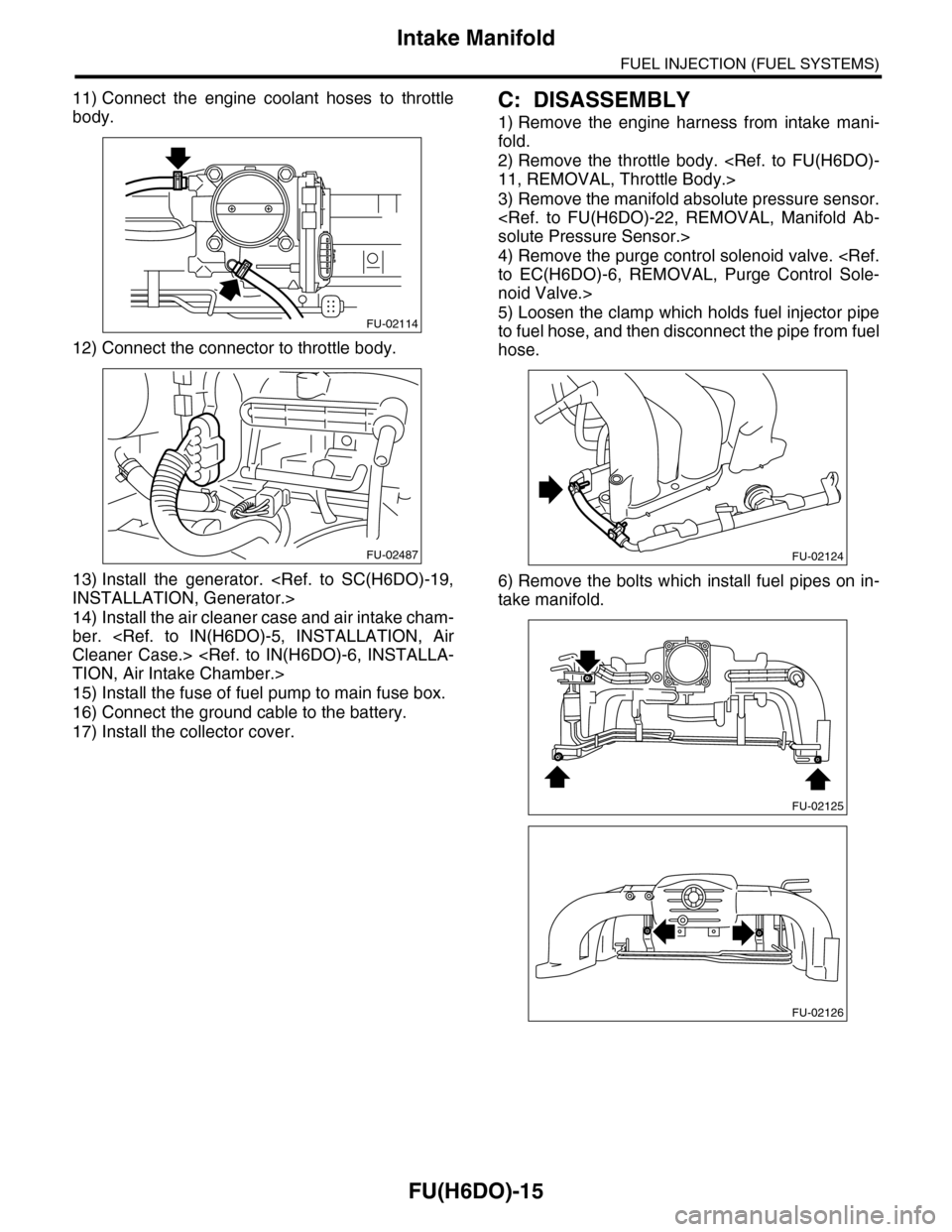

11) Connect the engine coolant hoses to throttle

body.

12) Connect the connector to throttle body.

13) Install the generator.

14) Install the air cleaner case and air intake cham-

ber.

15) Install the fuse of fuel pump to main fuse box.

16) Connect the ground cable to the battery.

17) Install the collector cover.

C: DISASSEMBLY

1) Remove the engine harness from intake mani-

fold.

2) Remove the throttle body.

3) Remove the manifold absolute pressure sensor.

4) Remove the purge control solenoid valve.

noid Valve.>

5) Loosen the clamp which holds fuel injector pipe

to fuel hose, and then disconnect the pipe from fuel

hose.

6) Remove the bolts which install fuel pipes on in-

take manifold.

FU-02114

FU-02487FU-02124

FU-02125

FU-02126

Page 1598 of 2453

FU(H6DO)-37

Fuel

FUEL INJECTION (FUEL SYSTEMS)

21.Fuel

A: PROCEDURE

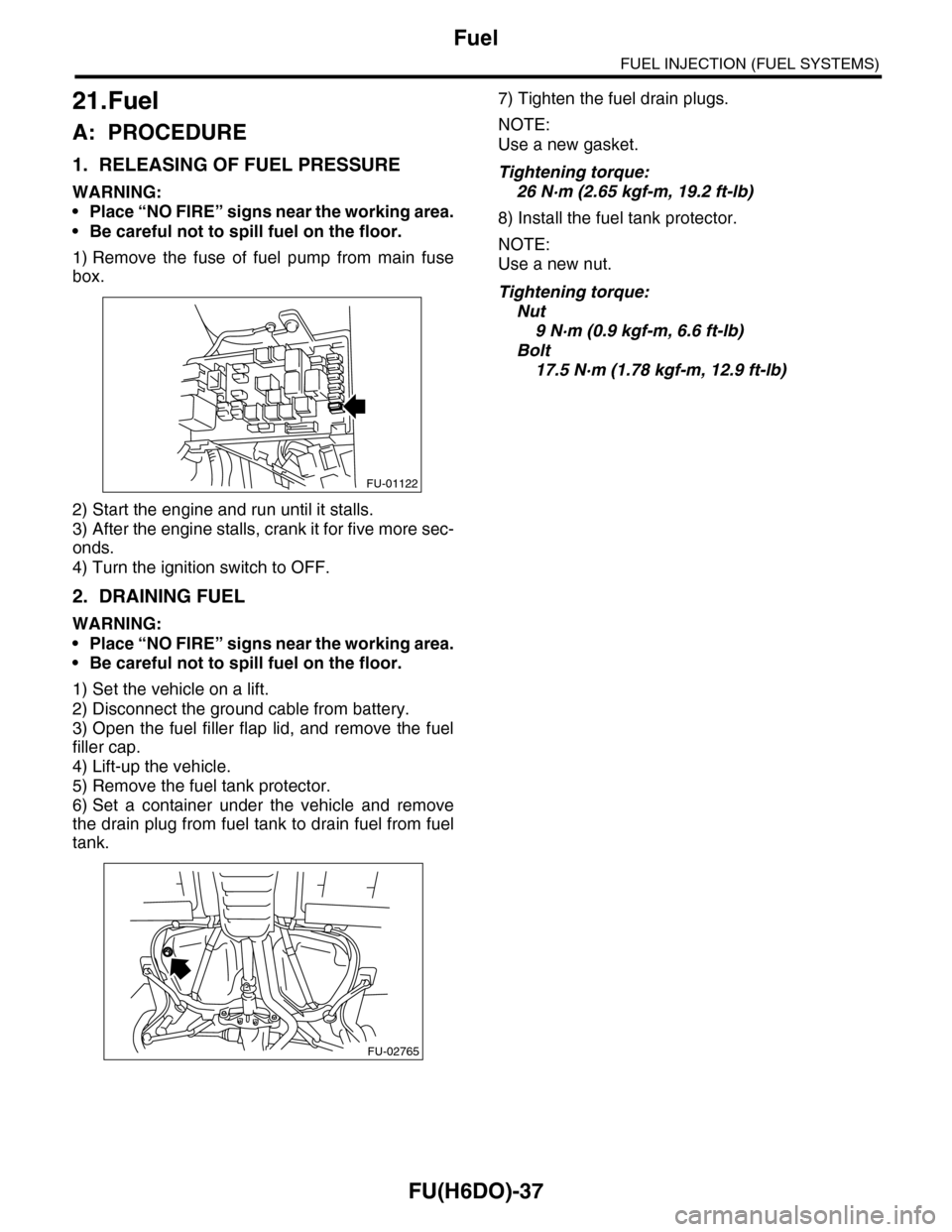

1. RELEASING OF FUEL PRESSURE

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Remove the fuse of fuel pump from main fuse

box.

2) Start the engine and run until it stalls.

3) After the engine stalls, crank it for five more sec-

onds.

4) Turn the ignition switch to OFF.

2. DRAINING FUEL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Open the fuel filler flap lid, and remove the fuel

filler cap.

4) Lift-up the vehicle.

5) Remove the fuel tank protector.

6) Set a container under the vehicle and remove

the drain plug from fuel tank to drain fuel from fuel

tank.

7) Tighten the fuel drain plugs.

NOTE:

Use a new gasket.

Tightening torque:

26 N·m (2.65 kgf-m, 19.2 ft-lb)

8) Install the fuel tank protector.

NOTE:

Use a new nut.

Tightening torque:

Nut

9 N·m (0.9 kgf-m, 6.6 ft-lb)

Bolt

17.5 N·m (1.78 kgf-m, 12.9 ft-lb)

FU-01122

FU-02765

Page 1601 of 2453

FU(H6DO)-40

Fuel Tank

FUEL INJECTION (FUEL SYSTEMS)

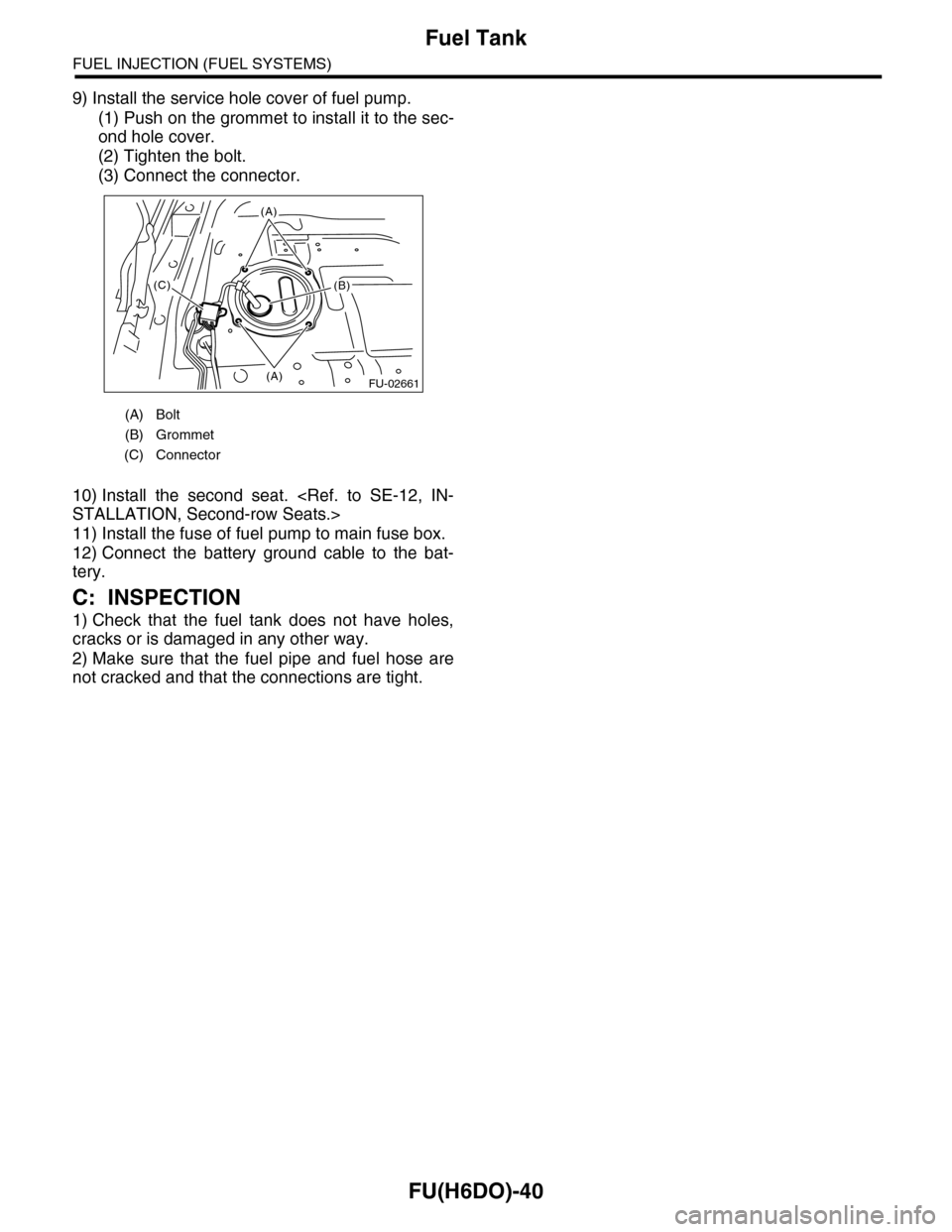

9) Install the service hole cover of fuel pump.

(1) Push on the grommet to install it to the sec-

ond hole cover.

(2) Tighten the bolt.

(3) Connect the connector.

10) Install the second seat.

11) Install the fuse of fuel pump to main fuse box.

12) Connect the battery ground cable to the bat-

tery.

C: INSPECTION

1) Check that the fuel tank does not have holes,

cracks or is damaged in any other way.

2) Make sure that the fuel pipe and fuel hose are

not cracked and that the connections are tight.

(A) Bolt

(B) Grommet

(C) Connector

FU-02661(A)

(A)

(B)(C)

Page 1892 of 2453

ME(H6DO)-26

Fuel Pressure

MECHANICAL

7. Fuel Pressure

A: INSPECTION

WARNING:

Before removing the fuel pressure gauge, re-

lease the fuel pressure.

1) Release the fuel pressure.

2) Disconnect the fuel delivery hose and connect

fuel pressure gauge.

(1) Disconnect the fuel delivery hose using the

ST1.

ST1 42099AE000 CONNECTOR REMOVER

(2) Connect the fuel pressure meter using the

ST2 and ST3.

NOTE:

ST2 is a genuine Subaru part.

ST2 42075AG690 FUEL HOSE

ST3 18471AA000 FUEL PIPE ADAPTER

3) Install the fuse of fuel pump to main fuse box.

4) Start the engine.

5) Measure the fuel pressure after warming up the

engine.

Fuel pressure:

Standard: 338 — 348 kPa (3.4 — 3.5 kgf/cm2,

49 — 50.5 psi)

NOTE:

The fuel pressure gauge registers 10 to 20 kPa (0.1

to 0.2 kgf/cm2, 1 to 3 psi) higher than standard val-

ues during high-altitude operations.

(A) ST 2

(B) ST 3

ME-02666

(A)

(B)

FU-01122

Page 1929 of 2453

ME(H6DO)-63

Cylinder Block

MECHANICAL

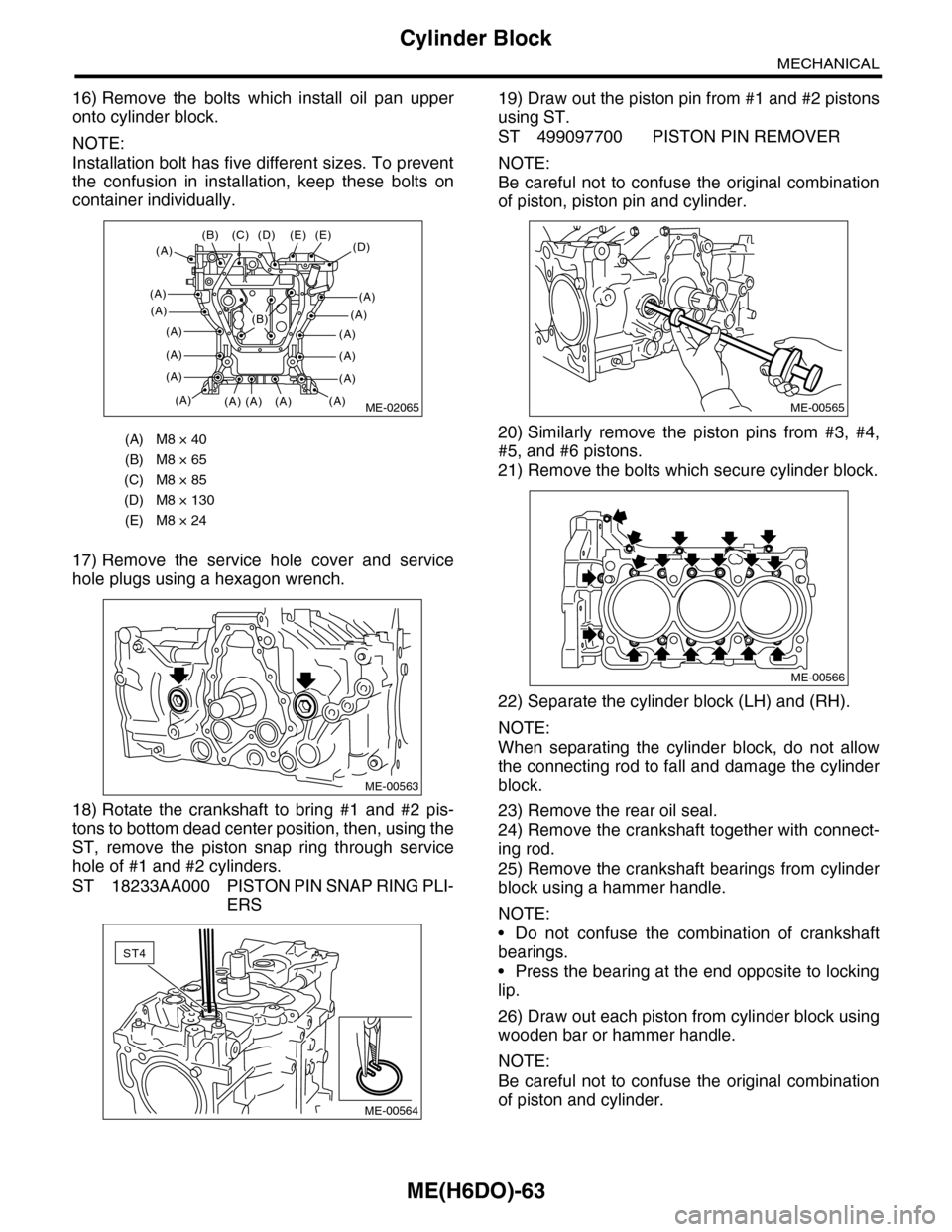

16) Remove the bolts which install oil pan upper

onto cylinder block.

NOTE:

Installation bolt has five different sizes. To prevent

the confusion in installation, keep these bolts on

container individually.

17) Remove the service hole cover and service

hole plugs using a hexagon wrench.

18) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, then, using the

ST, remove the piston snap ring through service

hole of #1 and #2 cylinders.

ST 18233AA000 PISTON PIN SNAP RING PLI-

ERS

19) Draw out the piston pin from #1 and #2 pistons

using ST.

ST 499097700 PISTON PIN REMOVER

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.

20) Similarly remove the piston pins from #3, #4,

#5, and #6 pistons.

21) Remove the bolts which secure cylinder block.

22) Separate the cylinder block (LH) and (RH).

NOTE:

When separating the cylinder block, do not allow

the connecting rod to fall and damage the cylinder

block.

23) Remove the rear oil seal.

24) Remove the crankshaft together with connect-

ing rod.

25) Remove the crankshaft bearings from cylinder

block using a hammer handle.

NOTE:

•Do not confuse the combination of crankshaft

bearings.

•Press the bearing at the end opposite to locking

lip.

26) Draw out each piston from cylinder block using

wooden bar or hammer handle.

NOTE:

Be careful not to confuse the original combination

of piston and cylinder.

(A) M8 × 40

(B) M8 × 65

(C) M8 × 85

(D) M8 × 130

(E) M8 × 24

ME-02065

(D)(E)

(A)

(A)

(A)

(A)

(A)

(A)

(A)

(E)

(A)(A)(A)

(C)(B)

(A)

(D)

(A)

(A)

(A)

(A)

(A)

(B)

ME-00563

ST4

ME-00564

ME-00565

ME-00566

Page 2144 of 2453

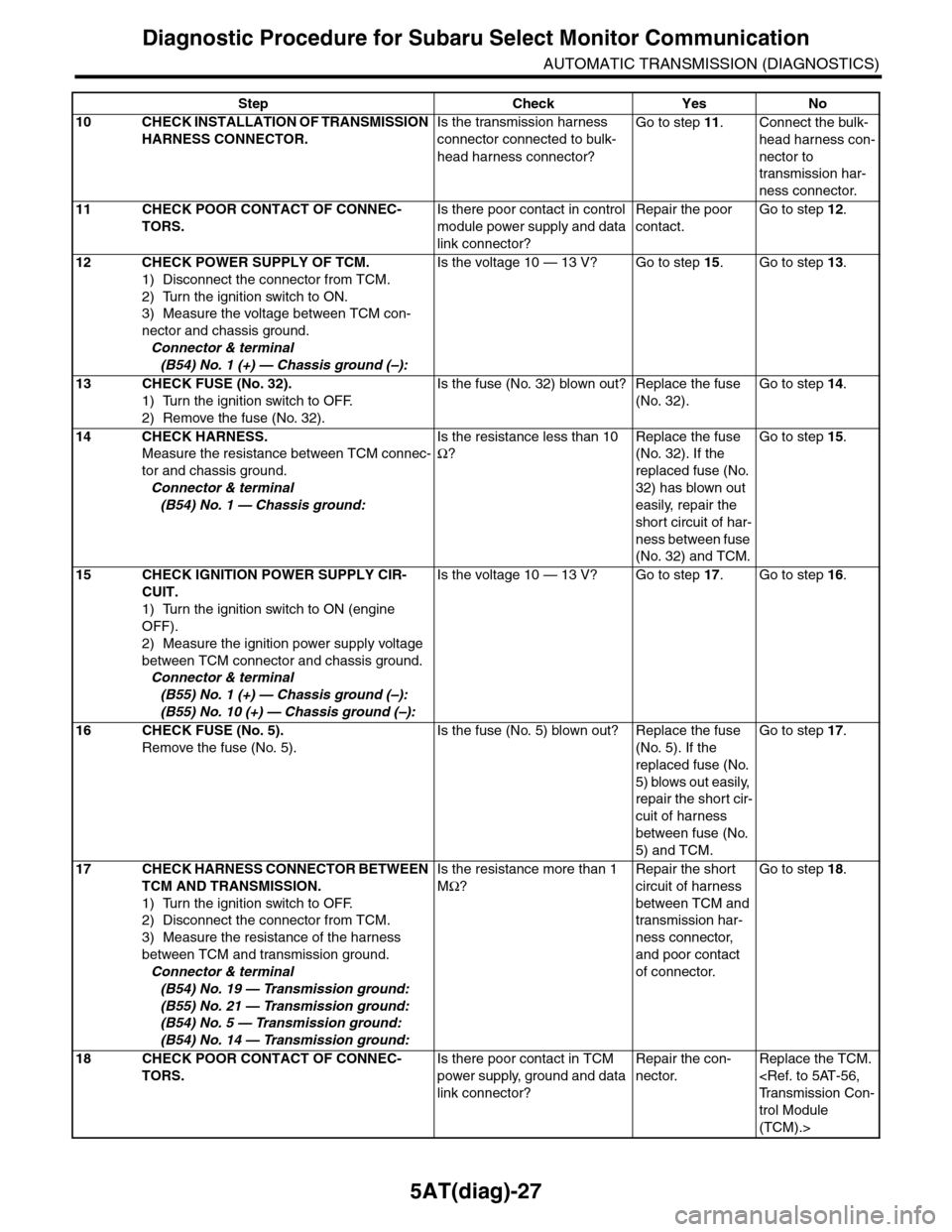

5AT(diag)-27

Diagnostic Procedure for Subaru Select Monitor Communication

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

10 CHECK INSTALLATION OF TRANSMISSION

HARNESS CONNECTOR.

Is the transmission harness

connector connected to bulk-

head harness connector?

Go to step 11.Connect the bulk-

head harness con-

nector to

transmission har-

ness connector.

11 CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in control

module power supply and data

link connector?

Repair the poor

contact.

Go to step 12.

12 CHECK POWER SUPPLY OF TCM.

1) Disconnect the connector from TCM.

2) Turn the ignition switch to ON.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B54) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 15.Go to step 13.

13 CHECK FUSE (No. 32).

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 32).

Is the fuse (No. 32) blown out? Replace the fuse

(No. 32).

Go to step 14.

14 CHECK HARNESS.

Measure the resistance between TCM connec-

tor and chassis ground.

Connector & terminal

(B54) No. 1 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the fuse

(No. 32). If the

replaced fuse (No.

32) has blown out

easily, repair the

short circuit of har-

ness between fuse

(No. 32) and TCM.

Go to step 15.

15 CHECK IGNITION POWER SUPPLY CIR-

CUIT.

1) Turn the ignition switch to ON (engine

OFF).

2) Measure the ignition power supply voltage

between TCM connector and chassis ground.

Connector & terminal

(B55) No. 1 (+) — Chassis ground (–):

(B55) No. 10 (+) — Chassis ground (–):

Is the voltage 10 — 13 V? Go to step 17.Go to step 16.

16 CHECK FUSE (No. 5).

Remove the fuse (No. 5).

Is the fuse (No. 5) blown out? Replace the fuse

(No. 5). If the

replaced fuse (No.

5) blows out easily,

repair the short cir-

cuit of harness

between fuse (No.

5) and TCM.

Go to step 17.

17 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM.

3) Measure the resistance of the harness

between TCM and transmission ground.

Connector & terminal

(B54) No. 19 — Transmission ground:

(B55) No. 21 — Transmission ground:

(B54) No. 5 — Transmission ground:

(B54) No. 14 — Transmission ground:

Is the resistance more than 1

MΩ?

Repair the short

circuit of harness

between TCM and

transmission har-

ness connector,

and poor contact

of connector.

Go to step 18.

18 CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in TCM

power supply, ground and data

link connector?

Repair the con-

nector.

Replace the TCM.

trol Module

(TCM).>

Step Check Yes No