fuse SUBARU TRIBECA 2009 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 497 of 2453

LAN(diag)-41

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

2CONTINUITY CHECK OF WIRING HAR-

NESS.

1) Disconnect the connector (i84) from body

integrated unit.

2) Turn the ignition switch to ON.

3) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for open or

shorted circuit

between body inte-

grated unit and

fuse.

3CHECK POOR CONTACT OF CONNECTOR.Is there poor contact in body

integrated unit connector?

Repair the poor

contact of connec-

tor.

Go to step 4.

4CHECK BODY INTEGRATED UNIT HAR-

NESS.

1) Connect all the connectors.

2) Perform the clear memory mode.

3) Read DTC.

Is the same DTC displayed? Replace the body

integrated unit.

Unit.>

Te m p o r a r y p o o r

contact occurs.

Step Check Yes No

Page 498 of 2453

LAN(diag)-42

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

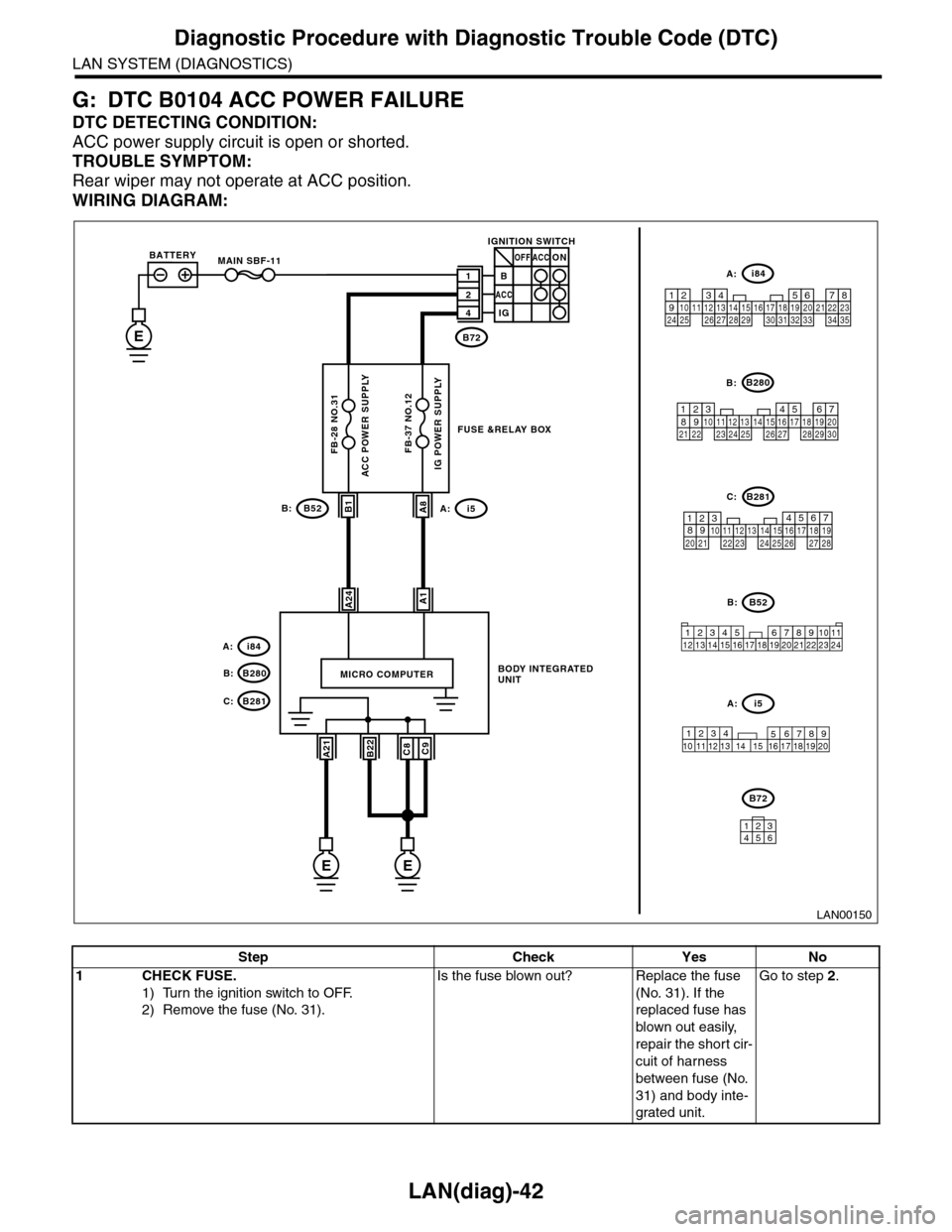

G: DTC B0104 ACC POWER FAILURE

DTC DETECTING CONDITION:

ACC power supply circuit is open or shorted.

TROUBLE SYMPTOM:

Rear wiper may not operate at ACC position.

WIRING DIAGRAM:

LAN00150

BODY INTEGRATED UNIT

A1A24

MICRO COMPUTER

B1A8

B72

IGNITION SWITCH

1B

2

4

ACC

ACCOFF

IG

ON

B52B:

34128910 1112 13 14 15 16 17 18 19 20 21 22 23 24567

B280B:

B281C:

567821943102422 2325111213141526 27281617181920 21

5467821931022 23111213141524 25 26 2716171828 29192021 30

i84A:

1234567891011121314151617181920212223242526272829303132333435

12345678910 11 12 19 2013 14 15 16 17 18

i5A:

ACC POWER SUPPLY

B52i5A:B:

E

MAIN SBF-11

FB-28 NO.31

BATTERY

IG POWER SUPPLY

i84

B280B:

A:

B281C:

A21C9B22C8

EE

FB-37 NO.12

B72

134562

FUSE &RELAY BOX

Step Check Yes No

1CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse (No. 31).

Is the fuse blown out? Replace the fuse

(No. 31). If the

replaced fuse has

blown out easily,

repair the short cir-

cuit of harness

between fuse (No.

31) and body inte-

grated unit.

Go to step 2.

Page 499 of 2453

LAN(diag)-43

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

2CONTINUITY CHECK OF WIRING HAR-

NESS.

1) Disconnect the connector (i84) from body

integrated unit.

2) Turn the ignition switch to ON.

3) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(i84) No. 24 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for open or

shorted circuit

between body inte-

grated unit and

fuse.

3CHECK POOR CONTACT OF CONNECTOR.Is there poor contact in body

integrated unit connector?

Repair the poor

contact of connec-

tor.

Go to step 4.

4CHECK BODY INTEGRATED UNIT HAR-

NESS.

1) Connect all the connectors.

2) Perform the clear memory mode.

3) Read DTC.

Is DTC displayed? Replace the body

integrated unit.

Unit.>

Te m p o r a r y p o o r

contact occurs.

Step Check Yes No

Page 500 of 2453

LAN(diag)-44

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

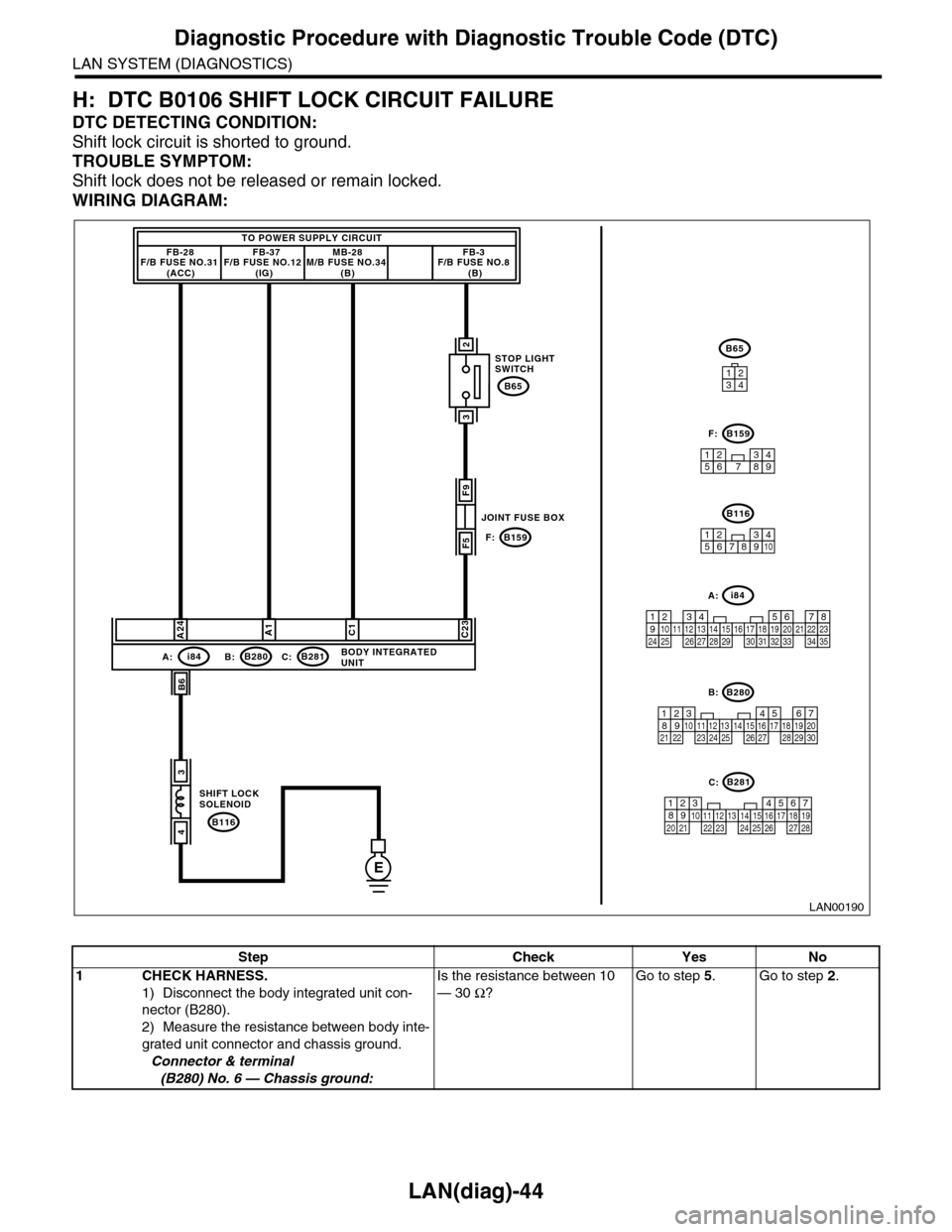

H: DTC B0106 SHIFT LOCK CIRCUIT FAILURE

DTC DETECTING CONDITION:

Shift lock circuit is shorted to ground.

TROUBLE SYMPTOM:

Shift lock does not be released or remain locked.

WIRING DIAGRAM:

B6

TO POWER SUPPLY CIRCUITFB-28F/B FUSE NO.31 (ACC)

FB-37F/B FUSE NO.12 (IG)

MB-28M/B FUSE NO.34 (B)

FB-3F/B FUSE NO.8 (B)

E

F9

F5

3

4

A24C23C1A1

i84A:B280B:B281C:

B159F:

BODY INTEGRATEDUNIT

B116

SHIFT LOCK SOLENOID

JOINT FUSE BOX

STOP LIGHTSWITCH

3

2

B65

LAN00190

12345678910

B116

123495678

B159F:

567821943102422 2325111213141526 27281617181920 21

B281C:

5467821931022 23111213141524 25 26 2716171828 29192021 30

B280B:

3412

1234567891011121314151617181920212223242526272829303132333435

A:i84

B65

Step Check Yes No

1CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Measure the resistance between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B280) No. 6 — Chassis ground:

Is the resistance between 10

— 30 Ω?

Go to step 5.Go to step 2.

Page 519 of 2453

LAN(diag)-63

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

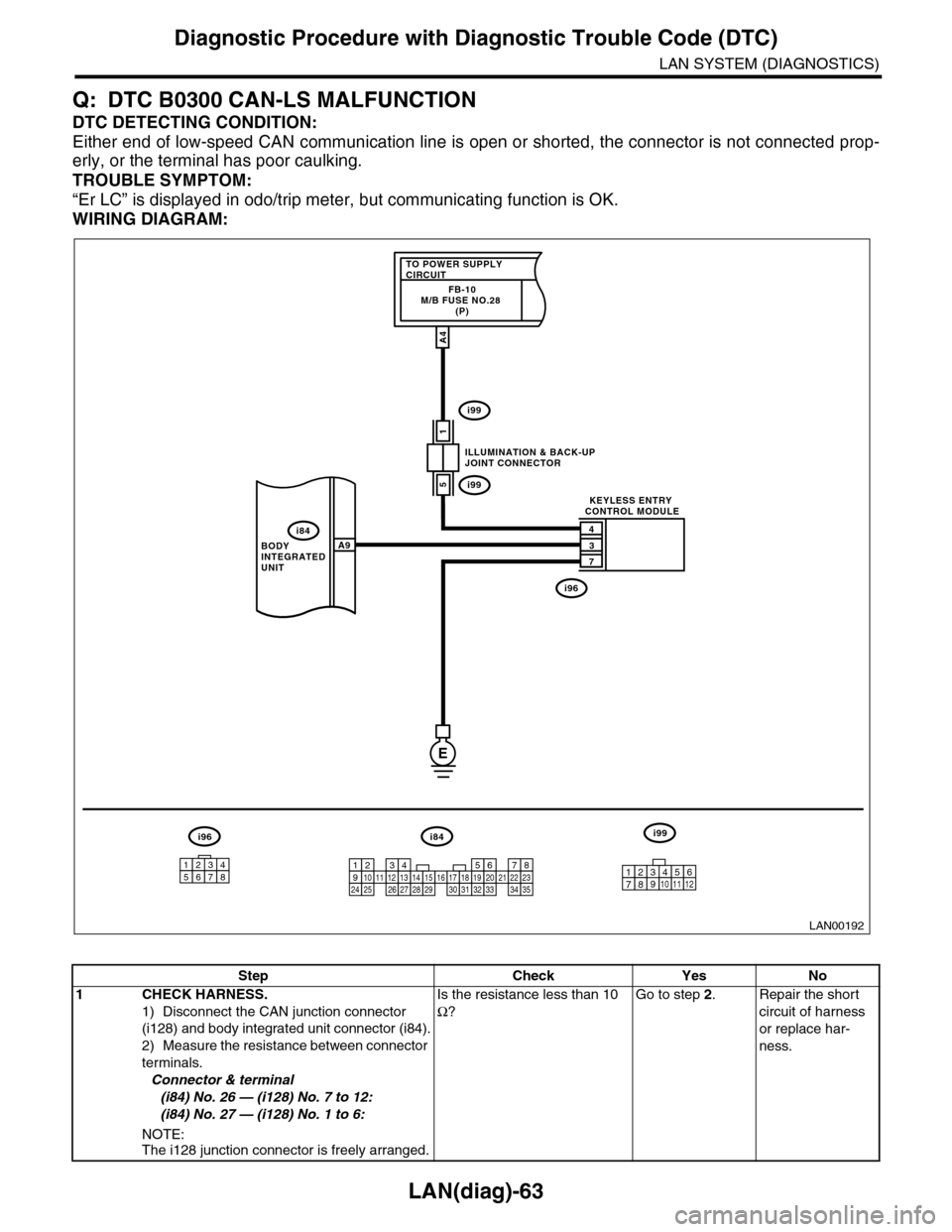

Q: DTC B0300 CAN-LS MALFUNCTION

DTC DETECTING CONDITION:

Either end of low-speed CAN communication line is open or shorted, the connector is not connected prop-

erly, or the terminal has poor caulking.

TROUBLE SYMPTOM:

“Er LC” is displayed in odo/trip meter, but communicating function is OK.

WIRING DIAGRAM:

LAN00192

TO POWER SUPPLY CIRCUITFB-10M/B FUSE NO.28 (P)

1

4

3

7

A9

A4

5

BODY INTEGRATED UNIT

ILLUMINATION & BACK-UPJOINT CONNECTOR

KEYLESS ENTRY CONTROL MODULE

i84

i99

i99

i96

E

i84i96i99

123456789101112131415161718192021222324252627282930313233343510 11 12349561728

12345678

Step Check Yes No

1CHECK HARNESS.

1) Disconnect the CAN junction connector

(i128) and body integrated unit connector (i84).

2) Measure the resistance between connector

terminals.

Connector & terminal

(i84) No. 26 — (i128) No. 7 to 12:

(i84) No. 27 — (i128) No. 1 to 6:

NOTE:The i128 junction connector is freely arranged.

Is the resistance less than 10

Ω?

Go to step 2.Repair the short

circuit of harness

or replace har-

ness.

Page 528 of 2453

LAN(diag)-72

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

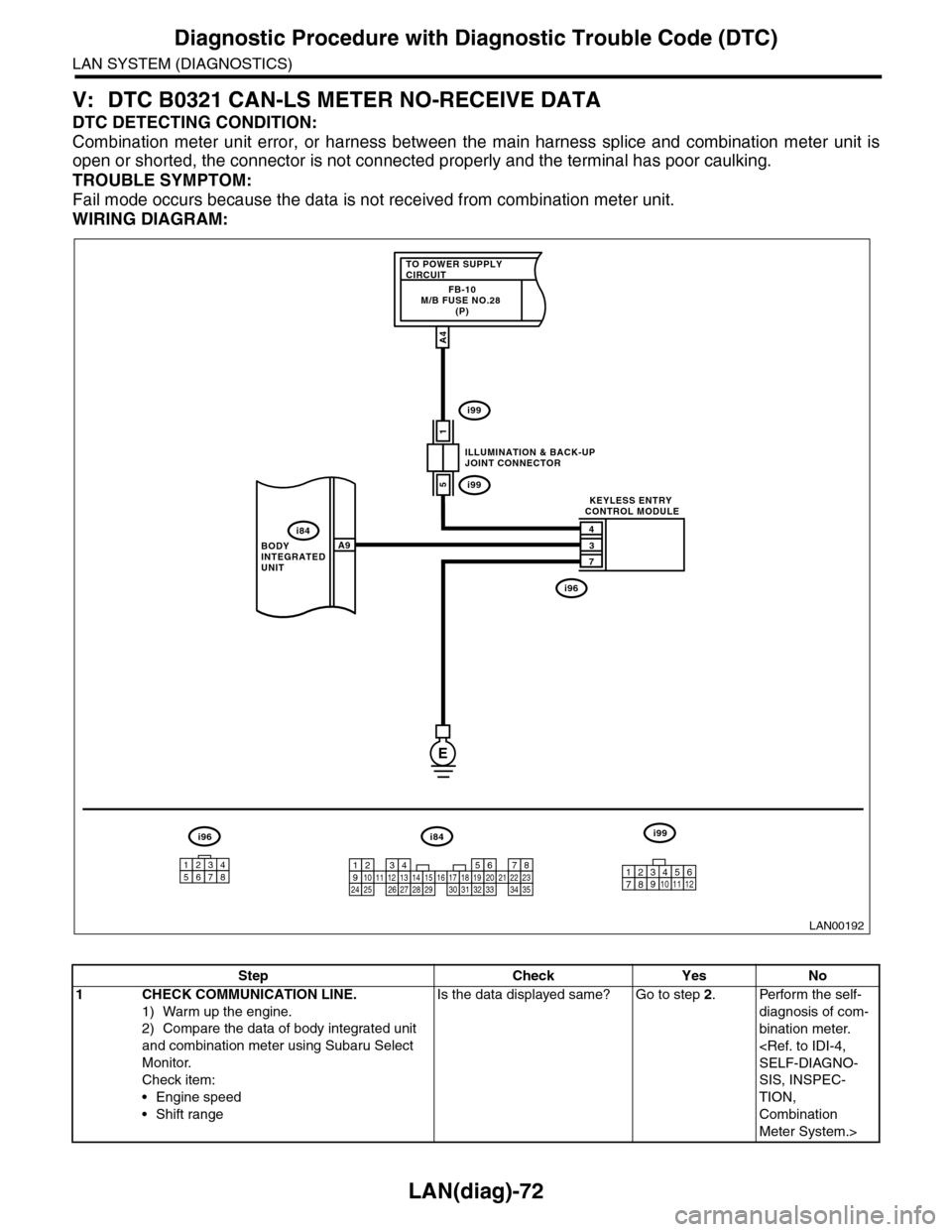

V: DTC B0321 CAN-LS METER NO-RECEIVE DATA

DTC DETECTING CONDITION:

Combination meter unit error, or harness between the main harness splice and combination meter unit is

open or shorted, the connector is not connected properly and the terminal has poor caulking.

TROUBLE SYMPTOM:

Fail mode occurs because the data is not received from combination meter unit.

WIRING DIAGRAM:

LAN00192

TO POWER SUPPLY CIRCUITFB-10M/B FUSE NO.28 (P)

1

4

3

7

A9

A4

5

BODY INTEGRATED UNIT

ILLUMINATION & BACK-UPJOINT CONNECTOR

KEYLESS ENTRY CONTROL MODULE

i84

i99

i99

i96

E

i84i96i99

123456789101112131415161718192021222324252627282930313233343510 11 12349561728

12345678

Step Check Yes No

1CHECK COMMUNICATION LINE.

1) Warm up the engine.

2) Compare the data of body integrated unit

and combination meter using Subaru Select

Monitor.

Check item:

•Engine speed

•Shift range

Is the data displayed same? Go to step 2.Perform the self-

diagnosis of com-

bination meter.

SIS, INSPEC-

TION,

Combination

Meter System.>

Page 593 of 2453

OD(diag)-25

List of Diagnostic Trouble Code (DTC)

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

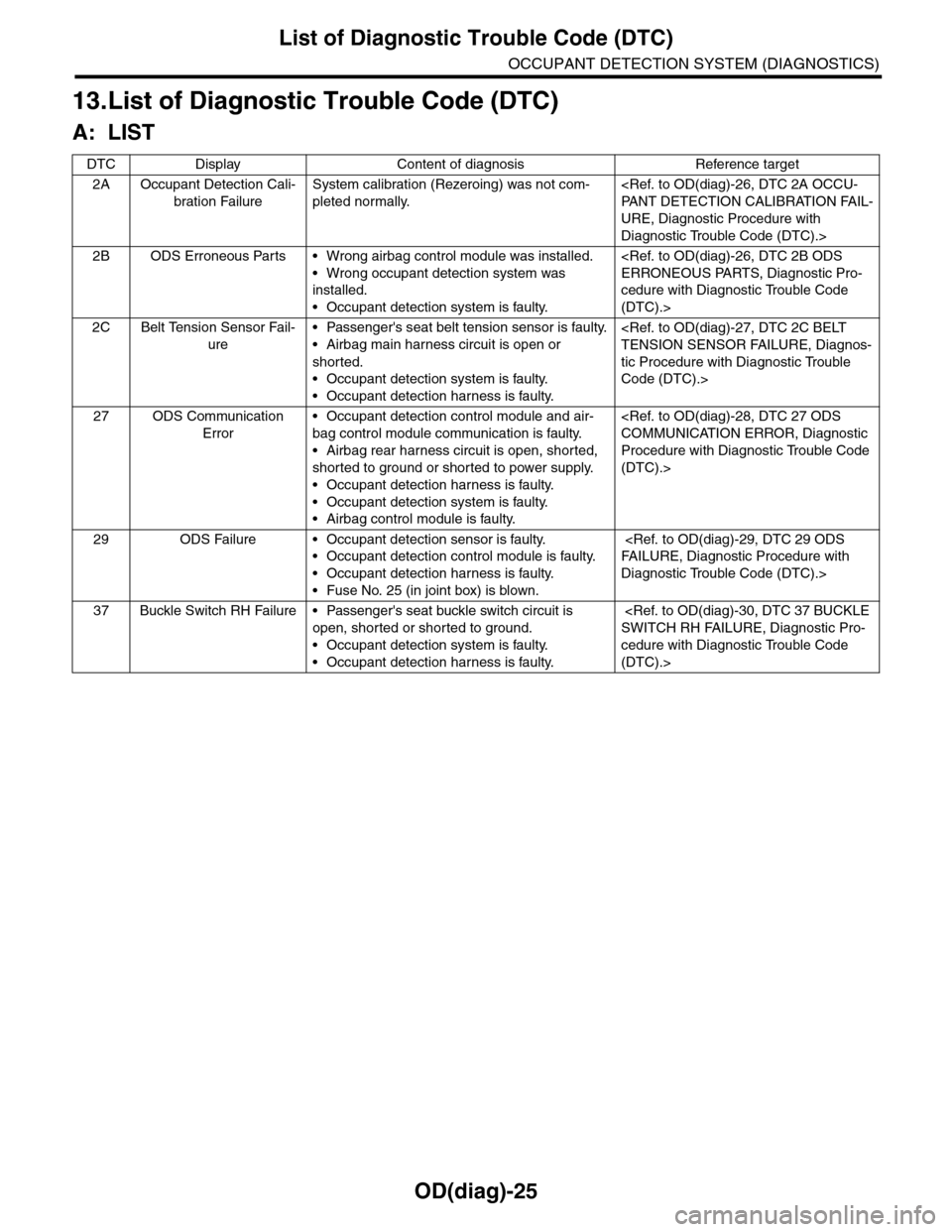

13.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Display Content of diagnosis Reference target

2A Occupant Detection Cali-

bration Failure

System calibration (Rezeroing) was not com-

pleted normally.

URE, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

2B ODS Erroneous Parts • Wrong airbag control module was installed.

•Wrong occupant detection system was

installed.

•Occupant detection system is faulty.

cedure with Diagnostic Trouble Code

(DTC).>

2C Belt Tension Sensor Fail-

ure

•Passenger's seat belt tension sensor is faulty.

•Airbag main harness circuit is open or

shorted.

•Occupant detection system is faulty.

•Occupant detection harness is faulty.

tic Procedure with Diagnostic Trouble

Code (DTC).>

27 ODS Communication

Error

•Occupant detection control module and air-

bag control module communication is faulty.

•Airbag rear harness circuit is open, shorted,

shorted to ground or shorted to power supply.

•Occupant detection harness is faulty.

•Occupant detection system is faulty.

•Airbag control module is faulty.

Procedure with Diagnostic Trouble Code

(DTC).>

29 ODS Failure • Occupant detection sensor is faulty.

•Occupant detection control module is faulty.

•Occupant detection harness is faulty.

•Fuse No. 25 (in joint box) is blown.

Diagnostic Trouble Code (DTC).>

37 Buckle Switch RH Failure • Passenger's seat buckle switch circuit is

open, shorted or shorted to ground.

•Occupant detection system is faulty.

•Occupant detection harness is faulty.

cedure with Diagnostic Trouble Code

(DTC).>

Page 595 of 2453

OD(diag)-27

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

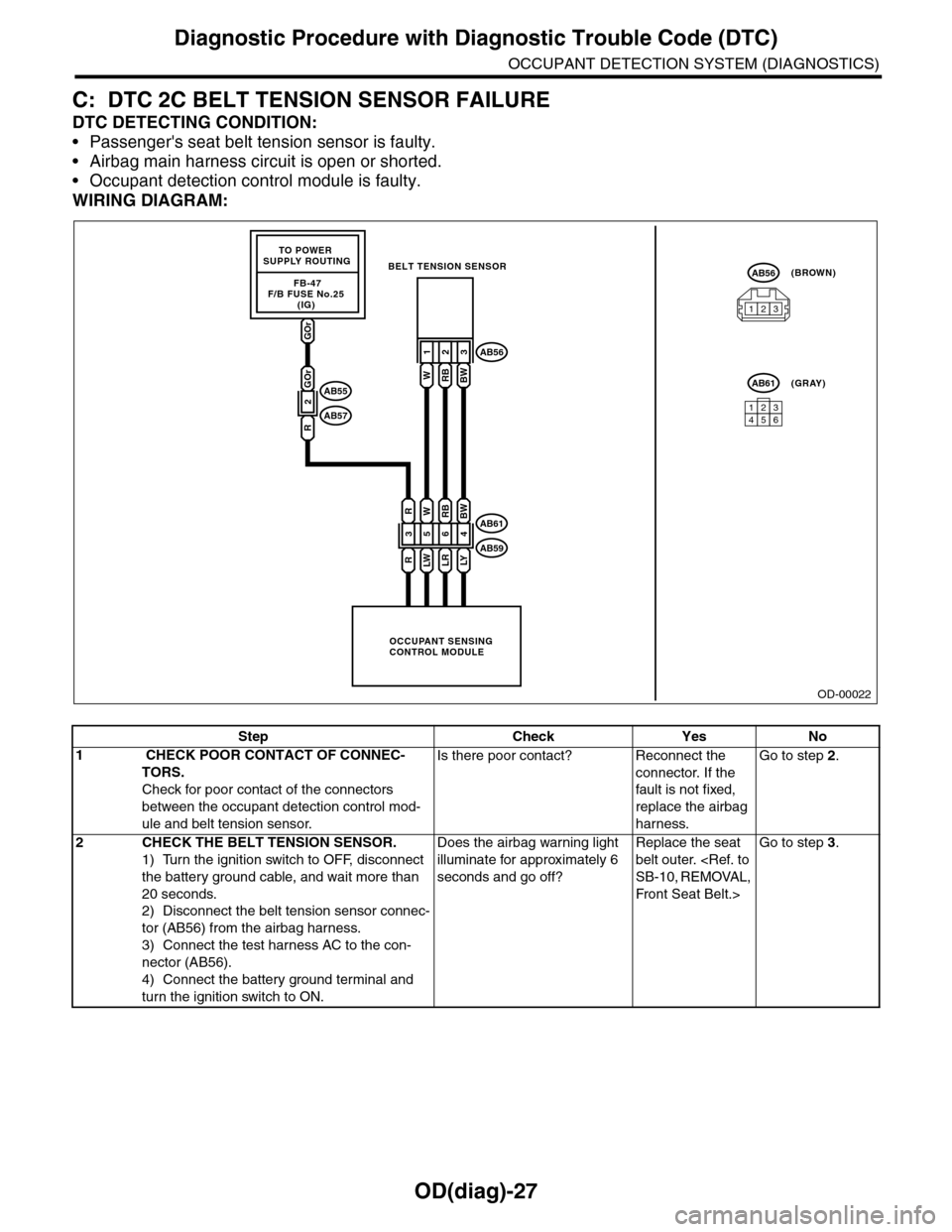

C: DTC 2C BELT TENSION SENSOR FAILURE

DTC DETECTING CONDITION:

•Passenger's seat belt tension sensor is faulty.

•Airbag main harness circuit is open or shorted.

•Occupant detection control module is faulty.

WIRING DIAGRAM:

OD-00022

GOr

FB-47F/B FUSE No.25 (IG)

TO POWER SUPPLY ROUTING

OCCUPANT SENSINGCONTROL MODULE

BELT TENSION SENSOR

3

R

R

5

LW

W

6

LR

RB

4

LY

BW

123

WRBBW

AB61

AB59

AB56

123456

AB61(GRAY)

AB56(BROWN)

123

2

GOr

R

AB55

AB57

Step Check Yes No

1 CHECK POOR CONTACT OF CONNEC-

TORS.

Check for poor contact of the connectors

between the occupant detection control mod-

ule and belt tension sensor.

Is there poor contact? Reconnect the

connector. If the

fault is not fixed,

replace the airbag

harness.

Go to step 2.

2CHECK THE BELT TENSION SENSOR.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the belt tension sensor connec-

tor (AB56) from the airbag harness.

3) Connect the test harness AC to the con-

nector (AB56).

4) Connect the battery ground terminal and

turn the ignition switch to ON.

Does the airbag warning light

illuminate for approximately 6

seconds and go off?

Replace the seat

belt outer.

Front Seat Belt.>

Go to step 3.

Page 597 of 2453

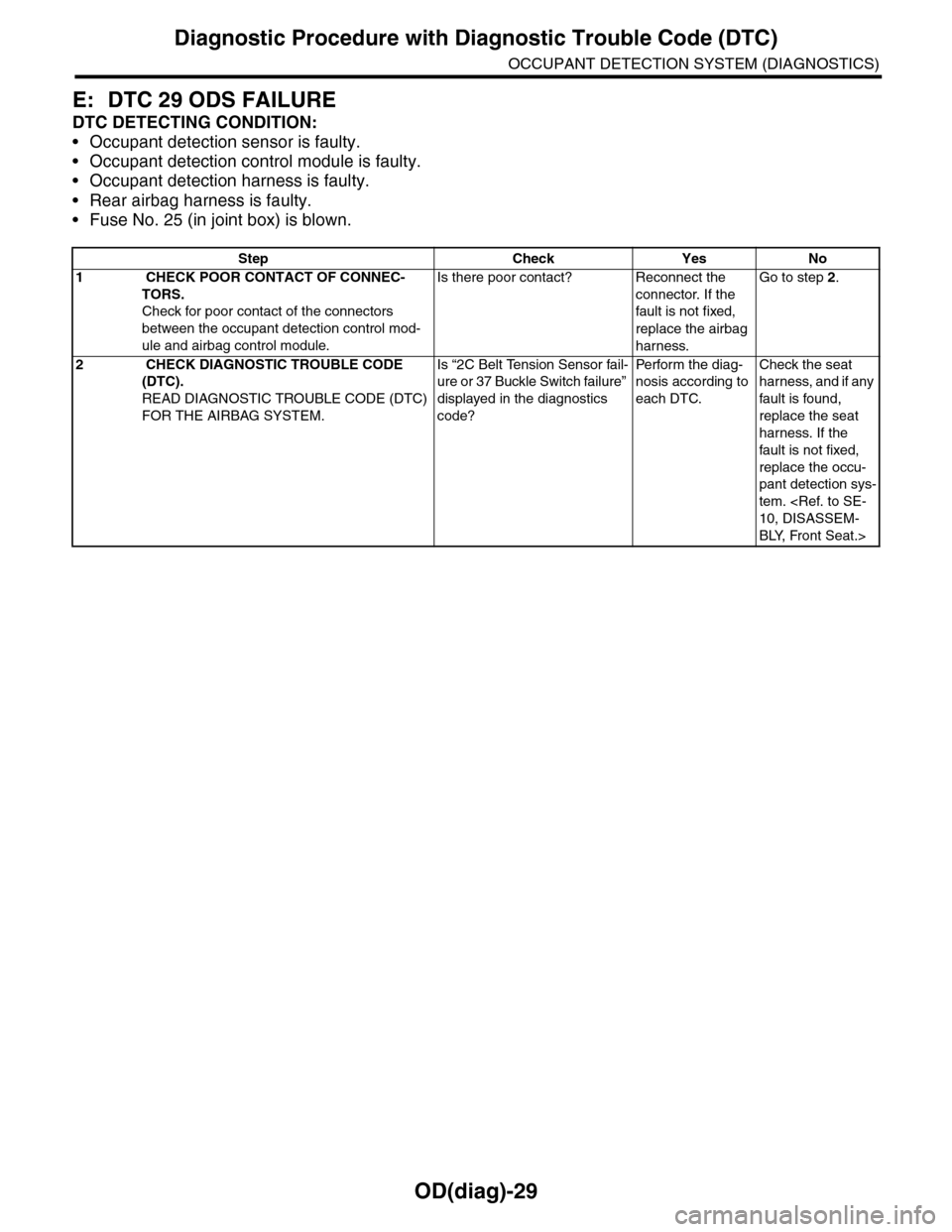

OD(diag)-29

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

E: DTC 29 ODS FAILURE

DTC DETECTING CONDITION:

•Occupant detection sensor is faulty.

•Occupant detection control module is faulty.

•Occupant detection harness is faulty.

•Rear airbag harness is faulty.

•Fuse No. 25 (in joint box) is blown.

Step Check Yes No

1 CHECK POOR CONTACT OF CONNEC-

TORS.

Check for poor contact of the connectors

between the occupant detection control mod-

ule and airbag control module.

Is there poor contact? Reconnect the

connector. If the

fault is not fixed,

replace the airbag

harness.

Go to step 2.

2 CHECK DIAGNOSTIC TROUBLE CODE

(DTC).

READ DIAGNOSTIC TROUBLE CODE (DTC)

FOR THE AIRBAG SYSTEM.

Is “2C Belt Tension Sensor fail-

ure or 37 Buckle Switch failure”

displayed in the diagnostics

code?

Pe r for m t h e d ia g -

nosis according to

each DTC.

Check the seat

harness, and if any

fault is found,

replace the seat

harness. If the

fault is not fixed,

replace the occu-

pant detection sys-

tem.

BLY, Front Seat.>

Page 637 of 2453

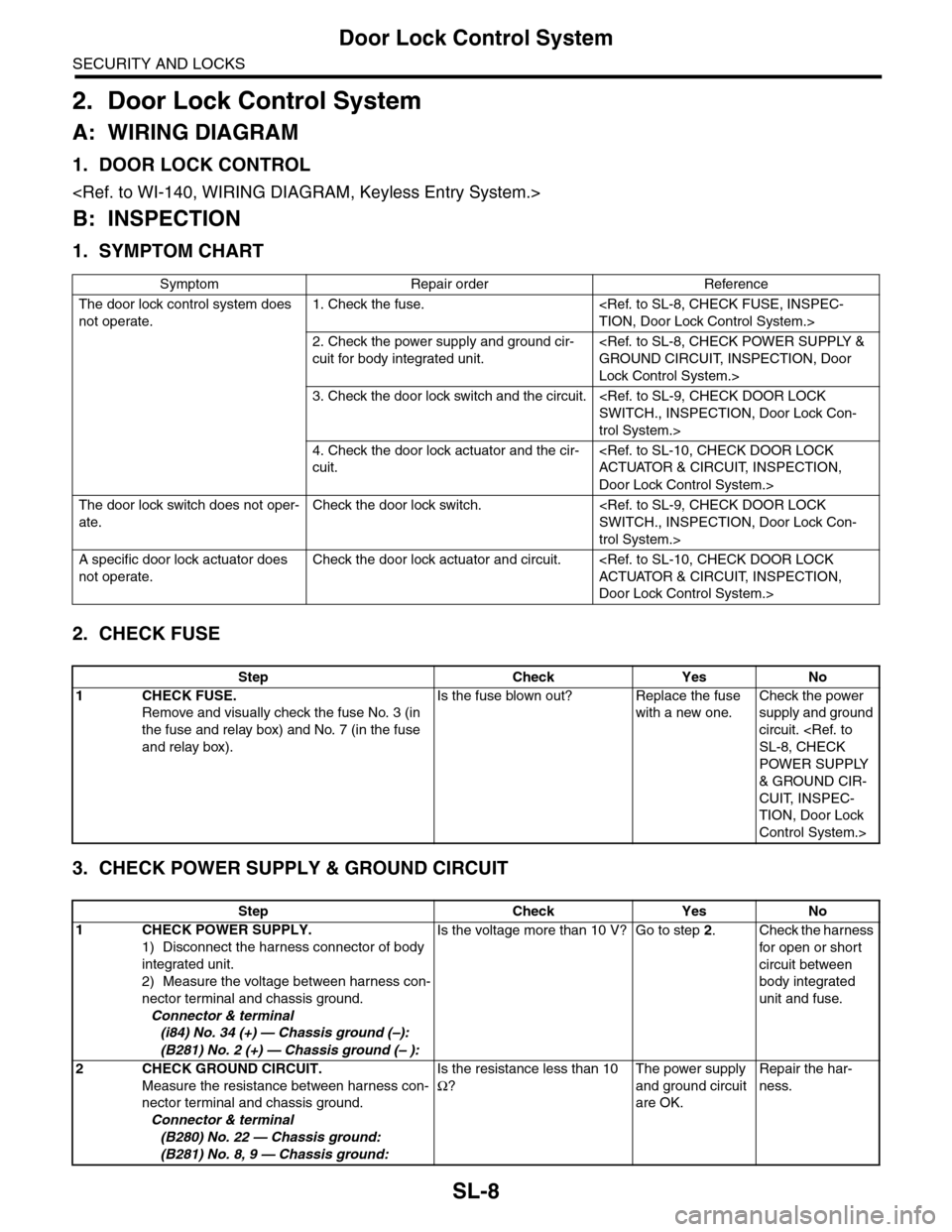

SL-8

Door Lock Control System

SECURITY AND LOCKS

2. Door Lock Control System

A: WIRING DIAGRAM

1. DOOR LOCK CONTROL

B: INSPECTION

1. SYMPTOM CHART

2. CHECK FUSE

3. CHECK POWER SUPPLY & GROUND CIRCUIT

Symptom Repair order Reference

The door lock control system does

not operate.

1. Check the fuse.

2. Check the power supply and ground cir-

cuit for body integrated unit.

Lock Control System.>

3. Check the door lock switch and the circuit.

trol System.>

4. Check the door lock actuator and the cir-

cuit.

Door Lock Control System.>

The door lock switch does not oper-

ate.

Check the door lock switch.

trol System.>

A specific door lock actuator does

not operate.

Check the door lock actuator and circuit.

Door Lock Control System.>

Step Check Yes No

1CHECK FUSE.

Remove and visually check the fuse No. 3 (in

the fuse and relay box) and No. 7 (in the fuse

and relay box).

Is the fuse blown out? Replace the fuse

with a new one.

Check the power

supply and ground

circuit.

POWER SUPPLY

& GROUND CIR-

CUIT, INSPEC-

TION, Door Lock

Control System.>

Step Check Yes No

1CHECK POWER SUPPLY.

1) Disconnect the harness connector of body

integrated unit.

2) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(i84) No. 34 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (– ):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

2CHECK GROUND CIRCUIT.

Measure the resistance between harness con-

nector terminal and chassis ground.

Connector & terminal

(B280) No. 22 — Chassis ground:

(B281) No. 8, 9 — Chassis ground:

Is the resistance less than 10

Ω?

The power supply

and ground circuit

are OK.

Repair the har-

ness.