fuse SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 700 of 2453

WW-5

Wiper and Washer System

WIPER AND WASHER SYSTEMS

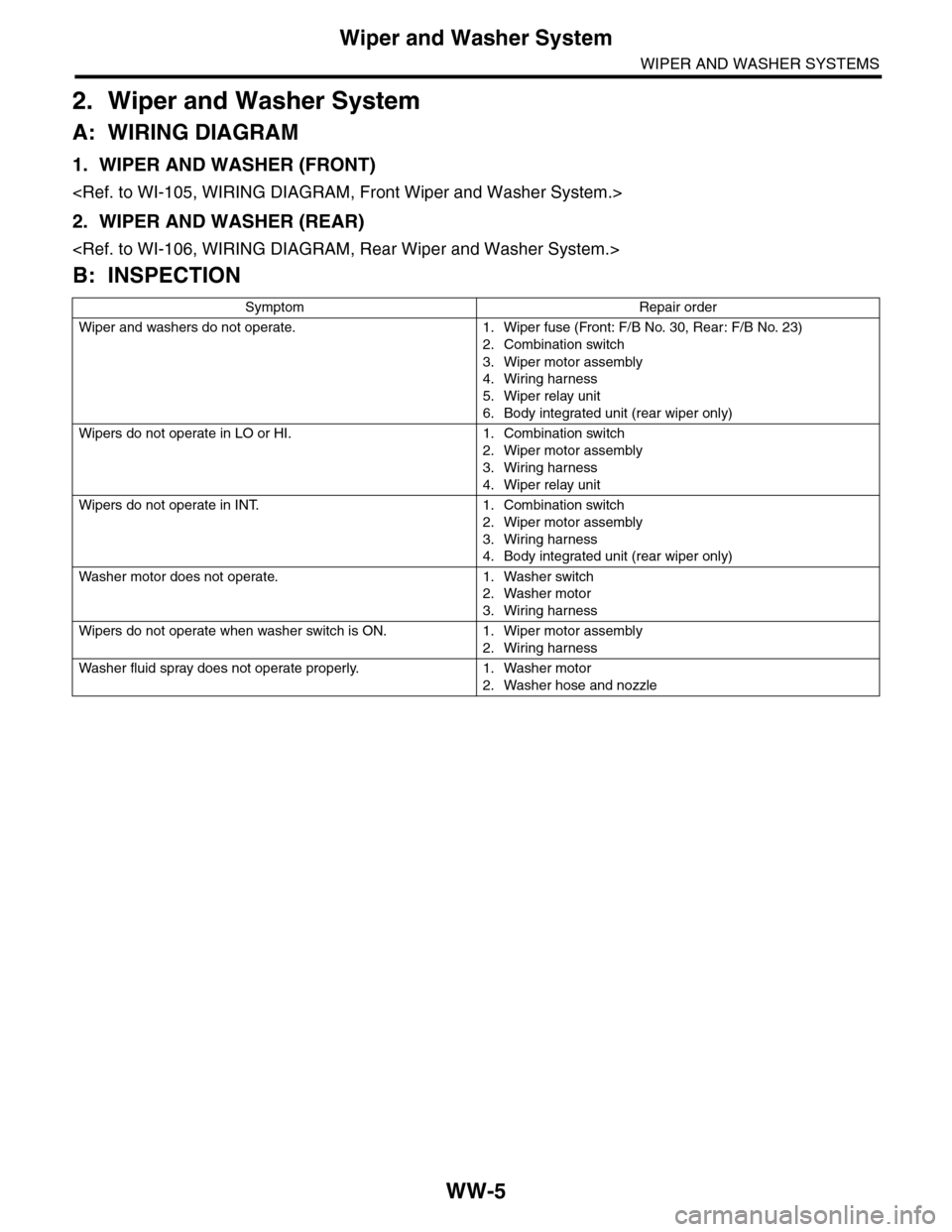

2. Wiper and Washer System

A: WIRING DIAGRAM

1. WIPER AND WASHER (FRONT)

2. WIPER AND WASHER (REAR)

B: INSPECTION

Symptom Repair order

Wiper and washers do not operate. 1. Wiper fuse (Front: F/B No. 30, Rear : F/B No. 23)

2. Combination switch

3. Wiper motor assembly

4. Wiring harness

5. Wiper relay unit

6. Body integrated unit (rear wiper only)

Wipers do not operate in LO or HI. 1. Combination switch

2. Wiper motor assembly

3. Wiring harness

4. Wiper relay unit

Wipers do not operate in INT. 1. Combination switch

2. Wiper motor assembly

3. Wiring harness

4. Body integrated unit (rear wiper only)

Wa sh e r mo to r do e s n ot o pe ra t e. 1 . Wa sh e r swit c h

2. Washer motor

3. Wiring harness

Wipers do not operate when washer switch is ON. 1. Wiper motor assembly

2. Wiring harness

Wa sh e r fl u id sp ray do e s n ot op e ra te pr o p er l y. 1 . Wa sh e r m ot o r

2. Washer hose and nozzle

Page 704 of 2453

WW-9

Combination Switch (Wiper)

WIPER AND WASHER SYSTEMS

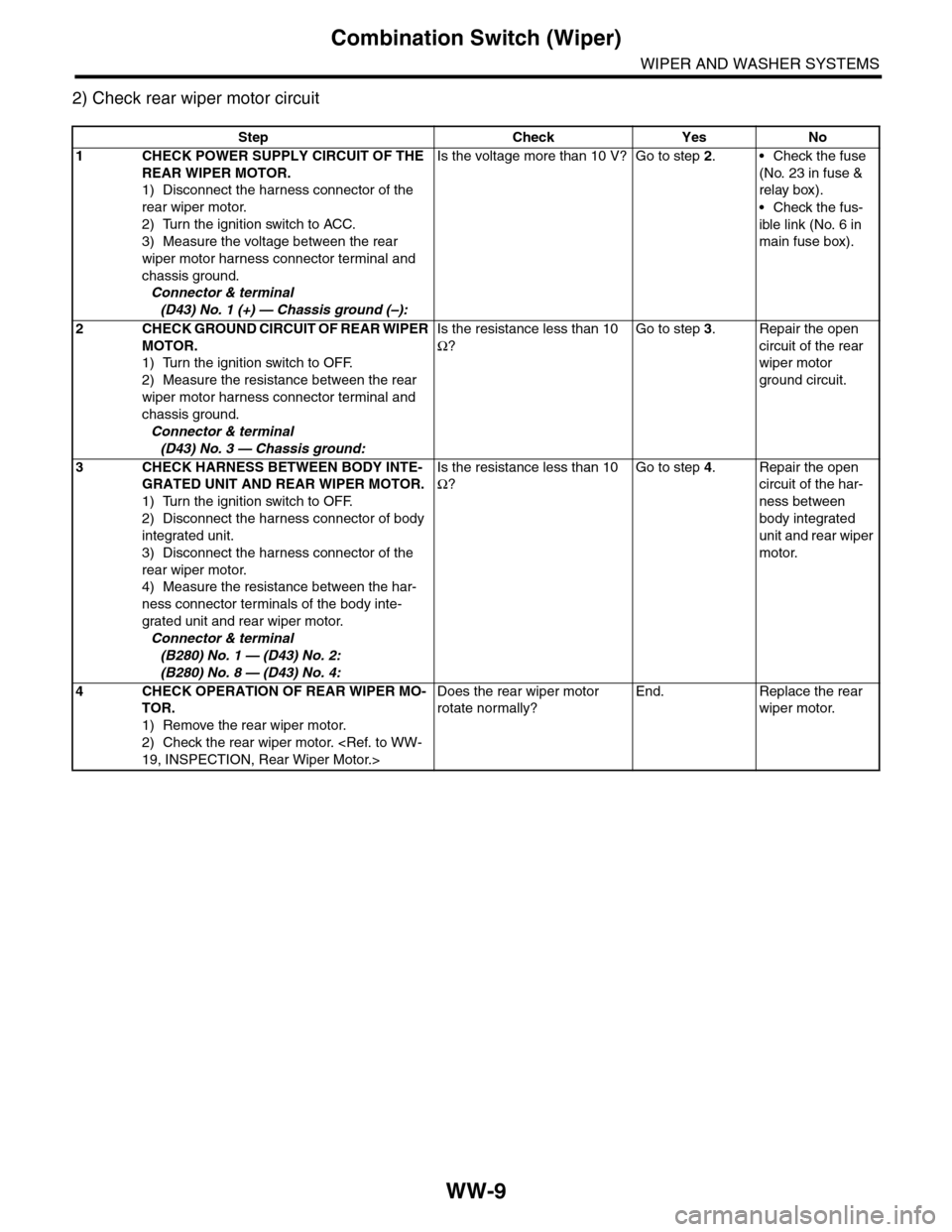

2) Check rear wiper motor circuit

Step Check Yes No

1CHECK POWER SUPPLY CIRCUIT OF THE

REAR WIPER MOTOR.

1) Disconnect the harness connector of the

rear wiper motor.

2) Turn the ignition switch to ACC.

3) Measure the voltage between the rear

wiper motor harness connector terminal and

chassis ground.

Connector & terminal

(D43) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.•Check the fuse

(No. 23 in fuse &

relay box).

•Check the fus-

ible link (No. 6 in

main fuse box).

2CHECK GROUND CIRCUIT OF REAR WIPER

MOTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between the rear

wiper motor harness connector terminal and

chassis ground.

Connector & terminal

(D43) No. 3 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 3.Repair the open

circuit of the rear

wiper motor

ground circuit.

3CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND REAR WIPER MOTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of body

integrated unit.

3) Disconnect the harness connector of the

rear wiper motor.

4) Measure the resistance between the har-

ness connector terminals of the body inte-

grated unit and rear wiper motor.

Connector & terminal

(B280) No. 1 — (D43) No. 2:

(B280) No. 8 — (D43) No. 4:

Is the resistance less than 10

Ω?

Go to step 4.Repair the open

circuit of the har-

ness between

body integrated

unit and rear wiper

motor.

4CHECK OPERATION OF REAR WIPER MO-

TOR.

1) Remove the rear wiper motor.

2) Check the rear wiper motor.

Does the rear wiper motor

rotate normally?

End. Replace the rear

wiper motor.

Page 779 of 2453

BVC(diag)-24

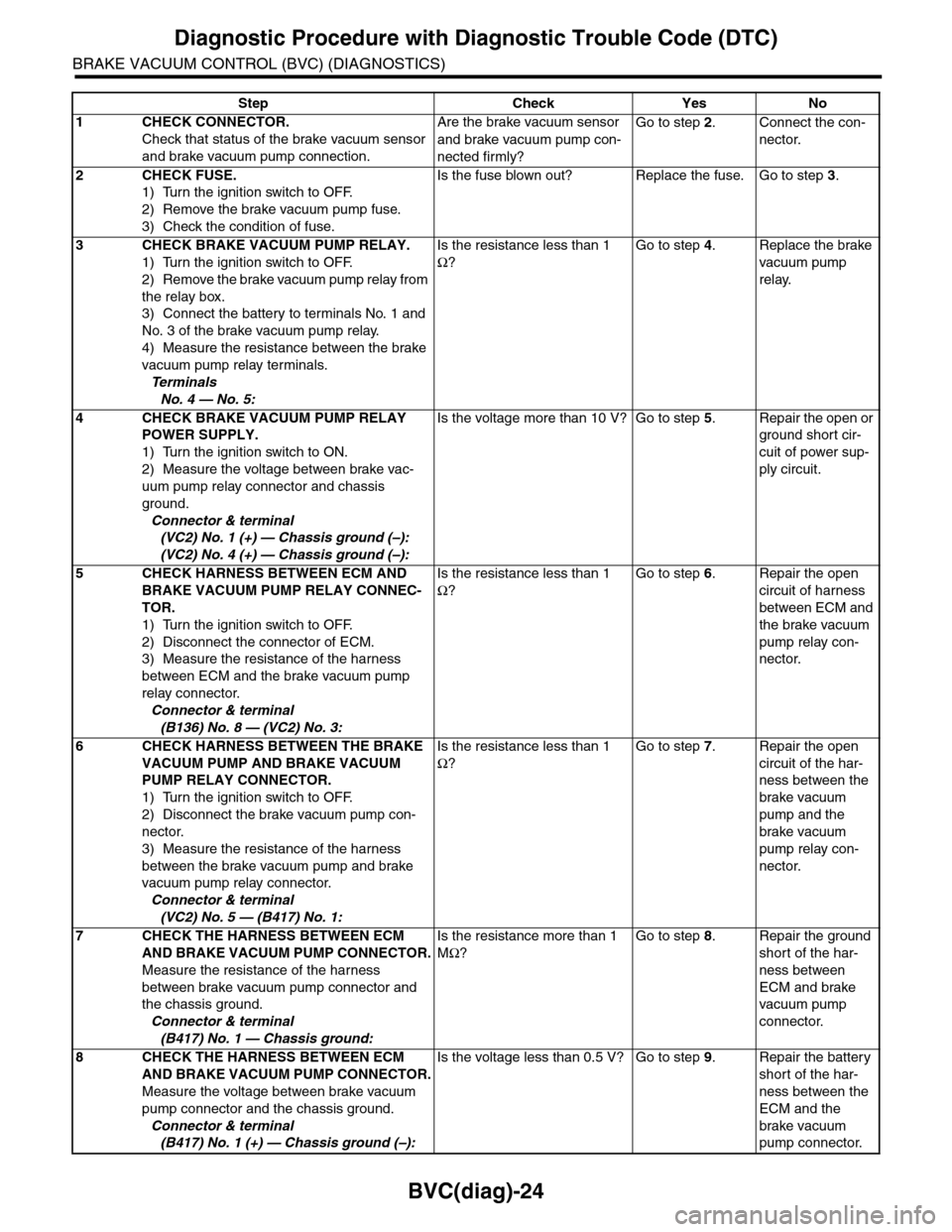

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

Step Check Yes No

1CHECK CONNECTOR.

Check that status of the brake vacuum sensor

and brake vacuum pump connection.

Are the brake vacuum sensor

and brake vacuum pump con-

nected firmly?

Go to step 2.Connect the con-

nector.

2CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the brake vacuum pump fuse.

3) Check the condition of fuse.

Is the fuse blown out? Replace the fuse. Go to step 3.

3CHECK BRAKE VACUUM PUMP RELAY.

1) Turn the ignition switch to OFF.

2) Remove the brake vacuum pump relay from

the relay box.

3) Connect the battery to terminals No. 1 and

No. 3 of the brake vacuum pump relay.

4) Measure the resistance between the brake

vacuum pump relay terminals.

Te r m i n a l s

No. 4 — No. 5:

Is the resistance less than 1

Ω?

Go to step 4.Replace the brake

vacuum pump

relay.

4CHECK BRAKE VACUUM PUMP RELAY

POWER SUPPLY.

1) Turn the ignition switch to ON.

2) Measure the voltage between brake vac-

uum pump relay connector and chassis

ground.

Connector & terminal

(VC2) No. 1 (+) — Chassis ground (–):

(VC2) No. 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 5.Repair the open or

ground short cir-

cuit of power sup-

ply circuit.

5CHECK HARNESS BETWEEN ECM AND

BRAKE VACUUM PUMP RELAY CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector of ECM.

3) Measure the resistance of the harness

between ECM and the brake vacuum pump

relay connector.

Connector & terminal

(B136) No. 8 — (VC2) No. 3:

Is the resistance less than 1

Ω?

Go to step 6.Repair the open

circuit of harness

between ECM and

the brake vacuum

pump relay con-

nector.

6CHECK HARNESS BETWEEN THE BRAKE

VACUUM PUMP AND BRAKE VACUUM

PUMP RELAY CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the brake vacuum pump con-

nector.

3) Measure the resistance of the harness

between the brake vacuum pump and brake

vacuum pump relay connector.

Connector & terminal

(VC2) No. 5 — (B417) No. 1:

Is the resistance less than 1

Ω?

Go to step 7.Repair the open

circuit of the har-

ness between the

brake vacuum

pump and the

brake vacuum

pump relay con-

nector.

7CHECK THE HARNESS BETWEEN ECM

AND BRAKE VACUUM PUMP CONNECTOR.

Measure the resistance of the harness

between brake vacuum pump connector and

the chassis ground.

Connector & terminal

(B417) No. 1 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 8.Repair the ground

short of the har-

ness between

ECM and brake

vacuum pump

connector.

8CHECK THE HARNESS BETWEEN ECM

AND BRAKE VACUUM PUMP CONNECTOR.

Measure the voltage between brake vacuum

pump connector and the chassis ground.

Connector & terminal

(B417) No. 1 (+) — Chassis ground (–):

Is the voltage less than 0.5 V? Go to step 9.Repair the battery

short of the har-

ness between the

ECM and the

brake vacuum

pump connector.

Page 937 of 2453

RS-4

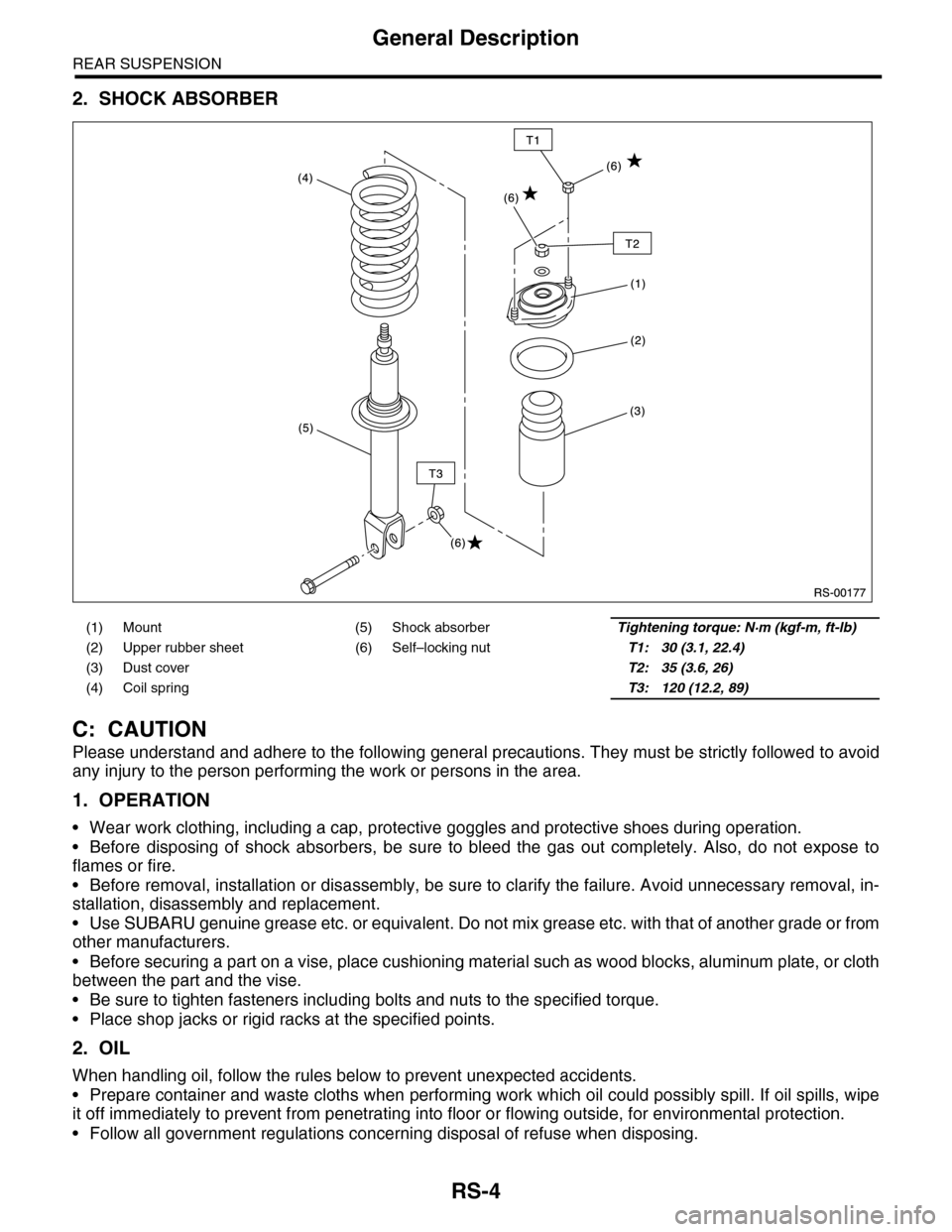

General Description

REAR SUSPENSION

2. SHOCK ABSORBER

C: CAUTION

Please understand and adhere to the following general precautions. They must be strictly followed to avoid

any injury to the person performing the work or persons in the area.

1. OPERATION

•Wear work clothing, including a cap, protective goggles and protective shoes during operation.

•Before disposing of shock absorbers, be sure to bleed the gas out completely. Also, do not expose to

flames or fire.

•Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, in-

stallation, disassembly and replacement.

•Use SUBARU genuine grease etc. or equivalent. Do not mix grease etc. with that of another grade or from

other manufacturers.

•Before securing a part on a vise, place cushioning material such as wood blocks, aluminum plate, or cloth

between the part and the vise.

•Be sure to tighten fasteners including bolts and nuts to the specified torque.

•Place shop jacks or rigid racks at the specified points.

2. OIL

When handling oil, follow the rules below to prevent unexpected accidents.

•Prepare container and waste cloths when performing work which oil could possibly spill. If oil spills, wipe

it off immediately to prevent from penetrating into floor or flowing outside, for environmental protection.

•Follow all government regulations concerning disposal of refuse when disposing.

(1) Mount (5) Shock absorberTightening torque: N·m (kgf-m, ft-lb)

(2) Upper rubber sheet (6) Self–locking nutT1: 30 (3.1, 22.4)

(3) Dust cover T2: 35 (3.6, 26)

(4) Coil spring T3: 120 (12.2, 89)

Page 964 of 2453

TPM(diag)-14

Subaru Select Monitor

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

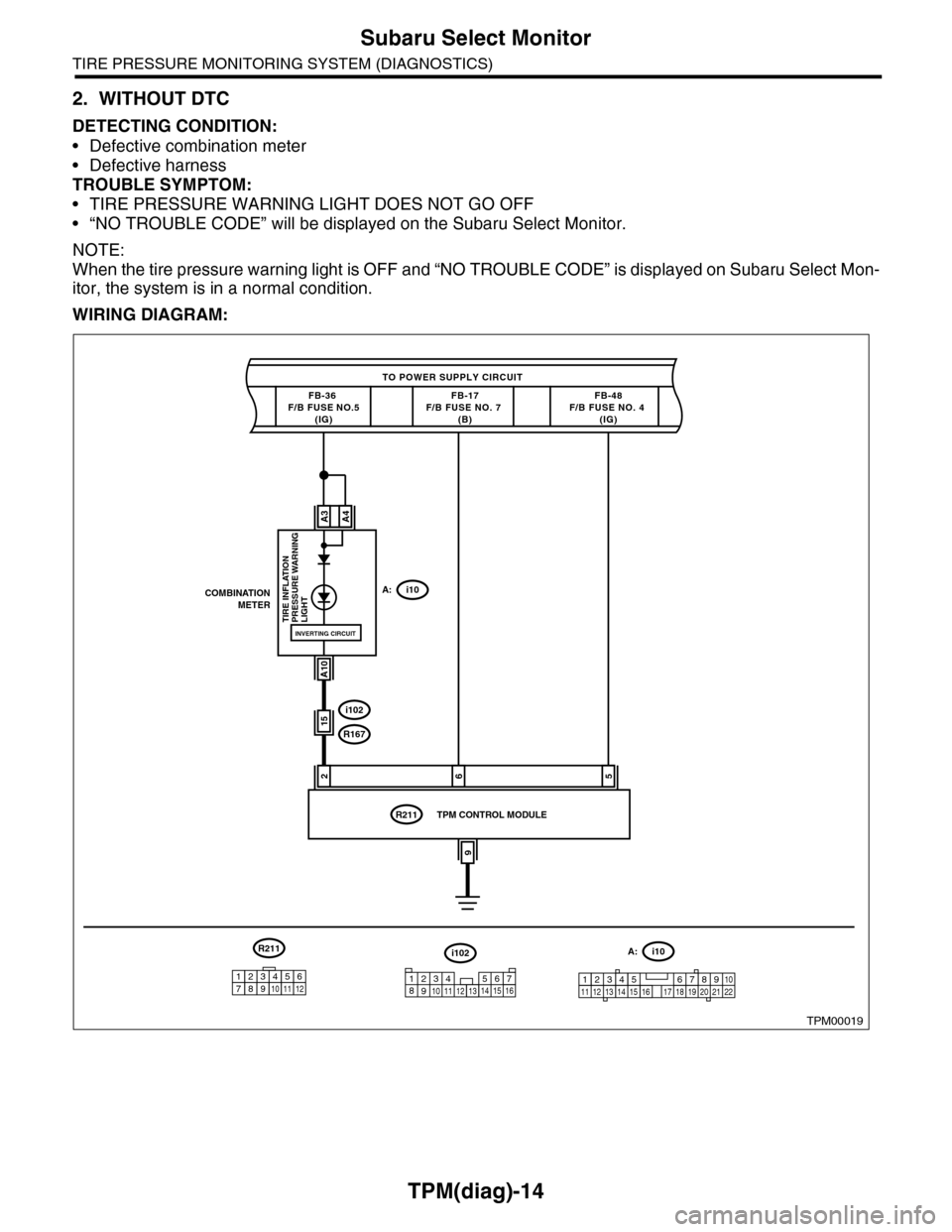

2. WITHOUT DTC

DETECTING CONDITION:

•Defective combination meter

•Defective harness

TROUBLE SYMPTOM:

•TIRE PRESSURE WARNING LIGHT DOES NOT GO OFF

•“NO TROUBLE CODE” will be displayed on the Subaru Select Monitor.

NOTE:

When the tire pressure warning light is OFF and “NO TROUBLE CODE” is displayed on Subaru Select Mon-

itor, the system is in a normal condition.

WIRING DIAGRAM:

TPM00019

TO POWER SUPPLY CIRCUIT

FB-36 F/B FUSE NO.5(IG)

26

COMBINATIONMETERA:i10

A3

A10

TIRE INFLATION PRESSURE WARNINGLIGHT

FB-17F/B FUSE NO. 7 (B)

i102

R167

R211

FB-48F/B FUSE NO. 4 (IG)

A4

INVERTING CIRCUIT

15

5

9

TPM CONTROL MODULE

i102

1238910411 12 1314 15 16567

A:i10

12345 678910111219 20 2113 14 15 161718 22

R211

123456789101112

Page 970 of 2453

TPM(diag)-20

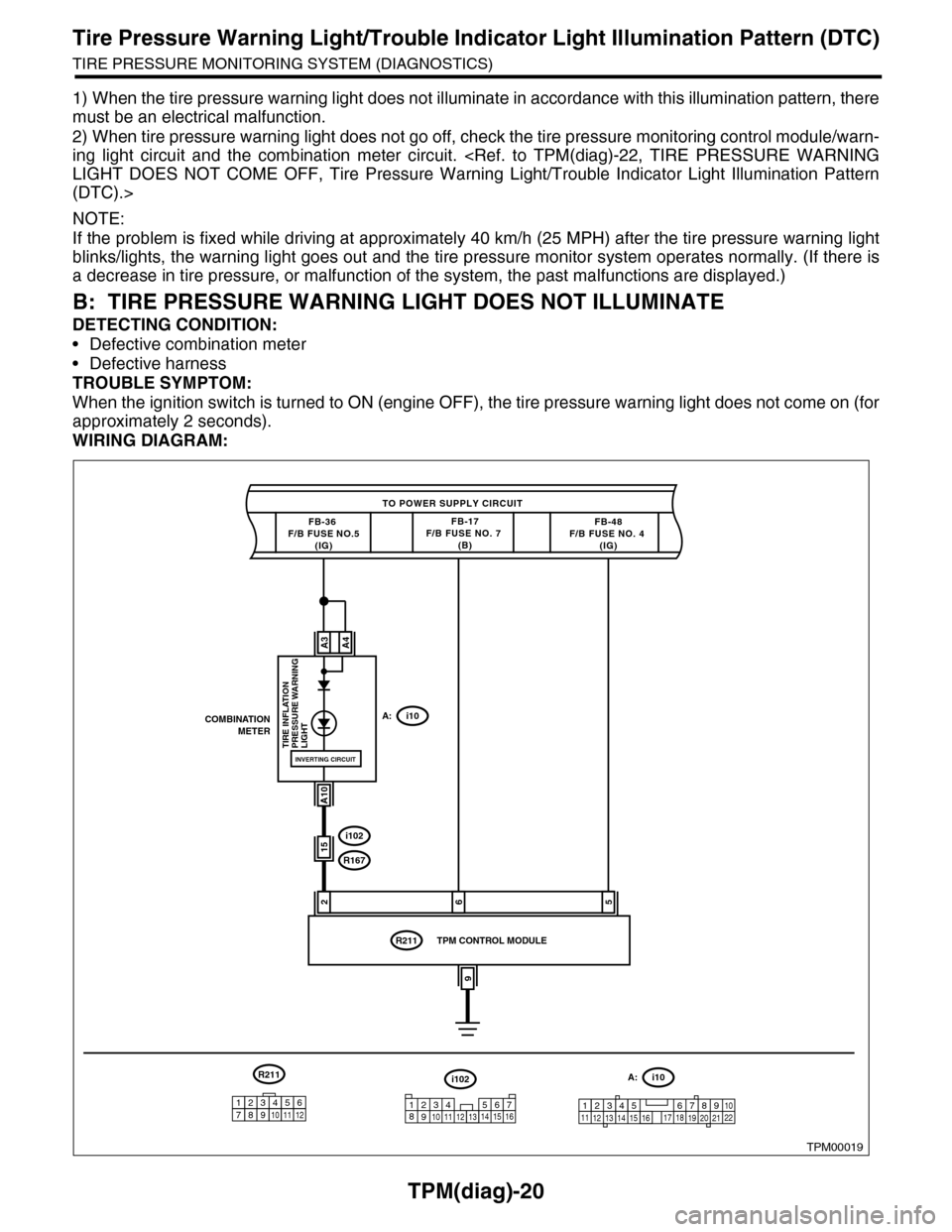

Tire Pressure Warning Light/Trouble Indicator Light Illumination Pattern (DTC)

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

1) When the tire pressure warning light does not illuminate in accordance with this illumination pattern, there

must be an electrical malfunction.

2) When tire pressure warning light does not go off, check the tire pressure monitoring control module/warn-

ing light circuit and the combination meter circuit.

(DTC).>

NOTE:

If the problem is fixed while driving at approximately 40 km/h (25 MPH) after the tire pressure warning light

blinks/lights, the warning light goes out and the tire pressure monitor system operates normally. (If there is

a decrease in tire pressure, or malfunction of the system, the past malfunctions are displayed.)

B: TIRE PRESSURE WARNING LIGHT DOES NOT ILLUMINATE

DETECTING CONDITION:

•Defective combination meter

•Defective harness

TROUBLE SYMPTOM:

When the ignition switch is turned to ON (engine OFF), the tire pressure warning light does not come on (for

approximately 2 seconds).

WIRING DIAGRAM:

TPM00019

TO POWER SUPPLY CIRCUIT

FB-36 F/B FUSE NO.5(IG)

26

COMBINATIONMETERA:i10

A3

A10

TIRE INFLATION PRESSURE WARNINGLIGHT

FB-17F/B FUSE NO. 7 (B)

i102

R167

R211

FB-48F/B FUSE NO. 4 (IG)

A4

INVERTING CIRCUIT

15

5

9

TPM CONTROL MODULE

i102

1238910411 12 1314 15 16567

A:i10

12345 678910111219 20 2113 14 15 161718 22

R211

123456789101112

Page 972 of 2453

TPM(diag)-22

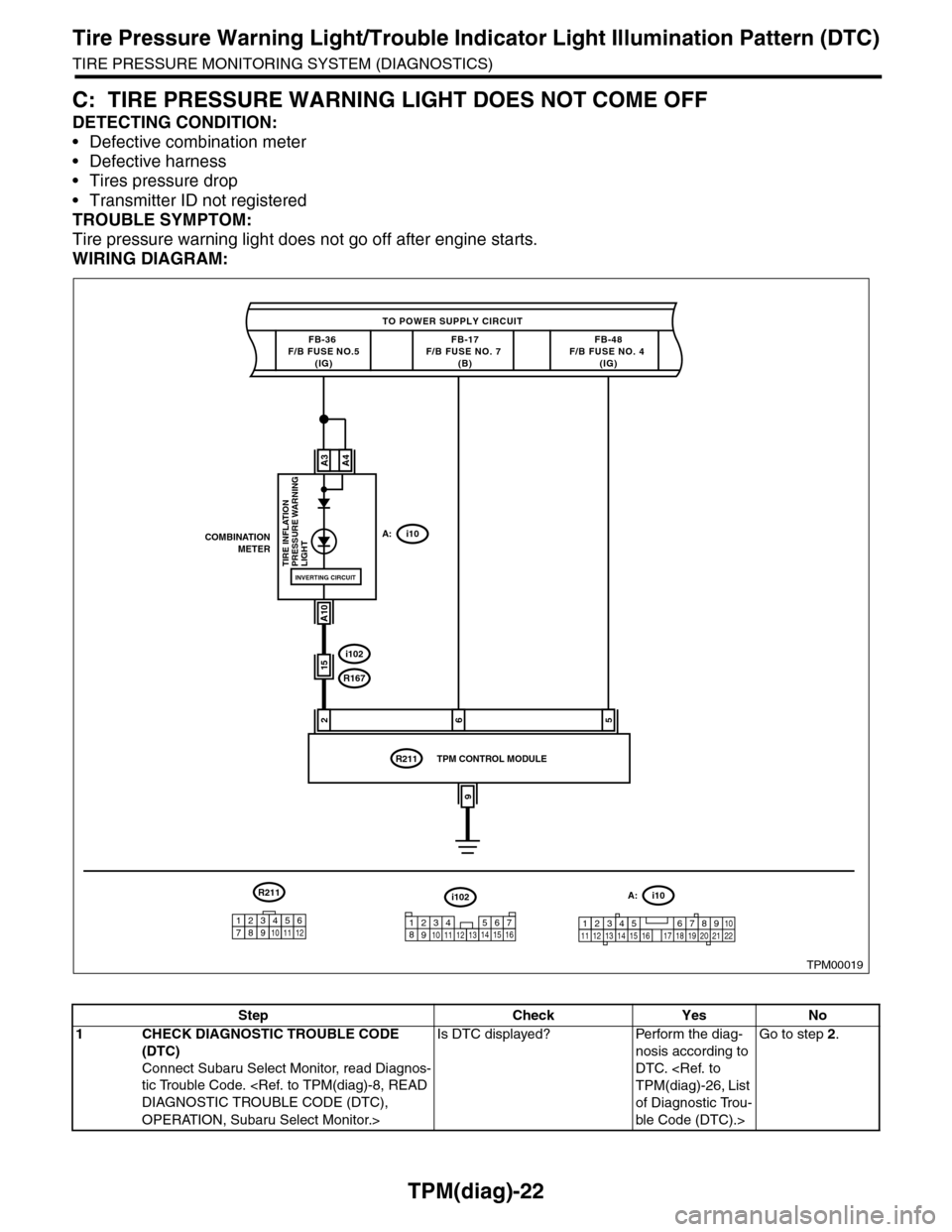

Tire Pressure Warning Light/Trouble Indicator Light Illumination Pattern (DTC)

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

C: TIRE PRESSURE WARNING LIGHT DOES NOT COME OFF

DETECTING CONDITION:

•Defective combination meter

•Defective harness

•Tires pressure drop

•Transmitter ID not registered

TROUBLE SYMPTOM:

Tire pressure warning light does not go off after engine starts.

WIRING DIAGRAM:

TPM00019

TO POWER SUPPLY CIRCUIT

FB-36 F/B FUSE NO.5(IG)

26

COMBINATIONMETERA:i10

A3

A10

TIRE INFLATION PRESSURE WARNINGLIGHT

FB-17F/B FUSE NO. 7 (B)

i102

R167

R211

FB-48F/B FUSE NO. 4 (IG)

A4

INVERTING CIRCUIT

15

5

9

TPM CONTROL MODULE

i102

1238910411 12 1314 15 16567

A:i10

12345 678910111219 20 2113 14 15 161718 22

R211

123456789101112

Step Check Yes No

1CHECK DIAGNOSTIC TROUBLE CODE

(DTC)

Connect Subaru Select Monitor, read Diagnos-

tic Trouble Code.

OPERATION, Subaru Select Monitor.>

Is DTC displayed? Perform the diag-

nosis according to

DTC.

of Diagnostic Trou-

ble Code (DTC).>

Go to step 2.

Page 974 of 2453

TPM(diag)-24

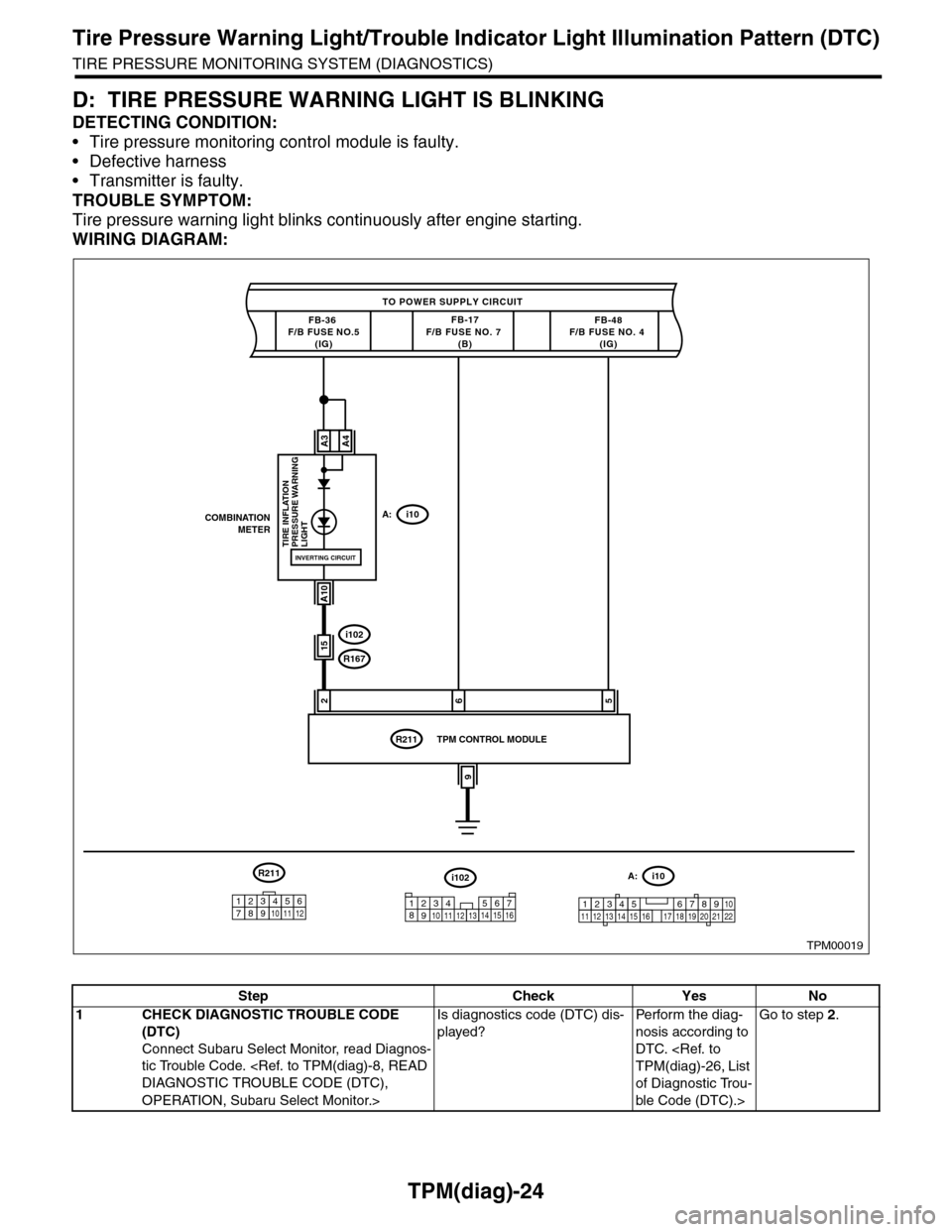

Tire Pressure Warning Light/Trouble Indicator Light Illumination Pattern (DTC)

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

D: TIRE PRESSURE WARNING LIGHT IS BLINKING

DETECTING CONDITION:

•Tire pressure monitoring control module is faulty.

•Defective harness

•Transmitter is faulty.

TROUBLE SYMPTOM:

Tire pressure warning light blinks continuously after engine starting.

WIRING DIAGRAM:

TPM00019

TO POWER SUPPLY CIRCUIT

FB-36 F/B FUSE NO.5(IG)

26

COMBINATIONMETERA:i10

A3

A10

TIRE INFLATION PRESSURE WARNINGLIGHT

FB-17F/B FUSE NO. 7 (B)

i102

R167

R211

FB-48F/B FUSE NO. 4 (IG)

A4

INVERTING CIRCUIT

15

5

9

TPM CONTROL MODULE

i102

1238910411 12 1314 15 16567

A:i10

12345 678910111219 20 2113 14 15 161718 22

R211

123456789101112

Step Check Yes No

1CHECK DIAGNOSTIC TROUBLE CODE

(DTC)

Connect Subaru Select Monitor, read Diagnos-

tic Trouble Code.

OPERATION, Subaru Select Monitor.>

Is diagnostics code (DTC) dis-

played?

Pe r for m t h e d ia g -

nosis according to

DTC.

of Diagnostic Trou-

ble Code (DTC).>

Go to step 2.

Page 984 of 2453

TPM(diag)-34

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

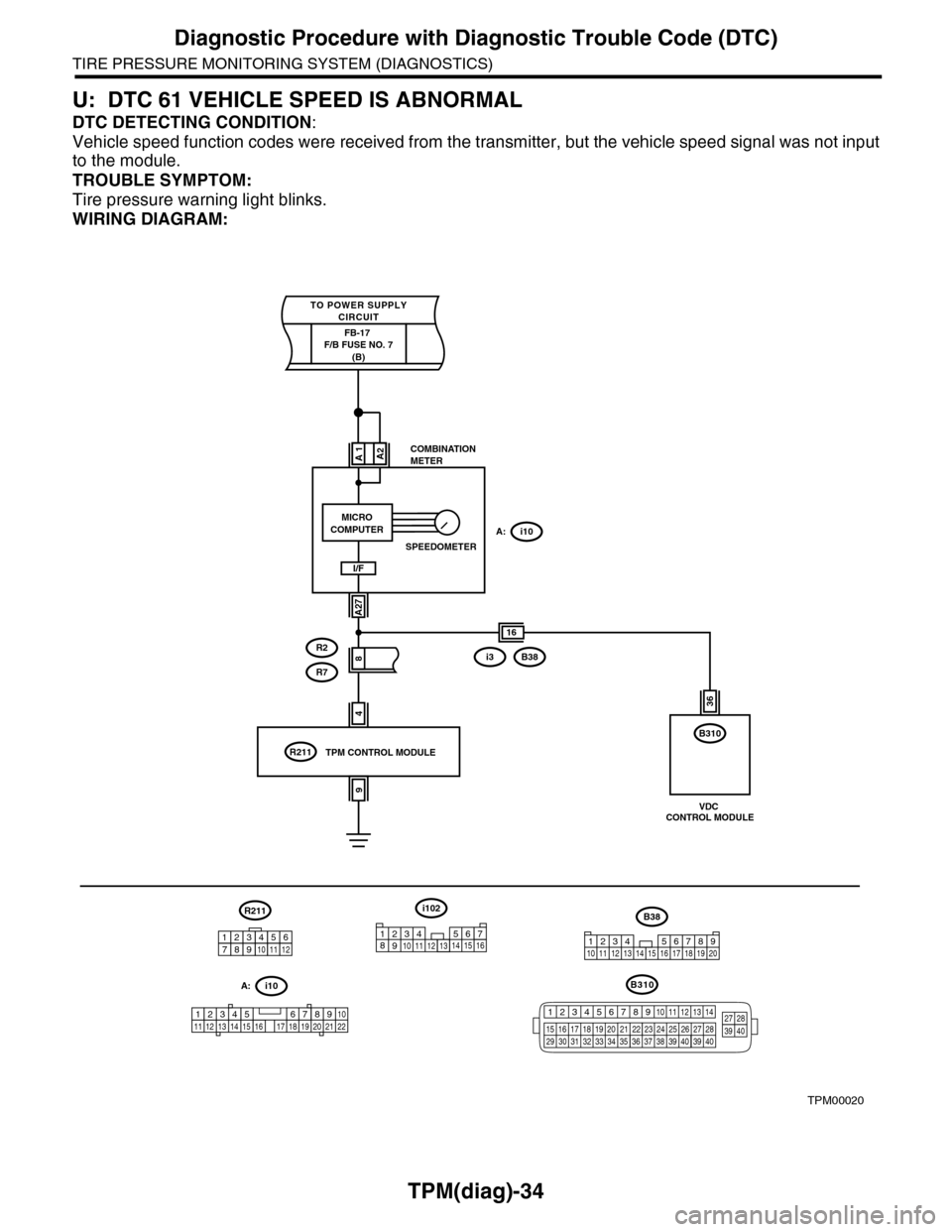

U: DTC 61 VEHICLE SPEED IS ABNORMAL

DTC DETECTING CONDITION:

Vehicle speed function codes were received from the transmitter, but the vehicle speed signal was not input

to the module.

TROUBLE SYMPTOM:

Tire pressure warning light blinks.

WIRING DIAGRAM:

TPM00020

4

COMBINATIONMETER

A:i10

A1

A27

R2

R7

R211

A2

I/F

8

9

TPM CONTROL MODULE

i102

1238910411 12 1314 15 16567

A:i10

12345 678910111219 20 2113 14 15 161718 22

R211

16

B310

MICROCOMPUTER

SPEEDOMETER

FB-17 F/B FUSE NO. 7(B)

TO POWER SUPPLYCIRCUIT

i3B38

B38

1234 5678910 11 12 13 14 15 16 17 18 19 20

36

VDC CONTROL MODULE

123456789101112

B310

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 283940

Page 1126 of 2453

CO(H6DO)-7

Radiator Fan System

COOLING

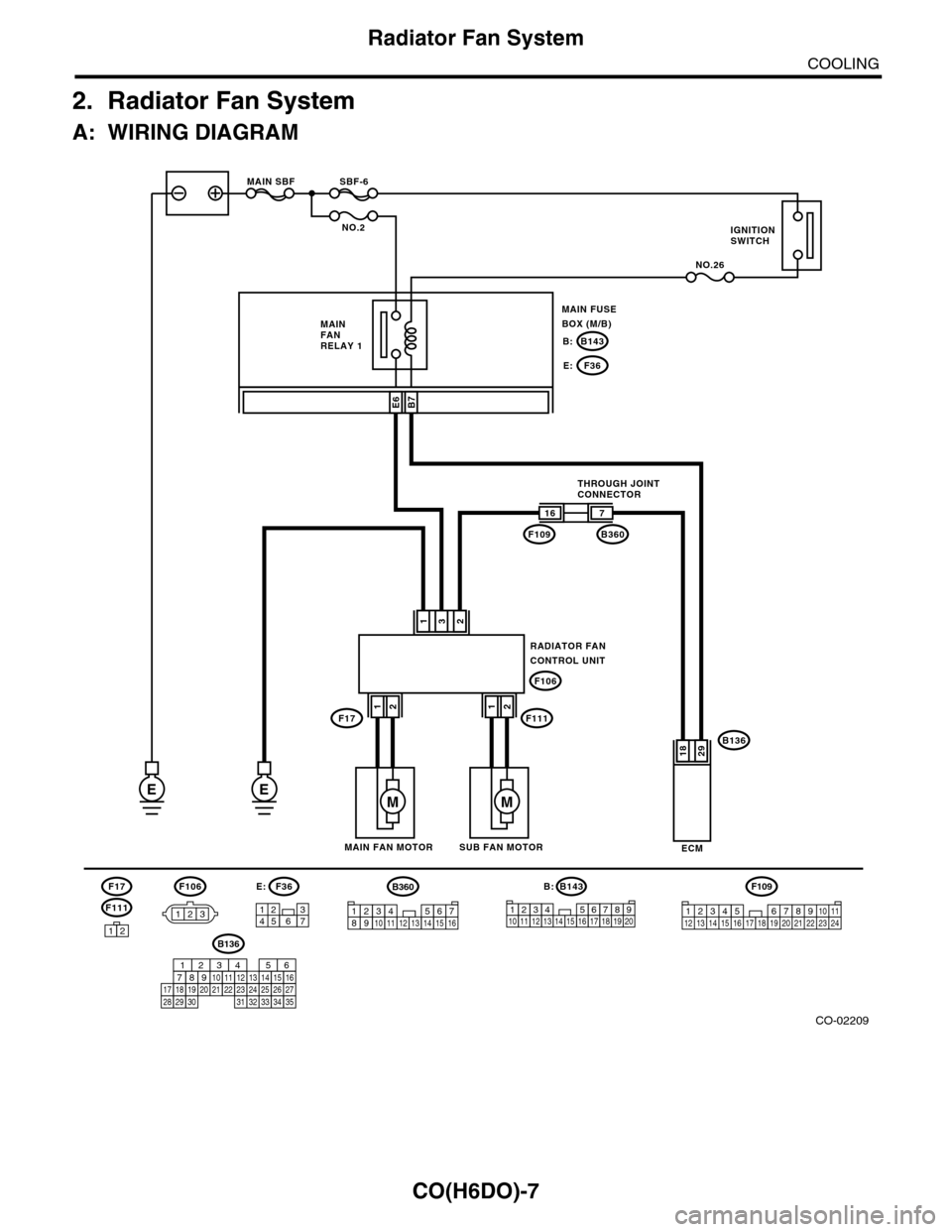

2. Radiator Fan System

A: WIRING DIAGRAM

CO-02209

RADIATOR FANCONTROL UNIT

132

B136

ECM

16

F109

F106

7

B360

2918

F106

123

B7

E

SBF-6MAIN SBF

NO.2

NO.26

B143B:

F36E:

E6

3127456

F36E:B143

123456712131415161718

B:

8191192010

EM

SUB FAN MOTORMAIN FAN MOTOR

THROUGH JOINTCONNECTOR

MAIN FANRELAY 1

MAIN FUSEBOX (M/B)

IGNITIONSWITCH

F17F11112

M

12

F111

F17

12

F109

3412 8910 1112 13 14 15 16 17 18 19 20 21 22 23 24567

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

B360

12345678910111213141516