SUZUKI GRAND VITARA 1987 Service Owners Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 91 of 962

Measured journal diameter

44.744 - 44.750 mm44.738 - 44.744 mm44.732 - 44.738 mm

(1.7616 - 1.7618 in.)(1.7614 - 1.7616 in.)(1.7612 - 1.7614 in.)

Alphabets stamped I AGreen & RedBlack & RedRed only

on mating surfaceBBlack & RedRed onlyYellow & Red

of cylinder blockCRed onlyYellow & RedBlue & Red

Undersize bearing to be installed.

Rear Oil Seal

Carefully inspect oil seal for wear or damage. If

its lip is worn or damaged, replace oil seal.

1. Rear oil seal

Fig. 3-5-49 Rear oil sealOil Pump

Flywheel

l If ring gear is damaged, cracked or worn,

replace flywheel.

l If surface contacting clutch disc is damaged,

or excessibly worn, replace flywheel.

l Check flywheel for face runout with a dial

wge.

If runout is out of limit, replace flywheel.

Limit on runout0.2 mm (0.0078 in.)

Fig. 3-5-50 Measuring runou t

1) Inspect oil seal lip for fault or other damage.

Replace as necessary.

2) Inspect outer and inner rotors, rotor plate,

and oil pump case for excessive wear or

damage.

l Radial clearance:

Check radial clearance between outer rotor

and case, using thickness gauge.

If clearance exceeds its limit, replace outer

rotor or case.

Outer rotor and case0.310 mm (0.0122 in.)

3-34

Page 92 of 962

3-6. ENGINE REASSEMBLY

NOTE:

l All parts to be used in reassembly must be

perfectly clean.

l Oil sliding and rubbing surfaces of engine

parts just before using them in reassembly.

Use engine oil (Refer to page l-8).

l Have liquid packing ready for use. SUZUKI

BOND NO. 1215 is specified for it. Use it

wherever its use is specified in order to

ensure leak-free (oil and water) workmanship

of reassembly.

l There are many running clearances. During

the course of engine reassembly, be sure to

check these clearances, one after another,

as they form.

l Gaskets, “0” rings and similar sealing mem-

bers must be in perfect condition. For these

members, use replacement parts in stock.

l Tightening torque is specified for impor-

tant fasteners - mainly bolts and nuts -of

the engine and other components. Use torque

wrenches and constantly refer to the specified

values given on p. 3-58.

l Do not disregard match marks provided on

parts. Some of them are those given at the

time of disassembly.

l There are many sets of parts. Crankshaft

bearings, connecting rods, pistons, etc., are

in combination sets. Do not disturb such

combinations and make sure that each part

goes back to where it came from.

Engine reassembly is the reverse of engine disas-

sembly as far as sequence is concerned, but

there are many reassembling steps that involve

measures necessary for restoring engine as close

to factory-assembled condition as possible. Only

those steps will be dealt with here.

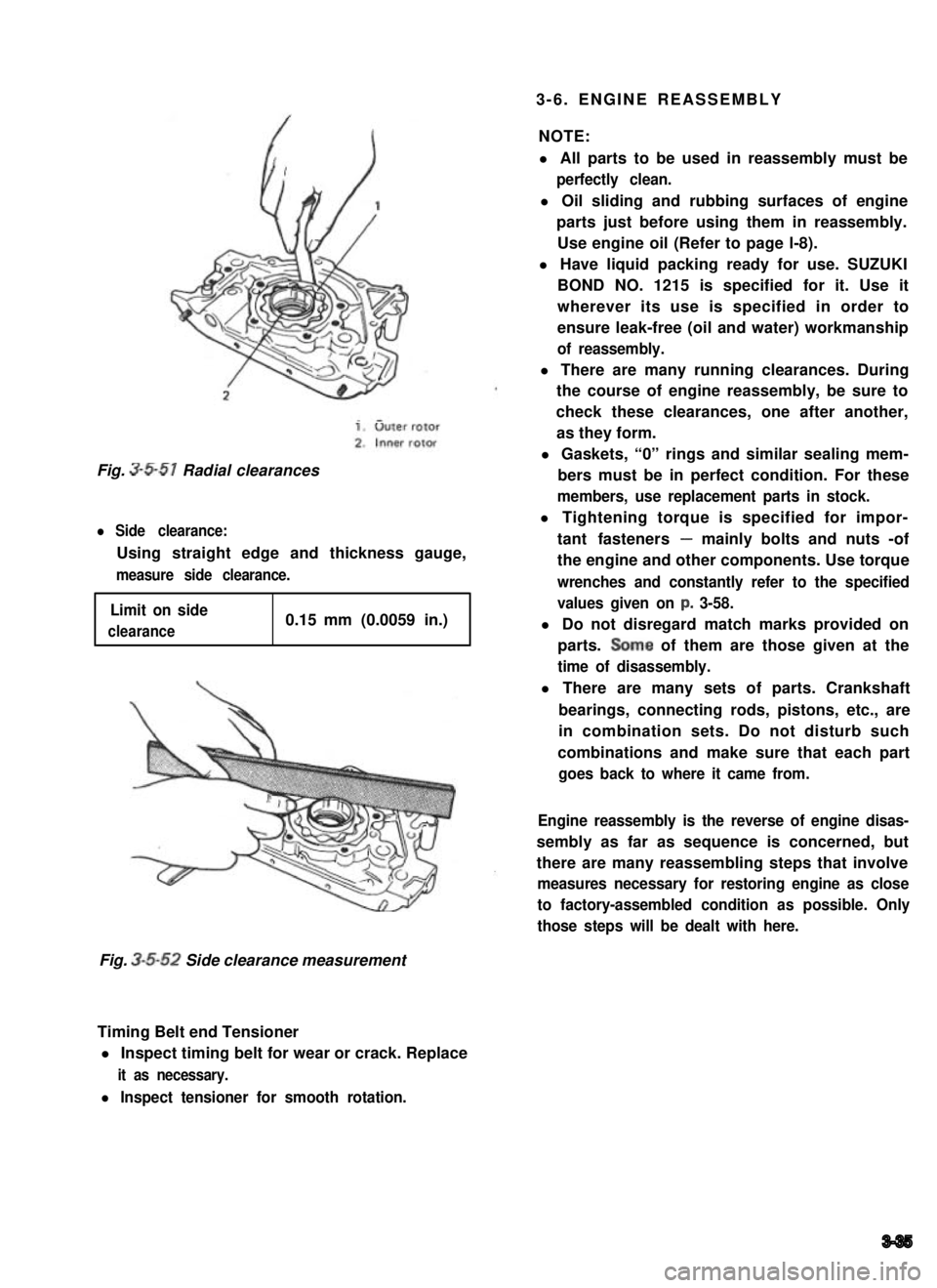

Fig. 3-5-51 Radial clearances

l Side clearance:

Using straight edge and thickness gauge,

measure side clearance.

Limit on side

clearance0.15 mm (0.0059 in.)

Fig. 3-5-52 Side clearance measurement

Timing Belt end Tensioner

l Inspect timing belt for wear or crack. Replace

it as necessary.

l Inspect tensioner for smooth rotation.

3-35

Page 93 of 962

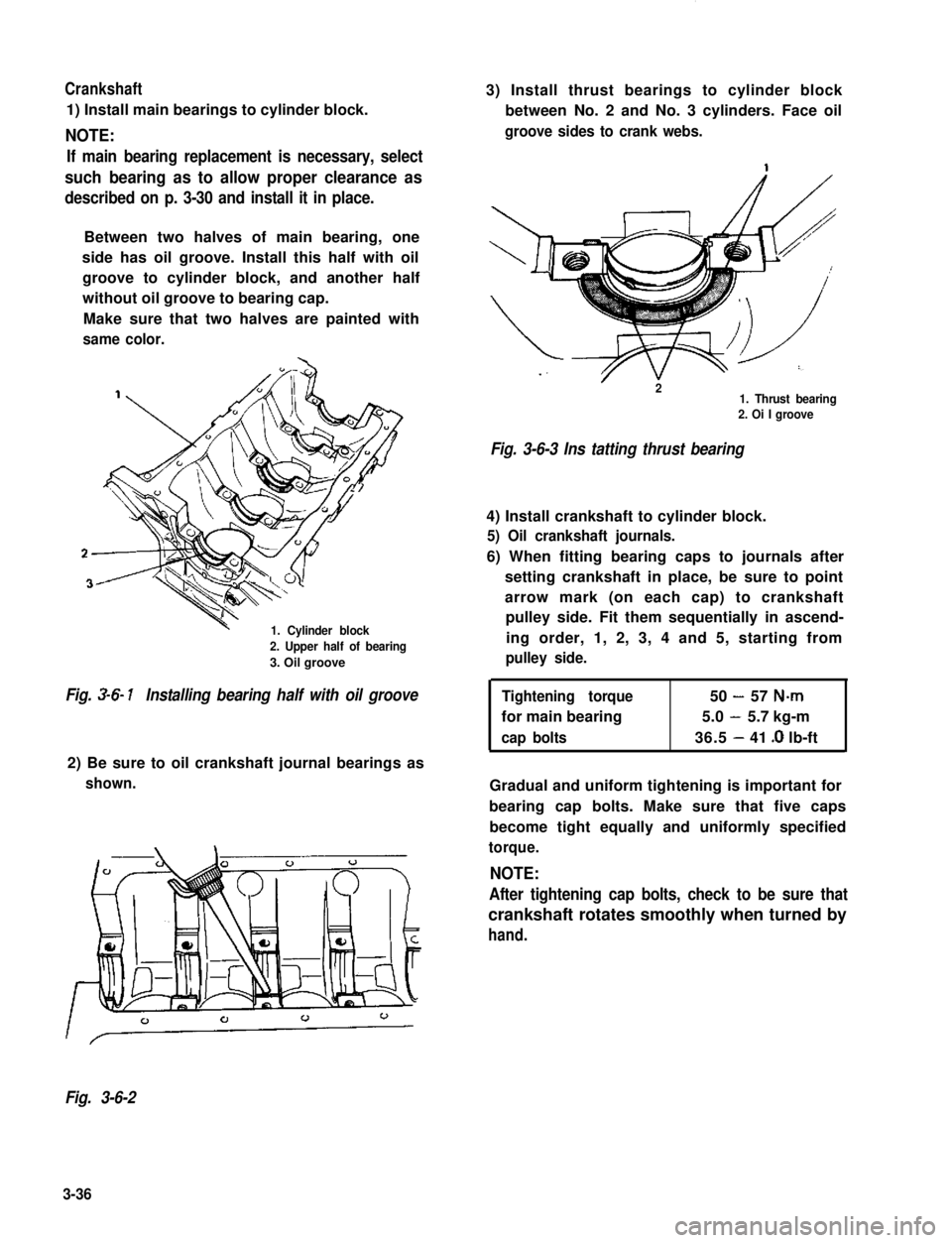

Crankshaft

1) Install main bearings to cylinder block.

NOTE:

If main bearing replacement is necessary, select

such bearing as to allow proper clearance as

described on p. 3-30 and install it in place.

Between two halves of main bearing, one

side has oil groove. Install this half with oil

groove to cylinder block, and another half

without oil groove to bearing cap.

Make sure that two halves are painted with

same color.

1. Cylinder block

2. Upper half of bearing

3. Oil groove

3) Install thrust bearings to cylinder block

between No. 2 and No. 3 cylinders. Face oil

groove sides to crank webs.

r21. Thrust bearing2. Oi I groove

Fig. 3-6-3 Ins tatting thrust bearing

4) Install crankshaft to cylinder block.

5) Oil crankshaft journals.

6) When fitting bearing caps to journals after

setting crankshaft in place, be sure to point

arrow mark (on each cap) to crankshaft

pulley side. Fit them sequentially in ascend-

ing order, 1, 2, 3, 4 and 5, starting from

pulley side.

Fig. 3-6- 1Installing bearing half with oil grooveTightening torque50-57 N-m

for main bearing5.0-5.7 kg-m

cap bolts36.5-41 .O lb-ft

2) Be sure to oil crankshaft journal bearings as

shown.Gradual and uniform tightening is important for

bearing cap bolts. Make sure that five caps

become tight equally and uniformly specified

torque.

NOTE:

After tightening cap bolts, check to be sure that

crankshaft rotates smoothly when turned by

hand.

Fig. 3-6-2

3-36

Page 94 of 962

n

U

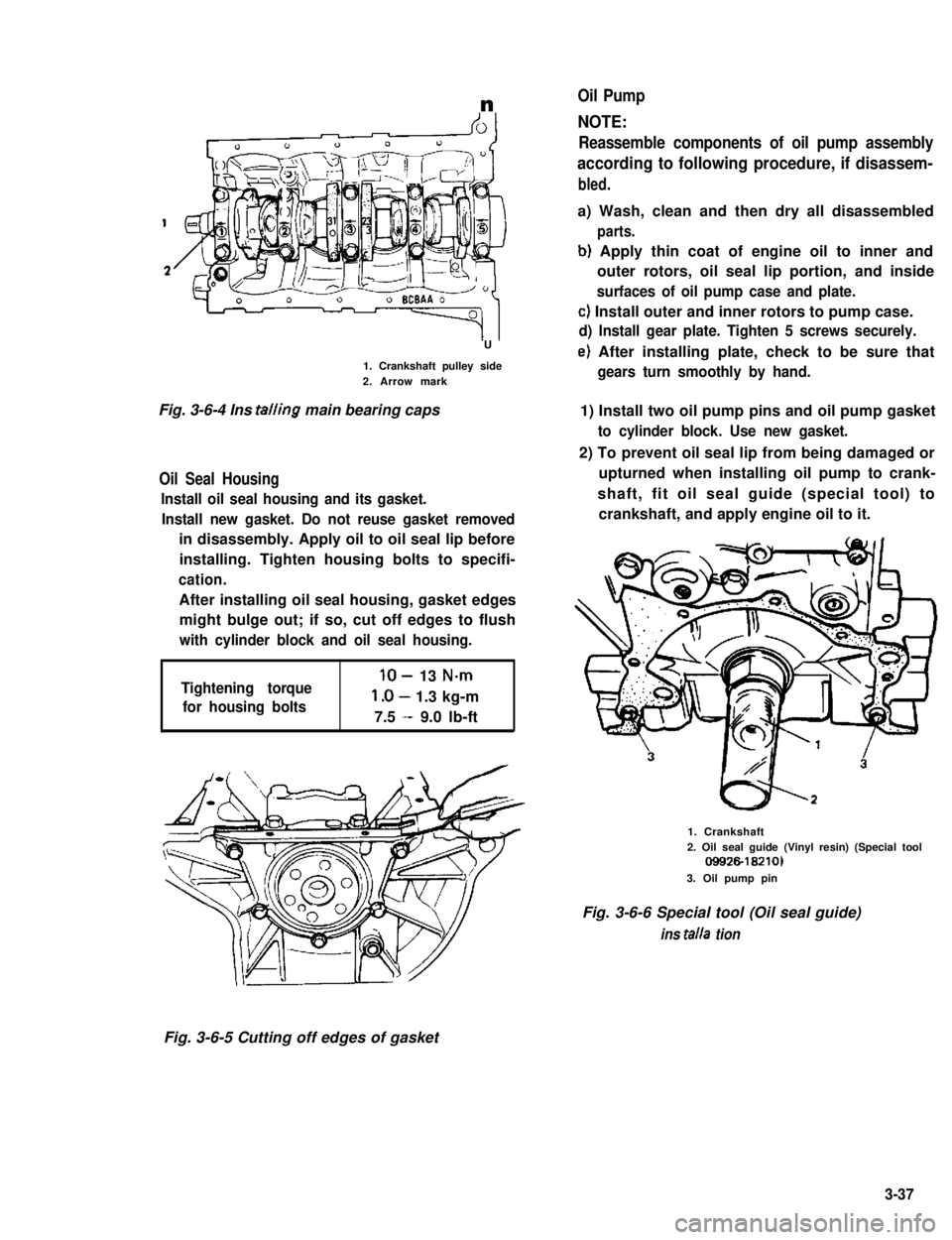

1. Crankshaft pulley side2. Arrow mark

Fig. 3-6-4 Ins tailing main bearing caps

Oil Seal Housing

Install oil seal housing and its gasket.

Install new gasket. Do not reuse gasket removed

in disassembly. Apply oil to oil seal lip before

installing. Tighten housing bolts to specifi-

cation.

After installing oil seal housing, gasket edges

might bulge out; if so, cut off edges to flush

with cylinder block and oil seal housing.

Tightening torque

for housing bolts

lo- 13 N-m

l.O- 1.3 kg-m

7.5 - 9.0 lb-ft

Oil Pump

NOTE:

Reassemble components of oil pump assembly

according to following procedure, if disassem-

bled.

a) Wash, clean and then dry all disassembled

parts.

b) Apply thin coat of engine oil to inner and

outer rotors, oil seal lip portion, and inside

surfaces of oil pump case and plate.

c) Install outer and inner rotors to pump case.

d) Install gear plate. Tighten 5 screws securely.

e) After installing plate, check to be sure that

gears turn smoothly by hand.

1) Install two oil pump pins and oil pump gasket

to cylinder block. Use new gasket.

2) To prevent oil seal lip from being damaged or

upturned when installing oil pump to crank-

shaft, fit oil seal guide (special tool) to

crankshaft, and apply engine oil to it.

1. Crankshaft2. Oil seal guide (Vinyl resin) (Special tool09926-18210)

3. Oil pump pin

Fig. 3-6-6 Special tool (Oil seal guide)

ins talla tion

Fig. 3-6-5 Cutting off edges of gasket

3-37

Page 95 of 962

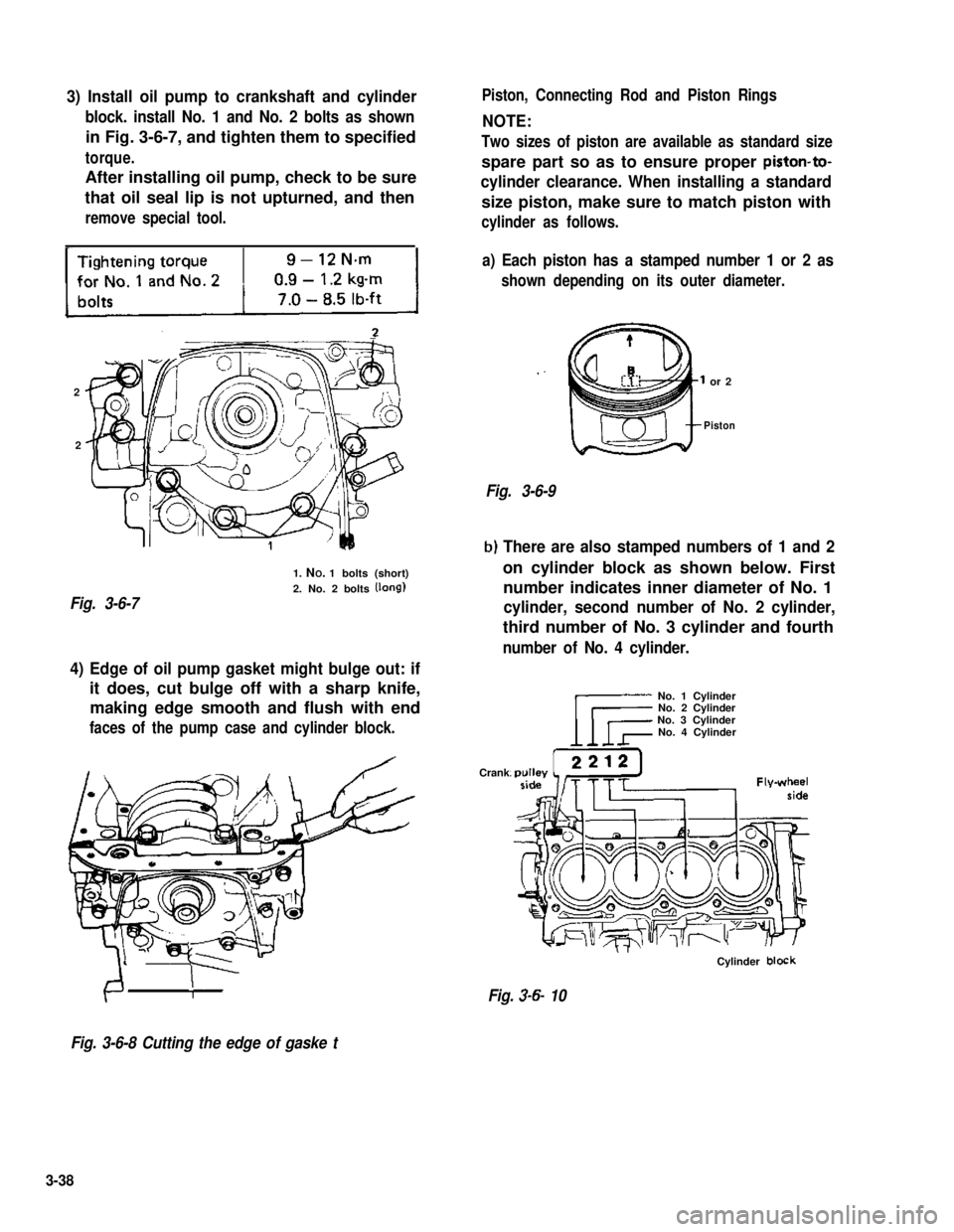

3) Install oil pump to crankshaft and cylinder

block. install No. 1 and No. 2 bolts as shown

in Fig. 3-6-7, and tighten them to specified

torque.

After installing oil pump, check to be sure

that oil seal lip is not upturned, and then

remove special tool.

-

2

2

Fig. 3-6-7

1. NO. 1 bolts (short)

2. No. 2 bolts (long)

Piston, Connecting Rod and Piston Rings

NOTE:

Two sizes of piston are available as standard size

spare part so as to ensure proper piston-to-

cylinder clearance. When installing a standard

size piston, make sure to match piston with

cylinder as follows.

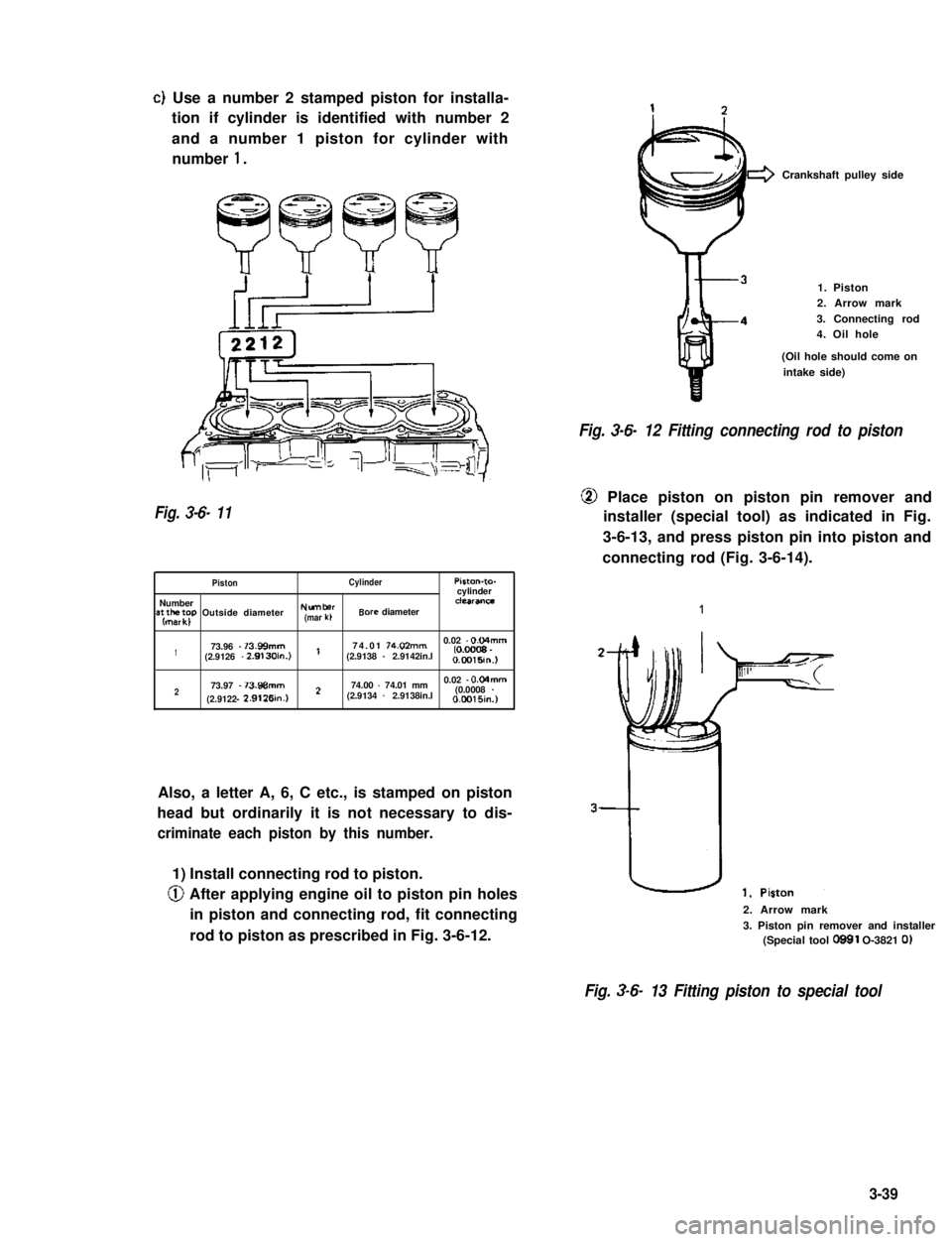

a) Each piston has a stamped number 1 or 2 as

shown depending on its outer diameter.

or 2

Piston

Fig. 3-6-9

b) There are also stamped numbers of 1 and 2

on cylinder block as shown below. First

number indicates inner diameter of No. 1

cylinder, second number of No. 2 cylinder,

third number of No. 3 cylinder and fourth

number of No. 4 cylinder.

4) Edge of oil pump gasket might bulge out: if

it does, cut bulge off with a sharp knife,

making edge smooth and flush with end

faces of the pump case and cylinder block.

Crank

No. 1 CylinderNo. 2 CylinderNo. 3 CylinderNo. 4 Cylinder

Cylinder block

Fig. 3-6- 10

Fig. 3-6-8 Cutting the edge of gaske t

3-38

Page 96 of 962

clUse a number 2 stamped piston for installa-

tion if cylinder is identified with number 2

and a number 1 piston for cylinder with

number 1.

Fig. 3-6- 11

PistonCylinderPiston-to-cylinderNumbera;$;r$p Outside diameterNWtlberck?arancE

(mar kbBore diameter

173.96 - 73.99mm’74.01 74.02mm0.02 - 0.04mm

(2.9126 - 2.9130in.)(2.9138 - 2.9142in.l~0.0009 -0.0016in.)

273.97 - 73.96mm74.00 - 74.01 mm0.02 - 0.04mm

2(2.9134 - 2.9138in.l(0.0008 -0.0016in.l

Also, a letter A, 6, C etc., is stamped on piston

head but ordinarily it is not necessary to dis-

criminate each piston by this number.

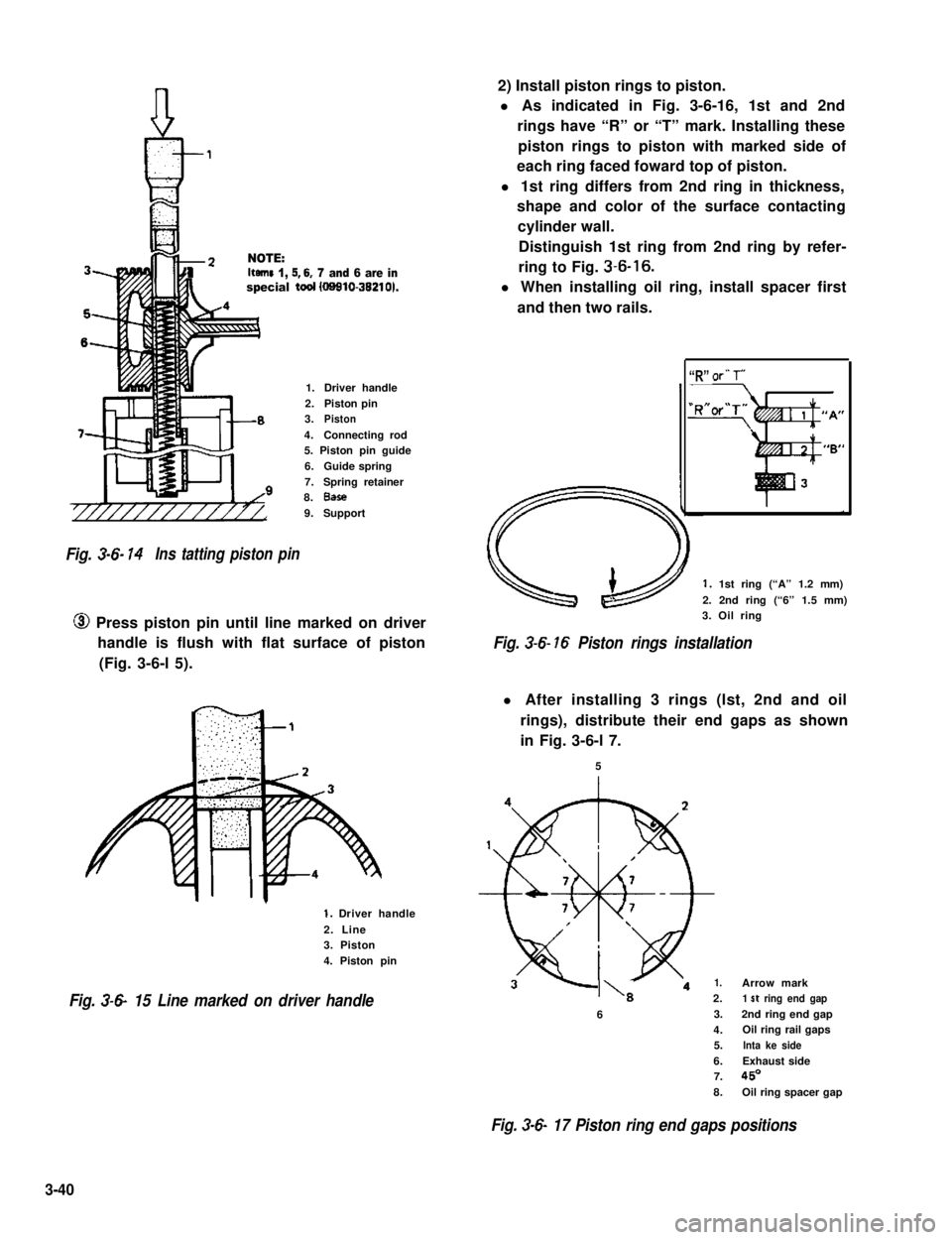

1) Install connecting rod to piston.

@ After applying engine oil to piston pin holes

in piston and connecting rod, fit connecting

rod to piston as prescribed in Fig. 3-6-12.

Crankshaft pulley side

1. Piston2. Arrow mark

3. Connecting rod4. Oil hole

(Oil hole should come on

intake side)

Fig. 3-6- 12 Fitting connecting rod to piston

@ Place piston on piston pin remover and

installer (special tool) as indicated in Fig.

3-6-13, and press piston pin into piston and

connecting rod (Fig. 3-6-14).

2. Arrow mark

3. Piston pin remover and installer(Special tool 0991 O-3821 0)

Fig. 3-6- 13 Fitting piston to special tool

3-39

(2.9122-

Page 97 of 962

NOTE:1kerns 1, 5,6, 7 and 6 are inspecial tad (09910-36210).

1.Driver handle

2.Piston pin3.Piston

4.Connecting rod5. Piston pin guide

6.Guide spring

7.Spring retainer8.Base

9.Support

Fig. 3-G 14Ins tatting piston pin

@ Press piston pin until line marked on driver

handle is flush with flat surface of piston

(Fig. 3-6-l 5).

1. Driver handle

2. Line3. Piston

4. Piston pin

Fig. 3-6- 15 Line marked on driver handle

2) Install piston rings to piston.

l As indicated in Fig. 3-6-16, 1st and 2nd

rings have “R” or “T” mark. Installing these

piston rings to piston with marked side of

each ring faced foward top of piston.

l 1st ring differs from 2nd ring in thickness,

shape and color of the surface contacting

cylinder wall.

Distinguish 1st ring from 2nd ring by refer-

ring to Fig. 3-6-16.

l When installing oil ring, install spacer first

and then two rails.

“R” or” T”

1. 1st ring (“A” 1.2 mm)

2. 2nd ring (“6” 1.5 mm)3. Oil ring

Fig. 3-6- 16 Piston rings installation

l After installing 3 rings (lst, 2nd and oil

rings), distribute their end gaps as shown

in Fig. 3-6-l 7.

5

1.Arrow mark

I\,

6

2.1 st ring end gap

3.2nd ring end gap

4.Oil ring rail gaps

5.lnta ke side

6.Exhaust side7.450

8.Oil ring spacer gap

Fig. 3-6- 17 Piston ring end gaps positions

3-40

Page 98 of 962

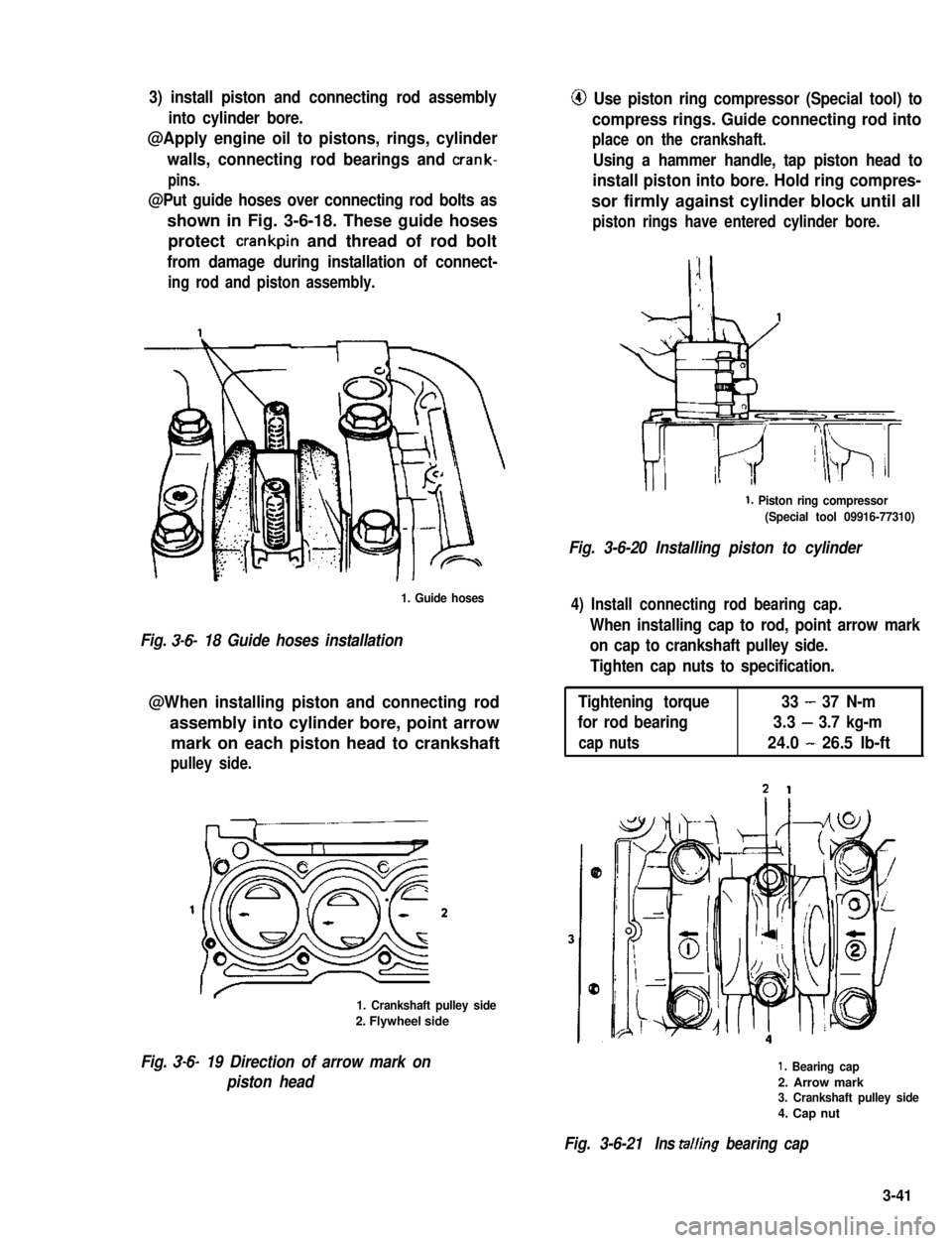

3) install piston and connecting rod assembly

into cylinder bore.

@Apply engine oil to pistons, rings, cylinder

walls, connecting rod bearings and crank-

pins.

@Put guide hoses over connecting rod bolts as

shown in Fig. 3-6-18. These guide hoses

protect crankpin and thread of rod bolt

from damage during installation of connect-

ing rod and piston assembly.

1. Guide hoses

Fig. 3-6- 18 Guide hoses installation

@When installing piston and connecting rod

assembly into cylinder bore, point arrow

mark on each piston head to crankshaft

pulley side.

1. Crankshaft pulley side

2. Flywheel side

Fig. 3-6- 19 Direction of arrow mark on

piston head

@ Use piston ring compressor (Special tool) to

compress rings. Guide connecting rod into

place on the crankshaft.

Using a hammer handle, tap piston head to

install piston into bore. Hold ring compres-

sor firmly against cylinder block until all

piston rings have entered cylinder bore.

1. Piston ring compressor

(Special tool 09916-77310)

Fig. 3-6-20 Installing piston to cylinder

4) Install connecting rod bearing cap.

When installing cap to rod, point arrow mark

on cap to crankshaft pulley side.

Tighten cap nuts to specification.

Tightening torque33-37 N-m

for rod bearing3.3-3.7 kg-m

cap nuts24.0-26.5 lb-ft

1. Bearing cap

2. Arrow mark3. Crankshaft pulley side

4. Cap nut

Fig. 3-6-21Ins tailing bearing cap

3-41

Page 99 of 962

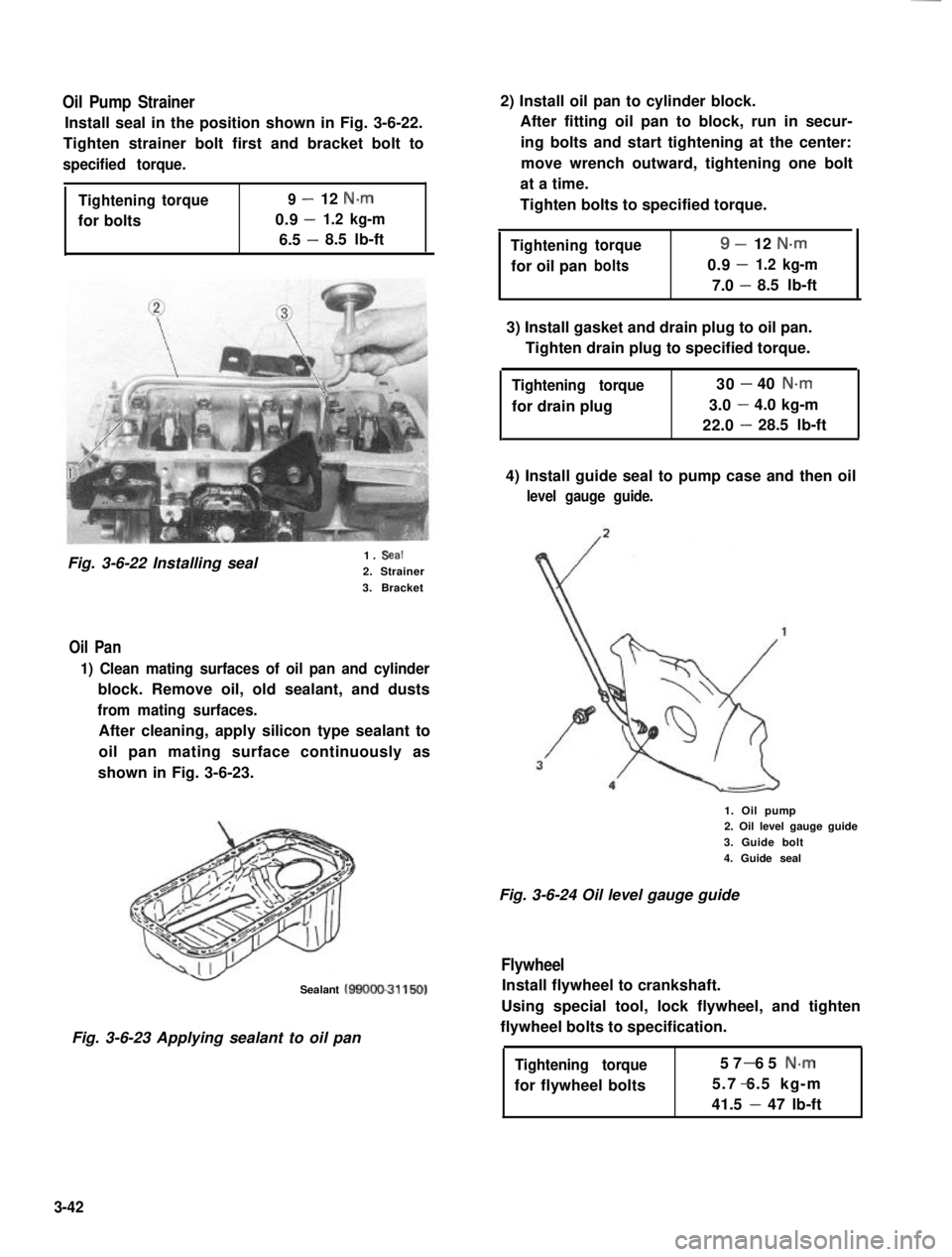

Oil Pump Strainer

Install seal in the position shown in Fig. 3-6-22.

Tighten strainer bolt first and bracket bolt to

specified torque.

Tighteningtorque9-12 N.m

0.9-for bolts1.2 kg-m

6.5 -8.5 lb-ft

Fig. 3-6-22 Installing seal1. Seal

2. Strainer

3. Bracket

Oil Pan

1) Clean mating surfaces of oil pan and cylinder

block. Remove oil, old sealant, and dusts

from mating surfaces.

After cleaning, apply silicon type sealant to

oil pan mating surface continuously as

shown in Fig. 3-6-23.

Sealant MOOO-31150)

Fig. 3-6-23 Applying sealant to oil pan

2) Install oil pan to cylinder block.

After fitting oil pan to block, run in secur-

ing bolts and start tightening at the center:

move wrench outward, tightening one bolt

at a time.

Tighten bolts to specified torque.

Tighteningtorque9-12 N-m

-for oil panbolts0.91.2 kg-m

7.0 -8.5 lb-ft

3) Install gasket and drain plug to oil pan.

Tighten drain plug to specified torque.

Tightening torque

for drain plug

30-40 N.m

3.0-4.0 kg-m

22.0-28.5 lb-ft

4) Install guide seal to pump case and then oil

level gauge guide.

1. Oil pump2. Oil level gauge guide

3. Guide bolt

4. Guide seal

Fig. 3-6-24 Oil level gauge guide

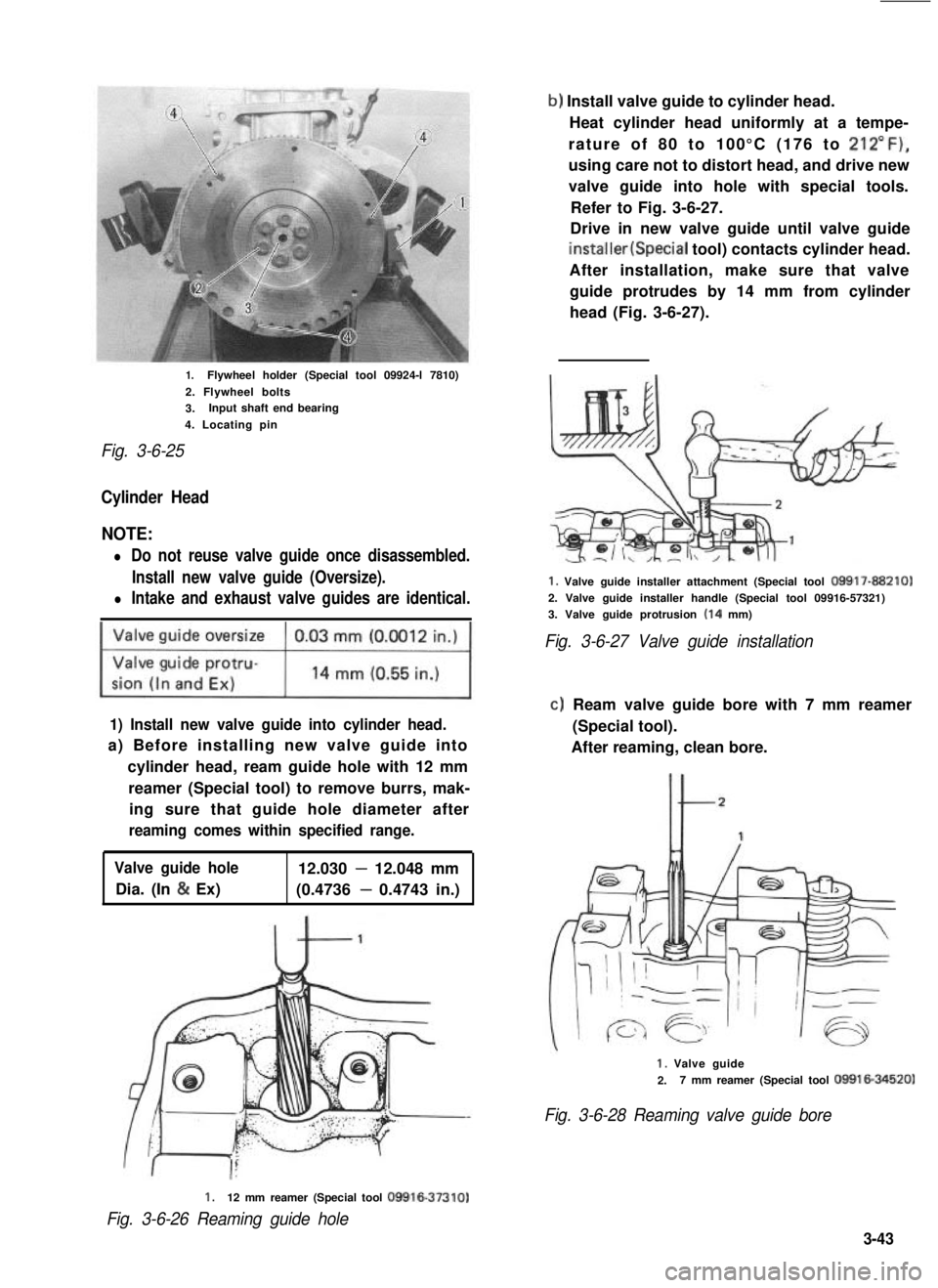

Flywheel

Install flywheel to crankshaft.

Using special tool, lock flywheel, and tighten

flywheel bolts to specification.

Tightening torque

for flywheel bolts

57 65 N-m-

5.7 6.5 kg-m-

41.5 - 47 lb-ft

3-42

Page 100 of 962

1.Flywheel holder (Special tool 09924-l 7810)

2. Flywheel bolts

3.Input shaft end bearing

4. Locating pin

Fig. 3-6-25

Cylinder Head

NOTE:

l Do not reuse valve guide once disassembled.

Install new valve guide (Oversize).

l Intake and exhaust valve guides are identical.

1) Install new valve guide into cylinder head.

a) Before installing new valve guide into

cylinder head, ream guide hole with 12 mm

reamer (Special tool) to remove burrs, mak-

ing sure that guide hole diameter after

reaming comes within specified range.

Valve guide hole12.030 - 12.048 mm

Dia. (In & Ex)(0.4736 - 0.4743 in.)

b) Install valve guide to cylinder head.

Heat cylinder head uniformly at a tempe-

rature of 80 to 100°C (176 to 212”F),

using care not to distort head, and drive new

valve guide into hole with special tools.

Refer to Fig. 3-6-27.

Drive in new valve guide until valve guide

installer(Special tool) contacts cylinder head.

After installation, make sure that valve

guide protrudes by 14 mm from cylinder

head (Fig. 3-6-27).

1. Valve guide installer attachment (Special tool 09917-88210)

2. Valve guide installer handle (Special tool 09916-57321)

3. Valve guide protrusion (14 mm)

Fig. 3-6-27 Valve guide installation

clReam valve guide bore with 7 mm reamer

(Special tool).

After reaming, clean bore.

1. Valve guide

2.7 mm reamer (Special tool 09916-34520)

Fig. 3-6-28 Reaming valve guide bore

1.12 mm reamer (Special tool 09916-37310)

Fig. 3-6-26 Reaming guide hole

3-43