SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

SWIFT 2000 1.G

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/7605/w960_7605-0.png

SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Trending: suspension, radio, tire pressure, rear suspension, glove box, change time, shaft

Page 351 of 447

BODY SERVICE 9-47

IGNITION SWITCH LOCK CYLINDER

REMOVAL AND INSTALLATION

Refer to “STEERING LOCK ASSEMBLY (IGNITION SWITCH)” in

Section 3C.

ELECTRICAL DIAGNOSIS

For ignition switch electrical troubleshooting, refer to “IGNITION

SWITCH” in Section 8.

EXTERIOR AND INTERIOR TRIM

FLOOR CARPET

REMOVAL

1) Remove front seats and rear seat cushion.

2) Remove seat belt lower anchor bolt.

3) Remove dash side trims, front side sill scuffs, center pillar inner lower trims, quarter inner trims and rear side

sill scuffs.

4) Remove parking brake lever cover and console box.

5) Remove floor carpet.

INSTALLATION

Reverse removal sequence to install front floor carpet, noting the following instruction.

For tightening torque of seat belt anchor bolt, refer to “FRONT SEAT BELT” in Section 10.

1. Floor carpet

2. Dash panel silencer

3. Silencer seat

Page 352 of 447

9-48 BODY SERVICE

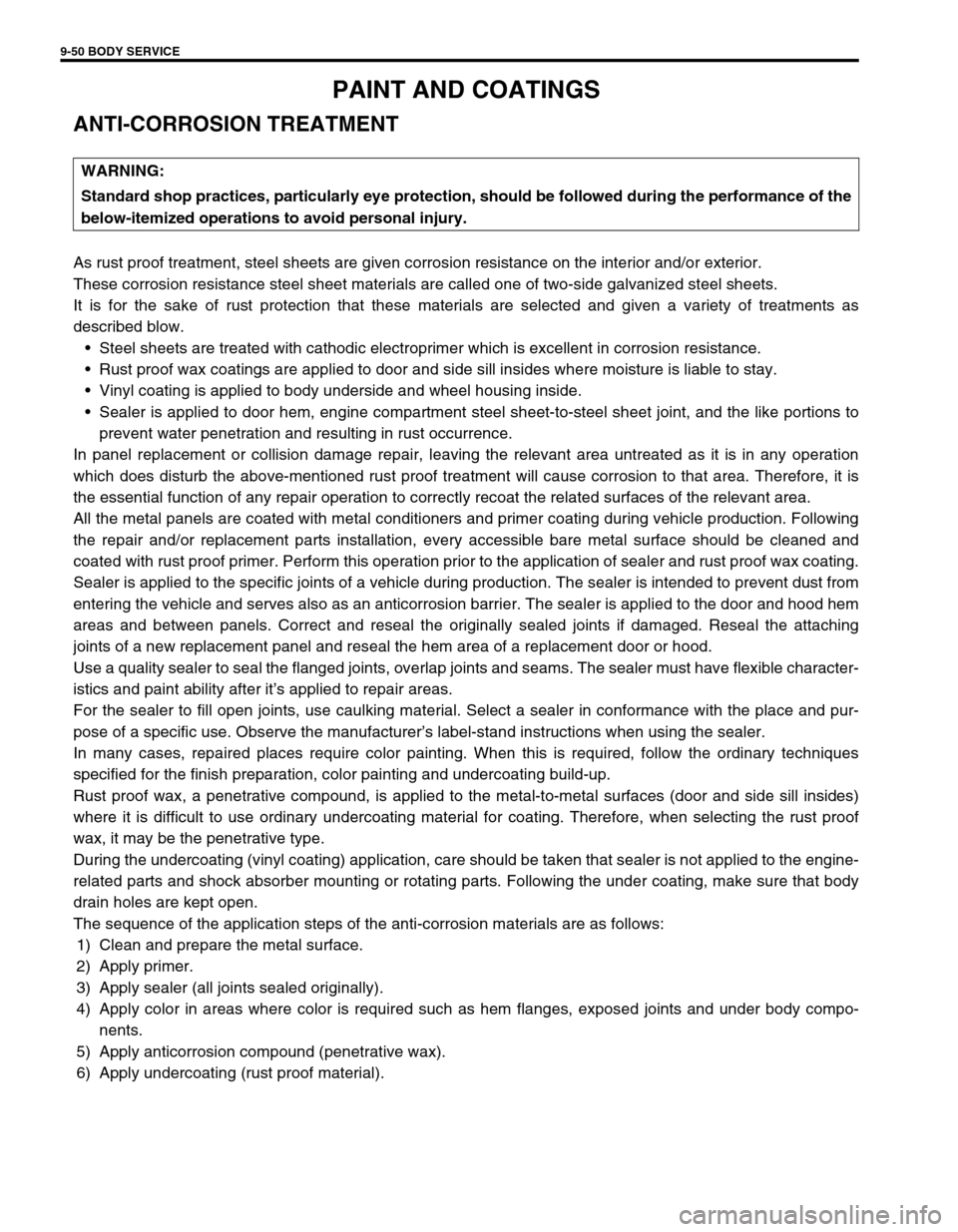

HEAD LINING

REMOVAL

1) Remove interior light (1).

2) Remove head lining clip (2).

3) Remove sun visor (3).

4) Remove luggage room light (1).

5) Remove head lining clip (2).

6) Remove assistant grip (1).

7) Remove door opening trim (2) and remove inner trims cover-

ing headlining (3).

8) Remove head lining clips (4) and remove head lining.

NOTE:

Adhesive is used to attach head lining.

Clear adhesive from headlining and roof after removing

head lining if applied.

[A] : For 3-door model

[B] : For 5-door model

1

11

4

4

1

2

2

3

3 3 2

33

[A]

[B]

Page 353 of 447

BODY SERVICE 9-49

INSTALLATION

Reverse removal procedure to install head lining noting the follow-

ing instructions.

Apply double-face tape (1) to head lining (2) as shown figure,

and then install head lining (2).

Tighten assistant grip screw (3) to specified torque.

Tightening torque

Assistant grip screw : 4 N·m (0.4 kg-m, 2.8 lb-ft)

Tighten sun visor screw (1) to specified torque.

Tightening torque

Sun visor screw (a) : 4 N·m (0.4 kg-m, 2.8 lb-ft)

11

1

3 3

32

Page 354 of 447

9-50 BODY SERVICE

PAINT AND COATINGS

ANTI-CORROSION TREATMENT

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials are called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as

described blow.

Steel sheets are treated with cathodic electroprimer which is excellent in corrosion resistance.

Rust proof wax coatings are applied to door and side sill insides where moisture is liable to stay.

Vinyl coating is applied to body underside and wheel housing inside.

Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to

prevent water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation

which does disturb the above-mentioned rust proof treatment will cause corrosion to that area. Therefore, it is

the essential function of any repair operation to correctly recoat the related surfaces of the relevant area.

All the metal panels are coated with metal conditioners and primer coating during vehicle production. Following

the repair and/or replacement parts installation, every accessible bare metal surface should be cleaned and

coated with rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the specific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anticorrosion barrier. The sealer is applied to the door and hood hem

areas and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching

joints of a new replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible character-

istics and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conformance with the place and pur-

pose of a specific use. Observe the manufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques

specified for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides)

where it is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof

wax, it may be the penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body

drain holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body compo-

nents.

5) Apply anticorrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).WARNING:

Standard shop practices, particularly eye protection, should be followed during the performance of the

below-itemized operations to avoid personal injury.

Page 355 of 447

BODY SERVICE 9-51

SEALANT APPLICATION AREAS

“A” : Apply sealant“C” : Wipe off excess sealant after application“E” : Smooth out sealant with a brush

“B” : Apply sealant without heeling“D” : Do not apply sealant

Page 356 of 447

9-52 BODY SERVICE

“A” : Apply sealant“C” : Do not apply sealant

“B” : Smooth out sealant with a brush“D” : Wipe off excess sealant after application

Page 357 of 447

BODY SERVICE 9-53

[A] : 3 door model“A” : Apply sealant“C” : Smooth out sealant with a brush

[B] : 5 door model“B” : Wipe off excess sealant after application“D” : Fill gap/hole with sealant

Page 358 of 447

9-54 BODY SERVICE

[A] : 3 door model“C” : Wipe off excess sealant after application

“A” : Apply sealant“D” : Never fill up drain holes with sealant

“B” : Be free from swell and protruded on hatched part

Page 359 of 447

BODY SERVICE 9-55

[B] : 5 door model“C” : Be free from swell and protruded on hatched part

“A” : Apply sealant“D” : Wipe off excess sealant after application

“B” : Never fill up drain holes with sealant

Page 360 of 447

9-56 BODY SERVICE

“A” : Apply sealant

“B” : Smooth out sealant with a brush

“C” : Wipe off excess sealant after application

Trending: sensor, 7b-56, charging, low beam, window, ECU, ground clearance

![SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual BODY SERVICE 9-53

[A] : 3 door model“A” : Apply sealant“C” : Smooth out sealant with a brush

[B] : 5 door model“B” : Wipe off excess sealant after application“D” : Fill gap/hole with s SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual BODY SERVICE 9-53

[A] : 3 door model“A” : Apply sealant“C” : Smooth out sealant with a brush

[B] : 5 door model“B” : Wipe off excess sealant after application“D” : Fill gap/hole with s](/img/20/7605/w960_7605-356.png)

![SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual 9-54 BODY SERVICE

[A] : 3 door model“C” : Wipe off excess sealant after application

“A” : Apply sealant“D” : Never fill up drain holes with sealant

“B” : Be free from swell and protrud SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual 9-54 BODY SERVICE

[A] : 3 door model“C” : Wipe off excess sealant after application

“A” : Apply sealant“D” : Never fill up drain holes with sealant

“B” : Be free from swell and protrud](/img/20/7605/w960_7605-357.png)

![SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual BODY SERVICE 9-55

[B] : 5 door model“C” : Be free from swell and protruded on hatched part

“A” : Apply sealant“D” : Wipe off excess sealant after application

“B” : Never fill up drain SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual BODY SERVICE 9-55

[B] : 5 door model“C” : Be free from swell and protruded on hatched part

“A” : Apply sealant“D” : Wipe off excess sealant after application

“B” : Never fill up drain](/img/20/7605/w960_7605-358.png)