SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 391 of 447

AIR BAG SYSTEM 10B-17

Fig. for STEP 3

Special tool

(A) : 09932-76010

Table B :

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Step Action Yes No

1 1) Set parking brake.

2) Note combination meter when ignition

switch is turned ON.

Does the “BRAKE” indicator (warning lamp)

come ON?Go to step 2.“BLK/WHT” wire, “IG

METER” fuse or J/B

(between ignition switch

and combination meter)

open or short to ground

2 1) With ignition switch OFF, disconnect SDM.

2) Check electrical connection check mecha-

nism.

Is it in good condition?Go to step 3. Repair electrical connec-

tion check mechanism.

3 1) Disconnect SDM.

2) Check proper connection to SDM at termi-

nal “Q06-2”.

3) If OK then check voltage from “Q06-2” ter-

minal of SDM connector to body ground

with ignition switch ON.

Is it 8 V or more?Substitute a known-good

SDM and recheck.Go to step 4.

4 1) Remove combination meter. Refer to COM-

BINATION METER in SECTION 8.

2) Check proper connection to combination

meter at “YEL/BLK” terminal for “AIR BAG”

warning lamp and to SDM at terminal “Q06-

2”.

3) If OK then check resistance between “YEL/

BLK” wire terminal of combination meter

connector (16-pin connector) and “Q06-2”

terminal of SDM connector.

Is resistance 1 Ω or less?Go to step 5. Repair high resistance or

open in “YEL/BLK” wire

circuit (between combina-

tion meter and SDM).

Page 392 of 447

10B-18 AIR BAG SYSTEM

Fig. for STEP 2

Fig. for STEP 3 and 5

Special tool

(A) : 09932-76010

Fig. for STEP 4

Special tool

(A) : 09932-76010 5 1) Measure voltage from “Q06-2” terminal of

SDM connector to body ground with ignition

switch ON.

Is it 8 V or more?Repair short from “YEL/

BLK” wire circuit (between

combination meter and

SDM) to power circuit.Go to step 6.

6 1) Remove and inspect “AIR BAG” bulb.

Is bulb good?Substitute a known-good

combination meter and

recheck.Replace bulb. Step Action Yes No

1. 16-pin connector (for combination meter)

2.“YEL/BLK” wire terminal

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 393 of 447

AIR BAG SYSTEM 10B-19

Table C :

Fig. for STEP 2

Special tool

(A) : 09932-76010 Step Action Yes No

1 1) Check “AIR BAG” monitor coupler.

Is it connected diagnosis switch terminal and

ground terminal in “AIR BAG” monitor coupler

by service wire?Remove service wire. Go to step 2.

2 1) With ignition switch OFF, disconnect SDM.

2) Measure resistance between “Q06-15” ter-

minal of SDM connector and body ground.

Is resistance 1 Ω or more?Substitute a known-good

SDM and recheck.Repair short from “PPL”

wire circuit to ground.

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 394 of 447

10B-20 AIR BAG SYSTEM

Table D :

Fig. for STEP 2

Special tool

(A) : 09932-76010 Step Action Yes No

1 1) Inspect connection between diagnostic

switch terminal on “AIR BAG” monitor cou-

pler and body ground by service wire.

Is it securely connected between them by ser-

vice wire?Go to step 2. Properly connection diag-

nostic switch terminal on

“AIR BAG” monitor cou-

pler and body ground by

service wire.

2 1) Disconnect SDM connector from SDM.

2) Check for proper connection at “PPL” wire

(“Q06-15” terminal of SDM connector and

“Q04-2” terminal of “AIR BAG” monitor cou-

pler) terminals.

3) If OK then measure resistance between

“Q06-15” terminal and “Q04-2” terminal.

Is resistance 1 Ω or more?Check “PPL” wire termi-

nals.

If OK then “PPL” wire cir-

cuit high resistance or

open.Substitute a known good

SDM and recheck

1.“AIR BAG” monitor coupler

2.“PPL” wire terminal

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 395 of 447

AIR BAG SYSTEM 10B-21

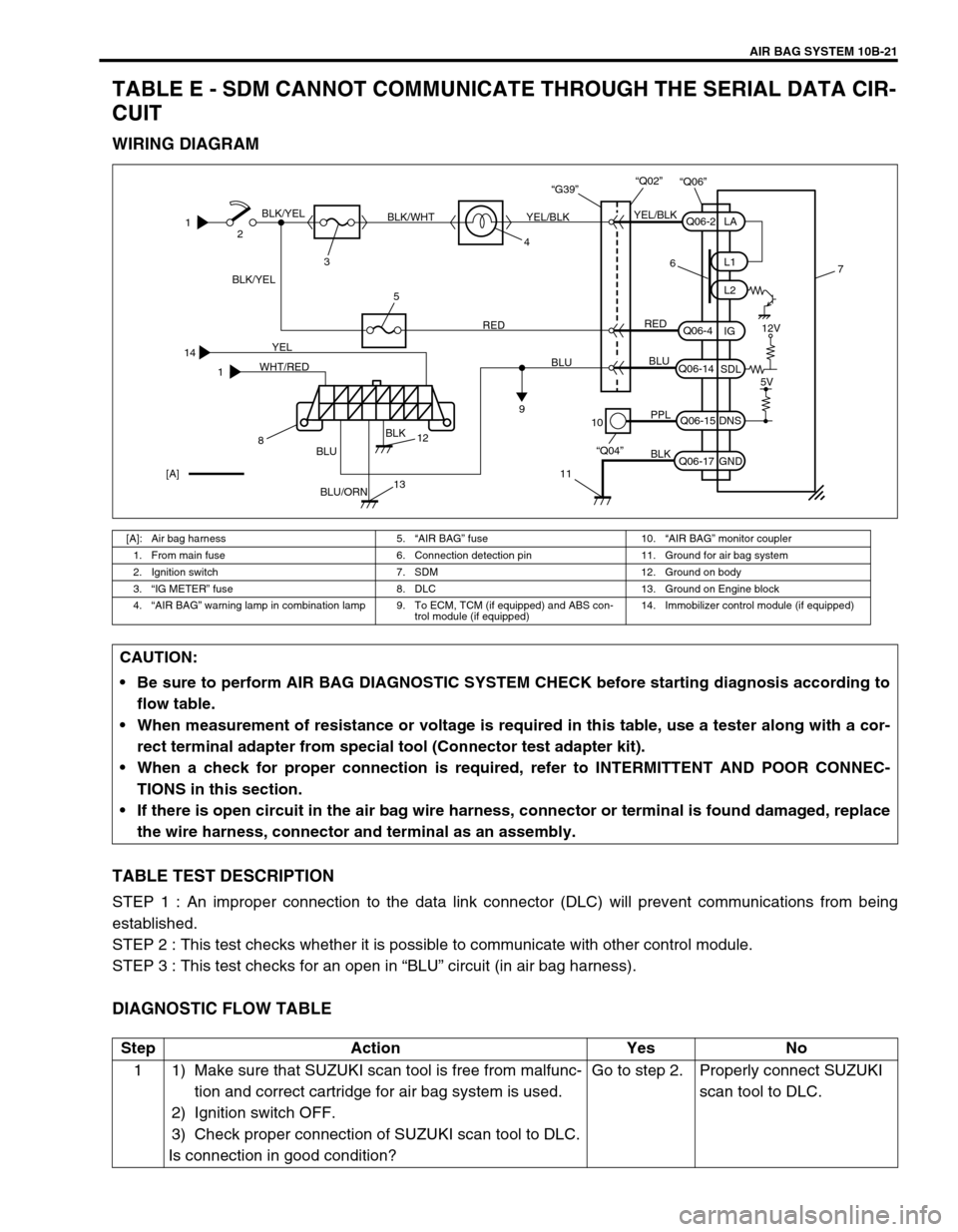

TABLE E - SDM CANNOT COMMUNICATE THROUGH THE SERIAL DATA CIR-

CUIT

WIRING DIAGRAM

TABLE TEST DESCRIPTION

STEP 1 : An improper connection to the data link connector (DLC) will prevent communications from being

established.

STEP 2 : This test checks whether it is possible to communicate with other control module.

STEP 3 : This test checks for an open in “BLU” circuit (in air bag harness).

DIAGNOSTIC FLOW TABLE

[A]: Air bag harness 5.“AIR BAG” fuse 10.“AIR BAG” monitor coupler

1. From main fuse 6. Connection detection pin 11. Ground for air bag system

2. Ignition switch 7. SDM 12. Ground on body

3.“IG METER” fuse 8. DLC 13. Ground on Engine block

4.“AIR BAG” warning lamp in combination lamp 9. To ECM, TCM (if equipped) and ABS con-

trol module (if equipped)14. Immobilizer control module (if equipped)

1

14

12

34 BLK/YEL

BLK/YEL

YELBLK/WHT

BLK

BLU/ORNYEL/BLKYEL/BLK

6

RED

WHT/REDRED

BLU

BLU

BLU

5

9

10

11

PPL

BLK

“Q04”“Q06”

Q06-2

Q06-4

Q06-14

Q06-15

Q06-17L1

L2

IG

SDL

DNS

GNDLA

7

[A]

12V

5V

“G39”“Q02”

812

13

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Step Action Yes No

1 1) Make sure that SUZUKI scan tool is free from malfunc-

tion and correct cartridge for air bag system is used.

2) Ignition switch OFF.

3) Check proper connection of SUZUKI scan tool to DLC.

Is connection in good condition?Go to step 2. Properly connect SUZUKI

scan tool to DLC.

Page 396 of 447

10B-22 AIR BAG SYSTEM

Fig. for STEP 1

Fig. for STEP 3

Special tool

(A) : 09932-76010 2 1) Check if communication is possible by trying communi-

cation with other control module (ECM, TCM (if

equipped) or ABS control module (if equipped)).

Is it possible to communicate with other control module?Go to step 3. Repair open in common

section of serial data circuit

(“BLU” wire circuit) used by

all controllers or short to

ground or power circuit

which has occurred some-

where in serial data circuit

(“BLU” wire circuit).

3 1) With ignition switch OFF, disconnect SDM and “Q02”

connector.

2) Check proper connection at “Q02-2” (“BLU” wire) termi-

nal for DLC.

3) If OK, then check resistance between “Q02-2” (“BLU”

wire) terminal and “Q06-14” terminal of SDM connec-

tor.

Is resistance 1 Ω or less?Substitute a

known-good

SDM and

recheck.Repair high resistance or

open in “BLU” wire circuit

(in air bag harness). Step Action Yes No

1. DLC

2. Scan tool

1. Air bag harness side connector

2.“BLU” wire terminal

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 397 of 447

AIR BAG SYSTEM 10B-23

DTC B1015 - PASSENGER AIR BAG INITIATOR CIRCUIT RESISTANCE HIGH

DTC B1016 - PASSENGER AIR BAG INITIATOR CIRCUIT RESISTANCE LOW

DTC B1018 - PASSENGER AIR BAG INITIATOR CIRCUIT SHORT TO GROUND

DTC B1019 - PASSENGER AIR BAG INITIATOR CIRCUIT SHORT TO POWER

CIRCUIT

WIRING DIAGRAM

DTC WILL SET WHEN

DTC B1015 :

The combined resistance of the passenger air bag (inflator) module, harness wiring and connector terminal con-

tact is above a specified value for specified time.

DTC B1016 :

The combined resistance of the passenger air bag (inflator) module, harness wiring and connector terminal con-

tact is below a specified value for specified time.

DTC B1018 :

The voltage measured at passenger air bag initiator circuit is below a specified value for specified time.

DTC B1019 :

The voltage measured at passenger air bag initiator circuit is above a specified value for specified time.

TABLE TEST DESCRIPTION

DTC B1015, B1016, B1018 and B1019 :

STEP 1 : Check whether malfunction is in passenger air bag (inflator) module.

STEP 2 : Check passenger air bag (inflator) module initiator circuit in air bag harness.

STEP 3 : Check passenger air bag (inflator) module initiator circuit in air bag harness. (for DTC B1019 only)

[A]: Shorting bar 1. From main fuse 3.“AIR BAG” fuse 5. Passenger air bag (inflator) module

[B]: Air bag harness 2. Ignition switch 4. SDM 6. Ground for air bag system

1

2RED BLK/YELRED

3

6

BLK“Q06”

Q06-4

Q06-17IG

GND4

“G39”“Q02”

BLU/RED

YEL/RED Q06-7

Q06-8 P- P+“Q03”

“Q06”

5

[A]

[B]

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adaptor from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Page 398 of 447

10B-24 AIR BAG SYSTEM

DIAGNOSTIC FLOW TABLE

DTC B1015 :

Fig. for STEP 1 and 2

Fig. for STEP 2

Special tool

(A) : 09932-76010

(B) : 09932-75010 Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1015 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this sec-

tion).

2 1) With ignition switch OFF, disconnect SDM.

2) Check proper connection to SDM at terminals “Q06-7”

and “Q06-8”.

3) If OK then measure resistance between “Q06-7” and

“Q06-8” terminals with connected Special Tool (B).

Is resistance 4.5 Ω or less?Substitute a

known-good SDM

and recheck.Repair high resistance

or open in “YEL/RED” or

“BLU/RED” wire circuit.

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 399 of 447

AIR BAG SYSTEM 10B-25

DTC B1016:

Fig. for STEP 1 and 2

Fig. for STEP 2

Special tool

(A) : 09932-76010

(B) : 09932-75010 Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1016 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this section).

2 1) With ignition switch OFF, disconnect SDM.

2) Check proper connection to SDM at terminals “Q06-7”

and “Q06-8”.

3) If OK then measure resistance between “Q06-7” and

“Q06-8” terminals with connected Special Tool (B).

Is resistance 1.4 Ω or more?Substitute a

known-good

SDM and

recheck.Repair short from “YEL/

RED” wire circuit to “BLU/

RED” wire circuit or from

“YEL/RED” or “BLU/RED”

wire circuit to other wire

circuit.

NOTE:

Upon completion of inspection and repair work, perform following items.

1) Reconnect all air bag system components, ensure all components are properly mounted.

2) Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

3) Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 400 of 447

10B-26 AIR BAG SYSTEM

DTC B1018:

Fig. for STEP 1, 2 and 3

Fig. for STEP 2Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1018 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this section).

2 1) With ignition switch OFF, disconnect Special Tool (B)

and SDM.

2) Measure resistance between “Q06-7” terminals and

body ground.

Is resistance 10 W or more?Go to step 3. Repair short from “BLU/

RED” wire circuit to

ground.

3 1) Measure resistance between “Q06-8” terminal and

body ground.

Is resistance 10 Ω or more?Substitute a

known-good

SDM and

recheck.Repair short from “YEL/

RED” wire circuit to

ground.