PS control module SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 930 of 1496

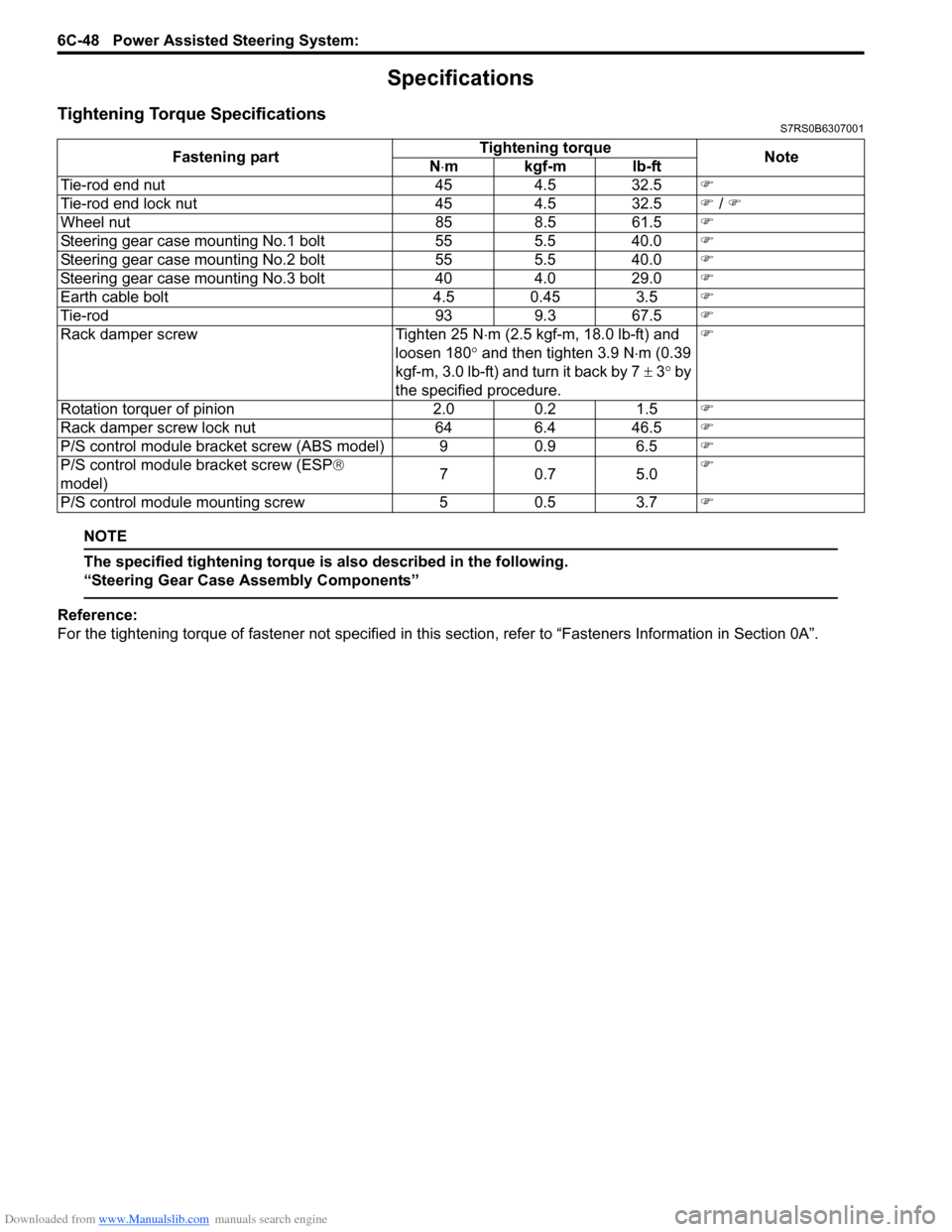

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

Specifications

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 939 of 1496

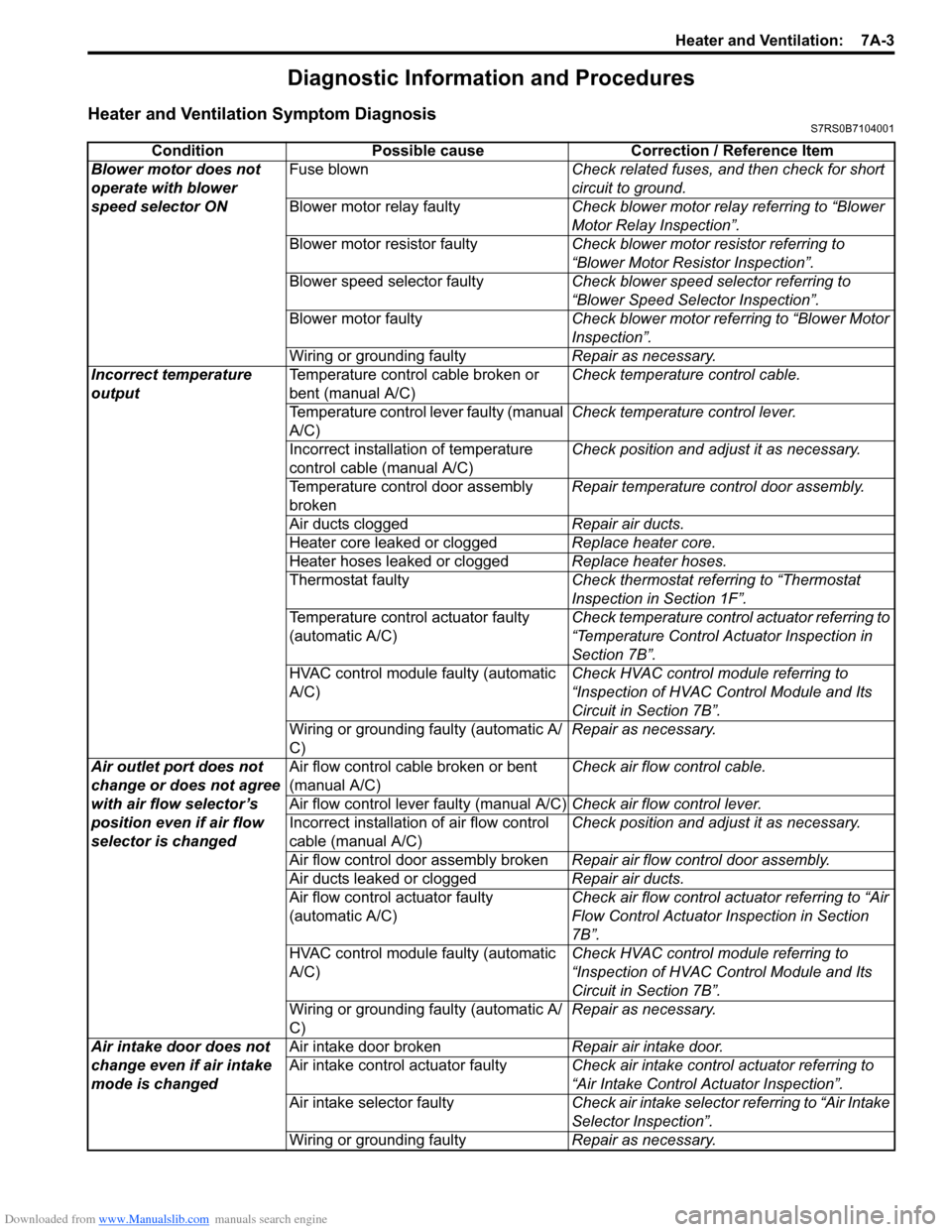

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-3

Diagnostic Information and Procedures

Heater and Ventilation Symptom DiagnosisS7RS0B7104001

ConditionPossible cause Correction / Reference Item

Blower motor does not

operate with blower

speed selector ON Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection”.

Blower motor resistor faulty Check blower motor resistor referring to

“Blower Motor Resistor Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection”.

Wiring or grounding faulty Repair as necessary.

Incorrect temperature

output Temperature control cable broken or

bent (manual A/C) Check temperature control cable.

Temperature control lever faulty (manual

A/C) Check temperature control lever.

Incorrect installation of temperature

control cable (manual A/C) Check position and adjust it as necessary.

Temperature control door assembly

broken Repair temperature control door assembly.

Air ducts clogged Repair air ducts.

Heater core leaked or clogged Replace heater core.

Heater hoses leaked or clogged Replace heater hoses.

Thermostat faulty Check thermostat referring to “Thermostat

Inspection in Section 1F”.

Temperature control actuator faulty

(automatic A/C) Check temperature control actuator referring to

“Temperature Control Actuator Inspection in

Section 7B”.

HVAC control module faulty (automatic

A/C) Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (automatic A/

C) Repair as necessary.

Air outlet port does not

change or does not agree

with air flow selector’s

position even if air flow

selector is changed Air flow control cable broken or bent

(manual A/C)

Check air flow control cable.

Air flow control lever faulty (manual A/C) Check air flow control lever.

Incorrect installation of air flow control

cable (manual A/C) Check position and adjust it as necessary.

Air flow control door assembly broken Repair air flow control door assembly.

Air ducts leaked or clogged Repair air ducts.

Air flow control actuator faulty

(automatic A/C) Check air flow control actuator referring to “Air

Flow Control Actuator

Inspection in Section

7B”.

HVAC control module faulty (automatic

A/C) Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (automatic A/

C) Repair as necessary.

Air intake door does not

change even if air intake

mode is changed Air intake door broken

Repair air intake door.

Air intake control actuator faulty Check air intake control actuator referring to

“Air Intake Control Actuator Inspection”.

Air intake selector faulty Check air intake selector referring to “Air Intake

Selector Inspection”.

Wiring or grounding faulty Repair as necessary.

Page 943 of 1496

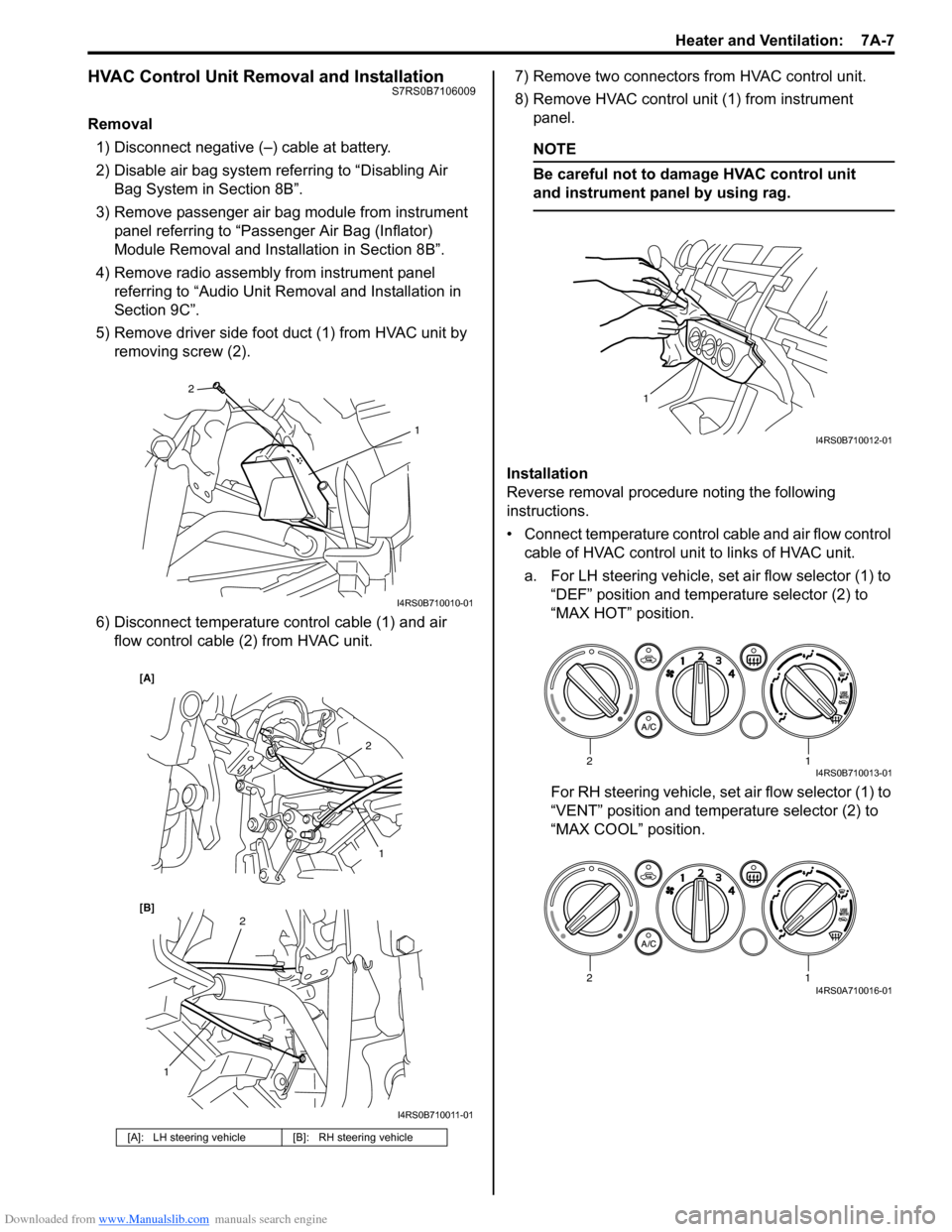

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

HVAC Control Unit Removal and InstallationS7RS0B7106009

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove driver side foot duct (1) from HVAC unit by removing screw (2).

6) Disconnect temperature control cable (1) and air flow control cable (2) from HVAC unit. 7) Remove two connectors from HVAC control unit.

8) Remove HVAC control unit (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control unit

and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set air flow selector (1) to “DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set air flow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

[A]: LH steering vehicle [B]: RH steering vehicle

2

1

I4RS0B710010-01

2

1

1

2

[B] [A]

I4RS0B710011-01

1

I4RS0B710012-01

12I4RS0B710013-01

12I4RS0A710016-01

Page 946 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-10 Heater and Ventilation:

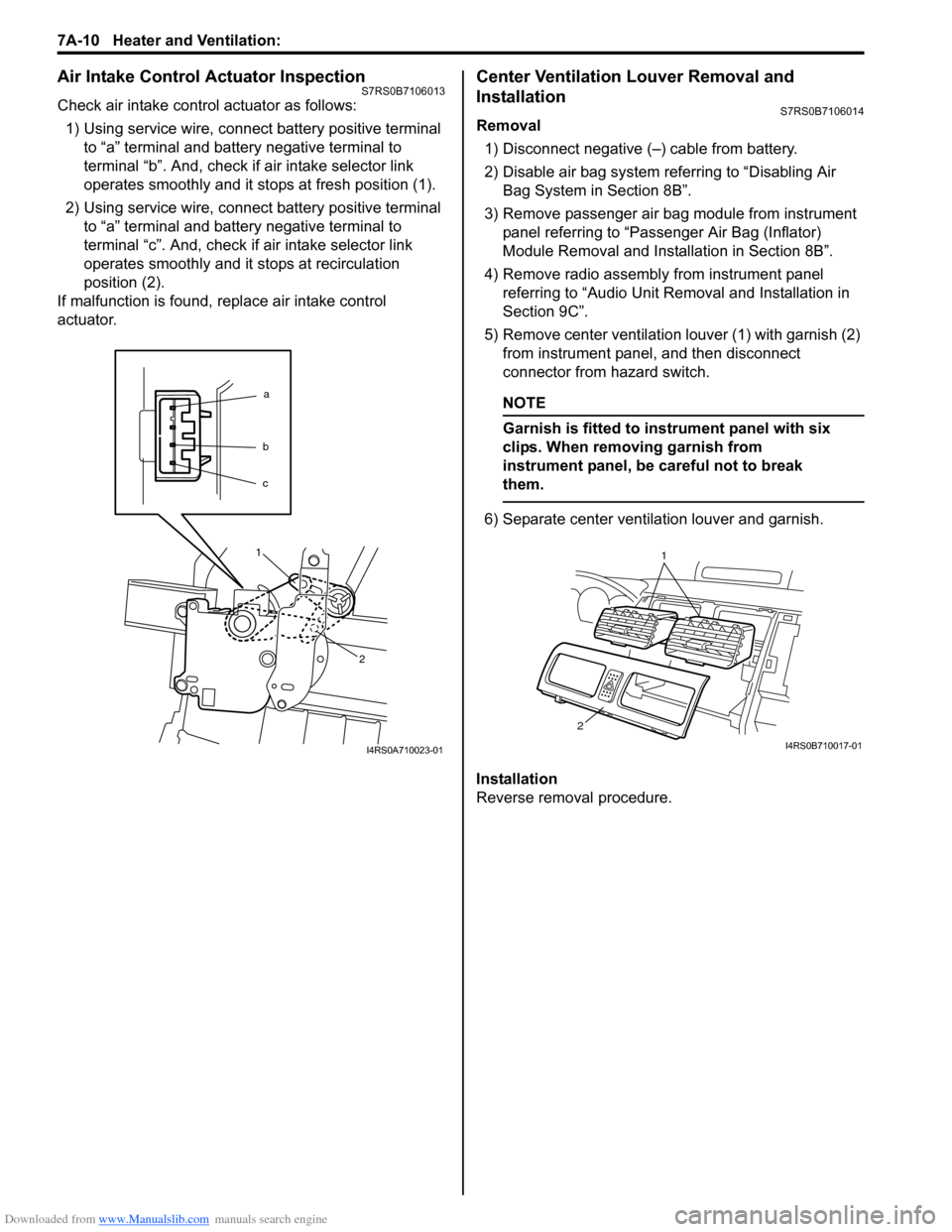

Air Intake Control Actuator InspectionS7RS0B7106013

Check air intake control actuator as follows:1) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “b”. And, check if air intake selector link

operates smoothly and it st ops at fresh position (1).

2) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “c”. And, check if air intake selector link

operates smoothly and it stops at recirculation

position (2).

If malfunction is found, replace air intake control

actuator.

Center Ventilation Louver Removal and

Installation

S7RS0B7106014

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove center ventilation louver (1) with garnish (2) from instrument panel, and then disconnect

connector from hazard switch.

NOTE

Garnish is fitted to in strument panel with six

clips. When removing garnish from

instrument panel, be careful not to break

them.

6) Separate center ventilation louver and garnish.

Installation

Reverse removal procedure.

a

b

c

1

2

I4RS0A710023-01

1

2

I4RS0B710017-01

Page 954 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-6 Air Conditioning System: Manual Type

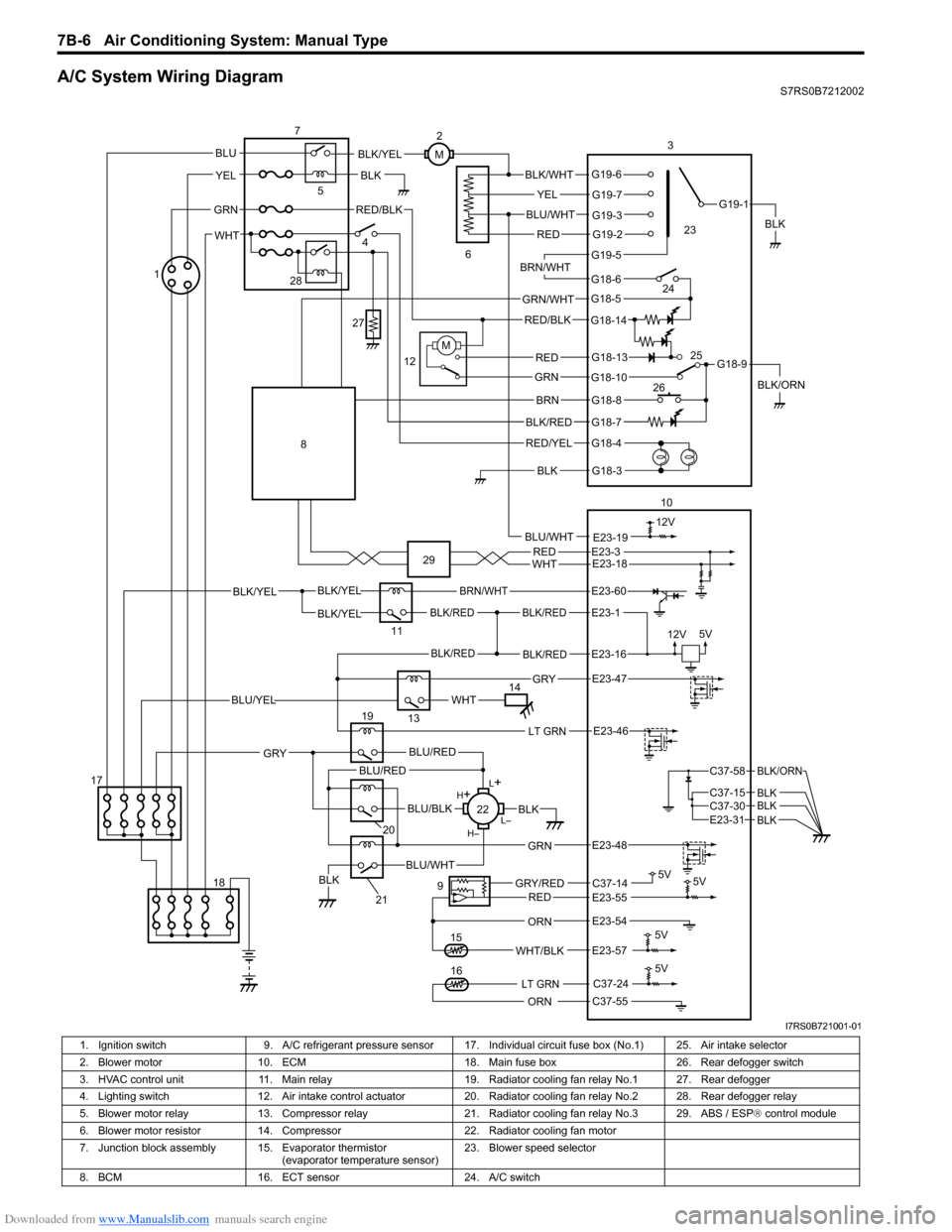

A/C System Wiring DiagramS7RS0B7212002

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V5V

5V 5V

5V11

E23-1

E23-60

BLK/REDBLK/REDE23-16

E23-57WHT/BLK

9

13

E23-55C37-14GRY/REDRED

BLK

ORN

E23-47 GRY

WHTBLU/YEL

RED/BLK

14 3

1

15

5

7

BLK

2

M

12VBLU/WHTE23-19

C37-24

C37-55ORN

5V

LT GRN16

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G18-5

G18-6

G19-5

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

BRN/WHT

GRN/WHT

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

12

10

M

E23-54

REDWHTE23-3E23-18

17 18

LT GRNE23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLU/WHTBLK

BLU/BLK

20

GRN

GRY

E23-48

19

21

22

BLU/REDC37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLU

YEL

GRN

WHT

23

24

26 25

28

27

8

29

I7RS0B721001-01

1. Ignition switch

9. A/C refrigerant pressure sensor 17. I ndividual circuit fuse box (No.1) 25. Air intake selector

2. Blower motor 10. ECM 18. Main fuse box 26. Rear defogger switch

3. HVAC control unit 11. Main relay 19. Radiator cooling fan relay No.1 27. Rear defogger

4. Lighting switch 12. Air intake control actuator 20. Radiator cooling fan relay No.2 28. Rear defogger relay

5. Blower motor relay 13. Compressor relay 21. Radiator cooling fan relay No.3 29. ABS / ESP ® control module

6. Blower motor resistor 14. Compressor 22. Radiator cooling fan motor

7. Junction block assembly 15. Evaporator thermistor (evaporator temperature sensor)23. Blower speed selector

8. BCM 16. ECT sensor 24. A/C switch

Page 982 of 1496

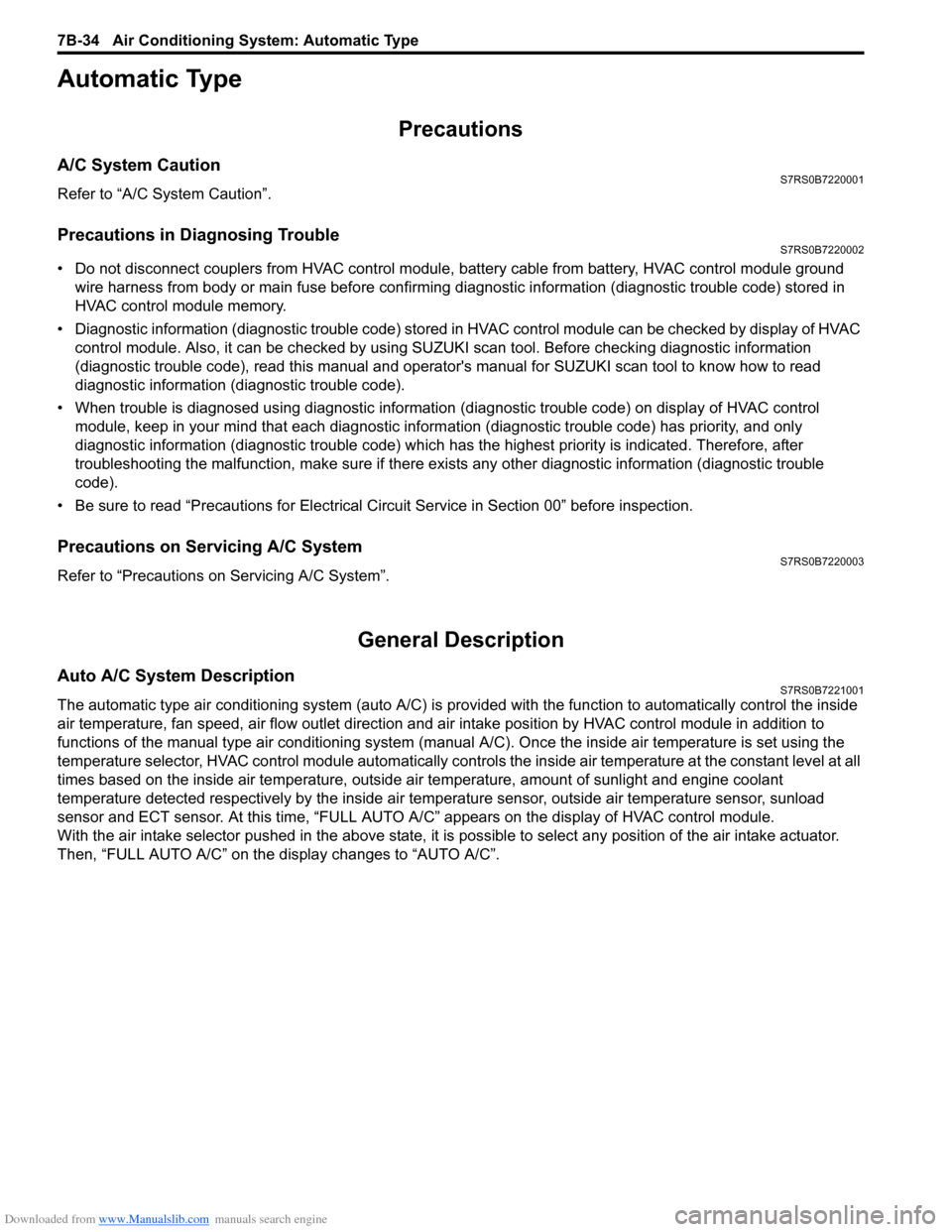

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.

Page 983 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-35

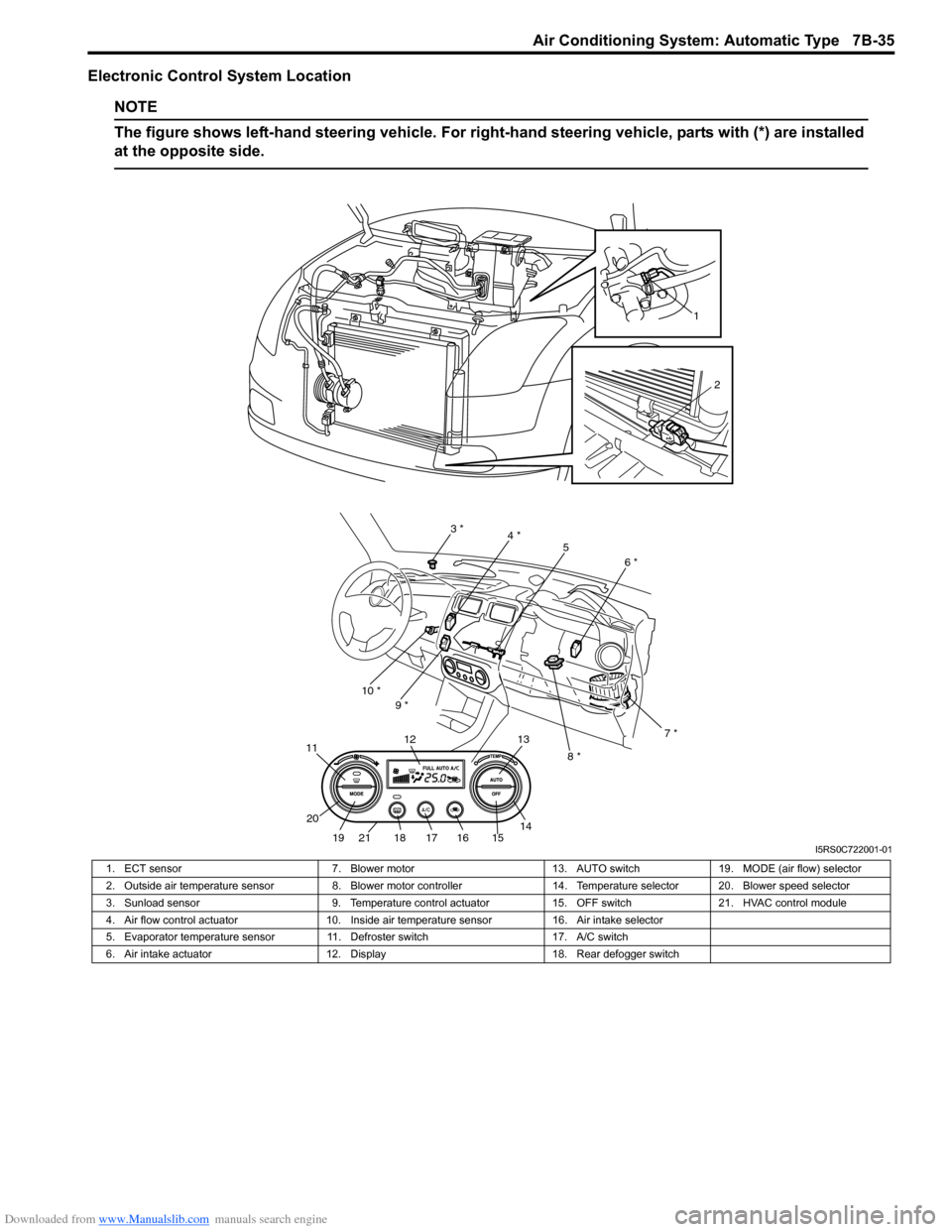

Electronic Control System Location

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

2

3 * 4 *

5

6 *

7 *

8 *

9 *

10 *

21

11

12 13

14

15161718

19

20

I5RS0C722001-01

1. ECT sensor

7. Blower motor13. AUTO switch19. MODE (air flow) selector

2. Outside air temperature sensor 8. Blower motor controller 14. Temperature selector 20. Blower speed selector

3. Sunload sensor 9. Temperature control actuator15. OFF switch21. HVAC control module

4. Air flow control actuator 10. Inside air temperature sensor 16. Air intake selector

5. Evaporator temperature sensor 11. Defroster switch 17. A/C switch

6. Air intake actuator 12. Display 18. Rear defogger switch

Page 984 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-36 Air Conditioning System: Automatic Type

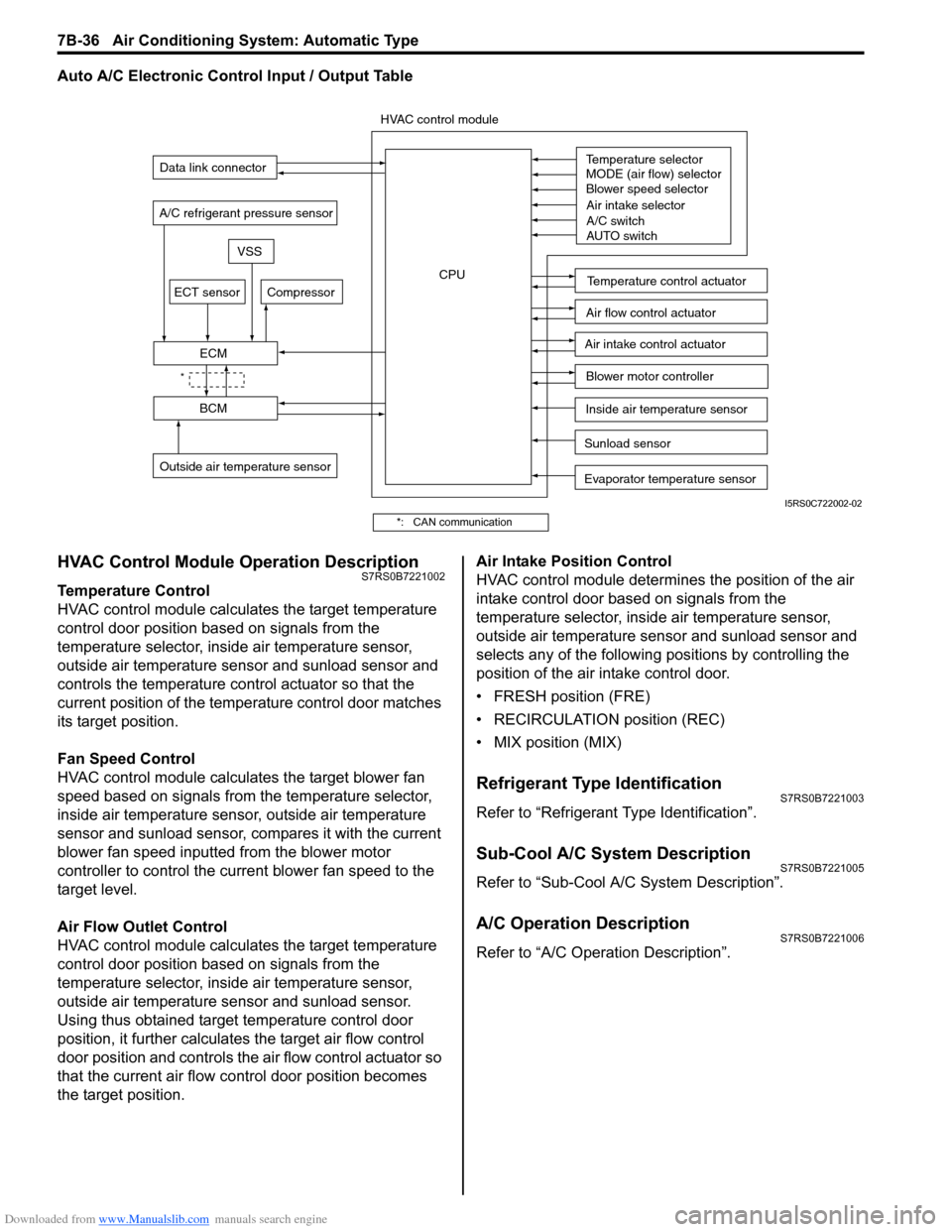

Auto A/C Electronic Control Input / Output Table

HVAC Control Module Operation DescriptionS7RS0B7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the ai r flow control actuator so

that the current air flow c ontrol door position becomes

the target position. Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)

Refrigerant Type IdentificationS7RS0B7221003

Refer to “Refrigerant Type Identification”.

Sub-Cool A/C System DescriptionS7RS0B7221005

Refer to “Sub-Cool A/C System Description”.

A/C Operation DescriptionS7RS0B7221006

Refer to “A/C Operation Description”.

Sunload sensor

Outside air temperature sensor Evaporator temperature sensor

A/C refrigerant pressure sensor

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch

A/C switch

Compressor

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Inside air temperature sensor

VSS

*

I5RS0C722002-02

*: CAN communication

Page 985 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-37

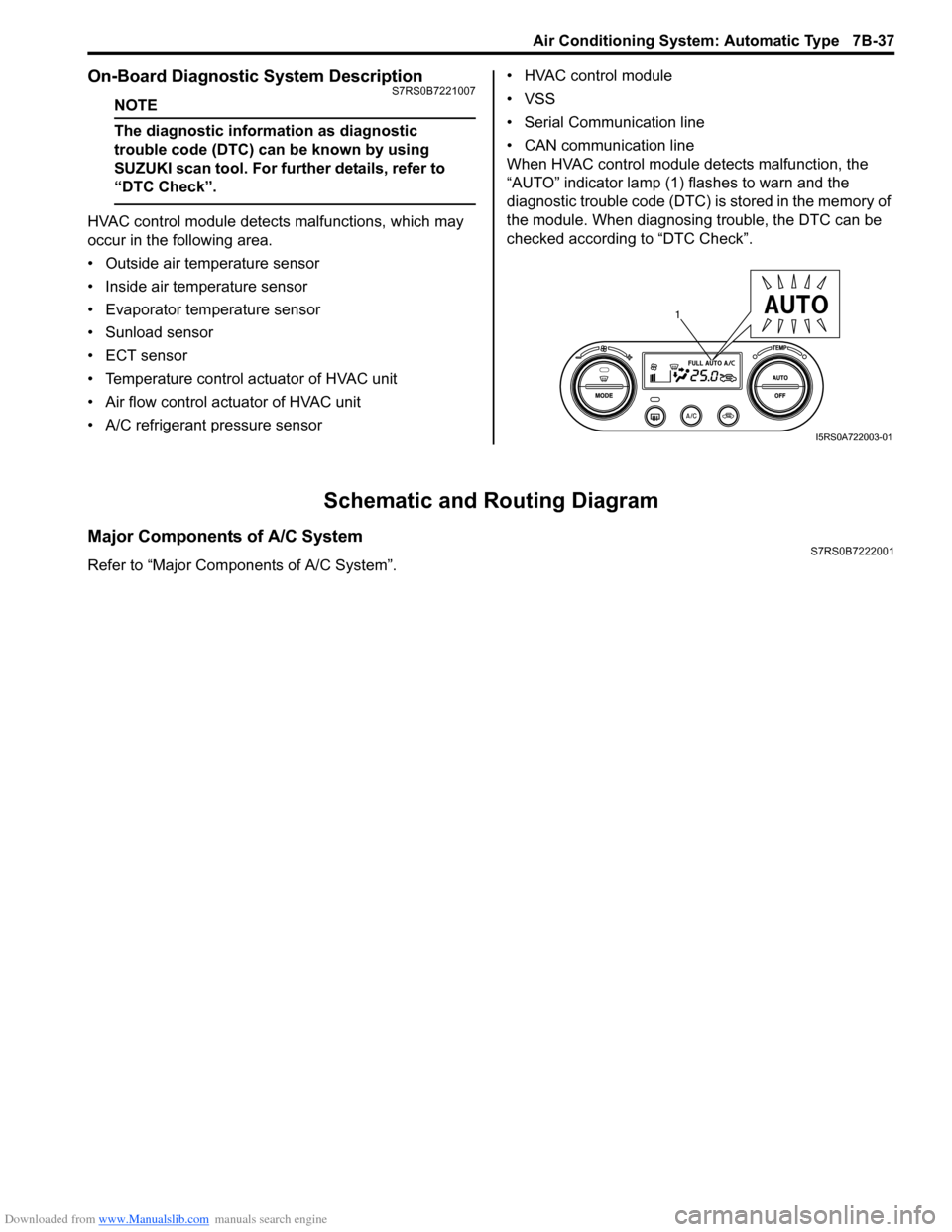

On-Board Diagnostic System DescriptionS7RS0B7221007

NOTE

The diagnostic information as diagnostic

trouble code (DTC) can be known by using

SUZUKI scan tool. For further details, refer to

“DTC Check”.

HVAC control module detect s malfunctions, which may

occur in the following area.

• Outside air temperature sensor

• Inside air temperature sensor

• Evaporator temperature sensor

• Sunload sensor

• ECT sensor

• Temperature control actuator of HVAC unit

• Air flow control actuator of HVAC unit

• A/C refrigerant pressure sensor • HVAC control module

• VSS

• Serial Communication line

• CAN communication line

When HVAC control module detects malfunction, the

“AUTO” indicator lamp (1) flashes to warn and the

diagnostic trouble code (DTC) is stored in the memory of

the module. When diagnosing trouble, the DTC can be

checked according to “DTC Check”.

Schematic and Routing Diagram

Major Components of A/C SystemS7RS0B7222001

Refer to “Major Components of A/C System”.

1

I5RS0A722003-01