300 SUZUKI SX4 2006 1.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 662 of 1556

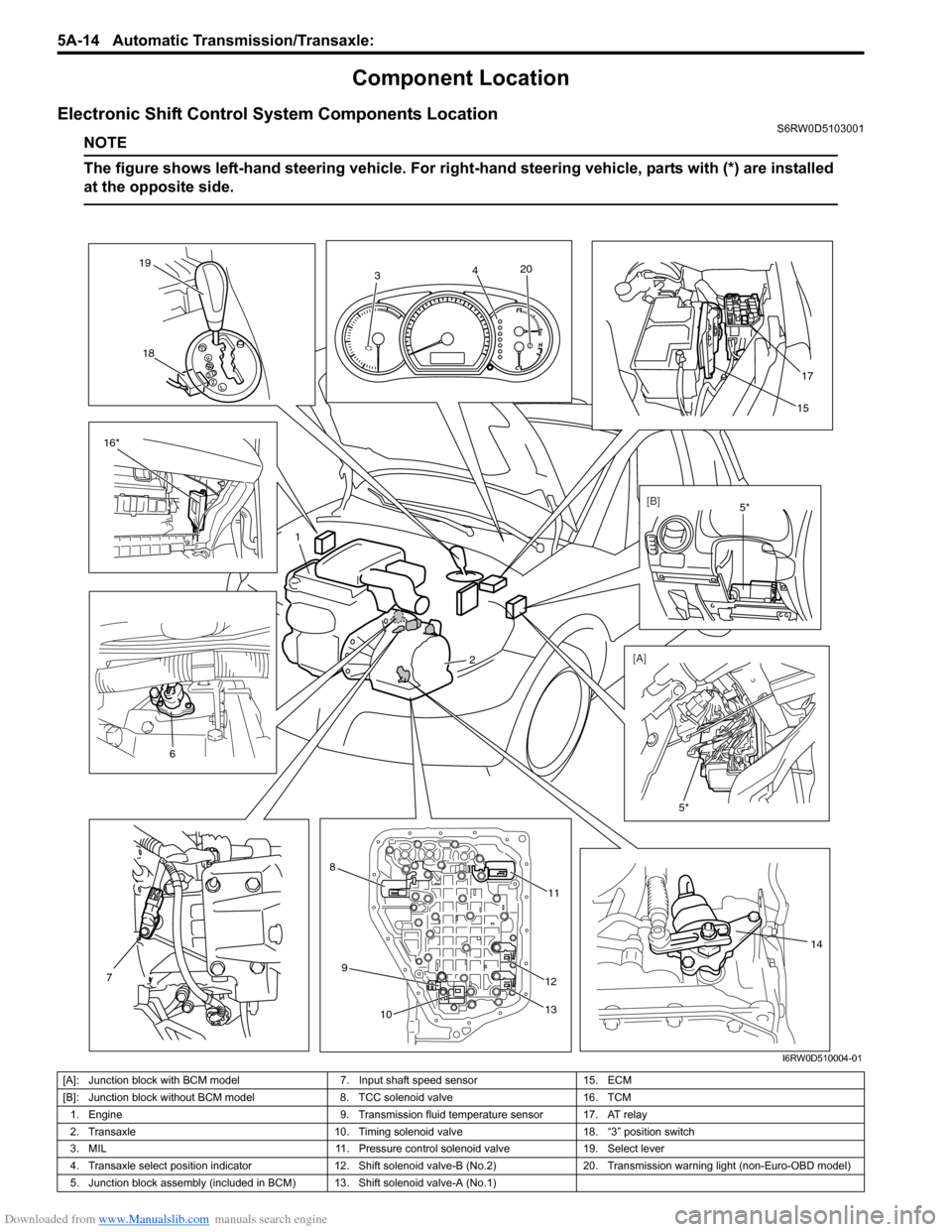

Downloaded from www.Manualslib.com manuals search engine 5A-14 Automatic Transmission/Transaxle:

Component Location

Electronic Shift Control System Components LocationS6RW0D5103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

5*

17

15

1

2

8

9

1011

12

13

16*18 19

14

7

6

3420

[B]

[A]5*

I6RW0D510004-01

[A]: Junction block with BCM model 7. Input shaft speed sensor 15. ECM

[B]: Junction block without BCM model 8. TCC solenoid valve 16. TCM

1. Engine 9. Transmission fluid temperature sensor 17. AT relay

2. Transaxle 10. Timing solenoid valve 18. “3” position switch

3. MIL 11. Pressure control solenoid valve 19. Select lever

4. Transaxle select position indicator 12. Shift solenoid valve-B (No.2) 20. Transmission warning light (non-Euro-OBD model)

5. Junction block assembly (included in BCM) 13. Shift solenoid valve-A (No.1)

Page 672 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-24 Automatic Transmission/Transaxle:

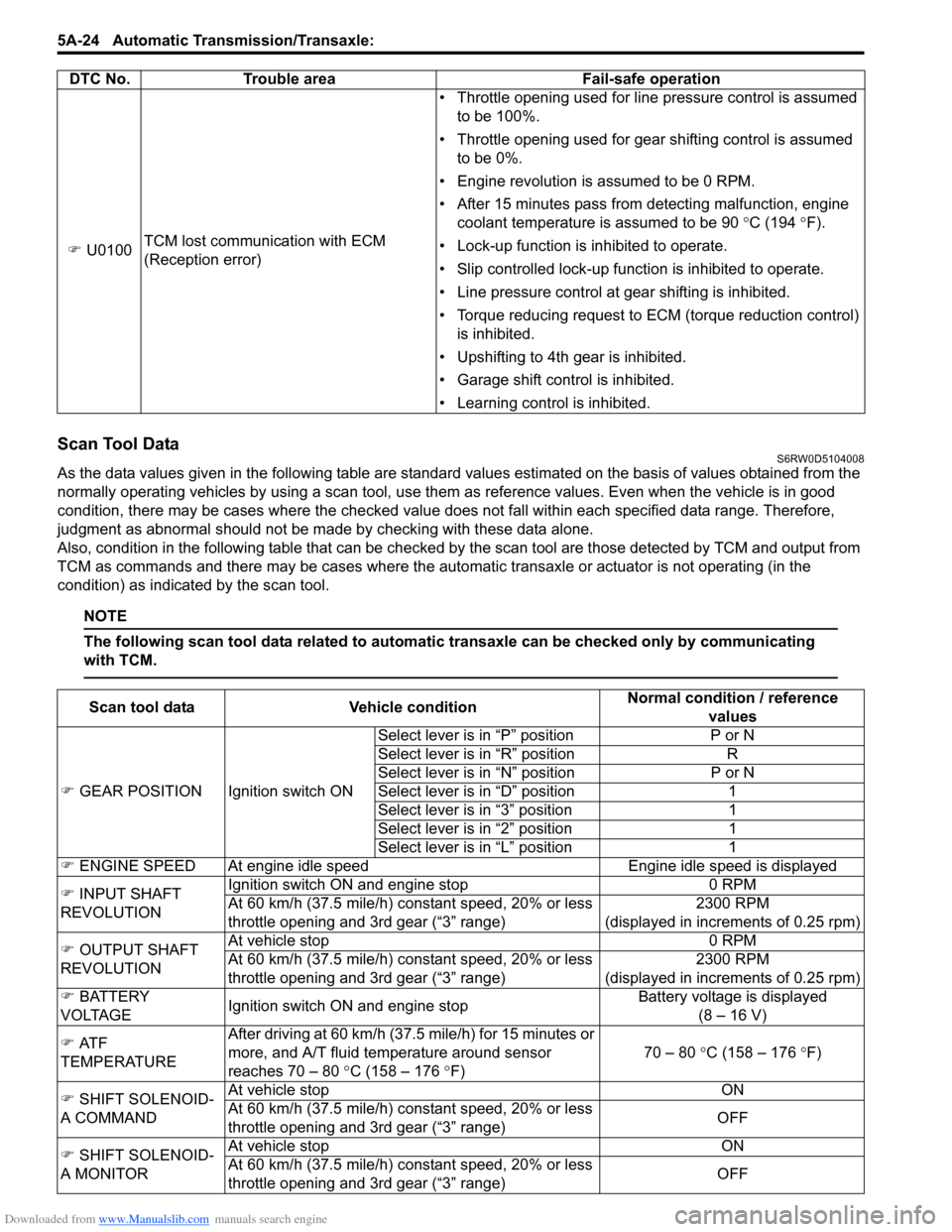

Scan Tool DataS6RW0D5104008

As the data values given in the following table are standard values estimated on the basis of values obtained from the

normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good

condition, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, condition in the following table that can be checked by the scan tool are those detected by TCM and output from

TCM as commands and there may be cases where the automatic transaxle or actuator is not operating (in the

condition) as indicated by the scan tool.

NOTE

The following scan tool data related to automatic transaxle can be checked only by communicating

with TCM.

�) U0100TCM lost communication with ECM

(Reception error)• Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed

to be 0%.

• Engine revolution is assumed to be 0 RPM.

• After 15 minutes pass from detecting malfunction, engine

coolant temperature is assumed to be 90 °C (194 °F).

• Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Upshifting to 4th gear is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited. DTC No. Trouble area Fail-safe operation

Scan tool data Vehicle conditionNormal condition / reference

values

�) GEAR POSITION Ignition switch ONSelect lever is in “P” position P or N

Select lever is in “R” position R

Select lever is in “N” position P or N

Select lever is in “D” position 1

Select lever is in “3” position 1

Select lever is in “2” position 1

Select lever is in “L” position 1

�) ENGINE SPEED At engine idle speed Engine idle speed is displayed

�) INPUT SHAFT

REVOLUTIONIgnition switch ON and engine stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)2300 RPM

(displayed in increments of 0.25 rpm)

�) OUTPUT SHAFT

REVOLUTIONAt vehicle stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)2300 RPM

(displayed in increments of 0.25 rpm)

�) BATTERY

VOLTAGEIgnition switch ON and engine stopBattery voltage is displayed

(8 – 16 V)

�) AT F

TEMPERATUREAfter driving at 60 km/h (37.5 mile/h) for 15 minutes or

more, and A/T fluid temperature around sensor

reaches 70 – 80 °C (158 – 176 °F)70 – 80 °C (158 – 176 °F)

�) SHIFT SOLENOID-

A COMMANDAt vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)OFF

�) SHIFT SOLENOID-

A MONITORAt vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)OFF

Page 800 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-152 Automatic Transmission/Transaxle:

43) Measure O/D and 2nd coast brake piston stroke.

• Measure dimension “a” from end face of transaxle

case to O/D and 2nd coast brake rear plate (1)

using straightedge and micrometer caliper.

• Measure dimension “b” from O/D and 2nd coast

brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of

dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.)

When piston stroke is out of specification, select O/D

and 2nd coast brake rear plate with proper thickness

from among the following table and replace it.

CAUTION!

When brake disc, retaining plate, separator

plate and/or rear plate of O/D and 2nd coast

brake have been replaced, all learned

contents, which have been stored in TCM

memory by executing learning control,

should be initialized referring to “Learning

Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

Available O/D and 2nd coast brake rear plate

thickness

44) After applying A/T fluid to new 2nd brake gaskets (1),

install them to transaxle case (2).

45) After applying A/T fluid to reverse clutch drum thrust

bearing (1), install it to forward and reverse clutch

assembly (2).

46) Remove sealant attached to mating surface of

transaxle rear cover (1) completely.

47) Apply sealant to mating surface of transaxle rear

cover (1) by using a nozzle (2) as shown in figure by

such amount that its section is 1.2 mm (0.047 in.) in

diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B) Thickness Identification mark

1.8 mm (0.071 in.) 1

2.0 mm (0.079 in.) 2

2.2 mm (0.087 in.) 3

2.4 mm (0.094 in.) 4

2.6 mm (0.102 in.) 5

I2RH0B510298-01

I2RH0B510299-01

I2RH0B510300-01

“A”2

1

I2RH0B510301-01

Page 854 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-1 Clutch:

Transmission / Transaxle

Clutch

General Description

Clutch (Hydraulic Type) ConstructionS6RW0D5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positioned on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing (incorporated in clutch operating cylinder) is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal causes the release bearing (incorporated in clutch operating cylinder) to advance and

pushes on the tips of the tapered fingers of the diaphragm spring. When this happens, the diaphragm spring pulls the

pressure plate away from the flywheel, thereby interrupting the flow of drive from flywheel through clutch disc to

transaxle input shaft. Clutch fluid is supplied from brake fluid reservoir. Clutch fluid level can be checked by brake fluid

level of brake fluid reservoir.

I5RW0A530001-01

1. Crankshaft 4. Pressure plate 7. Operating cylinder assembly

2. Flywheel 5. Clutch cover 8. Input shaft bearing

3. Clutch disc 6. Diaphragm spring 9. Input shaft

Page 856 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-3 Clutch:

Repair Instructions

Clutch Pedal InspectionS6RW0D5306001

Cylinder Push Rod Play “a”

1) Press clutch pedal (1) gradually with finger, stop

when slight increase of resistance is felt and

measure how much pedal has moved (push rod

play) as represented by “a” as shown.

Push rod play

“a”: Max. 3 mm (0.12 in.)

2) If “a” is not within specification, replace master

cylinder (3) or pedal arm (2).

Clutch Pedal Free Travel “b”

1) Depress clutch pedal (1), stop the moment clutch

resistance is felt, and measure how much pedal has

moved (clutch pedal free travel) as represented by

“b” in the figure.

Clutch pedal free travel

“b”

: 2 – 8 mm (0.08 – 0.31 in.)

2) If “b” is not within specification, check pedal arm (2)

and master cylinder (3) and replace defective part.

Clutch Release Margin “c”

1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral

gear position.

3) Without clutch pedal (1) depressed, slightly push the

shift lever to reverse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress

clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full

stroke point (5) on clutch pedal (1) which is shown by

“c” in the figure.

Clutch release margin

“c”: 25 – 55 mm (0.98 – 2.17 in.)6) If “c” is not within specification, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”.Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS6RW0D5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to the reservoir cap of the brake master

cylinder.

Air Bleeding of Clutch SystemS6RW0D5306003

CAUTION!

When operating the pedal stroke for air

bleeding of clutch system, after releasing the

clutch pedal, be sure to wait 1 second or

more before depressing it again. Otherwise,

the oil seal of operating cylinder will be

damaged, resulting in oil leakage.

Bleed air from clutch system.

Refer to “Air Bleeding of Brake System in Section 4A”.

I5RW0A530002-01

Page 857 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-4

Clutch Fluid Pipe and Hose LocationS6RW0D5306004

Clutch Fluid Pipe Removal and InstallationS6RW0D5306005

Removal

CAUTION!

Do not allow fluid to get on painted surface. It

may cause painted surface damage.

1) Remove dust and dirt from each joint of pipe to be

disconnected and clean around brake master

cylinder reservoir cap.

2) Take out fluid with syringe or such from brake master

cylinder reservoir.

3) Pull clamp (1) of clutch master cylinder (3) and pull

clamp (5) of fluid pipe joint (4), and then disconnect

clutch fluid pipe (2).

4) Pull clamp (6) of damper (7), and then disconnect

damper (7) from clutch fluid pipe (2).Installation

Reverse removal procedure for installation noting the

following.

CAUTION!

• Do not allow fluid to get on painted

surface.

• Do not allow pipe to contact hard against

vehicle body or other parts.

• Install each clamp securely.

• After installation, check clutch pedal free travel and

bleed air from clutch system referring to “Clutch Pedal

Inspection” and “Air Bleeding of Clutch System”.

• Check fluid leakage.

• Add fluid to MAX level of reservoir.

Clutch Fluid Pipe InspectionS6RW0D5306006

Check pipe (1) for damage, dirt and leak. Replace if

check result is not satisfactory.

4 [A]

3131

22

4

I5RW0A530003-02

[A]: RH steering vehicle 3. Clutch reservoir hose

1. Clutch master cylinder 4. Brake master cylinder reservoir

2. Clutch fluid pipe

2

6

5 74

3

1

2

I5RW0B530002-03

[A]: LH steering vehicle

[B]: RH steering vehicle

I5RW0A530005-01

Page 858 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-5 Clutch:

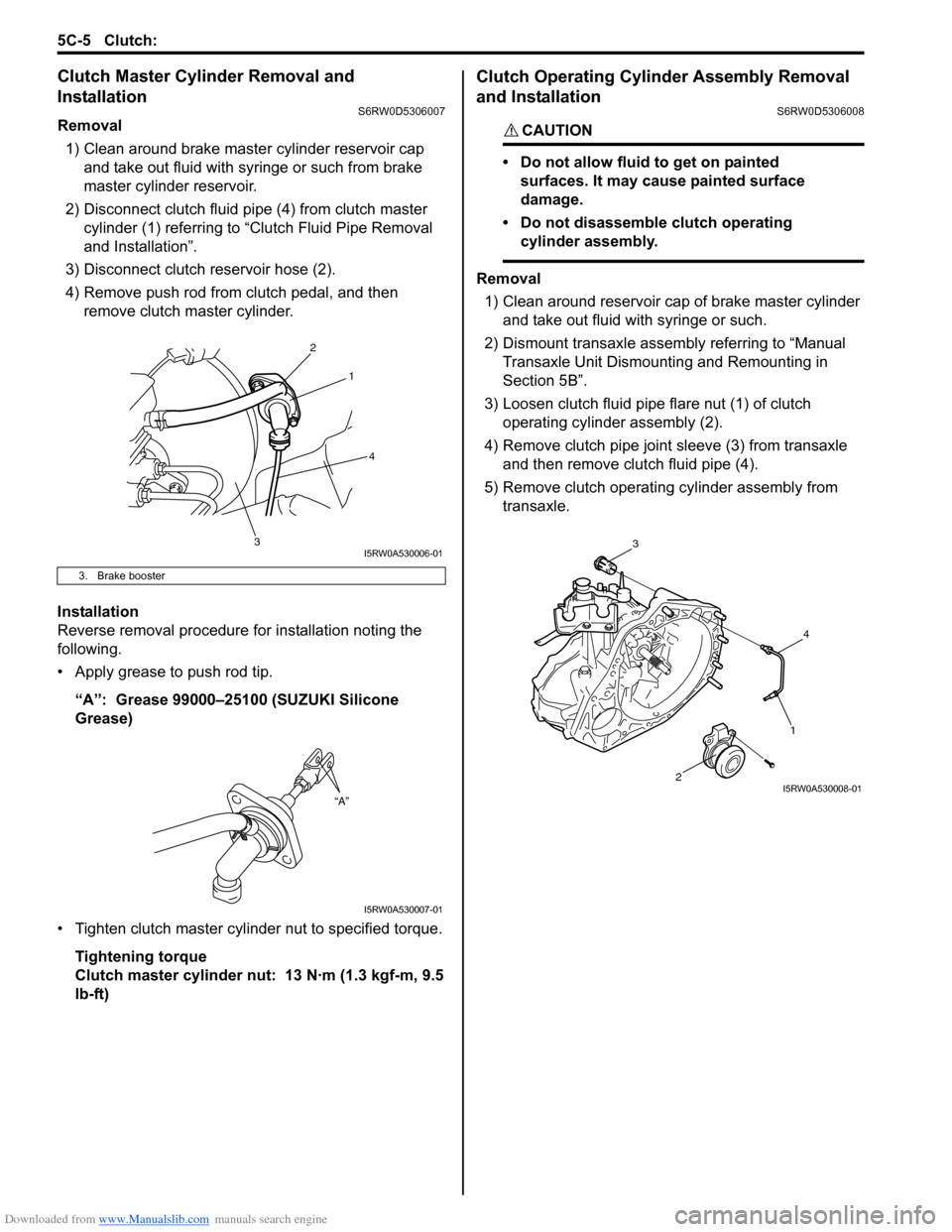

Clutch Master Cylinder Removal and

Installation

S6RW0D5306007

Removal

1) Clean around brake master cylinder reservoir cap

and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe (4) from clutch master

cylinder (1) referring to “Clutch Fluid Pipe Removal

and Installation”.

3) Disconnect clutch reservoir hose (2).

4) Remove push rod from clutch pedal, and then

remove clutch master cylinder.

Installation

Reverse removal procedure for installation noting the

following.

• Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

• Tighten clutch master cylinder nut to specified torque.

Tightening torque

Clutch master cylinder nut: 13 N·m (1.3 kgf-m, 9.5

lb-ft)

Clutch Operating Cylinder Assembly Removal

and Installation

S6RW0D5306008

CAUTION!

• Do not allow fluid to get on painted

surfaces. It may cause painted surface

damage.

• Do not disassemble clutch operating

cylinder assembly.

Removal

1) Clean around reservoir cap of brake master cylinder

and take out fluid with syringe or such.

2) Dismount transaxle assembly referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B”.

3) Loosen clutch fluid pipe flare nut (1) of clutch

operating cylinder assembly (2).

4) Remove clutch pipe joint sleeve (3) from transaxle

and then remove clutch fluid pipe (4).

5) Remove clutch operating cylinder assembly from

transaxle.

3. Brake booster

1

3

2

4

I5RW0A530006-01

“A”

I5RW0A530007-01

3

4

2

1

I5RW0A530008-01

Page 859 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-6

Installation

1) Install clutch operating cylinder assembly (2) to

transaxle. Tighten new mounting bolts to specified

torque.

Tightening torque

Clutch operating cylinder assembly mounting

bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect clutch fluid pipe (4) to clutch operating

cylinder assembly temporarily.

3) Install clutch pipe joint sleeve (3) to transaxle

securely and then tighten clutch fluid pipe flare nut

(1) to specified torque.

Tightening torque

Clutch fluid pipe flare nut (b): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)4) Remount transaxle assembly referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B”.

5) Bleed air from system and check clutch pedal free

travel. Refer to “Air Bleeding of Clutch System” and

“Clutch Pedal Inspection”.

Clutch Operating Cylinder Assembly InspectionS6RW0D5306013

Check clutch fluid leakage, spring for damage and

bearing for smooth rotation. If malfunction is found,

replace clutch operating cylinder assembly.

Clutch Cover, Clutch Disc and Flywheel ComponentsS6RW0D5306010

3

4

(a)

2

1, (b)

I5RW0A530009-01

I5RW0B530005-03

2

1

3(a)

6

4

5

(b)

I6RW0C530001-01

1. Clutch cover 4. Flywheel : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

2. Clutch disc 5. Input shaft bearing : 70 N⋅m (7.0 kgf-m, 51.0 lb-ft)

3. Clutch cover bolt 6. Flywheel bolt : Do not reuse.

Page 860 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-7 Clutch:

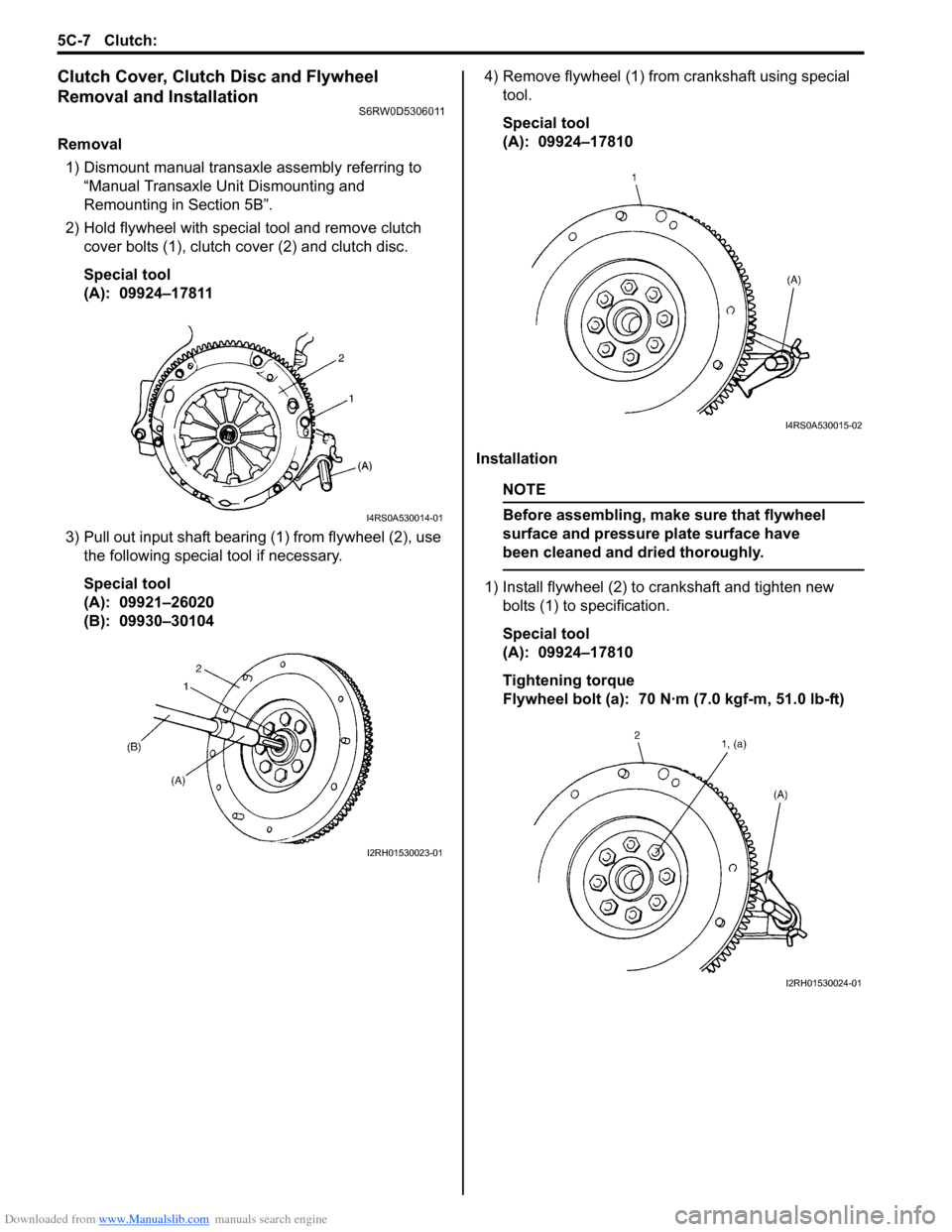

Clutch Cover, Clutch Disc and Flywheel

Removal and Installation

S6RW0D5306011

Removal

1) Dismount manual transaxle assembly referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

2) Hold flywheel with special tool and remove clutch

cover bolts (1), clutch cover (2) and clutch disc.

Special tool

(A): 09924–17811

3) Pull out input shaft bearing (1) from flywheel (2), use

the following special tool if necessary.

Special tool

(A): 09921–26020

(B): 09930–301044) Remove flywheel (1) from crankshaft using special

tool.

Special tool

(A): 09924–17810

Installation

NOTE

Before assembling, make sure that flywheel

surface and pressure plate surface have

been cleaned and dried thoroughly.

1) Install flywheel (2) to crankshaft and tighten new

bolts (1) to specification.

Special tool

(A): 09924–17810

Tightening torque

Flywheel bolt (a): 70 N·m (7.0 kgf-m, 51.0 lb-ft)

I4RS0A530014-01

I2RH01530023-01

I4RS0A530015-02

I2RH01530024-01

Page 861 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-8

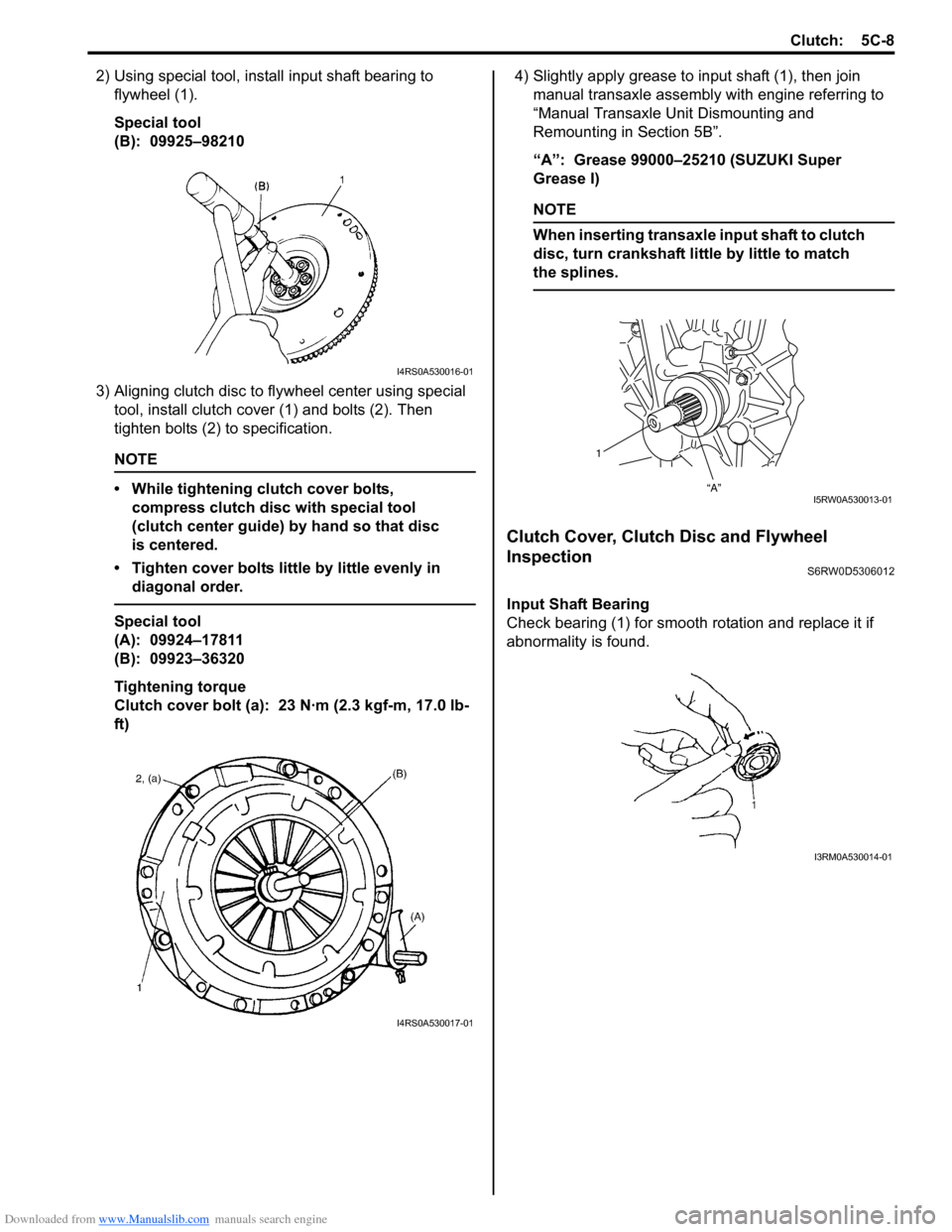

2) Using special tool, install input shaft bearing to

flywheel (1).

Special tool

(B): 09925–98210

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts,

compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in

diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)4) Slightly apply grease to input shaft (1), then join

manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft little by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S6RW0D5306012

Input Shaft Bearing

Check bearing (1) for smooth rotation and replace it if

abnormality is found.

I4RS0A530016-01

I4RS0A530017-01

1

“A”I5RW0A530013-01

I3RM0A530014-01