TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1161 of 2389

(e) Disconnect the vacuum hose from port R of the EGR

vacuum modulator and connect port R directly to the in-

take manifold with another hose.

(d) Check that the vacuum gauge indicates high vacuum at

2,500 rpm.

HINT: As large amount of EGR gas enters, the engine will

misfire slightly.

(e) Remove the vacuum gauge and reconnect the vacuum

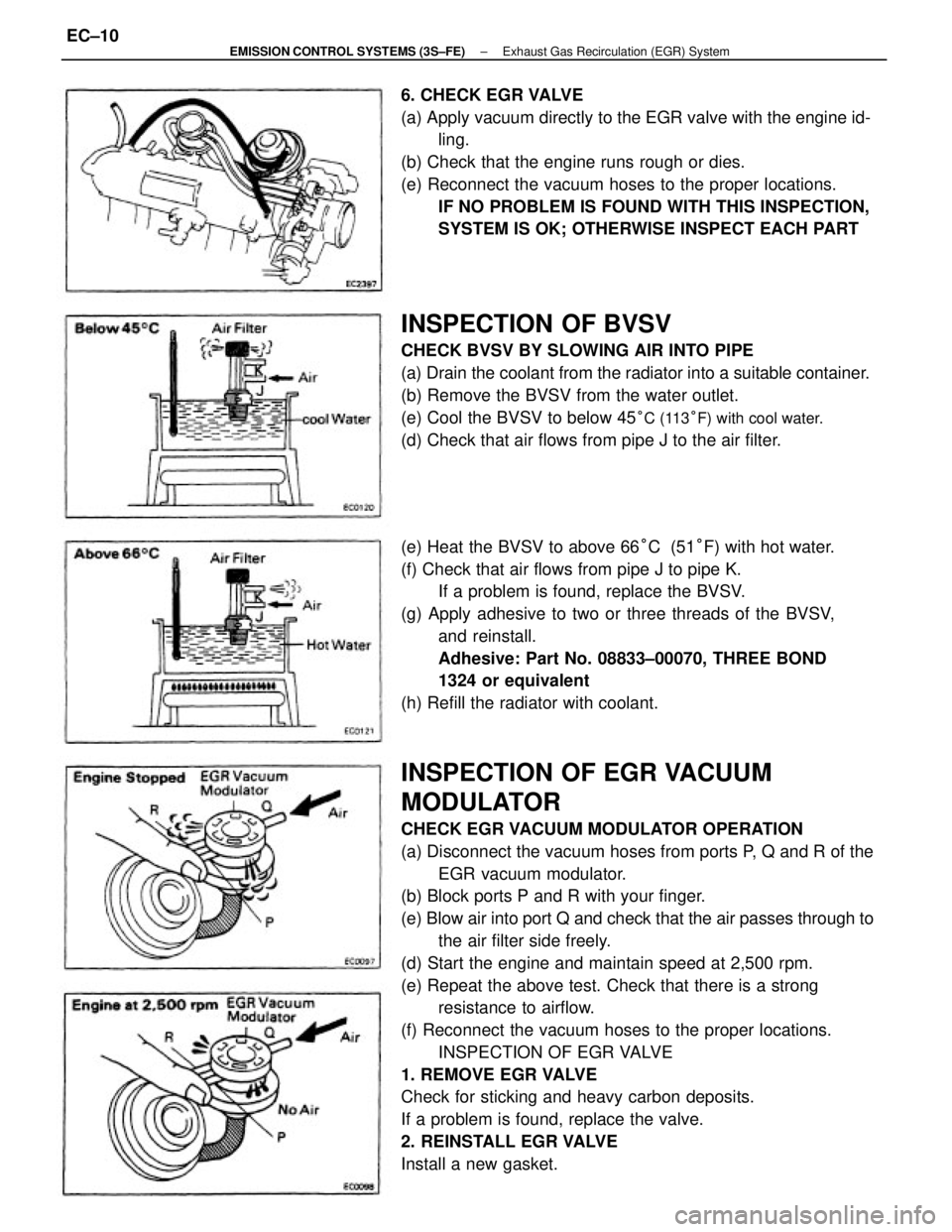

hoses to the proper locations. 2. PREPARATION

Using a 3±way connector, connect a vacuum gauge to the

hose between the EGR valve and vacuum pipe.

3. CHECK SEATING OF EGR VALVE

Start the engine and check that the engine starts and runs at

idle.

5. CHECK6VSV AND EGR VACUUM MODULATOR WITH

HOT ENGINE

(a) Warm up the engine.

(b) Check that the vacuum gauge indicates low vacuum at

2,500 rpm.

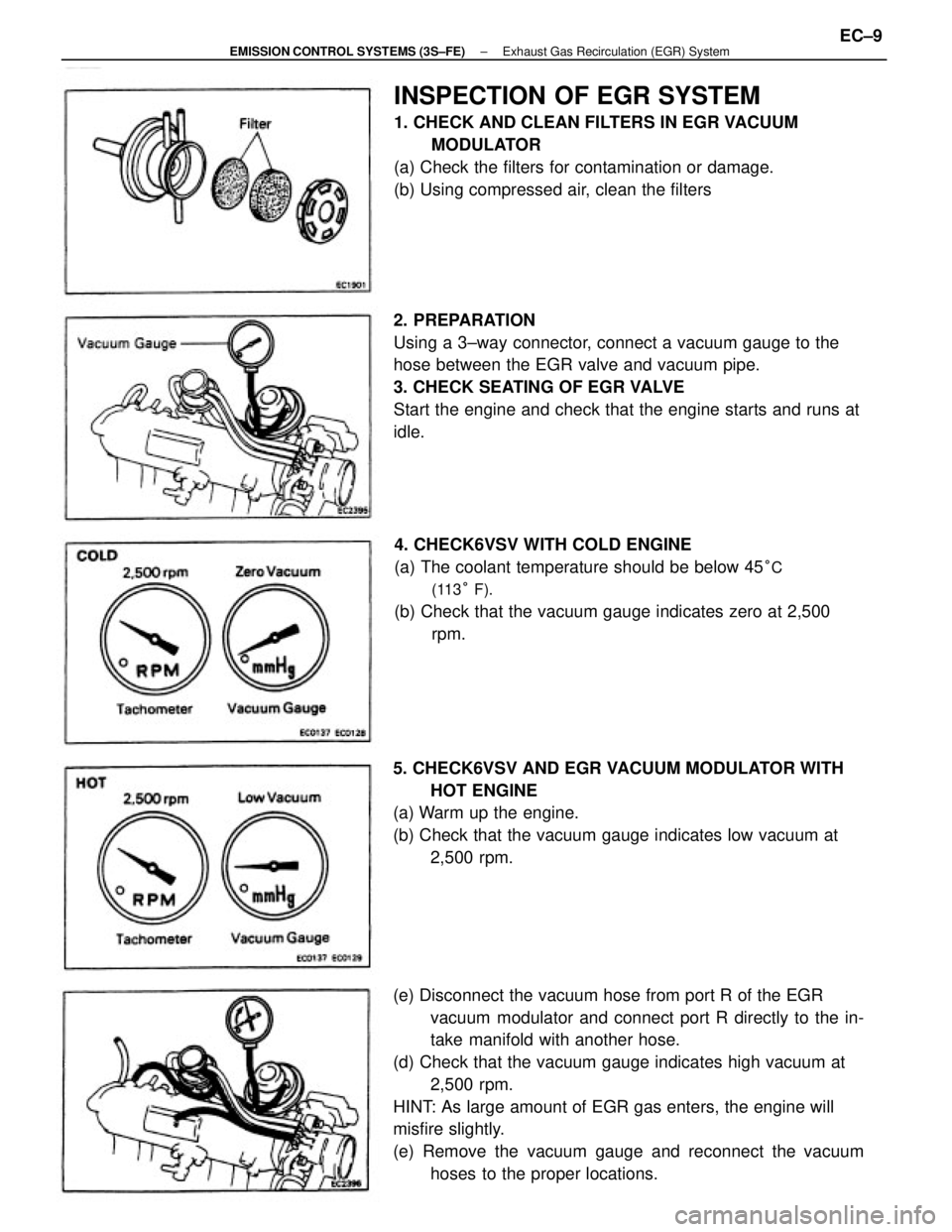

INSPECTION OF EGR SYSTEM

1. CHECK AND CLEAN FILTERS IN EGR VACUUM

MODULATOR

(a) Check the filters for contamination or damage.

(b) Using compressed air, clean the filters

4. CHECK6VSV WITH COLD ENGINE

(a) The coolant temperature should be below 45

°C

(113° F).

(b) Check that the vacuum gauge indicates zero at 2,500

rpm.

± EMISSION CONTROL SYSTEMS (3S±FE)Exhaust Gas Recirculation (EGR) SystemEC±9

Page 1162 of 2389

INSPECTION OF EGR VACUUM

MODULATOR

CHECK EGR VACUUM MODULATOR OPERATION

(a) Disconnect the vacuum hoses from ports P, Q and R of the

EGR vacuum modulator.

(b) Block ports P and R with your finger.

(e) Blow air into port Q and check that the air passes through to

the air filter side freely.

(d) Start the engine and maintain speed at 2,500 rpm.

(e) Repeat the above test. Check that there is a strong

resistance to airflow.

(f) Reconnect the vacuum hoses to the proper locations.

INSPECTION OF EGR VALVE

1. REMOVE EGR VALVE

Check for sticking and heavy carbon deposits.

If a problem is found, replace the valve.

2. REINSTALL EGR VALVE

Install a new gasket.

INSPECTION OF BVSV

CHECK BVSV BY SLOWING AIR INTO PIPE

(a) Drain the coolant from the radiator into a suitable container.

(b) Remove the BVSV from the water outlet.

(e) Cool the BVSV to below 45

°C (113°F) with cool water.

(d) Check that air flows from pipe J to the air filter.

(e) Heat the BVSV to above 66°C (51°F) with hot water.

(f) Check that air flows from pipe J to pipe K.

If a problem is found, replace the BVSV.

(g) Apply adhesive to two or three threads of the BVSV,

and reinstall.

Adhesive: Part No. 08833±00070, THREE BOND

1324 or equivalent

(h) Refill the radiator with coolant. 6. CHECK EGR VALVE

(a) Apply vacuum directly to the EGR valve with the engine id-

ling.

(b) Check that the engine runs rough or dies.

(e) Reconnect the vacuum hoses to the proper locations.

IF NO PROBLEM IS FOUND WITH THIS INSPECTION,

SYSTEM IS OK; OTHERWISE INSPECT EACH PART

± EMISSION CONTROL SYSTEMS (3S±FE)Exhaust Gas Recirculation (EGR) SystemEC±10

Page 1163 of 2389

INSPECTION OF EXHAUST PIPE

ASSEMBLY

CHECK CONNECTIONS FOR LOOSENESS OR DAMAGE

REPLACEMENT OF CATALYTIC

CONVERTERS

1. REMOVE CONVERTERS

(a) Jack up the vehicle.

(b) Check that the converter is cool.

(e) Remove the suspension lower crossmember.

(See page EM±44)

(d) Remove the front exhaust pipe (Sub±converter).

wLoosen the bolt, and disconnect the clamp the

exhaust pipe bracket.

wRemove the three nuts, and remove the exhaust pipe. Remove

the three nuts, and remove the exhaust pipe. Remove the gas-

ket.

(e) Remove the two bolts, two nuts and two converter stays.

(f) Remove the three bolts, two nuts, gasket, retainer, cushion and

main converter.

(g) Remove the eight bolts and two heat insulators from the main

converter.

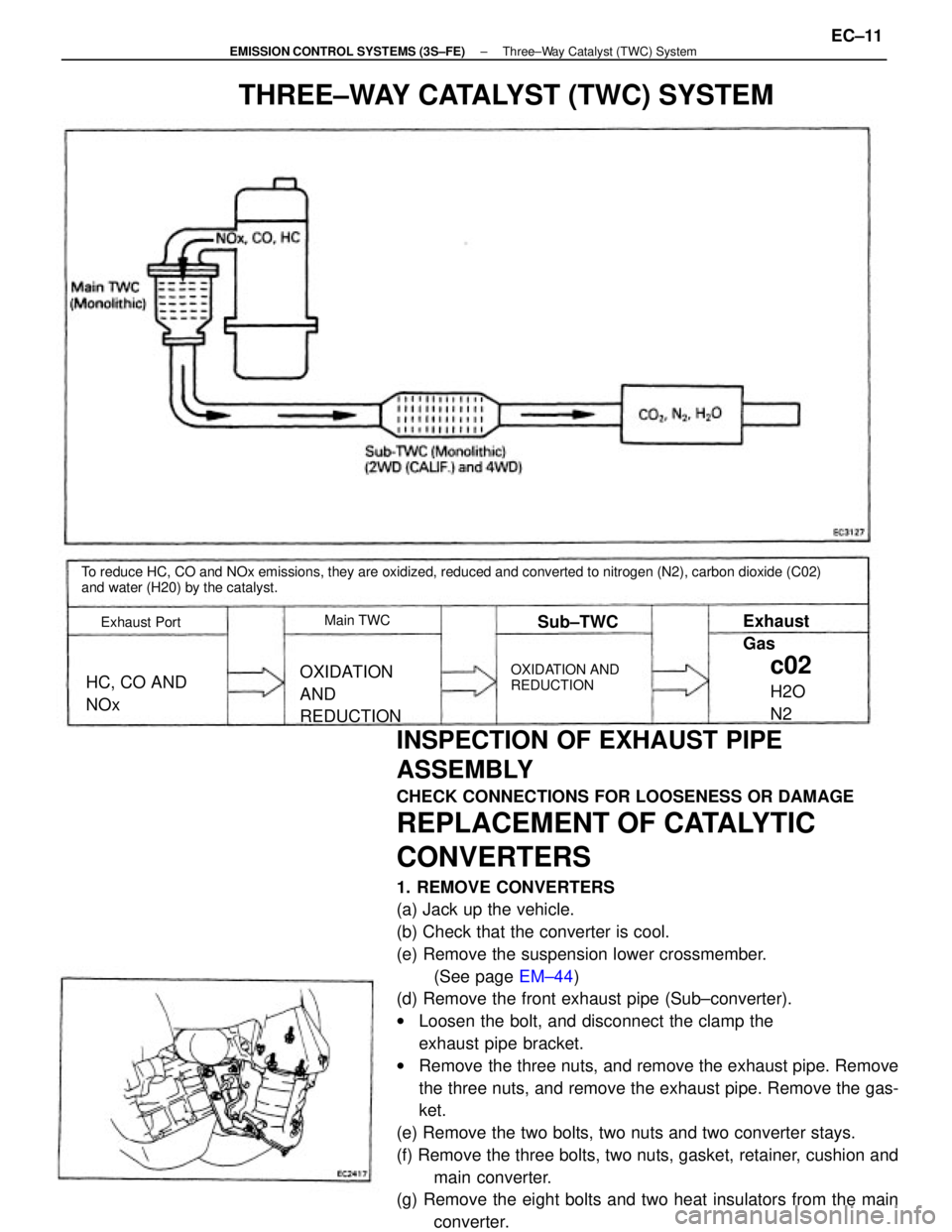

To reduce HC, CO and NOx emissions, they are oxidized, reduced and converted to nitrogen (N2), carbon dioxide (C02)

and water (H20) by the catalyst.

THREE±WAY CATALYST (TWC) SYSTEM

OXIDATION

AND

REDUCTIONOXIDATION AND

REDUCTIONHC, CO AND

NOx

Exhaust Port

c02

H2O

N2 Exhaust

Gas

Main TWCSub±TWC

± EMISSION CONTROL SYSTEMS (3S±FE)Three±Way Catalyst (TWC) SystemEC±11

Page 1164 of 2389

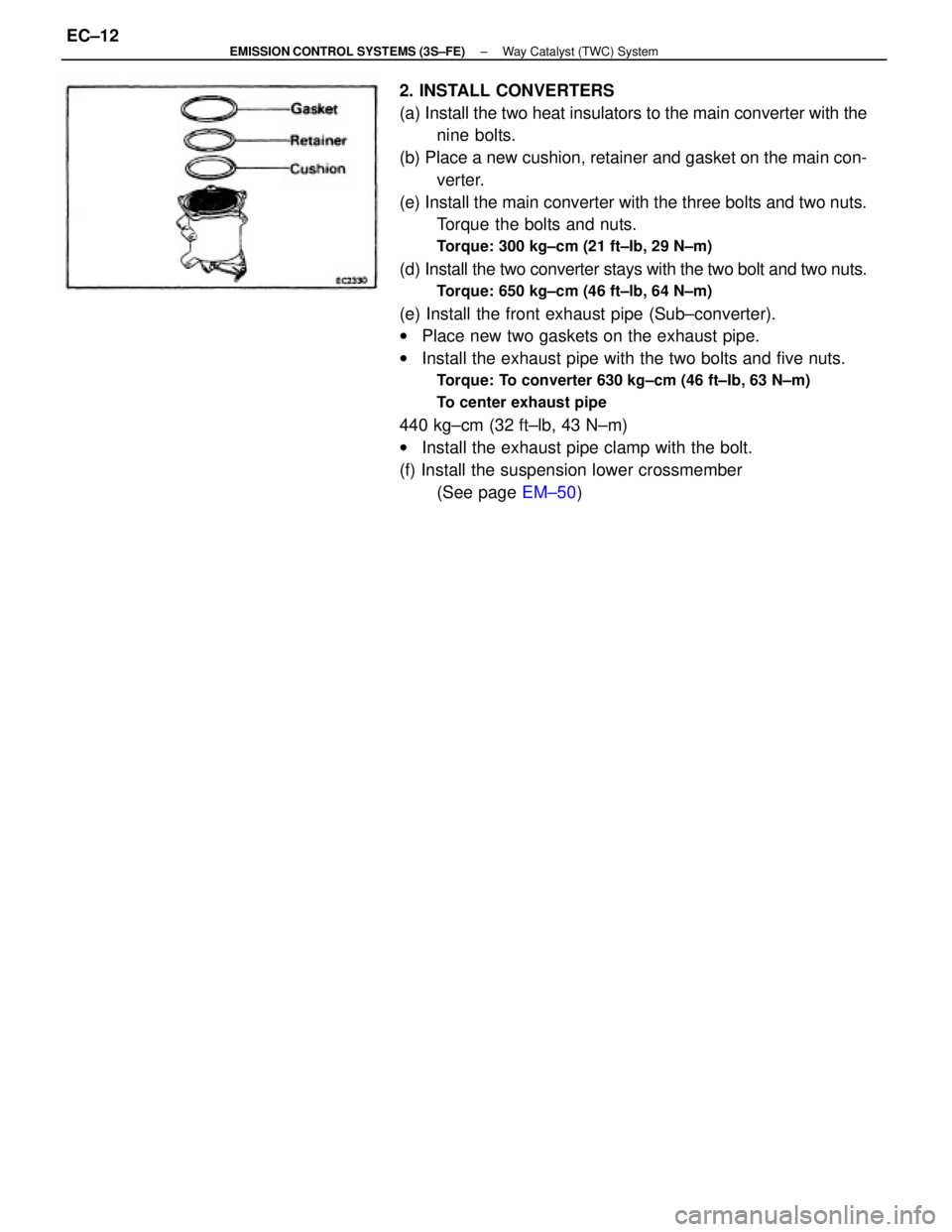

2. INSTALL CONVERTERS

(a) Install the two heat insulators to the main converter with the

nine bolts.

(b) Place a new cushion, retainer and gasket on the main con-

verter.

(e) Install the main converter with the three bolts and two nuts.

Torque the bolts and nuts.

Torque: 300 kg±cm (21 ft±Ib, 29 N±m)

(d) Install the two converter stays with the two bolt and two nuts.

Torque: 650 kg±cm (46 ft±lb, 64 N±m)

(e) Install the front exhaust pipe (Sub±converter).

wPlace new two gaskets on the exhaust pipe.

wInstall the exhaust pipe with the two bolts and five nuts.

Torque: To converter 630 kg±cm (46 ft±Ib, 63 N±m)

To center exhaust pipe

440 kg±cm (32 ft±lb, 43 N±m)

wInstall the exhaust pipe clamp with the bolt.

(f) Install the suspension lower crossmember

(See page EM±50)

± EMISSION CONTROL SYSTEMS (3S±FE)Way Catalyst (TWC) SystemEC±12

Page 1165 of 2389

Reduces blow±by gas (HC)

Reduces evaporative HC

Reduces HC and CO

Reduces NOx

Reduces HC, CO and NOx

Regulates all engine conditions for reduction of

exhaust emissions. Positive Crankcase ventilation

Fuel evaporative emission control

Dash pot

Exhaust gas recirculation

Three±way catalyst

Electronic fuel injection*

Remarks *For inspection and repair of the EFI system, refer to EFI section of this

manual.

SYSTEM PURPOSE

PCV

EVAP

DP

EGR

TWC

EFI Abbreviation

Purpose

System

± EMISSION CONTROL SYSTEMS (2VZ±FE)System PurposeEC±13

Page 1166 of 2389

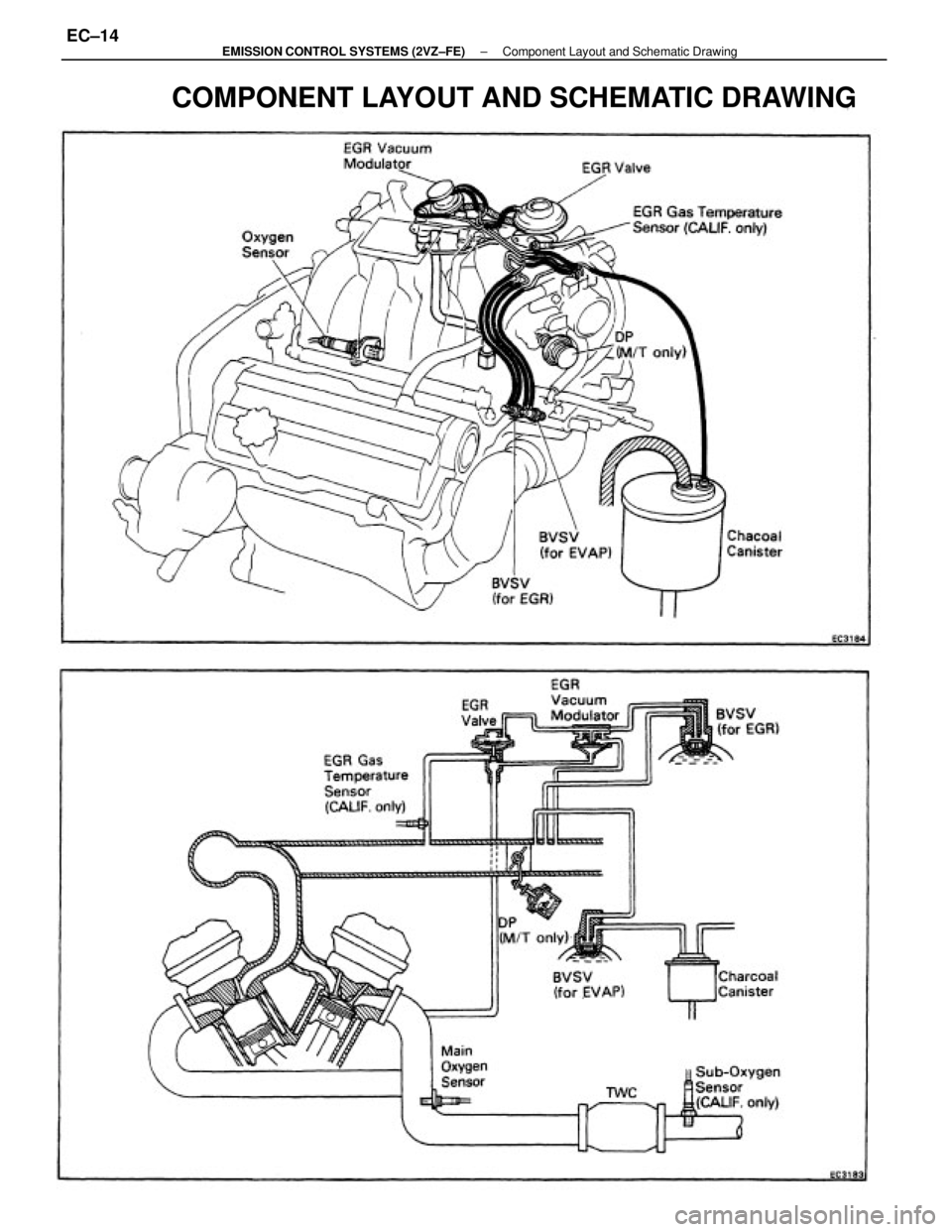

COMPONENT LAYOUT AND SCHEMATIC DRAWING

± EMISSION CONTROL SYSTEMS (2VZ±FE)Component Layout and Schematic DrawingEC±14

Page 1167 of 2389

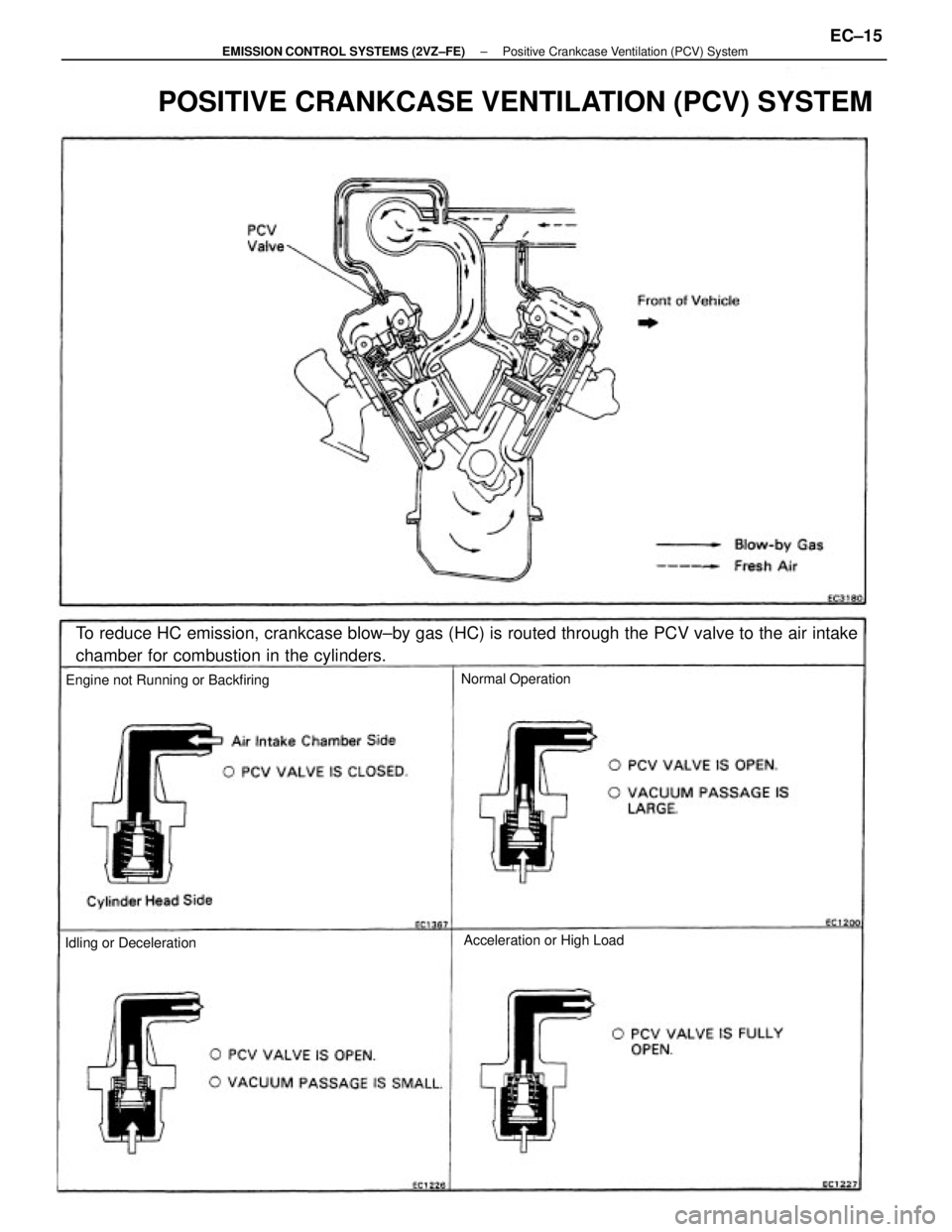

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

To reduce HC emission, crankcase blow±by gas (HC) is routed through the PCV valve to the air intake

chamber for combustion in the cylinders.

Engine not Running or Backfiring

Acceleration or High Load

Idling or DecelerationNormal Operation

± EMISSION CONTROL SYSTEMS (2VZ±FE)Positive Crankcase Ventilation (PCV) SystemEC±15

Page 1168 of 2389

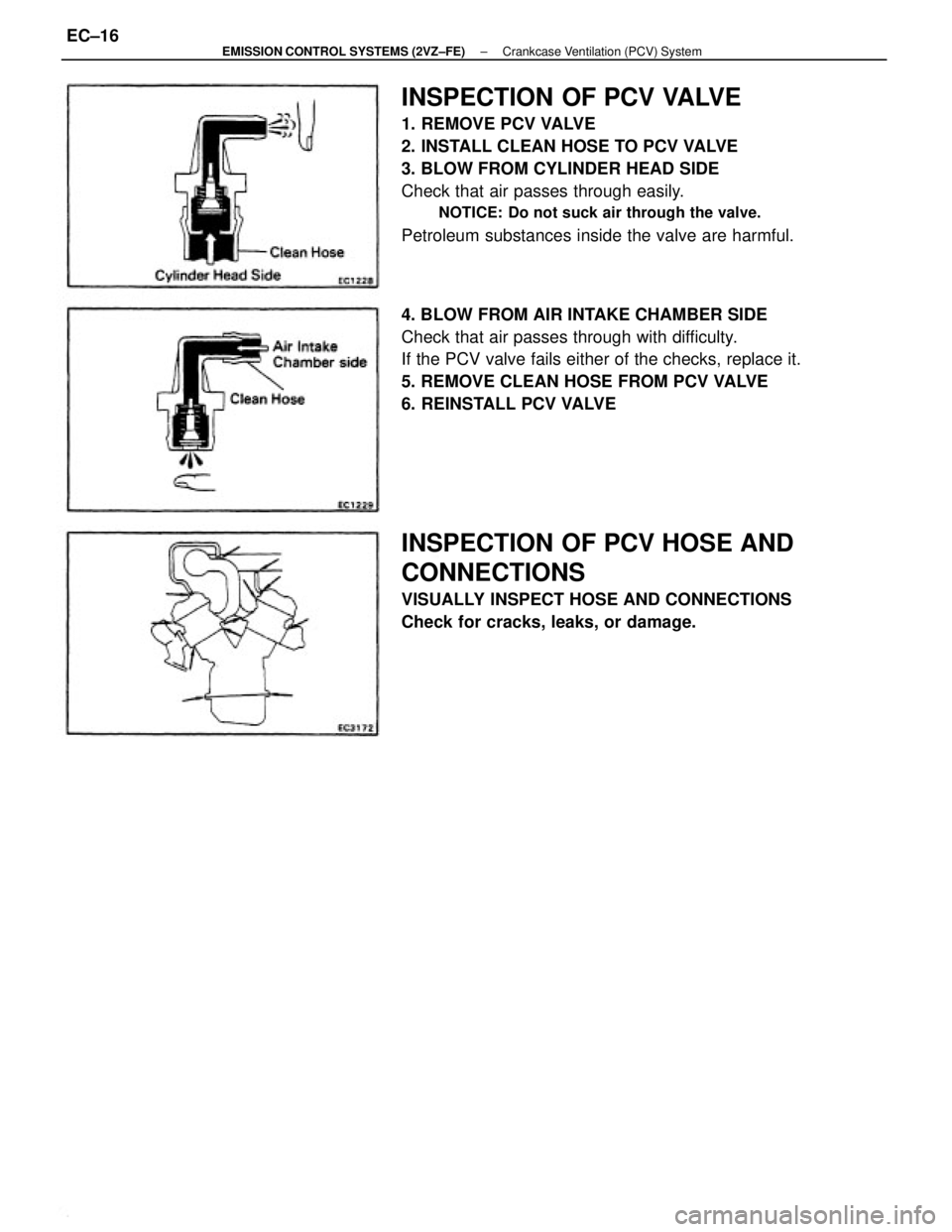

INSPECTION OF PCV VALVE

1. REMOVE PCV VALVE

2. INSTALL CLEAN HOSE TO PCV VALVE

3. BLOW FROM CYLINDER HEAD SIDE

Check that air passes through easily.

NOTICE: Do not suck air through the valve.

Petroleum substances inside the valve are harmful.

4. BLOW FROM AIR INTAKE CHAMBER SIDE

Check that air passes through with difficulty.

If the PCV valve fails either of the checks, replace it.

5. REMOVE CLEAN HOSE FROM PCV VALVE

6. REINSTALL PCV VALVE

INSPECTION OF PCV HOSE AND

CONNECTIONS

VISUALLY INSPECT HOSE AND CONNECTIONS

Check for cracks, leaks, or damage.

± EMISSION CONTROL SYSTEMS (2VZ±FE)Crankcase Ventilation (PCV) SystemEC±16

Page 1169 of 2389

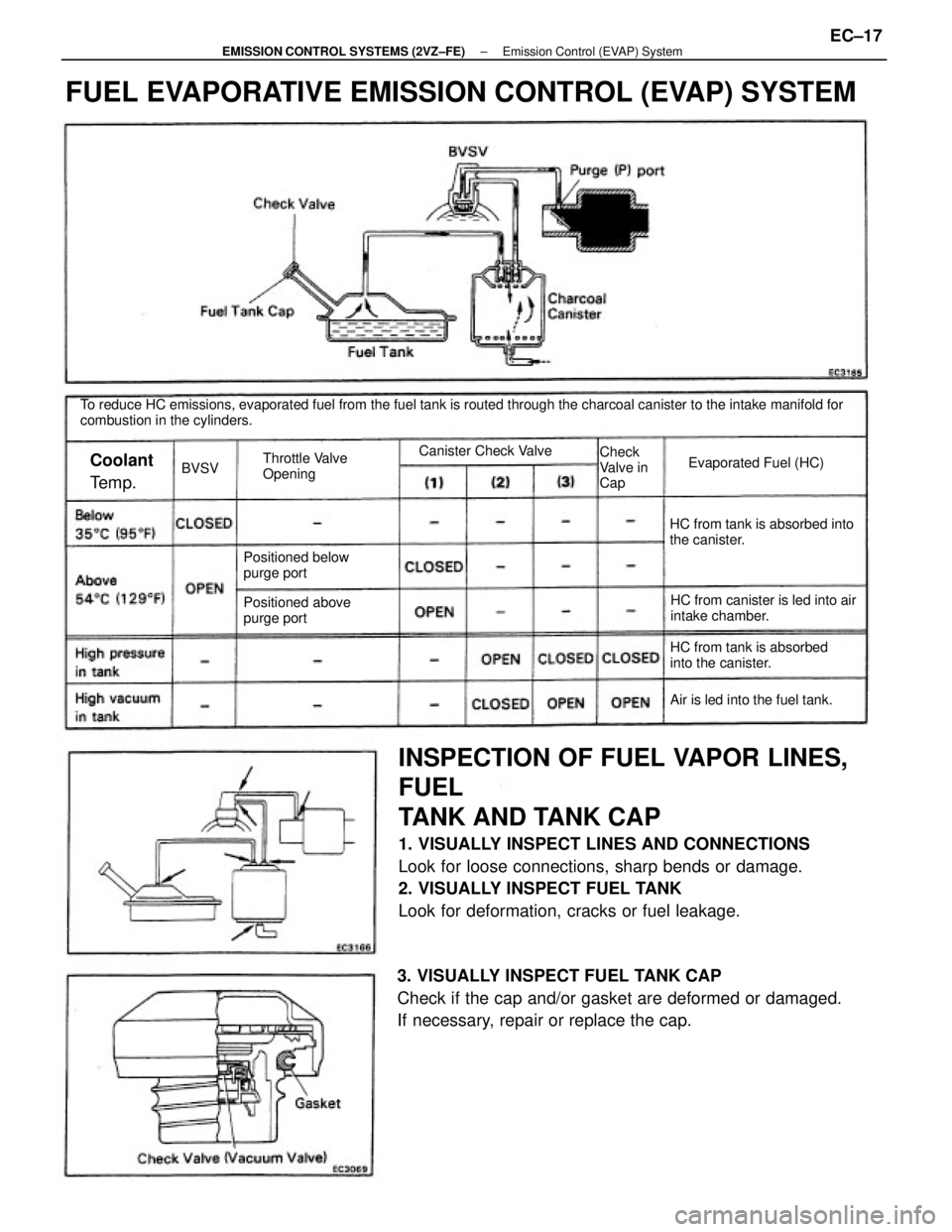

INSPECTION OF FUEL VAPOR LINES,

FUEL

TANK AND TANK CAP

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

To reduce HC emissions, evaporated fuel from the fuel tank is routed through the charcoal canister to the intake manifold for

combustion in the cylinders.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

FUEL EVAPORATIVE EMISSION CONTROL (EVAP) SYSTEM

HC from canister is led into air

intake chamber. HC from tank is absorbed into

the canister.

HC from tank is absorbed

into the canister. Positioned below

purge port

Positioned above

purge port

Air is led into the fuel tank. Throttle Valve

OpeningEvaporated Fuel (HC) Canister Check Valve

Check

Valve in

Cap

Coolant

Te m p .BVSV

± EMISSION CONTROL SYSTEMS (2VZ±FE)Emission Control (EVAP) SystemEC±17

Page 1170 of 2389

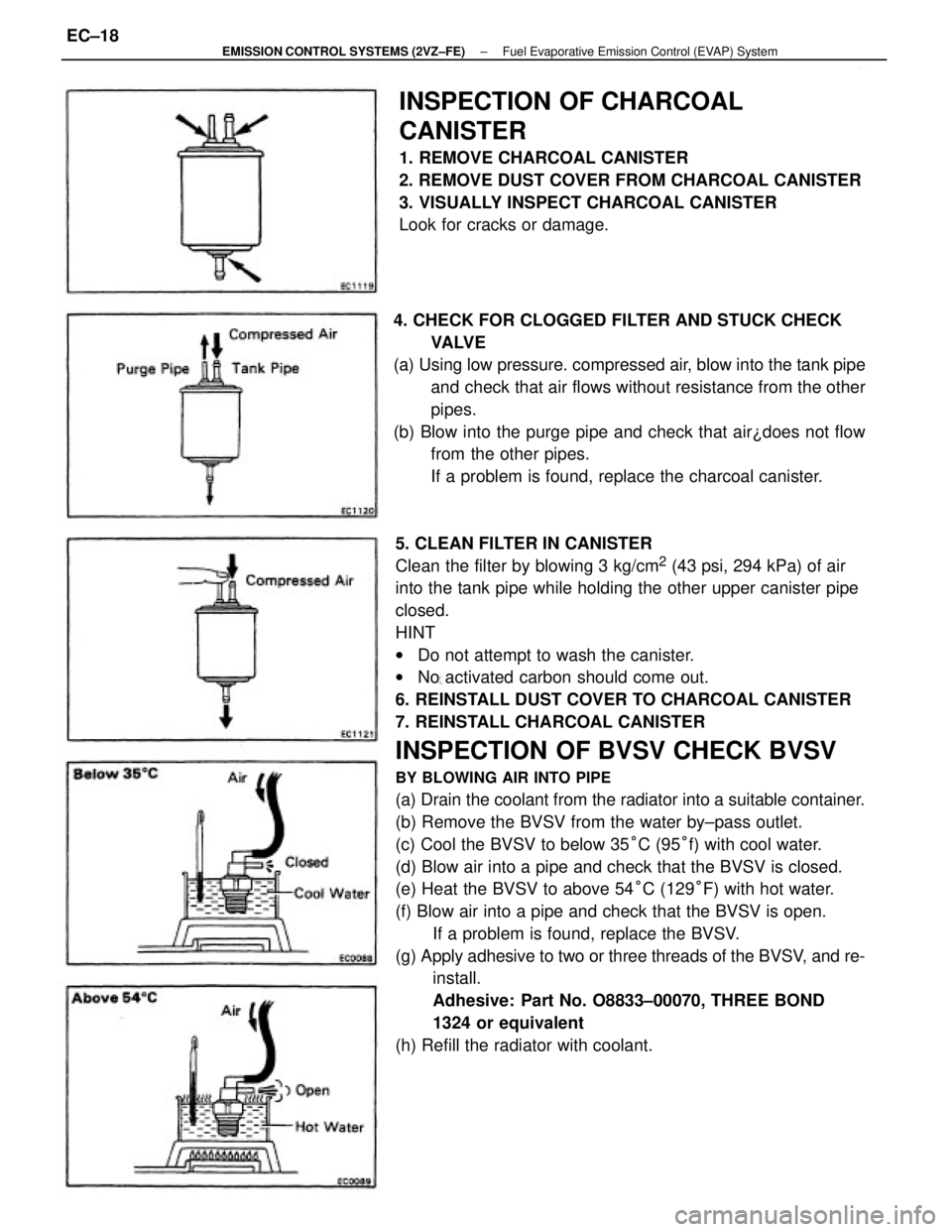

5. CLEAN FILTER IN CANISTER

Clean the filter by blowing 3 kg/cm

2 (43 psi, 294 kPa) of air

into the tank pipe while holding the other upper canister pipe

closed.

HINT

wDo not attempt to wash the canister.

wNo activated carbon should come out.

6. REINSTALL DUST COVER TO CHARCOAL CANISTER

7. REINSTALL CHARCOAL CANISTER

INSPECTION OF BVSV CHECK BVSV

BY BLOWING AIR INTO PIPE

(a) Drain the coolant from the radiator into a suitable container.

(b) Remove the BVSV from the water by±pass outlet.

(c) Cool the BVSV to below 35°C (95°f) with cool water.

(d) Blow air into a pipe and check that the BVSV is closed.

(e) Heat the BVSV to above 54°C (129°F) with hot water.

(f) Blow air into a pipe and check that the BVSV is open.

If a problem is found, replace the BVSV.

(g) Apply adhesive to two or three threads of the BVSV, and re-

install.

Adhesive: Part No. O8833±00070, THREE BOND

1324 or equivalent

(h) Refill the radiator with coolant.

INSPECTION OF CHARCOAL

CANISTER

1. REMOVE CHARCOAL CANISTER

2. REMOVE DUST COVER FROM CHARCOAL CANISTER

3. VISUALLY INSPECT CHARCOAL CANISTER

Look for cracks or damage.

4. CHECK FOR CLOGGED FILTER AND STUCK CHECK

VA LV E

(a) Using low pressure. compressed air, blow into the tank pipe

and check that air flows without resistance from the other

pipes.

(b) Blow into the purge pipe and check that air¿does not flow

from the other pipes.

If a problem is found, replace the charcoal canister.

± EMISSION CONTROL SYSTEMS (2VZ±FE)Fuel Evaporative Emission Control (EVAP) SystemEC±18