check engine TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1217 of 2389

INSPECTION OF TIMING BELT

COMPONENTS

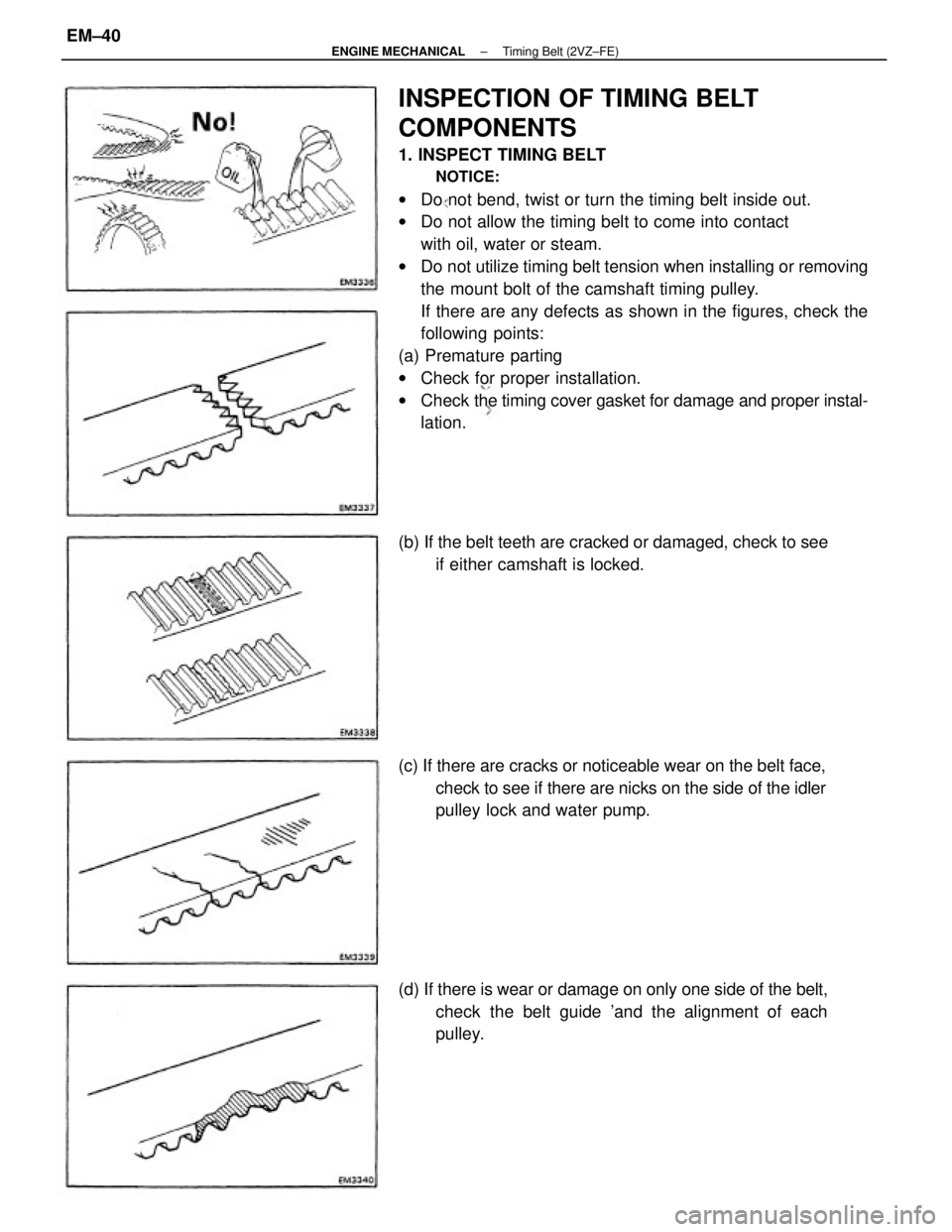

1. INSPECT TIMING BELT

NOTICE:

wDo not bend, twist or turn the timing belt inside out.

wDo not allow the timing belt to come into contact

with oil, water or steam.

wDo not utilize timing belt tension when installing or removing

the mount bolt of the camshaft timing pulley.

If there are any defects as shown in the figures, check the

following points:

(a) Premature parting

wCheck for proper installation.

wCheck the timing cover gasket for damage and proper instal-

lation.

(c) If there are cracks or noticeable wear on the belt face,

check to see if there are nicks on the side of the idler

pulley lock and water pump.

(d) If there is wear or damage on only one side of the belt,

check the belt guide 'and the alignment of each

pulley. (b) If the belt teeth are cracked or damaged, check to see

if either camshaft is locked.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±40

Page 1218 of 2389

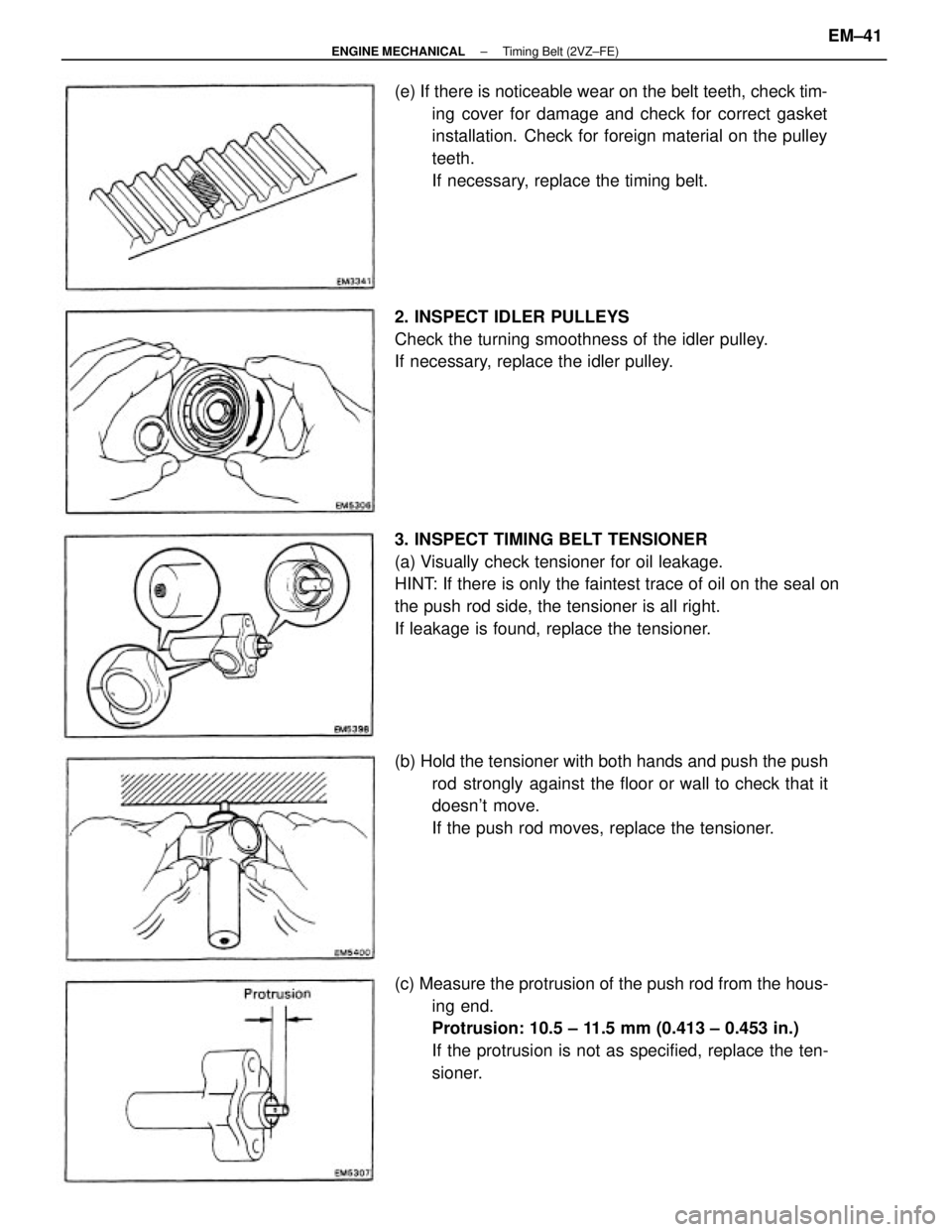

3. INSPECT TIMING BELT TENSIONER

(a) Visually check tensioner for oil leakage.

HINT: If there is only the faintest trace of oil on the seal on

the push rod side, the tensioner is all right.

If leakage is found, replace the tensioner. (e) If there is noticeable wear on the belt teeth, check tim-

ing cover for damage and check for correct gasket

installation. Check for foreign material on the pulley

teeth.

If necessary, replace the timing belt.

(c) Measure the protrusion of the push rod from the hous-

ing end.

Protrusion: 10.5 ± 11.5 mm (0.413 ± 0.453 in.)

If the protrusion is not as specified, replace the ten-

sioner. (b) Hold the tensioner with both hands and push the push

rod strongly against the floor or wall to check that it

doesn't move.

If the push rod moves, replace the tensioner. 2. INSPECT IDLER PULLEYS

Check the turning smoothness of the idler pulley.

If necessary, replace the idler pulley.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±41

Page 1219 of 2389

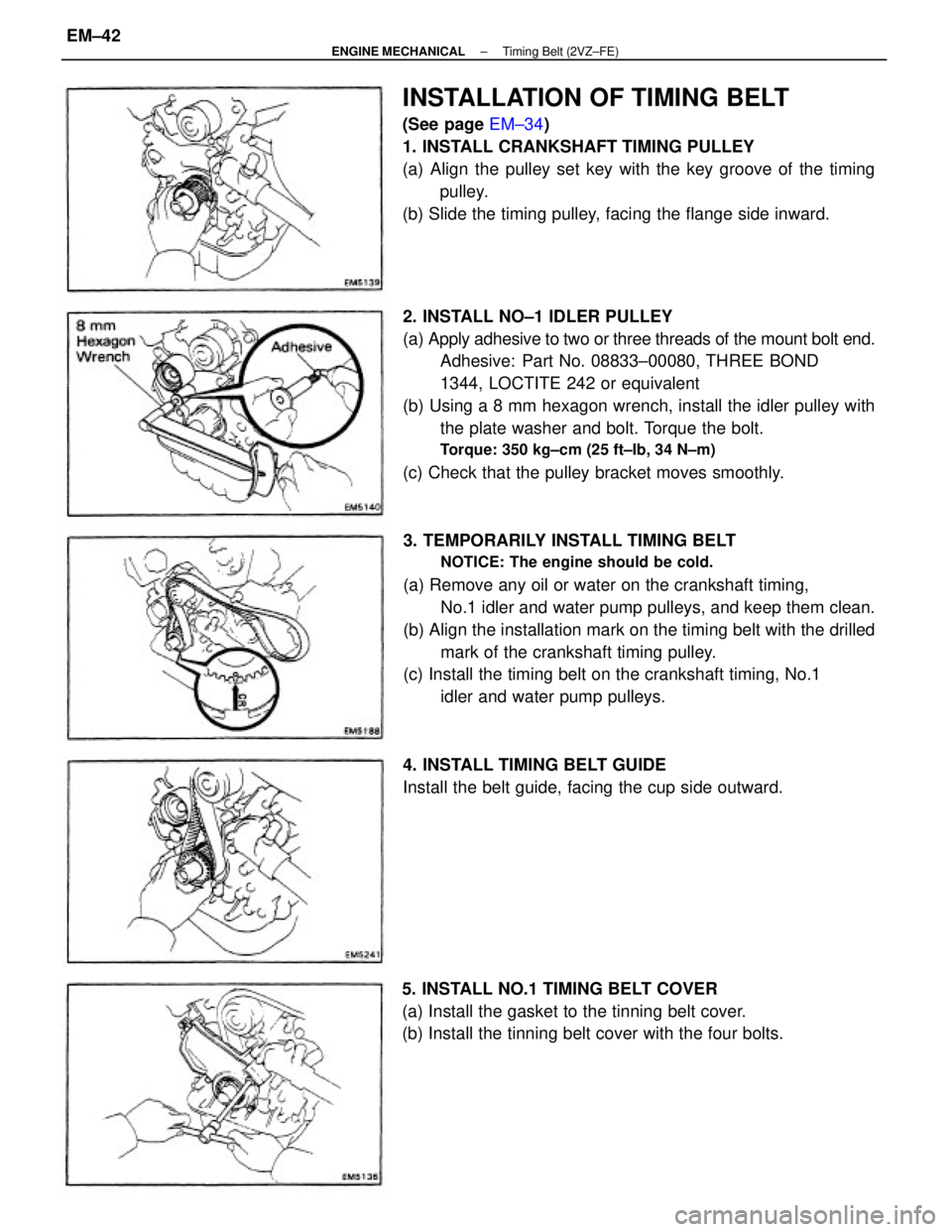

2. INSTALL NO±1 IDLER PULLEY

(a) Apply adhesive to two or three threads of the mount bolt end.

Adhesive: Part No. 08833±00080, THREE BOND

1344, LOCTITE 242 or equivalent

(b) Using a 8 mm hexagon wrench, install the idler pulley with

the plate washer and bolt. Torque the bolt.

Torque: 350 kg±cm (25 ft±Ib, 34 N±m)

(c) Check that the pulley bracket moves smoothly.

3. TEMPORARILY INSTALL TIMING BELT

NOTICE: The engine should be cold.

(a) Remove any oil or water on the crankshaft timing,

No.1 idler and water pump pulleys, and keep them clean.

(b) Align the installation mark on the timing belt with the drilled

mark of the crankshaft timing pulley.

(c) Install the timing belt on the crankshaft timing, No.1

idler and water pump pulleys.

INSTALLATION OF TIMING BELT

(See page EM±34)

1. INSTALL CRANKSHAFT TIMING PULLEY

(a) Align the pulley set key with the key groove of the timing

pulley.

(b) Slide the timing pulley, facing the flange side inward.

5. INSTALL NO.1 TIMING BELT COVER

(a) Install the gasket to the tinning belt cover.

(b) Install the tinning belt cover with the four bolts.4. INSTALL TIMING BELT GUIDE

Install the belt guide, facing the cup side outward.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±42

Page 1220 of 2389

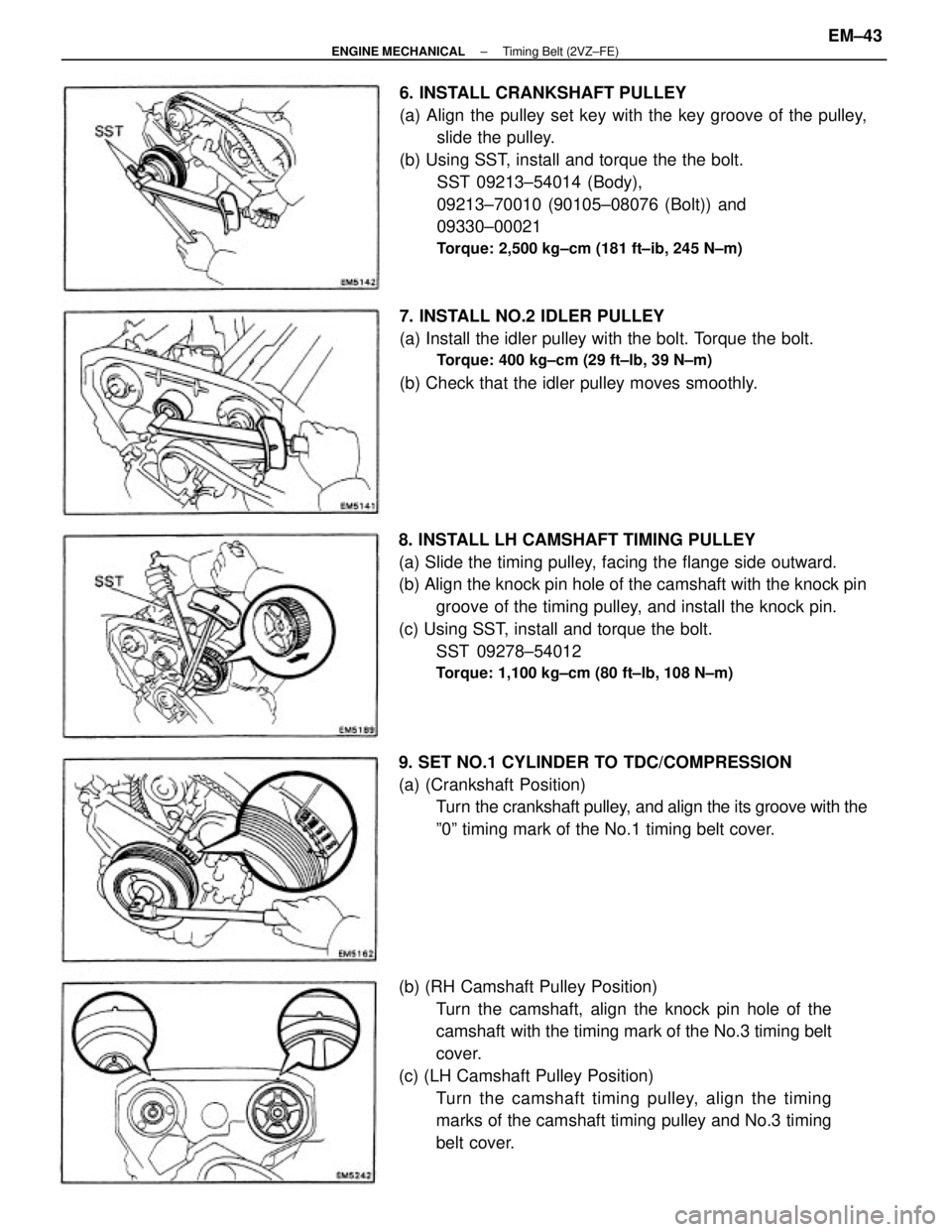

8. INSTALL LH CAMSHAFT TIMING PULLEY

(a) Slide the timing pulley, facing the flange side outward.

(b) Align the knock pin hole of the camshaft with the knock pin

groove of the timing pulley, and install the knock pin.

(c) Using SST, install and torque the bolt.

SST 09278±54012

Torque: 1,100 kg±cm (80 ft±lb, 108 N±m)

6. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the pulley,

slide the pulley.

(b) Using SST, install and torque the the bolt.

SST 09213±54014 (Body),

09213±70010 (90105±08076 (Bolt)) and

09330±00021

Torque: 2,500 kg±cm (181 ft±ib, 245 N±m)

(b) (RH Camshaft Pulley Position)

Turn the camshaft, align the knock pin hole of the

camshaft with the timing mark of the No.3 timing belt

cover.

(c) (LH Camshaft Pulley Position)

Turn the camshaft timing pulley, align the timing

marks of the camshaft timing pulley and No.3 timing

belt cover. 9. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) (Crankshaft Position)

Turn the crankshaft pulley, and align the its groove with the

º0º timing mark of the No.1 timing belt cover. 7. INSTALL NO.2 IDLER PULLEY

(a) Install the idler pulley with the bolt. Torque the bolt.

Torque: 400 kg±cm (29 ft±lb, 39 N±m)

(b) Check that the idler pulley moves smoothly.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±43

Page 1221 of 2389

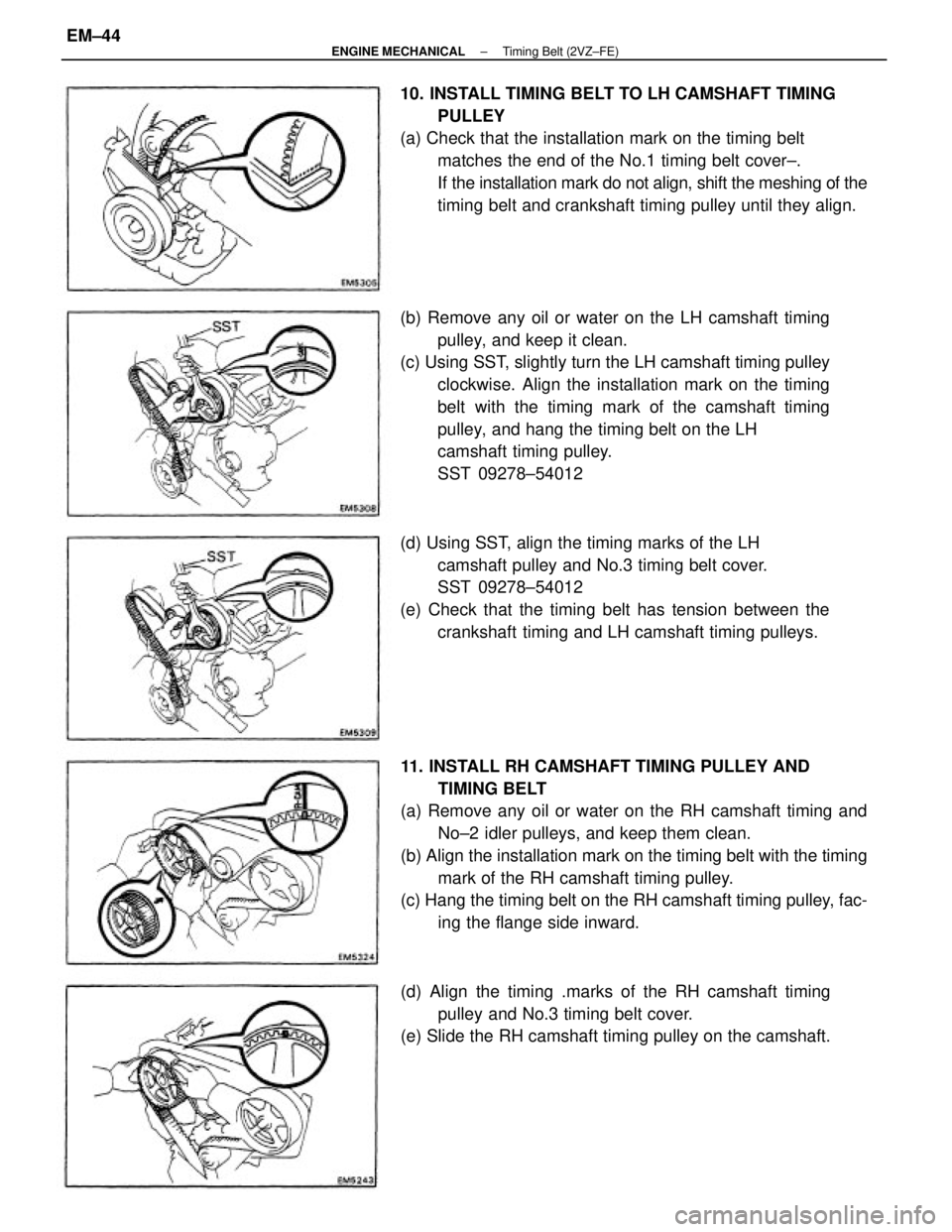

11. INSTALL RH CAMSHAFT TIMING PULLEY AND

TIMING BELT

(a) Remove any oil or water on the RH camshaft timing and

No±2 idler pulleys, and keep them clean.

(b) Align the installation mark on the timing belt with the timing

mark of the RH camshaft timing pulley.

(c) Hang the timing belt on the RH camshaft timing pulley, fac-

ing the flange side inward. (b) Remove any oil or water on the LH camshaft timing

pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing

belt with the timing mark of the camshaft timing

pulley, and hang the timing belt on the LH

camshaft timing pulley.

SST 09278±54012 10. INSTALL TIMING BELT TO LH CAMSHAFT TIMING

PULLEY

(a) Check that the installation mark on the timing belt

matches the end of the No.1 timing belt cover±.

If the installation mark do not align, shift the meshing of the

timing belt and crankshaft timing pulley until they align.

(d) Using SST, align the timing marks of the LH

camshaft pulley and No.3 timing belt cover.

SST 09278±54012

(e) Check that the timing belt has tension between the

crankshaft timing and LH camshaft timing pulleys.

(d) Align the timing .marks of the RH camshaft timing

pulley and No.3 timing belt cover.

(e) Slide the RH camshaft timing pulley on the camshaft.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±44

Page 1223 of 2389

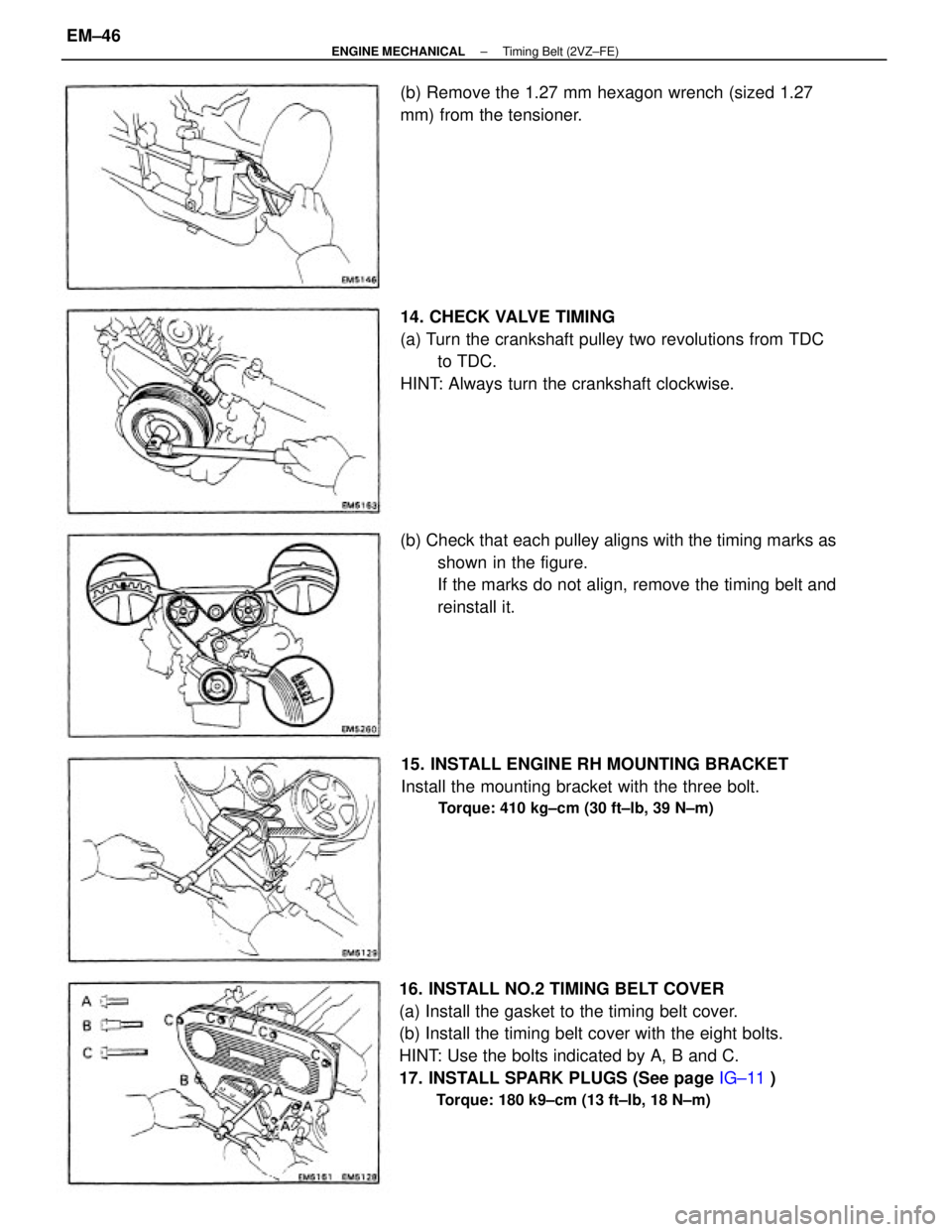

16. INSTALL NO.2 TIMING BELT COVER

(a) Install the gasket to the timing belt cover.

(b) Install the timing belt cover with the eight bolts.

HINT: Use the bolts indicated by A, B and C.

17. INSTALL SPARK PLUGS (See page IG±11 )

Torque: 180 k9±cm (13 ft±Ib, 18 N±m)

14. CHECK VALVE TIMING

(a) Turn the crankshaft pulley two revolutions from TDC

to TDC.

HINT: Always turn the crankshaft clockwise.

(b) Check that each pulley aligns with the timing marks as

shown in the figure.

If the marks do not align, remove the timing belt and

reinstall it.

15. INSTALL ENGINE RH MOUNTING BRACKET

Install the mounting bracket with the three bolt.

Torque: 410 kg±cm (30 ft±lb, 39 N±m)

(b) Remove the 1.27 mm hexagon wrench (sized 1.27

mm) from the tensioner.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±46

Page 1230 of 2389

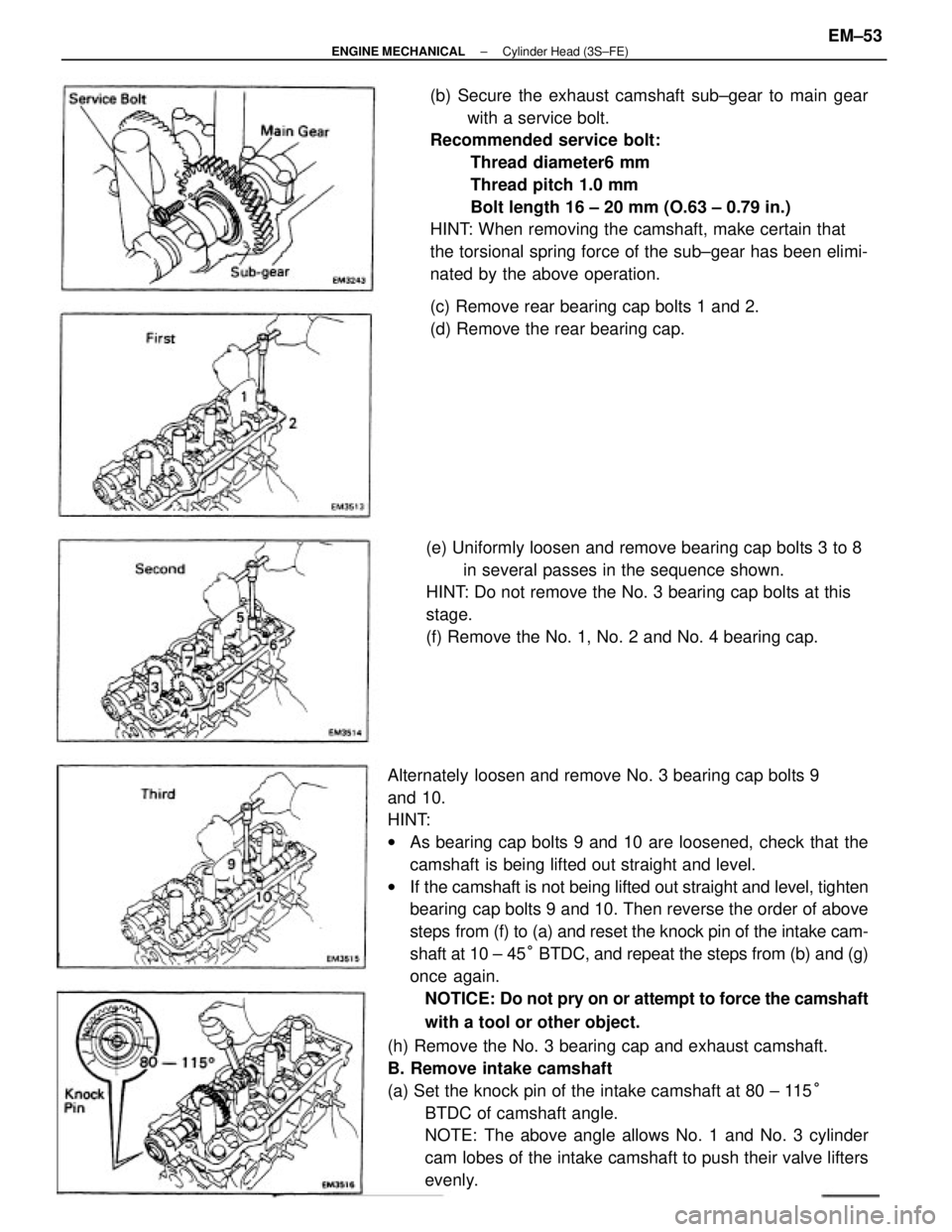

Alternately loosen and remove No. 3 bearing cap bolts 9

and 10.

HINT:

wAs bearing cap bolts 9 and 10 are loosened, check that the

camshaft is being lifted out straight and level.

wIf the camshaft is not being lifted out straight and level, tighten

bearing cap bolts 9 and 10. Then reverse the order of above

steps from (f) to (a) and reset the knock pin of the intake cam-

shaft at 10 ± 45° BTDC, and repeat the steps from (b) and (g)

once again.

NOTICE: Do not pry on or attempt to force the camshaft

with a tool or other object.

(h) Remove the No. 3 bearing cap and exhaust camshaft.

B. Remove intake camshaft

(a) Set the knock pin of the intake camshaft at 80 ± 115°

BTDC of camshaft angle.

NOTE: The above angle allows No. 1 and No. 3 cylinder

cam lobes of the intake camshaft to push their valve lifters

evenly.(b) Secure the exhaust camshaft sub±gear to main gear

with a service bolt.

Recommended service bolt:

Thread diameter6 mm

Thread pitch 1.0 mm

Bolt length 16 ± 20 mm (O.63 ± 0.79 in.)

HINT: When removing the camshaft, make certain that

the torsional spring force of the sub±gear has been elimi-

nated by the above operation.

(e) Uniformly loosen and remove bearing cap bolts 3 to 8

in several passes in the sequence shown.

HINT: Do not remove the No. 3 bearing cap bolts at this

stage.

(f) Remove the No. 1, No. 2 and No. 4 bearing cap.(c) Remove rear bearing cap bolts 1 and 2.

(d) Remove the rear bearing cap.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±53

Page 1231 of 2389

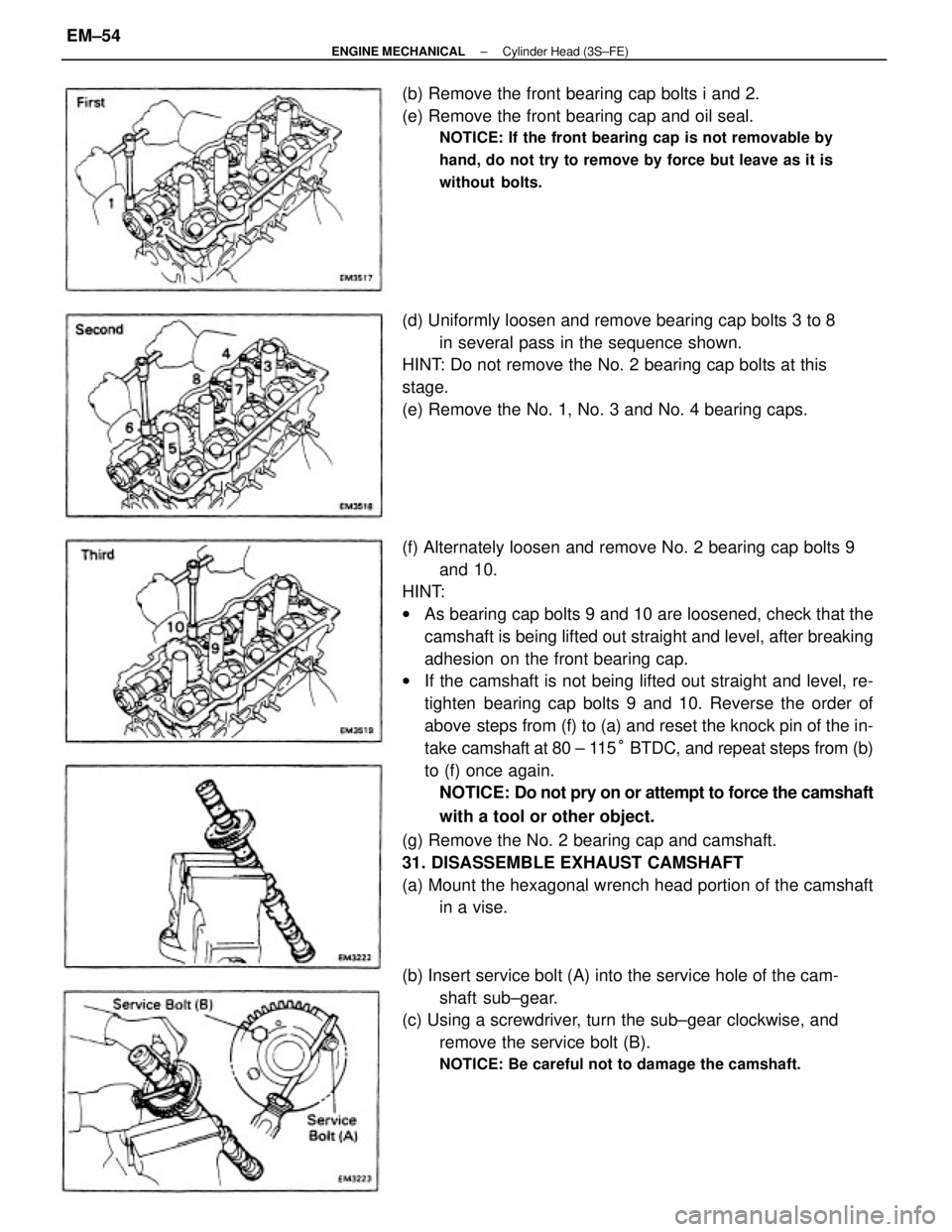

(f) Alternately loosen and remove No. 2 bearing cap bolts 9

and 10.

HINT:

wAs bearing cap bolts 9 and 10 are loosened, check that the

camshaft is being lifted out straight and level, after breaking

adhesion on the front bearing cap.

wIf the camshaft is not being lifted out straight and level, re-

tighten bearing cap bolts 9 and 10. Reverse the order of

above steps from (f) to (a) and reset the knock pin of the in-

take camshaft at 80 ± 115° BTDC, and repeat steps from (b)

to (f) once again.

NOTICE: Do not pry on or attempt to force the camshaft

with a tool or other object.

(g) Remove the No. 2 bearing cap and camshaft.

31. DISASSEMBLE EXHAUST CAMSHAFT

(a) Mount the hexagonal wrench head portion of the camshaft

in a vise.

(b) Insert service bolt (A) into the service hole of the cam-

shaft sub±gear.

(c) Using a screwdriver, turn the sub±gear clockwise, and

remove the service bolt (B).

NOTICE: Be careful not to damage the camshaft.

(d) Uniformly loosen and remove bearing cap bolts 3 to 8

in several pass in the sequence shown.

HINT: Do not remove the No. 2 bearing cap bolts at this

stage.

(e) Remove the No. 1, No. 3 and No. 4 bearing caps. (b) Remove the front bearing cap bolts i and 2.

(e) Remove the front bearing cap and oil seal.

NOTICE: If the front bearing cap is not removable by

hand, do not try to remove by force but leave as it is

without bolts.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±54

Page 1235 of 2389

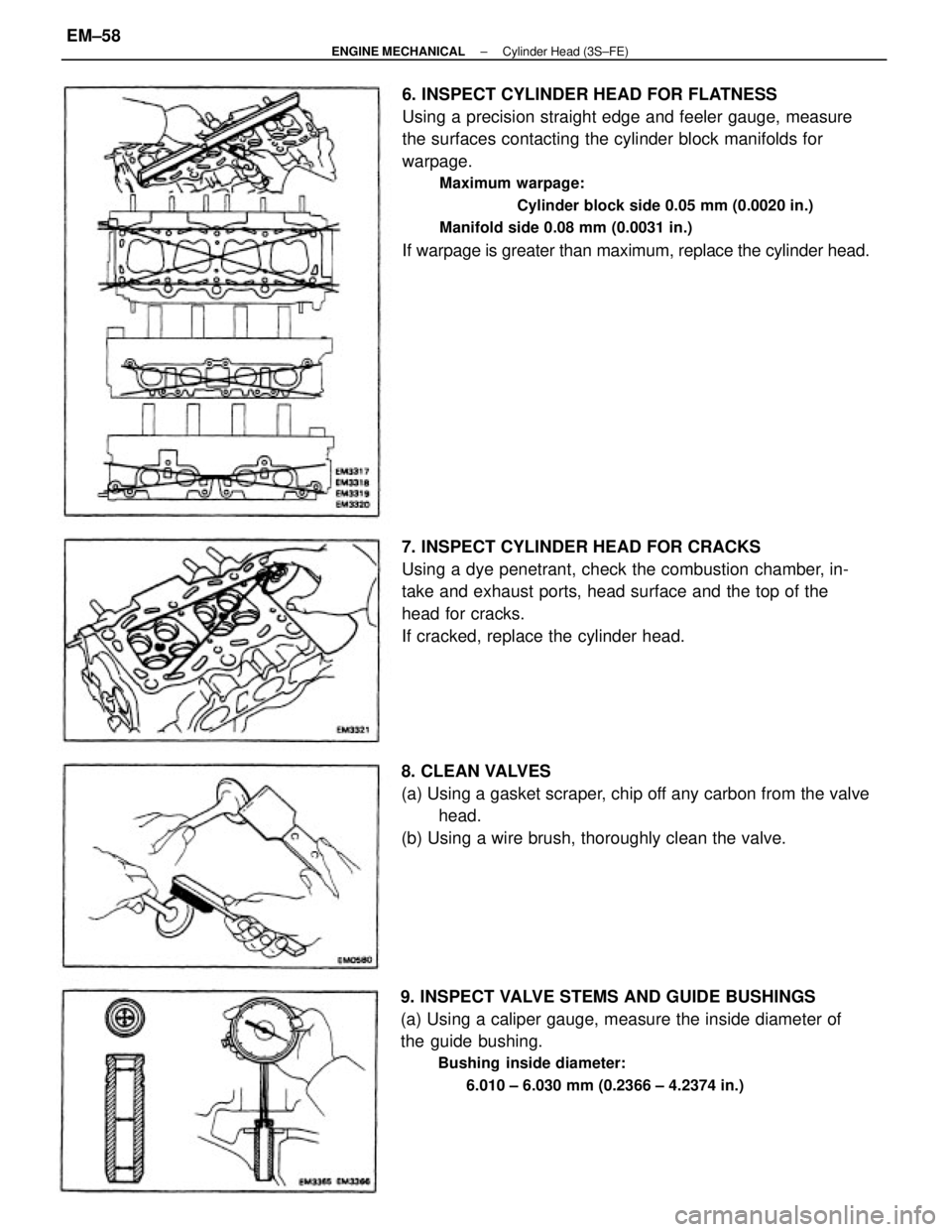

6. INSPECT CYLINDER HEAD FOR FLATNESS

Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder block manifolds for

warpage.

Maximum warpage:

Cylinder block side 0.05 mm (0.0020 in.)

Manifold side 0.08 mm (0.0031 in.)

If warpage is greater than maximum, replace the cylinder head.

7. INSPECT CYLINDER HEAD FOR CRACKS

Using a dye penetrant, check the combustion chamber, in-

take and exhaust ports, head surface and the top of the

head for cracks.

If cracked, replace the cylinder head.

9. INSPECT VALVE STEMS AND GUIDE BUSHINGS

(a) Using a caliper gauge, measure the inside diameter of

the guide bushing.

Bushing inside diameter:

6.010 ± 6.030 mm (0.2366 ± 4.2374 in.)

8. CLEAN VALVES

(a) Using a gasket scraper, chip off any carbon from the valve

head.

(b) Using a wire brush, thoroughly clean the valve.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±58

Page 1237 of 2389

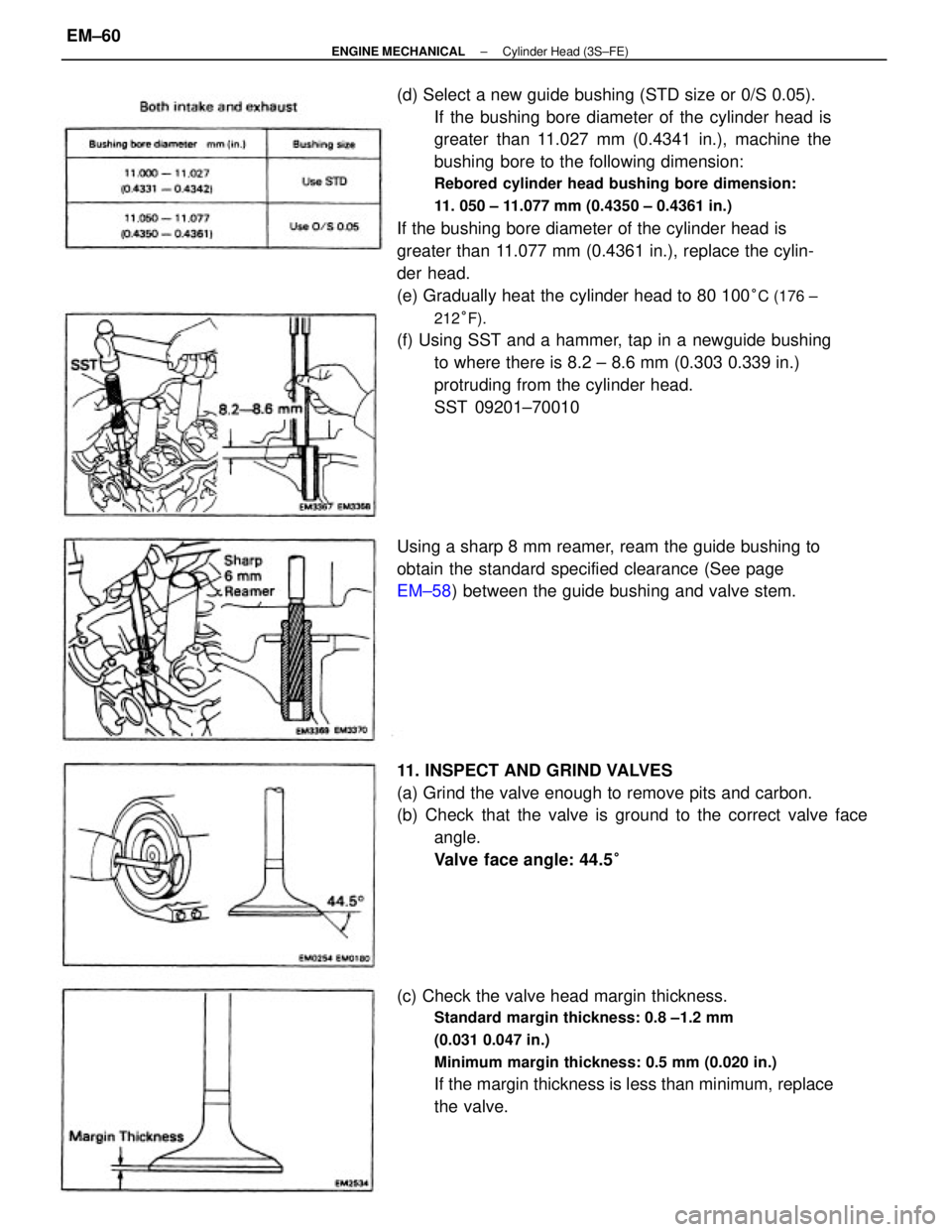

(d) Select a new guide bushing (STD size or 0/S 0.05).

If the bushing bore diameter of the cylinder head is

greater than 11.027 mm (0.4341 in.), machine the

bushing bore to the following dimension:

Rebored cylinder head bushing bore dimension:

11. 050 ± 11.077 mm (0.4350 ± 0.4361 in.)

If the bushing bore diameter of the cylinder head is

greater than 11.077 mm (0.4361 in.), replace the cylin-

der head.

(e) Gradually heat the cylinder head to 80 100

°C (176 ±

212°F).

(f) Using SST and a hammer, tap in a newguide bushing

to where there is 8.2 ± 8.6 mm (0.303 0.339 in.)

protruding from the cylinder head.

SST 09201±70010

(c) Check the valve head margin thickness.

Standard margin thickness: 0.8 ±1.2 mm

(0.031 0.047 in.)

Minimum margin thickness: 0.5 mm (0.020 in.)

If the margin thickness is less than minimum, replace

the valve. 11. INSPECT AND GRIND VALVES

(a) Grind the valve enough to remove pits and carbon.

(b) Check that the valve is ground to the correct valve face

angle.

Valve face angle: 44.5

°

Using a sharp 8 mm reamer, ream the guide bushing to

obtain the standard specified clearance (See page

EM±58) between the guide bushing and valve stem.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±60