TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: check transmission fluid, tire type, spark plugs, headlights, fuel type, steering wheel adjustment, brake rotor

Page 2101 of 2389

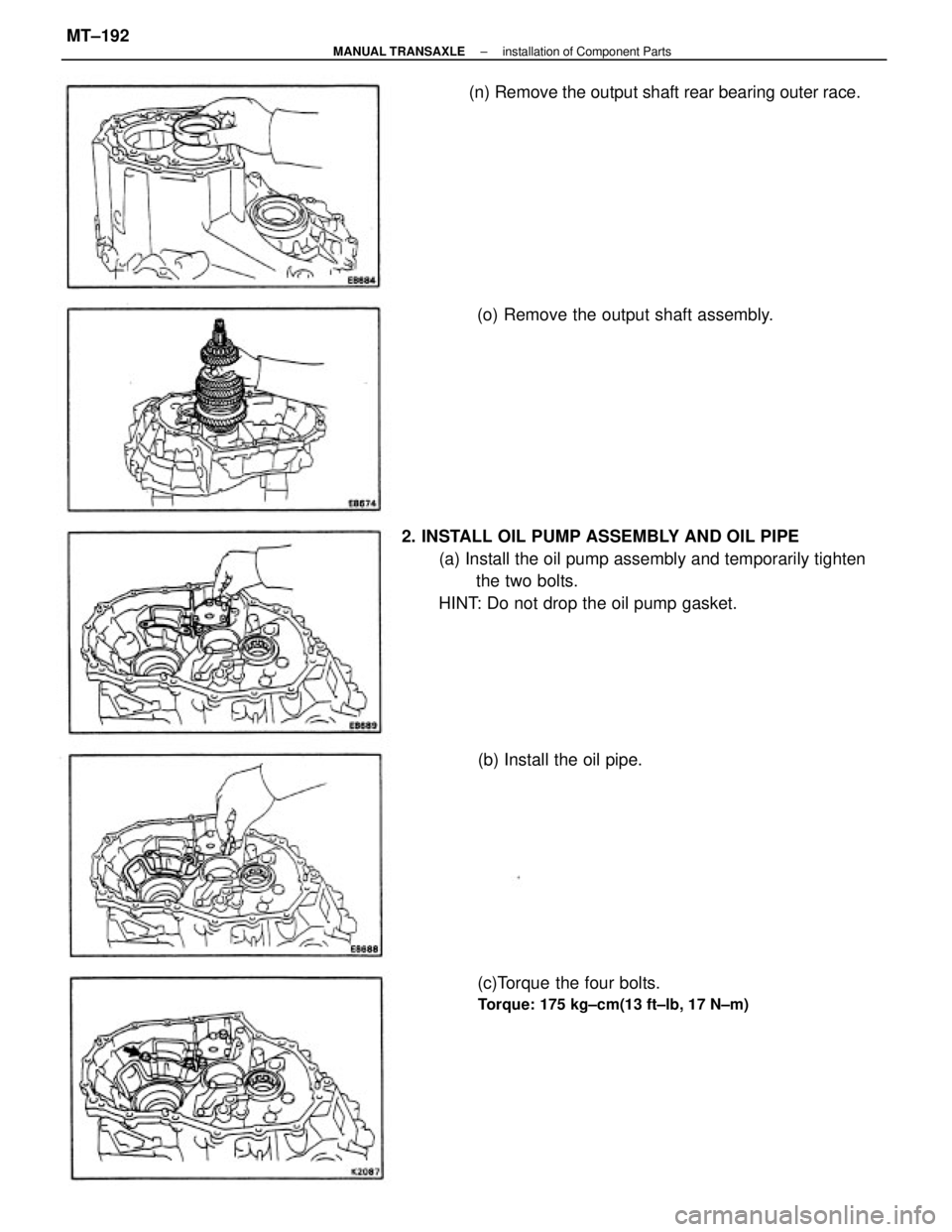

2. INSTALL OIL PUMP ASSEMBLY AND OIL PIPE

(a) Install the oil pump assembly and temporarily tighten

the two bolts.

HINT: Do not drop the oil pump gasket.(n) Remove the output shaft rear bearing outer race.

(c)Torque the four bolts.

Torque: 175 kg±cm(13 ft±lb, 17 N±m)

(o) Remove the output shaft assembly.

(b) Install the oil pipe.

± MANUAL TRANSAXLEinstallation of Component PartsMT±192

Page 2102 of 2389

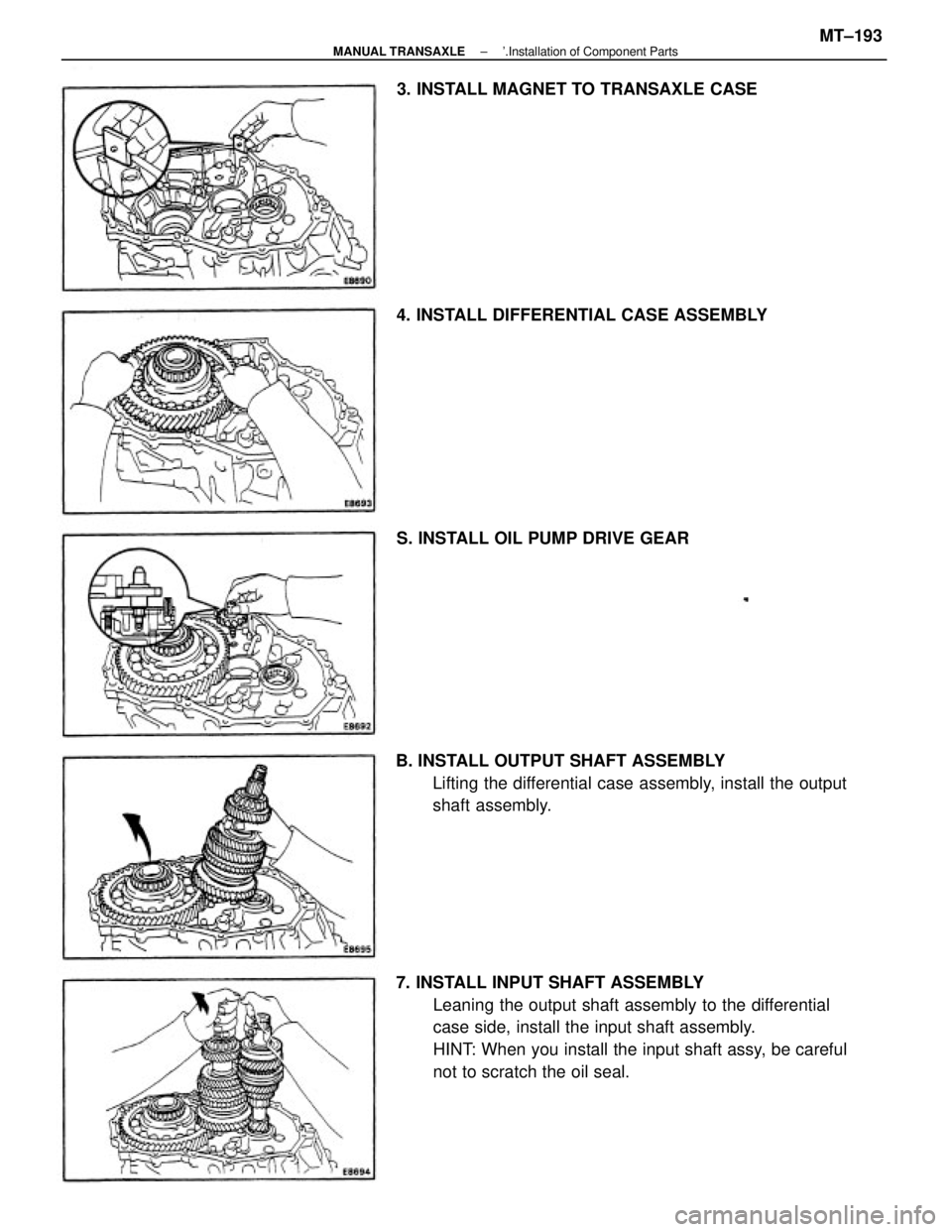

7. INSTALL INPUT SHAFT ASSEMBLY

Leaning the output shaft assembly to the differential

case side, install the input shaft assembly.

HINT: When you install the input shaft assy, be careful

not to scratch the oil seal. B. INSTALL OUTPUT SHAFT ASSEMBLY

Lifting the differential case assembly, install the output

shaft assembly. 4. INSTALL DIFFERENTIAL CASE ASSEMBLY3. INSTALL MAGNET TO TRANSAXLE CASE

S. INSTALL OIL PUMP DRIVE GEAR

± MANUAL TRANSAXLE'.Installation of Component PartsMT±193

Page 2103 of 2389

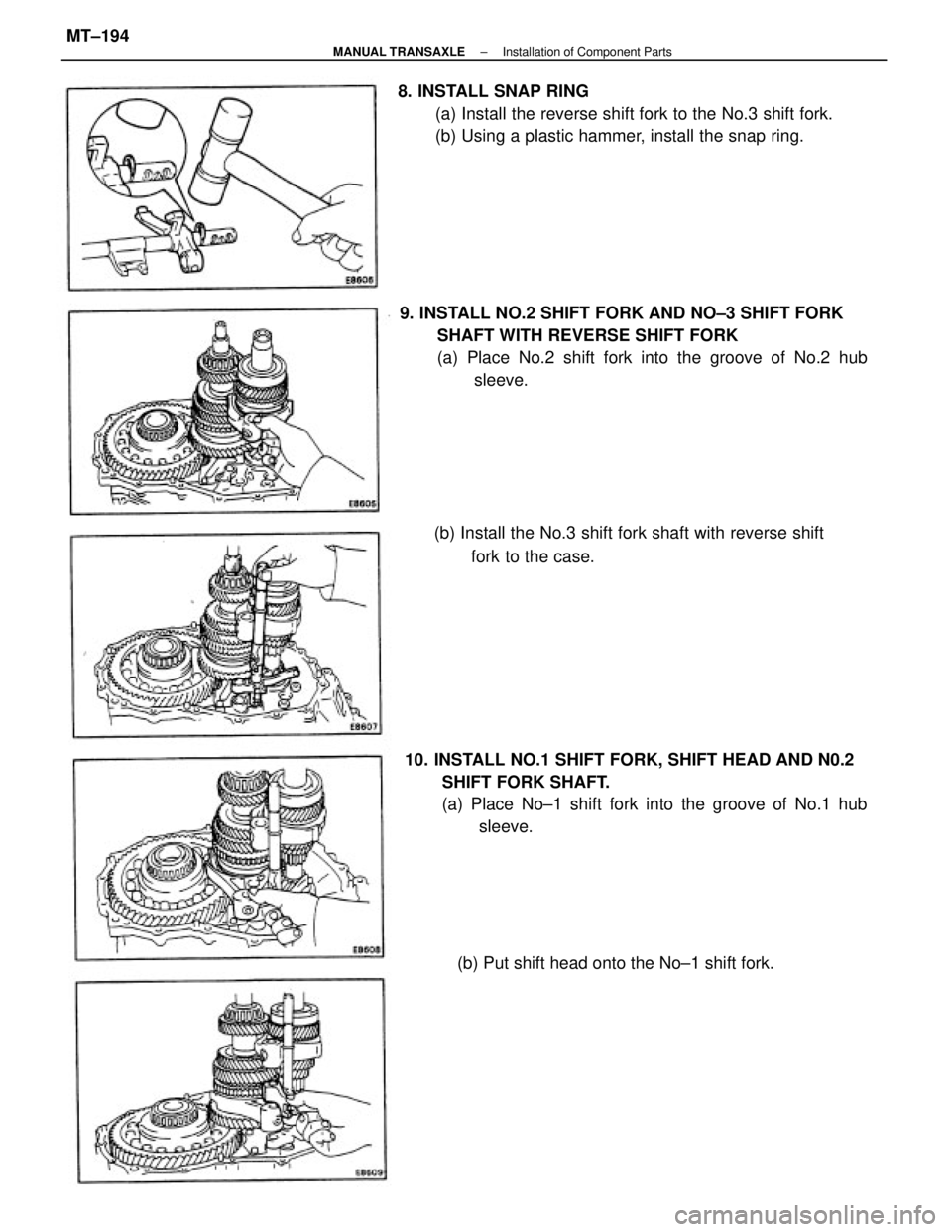

9. INSTALL NO.2 SHIFT FORK AND NO±3 SHIFT FORK

SHAFT WITH REVERSE SHIFT FORK

(a) Place No.2 shift fork into the groove of No.2 hub

sleeve.

10. INSTALL NO.1 SHIFT FORK, SHIFT HEAD AND N0.2

SHIFT FORK SHAFT.

(a) Place No±1 shift fork into the groove of No.1 hub

sleeve. 8. INSTALL SNAP RING

(a) Install the reverse shift fork to the No.3 shift fork.

(b) Using a plastic hammer, install the snap ring.

(b) Install the No.3 shift fork shaft with reverse shift

fork to the case.

(b) Put shift head onto the No±1 shift fork.

± MANUAL TRANSAXLEInstallation of Component PartsMT±194

Page 2104 of 2389

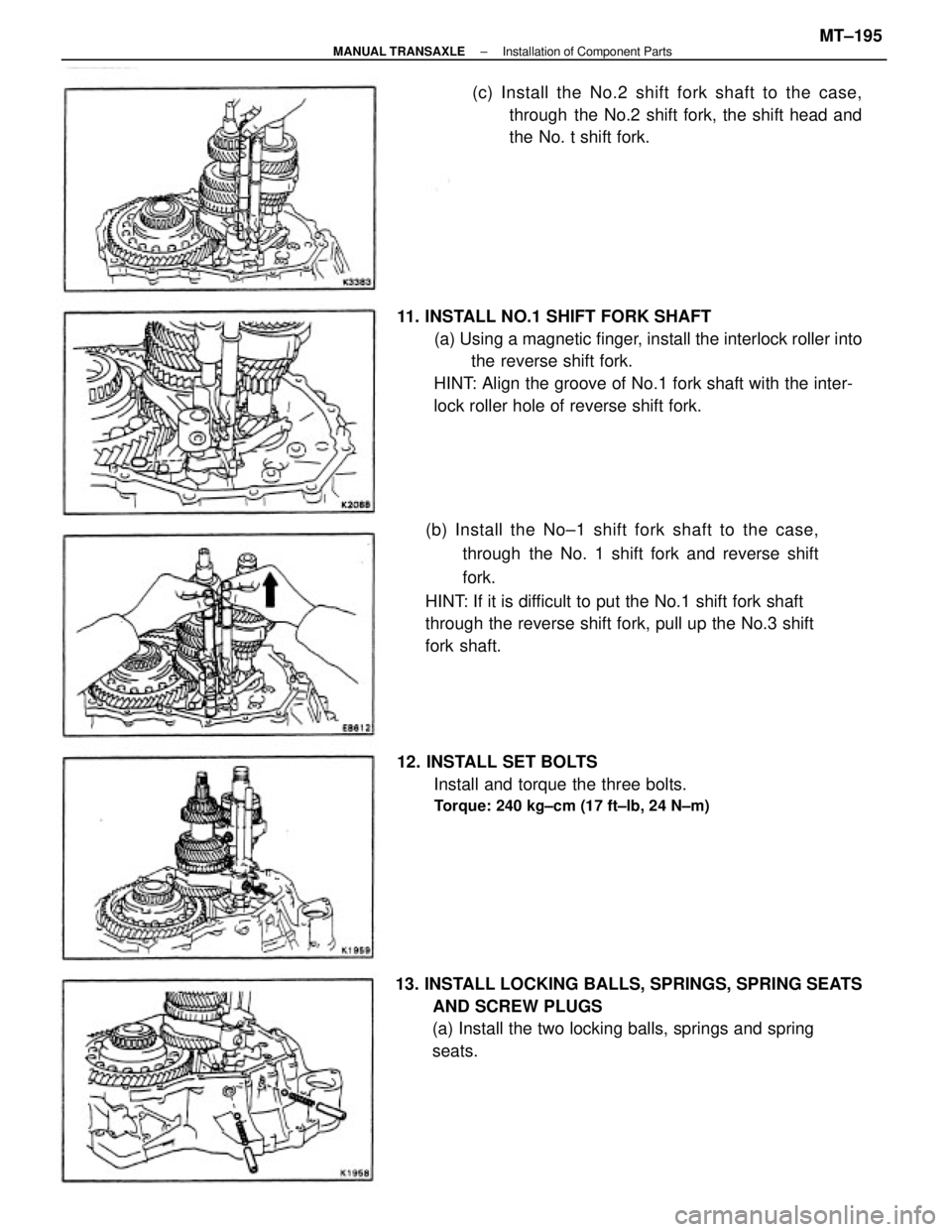

11. INSTALL NO.1 SHIFT FORK SHAFT

(a) Using a magnetic finger, install the interlock roller into

the reverse shift fork.

HINT: Align the groove of No.1 fork shaft with the inter-

lock roller hole of reverse shift fork.

(b) Install the No±1 shift fork shaft to the case,

through the No. 1 shift fork and reverse shift

fork.

HINT: If it is difficult to put the No.1 shift fork shaft

through the reverse shift fork, pull up the No.3 shift

fork shaft.

13. INSTALL LOCKING BALLS, SPRINGS, SPRING SEATS

AND SCREW PLUGS

(a) Install the two locking balls, springs and spring

seats.(c) Install the No.2 shift fork shaft to the case,

through the No.2 shift fork, the shift head and

the No. t shift fork.

12. INSTALL SET BOLTS

Install and torque the three bolts.

Torque: 240 kg±cm (17 ft±lb, 24 N±m)

± MANUAL TRANSAXLEInstallation of Component PartsMT±195

Page 2105 of 2389

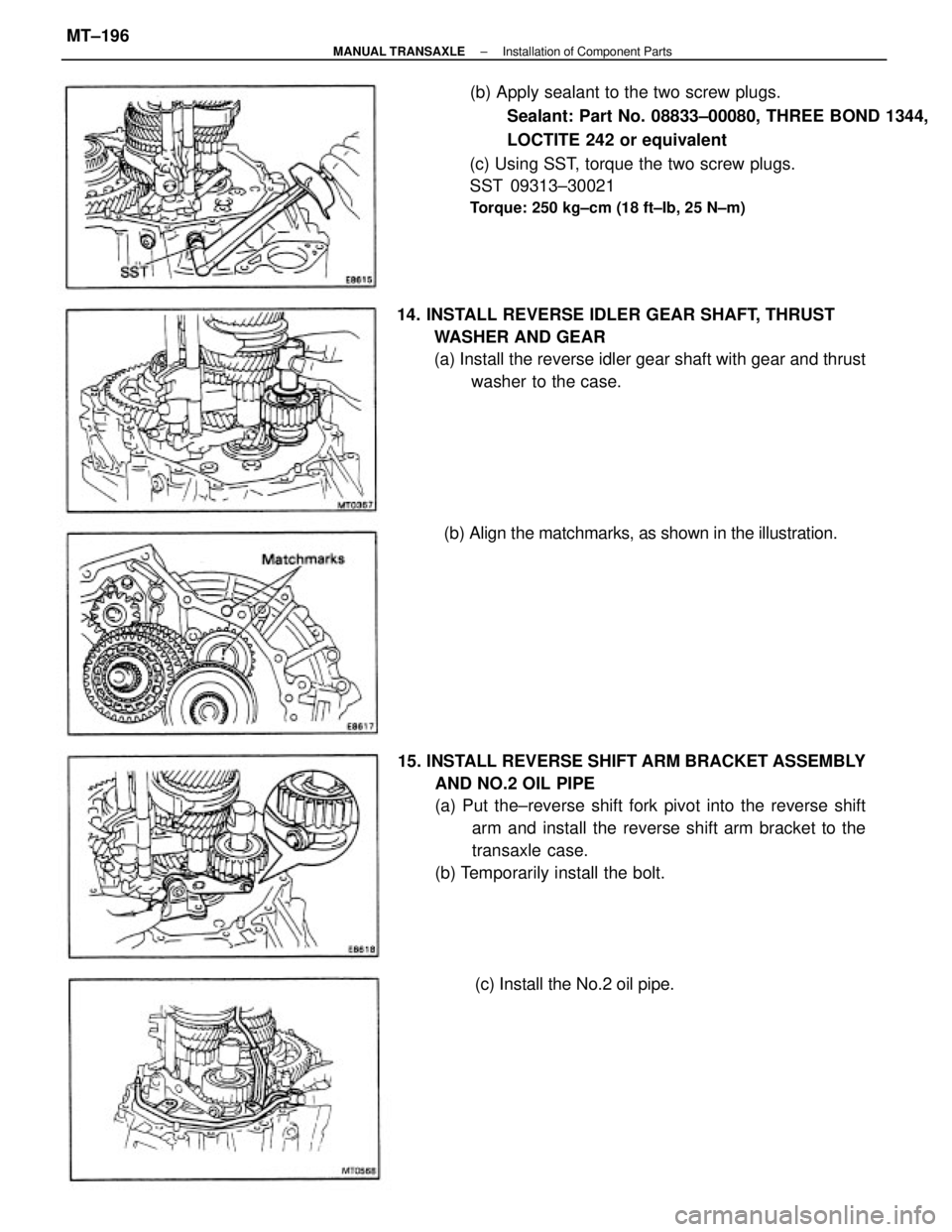

(b) Apply sealant to the two screw plugs.

Sealant: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(c) Using SST, torque the two screw plugs.

SST 09313±30021

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

15. INSTALL REVERSE SHIFT ARM BRACKET ASSEMBLY

AND NO.2 OIL PIPE

(a) Put the±reverse shift fork pivot into the reverse shift

arm and install the reverse shift arm bracket to the

transaxle case.

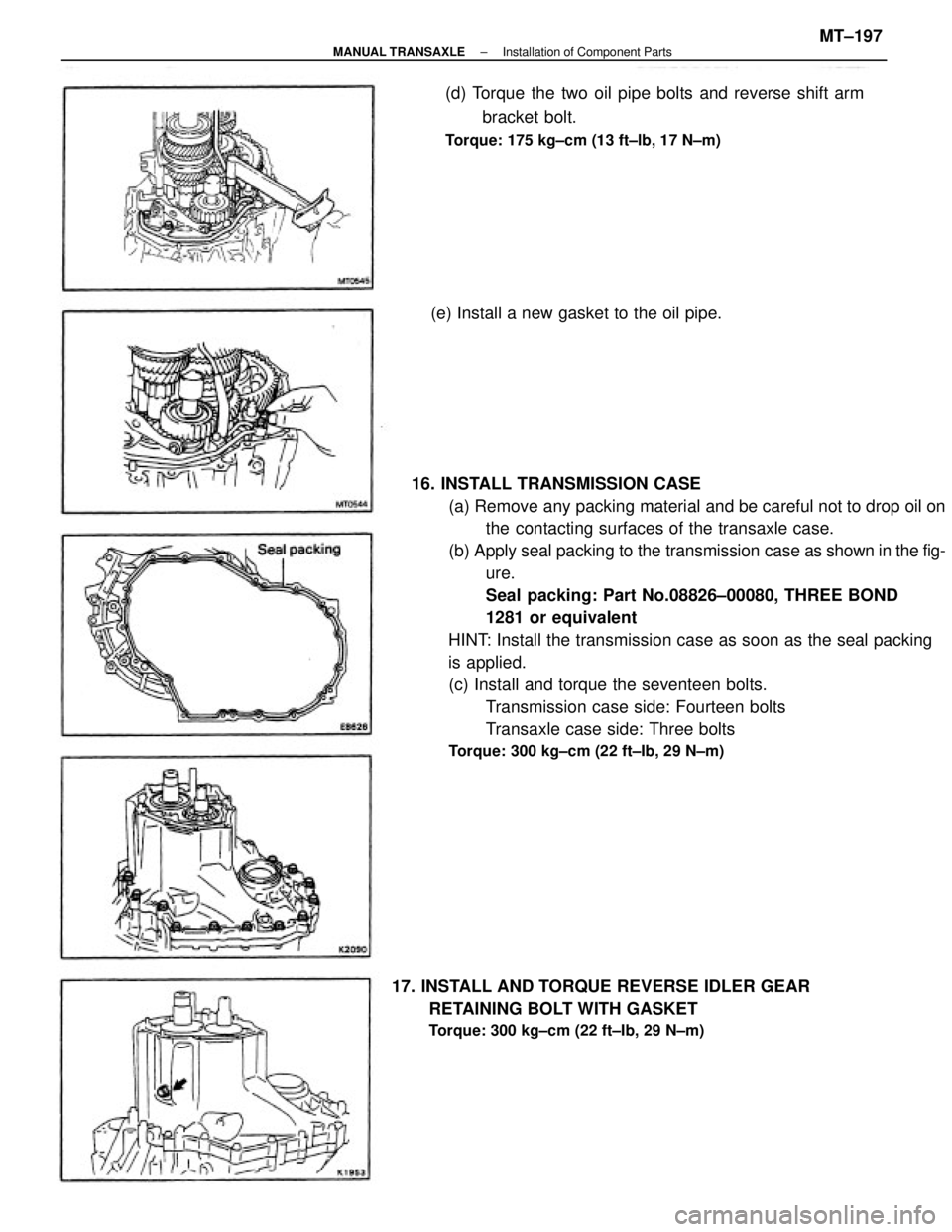

(b) Temporarily install the bolt. 14. INSTALL REVERSE IDLER GEAR SHAFT, THRUST

WASHER AND GEAR

(a) Install the reverse idler gear shaft with gear and thrust

washer to the case.

(b) Align the matchmarks, as shown in the illustration.

(c) Install the No.2 oil pipe.

± MANUAL TRANSAXLEInstallation of Component PartsMT±196

Page 2106 of 2389

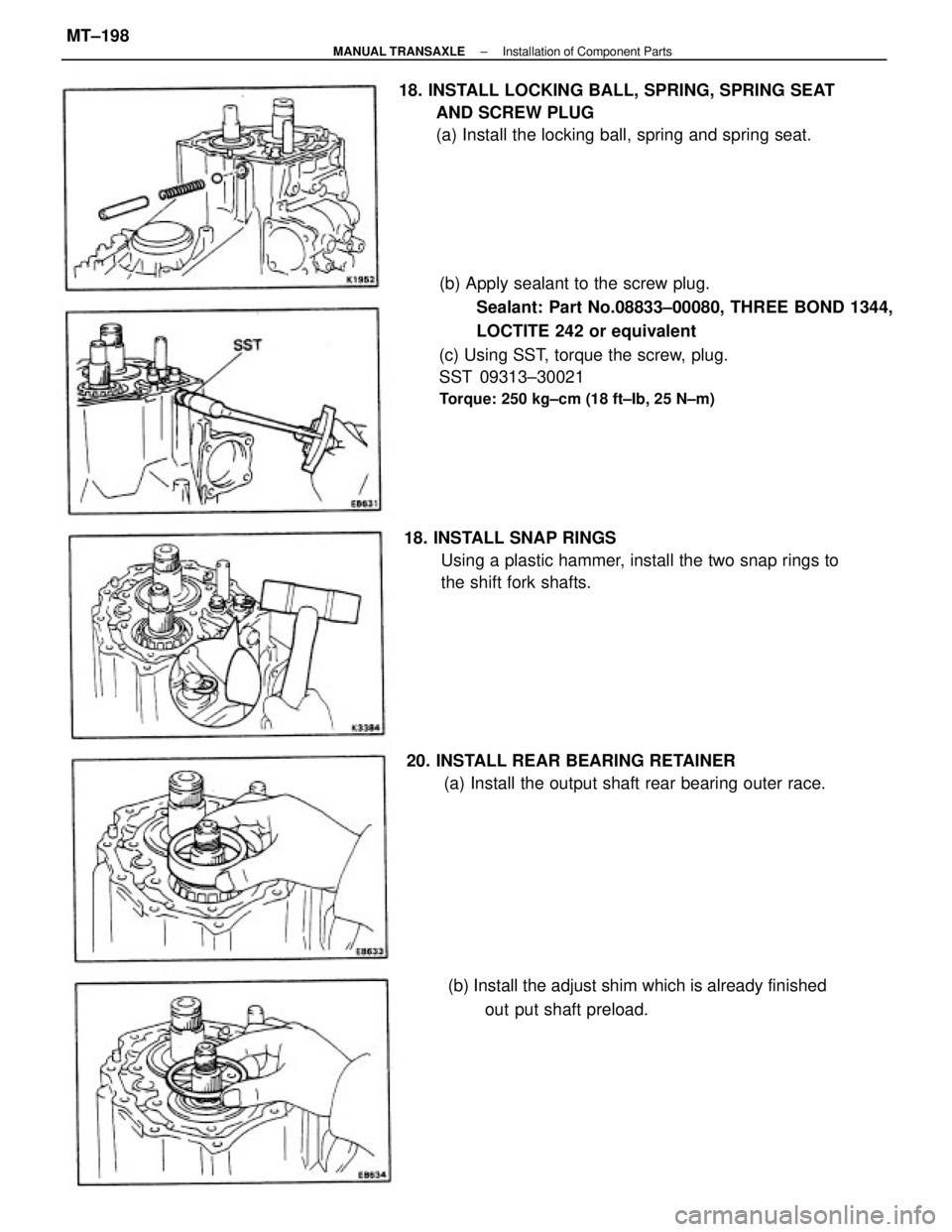

16. INSTALL TRANSMISSION CASE

(a) Remove any packing material and be careful not to drop oil on

the contacting surfaces of the transaxle case.

(b) Apply seal packing to the transmission case as shown in the fig-

ure.

Seal packing: Part No.08826±00080, THREE BOND

1281 or equivalent

HINT: Install the transmission case as soon as the seal packing

is applied.

(c) Install and torque the seventeen bolts.

Transmission case side: Fourteen bolts

Transaxle case side: Three bolts

Torque: 300 kg±cm (22 ft±Ib, 29 N±m)

(d) Torque the two oil pipe bolts and reverse shift arm

bracket bolt.

Torque: 175 kg±cm (13 ft±lb, 17 N±m)

17. INSTALL AND TORQUE REVERSE IDLER GEAR

RETAINING BOLT WITH GASKET

Torque: 300 kg±cm (22 ft±Ib, 29 N±m)

(e) Install a new gasket to the oil pipe.

± MANUAL TRANSAXLEInstallation of Component PartsMT±197

Page 2107 of 2389

(b) Apply sealant to the screw plug.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(c) Using SST, torque the screw, plug.

SST 09313±30021

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

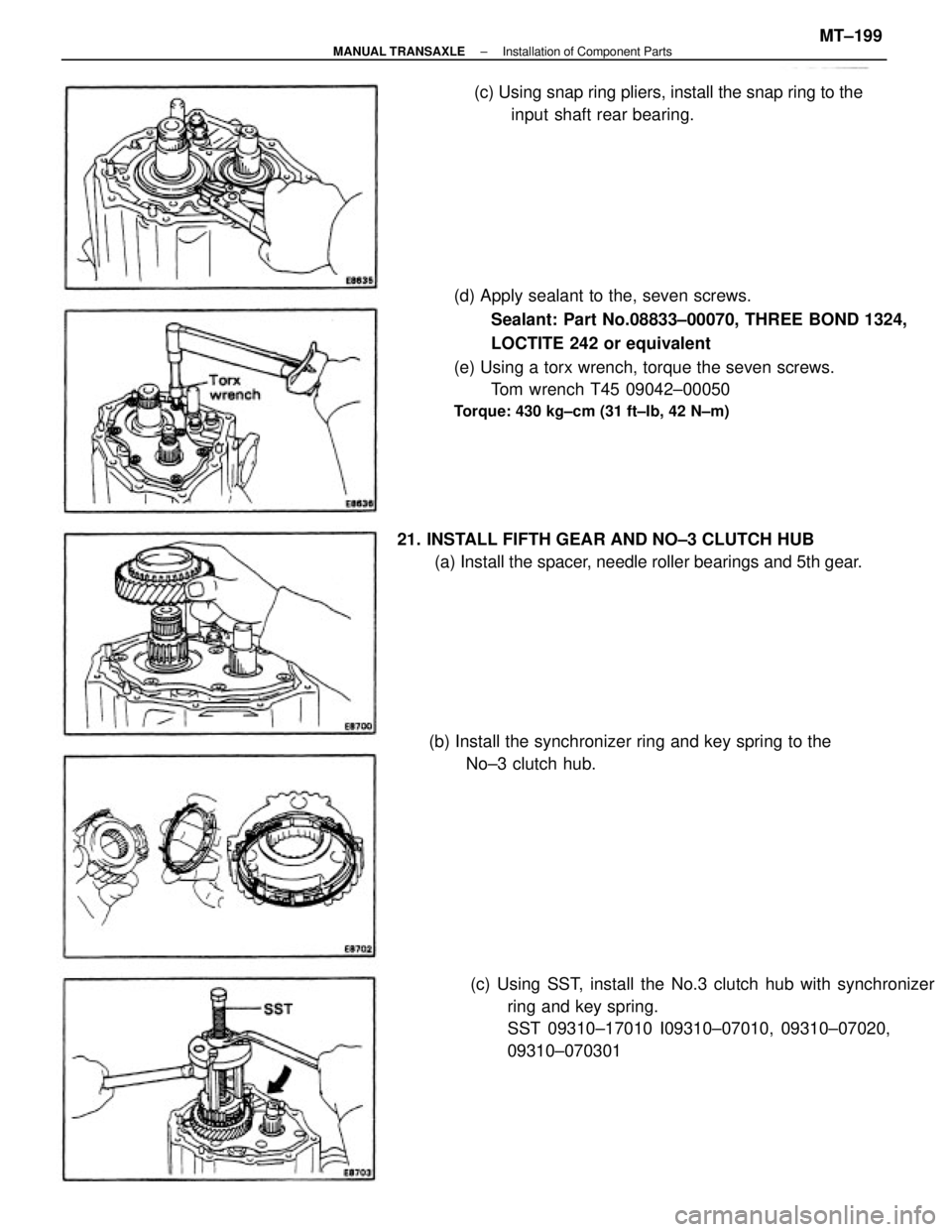

18. INSTALL LOCKING BALL, SPRING, SPRING SEAT

AND SCREW PLUG

(a) Install the locking ball, spring and spring seat.

18. INSTALL SNAP RINGS

Using a plastic hammer, install the two snap rings to

the shift fork shafts.

20. INSTALL REAR BEARING RETAINER

(a) Install the output shaft rear bearing outer race.

(b) Install the adjust shim which is already finished

out put shaft preload.

± MANUAL TRANSAXLEInstallation of Component PartsMT±198

Page 2108 of 2389

(d) Apply sealant to the, seven screws.

Sealant: Part No.08833±00070, THREE BOND 1324,

LOCTITE 242 or equivalent

(e) Using a torx wrench, torque the seven screws.

Tom wrench T45 09042±00050

Torque: 430 kg±cm (31 ft±Ib, 42 N±m)

(c) Using SST, install the No.3 clutch hub with synchronizer

ring and key spring.

SST 09310±17010 I09310±07010, 09310±07020,

09310±070301 21. INSTALL FIFTH GEAR AND NO±3 CLUTCH HUB

(a) Install the spacer, needle roller bearings and 5th gear.

(b) Install the synchronizer ring and key spring to the

No±3 clutch hub.(c) Using snap ring pliers, install the snap ring to the

input shaft rear bearing.

± MANUAL TRANSAXLEInstallation of Component PartsMT±199

Page 2109 of 2389

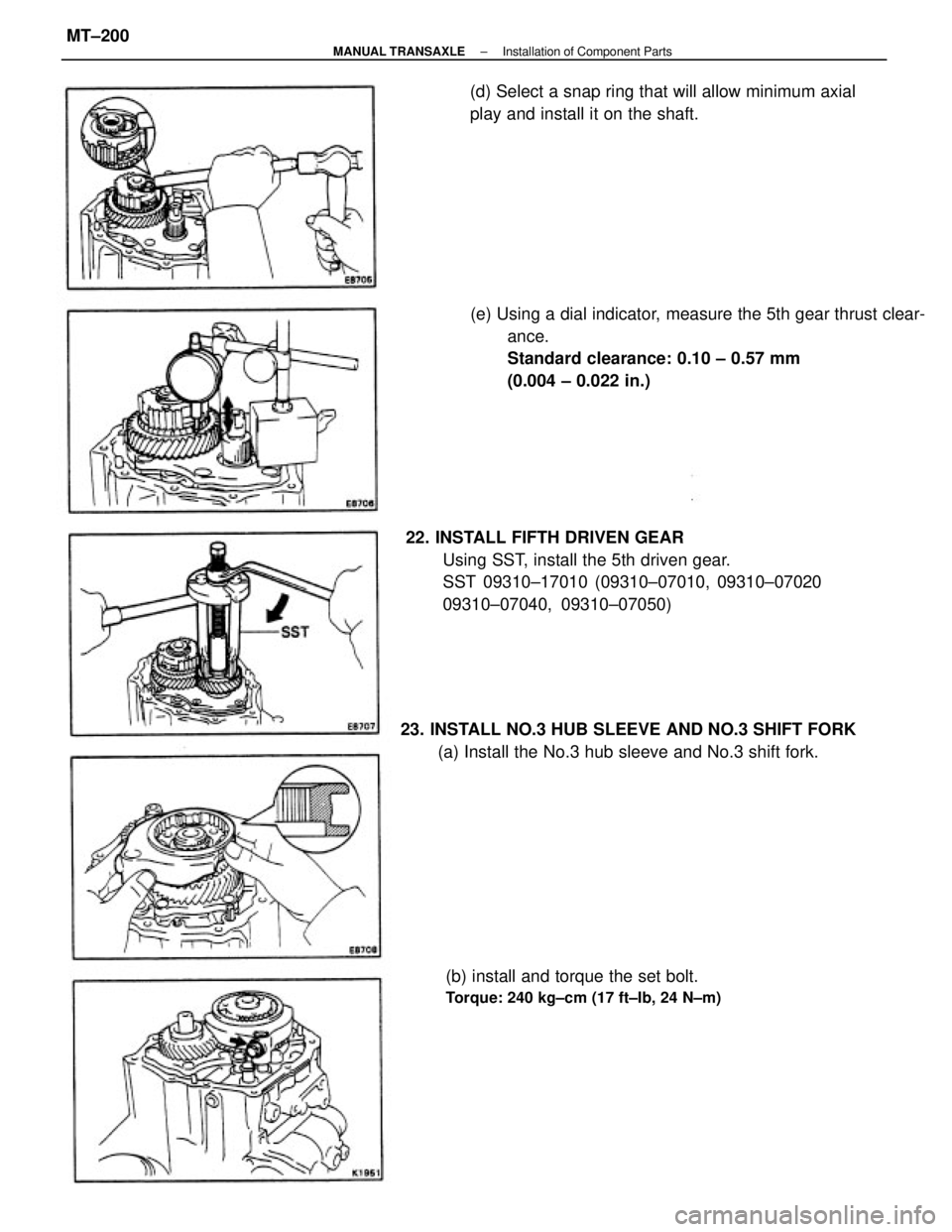

22. INSTALL FIFTH DRIVEN GEAR

Using SST, install the 5th driven gear.

SST 09310±17010 (09310±07010, 09310±07020

09310±07040, 09310±07050)(e) Using a dial indicator, measure the 5th gear thrust clear-

ance.

Standard clearance: 0.10 ± 0.57 mm

(0.004 ± 0.022 in.)

23. INSTALL NO.3 HUB SLEEVE AND NO.3 SHIFT FORK

(a) Install the No.3 hub sleeve and No.3 shift fork.(d) Select a snap ring that will allow minimum axial

play and install it on the shaft.

(b) install and torque the set bolt.

Torque: 240 kg±cm (17 ft±Ib, 24 N±m)

± MANUAL TRANSAXLEInstallation of Component PartsMT±200

Page 2110 of 2389

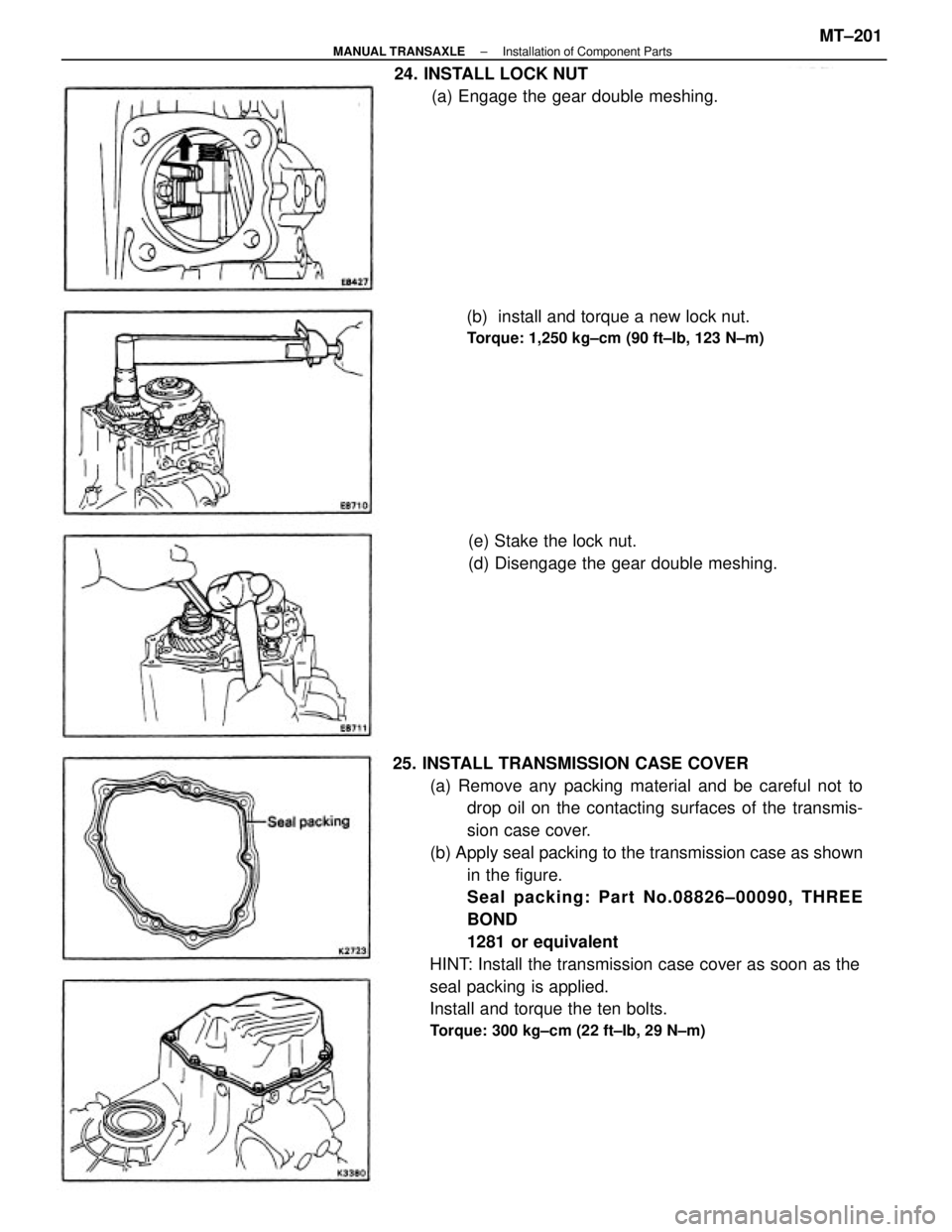

25. INSTALL TRANSMISSION CASE COVER

(a) Remove any packing material and be careful not to

drop oil on the contacting surfaces of the transmis-

sion case cover.

(b) Apply seal packing to the transmission case as shown

in the figure.

Seal packing: Part No.08826±00090, THREE

BOND

1281 or equivalent

HINT: Install the transmission case cover as soon as the

seal packing is applied.

Install and torque the ten bolts.

Torque: 300 kg±cm (22 ft±Ib, 29 N±m)

24. INSTALL LOCK NUT

(a) Engage the gear double meshing.

(b) install and torque a new lock nut.

Torque: 1,250 kg±cm (90 ft±Ib, 123 N±m)

(e) Stake the lock nut.

(d) Disengage the gear double meshing.

± MANUAL TRANSAXLEInstallation of Component PartsMT±201

Trending: wiper fluid, manual radio set, boot, brake, spark plugs replace, brake fluid, service schedule