TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: clock reset, air conditioning, fuel tank capacity, ad blue, high beam, wipers, CD player

Page 2071 of 2389

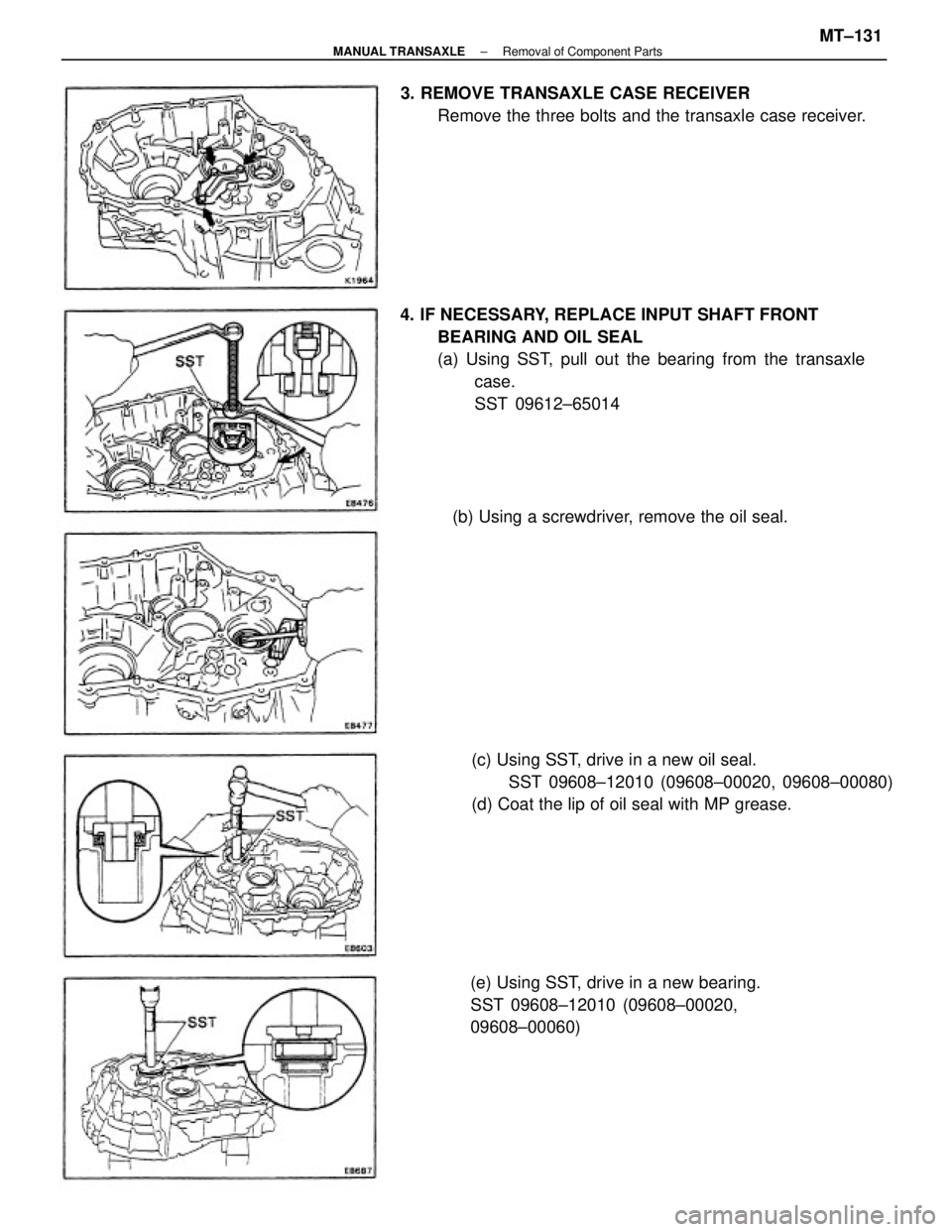

(e) Measure the clearance between the synchronizer ring back

and the gear spline end.

Standard clearance: 0.75 ± 1.65 mm

(0.0295 ± 0.0650 in.)

Minimum clearance: 0.6 mm (0.024 in.)

NOTE: Inspect the clearance of the gear's whole circumfer-

ence.

If the clearance is less than the limit, replace the synchronizer

ring.

2. MEASURE CLEARANCE OF SHIFT FORK AND HUB

SLEEVE

Using a feeler gauge, measure the clearance between

the hub sleeve and shift fork.

Maximum clearance: 1.0 mm (a.039 in.)

If the clearance exceeds the limit, replace the shift fork

or hub sleeve.

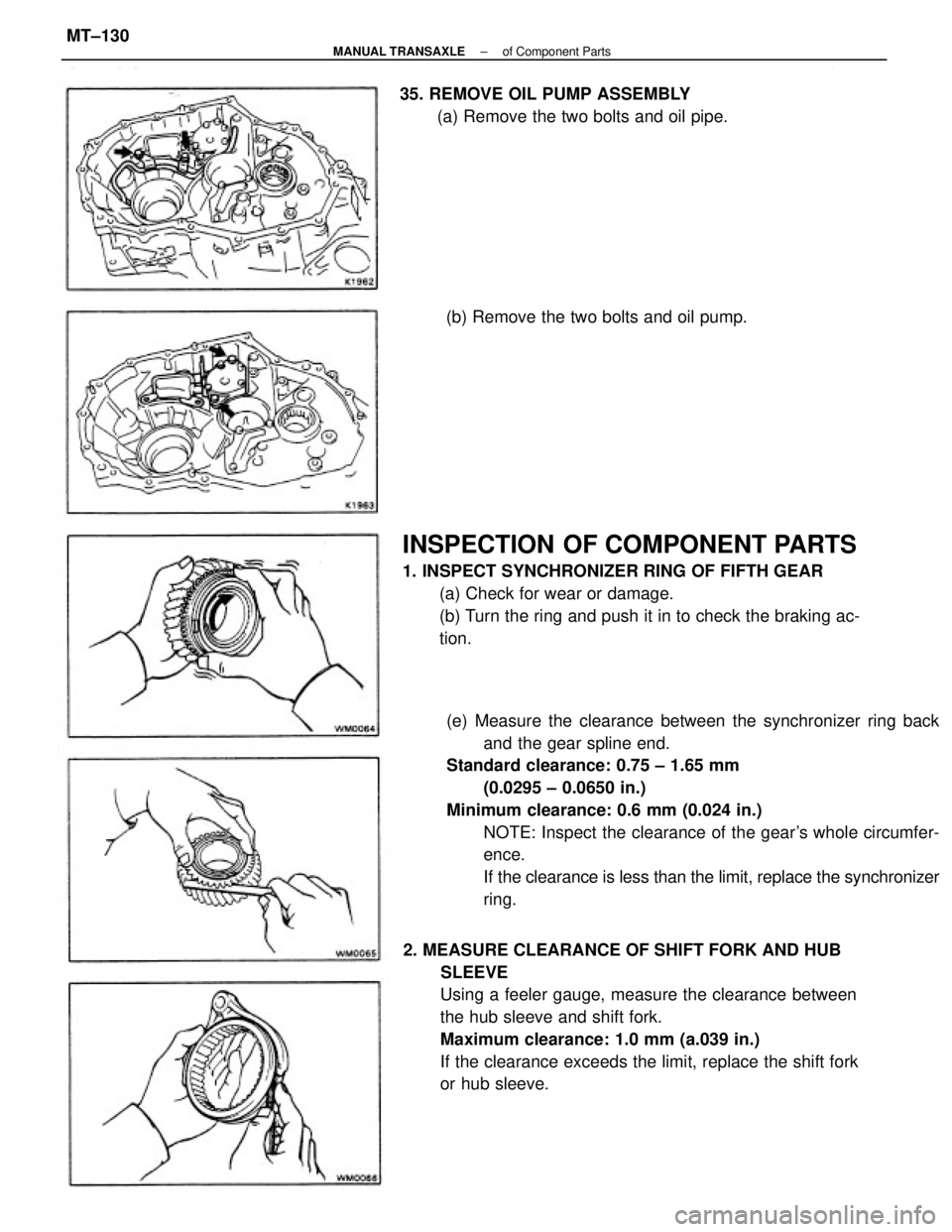

INSPECTION OF COMPONENT PARTS

1. INSPECT SYNCHRONIZER RING OF FIFTH GEAR

(a) Check for wear or damage.

(b) Turn the ring and push it in to check the braking ac-

tion. 35. REMOVE OIL PUMP ASSEMBLY

(a) Remove the two bolts and oil pipe.

(b) Remove the two bolts and oil pump.

± MANUAL TRANSAXLEof Component PartsMT±130

Page 2072 of 2389

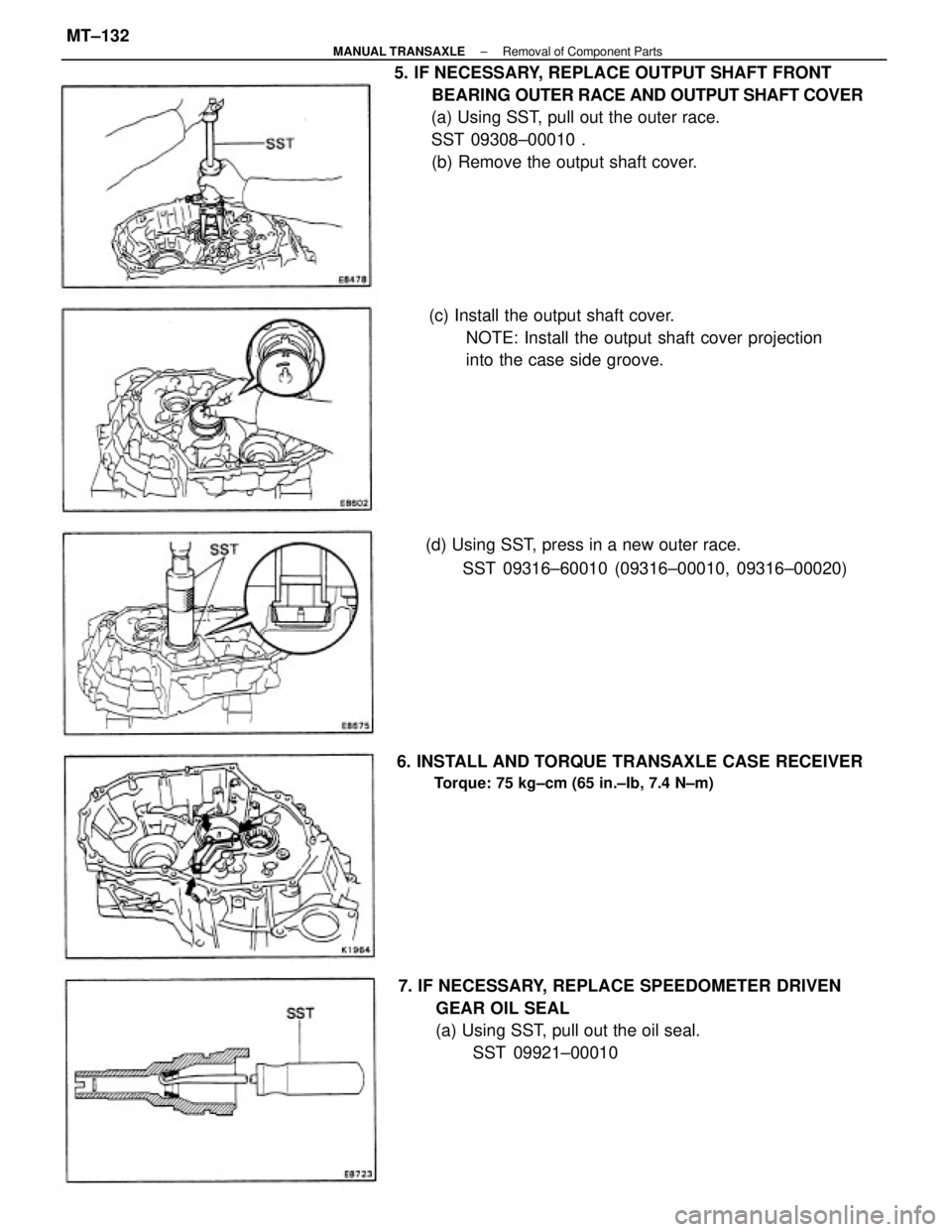

4. IF NECESSARY, REPLACE INPUT SHAFT FRONT

BEARING AND OIL SEAL

(a) Using SST, pull out the bearing from the transaxle

case.

SST 09612±65014

(c) Using SST, drive in a new oil seal.

SST 09608±12010 (09608±00020, 09608±00080)

(d) Coat the lip of oil seal with MP grease. 3. REMOVE TRANSAXLE CASE RECEIVER

Remove the three bolts and the transaxle case receiver.

(e) Using SST, drive in a new bearing.

SST 09608±12010 (09608±00020,

09608±00060) (b) Using a screwdriver, remove the oil seal.

± MANUAL TRANSAXLERemoval of Component PartsMT±131

Page 2073 of 2389

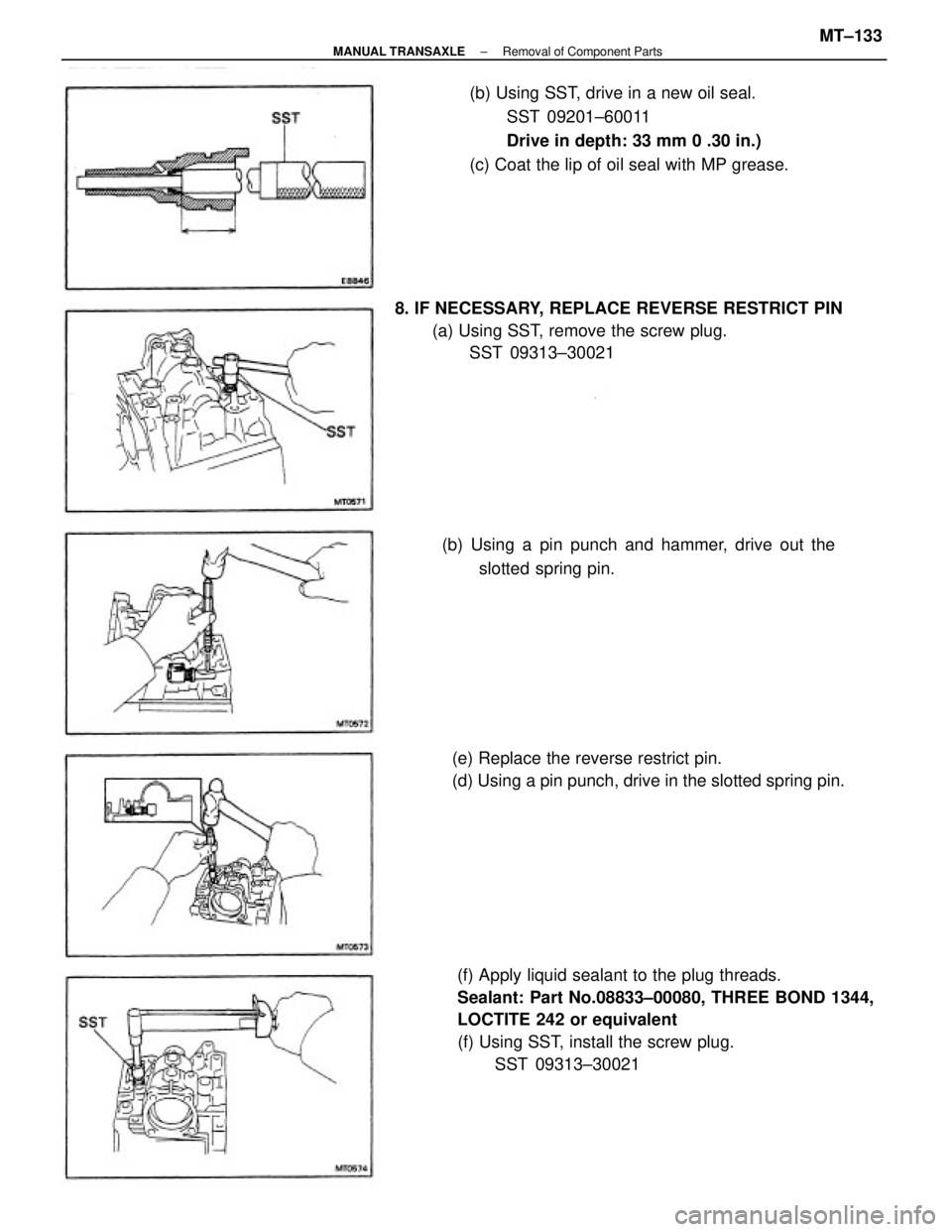

5. IF NECESSARY, REPLACE OUTPUT SHAFT FRONT

BEARING OUTER RACE AND OUTPUT SHAFT COVER

(a) Using SST, pull out the outer race.

SST 09308±00010 .

(b) Remove the output shaft cover.

7. IF NECESSARY, REPLACE SPEEDOMETER DRIVEN

GEAR OIL SEAL

(a) Using SST, pull out the oil seal.

SST 09921±00010 (c) Install the output shaft cover.

NOTE: Install the output shaft cover projection

into the case side groove.

6. INSTALL AND TORQUE TRANSAXLE CASE RECEIVER

Torque: 75 kg±cm (65 in.±Ib, 7.4 N±m)

(d) Using SST, press in a new outer race.

SST 09316±60010 (09316±00010, 09316±00020)

± MANUAL TRANSAXLERemoval of Component PartsMT±132

Page 2074 of 2389

(f) Apply liquid sealant to the plug threads.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(f) Using SST, install the screw plug.

SST 09313±30021 (b) Using SST, drive in a new oil seal.

SST 09201±60011

Drive in depth: 33 mm 0 .30 in.)

(c) Coat the lip of oil seal with MP grease.

8. IF NECESSARY, REPLACE REVERSE RESTRICT PIN

(a) Using SST, remove the screw plug.

SST 09313±30021

(e) Replace the reverse restrict pin.

(d) Using a pin punch, drive in the slotted spring pin. (b) Using a pin punch and hammer, drive out the

slotted spring pin.

± MANUAL TRANSAXLERemoval of Component PartsMT±133

Page 2075 of 2389

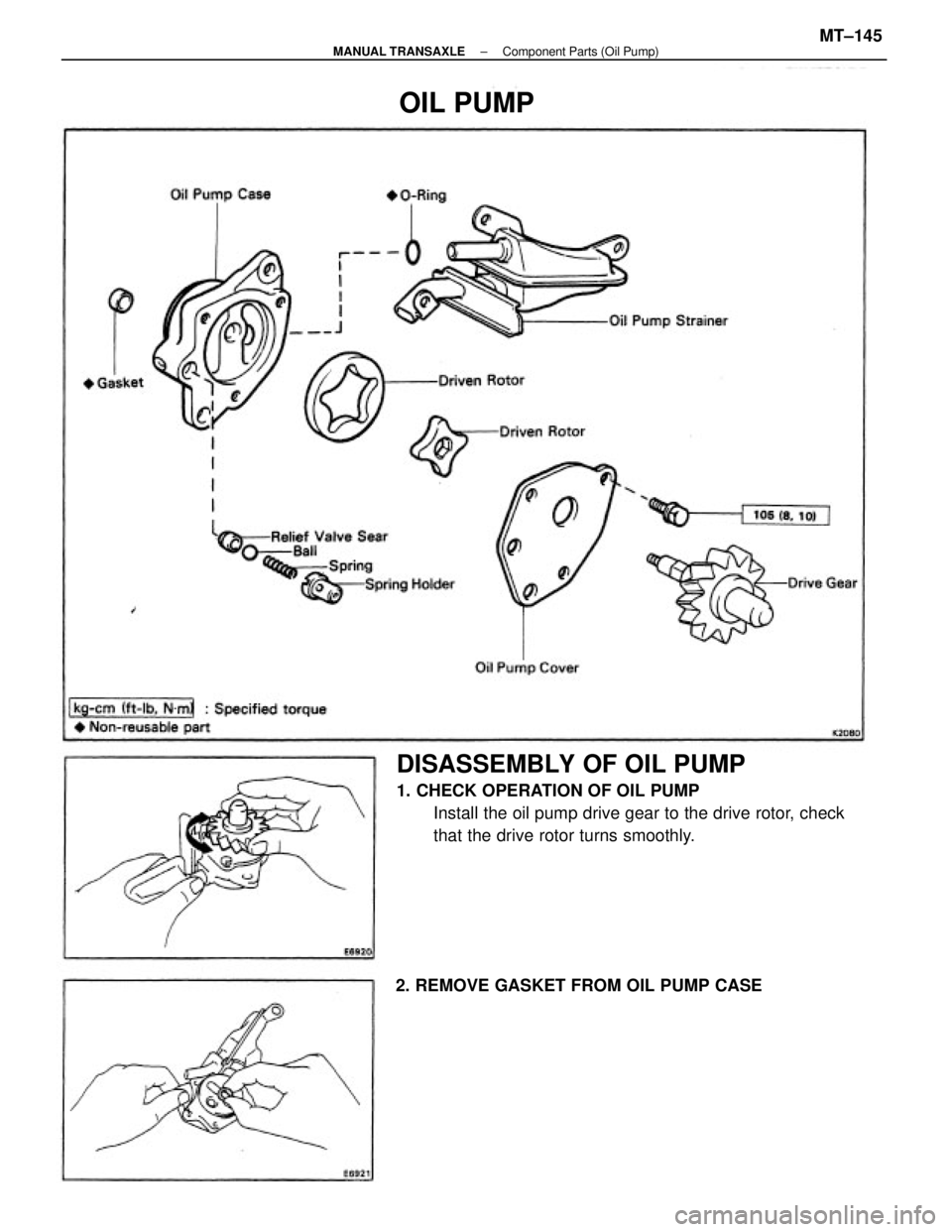

DISASSEMBLY OF OIL PUMP

1. CHECK OPERATION OF OIL PUMP

Install the oil pump drive gear to the drive rotor, check

that the drive rotor turns smoothly.

2. REMOVE GASKET FROM OIL PUMP CASE

OIL PUMP

± MANUAL TRANSAXLEComponent Parts (Oil Pump)MT±145

Page 2076 of 2389

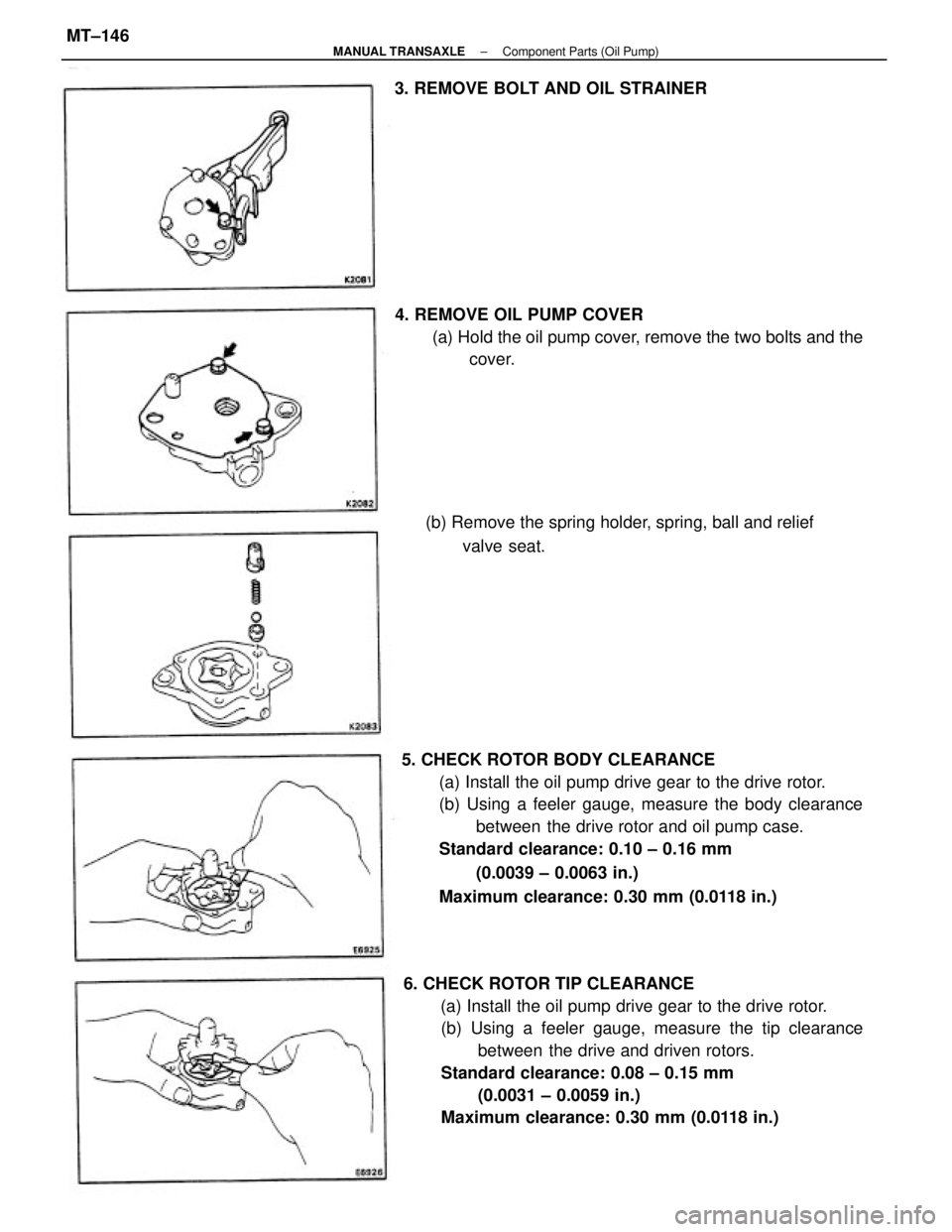

5. CHECK ROTOR BODY CLEARANCE

(a) Install the oil pump drive gear to the drive rotor.

(b) Using a feeler gauge, measure the body clearance

between the drive rotor and oil pump case.

Standard clearance: 0.10 ± 0.16 mm

(0.0039 ± 0.0063 in.)

Maximum clearance: 0.30 mm (0.0118 in.)

6. CHECK ROTOR TIP CLEARANCE

(a) Install the oil pump drive gear to the drive rotor.

(b) Using a feeler gauge, measure the tip clearance

between the drive and driven rotors.

Standard clearance: 0.08 ± 0.15 mm

(0.0031 ± 0.0059 in.)

Maximum clearance: 0.30 mm (0.0118 in.) 4. REMOVE OIL PUMP COVER

(a) Hold the oil pump cover, remove the two bolts and the

cover.

(b) Remove the spring holder, spring, ball and relief

valve seat. 3. REMOVE BOLT AND OIL STRAINER

± MANUAL TRANSAXLEComponent Parts (Oil Pump)MT±146

Page 2077 of 2389

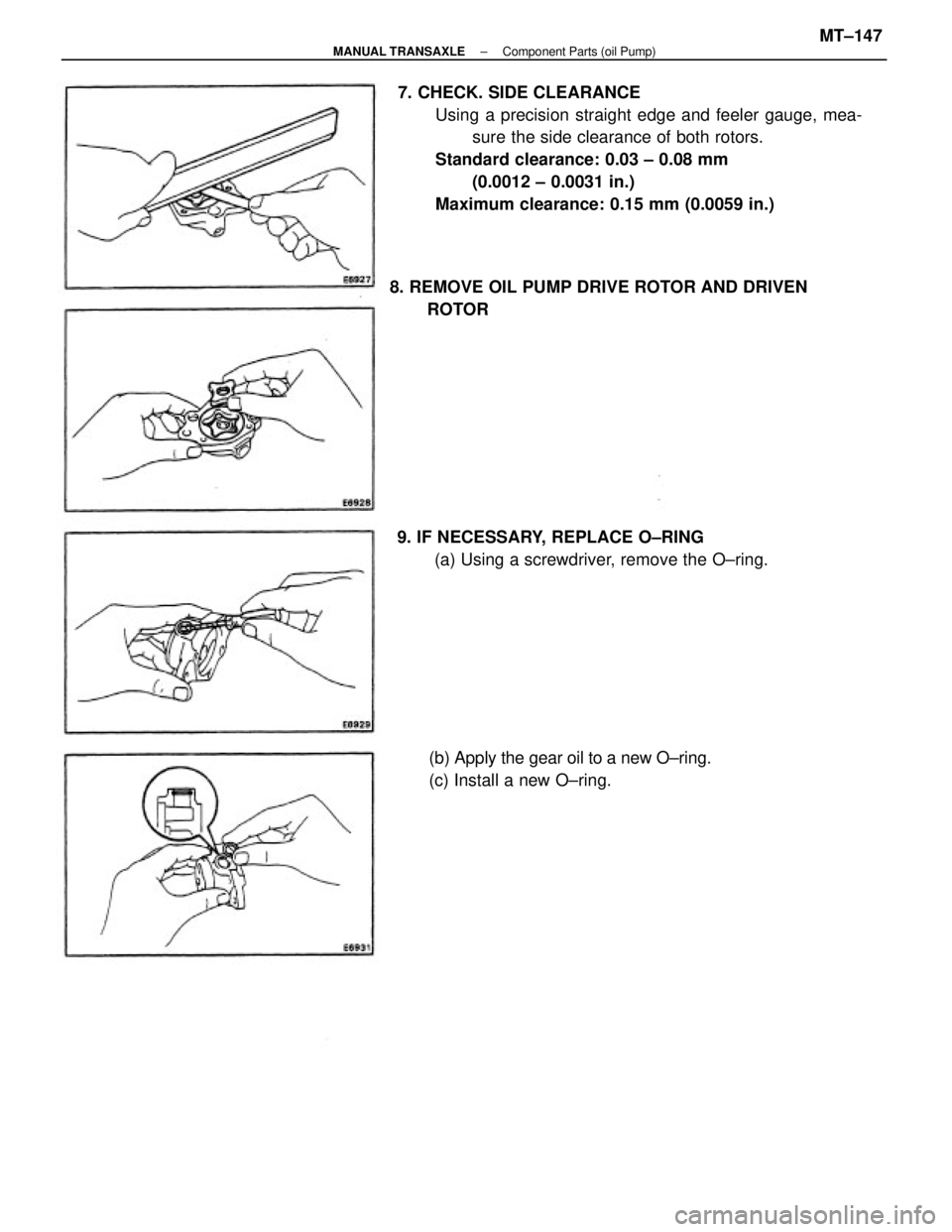

7. CHECK. SIDE CLEARANCE

Using a precision straight edge and feeler gauge, mea-

sure the side clearance of both rotors.

Standard clearance: 0.03 ± 0.08 mm

(0.0012 ± 0.0031 in.)

Maximum clearance: 0.15 mm (0.0059 in.)

8. REMOVE OIL PUMP DRIVE ROTOR AND DRIVEN

ROTOR

9. IF NECESSARY, REPLACE O±RING

(a) Using a screwdriver, remove the O±ring.

(b) Apply the gear oil to a new O±ring.

(c) Install a new O±ring.

± MANUAL TRANSAXLEComponent Parts (oil Pump)MT±147

Page 2078 of 2389

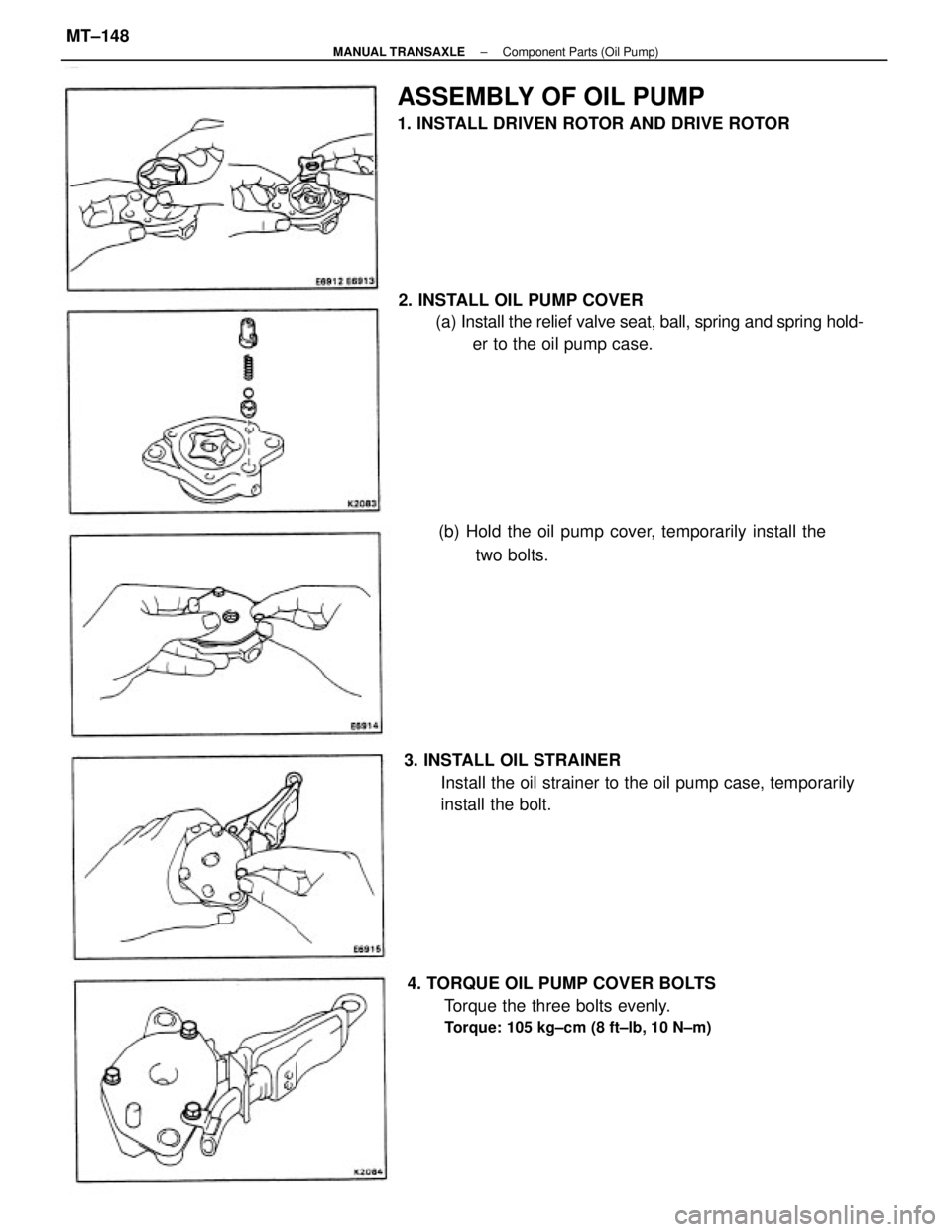

2. INSTALL OIL PUMP COVER

(a) Install the relief valve seat, ball, spring and spring hold-

er to the oil pump case.

3. INSTALL OIL STRAINER

Install the oil strainer to the oil pump case, temporarily

install the bolt.

4. TORQUE OIL PUMP COVER BOLTS

Torque the three bolts evenly.

Torque: 105 kg±cm (8 ft±lb, 10 N±m)

ASSEMBLY OF OIL PUMP

1. INSTALL DRIVEN ROTOR AND DRIVE ROTOR

(b) Hold the oil pump cover, temporarily install the

two bolts.

± MANUAL TRANSAXLEComponent Parts (Oil Pump)MT±148

Page 2079 of 2389

5. CHECK OPERATION OF OIL PUMP

Insert the oil pump drive gear to the drive rotor, check

that the drive rotor turns smoothly.

6. INSTALL GASKET

Install a new gasket to the oil pump case.

± MANUAL TRANSAXLEComponent Parts (Oil Pump)MT±149

Page 2080 of 2389

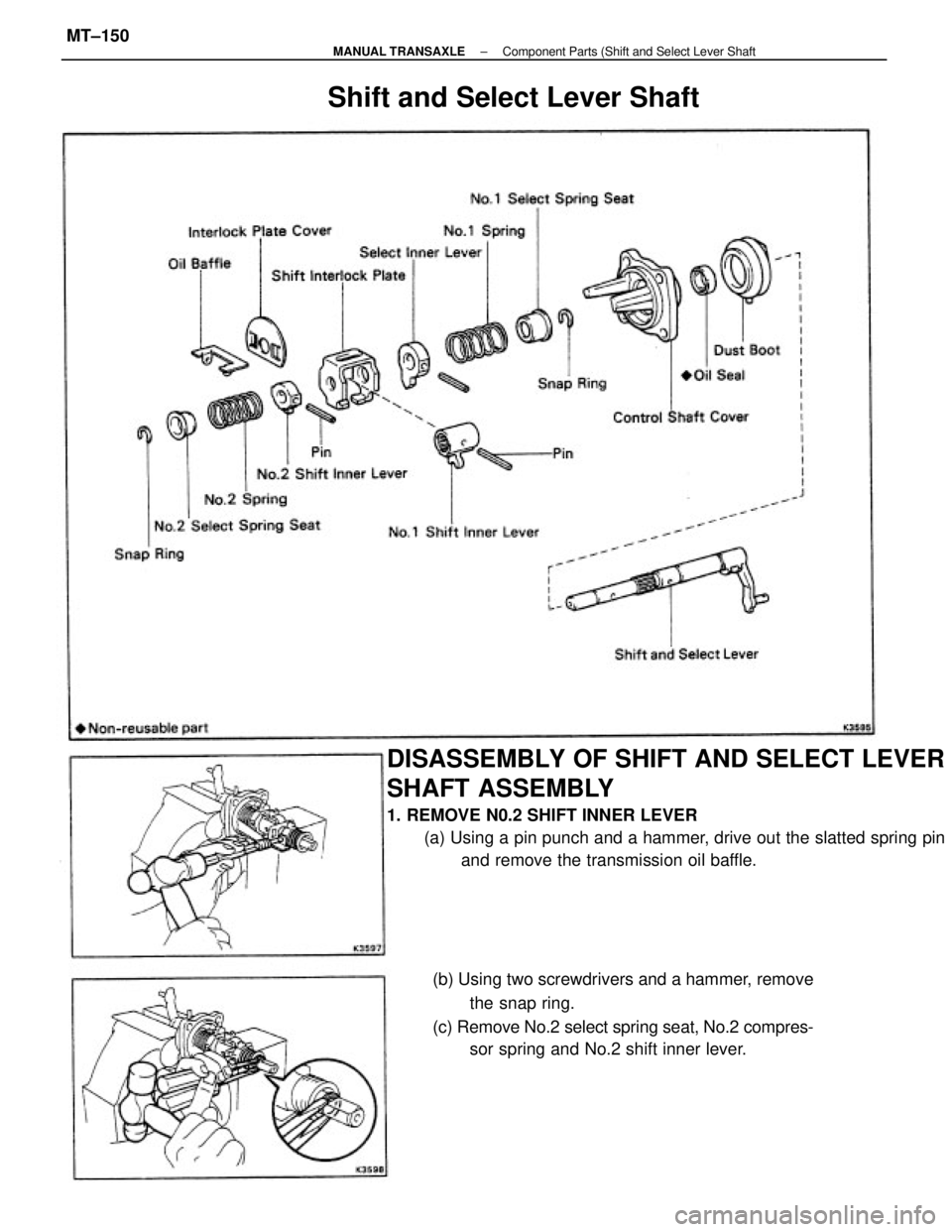

DISASSEMBLY OF SHIFT AND SELECT LEVER

SHAFT ASSEMBLY

1. REMOVE N0.2 SHIFT INNER LEVER

(a) Using a pin punch and a hammer, drive out the slatted spring pin

and remove the transmission oil baffle.

(b) Using two screwdrivers and a hammer, remove

the snap ring.

(c) Remove No.2 select spring seat, No.2 compres-

sor spring and No.2 shift inner lever.

Shift and Select Lever Shaft

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever ShaftMT±150

Trending: bulb, dead battery, ESP, Jack, jump cable, steering wheel adjustment, rear view mirror