TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: warning lights, door lock, height, service indicator, key battery, air filter, steering

Page 2111 of 2389

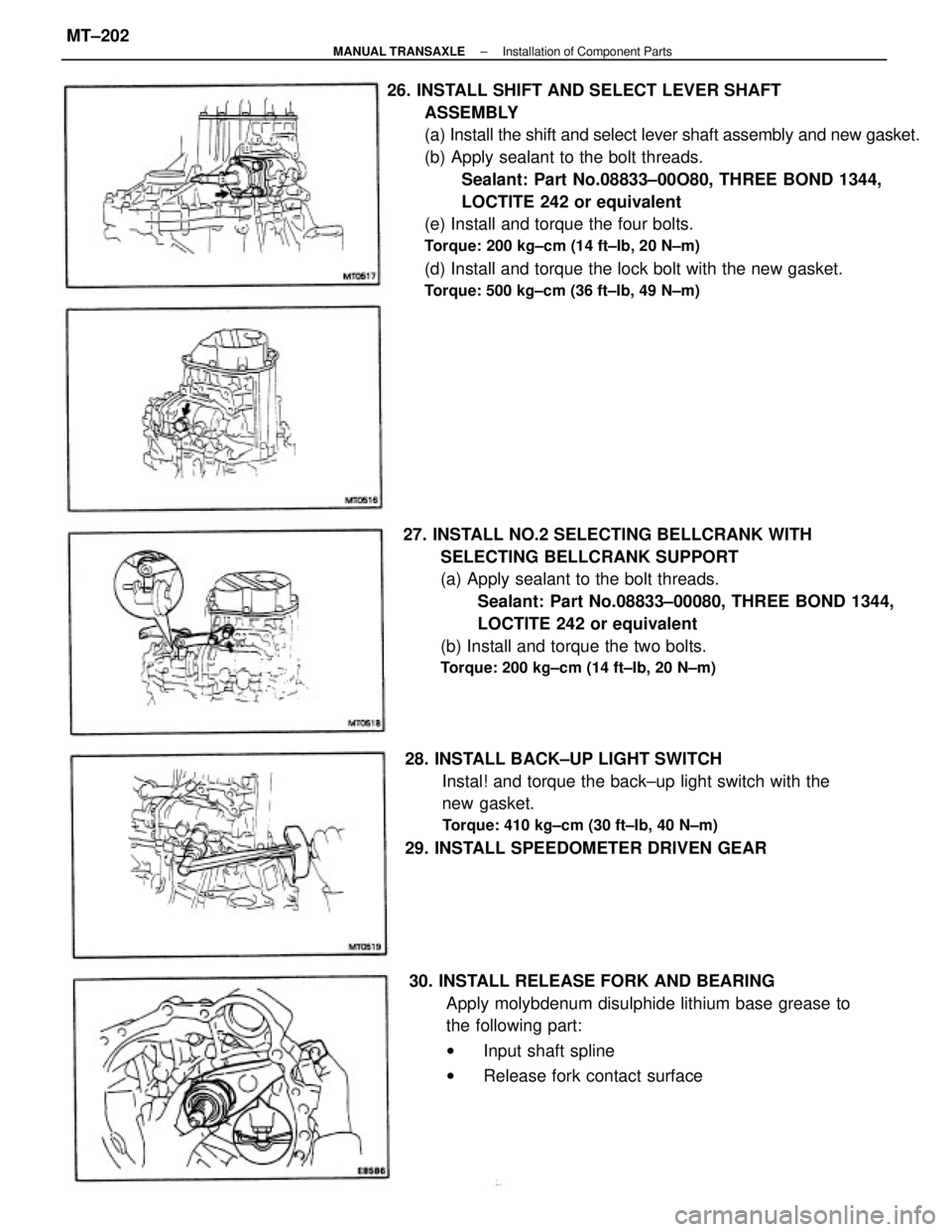

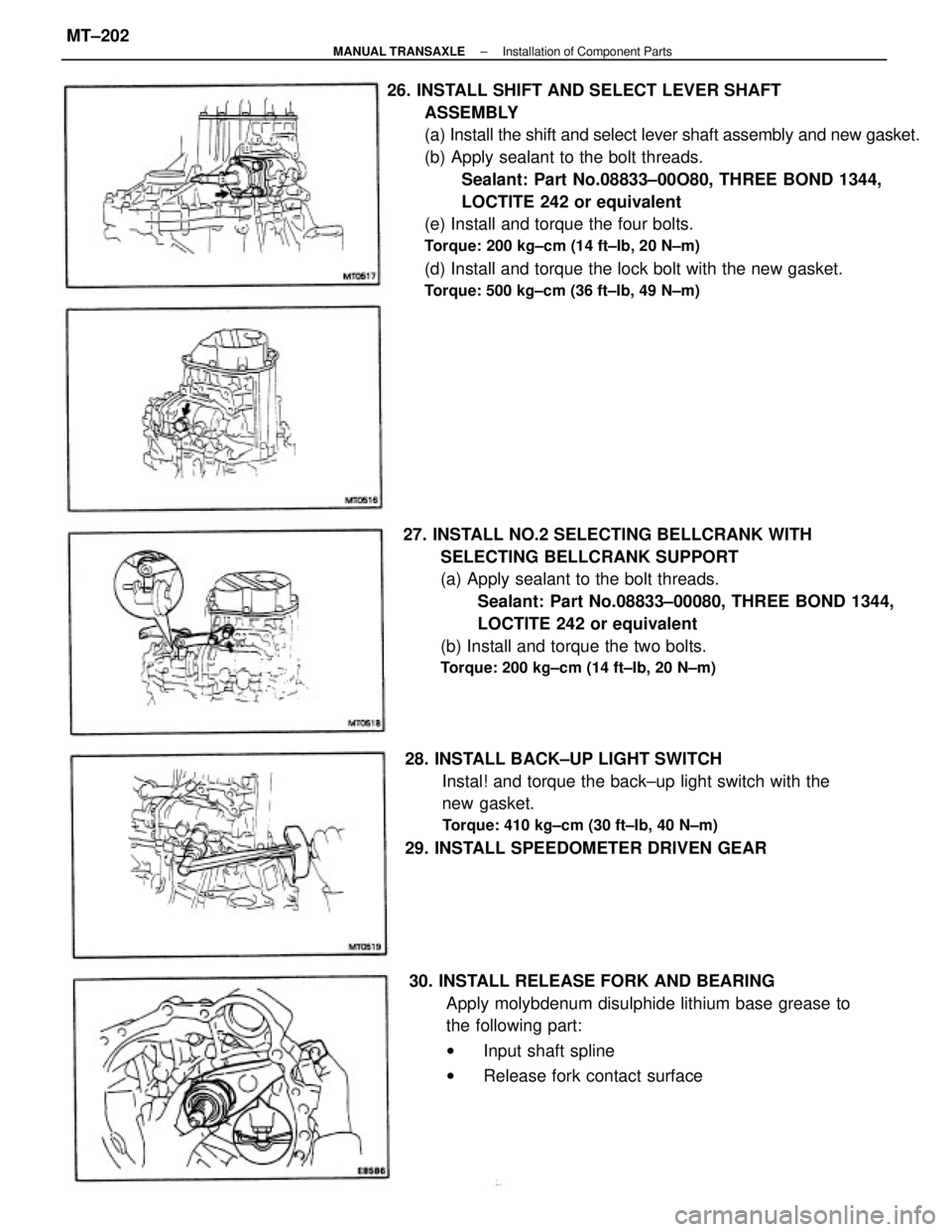

26. INSTALL SHIFT AND SELECT LEVER SHAFT

ASSEMBLY

(a) Install the shift and select lever shaft assembly and new gasket.

(b) Apply sealant to the bolt threads.

Sealant: Part No.08833±00O80, THREE BOND 1344,

LOCTITE 242 or equivalent

(e) Install and torque the four bolts.

Torque: 200 kg±cm (14 ft±Ib, 20 N±m)

(d) Install and torque the lock bolt with the new gasket.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

27. INSTALL NO.2 SELECTING BELLCRANK WITH

SELECTING BELLCRANK SUPPORT

(a) Apply sealant to the bolt threads.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Install and torque the two bolts.

Torque: 200 kg±cm (14 ft±Ib, 20 N±m)

28. INSTALL BACK±UP LIGHT SWITCH

Instal! and torque the back±up light switch with the

new gasket.

Torque: 410 kg±cm (30 ft±Ib, 40 N±m)

29. INSTALL SPEEDOMETER DRIVEN GEAR

30. INSTALL RELEASE FORK AND BEARING

Apply molybdenum disulphide lithium base grease to

the following part:

wInput shaft spline

wRelease fork contact surface

± MANUAL TRANSAXLEInstallation of Component PartsMT±202

Page 2112 of 2389

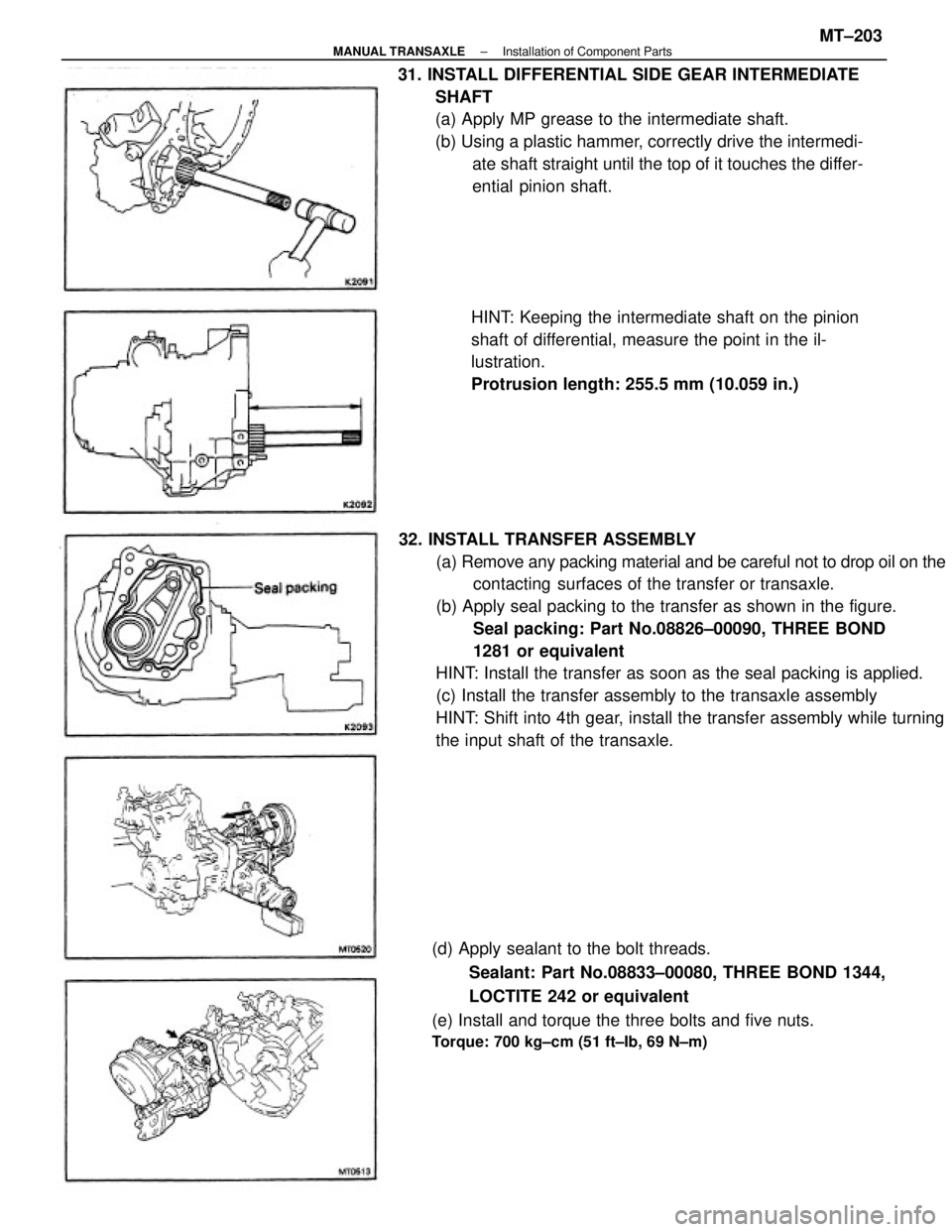

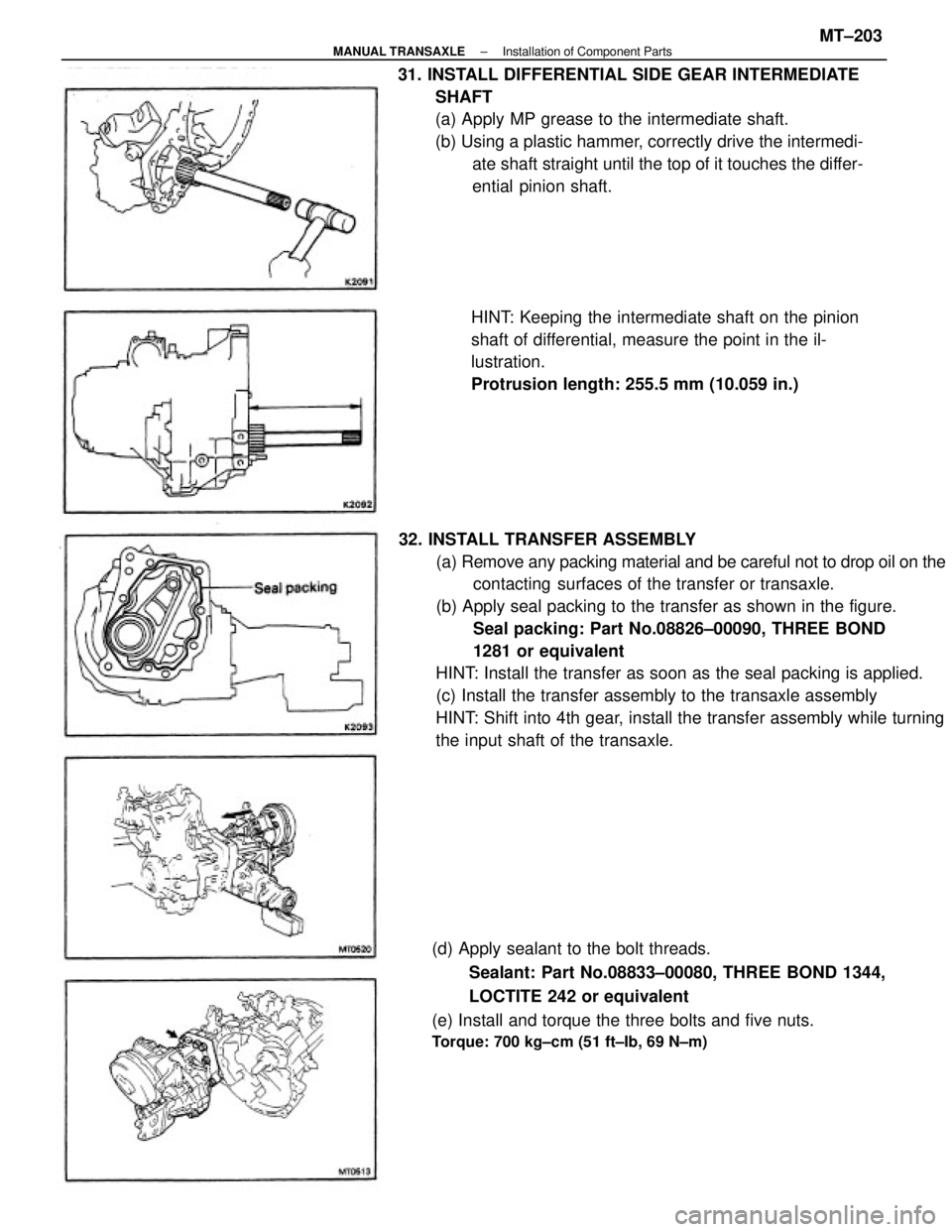

32. INSTALL TRANSFER ASSEMBLY

(a) Remove any packing material and be careful not to drop oil on the

contacting surfaces of the transfer or transaxle.

(b) Apply seal packing to the transfer as shown in the figure.

Seal packing: Part No.08826±00090, THREE BOND

1281 or equivalent

HINT: Install the transfer as soon as the seal packing is applied.

(c) Install the transfer assembly to the transaxle assembly

HINT: Shift into 4th gear, install the transfer assembly while turning

the input shaft of the transaxle. 31. INSTALL DIFFERENTIAL SIDE GEAR INTERMEDIATE

SHAFT

(a) Apply MP grease to the intermediate shaft.

(b) Using a plastic hammer, correctly drive the intermedi-

ate shaft straight until the top of it touches the differ-

ential pinion shaft.

(d) Apply sealant to the bolt threads.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(e) Install and torque the three bolts and five nuts.

Torque: 700 kg±cm (51 ft±Ib, 69 N±m)

HINT: Keeping the intermediate shaft on the pinion

shaft of differential, measure the point in the il-

lustration.

Protrusion length: 255.5 mm (10.059 in.)

± MANUAL TRANSAXLEInstallation of Component PartsMT±203

Page 2113 of 2389

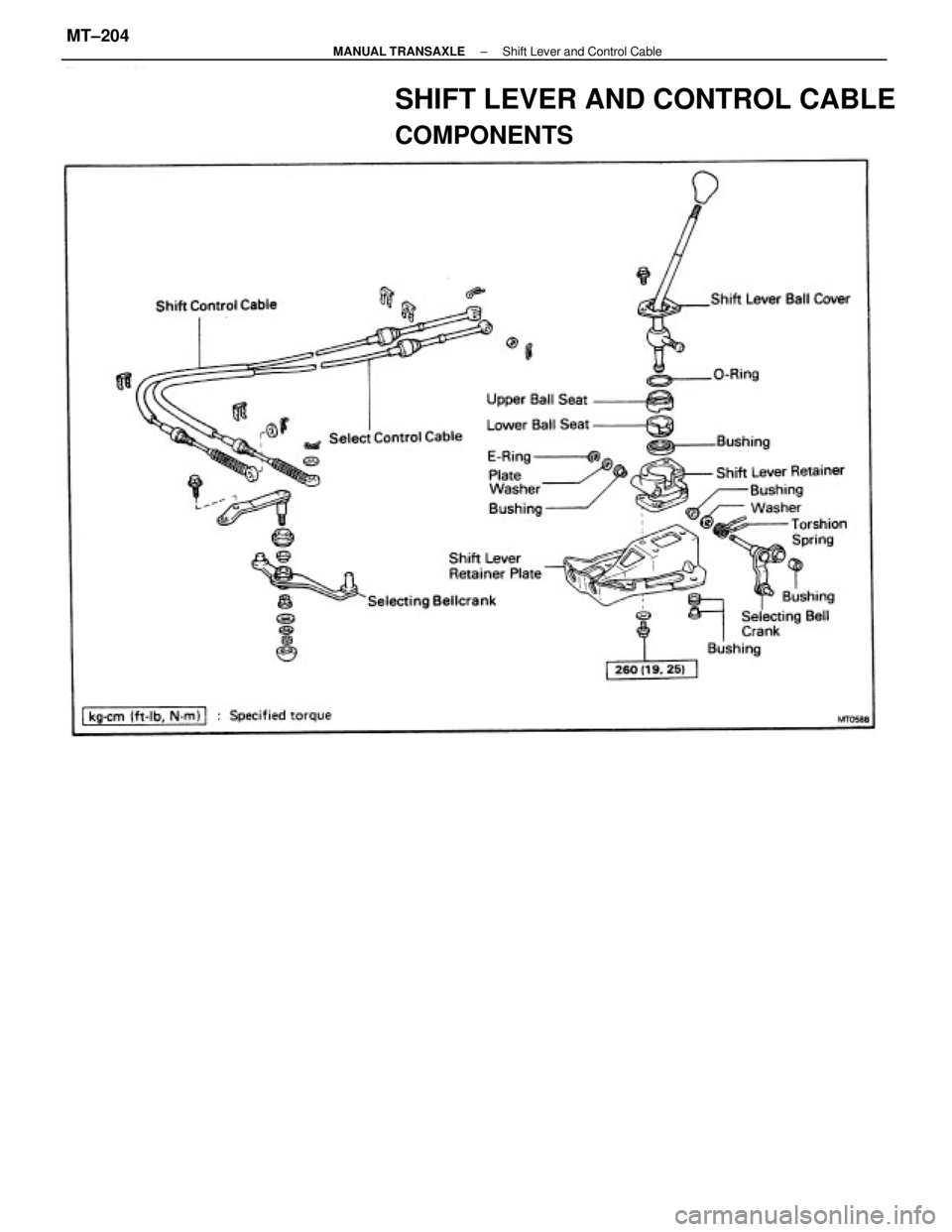

SHIFT LEVER AND CONTROL CABLE

COMPONENTS

± MANUAL TRANSAXLEShift Lever and Control CableMT±204

Page 2114 of 2389

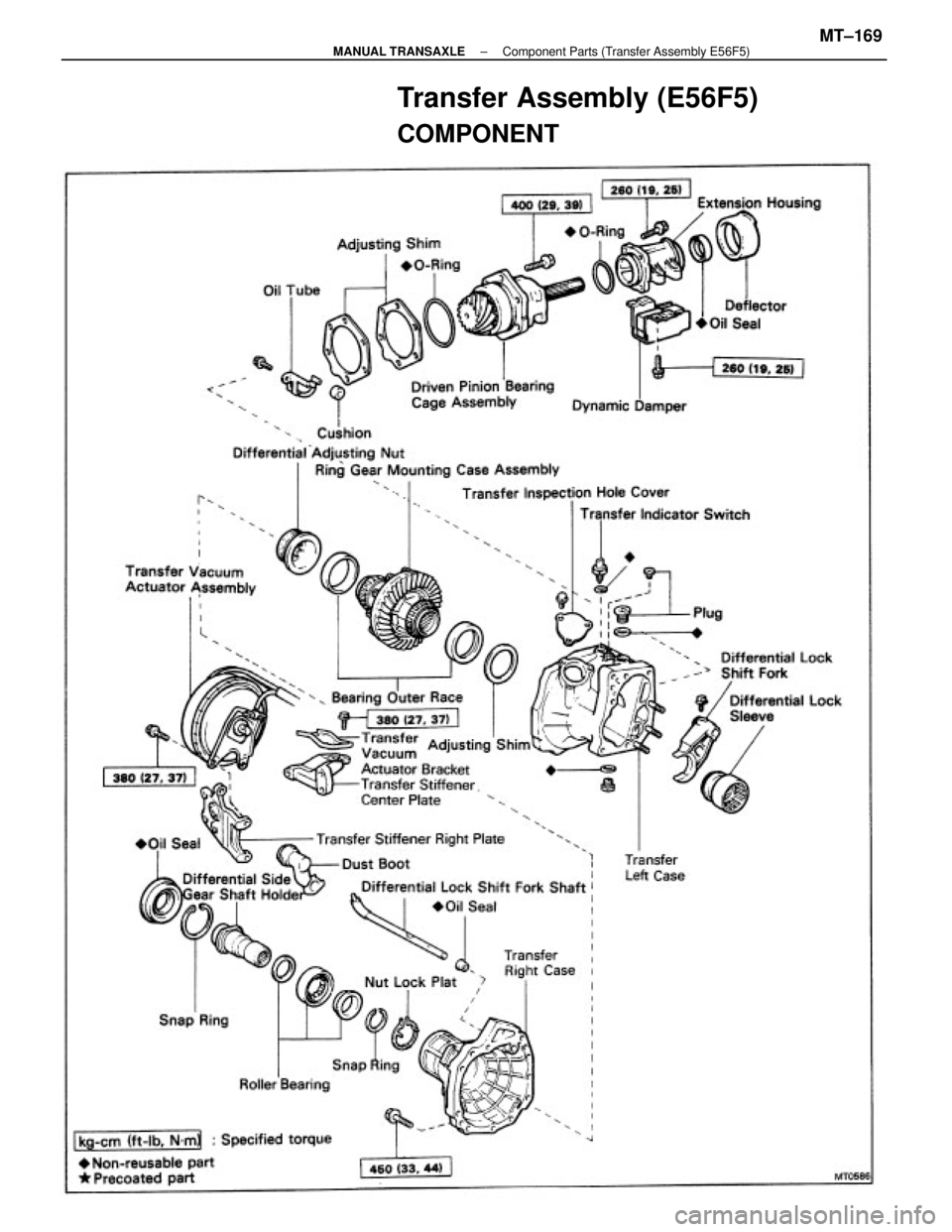

Transfer Assembly (E56F5)

COMPONENT

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±169

Page 2115 of 2389

DISASSEMBLY OF TRANSFER COMPONENT

PARTS

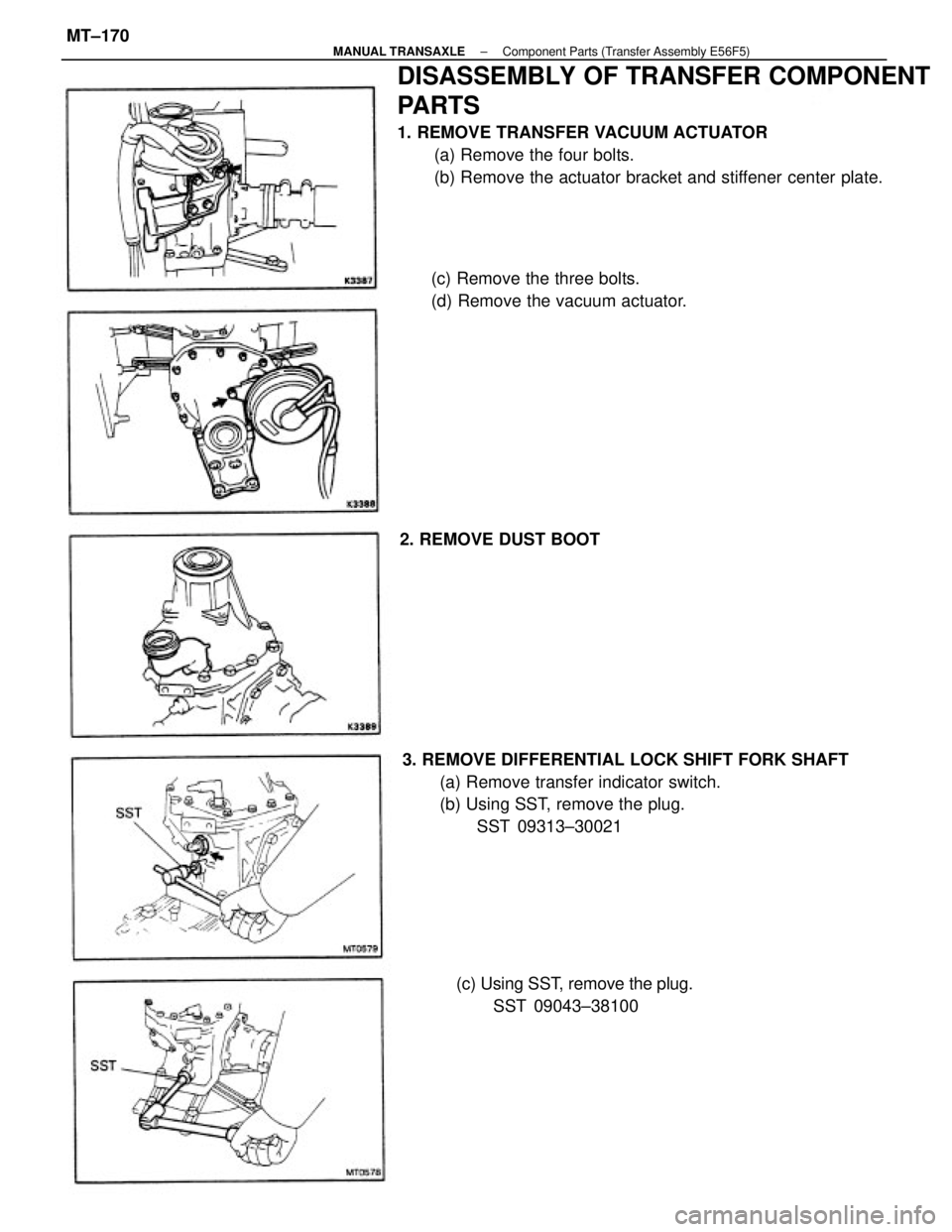

1. REMOVE TRANSFER VACUUM ACTUATOR

(a) Remove the four bolts.

(b) Remove the actuator bracket and stiffener center plate.

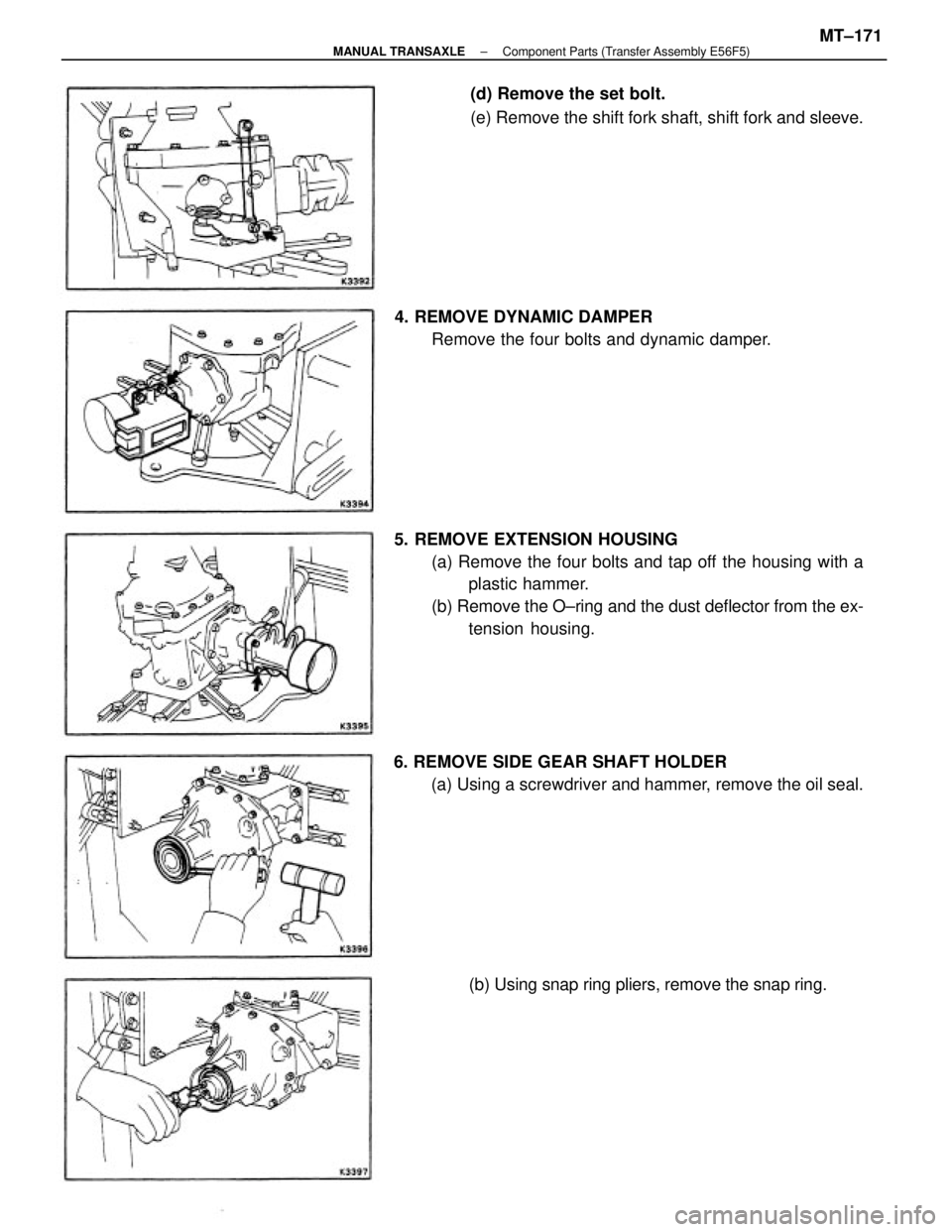

3. REMOVE DIFFERENTIAL LOCK SHIFT FORK SHAFT

(a) Remove transfer indicator switch.

(b) Using SST, remove the plug.

SST 09313±30021 (c) Remove the three bolts.

(d) Remove the vacuum actuator.

(c) Using SST, remove the plug.

SST 09043±38100 2. REMOVE DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±170

Page 2116 of 2389

5. REMOVE EXTENSION HOUSING

(a) Remove the four bolts and tap off the housing with a

plastic hammer.

(b) Remove the O±ring and the dust deflector from the ex-

tension housing.

6. REMOVE SIDE GEAR SHAFT HOLDER

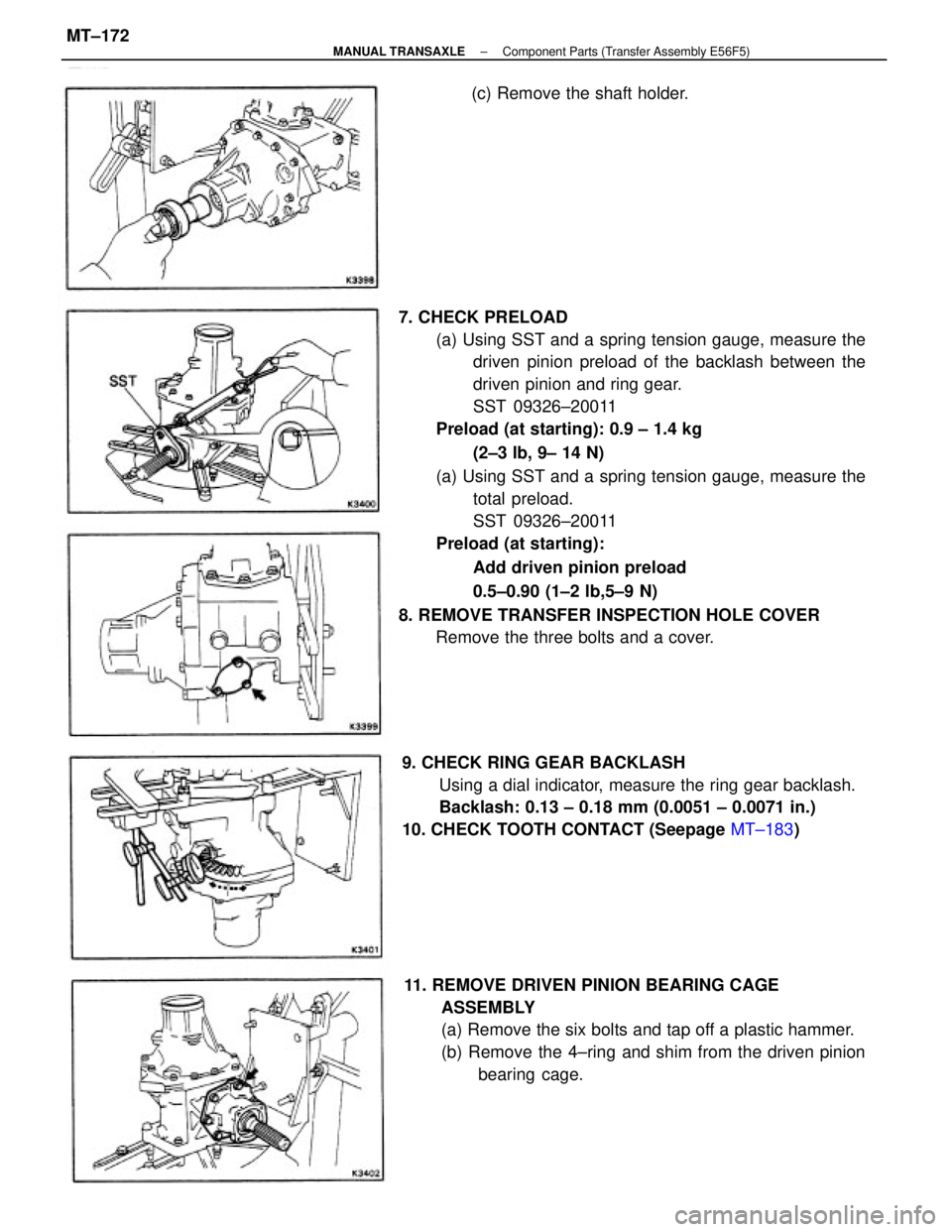

(a) Using a screwdriver and hammer, remove the oil seal. 4. REMOVE DYNAMIC DAMPER

Remove the four bolts and dynamic damper.(d) Remove the set bolt.

(e) Remove the shift fork shaft, shift fork and sleeve.

(b) Using snap ring pliers, remove the snap ring.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±171

Page 2117 of 2389

7. CHECK PRELOAD

(a) Using SST and a spring tension gauge, measure the

driven pinion preload of the backlash between the

driven pinion and ring gear.

SST 09326±20011

Preload (at starting): 0.9 ± 1.4 kg

(2±3 lb, 9± 14 N)

(a) Using SST and a spring tension gauge, measure the

total preload.

SST 09326±20011

Preload (at starting):

Add driven pinion preload

0.5±0.90 (1±2 lb,5±9 N)

8. REMOVE TRANSFER INSPECTION HOLE COVER

Remove the three bolts and a cover.

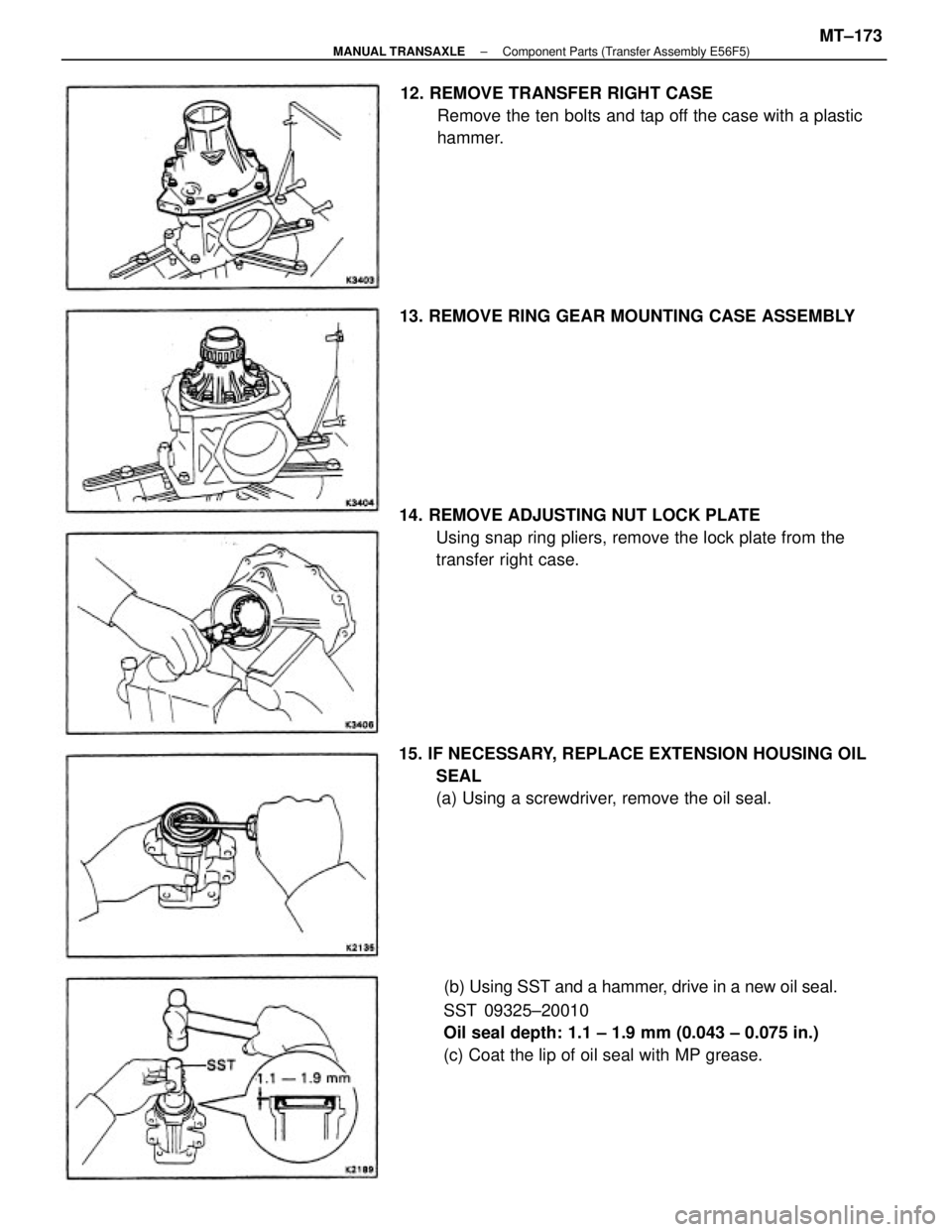

11. REMOVE DRIVEN PINION BEARING CAGE

ASSEMBLY

(a) Remove the six bolts and tap off a plastic hammer.

(b) Remove the 4±ring and shim from the driven pinion

bearing cage. 9. CHECK RING GEAR BACKLASH

Using a dial indicator, measure the ring gear backlash.

Backlash: 0.13 ± 0.18 mm (0.0051 ± 0.0071 in.)

10. CHECK TOOTH CONTACT (Seepage MT±183) (c) Remove the shaft holder.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±172

Page 2118 of 2389

14. REMOVE ADJUSTING NUT LOCK PLATE

Using snap ring pliers, remove the lock plate from the

transfer right case.

(b) Using SST and a hammer, drive in a new oil seal.

SST 09325±20010

Oil seal depth: 1.1 ± 1.9 mm (0.043 ± 0.075 in.)

(c) Coat the lip of oil seal with MP grease. 15. IF NECESSARY, REPLACE EXTENSION HOUSING OIL

SEAL

(a) Using a screwdriver, remove the oil seal. 12. REMOVE TRANSFER RIGHT CASE

Remove the ten bolts and tap off the case with a plastic

hammer.

13. REMOVE RING GEAR MOUNTING CASE ASSEMBLY

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±173

Page 2119 of 2389

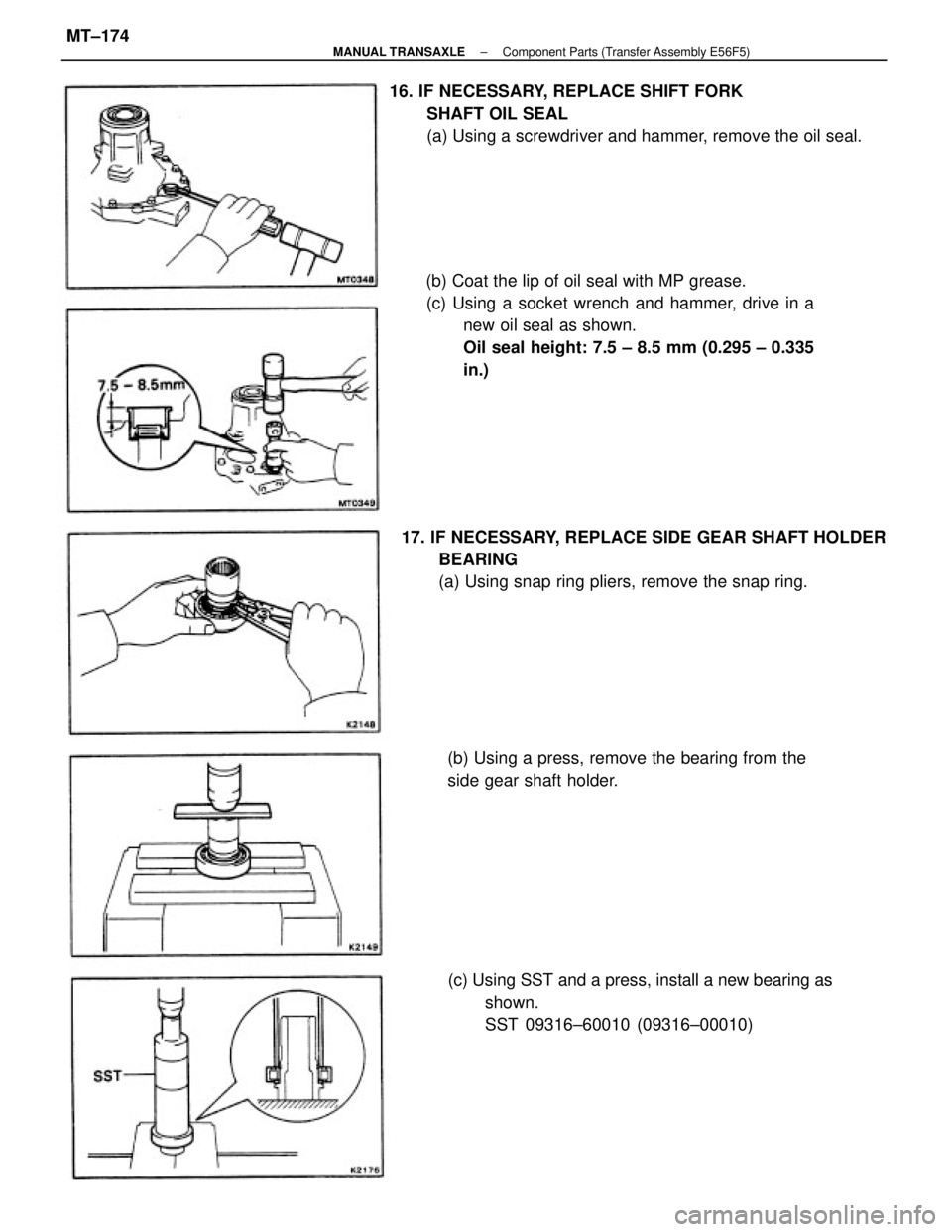

(b) Coat the lip of oil seal with MP grease.

(c) Using a socket wrench and hammer, drive in a

new oil seal as shown.

Oil seal height: 7.5 ± 8.5 mm (0.295 ± 0.335

in.) 16. IF NECESSARY, REPLACE SHIFT FORK

SHAFT OIL SEAL

(a) Using a screwdriver and hammer, remove the oil seal.

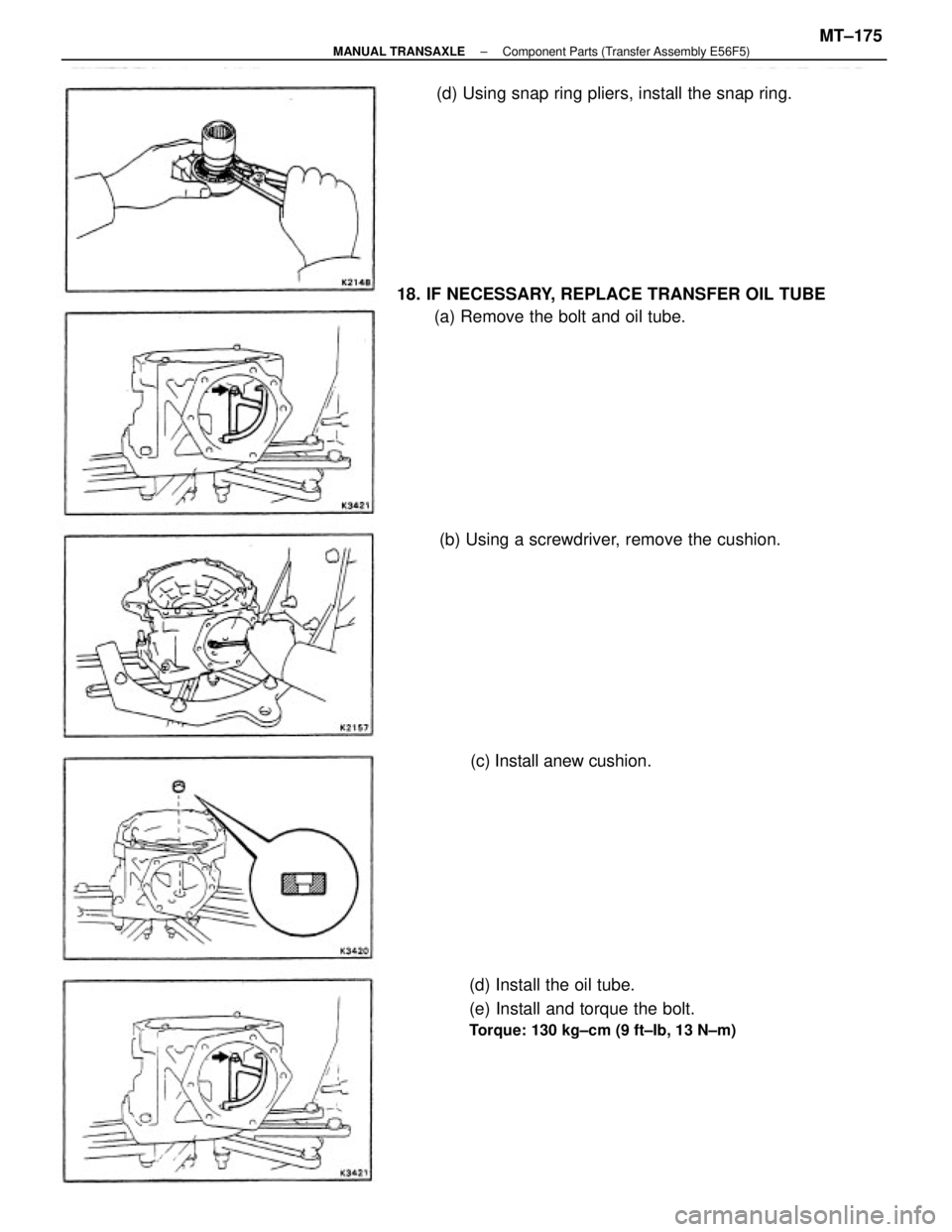

17. IF NECESSARY, REPLACE SIDE GEAR SHAFT HOLDER

BEARING

(a) Using snap ring pliers, remove the snap ring.

(c) Using SST and a press, install a new bearing as

shown.

SST 09316±60010 (09316±00010) (b) Using a press, remove the bearing from the

side gear shaft holder.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±174

Page 2120 of 2389

18. IF NECESSARY, REPLACE TRANSFER OIL TUBE

(a) Remove the bolt and oil tube.

(d) Install the oil tube.

(e) Install and torque the bolt.

Torque: 130 kg±cm (9 ft±Ib, 13 N±m)

(d) Using snap ring pliers, install the snap ring.

(b) Using a screwdriver, remove the cushion.

(c) Install anew cushion.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±175

Trending: width, power steering fluid, stop start, turn signal bulb, wheel torque, lighting, maintenance schedule