TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: heating, flat tire, remove seats, ECU, seat adjustment, fuel pump, trunk release

Page 2131 of 2389

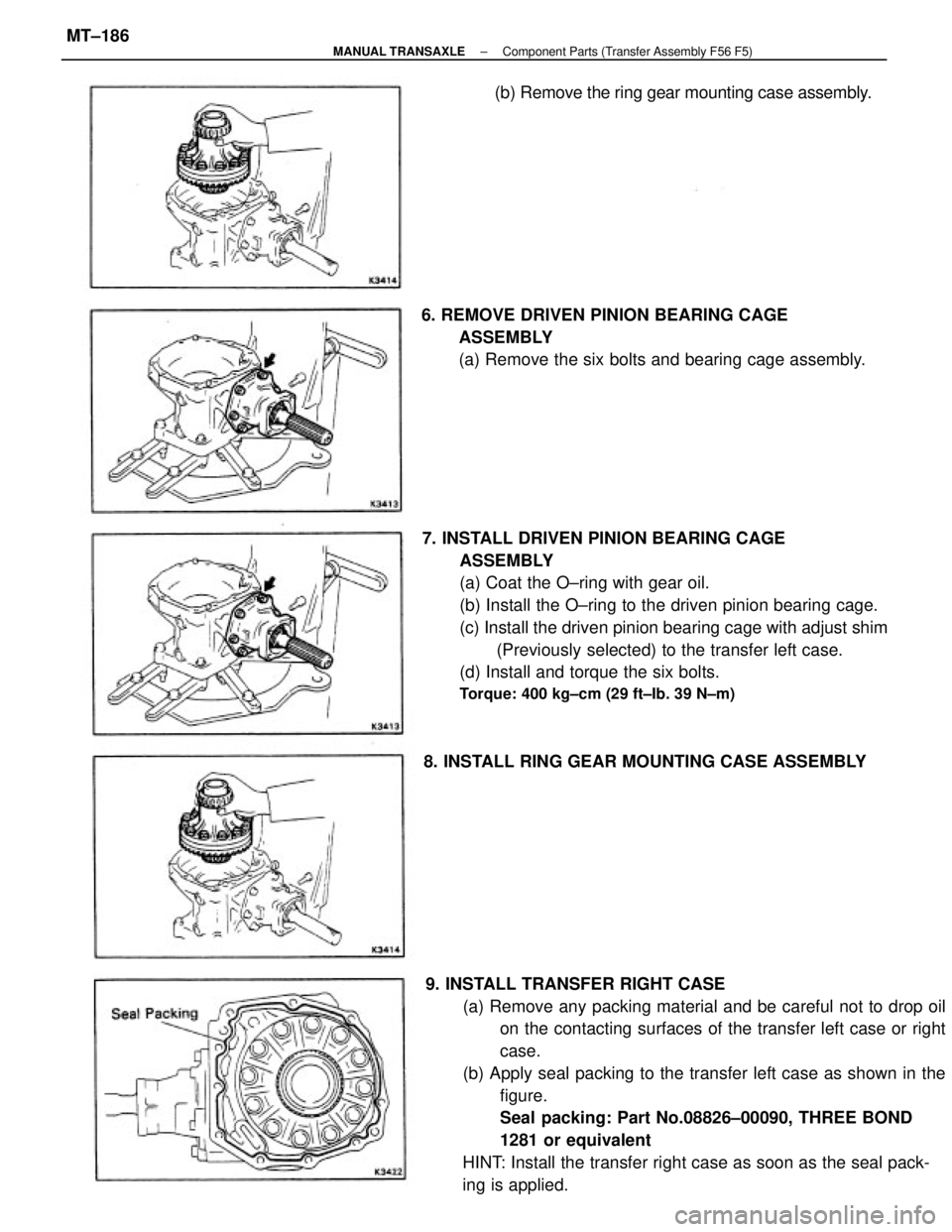

9. INSTALL TRANSFER RIGHT CASE

(a) Remove any packing material and be careful not to drop oil

on the contacting surfaces of the transfer left case or right

case.

(b) Apply seal packing to the transfer left case as shown in the

figure.

Seal packing: Part No.08826±00090, THREE BOND

1281 or equivalent

HINT: Install the transfer right case as soon as the seal pack-

ing is applied. 7. INSTALL DRIVEN PINION BEARING CAGE

ASSEMBLY

(a) Coat the O±ring with gear oil.

(b) Install the O±ring to the driven pinion bearing cage.

(c) Install the driven pinion bearing cage with adjust shim

(Previously selected) to the transfer left case.

(d) Install and torque the six bolts.

Torque: 400 kg±cm (29 ft±Ib. 39 N±m)

6. REMOVE DRIVEN PINION BEARING CAGE

ASSEMBLY

(a) Remove the six bolts and bearing cage assembly.

8. INSTALL RING GEAR MOUNTING CASE ASSEMBLY(b) Remove the ring gear mounting case assembly.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly F56 F5)MT±186

Page 2132 of 2389

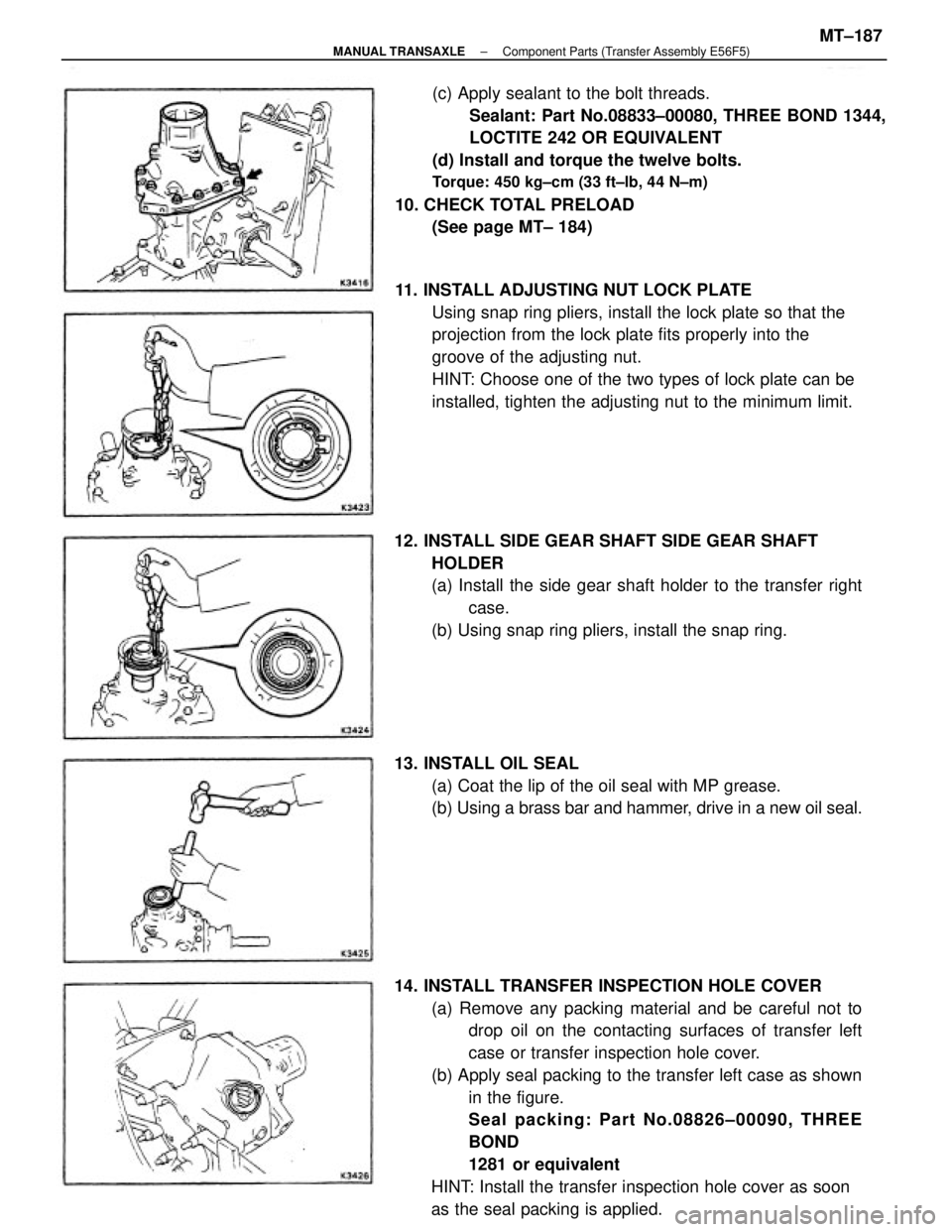

14. INSTALL TRANSFER INSPECTION HOLE COVER

(a) Remove any packing material and be careful not to

drop oil on the contacting surfaces of transfer left

case or transfer inspection hole cover.

(b) Apply seal packing to the transfer left case as shown

in the figure.

Seal packing: Part No.08826±00090, THREE

BOND

1281 or equivalent

HINT: Install the transfer inspection hole cover as soon

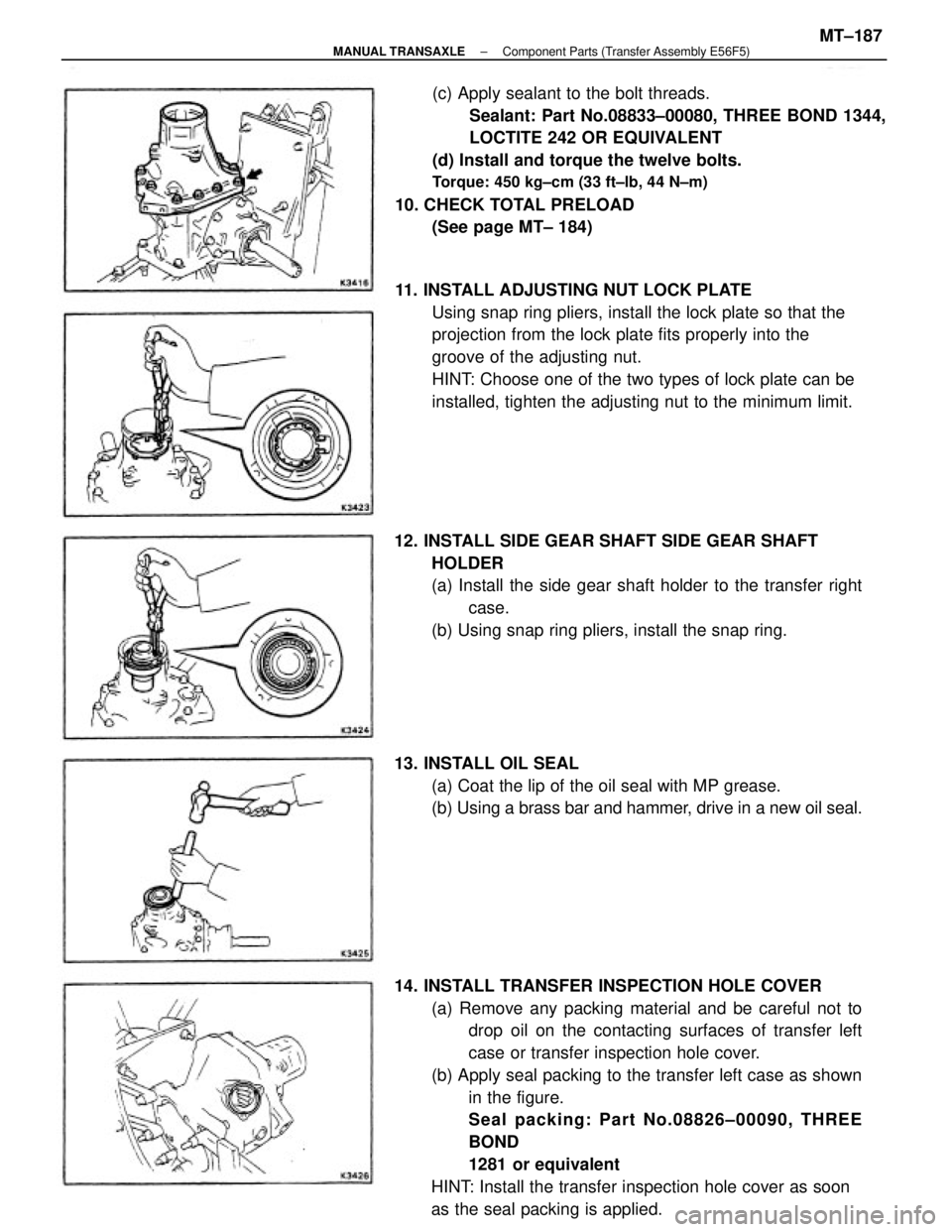

as the seal packing is applied.(c) Apply sealant to the bolt threads.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 OR EQUIVALENT

(d) Install and torque the twelve bolts.

Torque: 450 kg±cm (33 ft±lb, 44 N±m)

10. CHECK TOTAL PRELOAD

(See page MT± 184)

11. INSTALL ADJUSTING NUT LOCK PLATE

Using snap ring pliers, install the lock plate so that the

projection from the lock plate fits properly into the

groove of the adjusting nut.

HINT: Choose one of the two types of lock plate can be

installed, tighten the adjusting nut to the minimum limit.

12. INSTALL SIDE GEAR SHAFT SIDE GEAR SHAFT

HOLDER

(a) Install the side gear shaft holder to the transfer right

case.

(b) Using snap ring pliers, install the snap ring.

13. INSTALL OIL SEAL

(a) Coat the lip of the oil seal with MP grease.

(b) Using a brass bar and hammer, drive in a new oil seal.

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±187

Page 2133 of 2389

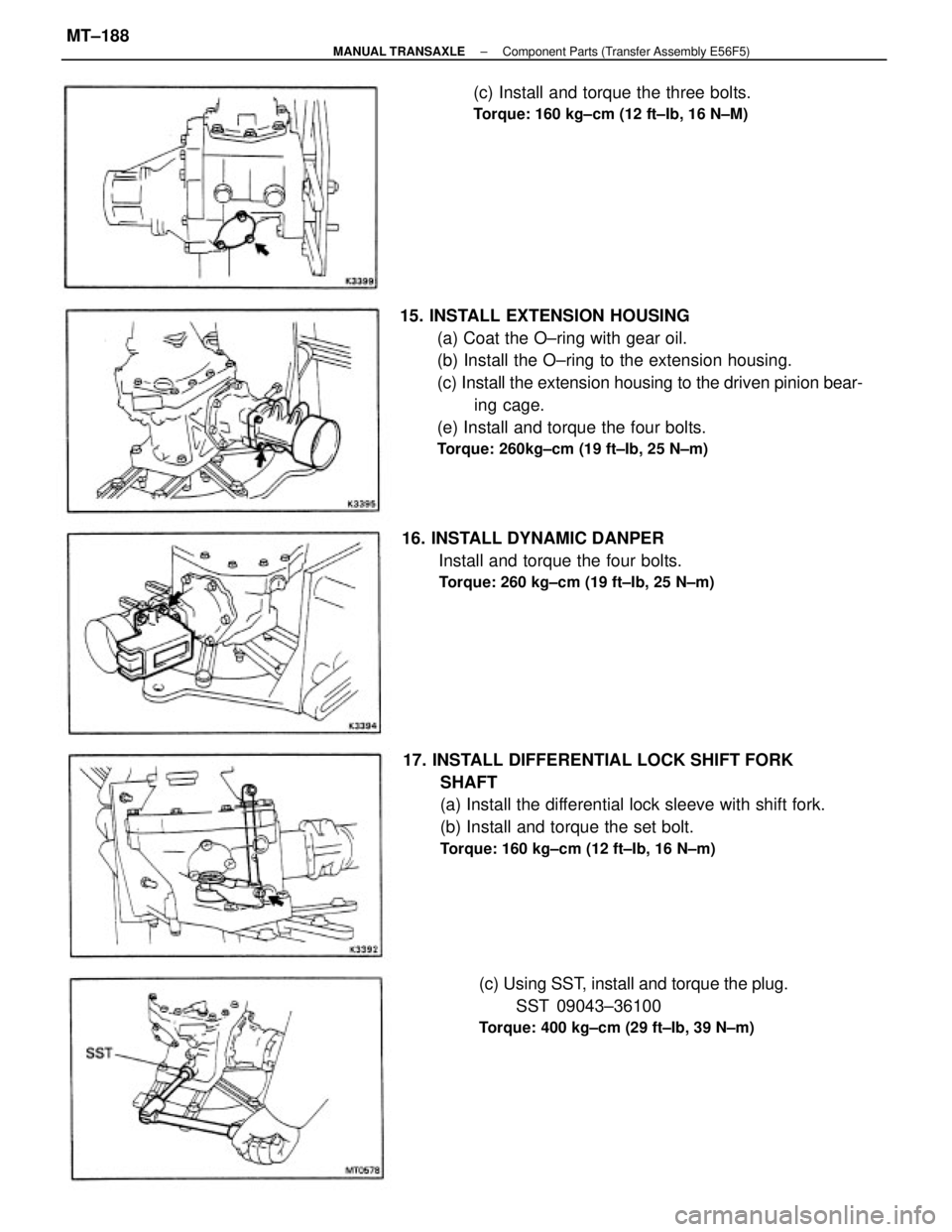

15. INSTALL EXTENSION HOUSING

(a) Coat the O±ring with gear oil.

(b) Install the O±ring to the extension housing.

(c) Install the extension housing to the driven pinion bear-

ing cage.

(e) Install and torque the four bolts.

Torque: 260kg±cm (19 ft±Ib, 25 N±m)

17. INSTALL DIFFERENTIAL LOCK SHIFT FORK

SHAFT

(a) Install the differential lock sleeve with shift fork.

(b) Install and torque the set bolt.

Torque: 160 kg±cm (12 ft±Ib, 16 N±m)

16. INSTALL DYNAMIC DANPER

Install and torque the four bolts.

Torque: 260 kg±cm (19 ft±Ib, 25 N±m)

(c) Using SST, install and torque the plug.

SST 09043±36100

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(c) Install and torque the three bolts.

Torque: 160 kg±cm (12 ft±Ib, 16 N±M)

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±188

Page 2134 of 2389

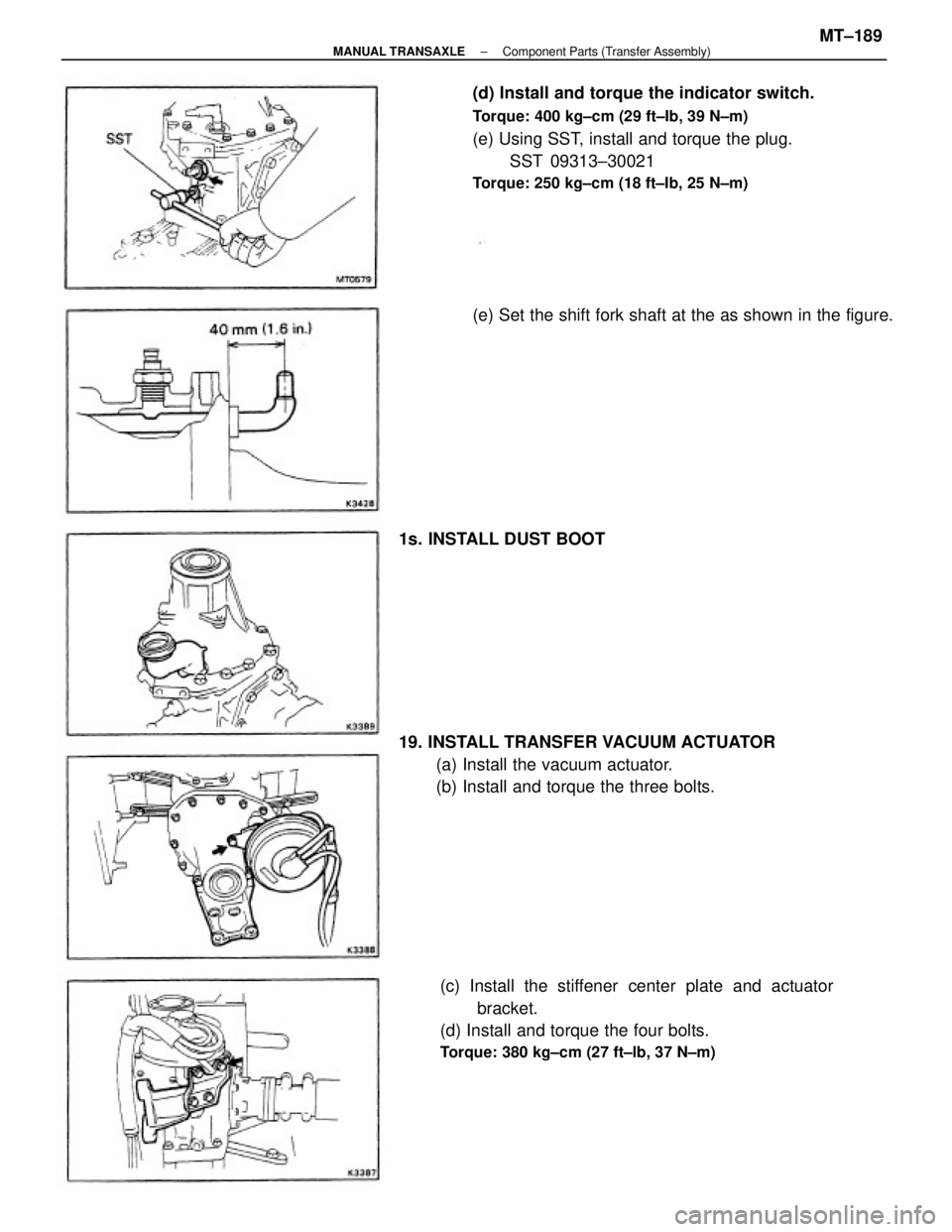

19. INSTALL TRANSFER VACUUM ACTUATOR

(a) Install the vacuum actuator.

(b) Install and torque the three bolts.(d) Install and torque the indicator switch.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(e) Using SST, install and torque the plug.

SST 09313±30021

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

(c) Install the stiffener center plate and actuator

bracket.

(d) Install and torque the four bolts.

Torque: 380 kg±cm (27 ft±lb, 37 N±m)

(e) Set the shift fork shaft at the as shown in the figure.

1s. INSTALL DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly)MT±189

Page 2135 of 2389

PROPELLER SHAFT

PROPELLER SHAFTPR±1

Page 2136 of 2389

Propeller and intermediate shafts runout

Propeller shafts imbalance

Front flange runout

Rear flange runout

Cross groove joint stuck or damaged

Transfer extension housing rear

bushing worn

Sleeve yoke spline stuck

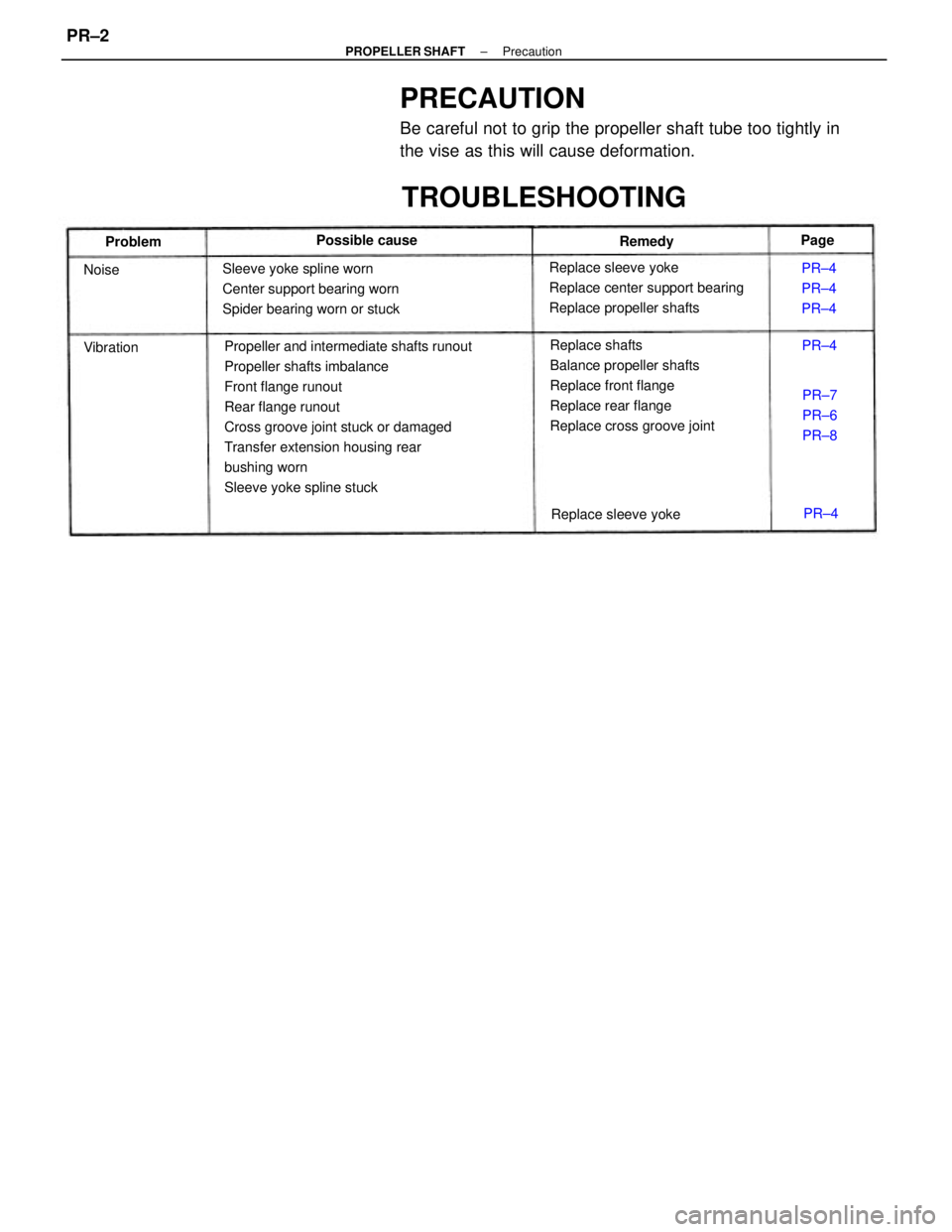

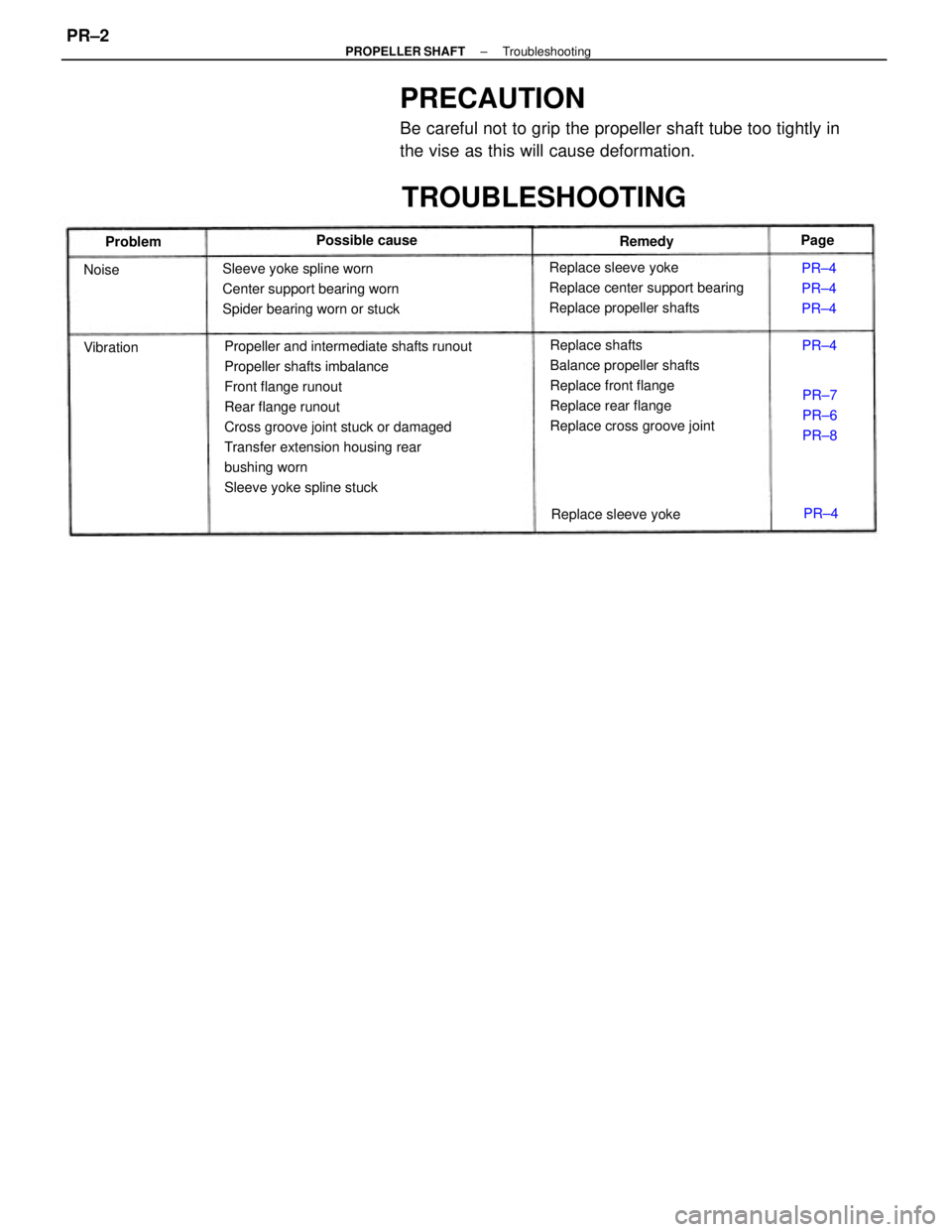

PRECAUTION

Be careful not to grip the propeller shaft tube too tightly in

the vise as this will cause deformation.

Replace shafts

Balance propeller shafts

Replace front flange

Replace rear flange

Replace cross groove joint Replace sleeve yoke

Replace center support bearing

Replace propeller shafts Sleeve yoke spline worn

Center support bearing worn

Spider bearing worn or stuck

TROUBLESHOOTING

Replace sleeve yokePR±4

PR±4

PR±4

PR±7

PR±6

PR±8 Possible cause

VibrationProblemRemedy

NoisePage

PR±4

PR±4

± PROPELLER SHAFTPrecautionPR±2

Page 2137 of 2389

Propeller and intermediate shafts runout

Propeller shafts imbalance

Front flange runout

Rear flange runout

Cross groove joint stuck or damaged

Transfer extension housing rear

bushing worn

Sleeve yoke spline stuck

PRECAUTION

Be careful not to grip the propeller shaft tube too tightly in

the vise as this will cause deformation.

Replace shafts

Balance propeller shafts

Replace front flange

Replace rear flange

Replace cross groove joint Replace sleeve yoke

Replace center support bearing

Replace propeller shafts Sleeve yoke spline worn

Center support bearing worn

Spider bearing worn or stuck

TROUBLESHOOTING

Replace sleeve yokePR±4

PR±4

PR±4

PR±7

PR±6

PR±8 Possible cause

VibrationProblemRemedy

NoisePage

PR±4

PR±4

± PROPELLER SHAFTTroubleshootingPR±2

Page 2138 of 2389

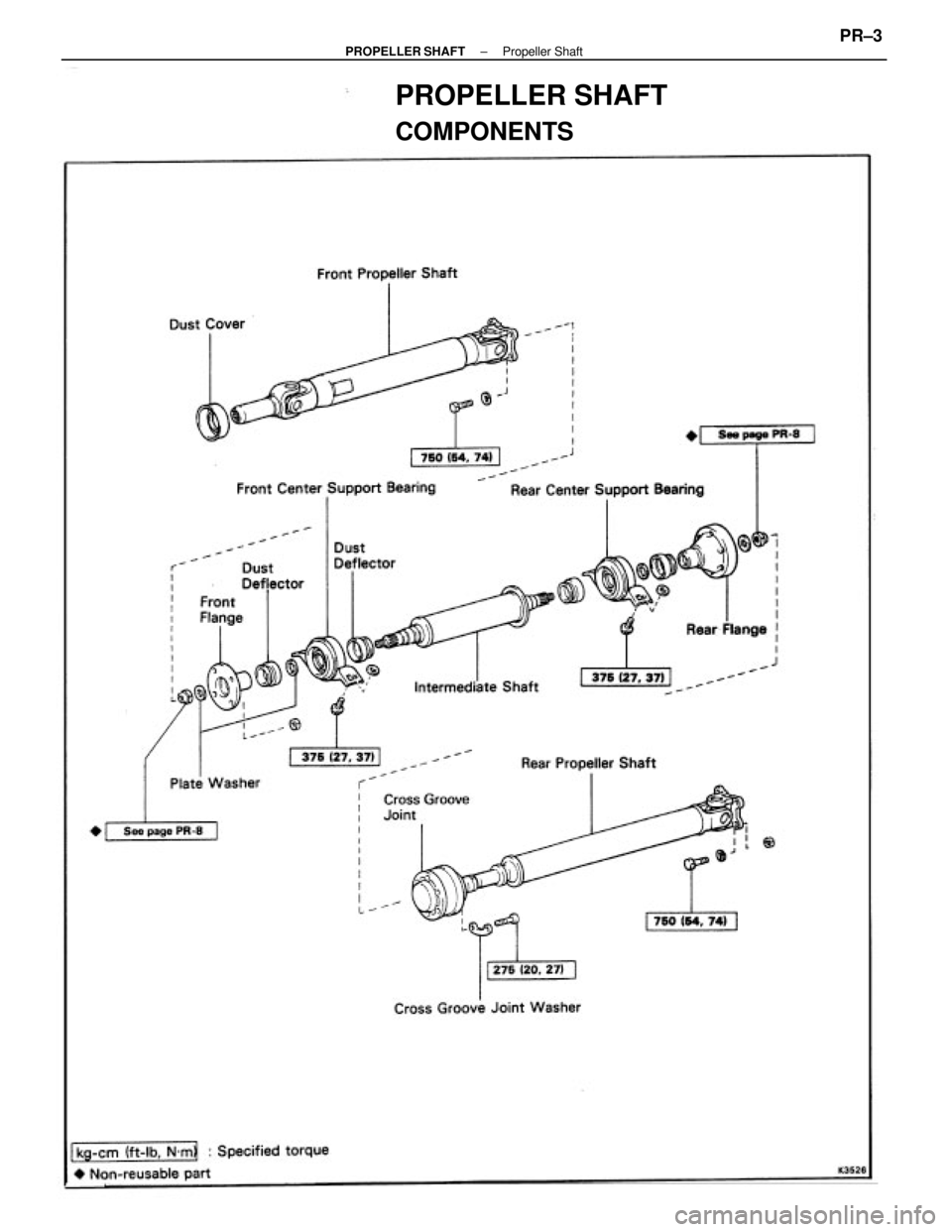

PROPELLER SHAFT

COMPONENTS

± PROPELLER SHAFTPropeller ShaftPR±3

Page 2139 of 2389

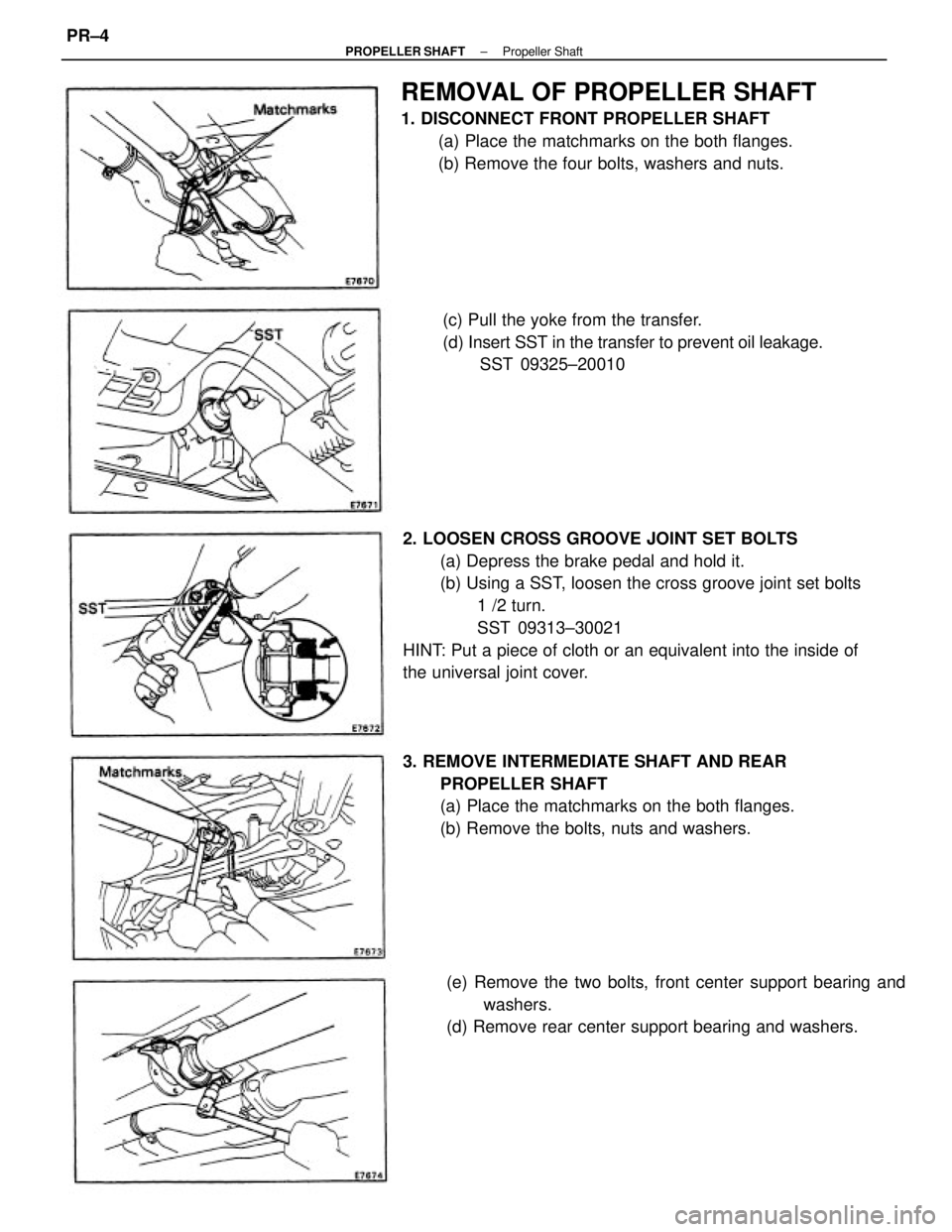

2. LOOSEN CROSS GROOVE JOINT SET BOLTS

(a) Depress the brake pedal and hold it.

(b) Using a SST, loosen the cross groove joint set bolts

1 /2 turn.

SST 09313±30021

HINT: Put a piece of cloth or an equivalent into the inside of

the universal joint cover.

REMOVAL OF PROPELLER SHAFT

1. DISCONNECT FRONT PROPELLER SHAFT

(a) Place the matchmarks on the both flanges.

(b) Remove the four bolts, washers and nuts.

3. REMOVE INTERMEDIATE SHAFT AND REAR

PROPELLER SHAFT

(a) Place the matchmarks on the both flanges.

(b) Remove the bolts, nuts and washers.

(e) Remove the two bolts, front center support bearing and

washers.

(d) Remove rear center support bearing and washers. (c) Pull the yoke from the transfer.

(d) Insert SST in the transfer to prevent oil leakage.

SST 09325±20010

± PROPELLER SHAFTPropeller ShaftPR±4

Page 2140 of 2389

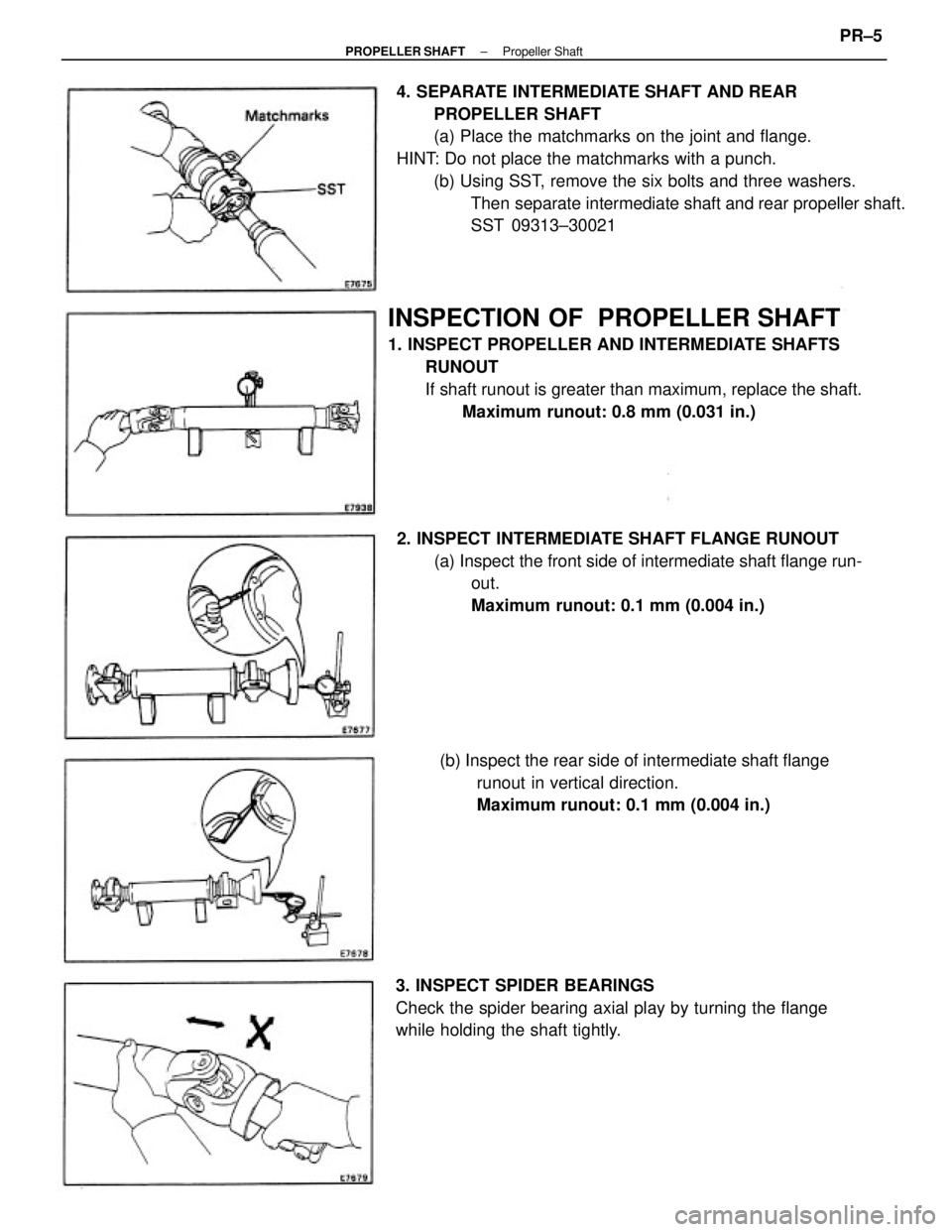

4. SEPARATE INTERMEDIATE SHAFT AND REAR

PROPELLER SHAFT

(a) Place the matchmarks on the joint and flange.

HINT: Do not place the matchmarks with a punch.

(b) Using SST, remove the six bolts and three washers.

Then separate intermediate shaft and rear propeller shaft.

SST 09313±30021

INSPECTION OF PROPELLER SHAFT

1. INSPECT PROPELLER AND INTERMEDIATE SHAFTS

RUNOUT

If shaft runout is greater than maximum, replace the shaft.

Maximum runout: 0.8 mm (0.031 in.)

2. INSPECT INTERMEDIATE SHAFT FLANGE RUNOUT

(a) Inspect the front side of intermediate shaft flange run-

out.

Maximum runout: 0.1 mm (0.004 in.)

(b) Inspect the rear side of intermediate shaft flange

runout in vertical direction.

Maximum runout: 0.1 mm (0.004 in.)

3. INSPECT SPIDER BEARINGS

Check the spider bearing axial play by turning the flange

while holding the shaft tightly.

± PROPELLER SHAFTPropeller ShaftPR±5

Trending: roof, check transmission fluid, clock reset, fuel cap, parking brake, trunk, open hood