TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: ground clearance, washer fluid, brakes, AUX, length, transmission oil, fold seats

Page 2081 of 2389

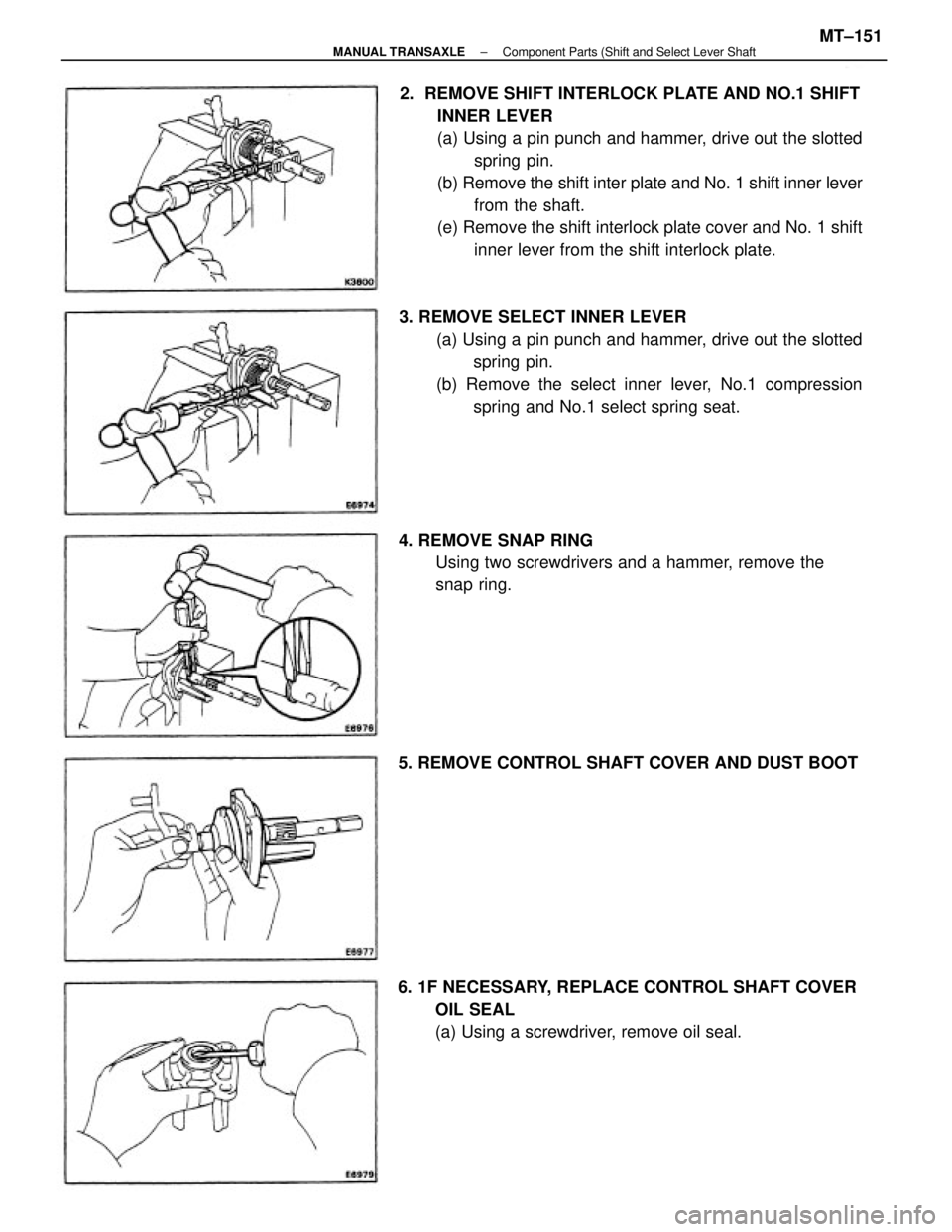

2. REMOVE SHIFT INTERLOCK PLATE AND NO.1 SHIFT

INNER LEVER

(a) Using a pin punch and hammer, drive out the slotted

spring pin.

(b) Remove the shift inter plate and No. 1 shift inner lever

from the shaft.

(e) Remove the shift interlock plate cover and No. 1 shift

inner lever from the shift interlock plate.

3. REMOVE SELECT INNER LEVER

(a) Using a pin punch and hammer, drive out the slotted

spring pin.

(b) Remove the select inner lever, No.1 compression

spring and No.1 select spring seat.

6. 1F NECESSARY, REPLACE CONTROL SHAFT COVER

OIL SEAL

(a) Using a screwdriver, remove oil seal. 4. REMOVE SNAP RING

Using two screwdrivers and a hammer, remove the

snap ring.

5. REMOVE CONTROL SHAFT COVER AND DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever ShaftMT±151

Page 2082 of 2389

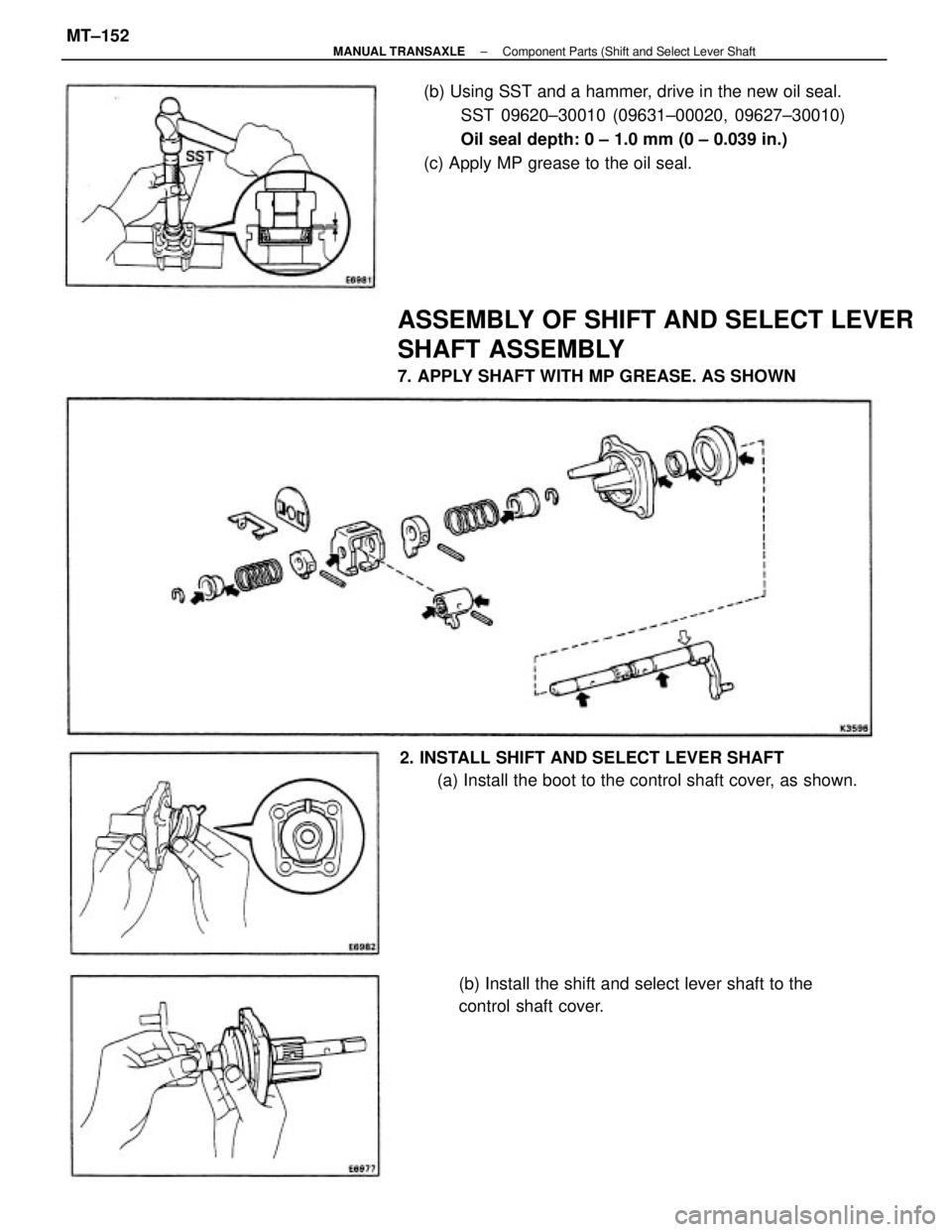

(b) Using SST and a hammer, drive in the new oil seal.

SST 09620±30010 (09631±00020, 09627±30010)

Oil seal depth: 0 ± 1.0 mm (0 ± 0.039 in.)

(c) Apply MP grease to the oil seal.

ASSEMBLY OF SHIFT AND SELECT LEVER

SHAFT ASSEMBLY

7. APPLY SHAFT WITH MP GREASE. AS SHOWN

2. INSTALL SHIFT AND SELECT LEVER SHAFT

(a) Install the boot to the control shaft cover, as shown.

(b) Install the shift and select lever shaft to the

control shaft cover.

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever ShaftMT±152

Page 2083 of 2389

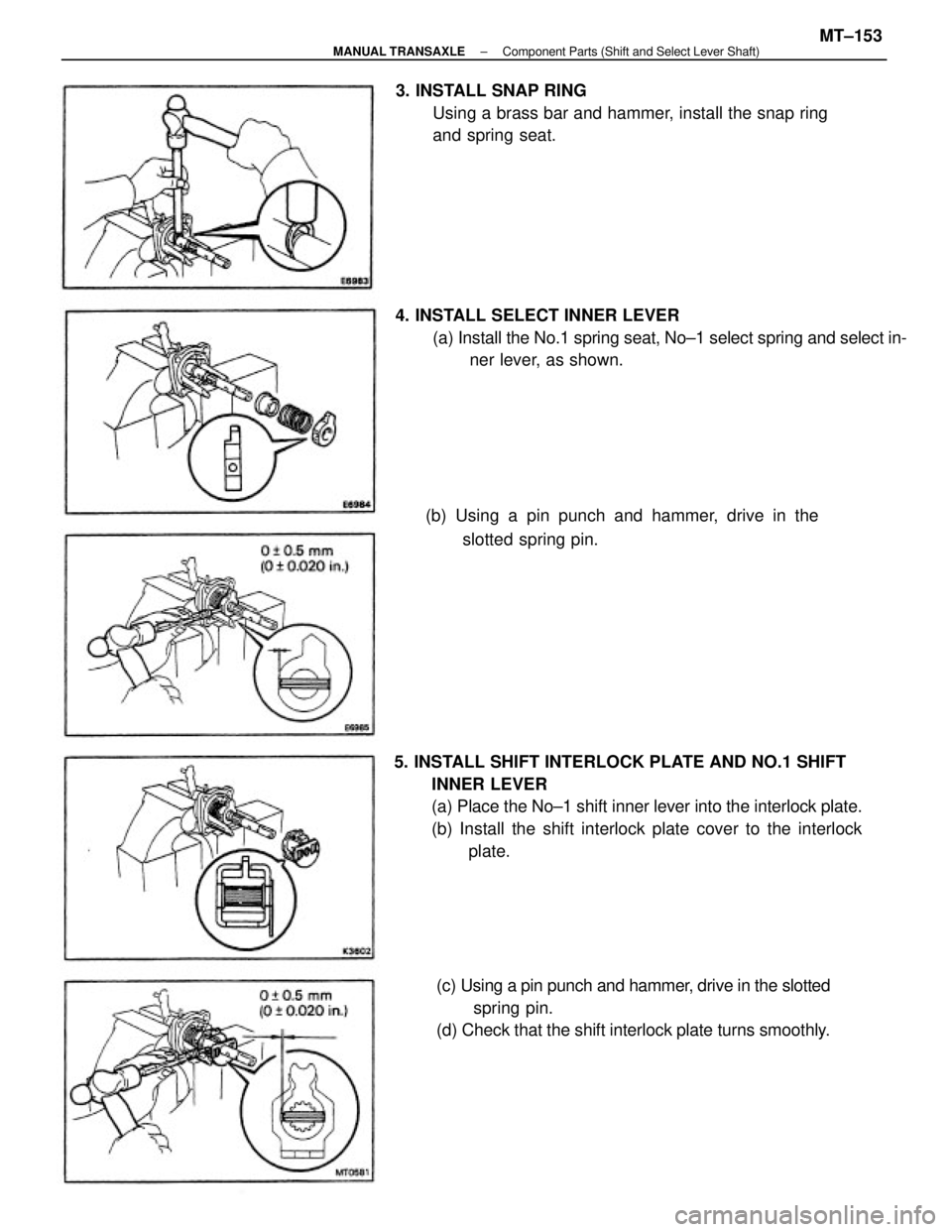

5. INSTALL SHIFT INTERLOCK PLATE AND NO.1 SHIFT

INNER LEVER

(a) Place the No±1 shift inner lever into the interlock plate.

(b) Install the shift interlock plate cover to the interlock

plate. 3. INSTALL SNAP RING

Using a brass bar and hammer, install the snap ring

and spring seat.

4. INSTALL SELECT INNER LEVER

(a) Install the No.1 spring seat, No±1 select spring and select in-

ner lever, as shown.

(c) Using a pin punch and hammer, drive in the slotted

spring pin.

(d) Check that the shift interlock plate turns smoothly. (b) Using a pin punch and hammer, drive in the

slotted spring pin.

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever Shaft)MT±153

Page 2084 of 2389

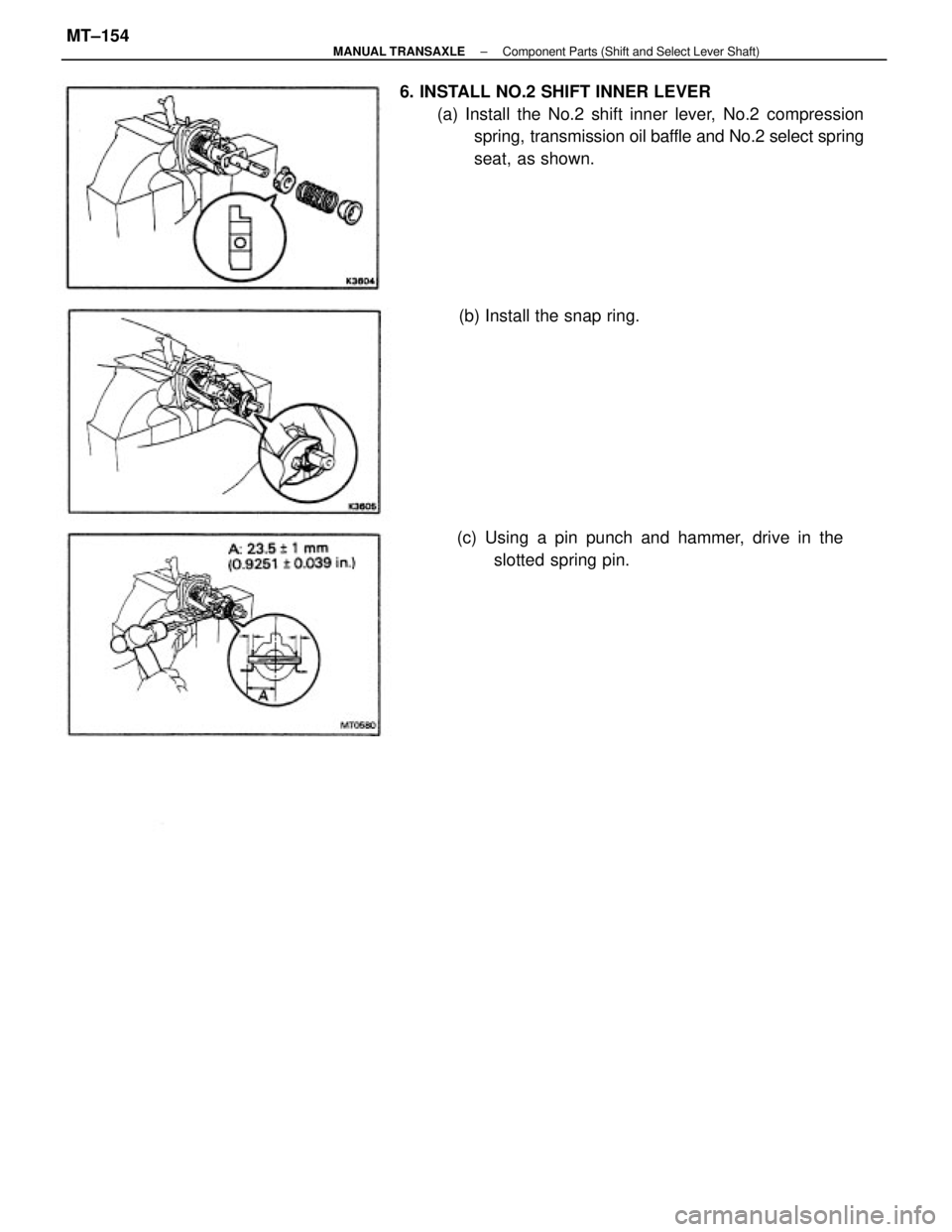

6. INSTALL NO.2 SHIFT INNER LEVER

(a) Install the No.2 shift inner lever, No.2 compression

spring, transmission oil baffle and No.2 select spring

seat, as shown.

(c) Using a pin punch and hammer, drive in the

slotted spring pin. (b) Install the snap ring.

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever Shaft)MT±154

Page 2085 of 2389

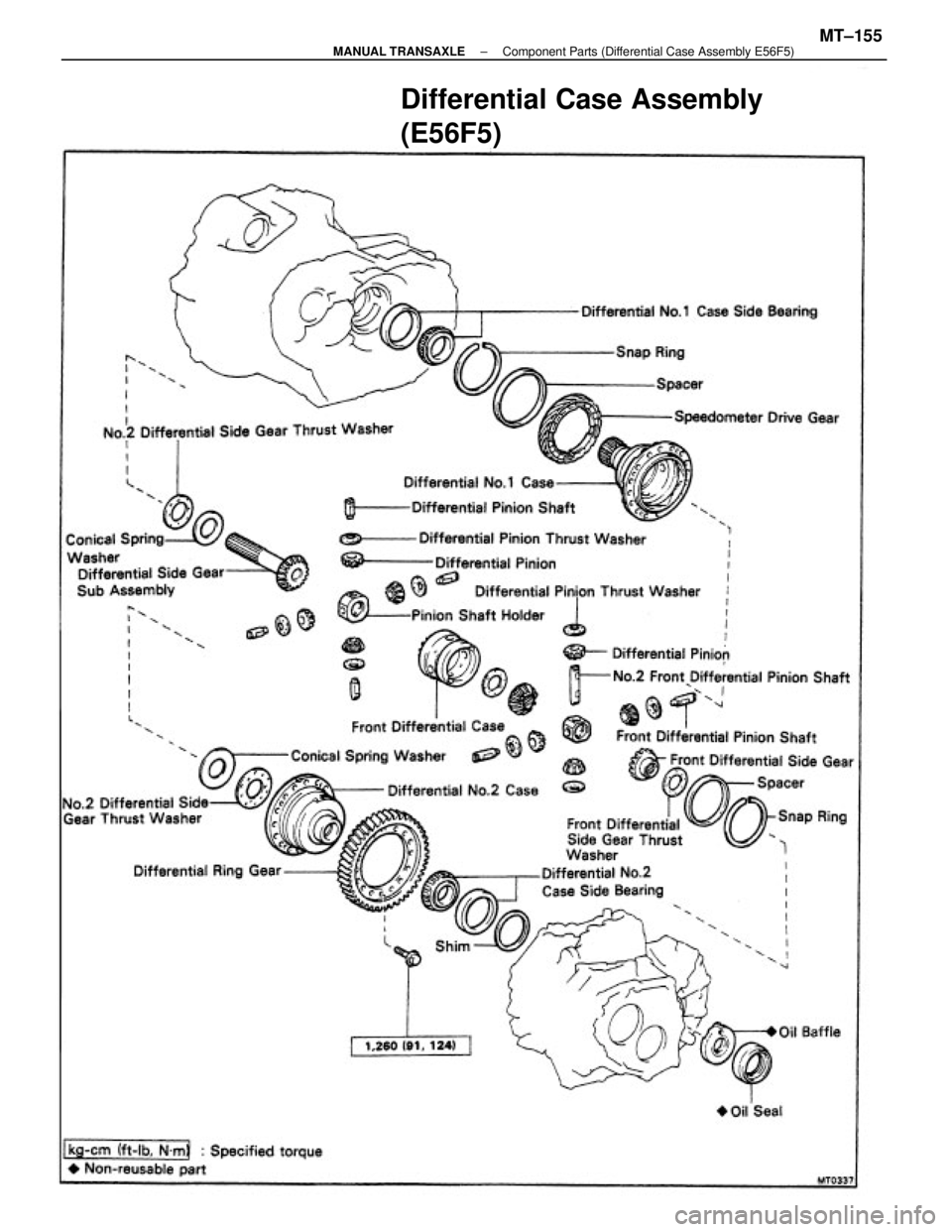

Differential Case Assembly

(E56F5)

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E56F5)MT±155

Page 2086 of 2389

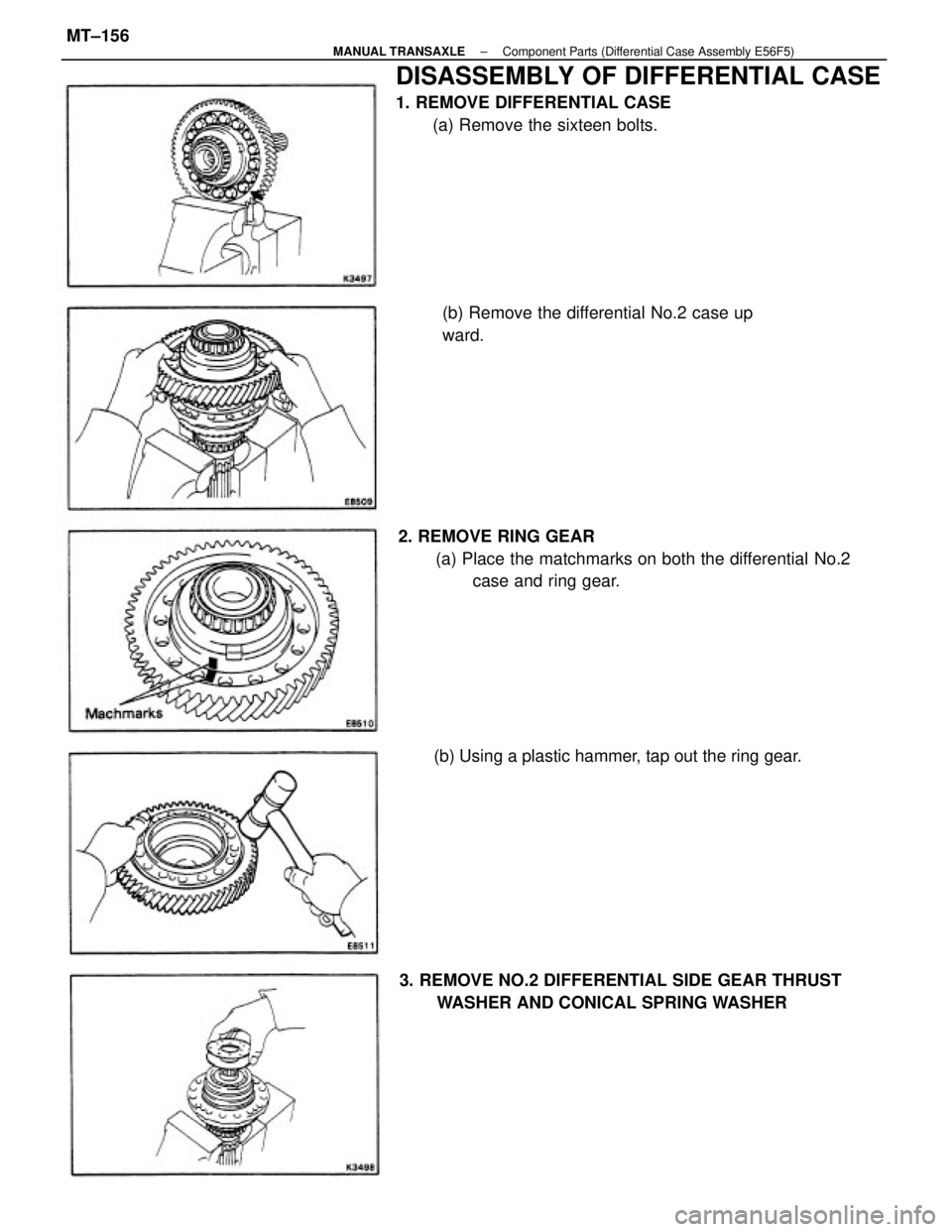

DISASSEMBLY OF DIFFERENTIAL CASE

1. REMOVE DIFFERENTIAL CASE

(a) Remove the sixteen bolts.

2. REMOVE RING GEAR

(a) Place the matchmarks on both the differential No.2

case and ring gear.

(b) Using a plastic hammer, tap out the ring gear.

3. REMOVE NO.2 DIFFERENTIAL SIDE GEAR THRUST

WASHER AND CONICAL SPRING WASHER(b) Remove the differential No.2 case up

ward.

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E56F5)MT±156

Page 2087 of 2389

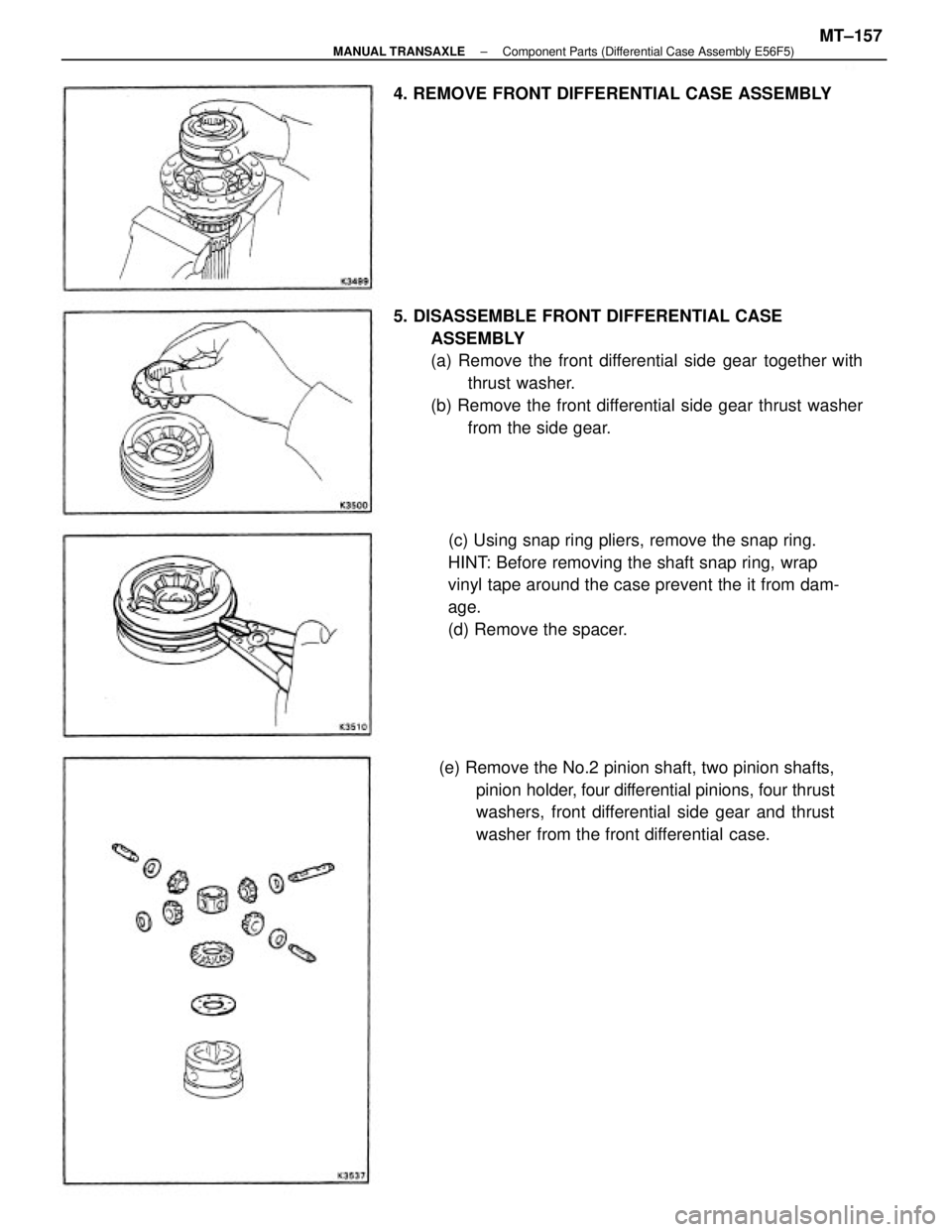

5. DISASSEMBLE FRONT DIFFERENTIAL CASE

ASSEMBLY

(a) Remove the front differential side gear together with

thrust washer.

(b) Remove the front differential side gear thrust washer

from the side gear.

(c) Using snap ring pliers, remove the snap ring.

HINT: Before removing the shaft snap ring, wrap

vinyl tape around the case prevent the it from dam-

age.

(d) Remove the spacer.

(e) Remove the No.2 pinion shaft, two pinion shafts,

pinion holder, four differential pinions, four thrust

washers, front differential side gear and thrust

washer from the front differential case. 4. REMOVE FRONT DIFFERENTIAL CASE ASSEMBLY

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E56F5)MT±157

Page 2088 of 2389

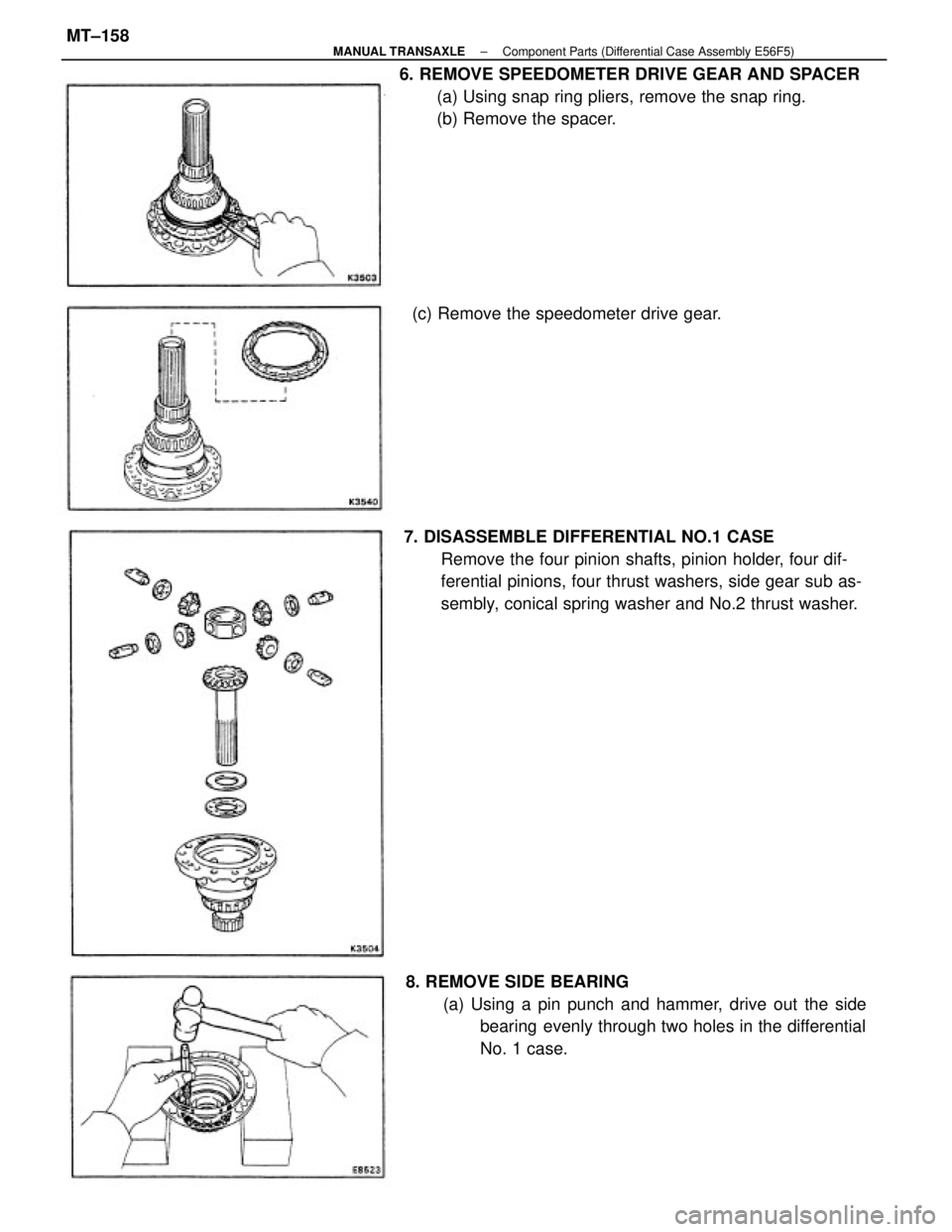

6. REMOVE SPEEDOMETER DRIVE GEAR AND SPACER

(a) Using snap ring pliers, remove the snap ring.

(b) Remove the spacer.

7. DISASSEMBLE DIFFERENTIAL NO.1 CASE

Remove the four pinion shafts, pinion holder, four dif-

ferential pinions, four thrust washers, side gear sub as-

sembly, conical spring washer and No.2 thrust washer.

8. REMOVE SIDE BEARING

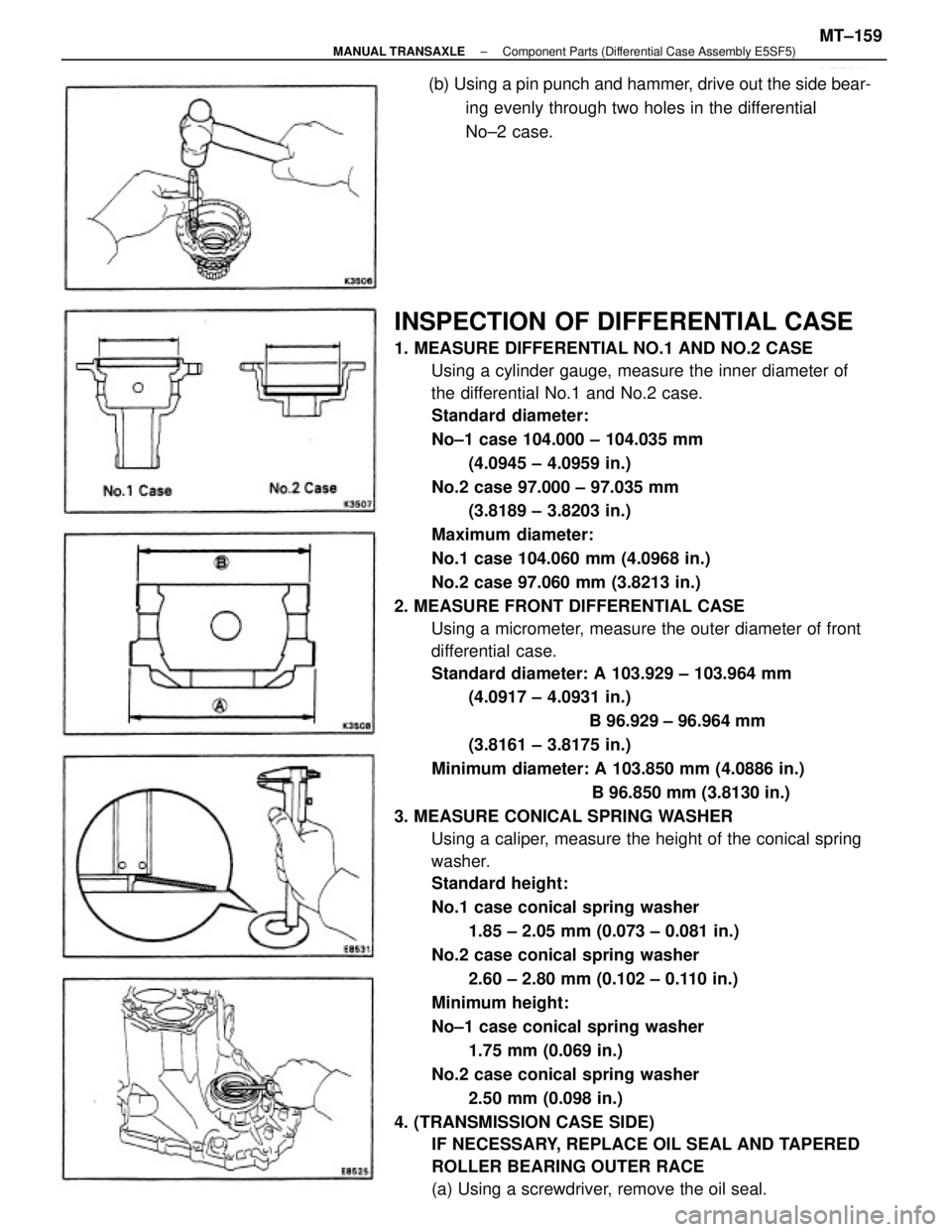

(a) Using a pin punch and hammer, drive out the side

bearing evenly through two holes in the differential

No. 1 case. (c) Remove the speedometer drive gear.

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E56F5)MT±158

Page 2089 of 2389

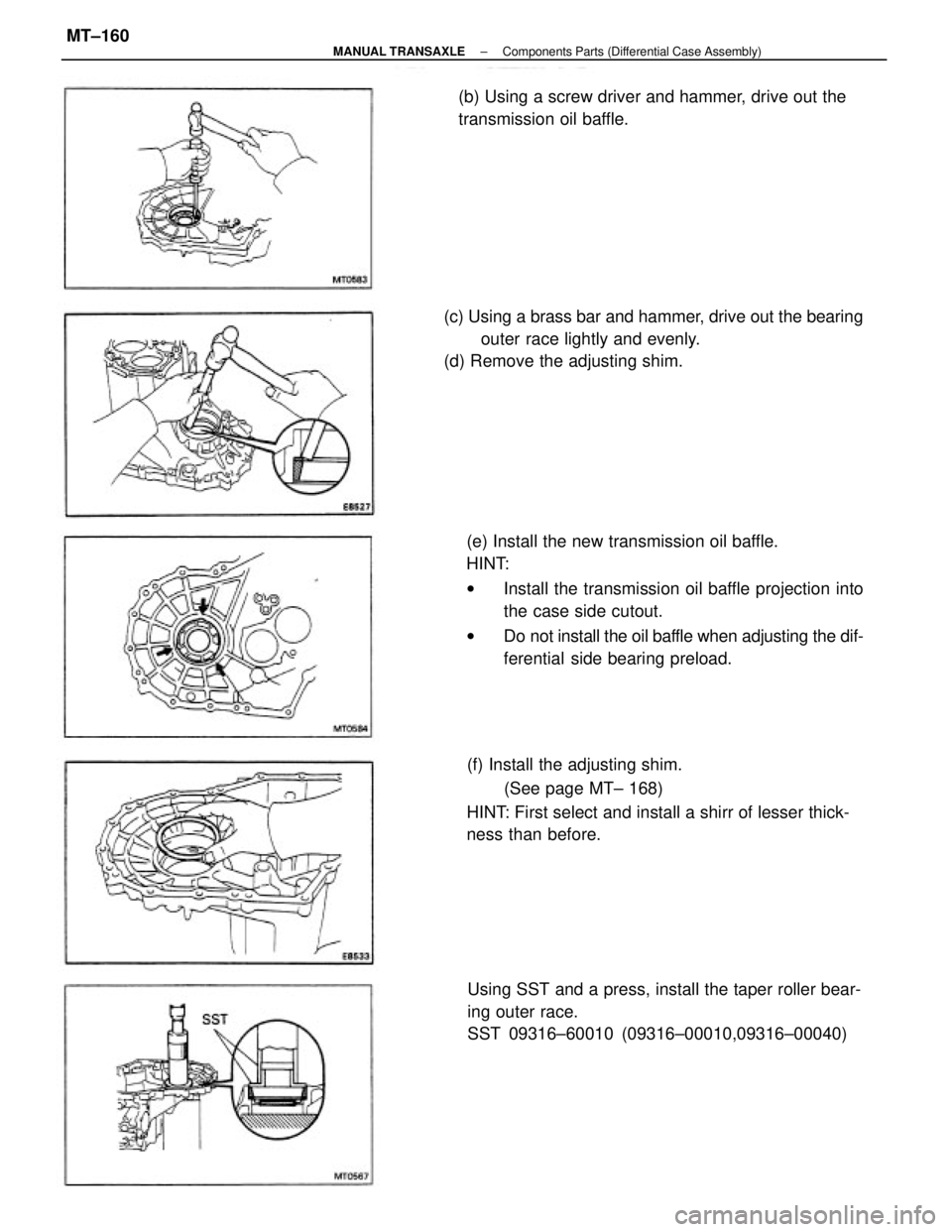

INSPECTION OF DIFFERENTIAL CASE

1. MEASURE DIFFERENTIAL NO.1 AND NO.2 CASE

Using a cylinder gauge, measure the inner diameter of

the differential No.1 and No.2 case.

Standard diameter:

No±1 case 104.000 ± 104.035 mm

(4.0945 ± 4.0959 in.)

No.2 case 97.000 ± 97.035 mm

(3.8189 ± 3.8203 in.)

Maximum diameter:

No.1 case 104.060 mm (4.0968 in.)

No.2 case 97.060 mm (3.8213 in.)

2. MEASURE FRONT DIFFERENTIAL CASE

Using a micrometer, measure the outer diameter of front

differential case.

Standard diameter: A 103.929 ± 103.964 mm

(4.0917 ± 4.0931 in.)

B 96.929 ± 96.964 mm

(3.8161 ± 3.8175 in.)

Minimum diameter: A 103.850 mm (4.0886 in.)

B 96.850 mm (3.8130 in.)

3. MEASURE CONICAL SPRING WASHER

Using a caliper, measure the height of the conical spring

washer.

Standard height:

No.1 case conical spring washer

1.85 ± 2.05 mm (0.073 ± 0.081 in.)

No.2 case conical spring washer

2.60 ± 2.80 mm (0.102 ± 0.110 in.)

Minimum height:

No±1 case conical spring washer

1.75 mm (0.069 in.)

No.2 case conical spring washer

2.50 mm (0.098 in.)

4. (TRANSMISSION CASE SIDE)

IF NECESSARY, REPLACE OIL SEAL AND TAPERED

ROLLER BEARING OUTER RACE

(a) Using a screwdriver, remove the oil seal. (b) Using a pin punch and hammer, drive out the side bear-

ing evenly through two holes in the differential

No±2 case.

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E5SF5)MT±159

Page 2090 of 2389

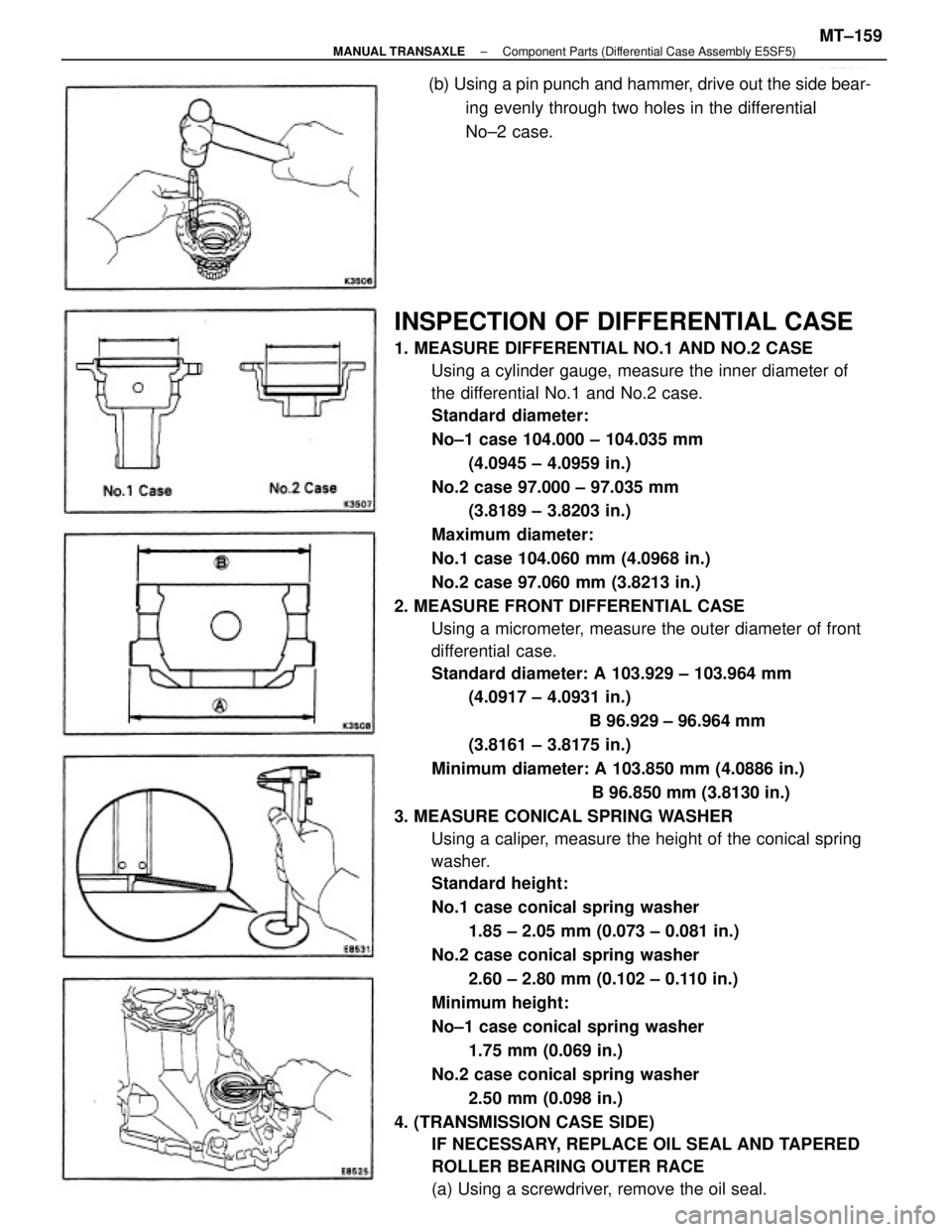

(e) Install the new transmission oil baffle.

HINT:

wInstall the transmission oil baffle projection into

the case side cutout.

wDo not install the oil baffle when adjusting the dif-

ferential side bearing preload.

(f) Install the adjusting shim.

(See page MT± 168)

HINT: First select and install a shirr of lesser thick-

ness than before. (c) Using a brass bar and hammer, drive out the bearing

outer race lightly and evenly.

(d) Remove the adjusting shim.

Using SST and a press, install the taper roller bear-

ing outer race.

SST 09316±60010 (09316±00010,09316±00040) (b) Using a screw driver and hammer, drive out the

transmission oil baffle.

± MANUAL TRANSAXLEComponents Parts (Differential Case Assembly)MT±160

Trending: alternator, parking sensors, width, catalytic converter, wheel alignment, Jack, tow