TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 211 of 2389

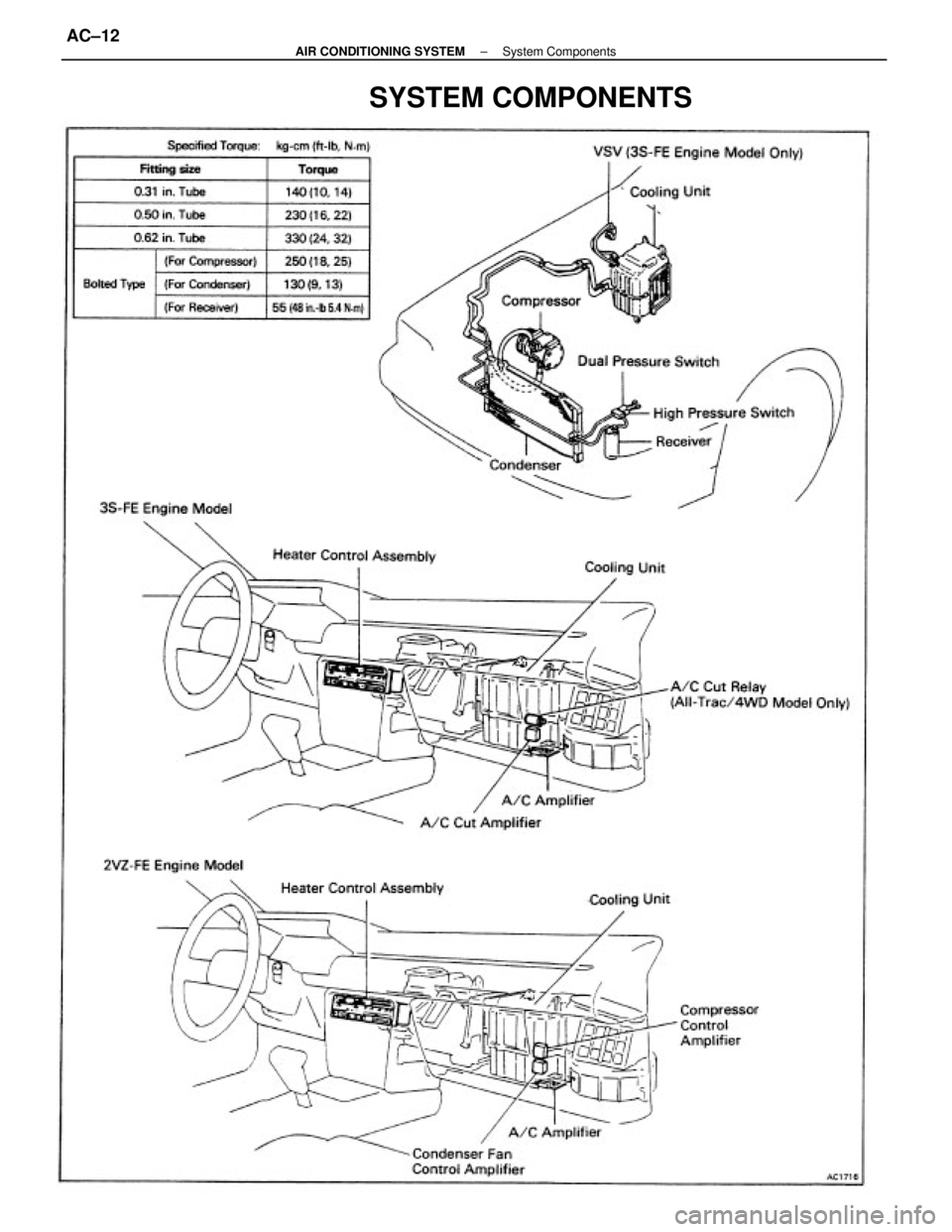

SYSTEM COMPONENTS

± AIR CONDITIONING SYSTEMSystem ComponentsAC±12

Page 212 of 2389

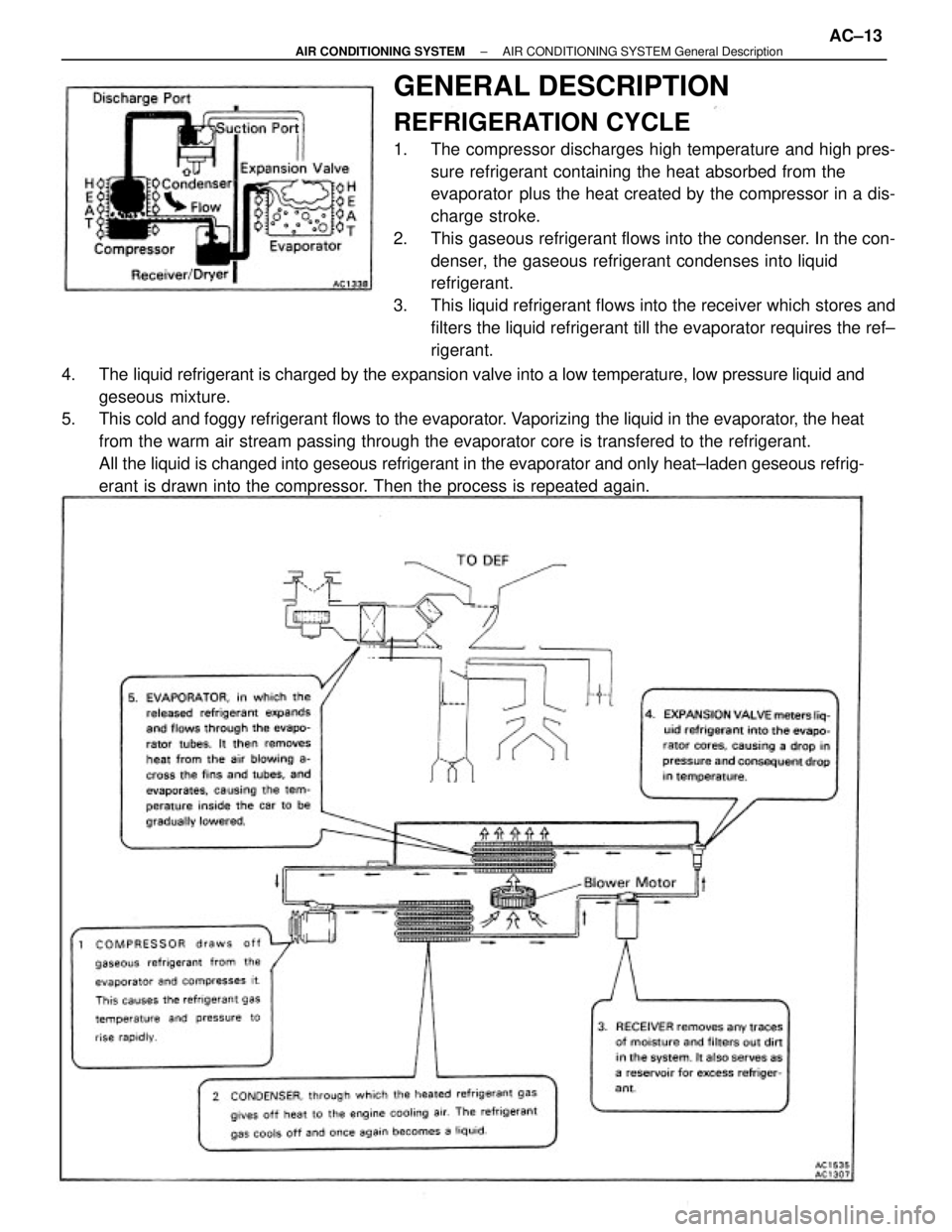

4. The liquid refrigerant is charged by the expansion valve into a low temperature, low pressure liquid and

geseous mixture.

5. This cold and foggy refrigerant flows to the evaporator. Vaporizing the liquid in the evaporator, the heat

from the warm air stream passing through the evaporator core is transfered to the refrigerant.

All the liquid is changed into geseous refrigerant in the evaporator and only heat±laden geseous refrig-

erant is drawn into the compressor. Then the process is repeated again.

GENERAL DESCRIPTION

REFRIGERATION CYCLE

1. The compressor discharges high temperature and high pres-

sure refrigerant containing the heat absorbed from the

evaporator plus the heat created by the compressor in a dis-

charge stroke.

2. This gaseous refrigerant flows into the condenser. In the con-

denser, the gaseous refrigerant condenses into liquid

refrigerant.

3. This liquid refrigerant flows into the receiver which stores and

filters the liquid refrigerant till the evaporator requires the ref±

rigerant.

± AIR CONDITIONING SYSTEMAIR CONDITIONING SYSTEM General DescriptionAC±13

Page 213 of 2389

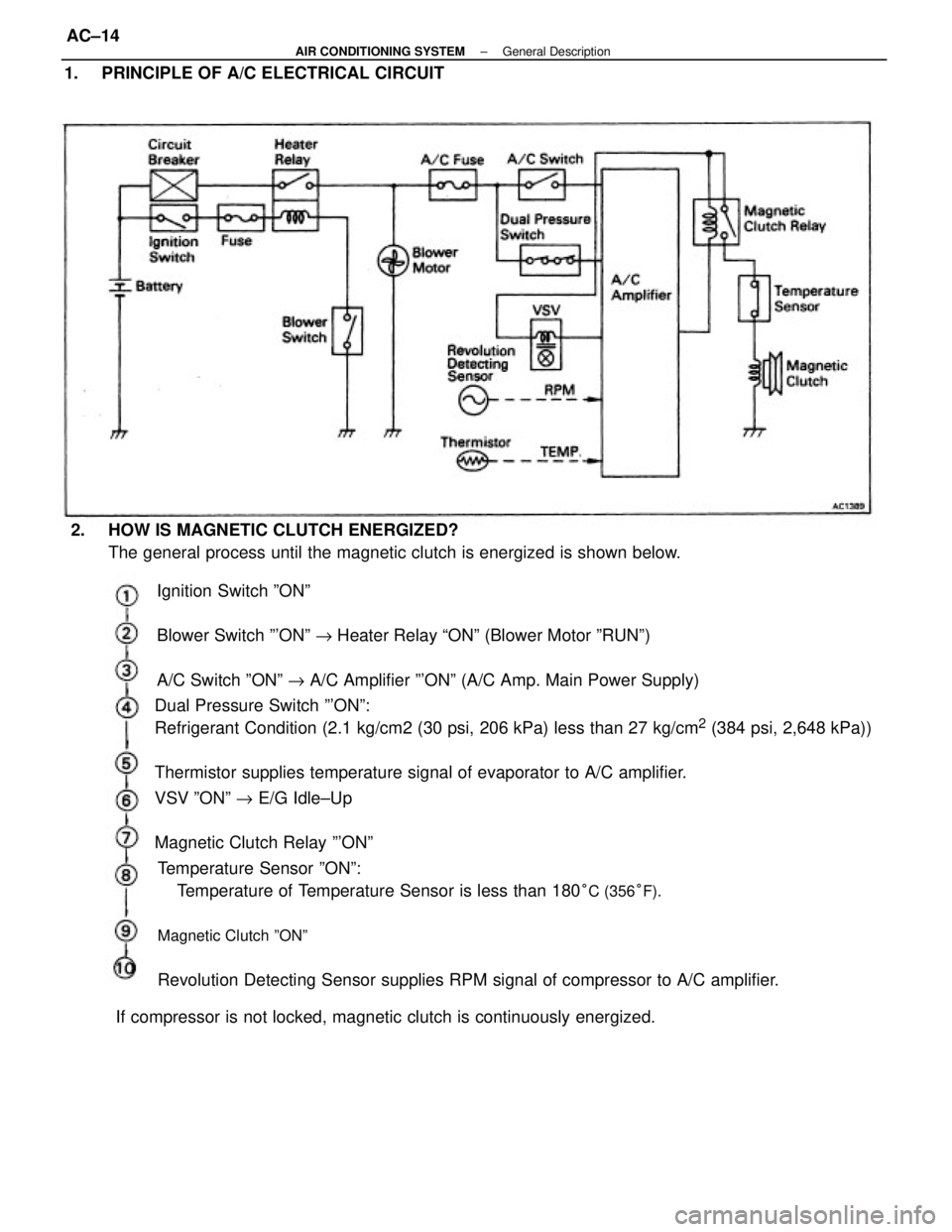

Ignition Switch ºONº

Blower Switch º'ONº " Heater Relay ªONº (Blower Motor ºRUNº)

A/C Switch ºONº " A/C Amplifier º'ONº (A/C Amp. Main Power Supply) 1. PRINCIPLE OF A/C ELECTRICAL CIRCUIT

2. HOW IS MAGNETIC CLUTCH ENERGIZED?

The general process until the magnetic clutch is energized is shown below.

Dual Pressure Switch º'ONº:

Refrigerant Condition (2.1 kg/cm2 (30 psi, 206 kPa) less than 27 kg/cm

2 (384 psi, 2,648 kPa))

Thermistor supplies temperature signal of evaporator to A/C amplifier.

VSV ºONº " E/G Idle±Up

Magnetic Clutch Relay º'ONº

Temperature Sensor ºONº:

Temperature of Temperature Sensor is less than 180

°C (356°F).

Magnetic Clutch ºONº

Revolution Detecting Sensor supplies RPM signal of compressor to A/C amplifier.

If compressor is not locked, magnetic clutch is continuously energized.

± AIR CONDITIONING SYSTEMGeneral DescriptionAC±14

Page 214 of 2389

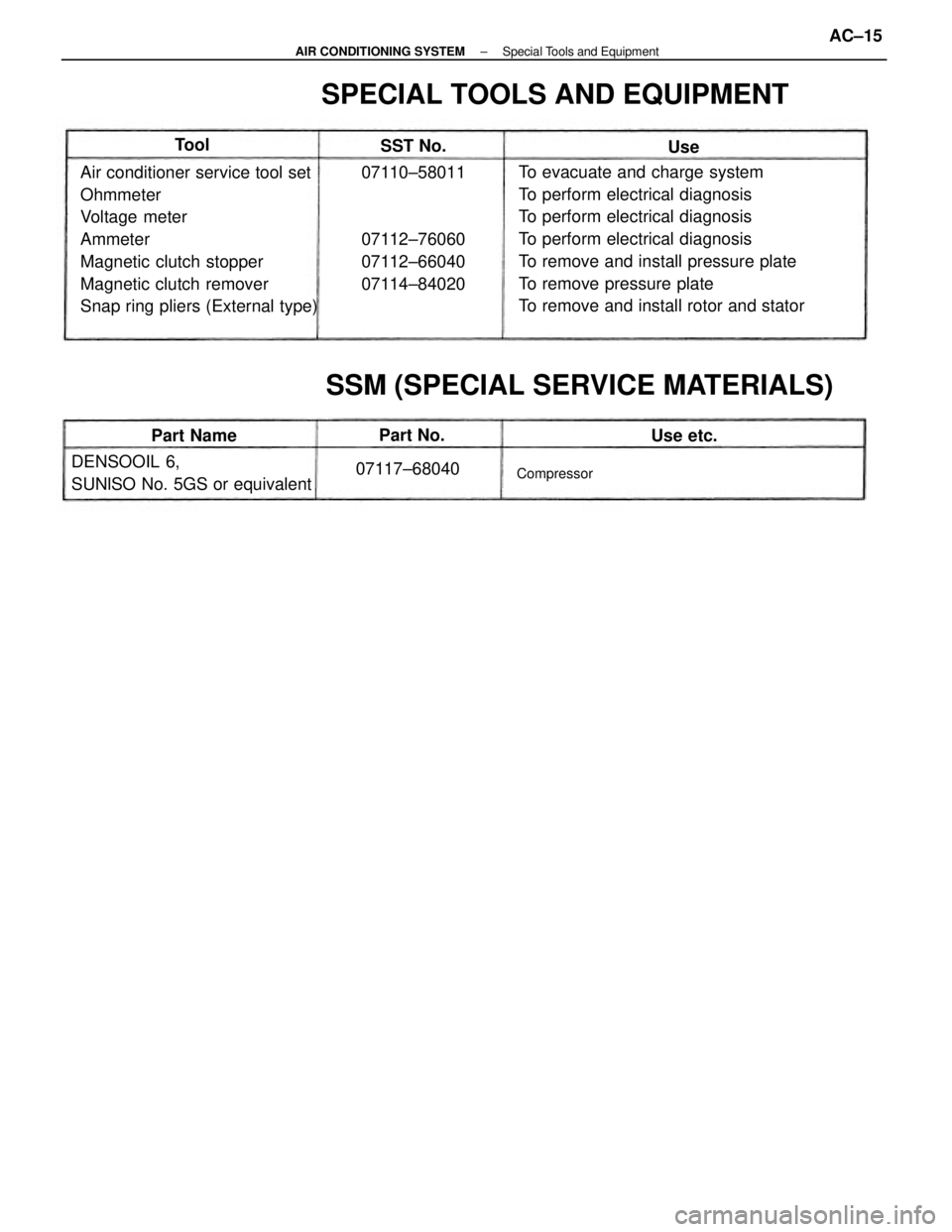

To evacuate and charge system

To perform electrical diagnosis

To perform electrical diagnosis

To perform electrical diagnosis

To remove and install pressure plate

To remove pressure plate

To remove and install rotor and stator Air conditioner service tool set

Ohmmeter

Voltage meter

Ammeter

Magnetic clutch stopper

Magnetic clutch remover

Snap ring pliers (External type)

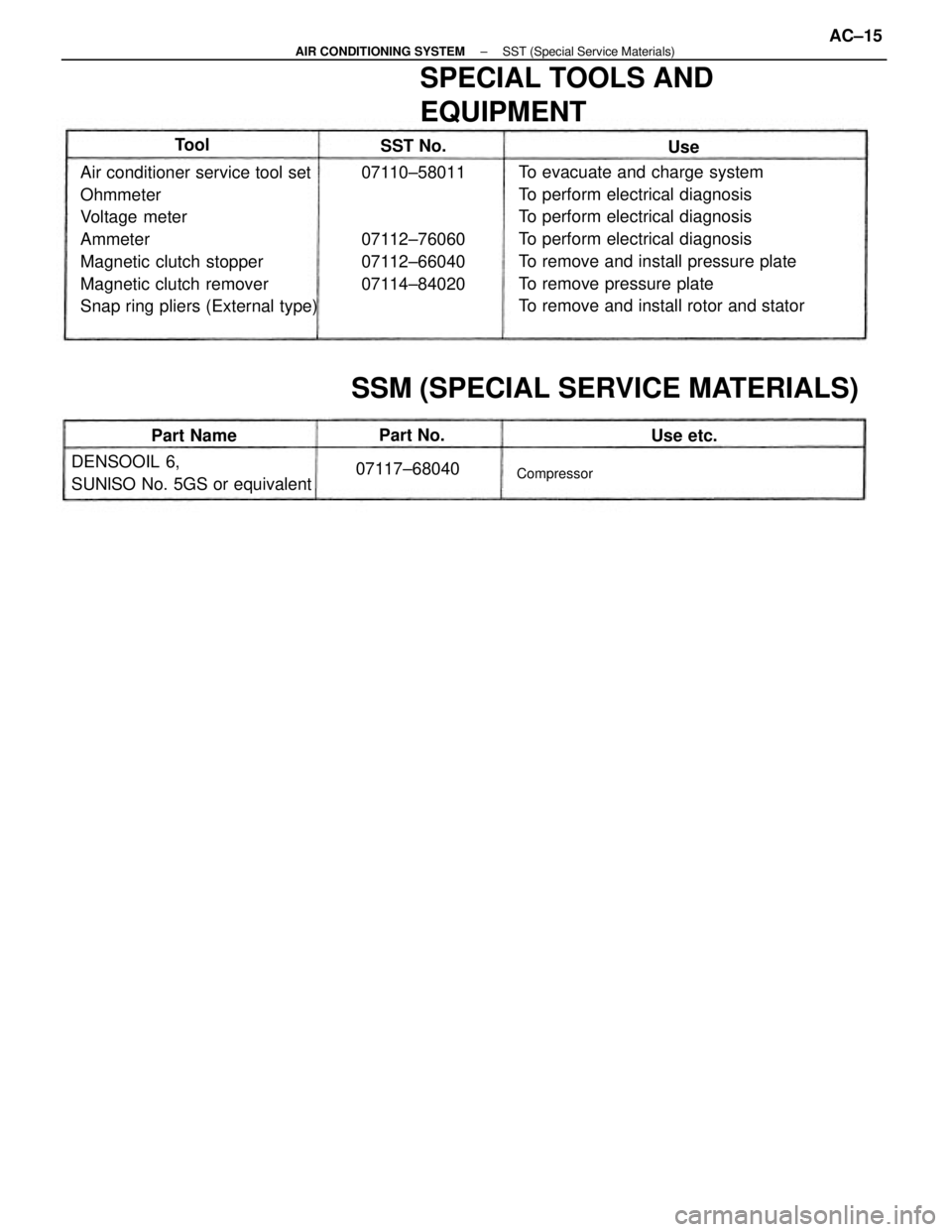

SPECIAL TOOLS AND EQUIPMENT

SSM (SPECIAL SERVICE MATERIALS)

07110±58011

07112±76060

07112±66040

07114±84020

DENSOOIL 6,

SUNlSO No. 5GS or equivalent07117±68040

Compressor

Part NameSST No.

Part No.

Use etc. Tool

Use

± AIR CONDITIONING SYSTEMSpecial Tools and EquipmentAC±15

Page 215 of 2389

To evacuate and charge system

To perform electrical diagnosis

To perform electrical diagnosis

To perform electrical diagnosis

To remove and install pressure plate

To remove pressure plate

To remove and install rotor and stator Air conditioner service tool set

Ohmmeter

Voltage meter

Ammeter

Magnetic clutch stopper

Magnetic clutch remover

Snap ring pliers (External type)

SPECIAL TOOLS AND

EQUIPMENT

SSM (SPECIAL SERVICE MATERIALS)

07110±58011

07112±76060

07112±66040

07114±84020

DENSOOIL 6,

SUNlSO No. 5GS or equivalent07117±68040

Compressor

Part NameSST No.

Part No.

Use etc. Tool

Use

± AIR CONDITIONING SYSTEMSST (Special Service Materials)AC±15

Page 216 of 2389

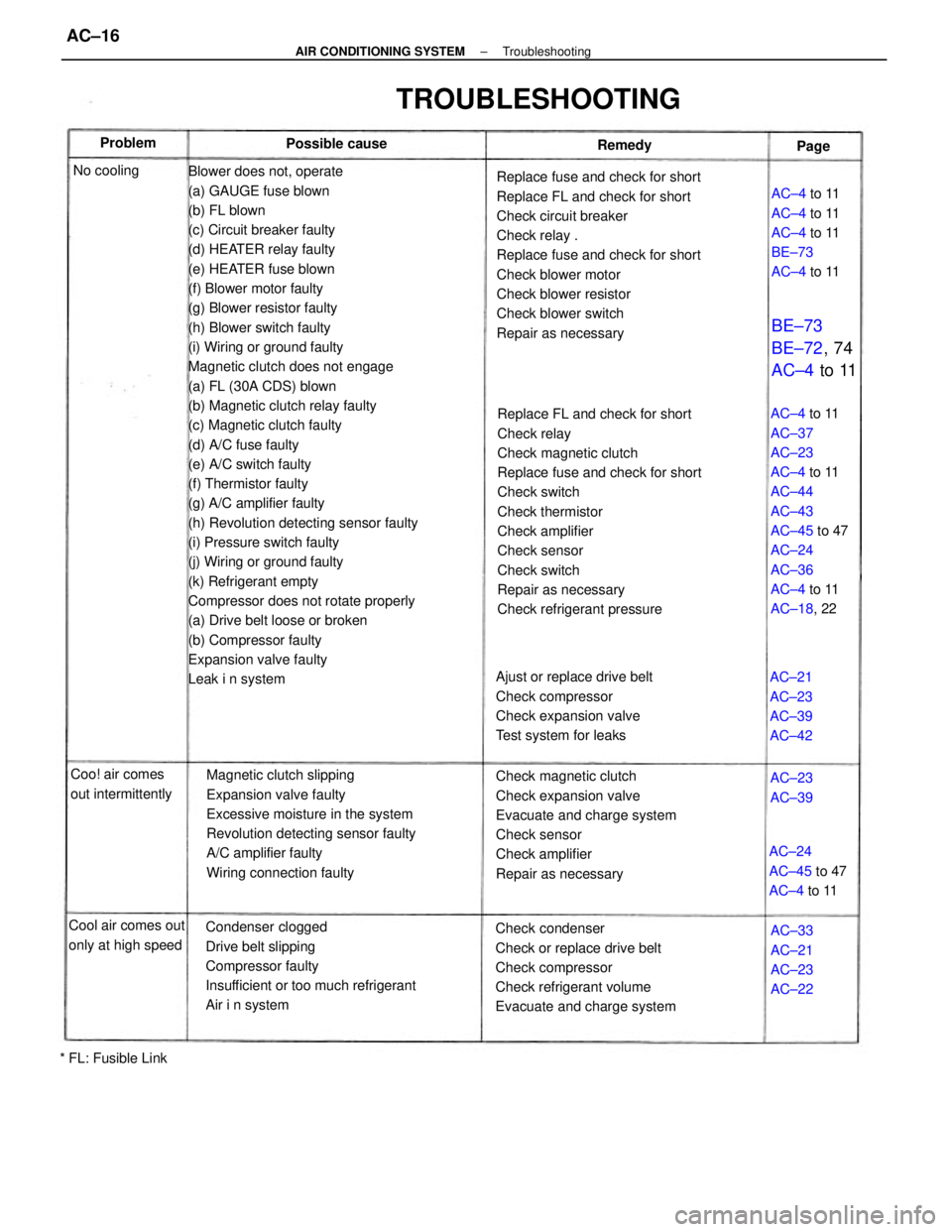

Blower does not, operate

(a) GAUGE fuse blown

(b) FL blown

(c) Circuit breaker faulty

(d) HEATER relay faulty

(e) HEATER fuse blown

(f) Blower motor faulty

(g) Blower resistor faulty

(h) Blower switch faulty

(i) Wiring or ground faulty

Magnetic clutch does not engage

(a) FL (30A CDS) blown

(b) Magnetic clutch relay faulty

(c) Magnetic clutch faulty

(d) A/C fuse faulty

(e) A/C switch faulty

(f) Thermistor faulty

(g) A/C amplifier faulty

(h) Revolution detecting sensor faulty

(i) Pressure switch faulty

(j) Wiring or ground faulty

(k) Refrigerant empty

Compressor does not rotate properly

(a) Drive belt loose or broken

(b) Compressor faulty

Expansion valve faulty

Leak i n systemReplace FL and check for short

Check relay

Check magnetic clutch

Replace fuse and check for short

Check switch

Check thermistor

Check amplifier

Check sensor

Check switch

Repair as necessary

Check refrigerant pressure Replace fuse and check for short

Replace FL and check for short

Check circuit breaker

Check relay .

Replace fuse and check for short

Check blower motor

Check blower resistor

Check blower switch

Repair as necessary

Magnetic clutch slipping

Expansion valve faulty

Excessive moisture in the system

Revolution detecting sensor faulty

A/C amplifier faulty

Wiring connection faulty

Condenser clogged

Drive belt slipping

Compressor faulty

Insufficient or too much refrigerant

Air i n systemCheck magnetic clutch

Check expansion valve

Evacuate and charge system

Check sensor

Check amplifier

Repair as necessary

Check condenser

Check or replace drive belt

Check compressor

Check refrigerant volume

Evacuate and charge systemAC±4 to 11

AC±37

AC±23

AC±4 to 11

AC±44

AC±43

AC±45 to 47

AC±24

AC±36

AC±4 to 11

AC±18, 22

Ajust or replace drive belt

Check compressor

Check expansion valve

Test system for leaks

TROUBLESHOOTING

AC±4 to 11

AC±4 to 11

AC±4 to 11

BE±73

AC±4 to 11

Cool air comes out

only at high speedAC±24

AC±45 to 47

AC±4 to 11 Coo! air comes

out intermittently

BE±73

BE±72, 74

AC±4 to 11

AC±33

AC±21

AC±23

AC±22 AC±21

AC±23

AC±39

AC±42

* FL: Fusible LinkPossible cause

AC±23

AC±39 No coolingRemedy Problem

Page

± AIR CONDITIONING SYSTEMTroubleshootingAC±16

Page 217 of 2389

Discharging of Refrigeration System

Evacuating and Charging of

Refrigeration System

(See Air Conditioning Fundamentals and Repairs Pub. No.

36950E)

Condenser clogged

Drive belt slipping

Magnetic clutch faulty

Compressor faulty

Expansion valve faulty

Thermistor faulty

A/C amplifier faulty

Insufficient or too much refrigerant

Air or excessive compressor oil in

system

Receiver clogged

Water valve cable set faultyCheck condenser .

Check or replace drive belt

Check magnetic clutch

Check compressor

Check expansion valve

Check thermistor

Check amplifier

Check refrigerant volume

Evacuate and charge system

Evaporator clogged or frosted

Air leakage from cooling unit or air duct

Air inlet blocked

Blower motor faulty

A/C amplifier faulty

Drive belt slipping

Revolution detecting sensor faulty

(w/Power steering)

A/C amplifier faultyAC±33

AC±21

AC±23

AC±23

AC±39

AC±43

AC±45 to 47

AC±22

Repair as necessary

Replace blower motor

Check amplifierClean evaporator fins or filters

Repair as necessary

Check or replace drive belt

Check sensor

Check receiver

Reset water valve cable

A/C switch

indicator

flashingInsufficient

velocity of cool

airAC±41

AC±39 to 42 Insufficient

cooling

Check amplifier Possible cause

AC±21

AC±24AC±32

BE±79

AC±39 to 42

AC±45 to 47

AC±45 to 47 Remedy ProblemPage

± AIR CONDITIONING SYSTEMTroubleshooting Refrigeration SystemAC±17

Page 218 of 2389

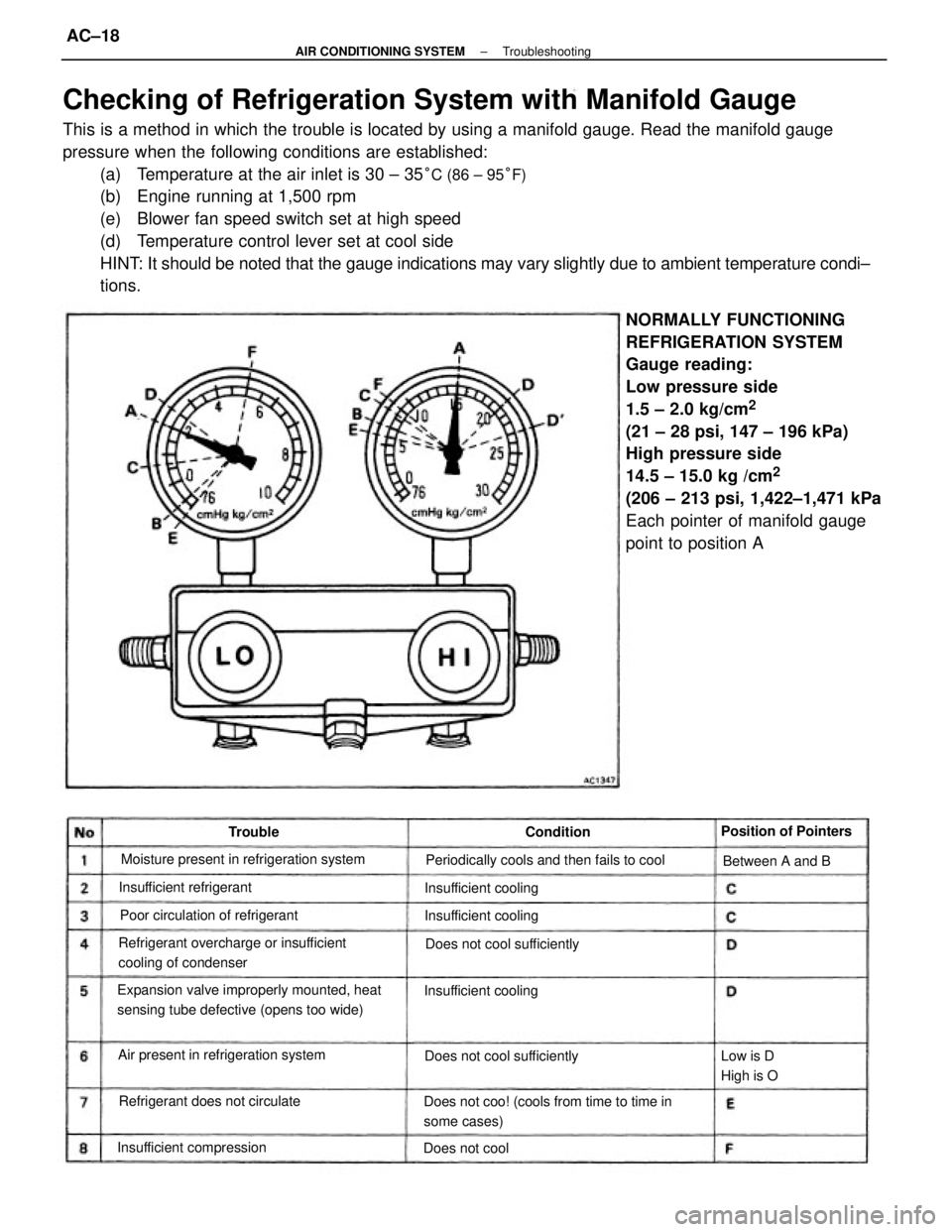

Checking of Refrigeration System with Manifold Gauge

This is a method in which the trouble is located by using a manifold gauge. Read the manifold gauge

pressure when the following conditions are established:

(a) Temperature at the air inlet is 30 ± 35

°C (86 ± 95°F)

(b) Engine running at 1,500 rpm

(e) Blower fan speed switch set at high speed

(d) Temperature control lever set at cool side

HINT: It should be noted that the gauge indications may vary slightly due to ambient temperature condi±

tions.

NORMALLY FUNCTIONING

REFRIGERATION SYSTEM

Gauge reading:

Low pressure side

1.5 ± 2.0 kg/cm

2

(21 ± 28 psi, 147 ± 196 kPa)

High pressure side

14.5 ± 15.0 kg /cm

2

(206 ± 213 psi, 1,422±1,471 kPa

Each pointer of manifold gauge

point to position A

Expansion valve improperly mounted, heat

sensing tube defective (opens too wide)

Does not coo! (cools from time to time in

some cases) Refrigerant overcharge or insufficient

cooling of condenserMoisture present in refrigeration system

Periodically cools and then fails to cool

Air present in refrigeration systemPoor circulation of refrigerant

Refrigerant does not circulateDoes not cool sufficiently

Does not cool sufficiently

Insufficient compressionInsufficient refrigerantPosition of Pointers

Insufficient cooling Insufficient cooling

Insufficient cooling

Low is D

High is OBetween A and B

Does not coolCondition Trouble

± AIR CONDITIONING SYSTEMTroubleshootingAC±18

Page 219 of 2389

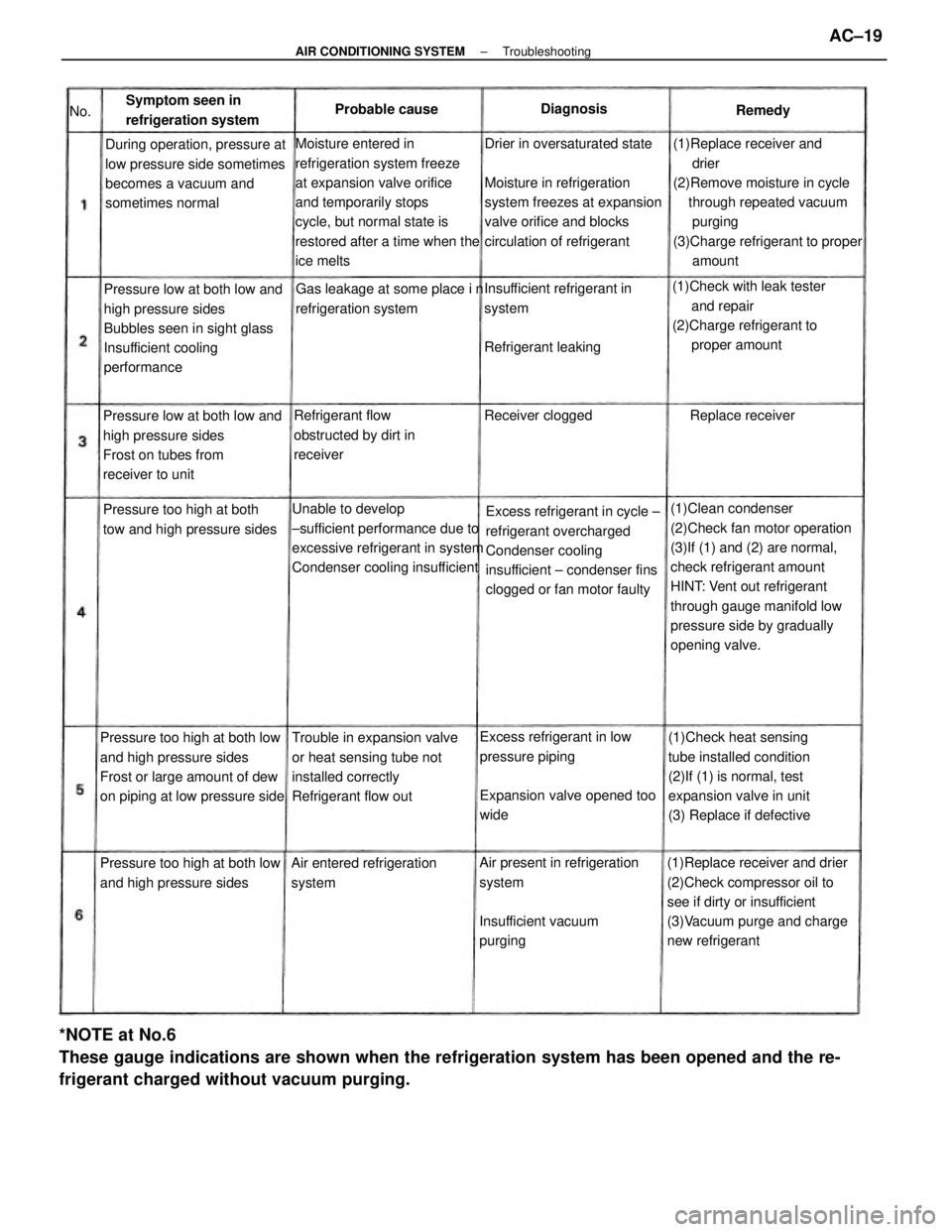

*NOTE at No.6

These gauge indications are shown when the refrigeration system has been opened and the re-

frigerant charged without vacuum purging.

(1)Clean condenser

(2)Check fan motor operation

(3)If (1) and (2) are normal,

check refrigerant amount

HINT: Vent out refrigerant

through gauge manifold low

pressure side by gradually

opening valve.

(1)Replace receiver and drier

(2)Check compressor oil to

see if dirty or insufficient

(3)Vacuum purge and charge

new refrigerant Drier in oversaturated state

Moisture in refrigeration

system freezes at expansion

valve orifice and blocks

circulation of refrigerant(1)Replace receiver and

drier

(2)Remove moisture in cycle

through repeated vacuum

purging

(3)Charge refrigerant to proper

amount

Excess refrigerant in cycle ±

refrigerant overcharged

Condenser cooling

insufficient ± condenser fins

clogged or fan motor faulty Unable to develop

±sufficient performance due to

excessive refrigerant in system

Condenser cooling insufficientMoisture entered in

refrigeration system freeze

at expansion valve orifice

and temporarily stops

cycle, but normal state is

restored after a time when the

ice melts

Pressure too high at both low

and high pressure sides

Frost or large amount of dew

on piping at low pressure side(1)Check heat sensing

tube installed condition

(2)If (1) is normal, test

expansion valve in unit

(3) Replace if defective Pressure low at both low and

high pressure sides

Bubbles seen in sight glass

Insufficient cooling

performance

Air present in refrigeration

system

Insufficient vacuum

purging During operation, pressure at

low pressure side sometimes

becomes a vacuum and

sometimes normal

Trouble in expansion valve

or heat sensing tube not

installed correctly

Refrigerant flow out Pressure low at both low and

high pressure sides

Frost on tubes from

receiver to unit(1)Check with leak tester

and repair

(2)Charge refrigerant to

proper amount

Excess refrigerant in low

pressure piping

Expansion valve opened too

wideInsufficient refrigerant in

system

Refrigerant leaking

Pressure too high at both low

and high pressure sidesPressure too high at both

tow and high pressure sidesGas leakage at some place i n

refrigeration system

Refrigerant flow

obstructed by dirt in

receiver

Air entered refrigeration

system Symptom seen in

refrigeration system

Receiver clogged Replace receiver Probable causeDiagnosis

Remedy

No.

± AIR CONDITIONING SYSTEMTroubleshootingAC±19

Page 220 of 2389

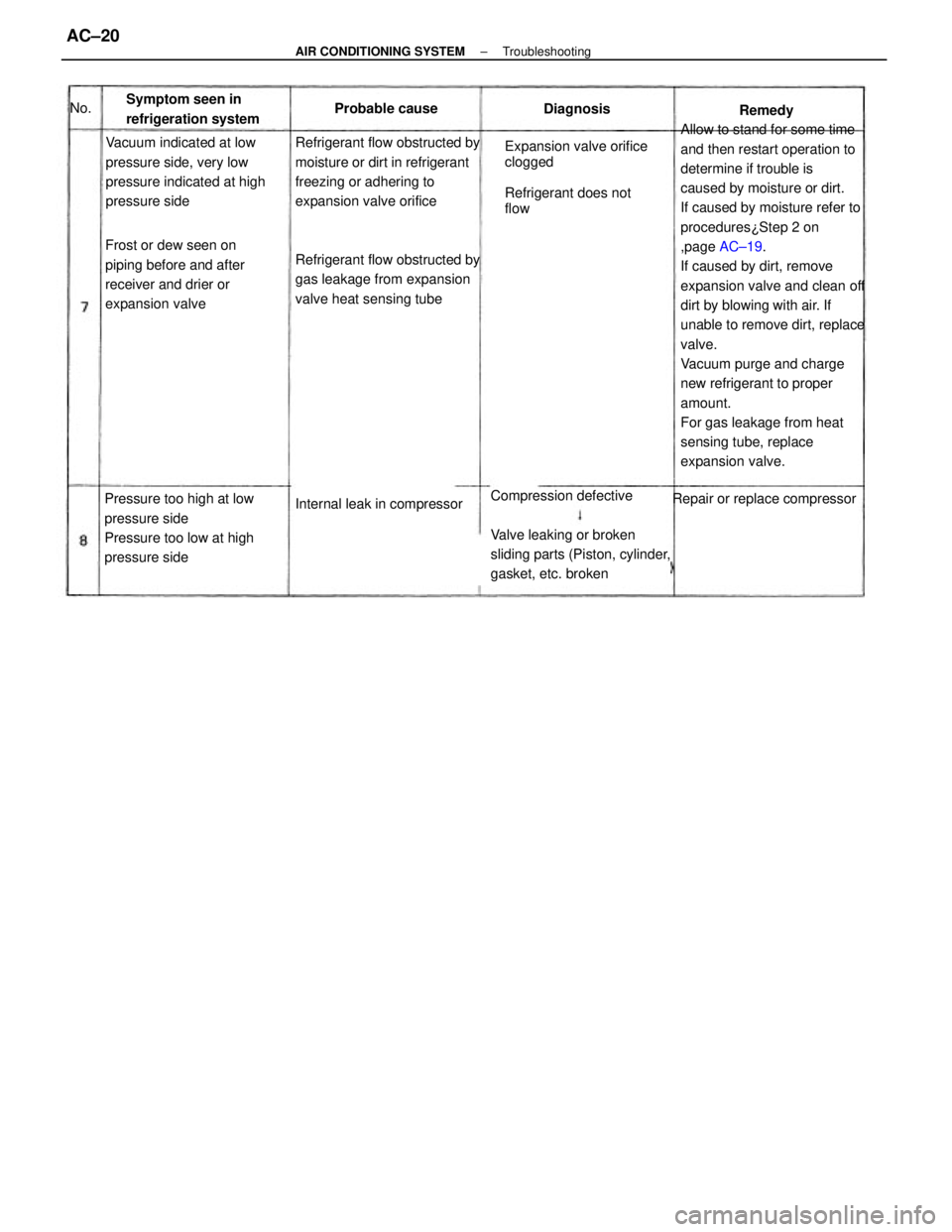

Allow to stand for some time

and then restart operation to

determine if trouble is

caused by moisture or dirt.

If caused by moisture refer to

procedures¿Step 2 on

,page AC±19.

If caused by dirt, remove

expansion valve and clean off

dirt by blowing with air. If

unable to remove dirt, replace

valve.

Vacuum purge and charge

new refrigerant to proper

amount.

For gas leakage from heat

sensing tube, replace

expansion valve. Refrigerant flow obstructed by

moisture or dirt in refrigerant

freezing or adhering to

expansion valve orifice

Refrigerant flow obstructed by

gas leakage from expansion

valve heat sensing tube

Internal leak in compressor Vacuum indicated at low

pressure side, very low

pressure indicated at high

pressure side

Pressure too high at low

pressure side

Pressure too low at high

pressure sideFrost or dew seen on

piping before and after

receiver and drier or

expansion valve

Repair or replace compressor Symptom seen in

refrigeration systemProbable cause

Diagnosis

Remedy No.

Expansion valve orifice

clogged

Refrigerant does not

flow

Compression defective

Valve leaking or broken

sliding parts (Piston, cylinder,

gasket, etc. broken

± AIR CONDITIONING SYSTEMTroubleshootingAC±20