TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: seats, set clock, open gas tank, alternator, radiator cap, check engine light, reset

Page 251 of 2389

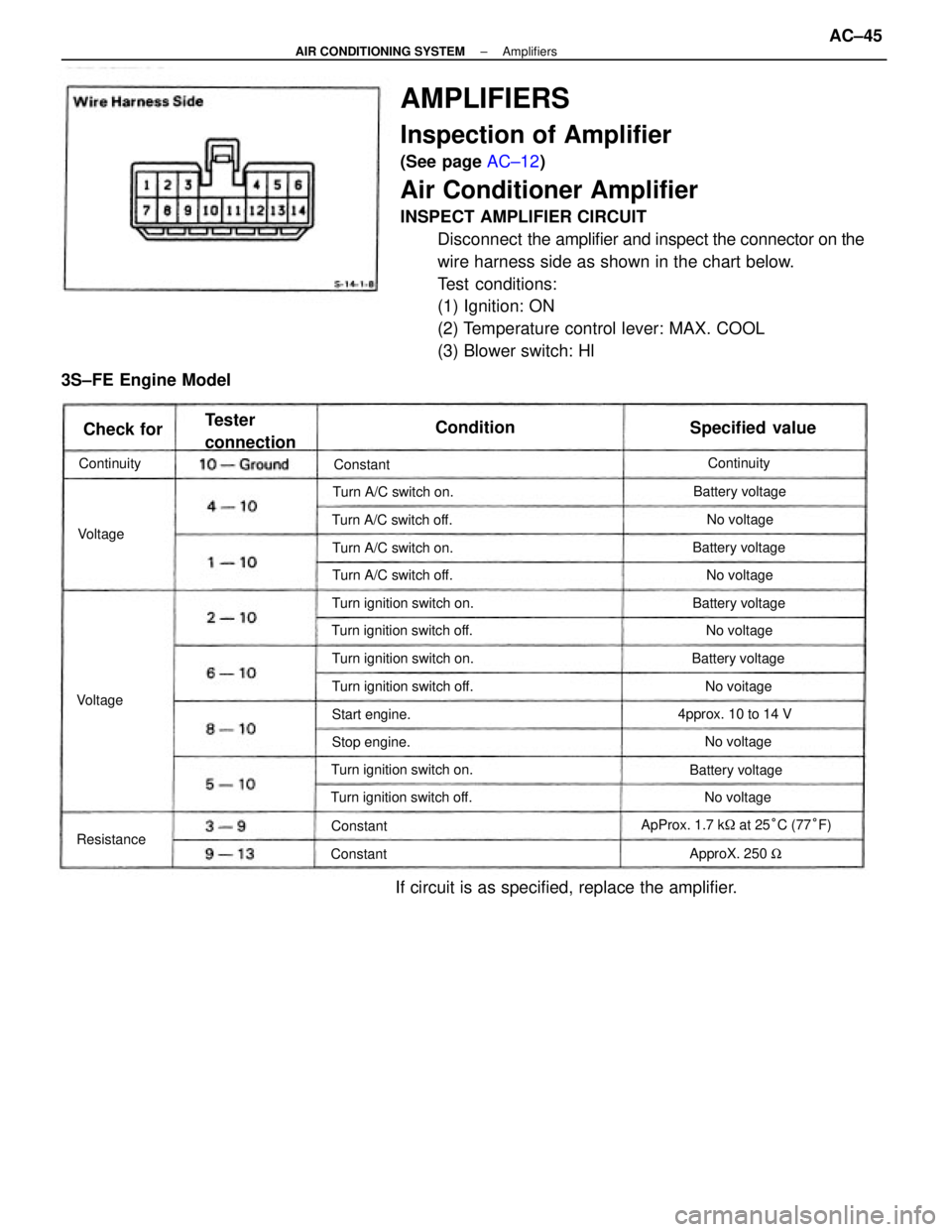

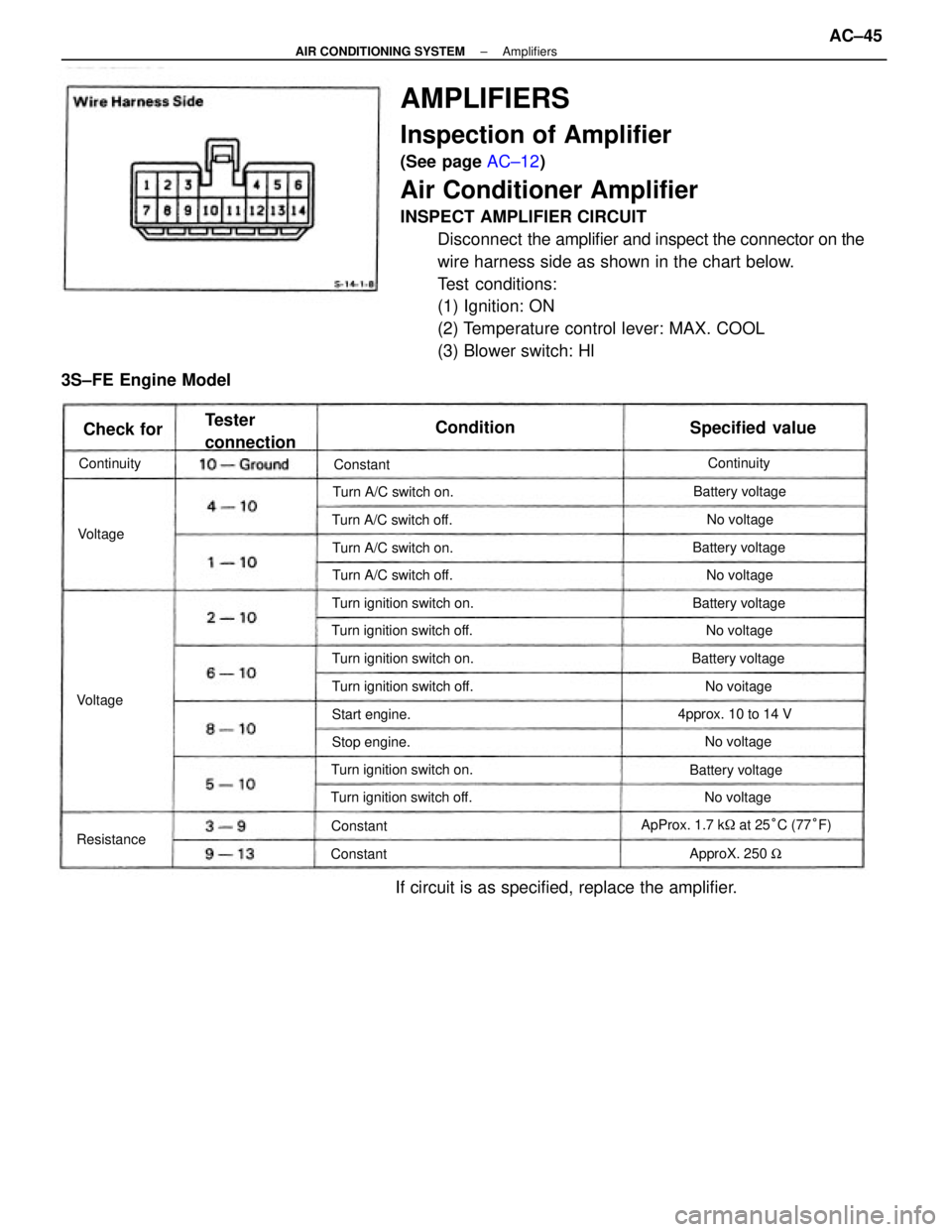

AMPLIFIERS

Inspection of Amplifier

(See page AC±12)

Air Conditioner Amplifier

INSPECT AMPLIFIER CIRCUIT

Disconnect the amplifier and inspect the connector on the

wire harness side as shown in the chart below.

Test conditions:

(1) Ignition: ON

(2) Temperature control lever: MAX. COOL

(3) Blower switch: Hl

If circuit is as specified, replace the amplifier.

ApProx. 1.7 k� at 25°C (77°F)

3S±FE Engine Model

Turn ignition switch off.Turn ignition switch on.

Turn ignition switch off.Turn ignition switch on.

Turn ignition switch off.

Turn ignition switch on.Turn A/C switch off.

Turn A/C switch on.

Turn A/C switch off.Turn A/C switch on.

4pprox. 10 to 14 V

Tester

connectionSpecified value

Battery voltage

Battery voltageBattery voltageBattery voltage

Battery voltage

ApproX. 250 W Start engine.

Stop engine.No voltageNo voltage

No voltage

No voitage

No voltageNo voltage ContinuityContinuity

Resistance

Condition

Check for

Constant

ConstantConstant

Voltage

Voltage

± AIR CONDITIONING SYSTEMAmplifiersAC±45

Page 252 of 2389

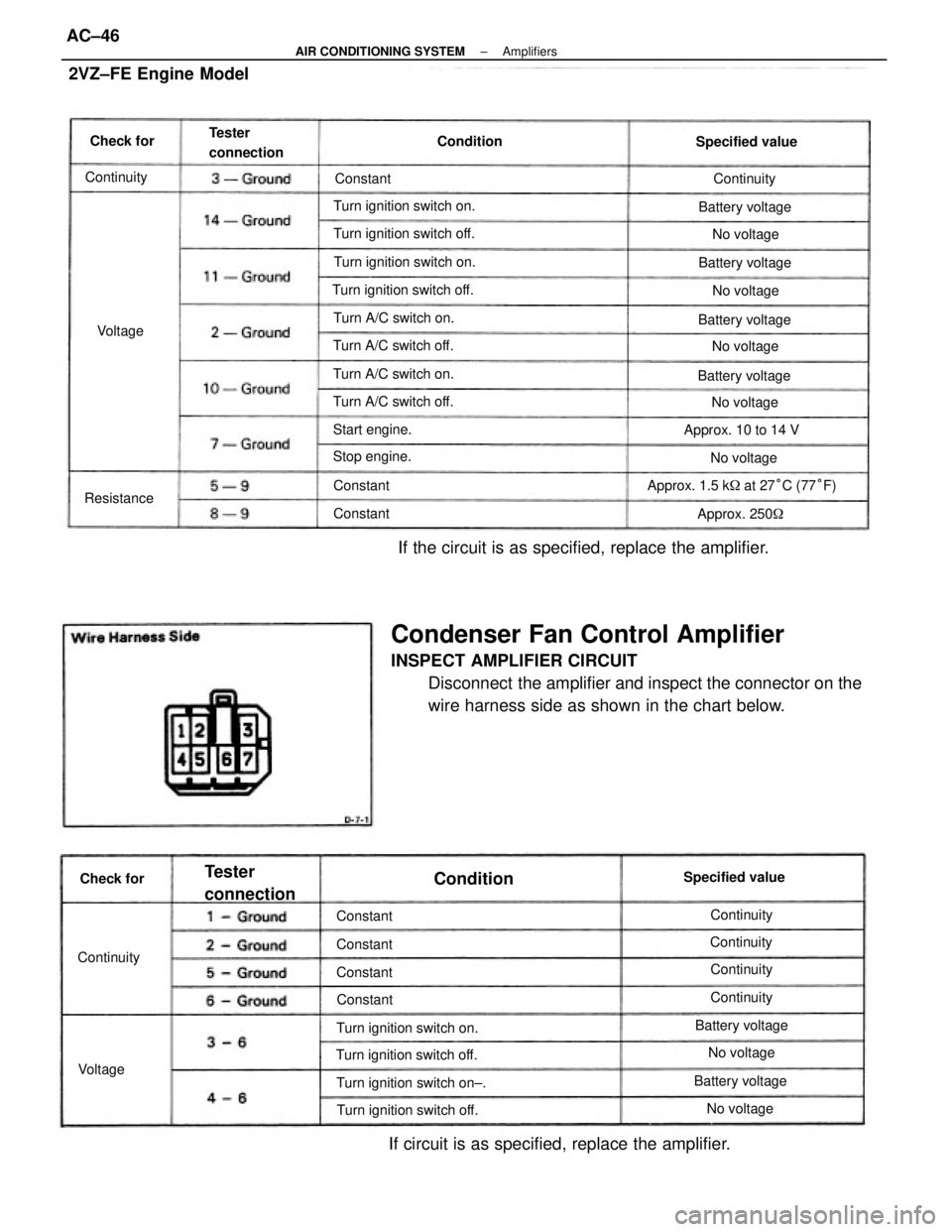

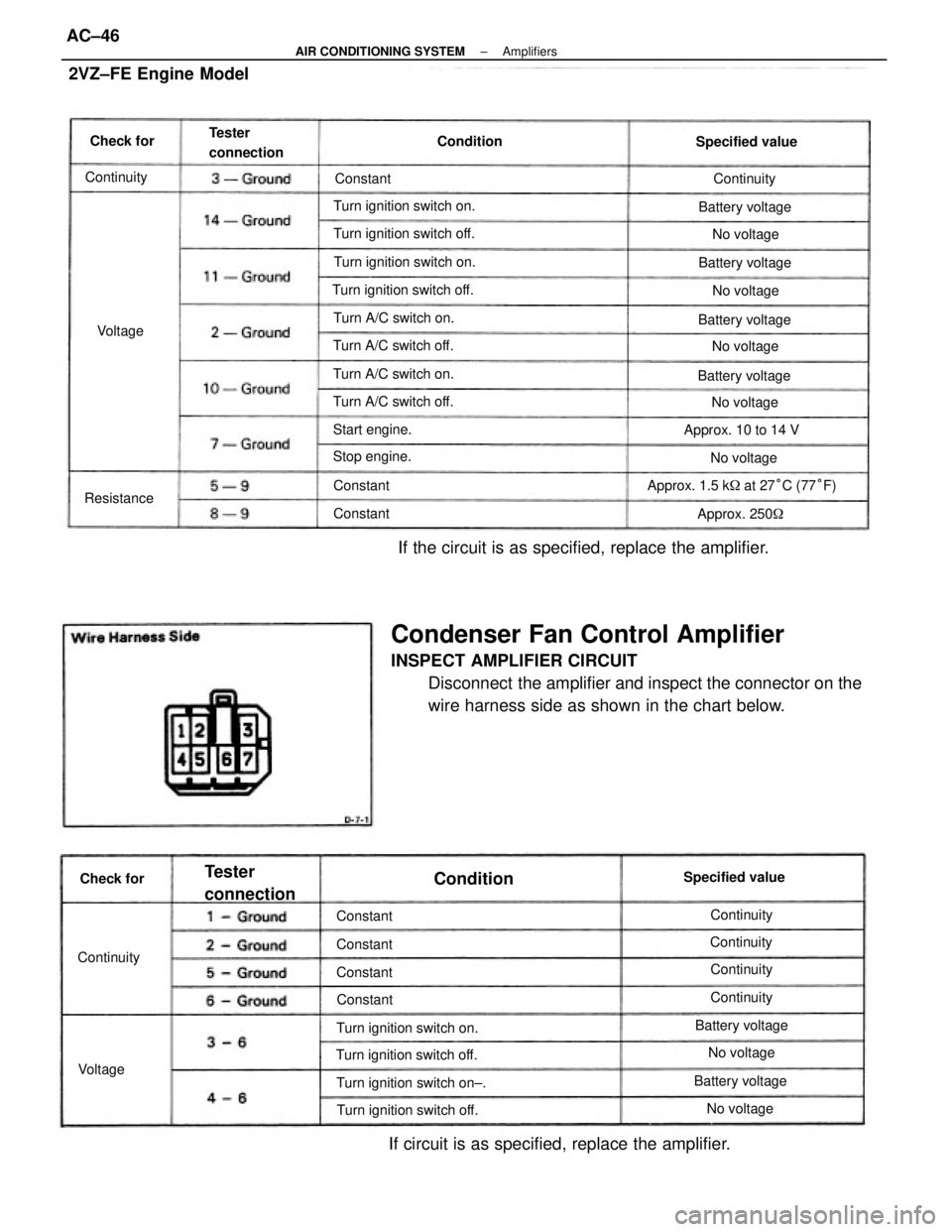

Condenser Fan Control Amplifier

INSPECT AMPLIFIER CIRCUIT

Disconnect the amplifier and inspect the connector on the

wire harness side as shown in the chart below. If the circuit is as specified, replace the amplifier.

If circuit is as specified, replace the amplifier. 2VZ±FE Engine Model

Approx. 1.5 k� at 27°C (77°F)

Turn ignition switch off.

Turn ignition switch off. Turn ignition switch on±. Turn ignition switch on. Turn ignition switch off.Turn ignition switch on. Turn ignition switch off. Turn ignition switch on.

Turn A/C switch on.

Turn A/C switch on.

Turn A/C switch off. Turn A/C switch off.

Tester

connection

Approx. 10 to 14 V Tester

connection

Specified valueSpecified value

Battery voltageBattery voltageBattery voltage Battery voltage

Battery voltage

Approx. 250� Battery voltage

Start engine.

Stop engine.

No voltageNo voltage

No voltage

No voltage

No voltage ContinuityNo voltageNo voltage

ContinuityContinuity

Continuity Continuity

Continuity

Condition

Continuity ResistanceCondition

Check forCheck for

Constant Constant Constant

Constant Constant

Constant Constant

VoltageVoltage

± AIR CONDITIONING SYSTEMAmplifiersAC±46

Page 253 of 2389

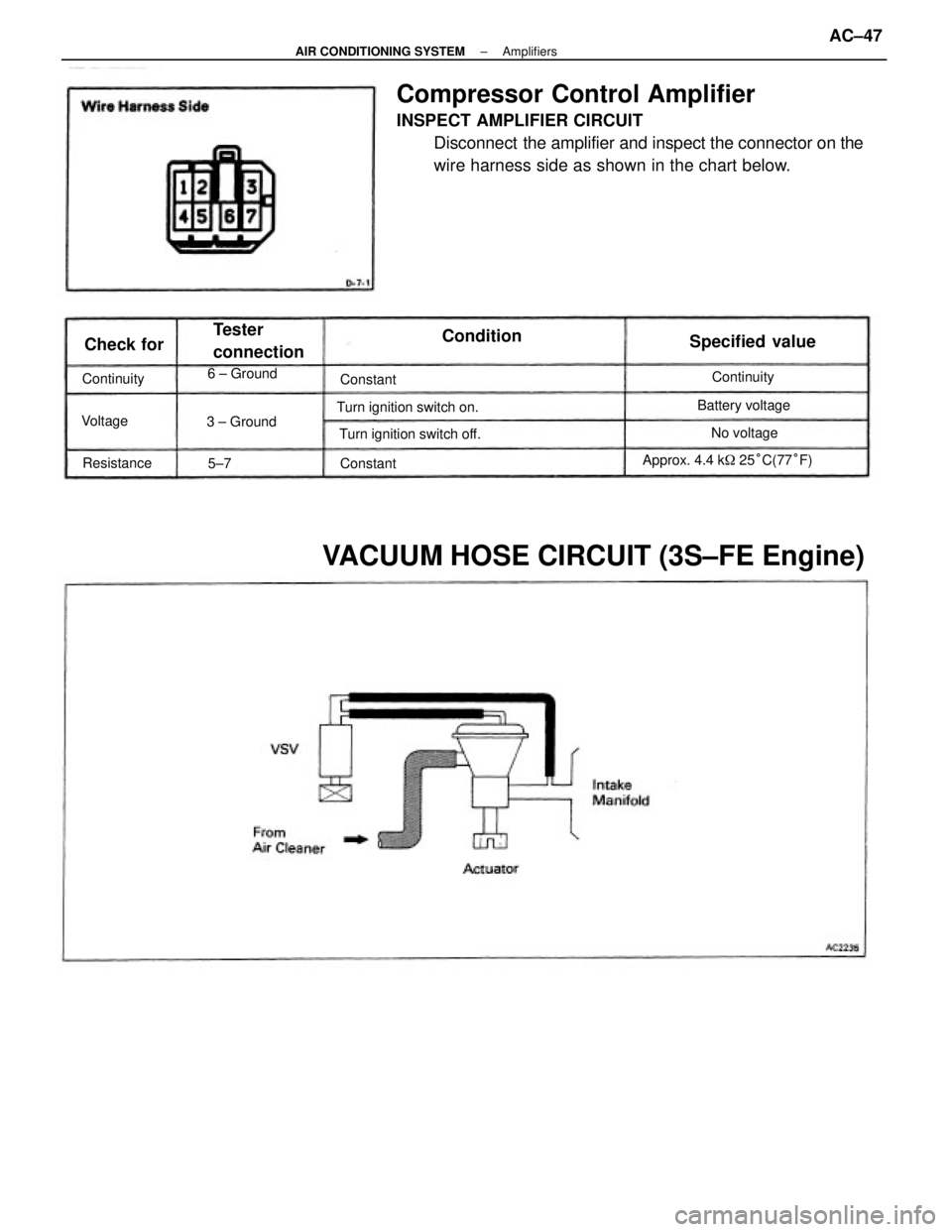

Compressor Control Amplifier

INSPECT AMPLIFIER CIRCUIT

Disconnect the amplifier and inspect the connector on the

wire harness side as shown in the chart below.

VACUUM HOSE CIRCUIT (3S±FE Engine)

Approx. 4.4 k� 25°C(77°F) Turn ignition switch on.

Turn ignition switch off.

Tester

connectionSpecified value

3 ± GroundBattery voltage 6 ± Ground

No voltage ContinuityContinuity

Resistance

Condition

Check for

Constant Constant

Voltage

5±7

± AIR CONDITIONING SYSTEMAmplifiersAC±47

Page 254 of 2389

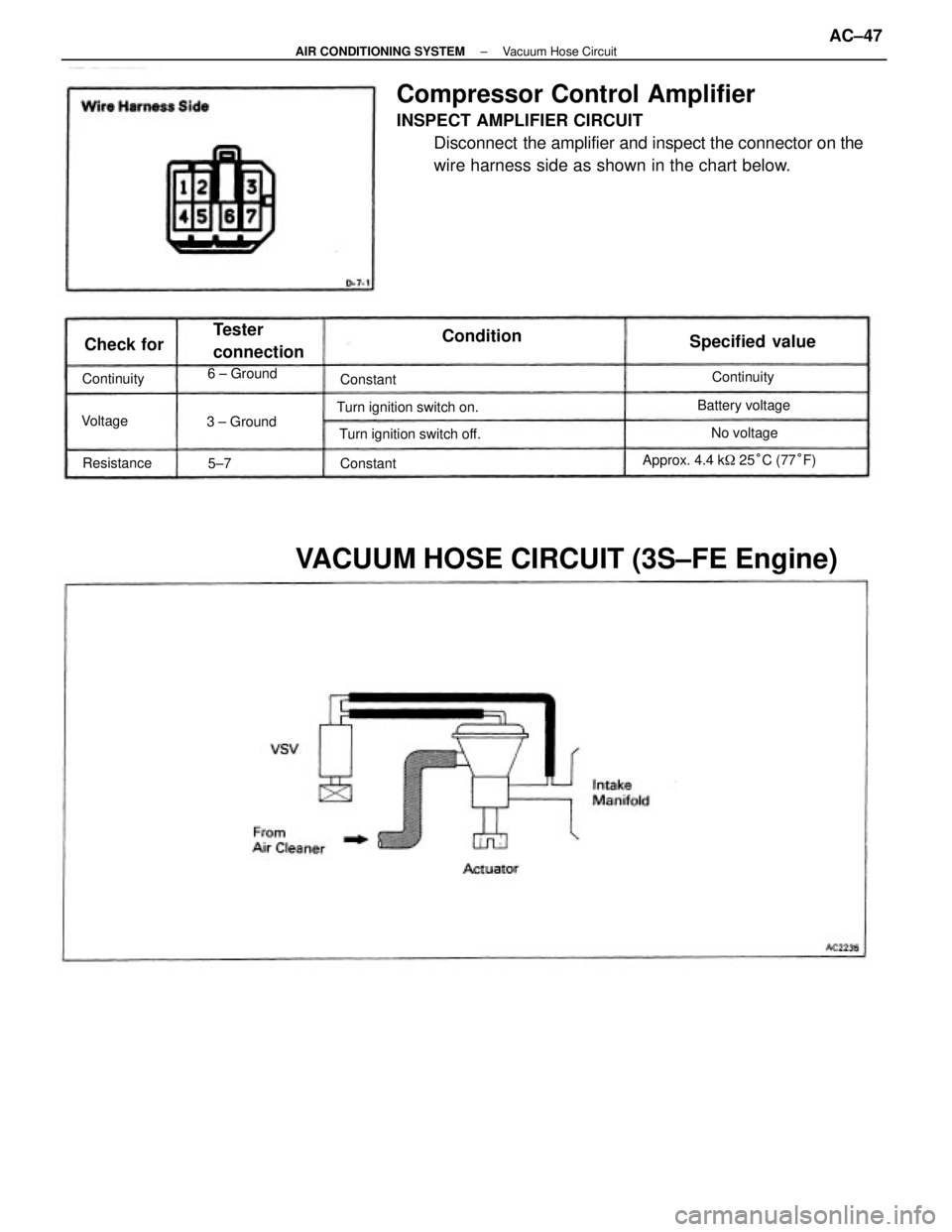

Compressor Control Amplifier

INSPECT AMPLIFIER CIRCUIT

Disconnect the amplifier and inspect the connector on the

wire harness side as shown in the chart below.

VACUUM HOSE CIRCUIT (3S±FE Engine)

Approx. 4.4 k� 25°C (77°F) Turn ignition switch on.

Turn ignition switch off.

Tester

connectionSpecified value

3 ± GroundBattery voltage 6 ± Ground

No voltage ContinuityContinuity

Resistance

Condition

Check for

Constant Constant

Voltage

5±7

± AIR CONDITIONING SYSTEMVacuum Hose CircuitAC±47

Page 255 of 2389

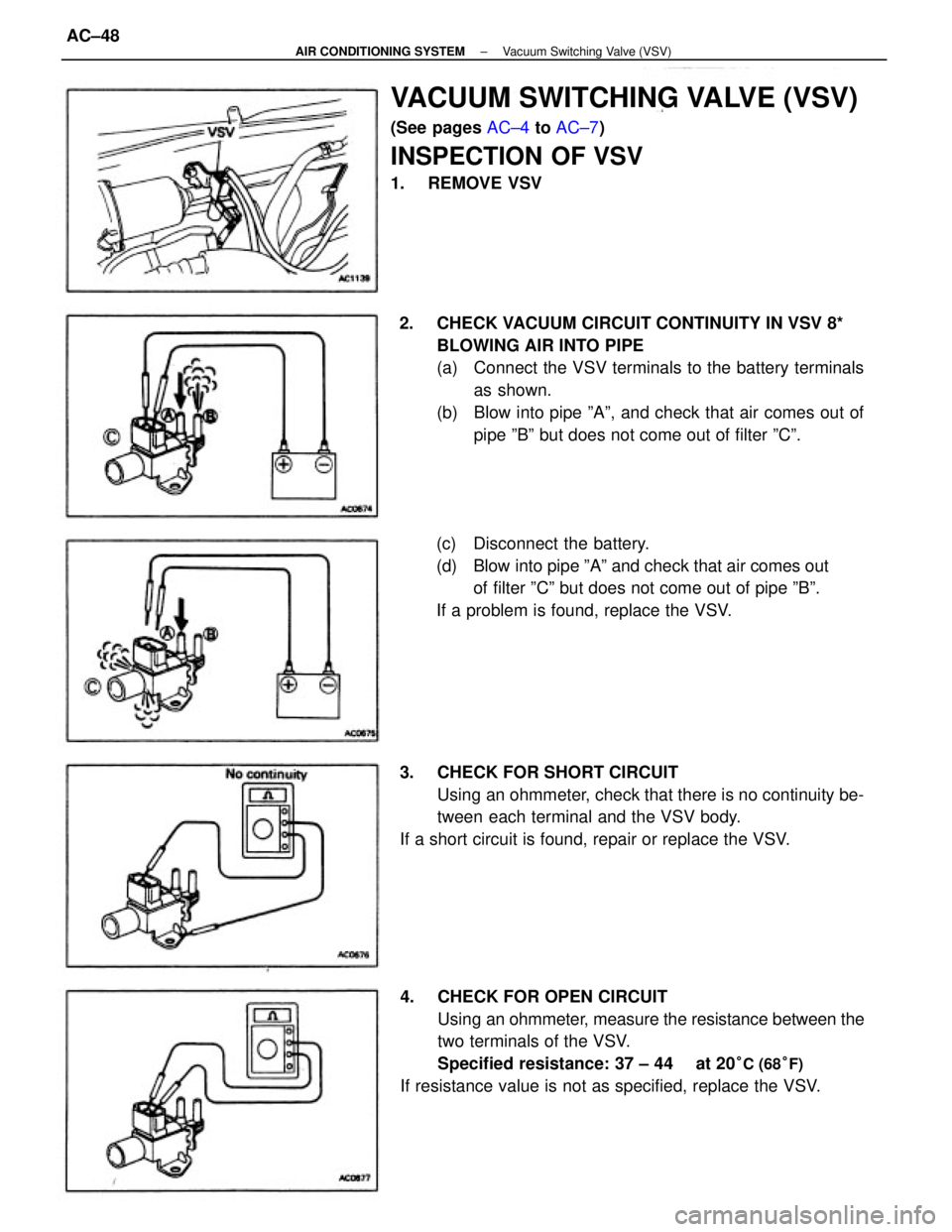

VACUUM SWITCHING VALVE (VSV)

(See pages AC±4 to AC±7)

INSPECTION OF VSV

1. REMOVE VSV

2. CHECK VACUUM CIRCUIT CONTINUITY IN VSV 8*

BLOWING AIR INTO PIPE

(a) Connect the VSV terminals to the battery terminals

as shown.

(b) Blow into pipe ºAº, and check that air comes out of

pipe ºBº but does not come out of filter ºCº.

4. CHECK FOR OPEN CIRCUIT

Using an ohmmeter, measure the resistance between the

two terminals of the VSV.

Specified resistance: 37 ± 44

� at 20°C (68°F)

If resistance value is not as specified, replace the VSV. 3. CHECK FOR SHORT CIRCUIT

Using an ohmmeter, check that there is no continuity be-

tween each terminal and the VSV body.

If a short circuit is found, repair or replace the VSV.(c) Disconnect the battery.

(d) Blow into pipe ºAº and check that air comes out

of filter ºCº but does not come out of pipe ºBº.

If a problem is found, replace the VSV.

± AIR CONDITIONING SYSTEMVacuum Switching Valve (VSV)AC±48

Page 256 of 2389

TROUBLESHOOTING

Basic Troubleshooting

Before troubleshooting an ECT, first determine whether the problem is electrical or mechanical.

To do this, just refer to the basic troubleshooting flow±chart provided below.

If the cause is already known, using the basic troubleshooting chart below along with the general

troubleshooting chart on the following pages should speed the procedure.

Stall Test, Time Lag Test and

Hydraulic Test Read Diagnostic Code

(See page AT±17)

Manual Shifting Test

(See page AT±23)

Electrical Control System CheckPreliminary Check

(See page AT±21 )Repair or

Replace

Repair or ReplaceRepair Transaxle Bad

BadBad

Bad

Bad

± AUTOMATIC TRANSAXLETroubleshooting (Basic Troubleshooting) (A140L and

A140E)AT±11

Page 257 of 2389

AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLEAT±1

Page 258 of 2389

MEMO

AUTOMATIC TRANSAXLEAT±2

Page 259 of 2389

A140L AND A140E

AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLEAT±3

Page 260 of 2389

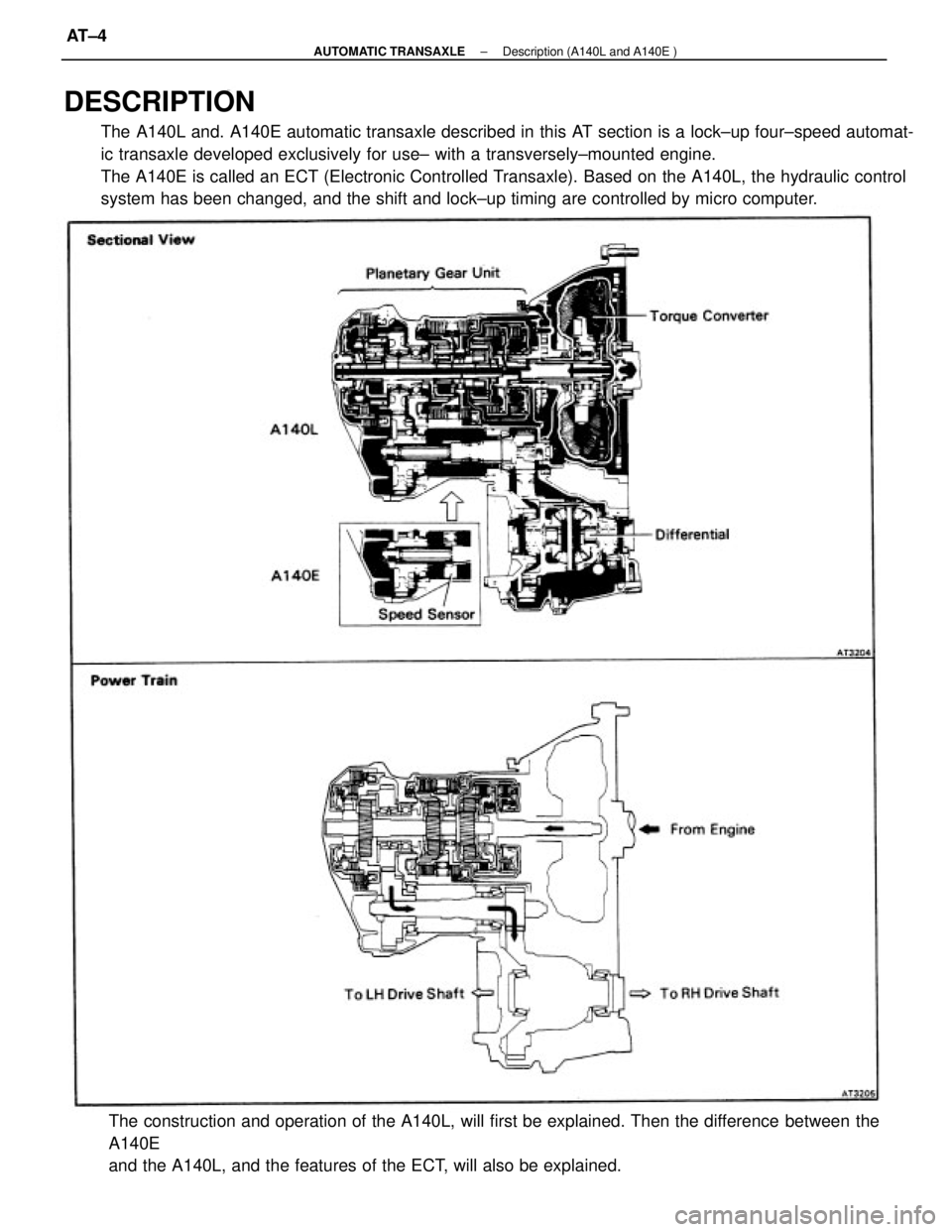

DESCRIPTION

The A140L and. A140E automatic transaxle described in this AT section is a lock±up four±speed automat-

ic transaxle developed exclusively for use± with a transversely±mounted engine.

The A140E is called an ECT (Electronic Controlled Transaxle). Based on the A140L, the hydraulic control

system has been changed, and the shift and lock±up timing are controlled by micro computer.

The construction and operation of the A140L, will first be explained. Then the difference between the

A140E

and the A140L, and the features of the ECT, will also be explained.

± AUTOMATIC TRANSAXLEDescription (A140L and A140E )AT±4

Trending: fuel pump, brakes, parking brake, wheel, gas type, headlights, reset