TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: CD player, height adjustment, headlight aiming, service indicator, warning lights, tire pressure reset, check engine light

Page 331 of 2389

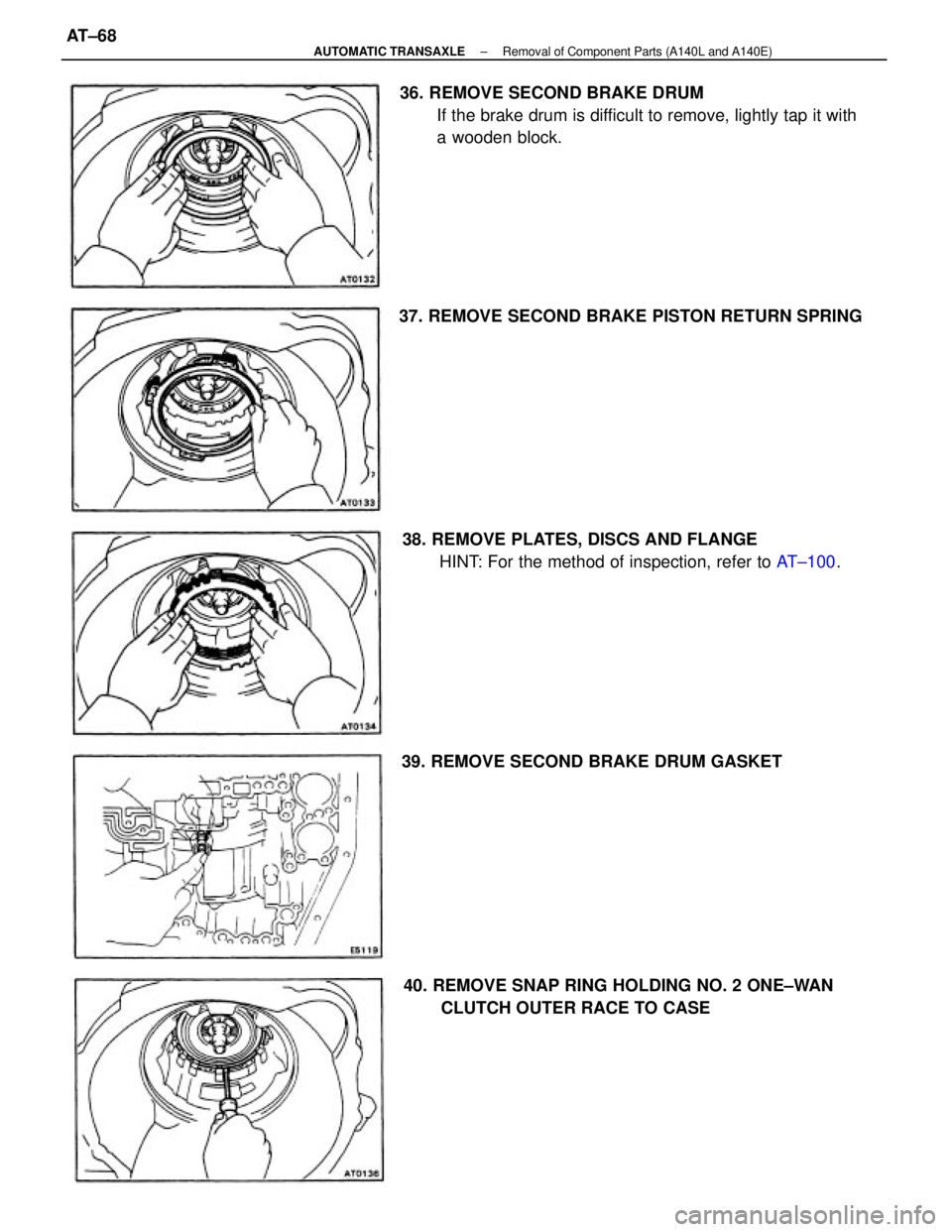

36. REMOVE SECOND BRAKE DRUM

If the brake drum is difficult to remove, lightly tap it with

a wooden block.

38. REMOVE PLATES, DISCS AND FLANGE

HINT: For the method of inspection, refer to AT±100.

40. REMOVE SNAP RING HOLDING NO. 2 ONE±WAN

CLUTCH OUTER RACE TO CASE 37. REMOVE SECOND BRAKE PISTON RETURN SPRING

39. REMOVE SECOND BRAKE DRUM GASKET

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±68

Page 332 of 2389

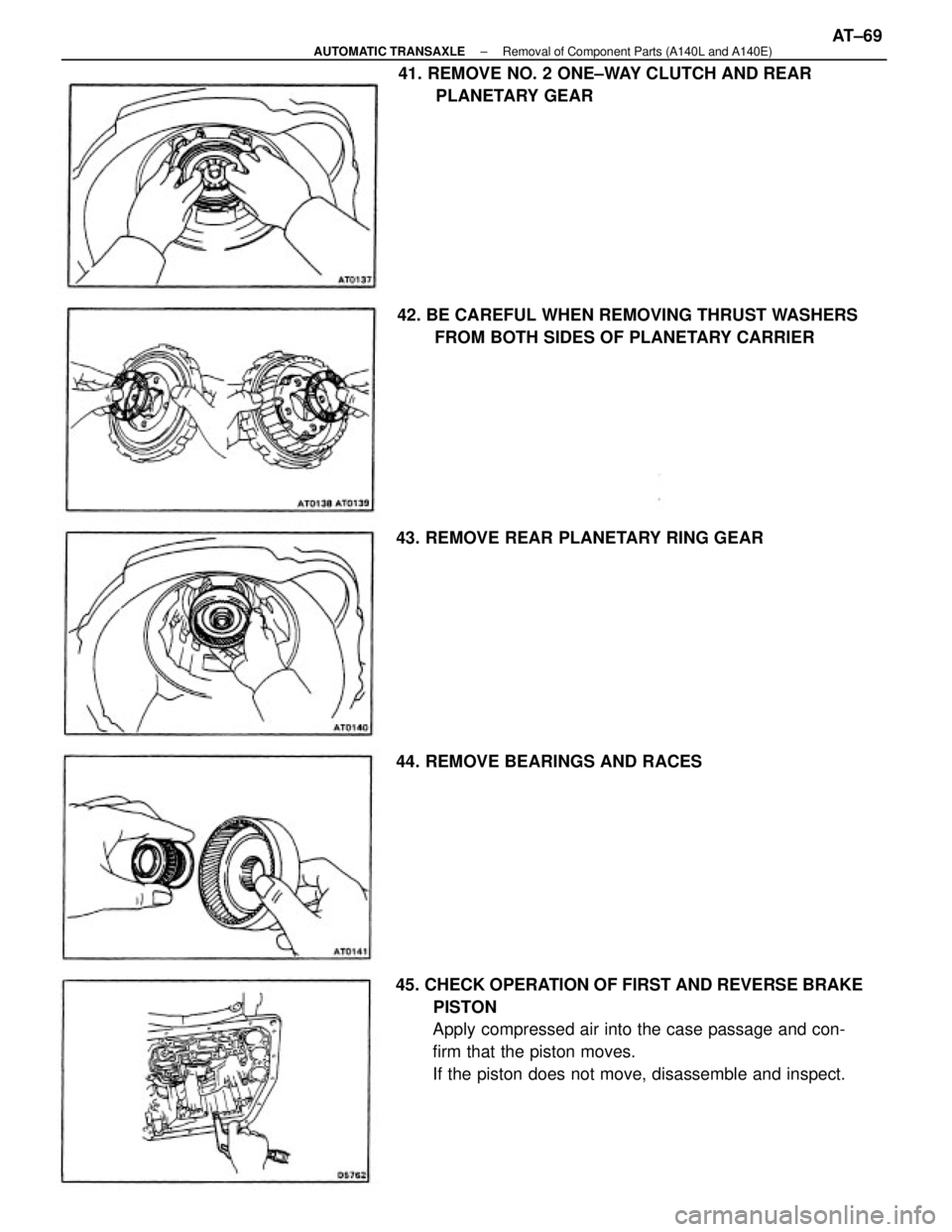

45. CHECK OPERATION OF FIRST AND REVERSE BRAKE

PISTON

Apply compressed air into the case passage and con-

firm that the piston moves.

If the piston does not move, disassemble and inspect. 41. REMOVE NO. 2 ONE±WAY CLUTCH AND REAR

PLANETARY GEAR

42. BE CAREFUL WHEN REMOVING THRUST WASHERS

FROM BOTH SIDES OF PLANETARY CARRIER

43. REMOVE REAR PLANETARY RING GEAR

44. REMOVE BEARINGS AND RACES

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±69

Page 333 of 2389

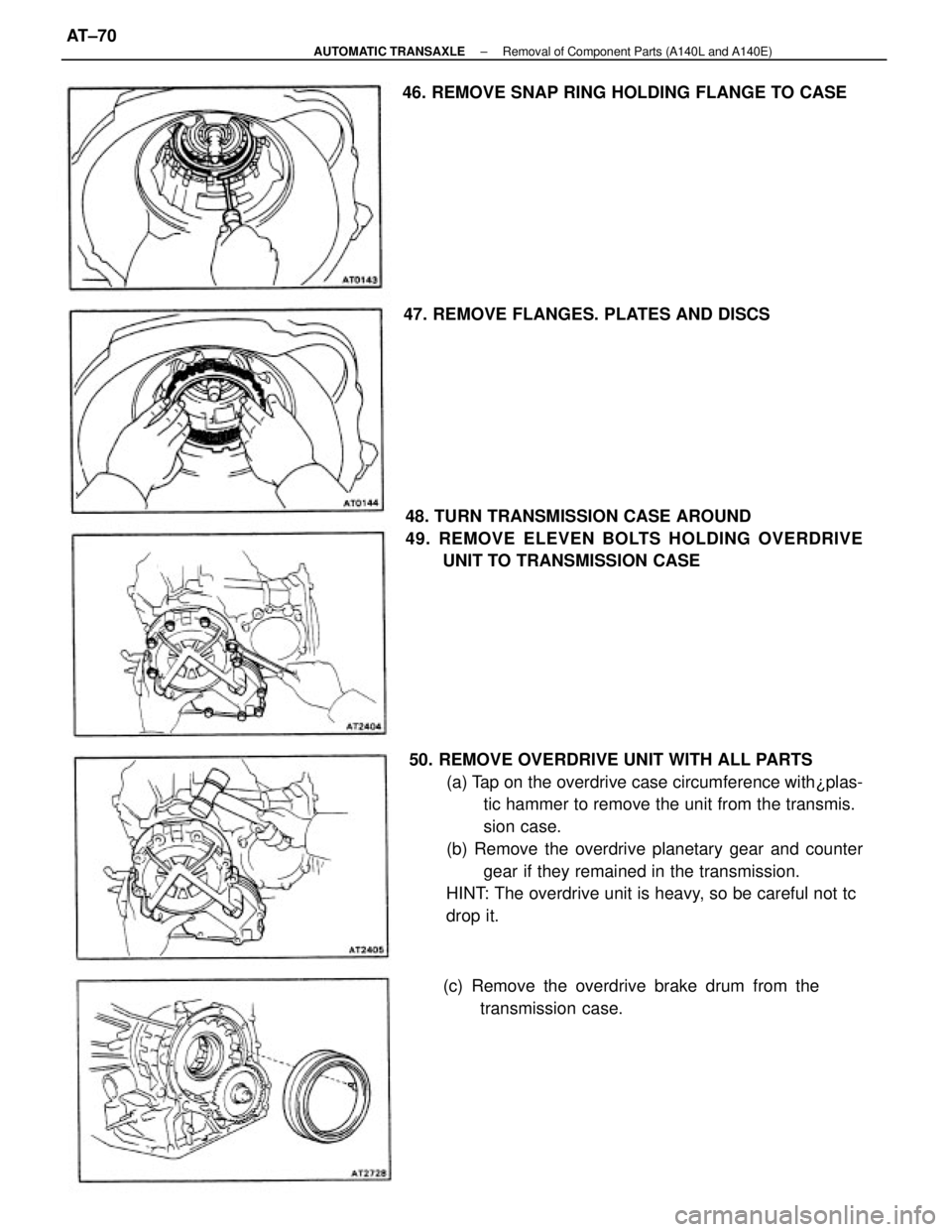

50. REMOVE OVERDRIVE UNIT WITH ALL PARTS

(a) Tap on the overdrive case circumference with¿plas-

tic hammer to remove the unit from the transmis.

sion case.

(b) Remove the overdrive planetary gear and counter

gear if they remained in the transmission.

HINT: The overdrive unit is heavy, so be careful not tc

drop it. 48. TURN TRANSMISSION CASE AROUND

49. REMOVE ELEVEN BOLTS HOLDING OVERDRIVE

UNIT TO TRANSMISSION CASE

(c) Remove the overdrive brake drum from the

transmission case. 46. REMOVE SNAP RING HOLDING FLANGE TO CASE

47. REMOVE FLANGES. PLATES AND DISCS

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±70

Page 334 of 2389

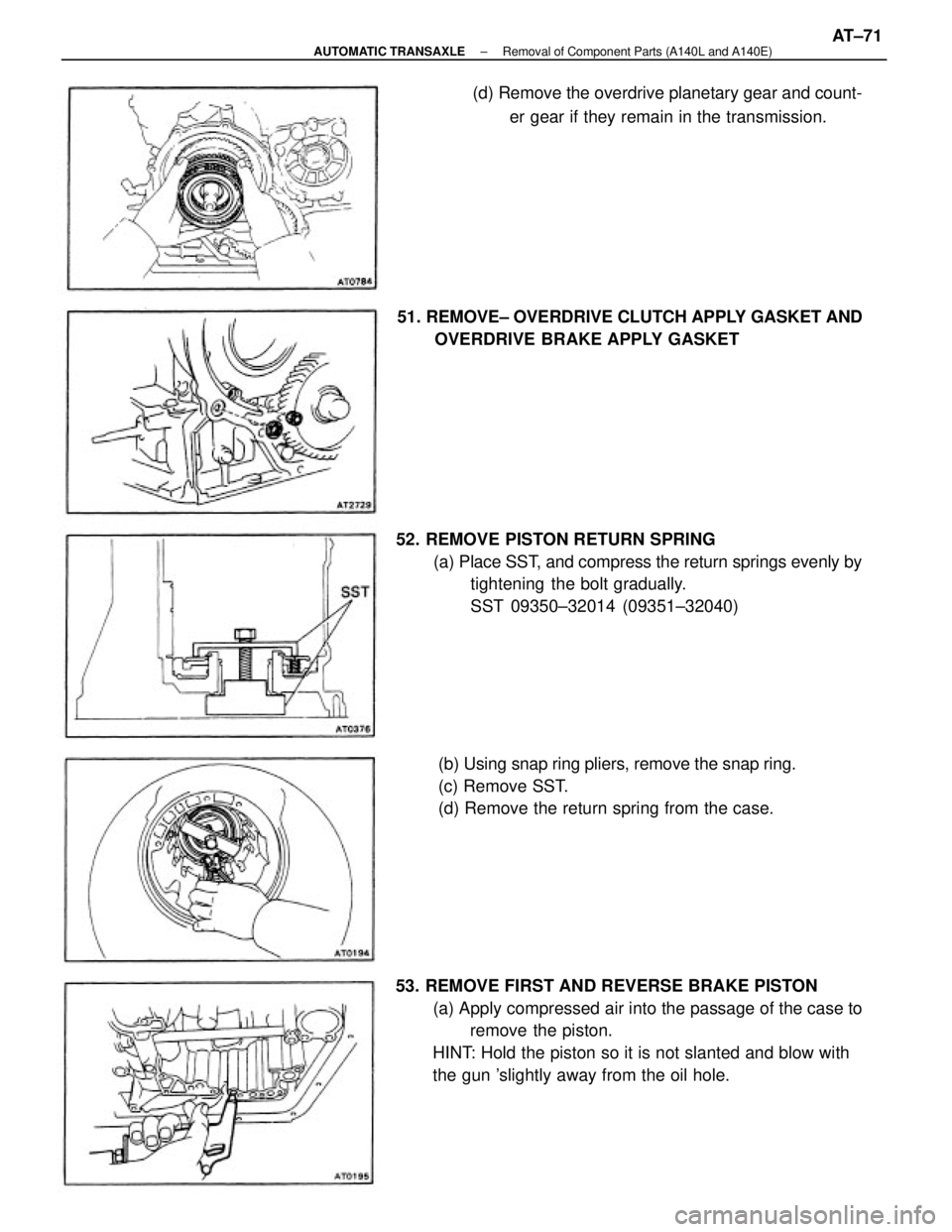

53. REMOVE FIRST AND REVERSE BRAKE PISTON

(a) Apply compressed air into the passage of the case to

remove the piston.

HINT: Hold the piston so it is not slanted and blow with

the gun 'slightly away from the oil hole. 52. REMOVE PISTON RETURN SPRING

(a) Place SST, and compress the return springs evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

(b) Using snap ring pliers, remove the snap ring.

(c) Remove SST.

(d) Remove the return spring from the case. 51. REMOVE± OVERDRIVE CLUTCH APPLY GASKET AND

OVERDRIVE BRAKE APPLY GASKET(d) Remove the overdrive planetary gear and count-

er gear if they remain in the transmission.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±71

Page 335 of 2389

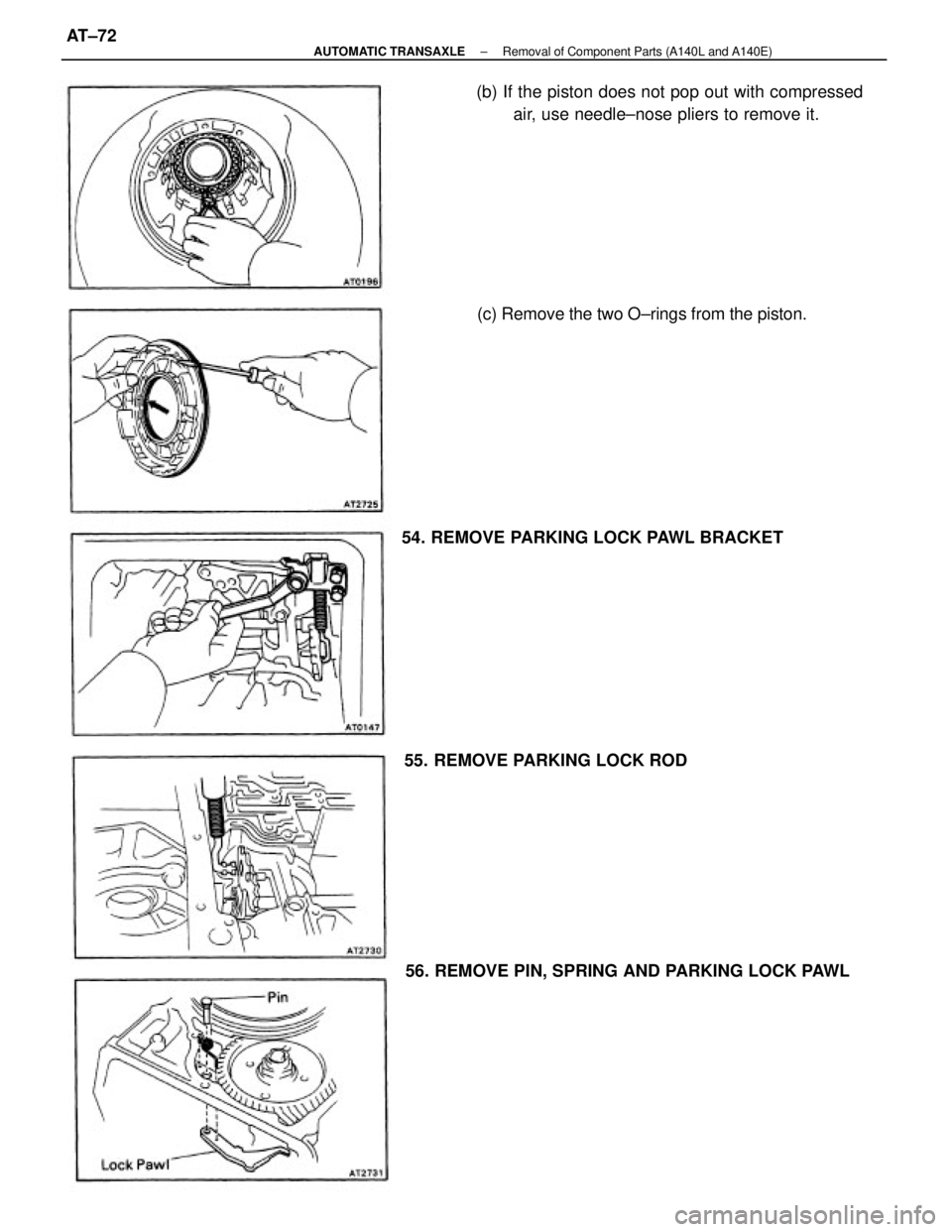

(b) If the piston does not pop out with compressed

air, use needle±nose pliers to remove it.

56. REMOVE PIN, SPRING AND PARKING LOCK PAWL 54. REMOVE PARKING LOCK PAWL BRACKET(c) Remove the two O±rings from the piston.

55. REMOVE PARKING LOCK ROD

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±72

Page 336 of 2389

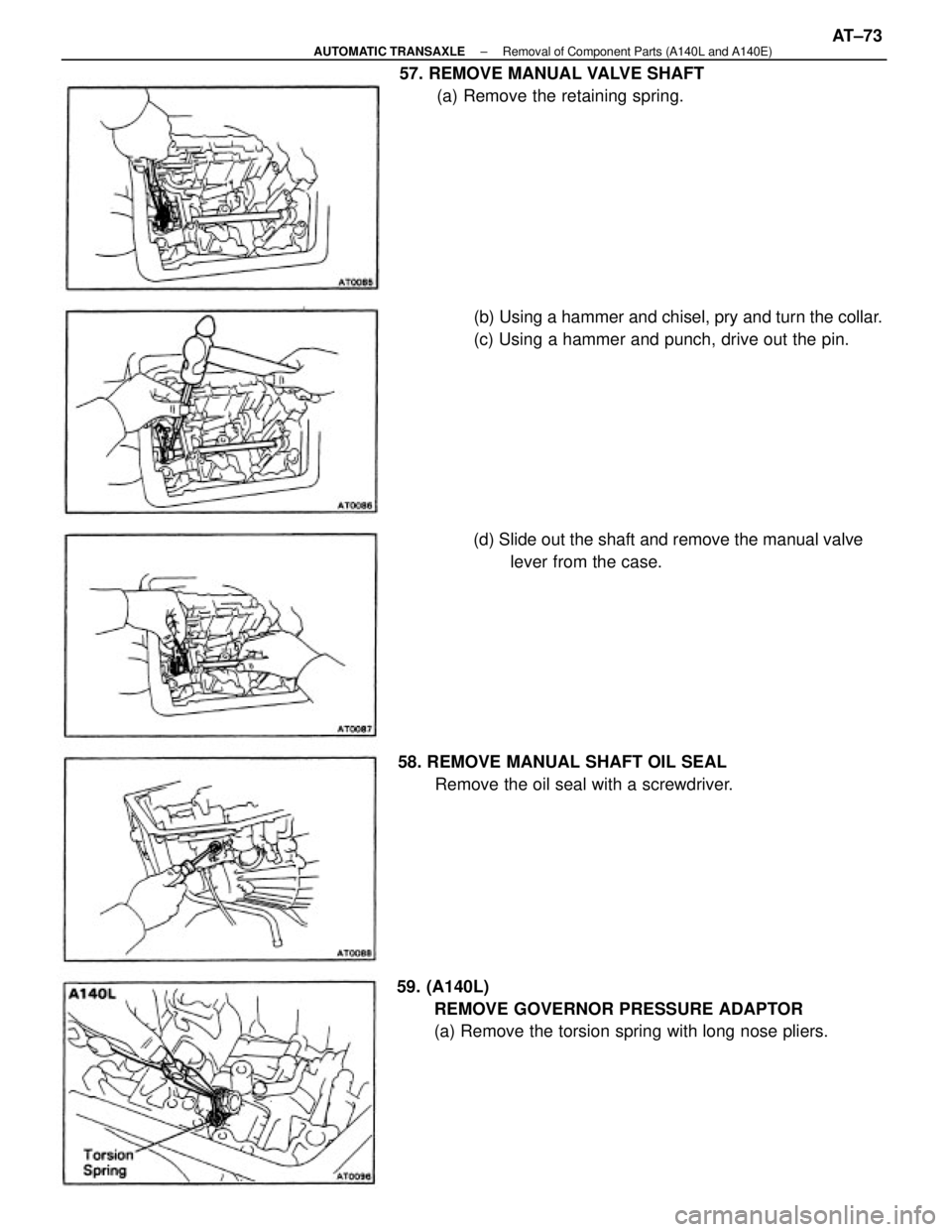

(b) Using a hammer and chisel, pry and turn the collar.

(c) Using a hammer and punch, drive out the pin.

59. (A140L)

REMOVE GOVERNOR PRESSURE ADAPTOR

(a) Remove the torsion spring with long nose pliers. 57. REMOVE MANUAL VALVE SHAFT

(a) Remove the retaining spring.

(d) Slide out the shaft and remove the manual valve

lever from the case.

58. REMOVE MANUAL SHAFT OIL SEAL

Remove the oil seal with a screwdriver.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±73

Page 337 of 2389

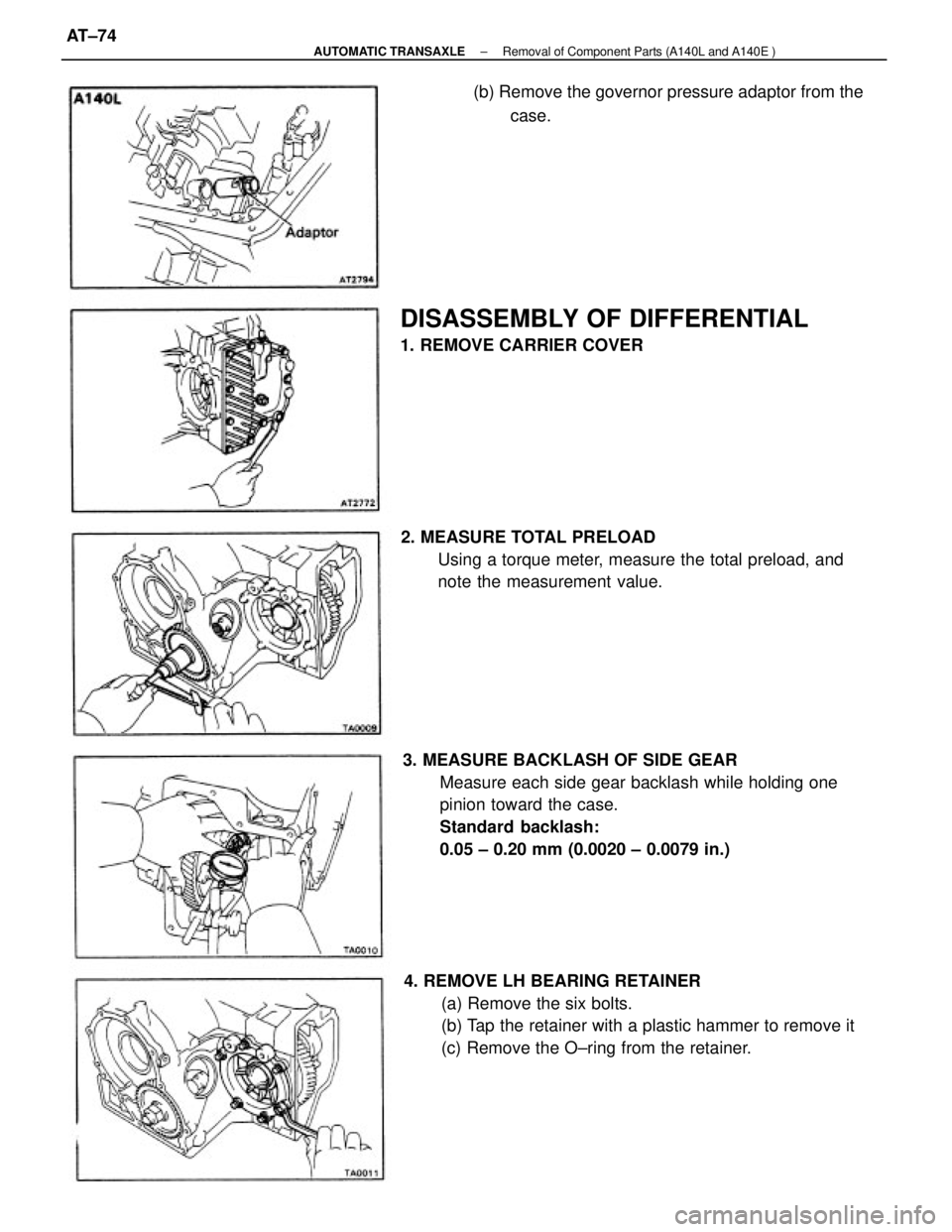

3. MEASURE BACKLASH OF SIDE GEAR

Measure each side gear backlash while holding one

pinion toward the case.

Standard backlash:

0.05 ± 0.20 mm (0.0020 ± 0.0079 in.)

4. REMOVE LH BEARING RETAINER

(a) Remove the six bolts.

(b) Tap the retainer with a plastic hammer to remove it

(c) Remove the O±ring from the retainer. 2. MEASURE TOTAL PRELOAD

Using a torque meter, measure the total preload, and

note the measurement value.

DISASSEMBLY OF DIFFERENTIAL

1. REMOVE CARRIER COVER(b) Remove the governor pressure adaptor from the

case.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E )AT±74

Page 338 of 2389

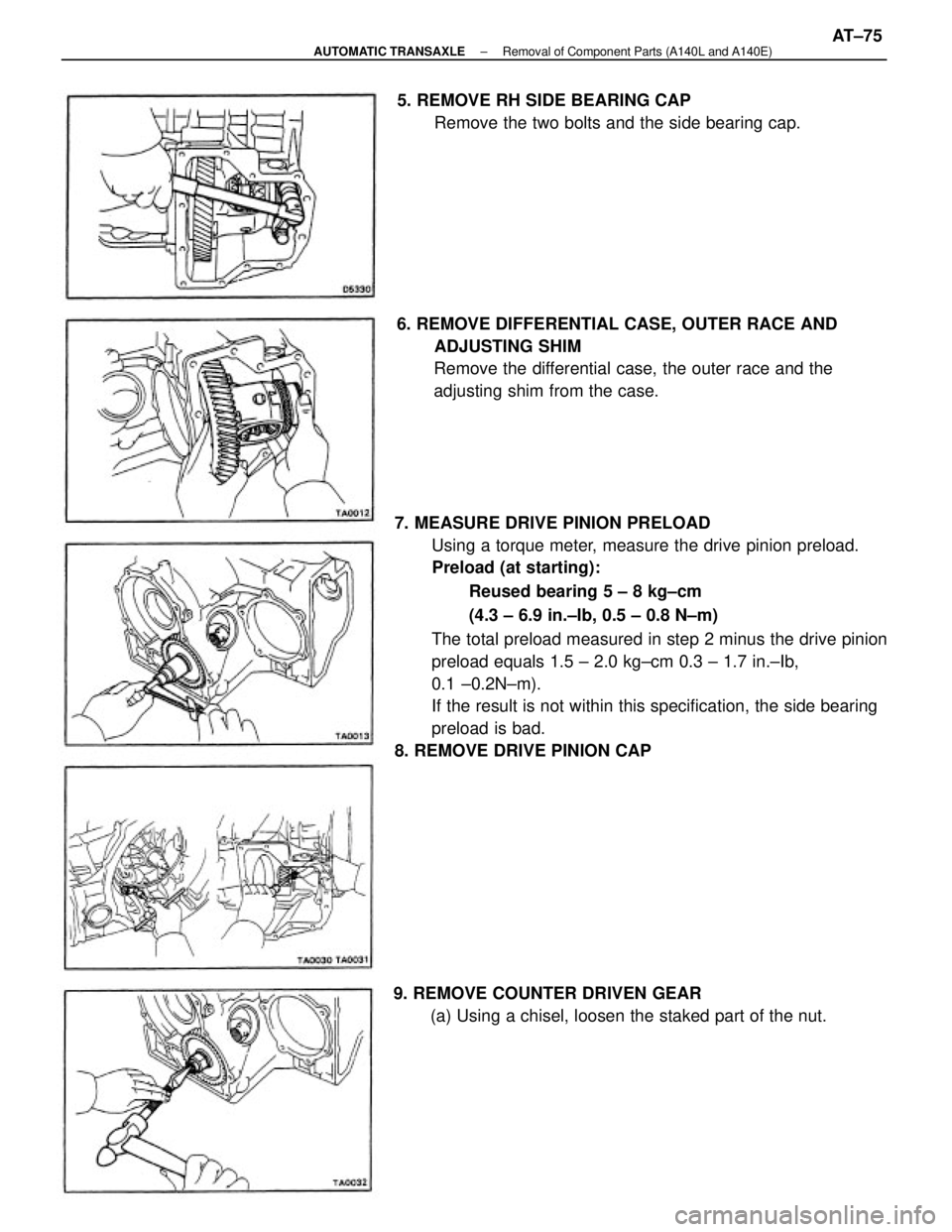

7. MEASURE DRIVE PINION PRELOAD

Using a torque meter, measure the drive pinion preload.

Preload (at starting):

Reused bearing 5 ± 8 kg±cm

(4.3 ± 6.9 in.±Ib, 0.5 ± 0.8 N±m)

The total preload measured in step 2 minus the drive pinion

preload equals 1.5 ± 2.0 kg±cm 0.3 ± 1.7 in.±Ib,

0.1 ±0.2N±m).

If the result is not within this specification, the side bearing

preload is bad.

8. REMOVE DRIVE PINION CAP6. REMOVE DIFFERENTIAL CASE, OUTER RACE AND

ADJUSTING SHIM

Remove the differential case, the outer race and the

adjusting shim from the case.

9. REMOVE COUNTER DRIVEN GEAR

(a) Using a chisel, loosen the staked part of the nut. 5. REMOVE RH SIDE BEARING CAP

Remove the two bolts and the side bearing cap.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±75

Page 339 of 2389

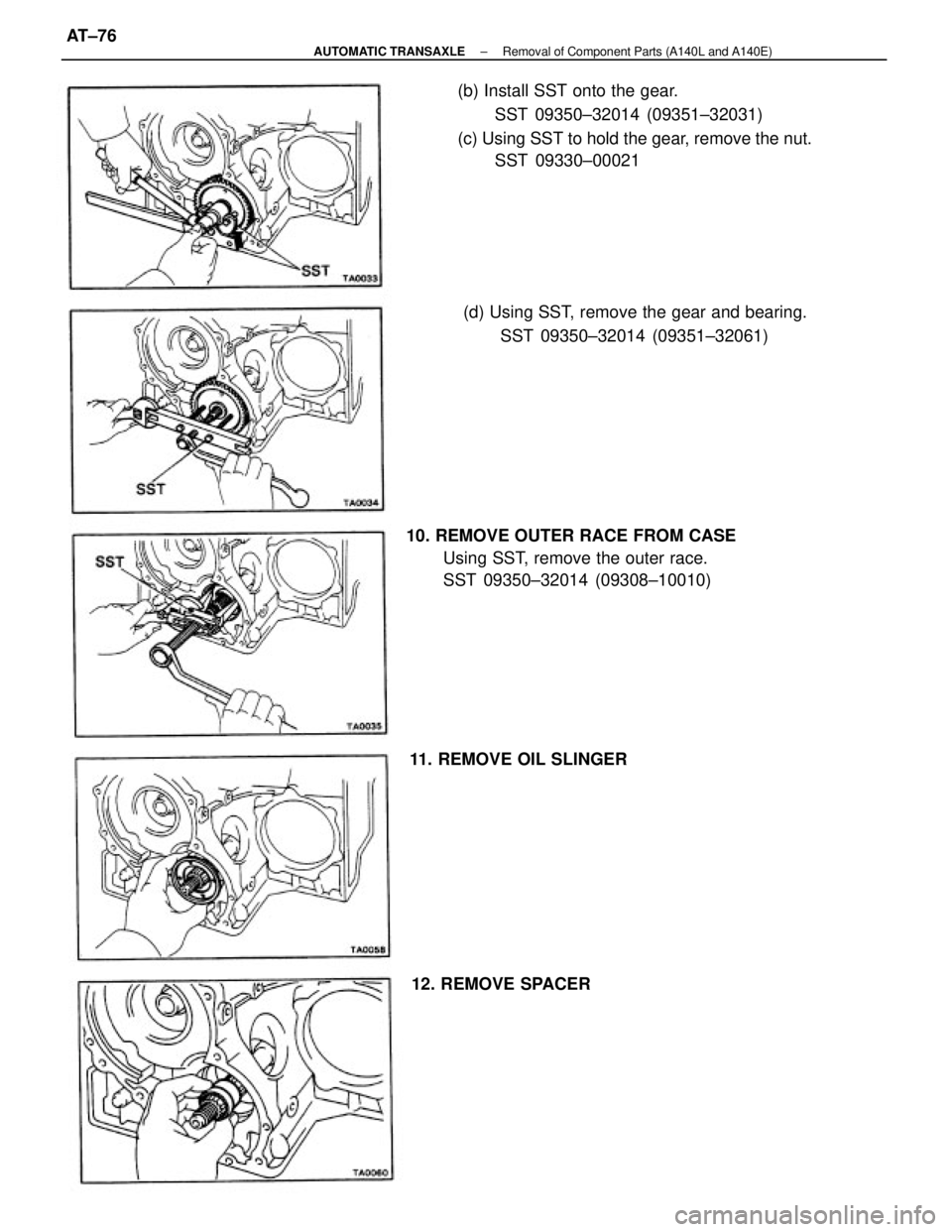

(b) Install SST onto the gear.

SST 09350±32014 (09351±32031)

(c) Using SST to hold the gear, remove the nut.

SST 09330±00021

10. REMOVE OUTER RACE FROM CASE

Using SST, remove the outer race.

SST 09350±32014 (09308±10010)(d) Using SST, remove the gear and bearing.

SST 09350±32014 (09351±32061)

11. REMOVE OIL SLINGER

12. REMOVE SPACER

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±76

Page 340 of 2389

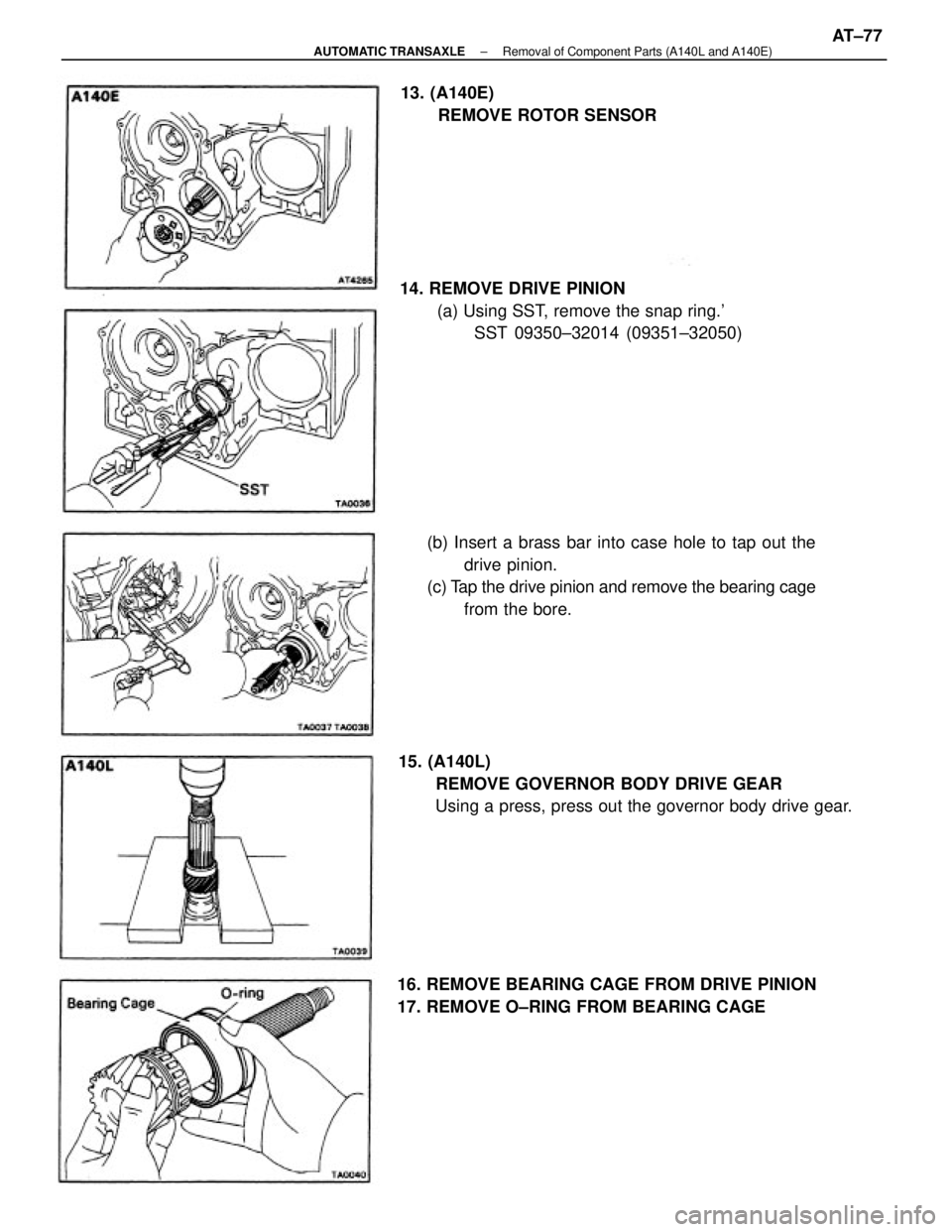

(b) Insert a brass bar into case hole to tap out the

drive pinion.

(c) Tap the drive pinion and remove the bearing cage

from the bore. 14. REMOVE DRIVE PINION

(a) Using SST, remove the snap ring.'

SST 09350±32014 (09351±32050)

15. (A140L)

REMOVE GOVERNOR BODY DRIVE GEAR

Using a press, press out the governor body drive gear.

16. REMOVE BEARING CAGE FROM DRIVE PINION

17. REMOVE O±RING FROM BEARING CAGE13. (A140E)

REMOVE ROTOR SENSOR

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±77

Trending: air bleeding, brake pads, jack points, adding oil, door lock, audio, Strut