TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: engine oil, air suspension, coolant temperature, mileage, power steering, differential, charging

Page 371 of 2389

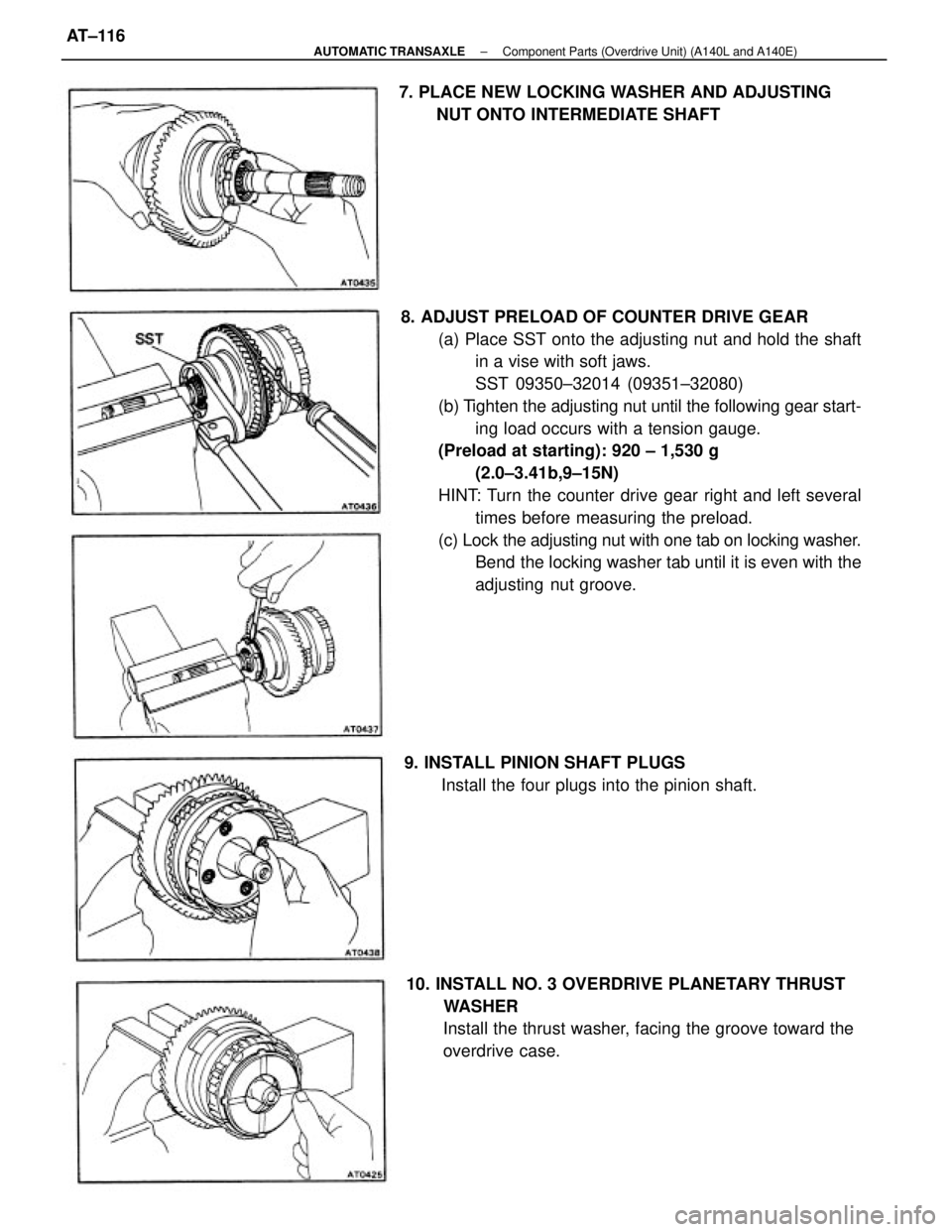

8. ADJUST PRELOAD OF COUNTER DRIVE GEAR

(a) Place SST onto the adjusting nut and hold the shaft

in a vise with soft jaws.

SST 09350±32014 (09351±32080)

(b) Tighten the adjusting nut until the following gear start-

ing load occurs with a tension gauge.

(Preload at starting): 920 ± 1,530 g

(2.0±3.41b,9±15N)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one tab on locking washer.

Bend the locking washer tab until it is even with the

adjusting nut groove.

10. INSTALL NO. 3 OVERDRIVE PLANETARY THRUST

WASHER

Install the thrust washer, facing the groove toward the

overdrive case. 7. PLACE NEW LOCKING WASHER AND ADJUSTING

NUT ONTO INTERMEDIATE SHAFT

9. INSTALL PINION SHAFT PLUGS

Install the four plugs into the pinion shaft.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±116

Page 372 of 2389

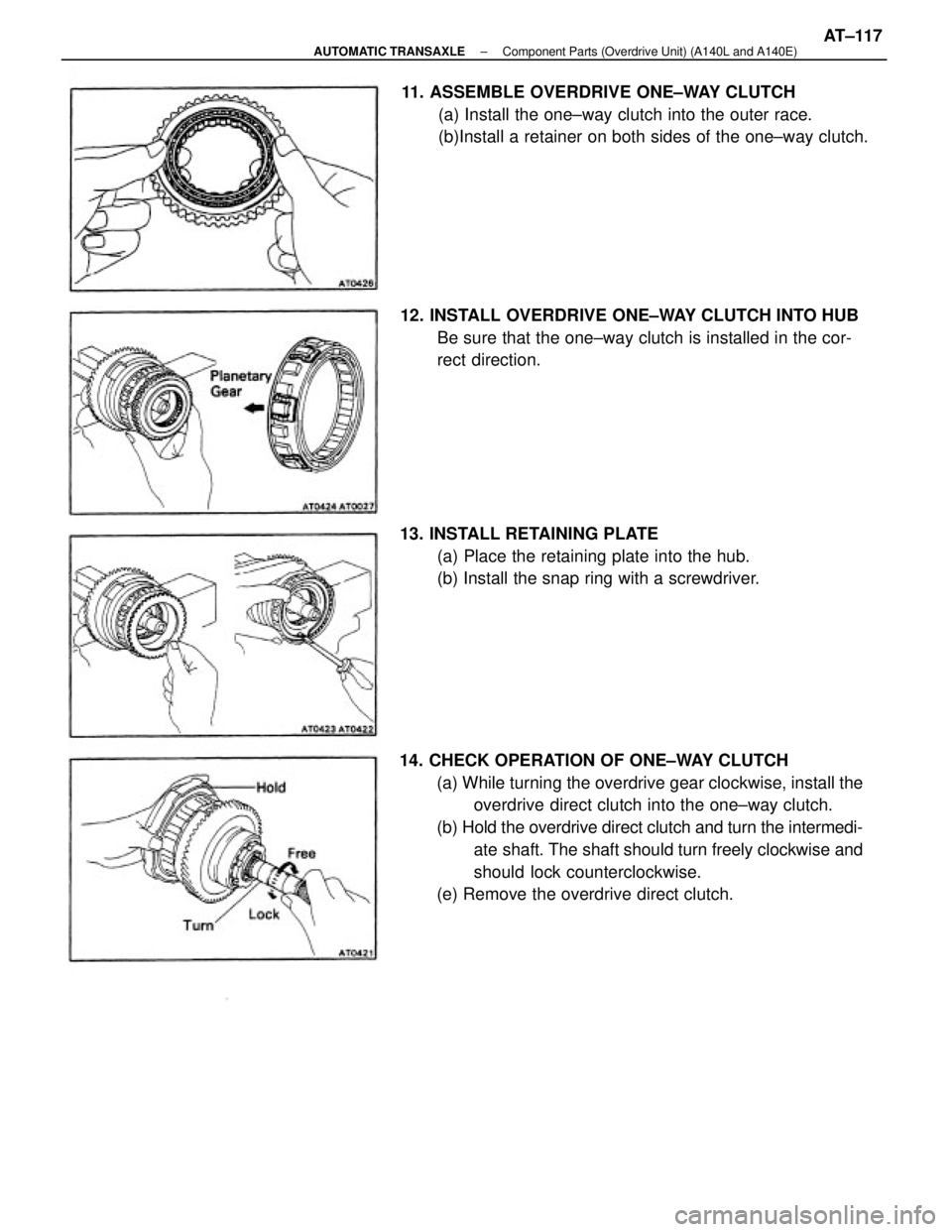

14. CHECK OPERATION OF ONE±WAY CLUTCH

(a) While turning the overdrive gear clockwise, install the

overdrive direct clutch into the one±way clutch.

(b) Hold the overdrive direct clutch and turn the intermedi-

ate shaft. The shaft should turn freely clockwise and

should lock counterclockwise.

(e) Remove the overdrive direct clutch. 11. ASSEMBLE OVERDRIVE ONE±WAY CLUTCH

(a) Install the one±way clutch into the outer race.

(b)Install a retainer on both sides of the one±way clutch.

12. INSTALL OVERDRIVE ONE±WAY CLUTCH INTO HUB

Be sure that the one±way clutch is installed in the cor-

rect direction.

13. INSTALL RETAINING PLATE

(a) Place the retaining plate into the hub.

(b) Install the snap ring with a screwdriver.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±117

Page 373 of 2389

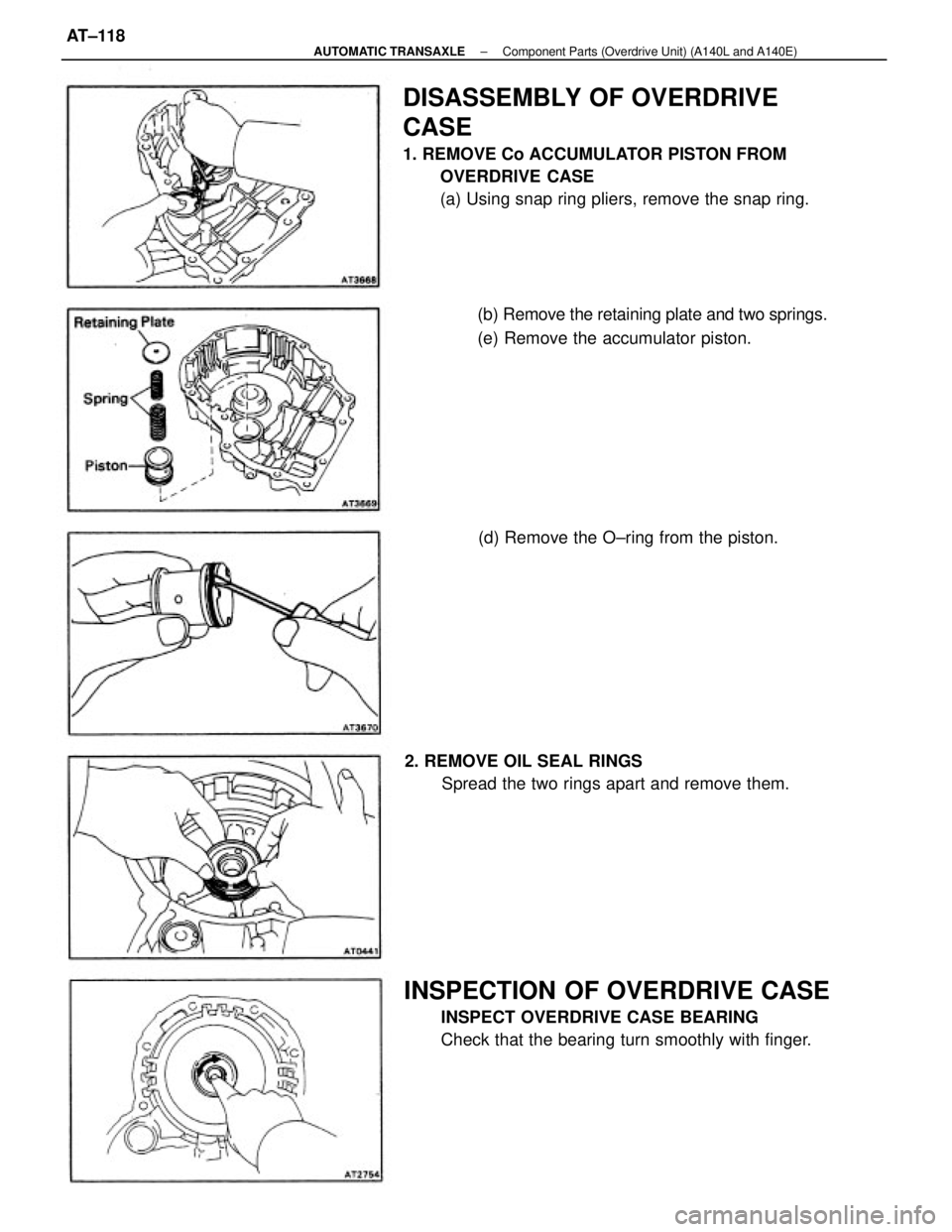

DISASSEMBLY OF OVERDRIVE

CASE

1. REMOVE Co ACCUMULATOR PISTON FROM

OVERDRIVE CASE

(a) Using snap ring pliers, remove the snap ring.

INSPECTION OF OVERDRIVE CASE

INSPECT OVERDRIVE CASE BEARING

Check that the bearing turn smoothly with finger. 2. REMOVE OIL SEAL RINGS

Spread the two rings apart and remove them.(b) Remove the retaining plate and two springs.

(e) Remove the accumulator piston.

(d) Remove the O±ring from the piston.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±118

Page 374 of 2389

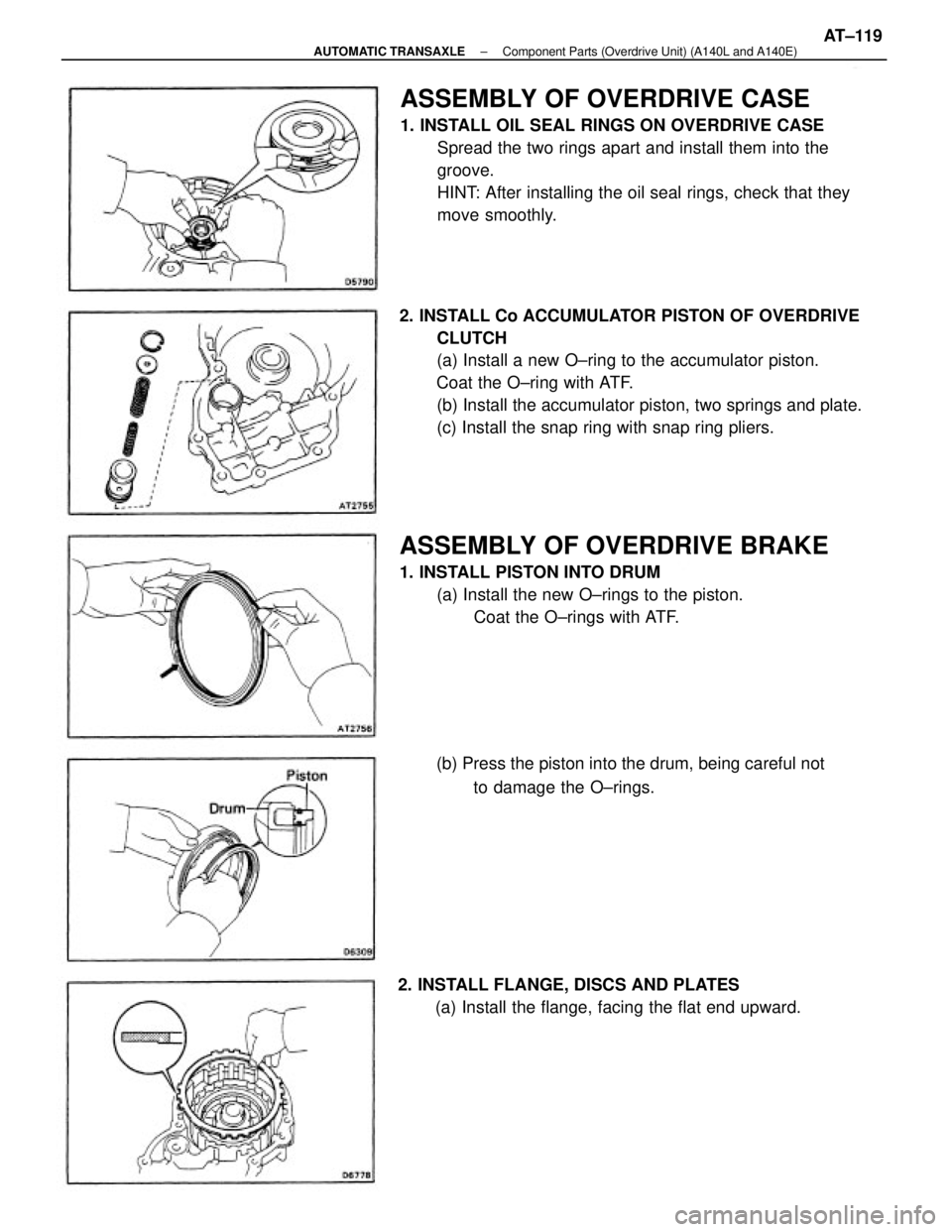

ASSEMBLY OF OVERDRIVE CASE

1. INSTALL OIL SEAL RINGS ON OVERDRIVE CASE

Spread the two rings apart and install them into the

groove.

HINT: After installing the oil seal rings, check that they

move smoothly.

2. INSTALL Co ACCUMULATOR PISTON OF OVERDRIVE

CLUTCH

(a) Install a new O±ring to the accumulator piston.

Coat the O±ring with ATF.

(b) Install the accumulator piston, two springs and plate.

(c) Install the snap ring with snap ring pliers.

ASSEMBLY OF OVERDRIVE BRAKE

1. INSTALL PISTON INTO DRUM

(a) Install the new O±rings to the piston.

Coat the O±rings with ATF.

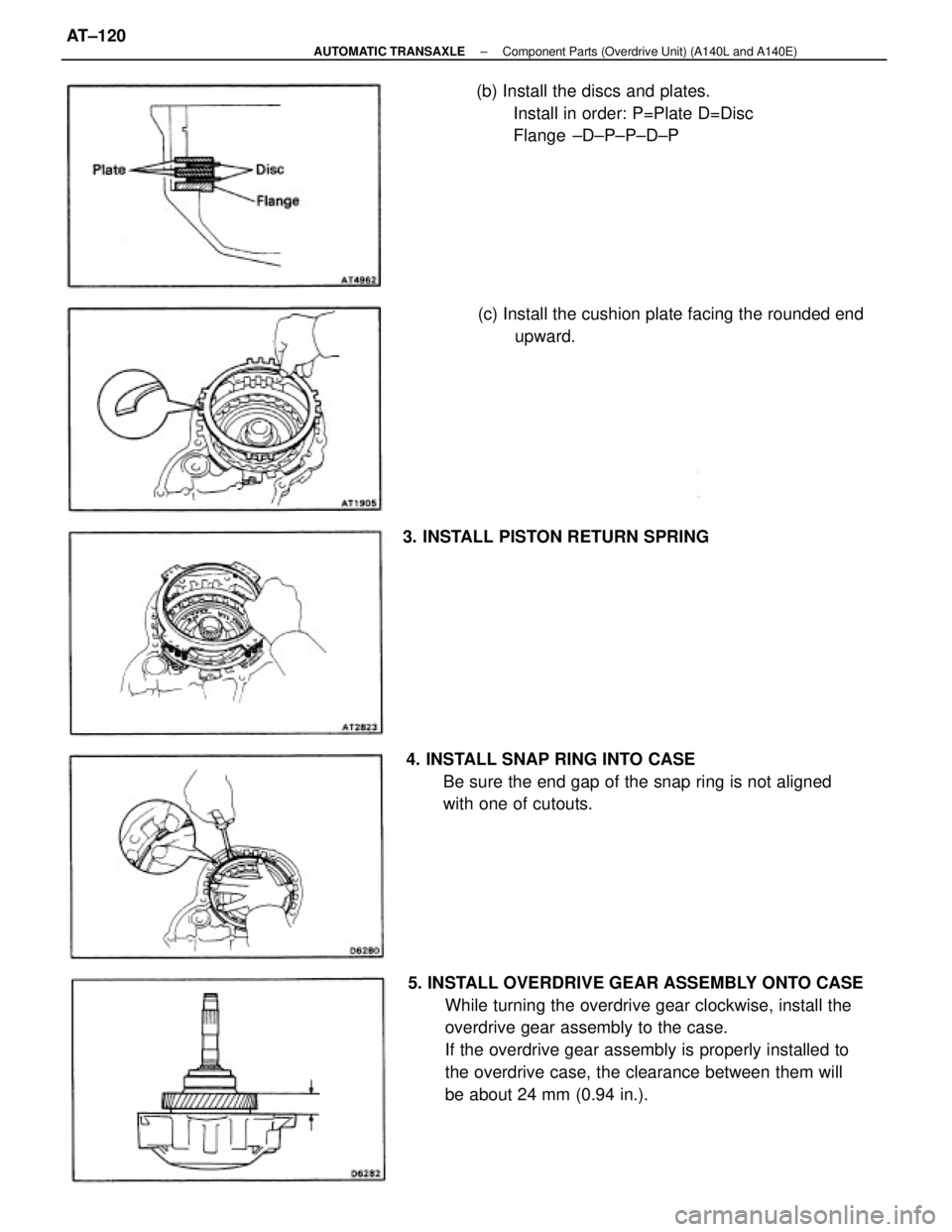

2. INSTALL FLANGE, DISCS AND PLATES

(a) Install the flange, facing the flat end upward.(b) Press the piston into the drum, being careful not

to damage the O±rings.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±119

Page 375 of 2389

5. INSTALL OVERDRIVE GEAR ASSEMBLY ONTO CASE

While turning the overdrive gear clockwise, install the

overdrive gear assembly to the case.

If the overdrive gear assembly is properly installed to

the overdrive case, the clearance between them will

be about 24 mm (0.94 in.). 4. INSTALL SNAP RING INTO CASE

Be sure the end gap of the snap ring is not aligned

with one of cutouts.(b) Install the discs and plates.

Install in order: P=Plate D=Disc

Flange ±D±P±P±D±P

(c) Install the cushion plate facing the rounded end

upward.

3. INSTALL PISTON RETURN SPRING

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±120

Page 376 of 2389

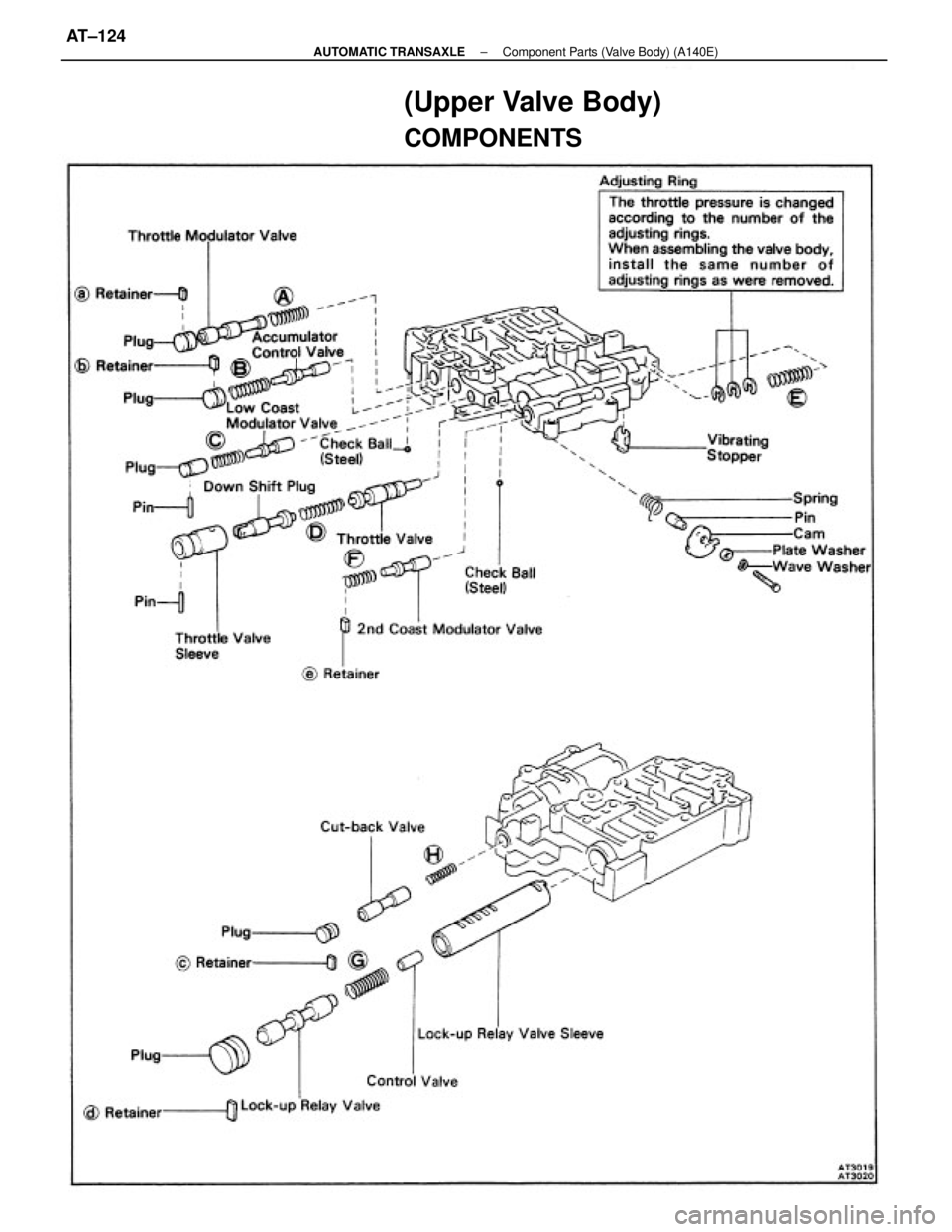

(Disassembly of Valve Body)

1. NOTE THE NUMBERS OF ADJUSTING RINGS

HINT: Count the number of adjusting rings before dis-

assembly of the valve body because the throttle pres-

sure is changed according to the number. (Some of the

valve bodies do not have any adjusting rings.)

2. REMOVE SOLENOIDS

(a) Remove the No. 1 and No. 2 solenoids.

(b) Remove the 4±rings from the solenoids.

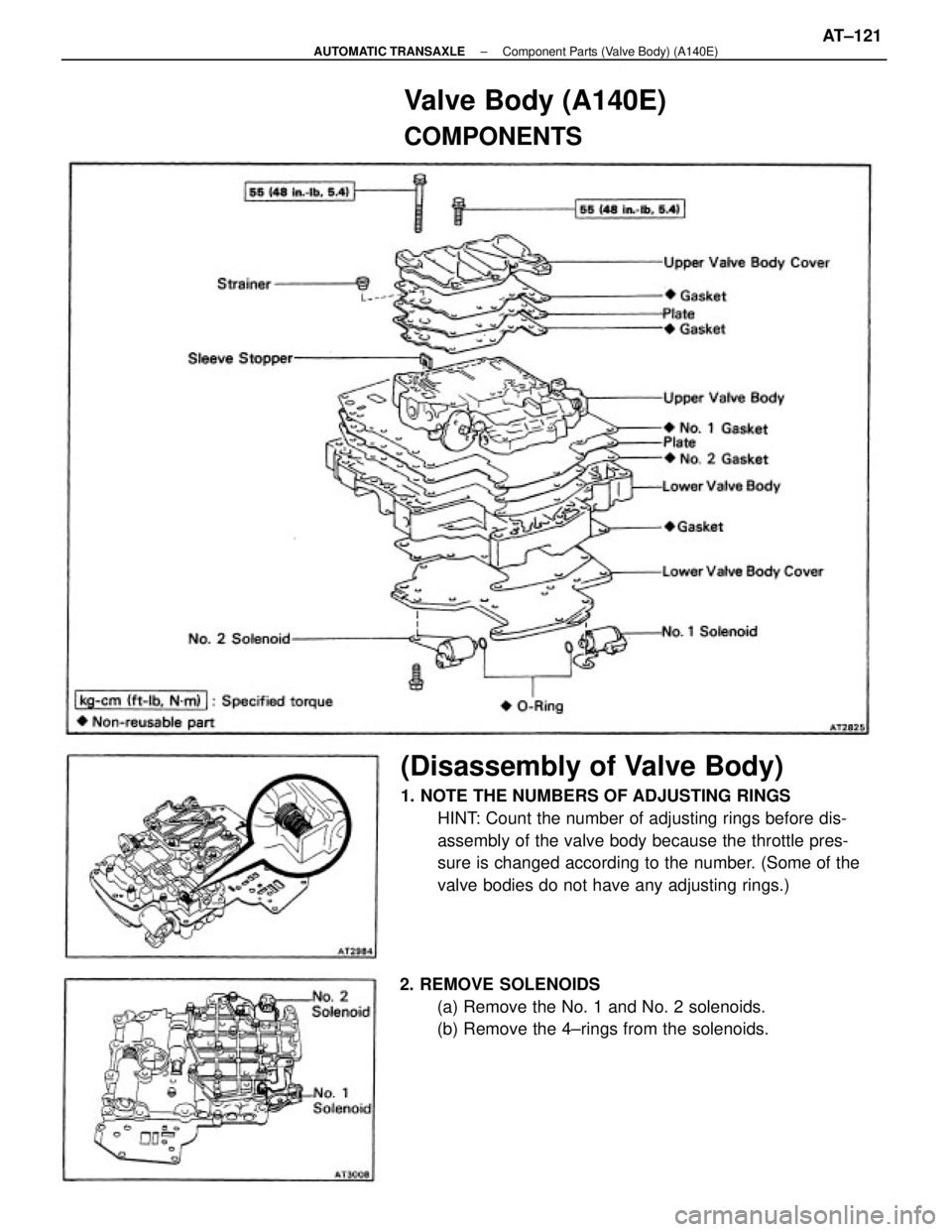

Valve Body (A140E)

COMPONENTS

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±121

Page 377 of 2389

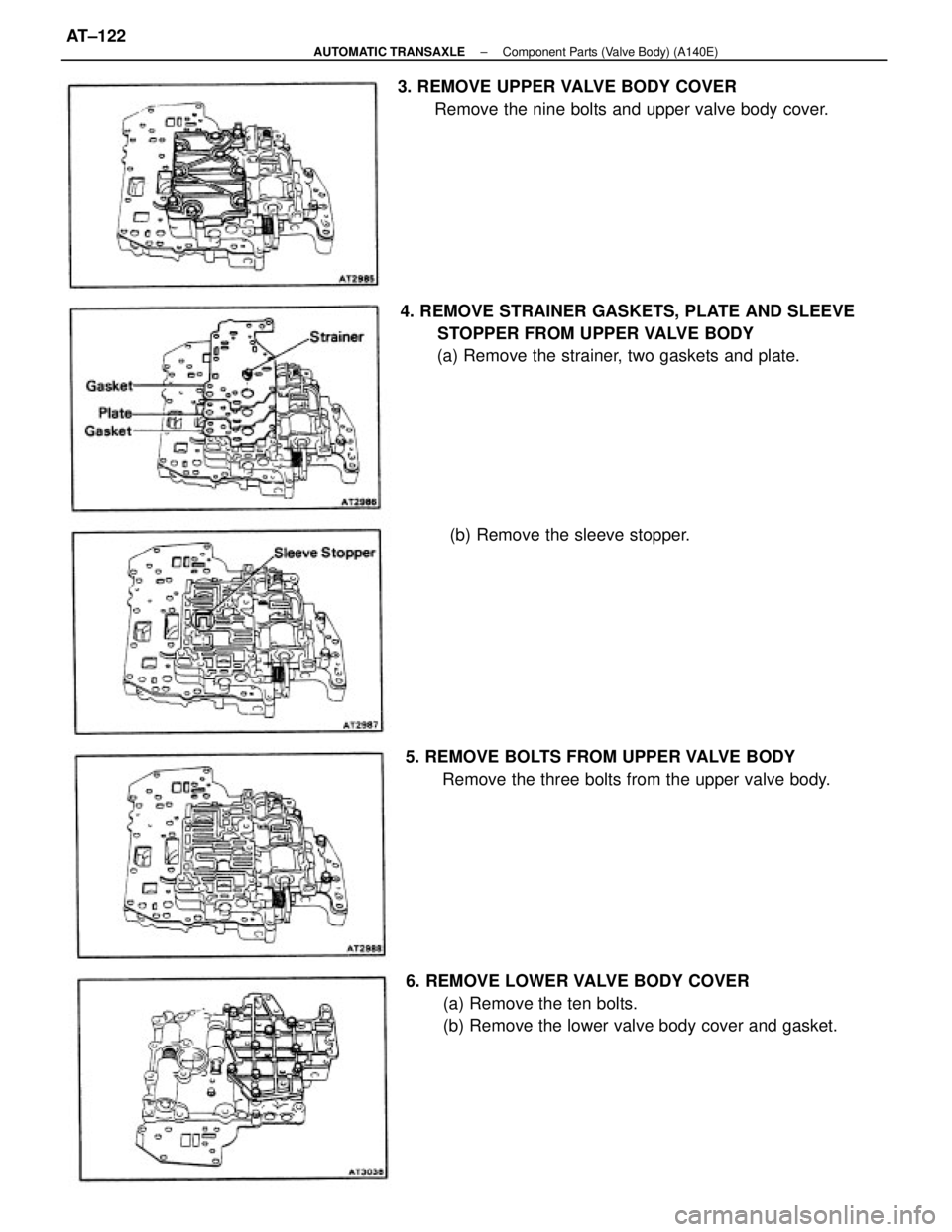

6. REMOVE LOWER VALVE BODY COVER

(a) Remove the ten bolts.

(b) Remove the lower valve body cover and gasket. 4. REMOVE STRAINER GASKETS, PLATE AND SLEEVE

STOPPER FROM UPPER VALVE BODY

(a) Remove the strainer, two gaskets and plate. 3. REMOVE UPPER VALVE BODY COVER

Remove the nine bolts and upper valve body cover.

5. REMOVE BOLTS FROM UPPER VALVE BODY

Remove the three bolts from the upper valve body.(b) Remove the sleeve stopper.

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±122

Page 378 of 2389

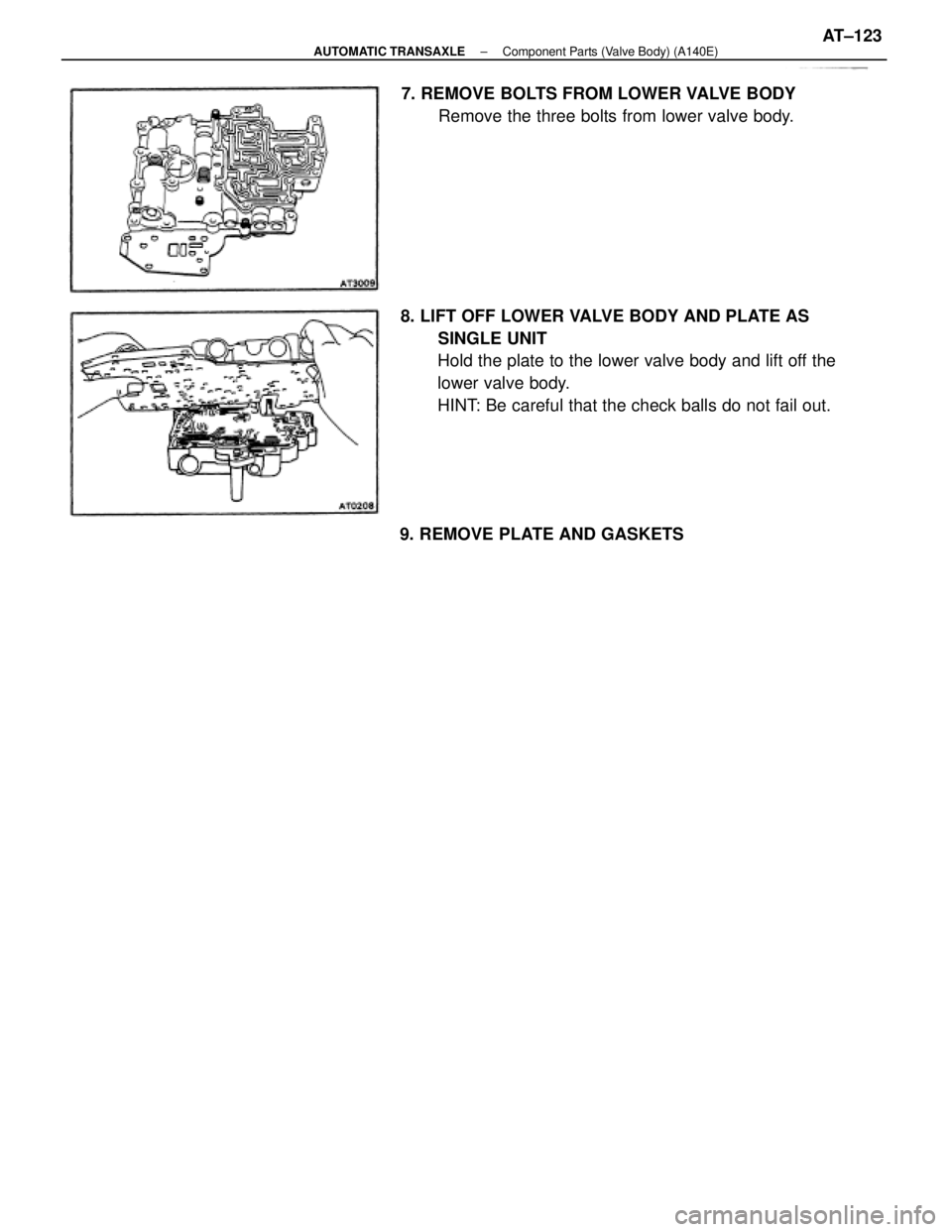

8. LIFT OFF LOWER VALVE BODY AND PLATE AS

SINGLE UNIT

Hold the plate to the lower valve body and lift off the

lower valve body.

HINT: Be careful that the check balls do not fail out. 7. REMOVE BOLTS FROM LOWER VALVE BODY

Remove the three bolts from lower valve body.

9. REMOVE PLATE AND GASKETS

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±123

Page 379 of 2389

(Upper Valve Body)

COMPONENTS

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±124

Page 380 of 2389

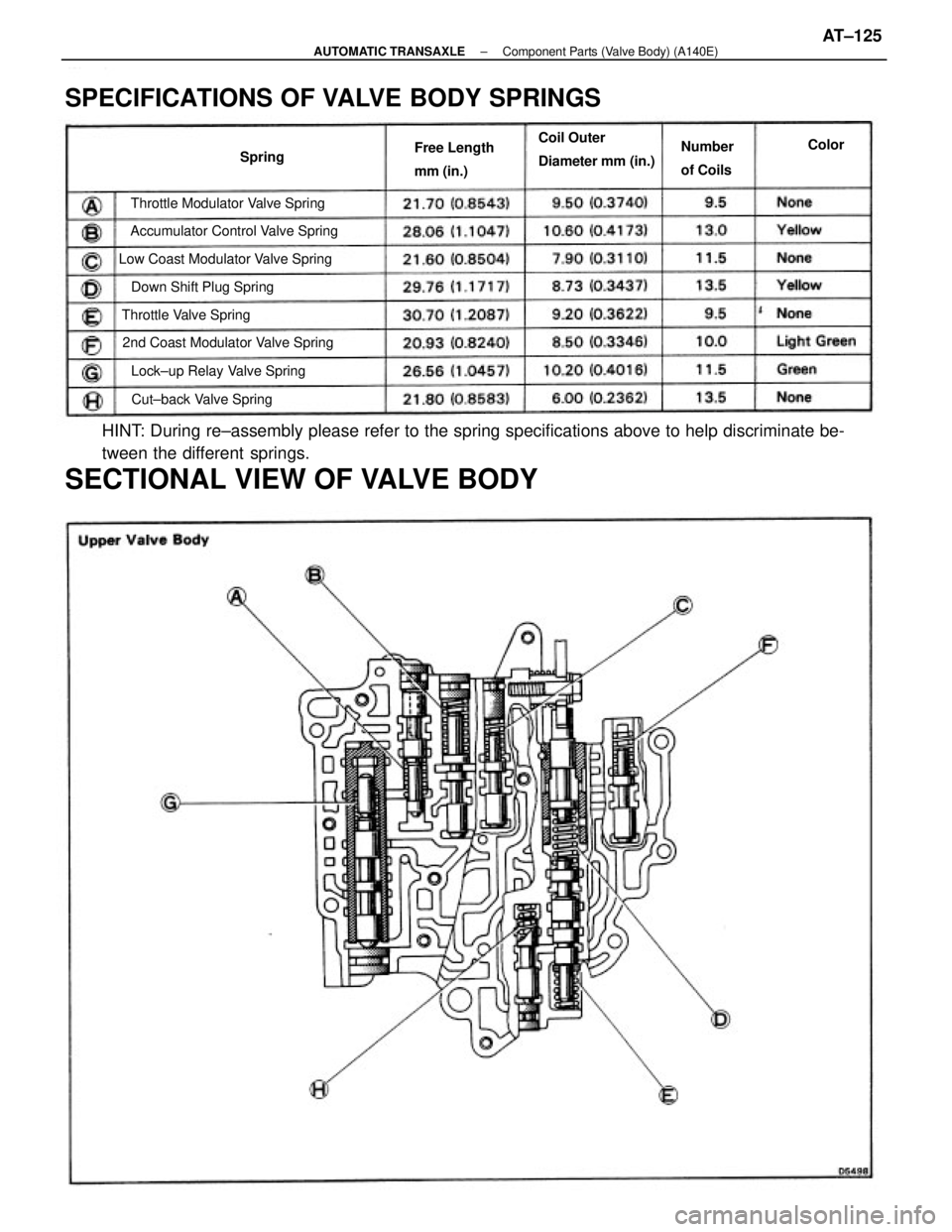

HINT: During re±assembly please refer to the spring specifications above to help discriminate be-

tween the different springs.

SECTIONAL VIEW OF VALVE BODY

SPECIFICATIONS OF VALVE BODY SPRINGS

Low Coast Modulator Valve Spring

2nd Coast Modulator Valve SpringAccumulator Control Valve SpringThrottle Modulator Valve Spring

Lock±up Relay Valve SpringCoil Outer

Diameter mm (in.)

Down Shift Plug Spring

Cut±back Valve Spring Throttle Valve SpringFree Length

mm (in.)Number

of Coils SpringColor

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±125

Trending: rims, battery replacement, cooling, fuel type, brake pads replacement, tire pressure, interior