check engine TOYOTA RAV4 1996 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 686 of 1632

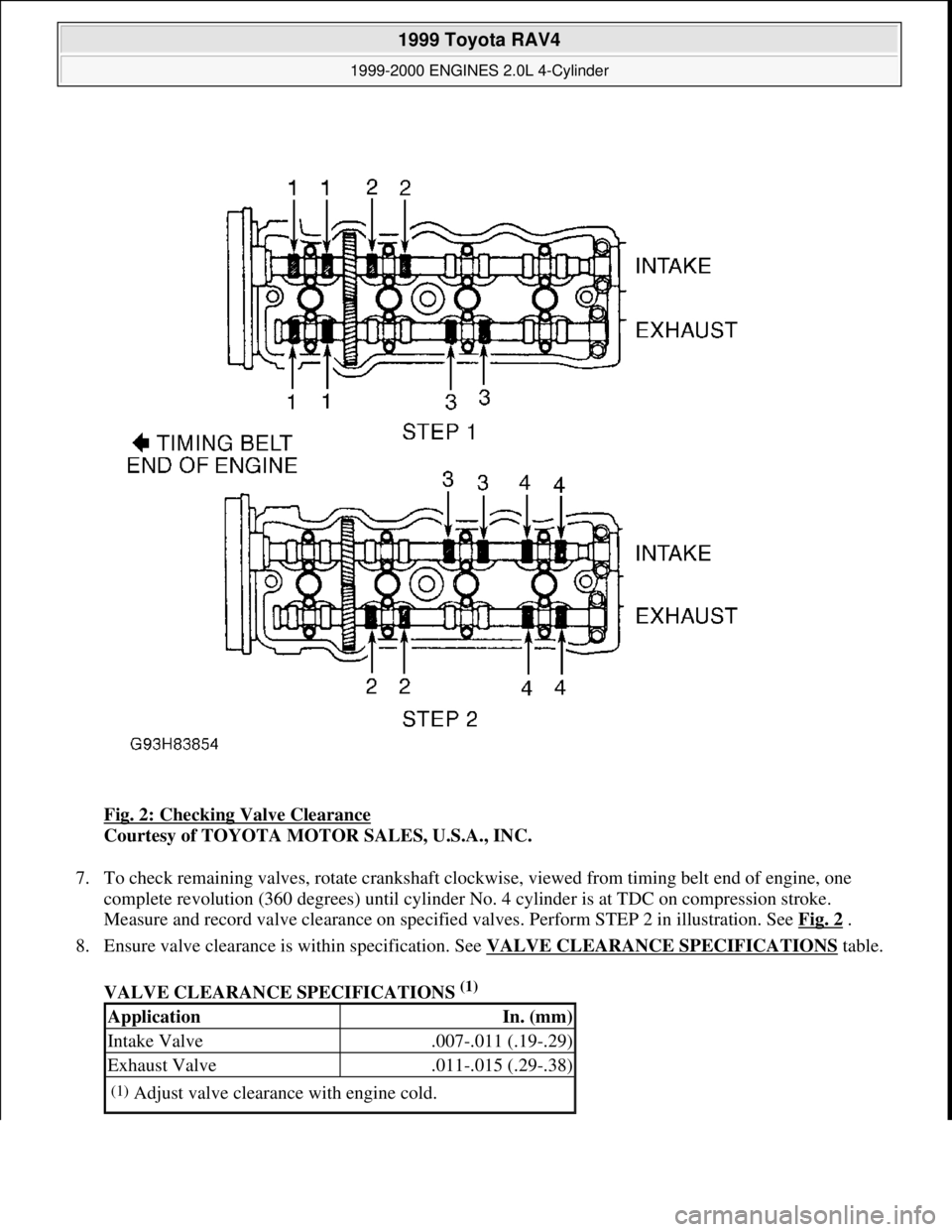

Fig. 2: Checking Valve Clearance

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7. To check remaining valves, rotate crankshaft clockwise, viewed from timing belt end of engine, one

complete revolution (360 degrees) until cylinder No. 4 cylinder is at TDC on compression stroke.

Measure and record valve clearance on specified valves. Perform STEP 2 in illustration. See Fig. 2

.

8. Ensure valve clearance is within specification. See VALVE CLEARANCE SPECIFICATIONS

table.

VALVE CLEARANCE SPECIFICATIONS

(1)

ApplicationIn. (mm)

Intake Valve.007-.011 (.19-.29)

Exhaust Valve.011-.015 (.29-.38)

(1)Adjust valve clearance with engine cold.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 691 of 1632

Fig. 5: Exhaust Valve Adjusting Shim Selection Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

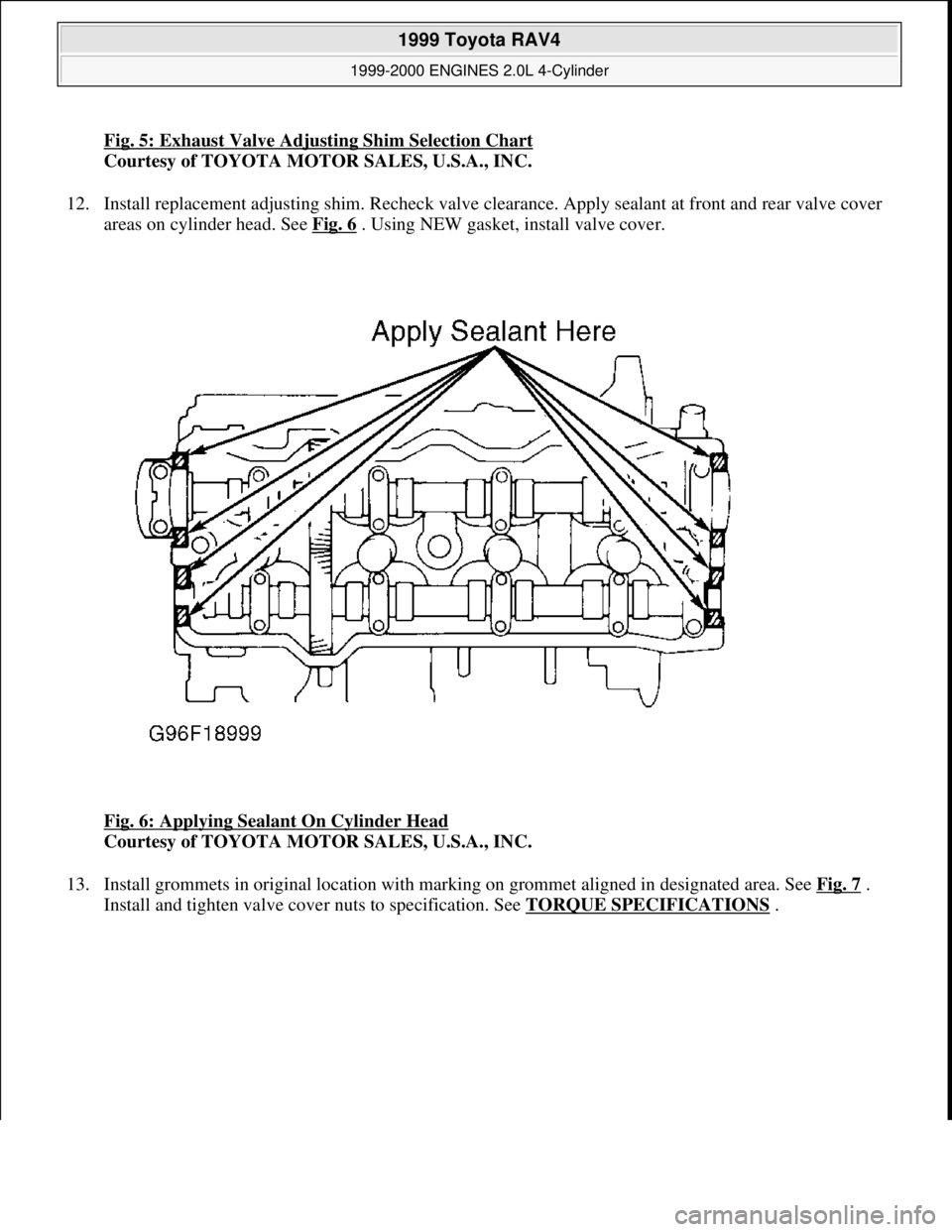

12. Install replacement adjusting shim. Recheck valve clearance. Apply sealant at front and rear valve cover

areas on cylinder head. See Fig. 6

. Using NEW gasket, install valve cover.

Fig. 6: Applying Sealant On Cylinder Head

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

13. Install grommets in original location with marking on grommet aligned in designated area. See Fig. 7

.

Install and ti

ghten valve cover nuts to specification. See TORQUE SPECIFICATIONS.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 704 of 1632

Inspection

1. Inspect cylinder head warpage at cylinder block, exhaust manifold and intake manifold surfaces. Replace

cylinder head if warpage exceeds specification. See CYLINDER HEAD

table under ENGINE

SPECIFICATIONS.

2. Inspect cylinder block deck surface for warpage. Replace cylinder block if deck surface warpage exceeds

specification. See CYLINDER BLOCK

table under ENGINE SPECIFICATIONS.

3. Inspect intake and exhaust manifold machined surfaces for warpage. Replace component if warpage

exceeds .0118" (.300 mm). Inspect camshaft and components. See CAMSHAFT

.

4. Measure valve lifter diameter and bore diameter. Ensure oil clearance is within specification. Replace

components if not within specification. See VALVE LIFTERS

table under ENGINE

SPECIFICATIONS.

Installation

1. Apply adhesive to 2 or 3 threads of oil pressure switch, and install switch. Install NEW insulator at

bottom of fuel injector and NEW grommet on top of fuel injector. Coat NEW "O" rings with gasoline and

install on fuel injector.

2. Install 2 spacers on cylinder head. Install fuel injectors on cylinder head. Install fuel delivery pipe on fuel

injectors. Using twisting motion, push fuel injectors into fuel delivery pipe.

3. Install and slightly tighten fuel delivery pipe-to-cylinder head bolts. Ensure all fuel injectors rotate

smoothly. If fuel injector fails to rotate smoothly, check for improperly installed or damaged "O" rings.

4. Position electrical connector on fuel injector facing toward top of engine. Tighten fuel delivery pipe-to-

cylinder head bolts to specification. See TORQUE SPECIFICATIONS

.

5. Using NEW gasket, install intake manifold. Install and tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Install air tube on side of intake manifold.

6. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

7. Install NEW gasket for cylinder head on cylinder block. Ensure all holes in gasket align with holes in

cylinder block.

8. Install cylinder head. Coat threads and bolt-to-cylinder contact surfaces on cylinder head bolts with

engine oil. Install and tighten cylinder head bolts in several steps, to specification in sequence. See Fig.

15 . See TORQUE SPECIFICATIONS .

9. If removed, install spark plug tubes. Install camshafts using proper procedure. See CAMSHAFT

. Install

No. 3 timing belt cover. Install and tighten bolts to specification. See TORQUE SPECIFICATIONS

.

10. To install remaining components, reverse removal procedure. If camshaft or cylinder head components

are serviced, adjust valve clearance. See VALVE CLEARANCE ADJUSTMENT

under

ADJUSTMENTS.

11. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 6

. Using NEW gasket, install valve cover.

12. Install grommets in original location with marking on grommet aligned in designated area. See Fig. 7

.

Install and tighten valve cover nuts to specification. See TORQUE SPECIFICATIONS

.

13. Install VSV for EGR. Connect ground cable to intake manifold with bolt. Connect knock sensor

connector. Connect power steerin

g idle-up air hoses to air tube. On A/T models, connect A/T throttle

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 705 of 1632

control cable to intake manifold. On all models, install NEW gasket and EGR valve with union nut and 2

nuts. Install vacuum modulator to clamp on intake manifold. Connect vacuum hoses to EGR VSV.

Connect fuel inlet hose to fuel filter

14. Connect vacuum sensor hose to gas filter, and brake booster vacuum hose to intake manifold. Install

throttle body. Install NEW "O" ring on coolant by-pass pipe, and NEW gasket on water pump cover

before installing coolant by-pass pipe. Apply soapy water solution to "O" ring before installing coolant

by-pass pipe. Install by-pass pipe.

15. Install NEW gasket and water outlet. Connect radiator, water by-pass and heater water hoses. Connect

ECT sensor and sender gauge connectors. Connect oil pressure switch.

16. Install ignition coils, manifold stay and spark plug wires. Connect wire clamp to manifold stay. Connect

spark plug wires to spark plugs and clamps on cylinder head cover. Connect ignition coil connectors.

17. Install 2 heat insulators. Install lower heat insulator. On California models, install A/F sensor to exhaust

manifold. All others, install oxygen sensor (bank 1 sensor 1) to exhaust manifold.

18. Using a new gasket, install exhaust manifold and heat insulator assembly. Install right-side exhaust

manifolds stay (California). Install left-side exhaust manifold stay. Install upper manifold heat insulator.

Connect A/F sensor connectors (California), or Oxygen sensor (bank 1 sensor 1).

19. Use NEW gasket and NEW nuts when installing front exhaust pipe. Ensure all bolts/nuts are loosely

installed on front exhaust pipe before tightening to specification. See TORQUE SPECIFICATIONS

20. Install generator and air cleaner and cap. Connect accelerator cable to throttle body and cable bracket. On

A/T models, connect throttle cable to throttle body and cable bracket. On all models, start engine and

check for leaks. Recheck engine coolant and oil level. Install right-side engine undercover.

CRANKSHAFT FRONT SEAL

Removal & Installation (Oil Pump Installed)

1. Remove timing belt and crankshaft sprocket. See TIMING BELT . Using a knife, cut lip from seal. Pry

seal from oil pump housing. DO NOT damage sealing surfaces.

2. To install, apply grease to lip of new seal. Using hammer and Seal Installer (SST 09226-10010), install

seal until seal surface is even with oil pump housing. To install remaining components, reverse removal

procedure.

Removal & Installation (Oil Pump Removed)

Using hammer and drift, remove seal from oil pump housing. To install, use hammer and Seal Installer (SST

09226-10010). Install seal until seal surface is even with oil pump housing. Apply grease to lip of new seal.

TIMING BELT

CAUTION: If reusing timing belt, mark direction of timing belt rotation, and place

reference mark on timing belt at camshaft sprocket for reassembly

reference. Also, place reference mark on timing belt at upper edge of No. 1

timing belt cover. DO NOT bend, twist or turn timing belt inside-out. DO

NOT expose timing to oil, water or steam.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 711 of 1632

VALVE LIFTER

Removal

Remove camshaft. See CAMSHAFT . Note location of adjusting shims and valve lifters for reassembly

reference. Remove adjusting shims and valve lifters from cylinder head.

Inspection

Inspect components for damage. Measure valve lifter diameter and bore diameter. Ensure oil clearance is within

specification. Replace components if not within specification. See VALVE LIFTERS

table under ENGINE

SPECIFICATIONS.

Installation

To install, reverse removal procedure. Ensure components are installed in original location and valve lifters

rotate smoothly in cylinder head. If camshaft, adjusting shims or valve lifters are replaced, check valve

clearance. See VALVE CLEARANCE ADJUSTMENT

under ADJUSTMENTS.

CAMSHAFT

Removal (Exhaust Side)

1. Remove timing belt and camshaft sprocket. See TIMING BELT . Remove No. 3 timing belt cover. See

Fig. 14

.

2. Disconnect power steering fluid reservoir, PCV hoses, cable brackets and control cables for access to

valve cover. Disconnect spark plug wires from spark plugs. Remove nuts, grommets, valve cover and

gasket. Note location of grommets for reassembly reference, as grommets must be installed in original

location.

3. For servicing of exhaust camshaft, rotate intake camshaft so knock pin is 10-45 degrees from vertical

position. See Fig. 19

. This aids in exhaust camshaft removal by using camshaft lobes on cylinders No. 2

and 4 to push on valve lifters. CAUTION: Camshafts must be properly positioned to lift camshaft straight from

cylinder head to prevent damage to cylinder head and camshaft. DO

NOT pry or force camshafts from cylinder head or component

damage will result.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 28 © 2005 Mitchell Repair Information Company, LLC.

Page 718 of 1632

lifted upward as No. 2 camshaft bearing cap bolts are loosened.

4. If intake camshaft is not lifted upward, reinstall all camshaft bearing caps. Reposition intake camshaft so

knock pin is 80-115 degrees from vertical position. See Fig. 19

. Repeat steps 9) and 10) . Remove No. 2

camshaft bearing cap and intake camshaft.

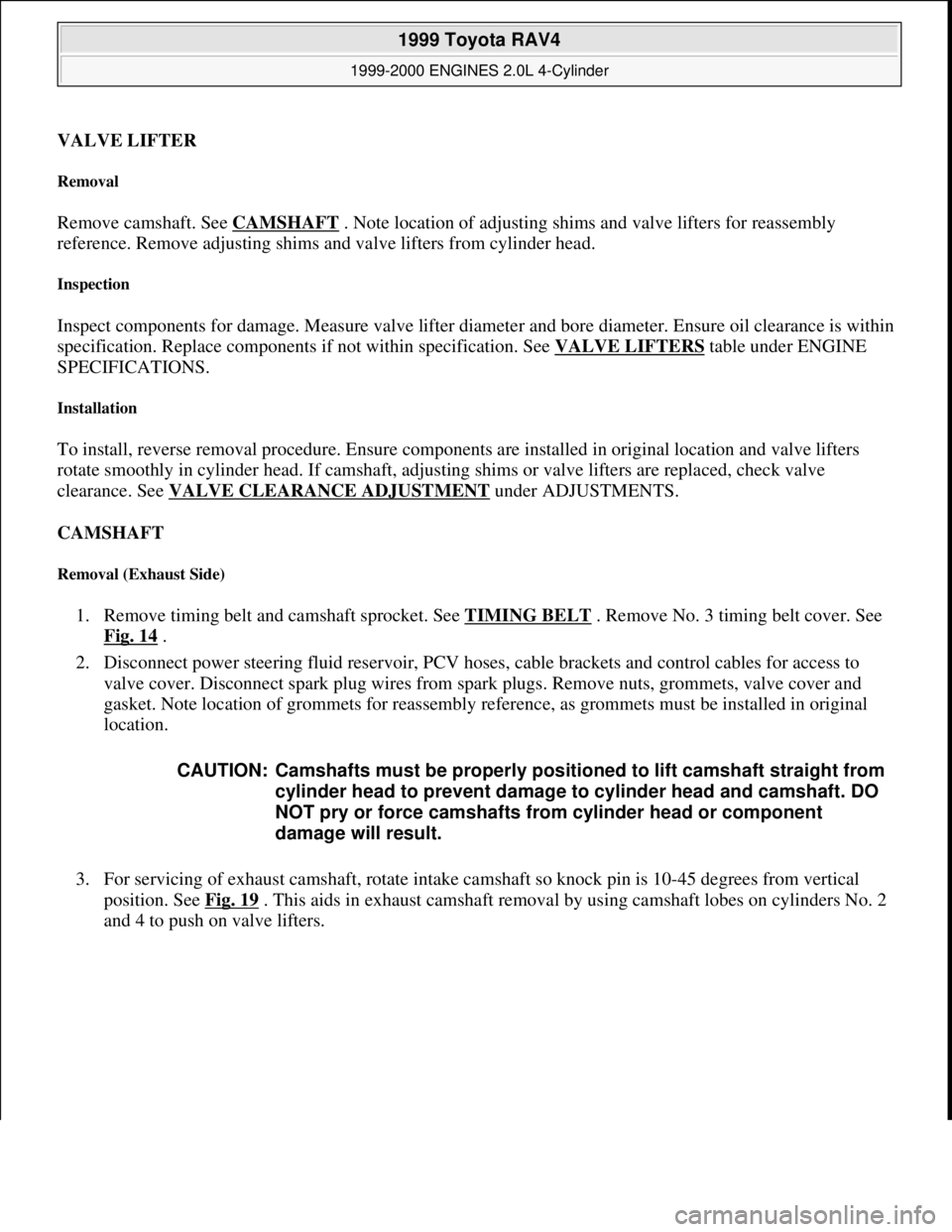

5. If removing sub-gear from exhaust camshaft, mount camshaft in soft-jaw vise on hexagonal area of

camshaft. Install service bolt "A" in camshaft. See Fig. 24

.

Fig. 24: Removing & Installing Sub

-Gear On Main Gear

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6. Using screwdriver, rotate sub-gear clockwise and remove service bolt "B". Remove snap ring, wave

washer, sub-gear and camshaft gear spring from exhaust camshaft. See Fig. 14

.

7. Note location of adjusting shims and valve lifters for reassembly reference. Remove adjusting shims and

valve lifters from cylinder head (if necessary).

Inspection

1. Inspect components for damage. Check camshaft journal diameter, lobe height and journal runout.

Replace camshaft if not within specification. See CAMSHAFT

table under ENGINE

SPECIFICATIONS. Install camshaft in cylinder head.

2. Using Plastigage, check camshaft oil clearance with camshaft bearing cap bolts tightened to specification

in sequence. See Fig. 22

and Fig. 23 . See TORQUE SPECIFICATIONS.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 35 © 2005 Mitchell Repair Information Company, LLC.

Page 719 of 1632

3. Check camshaft end play with camshaft bearing cap bolts tightened to specification. Replace camshaft

and/or cylinder head if camshaft end play is not within specification. See CAMSHAFT

table under

ENGINE SPECIFICATIONS.

4. Install both camshafts in cylinder head without sub-gear installed on exhaust camshaft. Install and tighten

camshaft bearing cap bolts to specification in sequence. See Fig. 22

and Fig. 23 . See TORQUE

SPECIFICATIONS .

5. Using dial indicator, check gear backlash between gears on camshafts. Replace camshafts if gear backlash

exceeds specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS.

6. Measure length of camshaft gear spring. Replace camshaft gear spring if distance is not within

specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS. Measure valve lifter diameter

and bore diameter. Ensure oil clearance is within specification. Replace components if not within

specification. See VALVE LIFTERS

table under ENGINE SPECIFICATIONS.

Installation

1. If installing sub-gear on exhaust camshaft, install camshaft gear spring, sub-gear, wave washer and snap

ring on exhaust camshaft. Ensure pins on main gear and sub-gear engage with ends of camshaft gear

spring.

2. Install service bolt "A" on sub-gear. See Fig. 24

. Using screwdriver, rotate sub-gear clockwise and align

hole in sub-gear with hole on main gear. Install service bolt "B". Remove service bolt "A".

3. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

4. Coat thrust surfaces of camshafts with multipurpose grease. To install intake camshaft, rotate intake

camshaft so knock pin is at 80-115 degrees from vertical position, and install into cylinder head. See Fig.

19 .

5. Coat seal lip of NEW oil seal for intake camshaft with grease. Install oil seal onto front of intake camshaft

until oil seal is fully seated in cylinder head. Apply sealant to front camshaft bearing cap for intake

camshaft. See Fig. 25

.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 36 © 2005 Mitchell Repair Information Company, LLC.

Page 721 of 1632

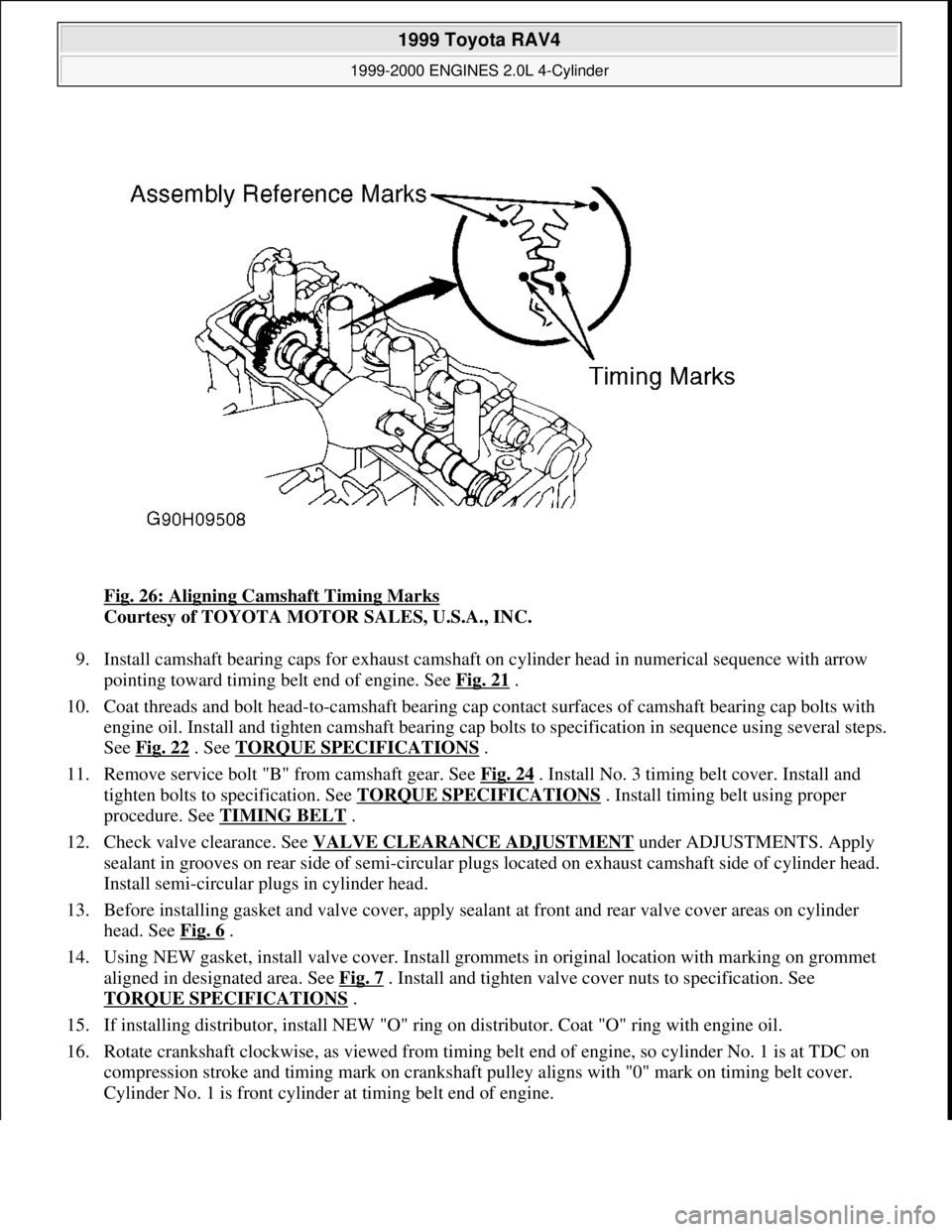

Fig. 26: Aligning Camshaft Timing Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9. Install camshaft bearing caps for exhaust camshaft on cylinder head in numerical sequence with arrow

pointing toward timing belt end of engine. See Fig. 21

.

10. Coat threads and bolt head-to-camshaft bearing cap contact surfaces of camshaft bearing cap bolts with

engine oil. Install and tighten camshaft bearing cap bolts to specification in sequence using several steps.

See Fig. 22

. See TORQUE SPECIFICATIONS .

11. Remove service bolt "B" from camshaft gear. See Fig. 24

. Install No. 3 timing belt cover. Install and

tighten bolts to specification. See TORQUE SPECIFICATIONS

. Install timing belt using proper

procedure. See TIMING BELT

.

12. Check valve clearance. See VALVE CLEARANCE ADJUSTMENT

under ADJUSTMENTS. Apply

sealant in grooves on rear side of semi-circular plugs located on exhaust camshaft side of cylinder head.

Install semi-circular plugs in cylinder head.

13. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 6

.

14. Using NEW gasket, install valve cover. Install grommets in original location with marking on grommet

aligned in designated area. See Fig. 7

. Install and tighten valve cover nuts to specification. See

TORQUE SPECIFICATIONS

.

15. If installing distributor, install NEW "O" ring on distributor. Coat "O" ring with engine oil.

16. Rotate crankshaft clockwise, as viewed from timing belt end of engine, so cylinder No. 1 is at TDC on

compression stroke and timing mark on crankshaft pulley aligns with "0" mark on timing belt cover.

C

ylinder No. 1 is front cylinder at timing belt end of engine.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 38 © 2005 Mitchell Repair Information Company, LLC.

Page 725 of 1632

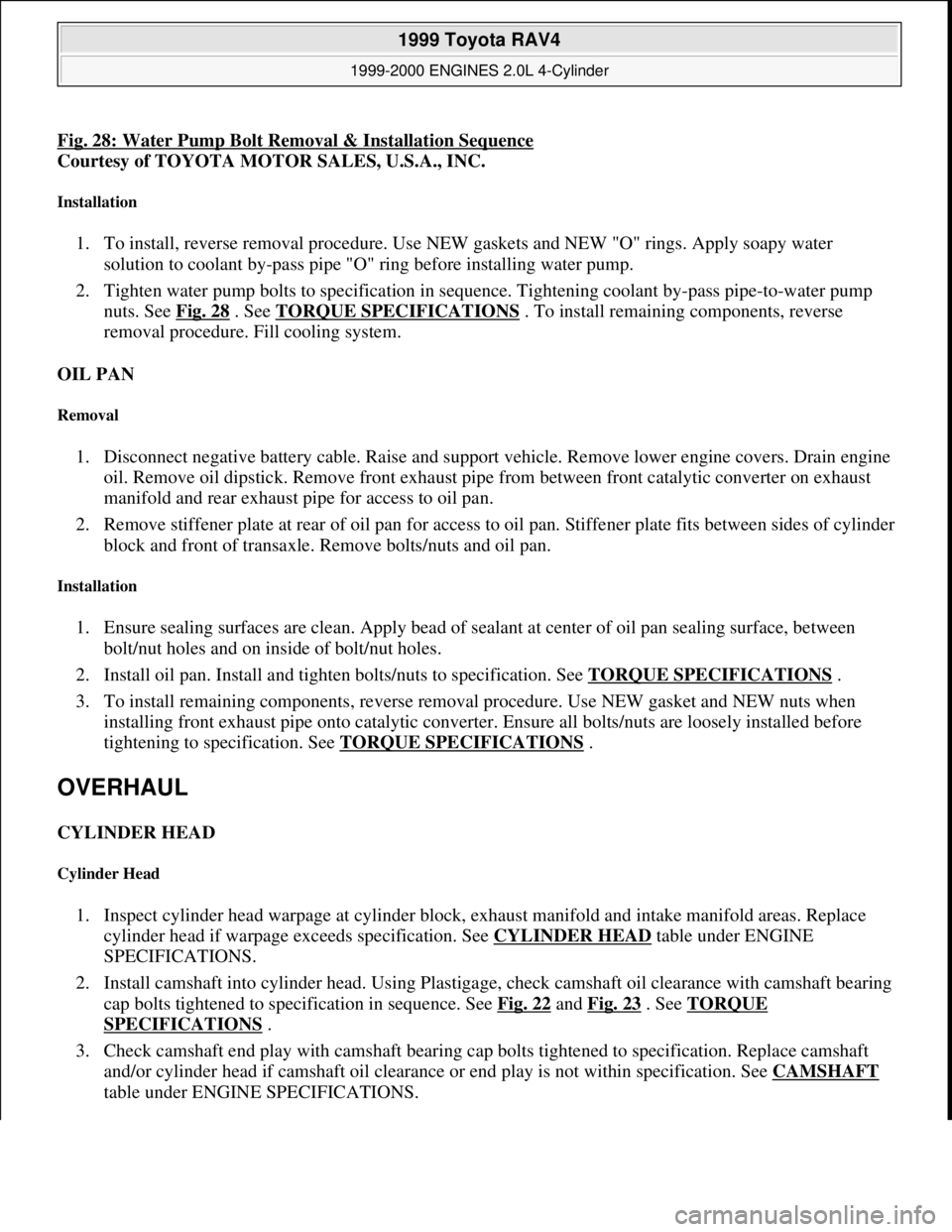

Fig. 28: Water Pump Bolt Removal & Installation Sequence

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

1. To install, reverse removal procedure. Use NEW gaskets and NEW "O" rings. Apply soapy water

solution to coolant by-pass pipe "O" ring before installing water pump.

2. Tighten water pump bolts to specification in sequence. Tightening coolant by-pass pipe-to-water pump

nuts. See Fig. 28

. See TORQUE SPECIFICATIONS . To install remaining components, reverse

removal procedure. Fill cooling system.

OIL PAN

Removal

1. Disconnect negative battery cable. Raise and support vehicle. Remove lower engine covers. Drain engine

oil. Remove oil dipstick. Remove front exhaust pipe from between front catalytic converter on exhaust

manifold and rear exhaust pipe for access to oil pan.

2. Remove stiffener plate at rear of oil pan for access to oil pan. Stiffener plate fits between sides of cylinder

block and front of transaxle. Remove bolts/nuts and oil pan.

Installation

1. Ensure sealing surfaces are clean. Apply bead of sealant at center of oil pan sealing surface, between

bolt/nut holes and on inside of bolt/nut holes.

2. Install oil pan. Install and tighten bolts/nuts to specification. See TORQUE SPECIFICATIONS

.

3. To install remaining components, reverse removal procedure. Use NEW gasket and NEW nuts when

installing front exhaust pipe onto catalytic converter. Ensure all bolts/nuts are loosely installed before

tightening to specification. See TORQUE SPECIFICATIONS

.

OVERHAUL

CYLINDER HEAD

Cylinder Head

1. Inspect cylinder head warpage at cylinder block, exhaust manifold and intake manifold areas. Replace

cylinder head if warpage exceeds specification. See CYLINDER HEAD

table under ENGINE

SPECIFICATIONS.

2. Install camshaft into cylinder head. Using Plastigage, check camshaft oil clearance with camshaft bearing

cap bolts tightened to specification in sequence. See Fig. 22

and Fig. 23 . See TORQUE

SPECIFICATIONS .

3. Check camshaft end play with camshaft bearing cap bolts tightened to specification. Replace camshaft

and/or cylinder head if camshaft oil clearance or end play is not within specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 42 © 2005 Mitchell Repair Information Company, LLC.

Page 739 of 1632

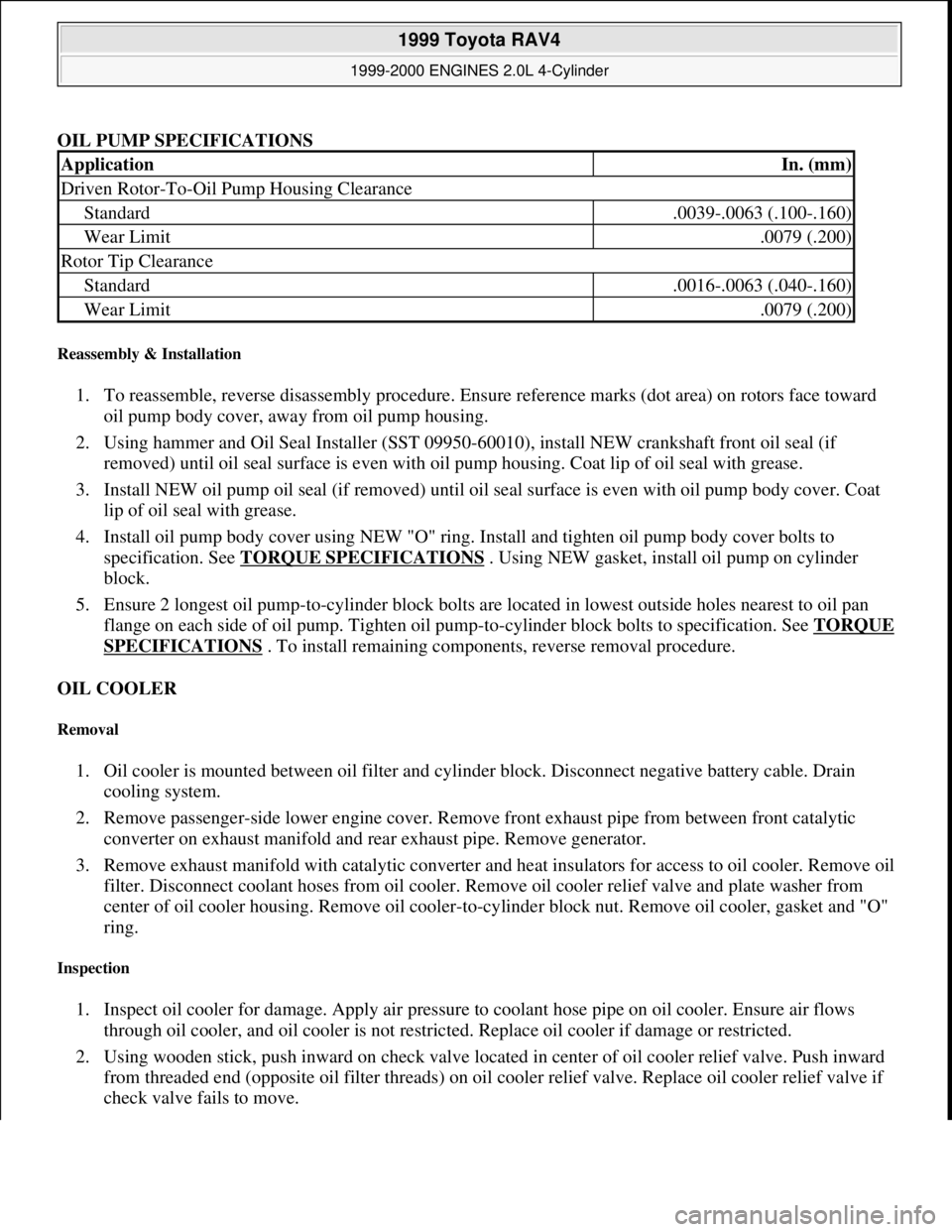

OIL PUMP SPECIFICATIONS

Reassembly & Installation

1. To reassemble, reverse disassembly procedure. Ensure reference marks (dot area) on rotors face toward

oil pump body cover, away from oil pump housing.

2. Using hammer and Oil Seal Installer (SST 09950-60010), install NEW crankshaft front oil seal (if

removed) until oil seal surface is even with oil pump housing. Coat lip of oil seal with grease.

3. Install NEW oil pump oil seal (if removed) until oil seal surface is even with oil pump body cover. Coat

lip of oil seal with grease.

4. Install oil pump body cover using NEW "O" ring. Install and tighten oil pump body cover bolts to

specification. See TORQUE SPECIFICATIONS

. Using NEW gasket, install oil pump on cylinder

block.

5. Ensure 2 longest oil pump-to-cylinder block bolts are located in lowest outside holes nearest to oil pan

flange on each side of oil pump. Tighten oil pump-to-cylinder block bolts to specification. See TORQUE

SPECIFICATIONS . To install remaining components, reverse removal procedure.

OIL COOLER

Removal

1. Oil cooler is mounted between oil filter and cylinder block. Disconnect negative battery cable. Drain

cooling system.

2. Remove passenger-side lower engine cover. Remove front exhaust pipe from between front catalytic

converter on exhaust manifold and rear exhaust pipe. Remove generator.

3. Remove exhaust manifold with catalytic converter and heat insulators for access to oil cooler. Remove oil

filter. Disconnect coolant hoses from oil cooler. Remove oil cooler relief valve and plate washer from

center of oil cooler housing. Remove oil cooler-to-cylinder block nut. Remove oil cooler, gasket and "O"

ring.

Inspection

1. Inspect oil cooler for damage. Apply air pressure to coolant hose pipe on oil cooler. Ensure air flows

through oil cooler, and oil cooler is not restricted. Replace oil cooler if damage or restricted.

2. Using wooden stick, push inward on check valve located in center of oil cooler relief valve. Push inward

from threaded end (opposite oil filter threads) on oil cooler relief valve. Replace oil cooler relief valve if

check valve fails to move.

ApplicationIn. (mm)

Driven Rotor-To-Oil Pump Housing Clearance

Standard.0039-.0063 (.100-.160)

Wear Limit.0079 (.200)

Rotor Tip Clearance

Standard.0016-.0063 (.040-.160)

Wear Limit.0079 (.200)

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 56 © 2005 Mitchell Repair Information Company, LLC.