check engine TOYOTA RAV4 1996 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 403 of 1632

BELT TENSION

4-Cylinder

Check belt tension using Burroughs Tension Gauge (BT-33-73F) at longest belt run. Adjust belt tension if

necessary. See BELT TENSION SPECIFICATIONS (4

-CYLINDER) table.

BELT TENSION SPECIFICATIONS (4-CYLINDER)

(1)

V6

Check belt tension using Burroughs Tension Gauge (BT-33-73F) at longest belt run. Adjust belt tension if

necessary. See BELT TENSION SPECIFICATIONS (V6) table.

BELT TENSION SPECIFICATIONS (V6)

(1) NOTE: New belt refers to a belt which has been used 5 minutes or less on a running

engine. Used belt refers to a belt which has been used more than 5 minutes on

a running engine. After installing new belt(s), run engine for at least 5 minutes

and recheck tension.

NOTE: Corolla uses an automatic belt tensioner. Adjustment is not required.

ApplicationNew Belt Lbs. (kg)Used Belt Lbs. (kg)

Camry, Camry Solara & RAV4

Generator

With A/C140-190 (64-86)100-120 (45-54)

Without A/C100-150 (45-68)75-115 (34-52)

Power Steering95-145 (43-66)60-100 (27-45)

Celica

Generator

With A/C170-180 (77-82)95-135 (43-61)

Without A/C100-150 (45-68)75-115 (34-52)

Power Steering99-121 (45-55)44-77 (20-35)

Corolla(2) (2)

Tacoma & 4Runner

A/C135-185 (61-84)80-100 (36-45)

Generator116-169 (53-77)66-88 (30-40)

Power Steering135-180 (61-82)85-120 (39-54)

(1)Measure belt tension with Burroughs (BT-33-73F) tension gauge.

(2)Automatic belt tensioner is used. Adjustment is not required.

ApplicationNew Belt Lbs. (kg)Used Belt Lbs. (kg)

Avalon, Camry, Camry Solara & Sienna

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 405 of 1632

Check all fuses, fusible links, ignition switch and appropriate relays (if equipped). Check generator output. See

NO

-LOAD TEST under ON-VEHICLE TESTING.

ON-VEHICLE TESTING

NO-LOAD TEST

1. Disconnect battery-to-generator terminal "B" wire. See Fig. 2

. Using an ammeter and voltmeter, connect

negative ammeter lead to disconnected generator terminal "B" wire end, and connect positive ammeter

lead to generator terminal "B".

2. Connect voltmeter positive lead to generator terminal "B" and negative lead to ground. See Fig. 2

. Start

engine and increase engine speed to 2000 RPM. Both meters should read within specification. See

GENERATOR REGULATED OUTPUT SPECIFICATIONS

table. If voltage is more than specified,

replace IC regulator. If voltage is less than specified, go to next step.

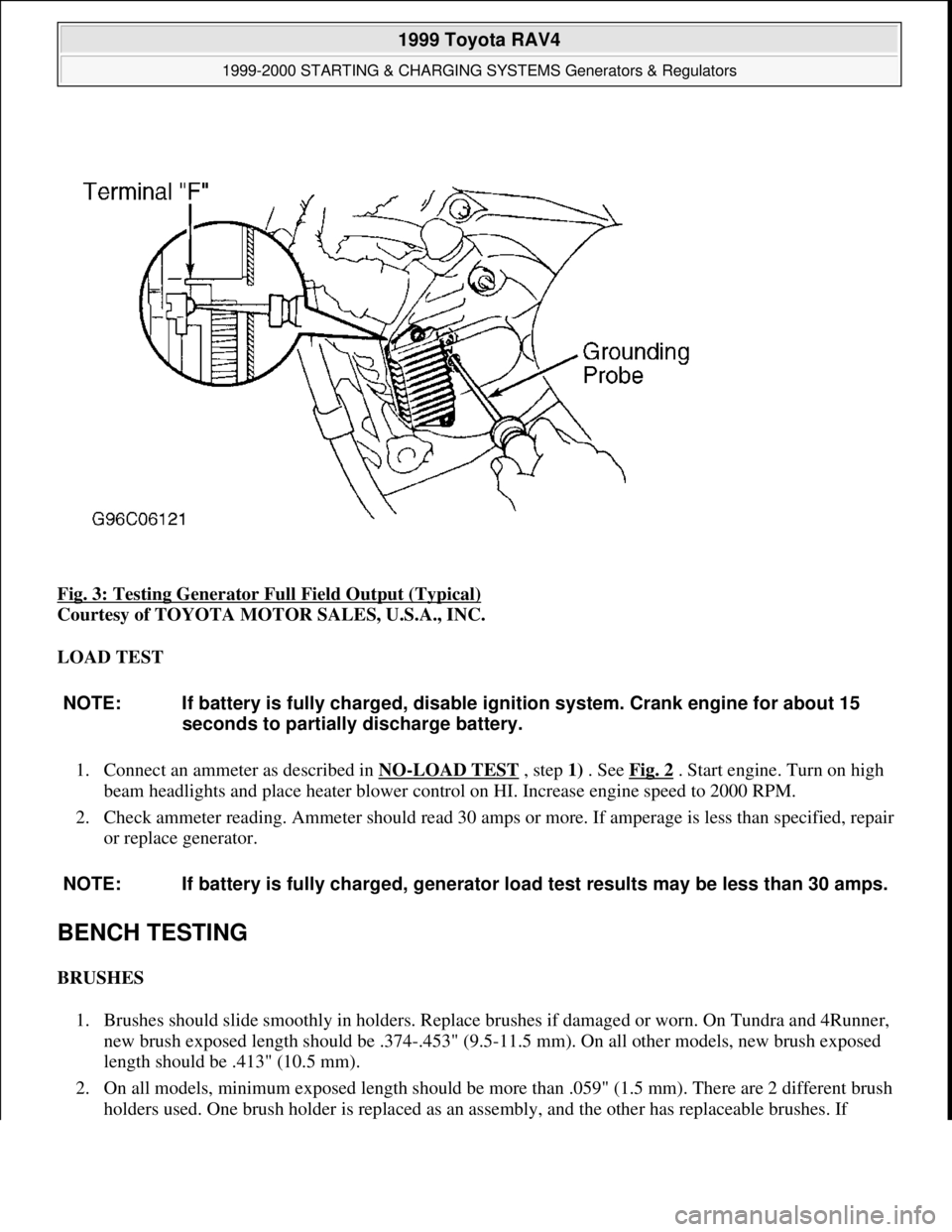

3. Locate small hole in back of generator. See Fig. 3

. It may be necessary to remove generator end cover to

access hole. Using a probe, ground generator terminal "F" (full field) to generator case. See Fig. 3

. If

voltage is more than specified range, replace IC regulator. If voltage is less than specified range, repair or

replace generator.

GENERATOR REGULATED OUTPUT SPECIFICATIONS

(1) NOTE: See TROUBLE SHOOTING article in GENERAL INFORMATION.

ApplicationAmpsVolts

Avalon10 Or Less13.2-14.8

Camry, Camry Solara & Corolla10 Or Less13.5-15.1

Celica & RAV4

With Temperature At 77°F (25°C)10 Or Less14.0-15.1

With Temperature At 239°F (115°C)10 Or Less13.5-14.3

Land Cruiser & Sienna10 Or Less13.2-14.8

Tacoma

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

Tundra

V610 Or Less13.2-14.8

V8

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

4Runner

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

(1)Specification given is with engine speed at 2000 RPM.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 407 of 1632

Fig. 3: Testing Generator Full Field Output (Typical)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LOAD TEST

1. Connect an ammeter as described in NO

-LOAD TEST , step 1) . See Fig. 2 . Start engine. Turn on high

beam headlights and place heater blower control on HI. Increase engine speed to 2000 RPM.

2. Check ammeter reading. Ammeter should read 30 amps or more. If amperage is less than specified, repair

or replace generator.

BENCH TESTING

BRUSHES

1. Brushes should slide smoothly in holders. Replace brushes if damaged or worn. On Tundra and 4Runner,

new brush exposed length should be .374-.453" (9.5-11.5 mm). On all other models, new brush exposed

length should be .413" (10.5 mm).

2. On all models, minimum exposed length should be more than .059" (1.5 mm). There are 2 different brush

holders used. One brush holder is replaced as an assembl

y, and the other has replaceable brushes. If

NOTE: If battery is fully charged, disable ignition system. Crank engine for about 15

seconds to partially discharge battery.

NOTE: If battery is fully charged, generator load test results may be less than 30 amps.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 408 of 1632

exposed brush length is less than minimum, replace brushes or brush holder assembly. Install new brush

springs when replacing brushes.

ROTOR

1. Check rotor for open field windings by using an ohmmeter across slip rings. Rotor resistance should be

within specification. See ROTOR RESISTANCE SPECIFICATIONS

table.

2. Check rotor for shorts to ground by connecting ohmmeter between slip ring and rotor shaft. Ohmmeter

should indicate no continuity. Check slip rings for wear or pitting. Standard slip ring diameter is .559-

.567" (14.2-14.4 mm). Turn slip rings on lathe if necessary. Minimum slip ring diameter is .504" (12.8

mm).

ROTOR RESISTANCE SPECIFICATIONS

STATOR

Connect ohmmeter between 2 stator leads. Continuity should exist between all stator leads. Connect ohmmeter

between each stator lead and metal core. Continuity should not exist. If stator does not test as indicated, replace

stator.

DIODES

1. With diode/rectifier assembly removed and on bench, contact positive diode plate terminal with one

ohmmeter probe. Using other ohmmeter probe, contact each diode lead in same plate. Note ohmmeter

reading. Reverse ohmmeter probes, and repeat tests for all diodes.

2. All diodes should show continuity in one direction and no continuity in opposite direction. If any diode is

defective, replace diode/rectifier assembly.

REMOVAL & INSTALLATION

GENERATOR

Removal & Installation (Land Cruiser)

1. Disconnect negative battery cable. Drain engine coolant. Rotate belt tensioner counterclockwise to release

tension on belt and remove drive belt. Remove splash shield from underneath en

gine. Remove radiator

Application(1) Ohms

Avalon2.1-2.5

Camry & Camry Solara

4-Cyl.2.7-3.1

V62.1-2.5

Land Cruiser, Sienna, Tacoma, Tundra & 4Runner2.1-2.5

All Other Models2.7-3.1

(1)Specification given is with temperature at 68°F (20°C).

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 471 of 1632

1999-2000 ENGINE COOLING

Electric Cooling Fans

IDENTIFICATION

ELECTRIC COOLING FAN IDENTIFICATION

DESCRIPTION & OPERATION

Land Cruiser, Tacoma, Tundra and 4Runner use a belt-driven cooling fan attached to the water pump. All other

models use 2 electric cooling fans located directly behind the radiator. Fans are controlled via Engine Coolant

Temperature (ECT) switches/sensors, and turn on when engine coolant temperature is above 208°F (98°C) on

Avalon, Camry with 3.0L, Camry Solara with 3.0L and Sienna. On Camry with 2.2L, Camry Solara with 2.2L,

Celica, Corolla, ECHO, MR2 and RAV4, ECT turns cooling fans on above 199°F (93°C). On Avalon, Camry

with 3.0L, Camry Solara with 3.0L and Sienna, fans will turn off when engine coolant temperature falls below

190°F (88°C). On Camry with 2.2L, Camry Solara with 2.2L, Celica, Corolla and RAV4, fans will turn off

below 181°F (83°C).

SYSTEM TESTS

ELECTRIC COOLING FAN

Avalon (1999), Camry 3.0L, Camry Solara 3.0L & Sienna

1. With engine coolant temperature below 190°F (88°C), turn ignition switch to ON position (engine off).

Ensure fans stop.

2. If fan do not stop, test cooling fan relay and ECT switch. See COOLING FAN RELAYS

and ECT

SWITCH . Check for loose or broken connector or wiring between relay and ECT switch. Repair as

necessary.

3. Disconnect No. 1 ECT switch connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay, cooling fan relay and

cooling fan motor. Check for short between cooling fan relay and ECT switch.

4. Start engine and raise temperature above 208°F (98°C). Ensure cooling fan turns. If not, replace No. 1

ECT switch.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

Avalon (2000)

ApplicationCooling Fan Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:21:45 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 472 of 1632

1. With engine coolant temperature below 181°F (83°C), turn ignition switch to ON position (engine off).

Ensure fans stop.

2. If fans do not stop, test cooling fan relays and ECT switches. See COOLING FAN RELAYS

and ECT

SWITCH . Check for loose or broken connector or wiring between relay and ECT switch. Repair as

necessary.

3. Disconnect No. 1 ECT switch wire connector. Connect jumper wire to No. 1 ECT terminals. Ensure fan

rotates at high speed. If fan does not rotate, check No. 1 cooling fan relay and cooling fan. Reconnect No.

1 switch connector.

4. Disconnect No. 2 switch connector. Ground terminal on No. 2 ECT switch wire harness side connector.

Ensure No. 1 and No. 2 fans rotate at low speed. If fans do not rotate, check No. 2 cooling fan relay, No.

3 cooling fan relay and No. 2 cooling fan. Reconnect No. 2 ECT switch connector.

5. Inspect No. 1 and No. 2 cooling fans. Disconnect cooling fan connector. With battery connected to

ammeter (positive battery terminal to positive ammeter terminal and negative battery and negative

ammeter terminals to each connector pin), test amperage readings. See Fig. 1

. If readings are not as

specified, replace cooling fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan

connector.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 474 of 1632

Fig. 1: Testing Amperage At Fan Connectors (Corolla Shown; Other Models Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Camry 2.2L, Camry Solara 2.2L, Celica, Corolla, ECHO, MR2 & RAV4

1. With engine coolant temperature below 181°F (83°C), turn ignition switch to ON position (engine off).

Ensure fan stops.

2. If fan does not stop, test cooling fan relay and ECT switch/sensor. See COOLING FAN RELAYS

and

ECT SWITCH

or ECT SENSOR . Check for loose or broken connector or wiring between relay and

ECT switch. Repair as necessary.

3. Disconnect ECT switch/sensor connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay (if equipped), cooling fan

relay, and cooling fan motor. On MR2, check ECM. On all models, check for short between cooling fan

relay and ECT switch.

4. Start engine and raise temperature above 199°F (93°C). Ensure cooling fan turns. If not, replace ECT

switch/sensor.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

ECT SWITCH LOCATIONS

COOLING FAN AMPERAGE READINGS

ApplicationECT Switch Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

ApplicationAmps @ 68°F (20°C)

Avalon

19999.2-11.0

20008.5-11.5

Camry & Camry Solara

5S-FE4.9-8.5

1MZ-FE8.3-11.3

Celica

19996.4-7.4

20005.2-8.2

Corolla5.2-8.2

ECHO (1) 7.8-11.8

MR25.7-7.7

RAV49.1-11.1

Sienna

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 475 of 1632

COMPONENT TESTS

COOLING FAN RELAYS

Cooling Fan Relay No. 1 (Avalon, Celica & RAV4 - 1999)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 2 , Fig.

5 and Fig. 10 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3

and 4 on Denso type relays. See Fig. 13

. On Bosch type relays, check for continuity between relay

terminals No. 85 and 86, and No. 30 and 87a. If no continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 86

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 85 (Bosch type). Check that no

continuity exists between relay terminals No. 3 and 4 on Denso type relays. On Bosch type relays, check

that no continuity exists between relay terminals No. 30 and 87a. If continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

Cooling Fan Relay No. 1 (Avalon, Celica, ECHO & RAV4 - 2000)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 3 , Fig.

6 , Fig. 8 and Fig. 11 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2. See

Fig. 14

. If there is no continuity, replace relay. Check that no continuity exists between relay terminals

No. 3 and 5. If continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check for continuity between relay terminals No. 3 and 5. If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

Cooling Fan Relay No. 1 (Camry, Camry Solara, Corolla & Sienna)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 4 , Fig.

7 and Fig. 12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3

and 4. See Fig. 15

. If no continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check that no continuity exists between relay terminals No. 3 and 4. If continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

With "S" Mark8.5-11.5

With "T" Mark14.0-20.0

(1)Amps @ 77°F (25°C)

CAUTION: When battery is disconnected, vehicle computer and memory systems

may lose memory data. Driveability problems may exist until computer

systems have completed a relearn cycle.

NOTE: Place match marks on all relays for proper reinstallation.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 476 of 1632

Cooling Fan Relay No. 2 (Except Avalon)

1. Disconnect negative battery cable. Remove cooling fan relay No. 2 from fuse/relay box. See Fig. 4 -Fig.

12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3 and 4. See

Fig. 13

-Fig. 15 . If no continuity exists, replace relay. Check that no continuity exists between relay

terminals No. 3 and 5. If continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check that no continuity exists between relay terminals No. 3 and 4. If continuity exists, replace relay.

Check for continuity between relay terminals No. 3 and 5. If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 2.

Cooling Fan Relay No. 2 (Avalon)

1. Disconnect negative battery cable. Remove cooling fan relay No. 2 from fuse/relay box. See Fig. 2 and

Fig. 3

. Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3 and 4 on

Denso type relay. On Bosch type relay, check for continuity between relay terminals No. 85 and 86, and

No. 30 and 87a. See Fig. 13

and Fig. 14 . If there is no continuity, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 85

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 86 (Bosch type). Check that no

continuity exists between relay terminals No. 3 and 4 (Denso type), or No. 30 and 87a (Bosch type). If

continuity exists, replace relay. Check for continuity between relay terminals No. 3 and 5 (Denso), or No.

30 and 87 (Bosch). If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 2.

Cooling Fan Relay No. 3

1. Disconnect negative battery cable. Remove cooling fan relay No. 3 from fuse/relay box. See Fig. 2 - Fig.

12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2 (Denso type), or No.

85 and 86 (Bosch type). See Fig. 13

- Fig. 15 . If no continuity exists, replace relay. Check that no

continuity exists between relay terminals No. 3 and 5 (Denso type), or No. 30 and 87 (Bosch type). If

continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 86

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 85 (Bosch type). Check for

continuity between relay terminals No. 3 and 5 (Denso type), or No. 30 and 87 (Bosch type). If no

continuity exists, replace relay.

3. Reinstall cooling fan relay No. 3.

Engine Main Relay (Except 2000 Avalon, 2000 Celica, ECHO & MR2)

1. Disconnect negative battery cable. Remove engine main relay from fuse/relay box. See Fig. 2 -Fig. 12 .

Using an ohmmeter, check for continuity between relay terminals No. 3 and 5, and No. 2 and 4. See Fig.

16 . If no continuity exists, replace relay. Check that no continuity exists between relay terminals No. 1

and 2. If continuit

y exists, replace relay. NOTE: ECHO is not equipped with cooling fan relay No. 3.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 477 of 1632

2. To check relay operation, connect positive battery voltage to terminal No. 3 and ground to terminal No. 5.

Check that no continuity exists between relay terminals No. 2 and 4. If continuity exists, replace relay.

Check for continuity between relay terminals No. 1 and 2. If no continuity exists, replace relay.

3. Reinstall en

gine main relay.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.