check engine TOYOTA RAV4 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 136 of 1632

for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Adjust shift linkage and fill with ATF. See appropriate TRANSMISSION

SERVICING article.

Removal (Tacoma 2WD 2.4L 4-Cyl.)

1. Manufacturer recommends removing engine and transmission as an assembly and then remove

transmission from engine. See 2.4L & 2.7L 4-CYLINDER article in ENGINES for engine removal.

2. With engine and transmission removed, remove starter. Remove bolts and stiffener plates. Stiffener plate

fits between each side of cylinder block and front of transmission.

3. Remove torque converter cover from front of transmission. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Separate transmission from engine.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Once engine and transmission are installed, adjust all cables and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (Tacoma 2WD 2.7L 4-Cyl. & 3.4L V6)

1. Manufacturer recommends removing engine and transmission as an assembly and then remove

transmission from engine. See 2.4L & 2.7L 4-CYLINDER article or 3.4L V6 article in ENGINES for

engine removal.

2. With engine and transmission removed, remove transmission oil dipstick, dipstick tube and "O" ring.

Remove oil cooler pipes and brackets from engine and transmission. Disconnect necessary wiring

connectors from transmission.

3. Remove torque converter cover from front of transmission. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Separate transmission from engine.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked ri

ght next to the starter ring gear on the drive plate. Replace drive plate if runout

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 137 of 1632

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .707" (17.95 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Once engine and transmission are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Tacoma 4WD)

1. Disconnect negative battery cable. Remove transmission oil dipstick. Disconnect throttle valve cable from

throttle body.

2. Raise and support vehicle. Remove lower engine cover. Remove fan shroud from radiator. Remove rear

console box, located between the seats. Remove screws from front console, located near transfer case and

transmission shift levers.

3. Remove front console with transfer case shift lever knob. Disconnect electrical connectors for removal of

transmission shift lever assembly. Disconnect shift linkage at transmission shift lever assembly. Remove

transmission shift lever assembly.

4. Remove snap ring and transfer case shift lever from transfer case. Remove transmission oil dipstick tube

and "O" ring. Place reference marks on drive shaft flanges for reassembly reference. Remove drive shafts.

5. Remove exhaust pipes as necessary for access to transmission and transfer case. Disconnect speedometer

cable and necessary electrical connectors for transmission and transfer case removal. Remove

transmission oil cooler pipes and brackets as necessary.

6. Remove starter and stabilizer bar. Remove torque converter cover from front of transmission. Remove

torque converter bolts. Front differential assembly rear mount must be removed for transmission removal.

Rear mount is located on front differential assembly, just behind the drive shaft flange.

7. Support front differential assembly with jack. Remove front differential assembly rear mount-to-

crossmember nut. Slightly raise front differential assembly. Remove the 2 front differential assembly rear

mount bolts.

8. Support transmission with transmission jack. Remove transmission mount-to-transmission crossmember

bolts. Remove transmission crossmember, located below transmission and transfer case. Remove

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is full

y seated, torque converter

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 138 of 1632

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) on 2.7L 4-cylinder or .707" (17.95 mm)

on 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Apply grease to transfer case shift lever before installing. Use NEW gasket when installing exhaust pipe.

Adjust all cables, shift linkages and fill with ATF. See appropriate TRANSMISSION SERVICING

article.

Removal (Tercel)

1. Disconnect negative battery cable. Remove battery. Disconnect throttle valve cable from throttle body.

Remove air cleaner assembly along with air intake duct to air cleaner.

2. Remove starter. Remove the 2 upper transaxle-to-cylinder block bolts, located at top of transaxle. Raise

and support vehicle. Remove lower engine covers.

3. Support engine with hoist. Remove front wheels. Drain transaxle fluid. Remove axle shafts from

transaxle. See FWD AXLE SHAFTS article in DRIVE AXLES.

4. Disconnect necessary electrical connectors, ground cables, speedometer cable, control cables and oil

cooler lines for transaxle removal. Remove exhaust pipe as necessary for access to transaxle.

5. Support transaxle with transmission jack. Remove the 2 vertical bottom bolts from front (radiator side)

transaxle mount.

6. Remove through-

bolt and rear (firewall side) engine mount assembly for transaxle removal. Remove plug

from front of transaxle for access to torque converter bolts. Remove torque converter bolts. Remove

remaining transaxle-to-cylinder block bolts. Lower transaxle from vehicle.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transaxle. To ensure torque converter is fully seated, torque converter depth

should be checked. Using straightedge and caliper, measure torque converter depth from torque converter

bolt lug on torque converter to the surface on transaxle. See Fig. 1

.

3. Torque converter depth on 3-speed transaxle should be more than .512" (13.00 mm). Torque converter

depth on 4-speed transaxle should be more than .538" (13.40 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Tighten the lower transaxle-to-cylinder block bolts to specification as indicated.

See Fig. 9

and Fig. 10 .

5. When installing torque converter bolts, apply Loctite to torque converter bolt threads before installing.

Ad

just all cables and fill with ATF. See appropriate TRANSMISSION SERVICING article.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 141 of 1632

2. With engine and transmission removed, remove starter if not previously removed. Remove torque

converter cover from front of transmission. Remove torque converter bolts. Remove transmission-to-

cylinder block bolts. Separate transmission from engine.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) for 2.7L 4-cylinder or .707" (17.95 mm)

for 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing.

5. Once engine and transmission are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (T100 4WD)

1. Disconnect negative battery cable. Remove knob from transfer case shift lever. Remove screws and boot

from transfer case shift lever. Remove snap ring and transfer case shift lever from transfer case.

2. Disconnect throttle valve cable from throttle body. Raise and support vehicle. Remove lower engine

cover. Remove transmission oil dipstick, dipstick tube and "O" ring.

3. Place reference marks on drive shaft flanges for reassembly reference. Remove drive shafts. Remove

front exhaust pipe located between exhaust manifold and catalytic converter.

4. Disconnect speedometer cable and necessary electrical connectors for transmission and transfer case

removal. Disconnect shift linkage at side of transmission. Remove shift linkage cross shaft located

between frame and shift lever on transmission.

5. Remove starter. Remove transmission oil cooler pipes and brackets as necessary. Remove stiffener plates

located on each side of cylinder block. Stiffener plate fits between side of cylinder block and front of

transmission.

6. Remove stabilizer bar. Support transmission with floor jack. Remove bolts and dynamic damper

transmission crossmember. Dynamic damper is located on driver's side of transmission crossmember,

next to transmission mount bolts and is fastened to bottom of transmission crossmember using 2 bolts.

7. Remove transmission mount-to-transmission crossmember bolts. Remove transmission crossmember

located below transmission and transfer case.

8. Remove torque converter cover from front of transmission. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 142 of 1632

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .707" (17.95 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing.

5. Apply grease to transfer case shift lever before installing. Use NEW gasket when installing front exhaust

pipe. Adjust all cables, shift linkages and fill with ATF. See appropriate TRANSMISSION SERVICING

article.

Removal (4Runner 2WD)

1. Disconnect negative battery cable. Remove transmission oil dipstick, dipstick tube and "O" ring.

Disconnect throttle valve cable from throttle body.

2. Raise and support vehicle. Remove lower engine cover. Disconnect shift linkage for transmission at

gearshift. Remove front exhaust pipe, located between exhaust manifold and catalytic converter on rear

exhaust pipe.

3. Place reference marks on drive shaft flange for reassembly reference. Remove drive shaft. Disconnect

necessary electrical connectors for transmission removal. Remove transmission oil cooler pipes and

brackets as necessary.

4. Support transmission with floor jack. Remove transmission crossmember, located below transmission.

Remove starter.

5. Remove cover from front of transmission for access to torque converter bolts. On 3.4L, note location of

Green torque converter bolt for reassembly reference. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Lower transmission from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) for 2.7L 4-cylinder or .707" (17.95 mm)

for 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installin

g. On 3.4L V6, ensure the Green torque converter bolt is installed first before

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 143 of 1632

installing the remaining torque converter bolts.

5. Use NEW gasket when installing front exhaust pipe. Adjust all cables, shift linkages and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (4Runner 4WD)

1. Disconnect negative battery cable. Remove rear console upper panel and disconnect electrical connectors.

Rear console upper panel is located on the top of the console, near emergency brake lever.

2. Remove heater control knobs from instrument panel. Using screwdriver, pry heater control plate from

center finish panel on instrument panel. Center finish panel is the panel that fits around the radio and air

outlet ducts, located at center of instrument panel.

3. Remove screws and disconnect electrical connectors from center finish panel from instrument panel.

Remove center finish panel.

4. On models without 2-4 selector button on side of transfer case shift lever, unscrew knob from transfer

case shift lever. On models with2-4 selector button on side of transfer case shift lever, remove screw from

knob on transfer case shift lever. Remove knob from transfer case shift lever and lay aside with wire

attached.

5. On all models, remove upper console panel which contains boot for transfer case shift lever and is located

on center console. On models with 2-4 selector button on side of transfer case shift lever, disconnect

electrical connector for 2-4 selector button and remove knob on transfer case shift lever.

6. On all models, remove screws, clips and front console box, located around transmission shift lever

assembly and transfer case shift lever. Raise and support vehicle. Disconnect shift linkage at transmission

shift lever.

7. Disconnect electrical connectors for removal of transmission shift lever assembly. Remove transmission

shift lever assembly. Remove snap ring and transfer case shift lever.

8. Remove transmission oil dipstick, dipstick tube and "O" ring. Remove lower engine covers. Place

reference marks on drive shaft flanges for reassembly reference. Remove drive shafts.

9. Remove front exhaust pipe, located between exhaust manifold and catalytic converter on rear exhaust

pipe. Disconnect and necessary electrical connectors for transmission and transfer case removal. Separate

wiring harness from transmission and transfer case.

10. Remove starter. Remove transmission oil cooler pipes and brackets as necessary. On 3.4L V6, it may be

necessary to remove stabilizer bar.

11. On all models, support transmission with floor jack. Remove rear transmission mount-to-transmission

crossmember bolts. Remove transmission crossmember, located below transmission and transfer case.

12. Remove torque converter cover from front of transmission. On 3.4L, note location of Green torque

converter bolt for re-installation reference. Remove torque converter bolts. Remove transmission-to-

cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 31 © 2005 Mitchell Repair Information Company, LLC.

Page 144 of 1632

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) for 2.7L 4-cylinder or .707" (17.95 mm)

for 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. On 3.4L V6, ensure the Green torque converter bolt is installed first before

installing the remaining torque converter bolts.

5. Apply grease to transfer case shift lever before installing. Use NEW gasket when installing front exhaust

pipe. Adjust all cables, shift linkages and fill with ATF. See appropriate TRANSMISSION SERVICING

article.

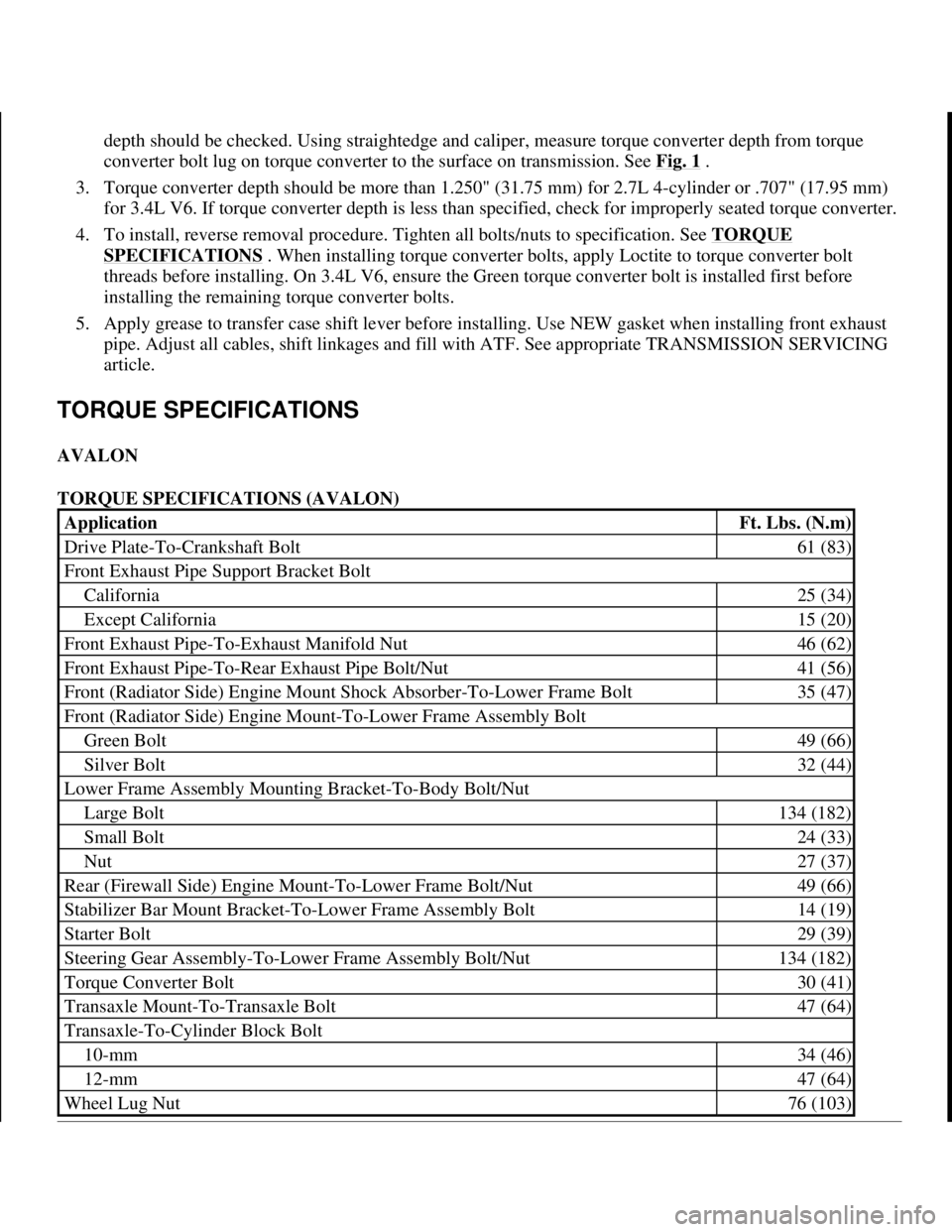

TORQUE SPECIFICATIONS

AVALON

TORQUE SPECIFICATIONS (AVALON)

ApplicationFt. Lbs. (N.m)

Drive Plate-To-Crankshaft Bolt61 (83)

Front Exhaust Pipe Support Bracket Bolt

California25 (34)

Except California15 (20)

Front Exhaust Pipe-To-Exhaust Manifold Nut46 (62)

Front Exhaust Pipe-To-Rear Exhaust Pipe Bolt/Nut41 (56)

Front (Radiator Side) Engine Mount Shock Absorber-To-Lower Frame Bolt35 (47)

Front (Radiator Side) Engine Mount-To-Lower Frame Assembly Bolt

Green Bolt49 (66)

Silver Bolt32 (44)

Lower Frame Assembly Mounting Bracket-To-Body Bolt/Nut

Large Bolt134 (182)

Small Bolt24 (33)

Nut27 (37)

Rear (Firewall Side) Engine Mount-To-Lower Frame Bolt/Nut49 (66)

Stabilizer Bar Mount Bracket-To-Lower Frame Assembly Bolt14 (19)

Starter Bolt29 (39)

Steering Gear Assembly-To-Lower Frame Assembly Bolt/Nut134 (182)

Torque Converter Bolt30 (41)

Transaxle Mount-To-Transaxle Bolt47 (64)

Transaxle-To-Cylinder Block Bolt

10-mm34 (46)

12-mm47 (64)

Wheel Lug Nut76 (103)

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 32 © 2005 Mitchell Repair Information Company, LLC.

Page 161 of 1632

clutch.

Vehicle Does Not Move In Reverse ("R")

Check 1-2 shift valve, 2-3 shift valve, 2nd coast brake, front planetary gear, rear planetary gear, direct clutch,

OD direct clutch and 1st and reverse brake.

No 1-2 &/Or 2-3 Upshift

Check Throttle Position (TP) sensor circuit, No. 1 and No. 2 shift solenoid circuit, Vehicle Speed Sensor (VSS)

circuit, Electronic Control Transmission Electronic Control Module (ECT ECM), 1-2 shift valve, 2-3 shift

valve, 2nd brake, direct clutch and No. 1 one-way clutch.

No 3-O/D Upshift

Check OD switch and OD OFF indicator switch circuit, OD cancel signal circuit, No. 1 and No. 2 shift solenoid

circuit, VSS, Engine Coolant Temperature (ECT) circuit, ECT ECM, 3-4 shift valve and OD brake.

No O/D-3 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, OD cancel signal circuit, ECT ECM and 3-4 shift

valve.

No 3-2 &/Or 2-1 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, TP sensor circuit, ECT ECM, 2-3 shift valve, 1-2 shift

valve and 2nd coast brake.

No Torque Converter Lock-Up

Check shift solenoid valve SL circuit, TP sensor circuit, VSS circuit, OD cancel circuit, brakelight circuit, ECT

circuit, ECT ECM, lock-up relay valve and torque converter clutch.

Torque Converter Lock-Up Will Not Release

Check shift solenoid valve SL circuit, TP sensor circuit, brakelight circuit, ECT ECM circuit, lock-up relay

valve and torque converter clutch.

Shift Speeds Too High Or Too Low

Check TP sensor circuit, VSS circuit, shift solenoid valve SL circuit, OD cancel signal circuit, pattern select

switch circuit and ECT ECM.

Harsh Engagement Neutral To Reverse

Check direct clutch accumulator, direct clutch, throttle valve and 1st and reverse brake.

Harsh Engagement Neutral To Drive

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:16 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 162 of 1632

Check forward clutch accumulator, throttle valve and forward clutch.

No Engine Braking In Low

Check low coast modulator valve and 1st and reverse brake.

No Engine Braking In 2nd

Check 2nd coast modulator valve and 2nd coast brake.

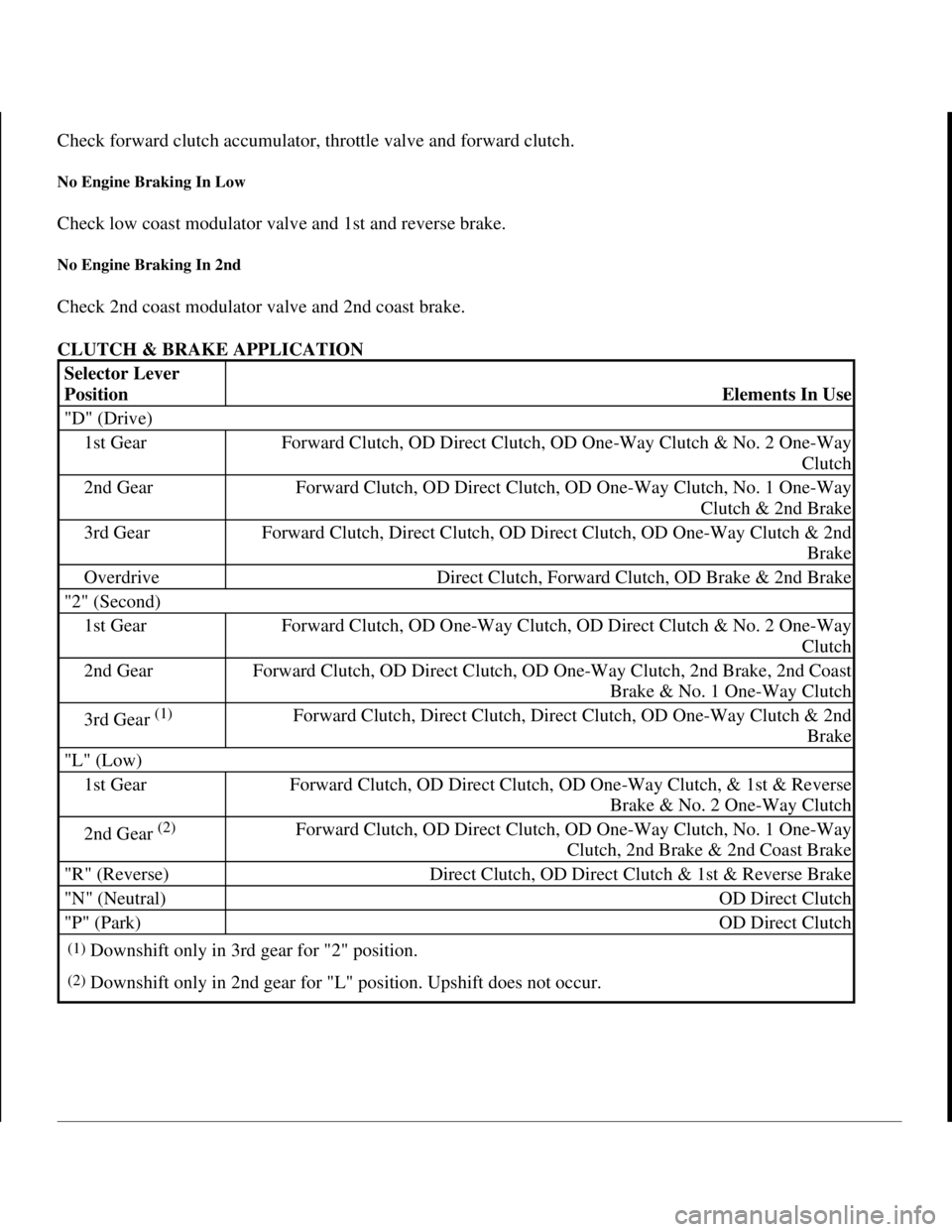

CLUTCH & BRAKE APPLICATION

Selector Lever

Position

Elements In Use

"D" (Drive)

1st GearForward Clutch, OD Direct Clutch, OD One-Way Clutch & No. 2 One-Way

Clutch

2nd GearForward Clutch, OD Direct Clutch, OD One-Way Clutch, No. 1 One-Way

Clutch & 2nd Brake

3rd GearForward Clutch, Direct Clutch, OD Direct Clutch, OD One-Way Clutch & 2nd

Brake

OverdriveDirect Clutch, Forward Clutch, OD Brake & 2nd Brake

"2" (Second)

1st GearForward Clutch, OD One-Way Clutch, OD Direct Clutch & No. 2 One-Way

Clutch

2nd GearForward Clutch, OD Direct Clutch, OD One-Way Clutch, 2nd Brake, 2nd Coast

Brake & No. 1 One-Way Clutch

3rd Gear (1)Forward Clutch, Direct Clutch, Direct Clutch, OD One-Way Clutch & 2nd

Brake

"L" (Low)

1st GearForward Clutch, OD Direct Clutch, OD One-Way Clutch, & 1st & Reverse

Brake & No. 2 One-Way Clutch

2nd Gear (2)Forward Clutch, OD Direct Clutch, OD One-Way Clutch, No. 1 One-Way

Clutch, 2nd Brake & 2nd Coast Brake

"R" (Reverse)Direct Clutch, OD Direct Clutch & 1st & Reverse Brake

"N" (Neutral)OD Direct Clutch

"P" (Park)OD Direct Clutch

(1)Downshift only in 3rd gear for "2" position.

(2)Downshift only in 2nd gear for "L" position. Upshift does not occur.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 164 of 1632

1. If shift lever is actuated with engine idling, a time lag will be noted before shock can be felt. This test is

used for checking condition of OD direct clutch, forward clutch, direct clutch, and 1st and reverse brake.

2. Apply parking brake. Start engine. On RAV4, ensure idle speed is 700-800 RPM. On all other models,

ensure idle speed is 650-750 RPM. Shift transaxle from "N" into "D" range. Use a stop watch to measure

elapsed time between shifting of lever until shock is felt. Standard time lag is less than 1.2 seconds.

3. Repeat procedure outlined in step 2) to measure time lag for "N" to "R". Standard lag time is less than 1.5

seconds.

4. If "N" to "D" time lag is longer than specification, line pressure is too low, forward clutch may be worn,

or OD one-way clutch is not operating properly.

5. If "N" to "R" time lag is longer than specified, direct clutch may be worn, 1st and reverse brake may be

worn, line pressure is too low or OD one-way clutch is not operating properly.

ROAD TEST

"D" Range Test In NORM & PWR Pattern Ranges

1. Shift into "D" range. Hold accelerator pedal constant at full throttle. Place shift mode button in NORM or

PWR position. Check 1-2, 2-3, and 3-OD lock-up and upshift points. See appropriate table under SHIFT

SPEED SPECIFICATIONS .

�zIf no 1-2 upshift occurs, check 1-2 shift valve or solenoid.

�zIf no 2-3 upshift occurs, check 2-3 shift valve or solenoid.

�zIf no 3-OD upshift occurs, check 3-OD shift valve.

�zIf all shift points are incorrect, check throttle valve, 1-2 shift valve, 2-3 shift valve and 3-OD shift

valve.

�zIf all lock-up points are incorrect, check lock-up relay valve or shift solenoid valve SL.

2. Use procedure outlined in step 1) to check for shock and slip between 1-2, 2-3, and 3-OD upshifts. If

shock is harsh, line pressure may be too high. Check accumulator or check ball.

3. Run vehicle in "D" range lock-up or overdrive gear. Check for abnormal noise and vibration.

4. While running in "D" range, confirm correct kickdown vehicle speed limits for 2-1, 3-2, OD-3 shift

points. Check for abnormal shock and slip at kickdown.

5. Check loc

k-up function. Drive vehicle in OD gear of "D" range with lock-up on. Hold vehicle speed NOTE: Perform test at normal operating fluid temperature of 122-176°F (50-80°C).

NOTE: There is no overdrive upshift when coolant temperature is below 140°F

(60°C). There is no lock-up when vehicle speed is 6 MPH less than the set

cruise control speed.

NOTE: Check for cause of abnormal noise and vibration must be made with

extreme care as problem could be due to an unbalanced drive shaft,

differential, tire, torque converter, etc.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.