check engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 753 of 2000

EM–1162GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

17. INSTALL WATER INLET PIPE

(a) Install the water inlet pipe with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(b) Install the water by-pass hose.

18. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 1)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

damage the gasket with the bottom part of the

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

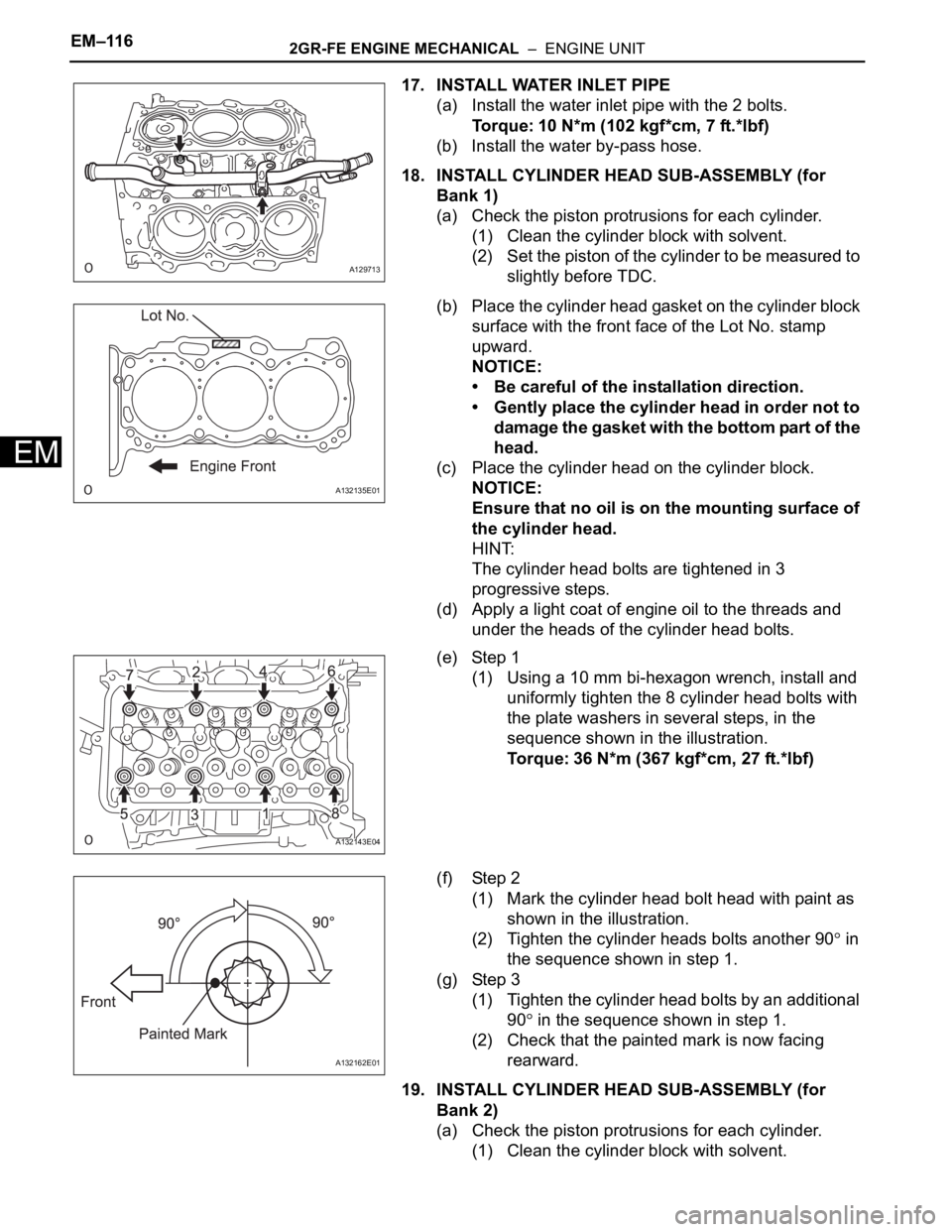

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

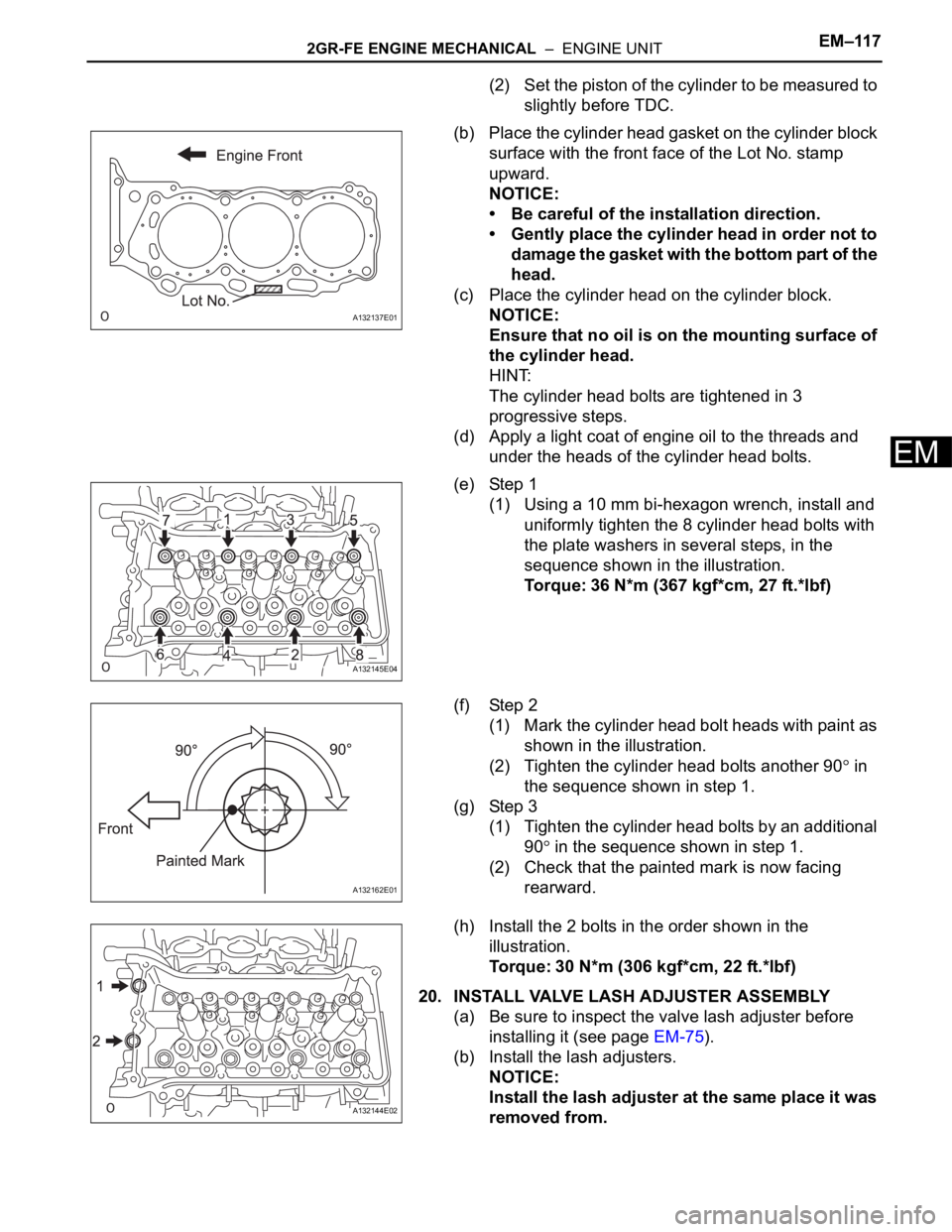

(f) Step 2

(1) Mark the cylinder head bolt head with paint as

shown in the illustration.

(2) Tighten the cylinder heads bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

19. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 2)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

A129713

A132135E01

A132143E04

A132162E01

Page 754 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–117

EM

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

dama ge the gaske t wi th t he b ottom part of t he

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

(f) Step 2

(1) Mark the cylinder head bolt heads with paint as

shown in the illustration.

(2) Tighten the cylinder head bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

(h) Install the 2 bolts in the order shown in the

illustration.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

20. INSTALL VALVE LASH ADJUSTER ASSEMBLY

(a) Be sure to inspect the valve lash adjuster before

installing it (see page EM-75).

(b) Install the lash adjusters.

NOTICE:

Install the lash adjuster at the same place it was

removed from.

A132137E01

A132145E04

A132162E01

A132144E02

Page 763 of 2000

EM–1262GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

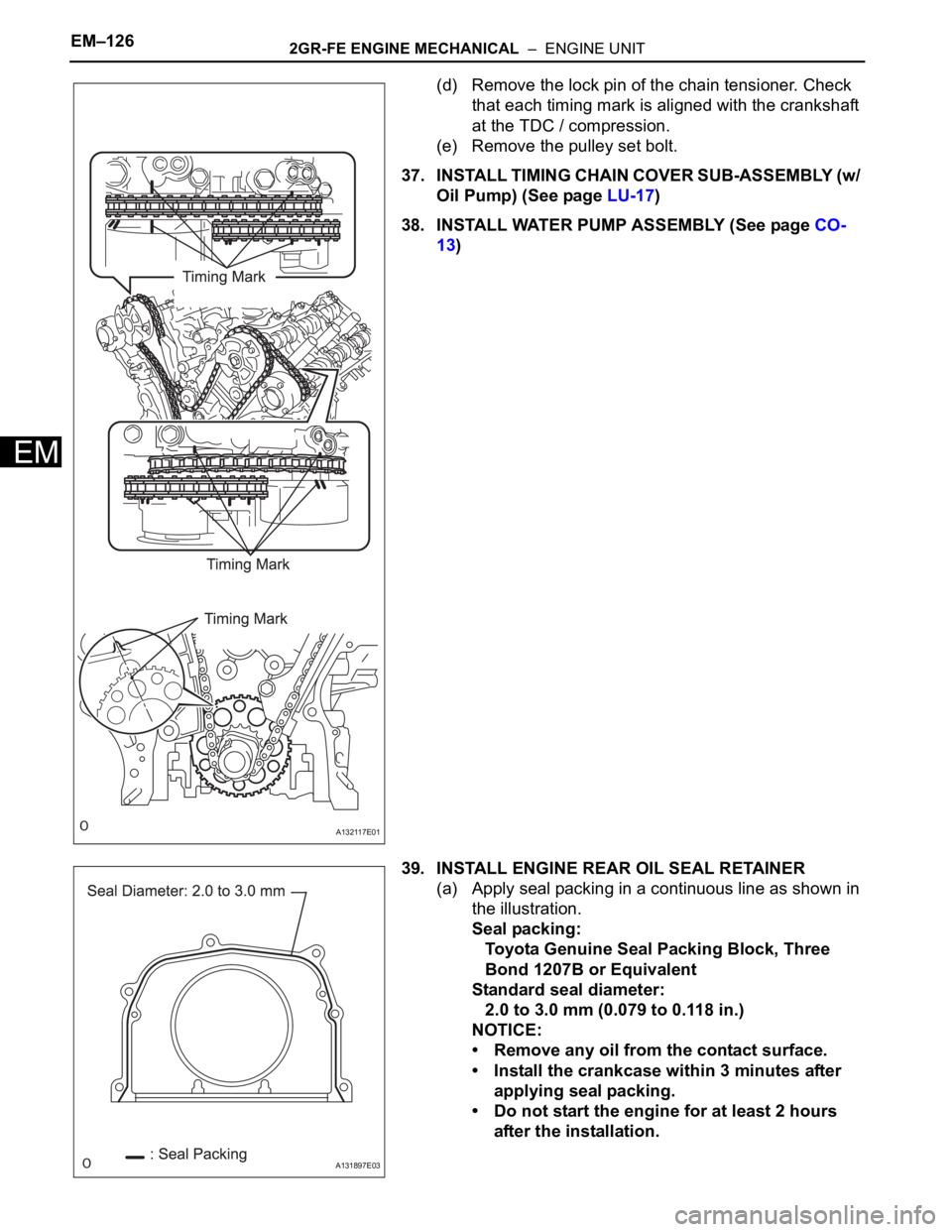

(d) Remove the lock pin of the chain tensioner. Check

that each timing mark is aligned with the crankshaft

at the TDC / compression.

(e) Remove the pulley set bolt.

37. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY (w/

Oil Pump) (See page LU-17)

38. INSTALL WATER PUMP ASSEMBLY (See page CO-

13)

39. INSTALL ENGINE REAR OIL SEAL RETAINER

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

Standard seal diameter:

2.0 to 3.0 mm (0.079 to 0.118 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the crankcase within 3 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

A132117E01

A131897E03

Page 768 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–131

EM

REPAIR

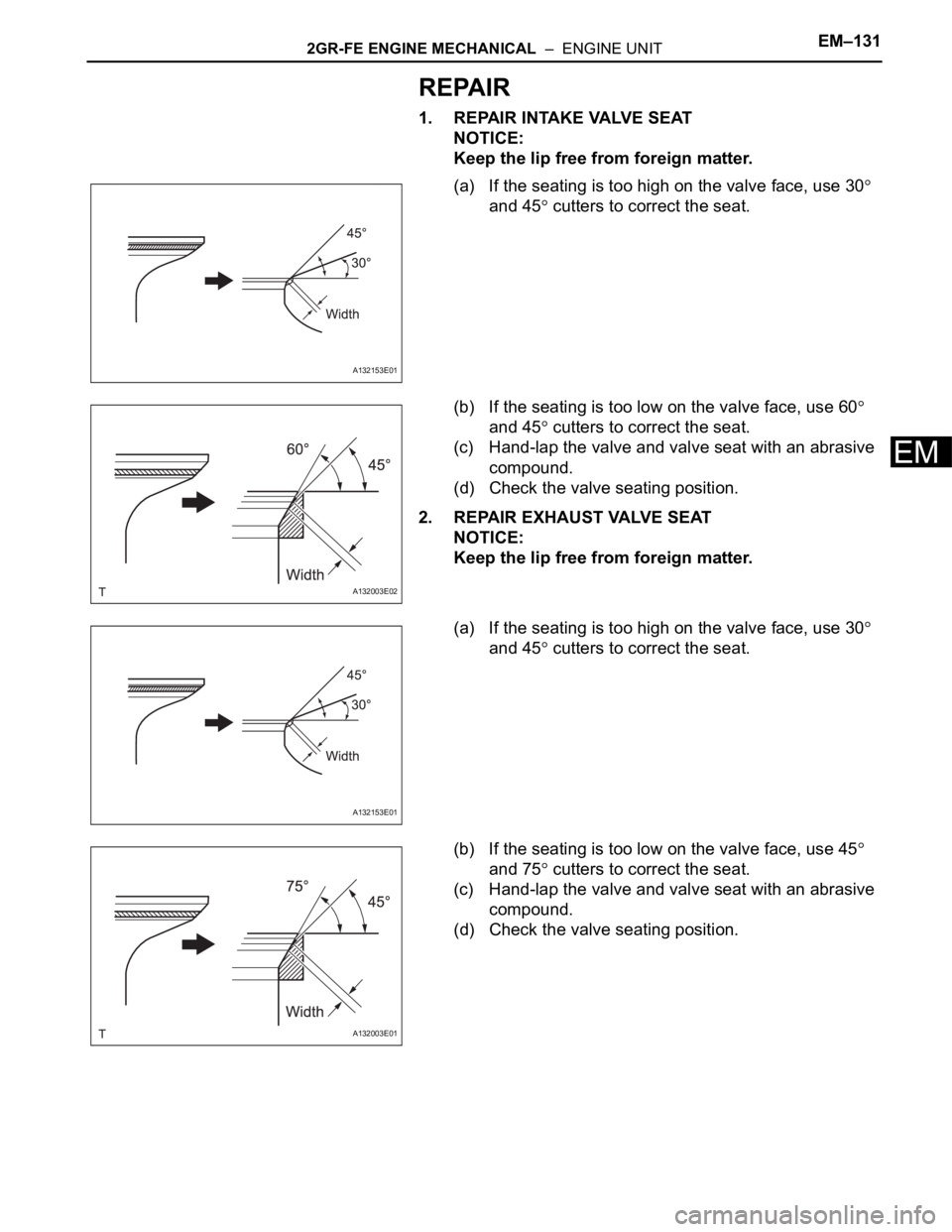

1. REPAIR INTAKE VALVE SEAT

NOTICE:

Keep the lip free from foreign matter.

(a) If the seating is too high on the valve face, use 30

and 45

cutters to correct the seat.

(b) If the seating is too low on the valve face, use 60

and 45

cutters to correct the seat.

(c) Hand-lap the valve and valve seat with an abrasive

compound.

(d) Check the valve seating position.

2. REPAIR EXHAUST VALVE SEAT

NOTICE:

Keep the lip free from foreign matter.

(a) If the seating is too high on the valve face, use 30

and 45

cutters to correct the seat.

(b) If the seating is too low on the valve face, use 45

and 75

cutters to correct the seat.

(c) Hand-lap the valve and valve seat with an abrasive

compound.

(d) Check the valve seating position.

A132153E01

A132003E02

A132153E01

A132003E01

Page 769 of 2000

2AZ-FE FUEL – FUEL INJECTORFU–9

FU

REMOVAL

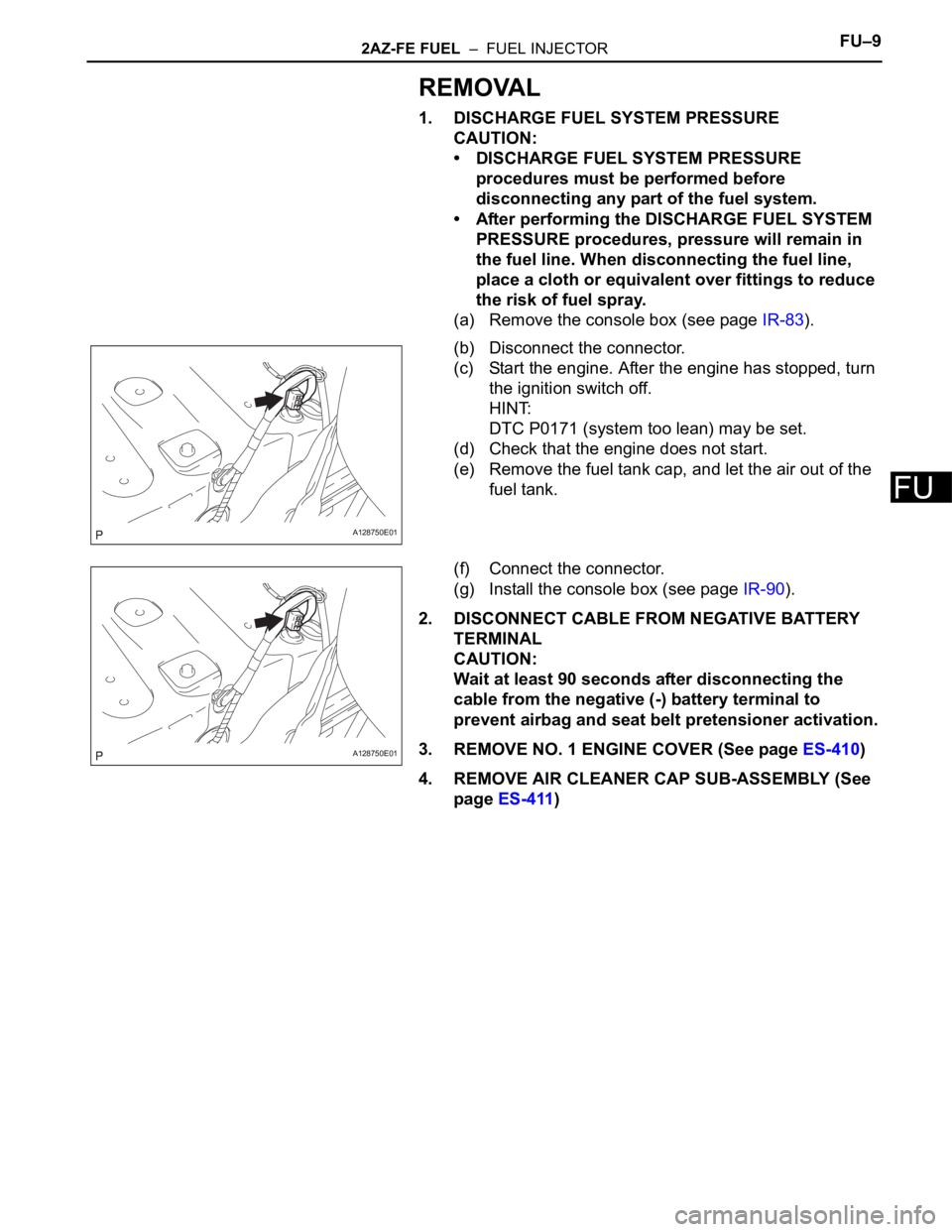

1. DISCHARGE FUEL SYSTEM PRESSURE

CAUTION:

• DISCHARGE FUEL SYSTEM PRESSURE

procedures must be performed before

disconnecting any part of the fuel system.

• After performing the DISCHARGE FUEL SYSTEM

PRESSURE procedures, pressure will remain in

the fuel line. When disconnecting the fuel line,

place a cloth or equivalent over fittings to reduce

the risk of fuel spray.

(a) Remove the console box (see page IR-83).

(b) Disconnect the connector.

(c) Start the engine. After the engine has stopped, turn

the ignition switch off.

HINT:

DTC P0171 (system too lean) may be set.

(d) Check that the engine does not start.

(e) Remove the fuel tank cap, and let the air out of the

fuel tank.

(f) Connect the connector.

(g) Install the console box (see page IR-90).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE NO. 1 ENGINE COVER (See page ES-410)

4. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-411)

A128750E01

A128750E01

Page 774 of 2000

FU–142AZ-FE FUEL – FUEL INJECTOR

FU

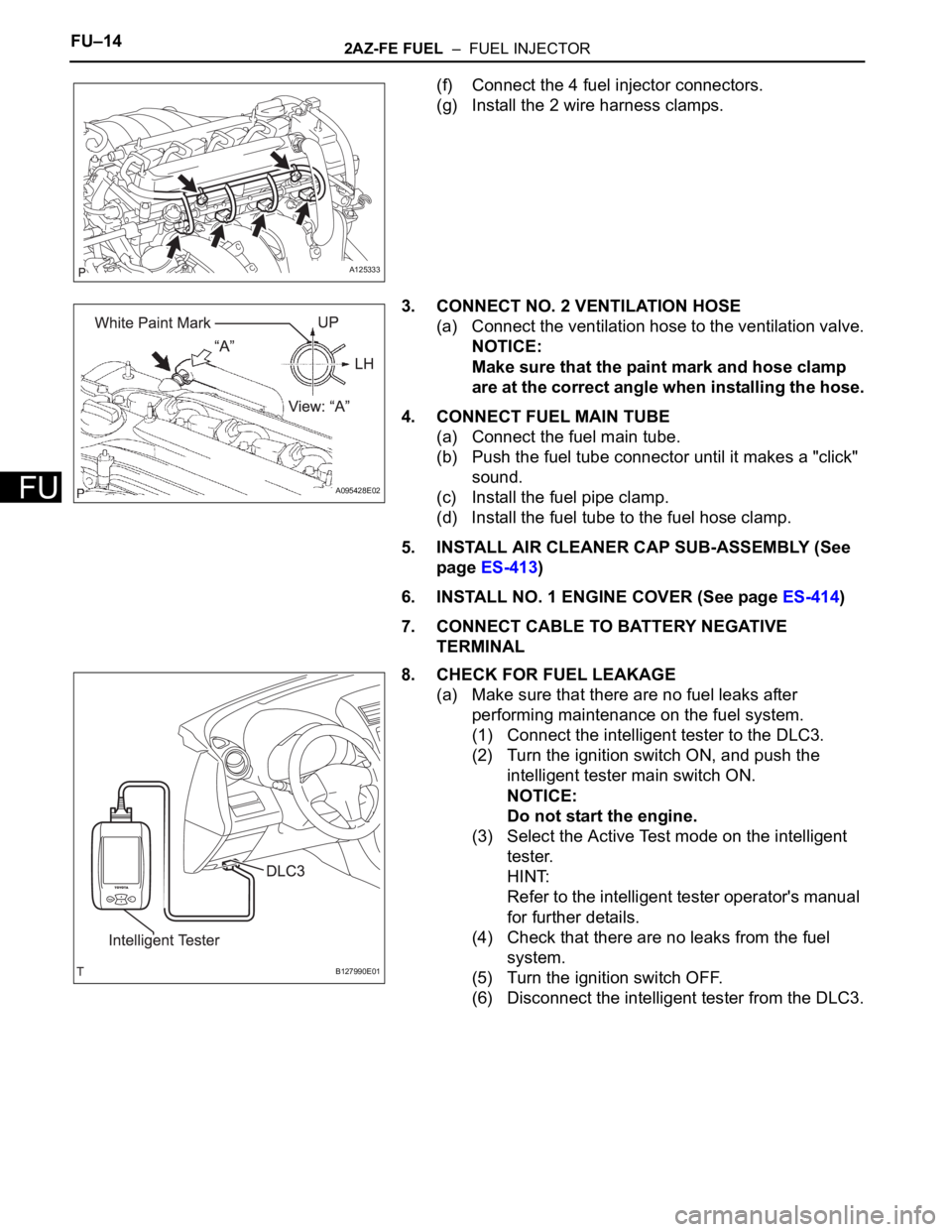

(f) Connect the 4 fuel injector connectors.

(g) Install the 2 wire harness clamps.

3. CONNECT NO. 2 VENTILATION HOSE

(a) Connect the ventilation hose to the ventilation valve.

NOTICE:

Make sure that the paint mark and hose clamp

are at the correct angle when installing the hose.

4. CONNECT FUEL MAIN TUBE

(a) Connect the fuel main tube.

(b) Push the fuel tube connector until it makes a "click"

sound.

(c) Install the fuel pipe clamp.

(d) Install the fuel tube to the fuel hose clamp.

5. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-413)

6. INSTALL NO. 1 ENGINE COVER (See page ES-414)

7. CONNECT CABLE TO BATTERY NEGATIVE

TERMINAL

8. CHECK FOR FUEL LEAKAGE

(a) Make sure that there are no fuel leaks after

performing maintenance on the fuel system.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON, and push the

intelligent tester main switch ON.

NOTICE:

Do not start the engine.

(3) Select the Active Test mode on the intelligent

tester.

HINT:

Refer to the intelligent tester operator's manual

for further details.

(4) Check that there are no leaks from the fuel

system.

(5) Turn the ignition switch OFF.

(6) Disconnect the intelligent tester from the DLC3.

A125333

A095428E02

B127990E01

Page 783 of 2000

2AZ-FE FUEL – FUEL PRESSURE PULSATION DAMPERFU–27

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE COVER (See page ES-410)

4. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-411)

5. DISCONNECT FUEL MAIN TUBE (See page FU-10)

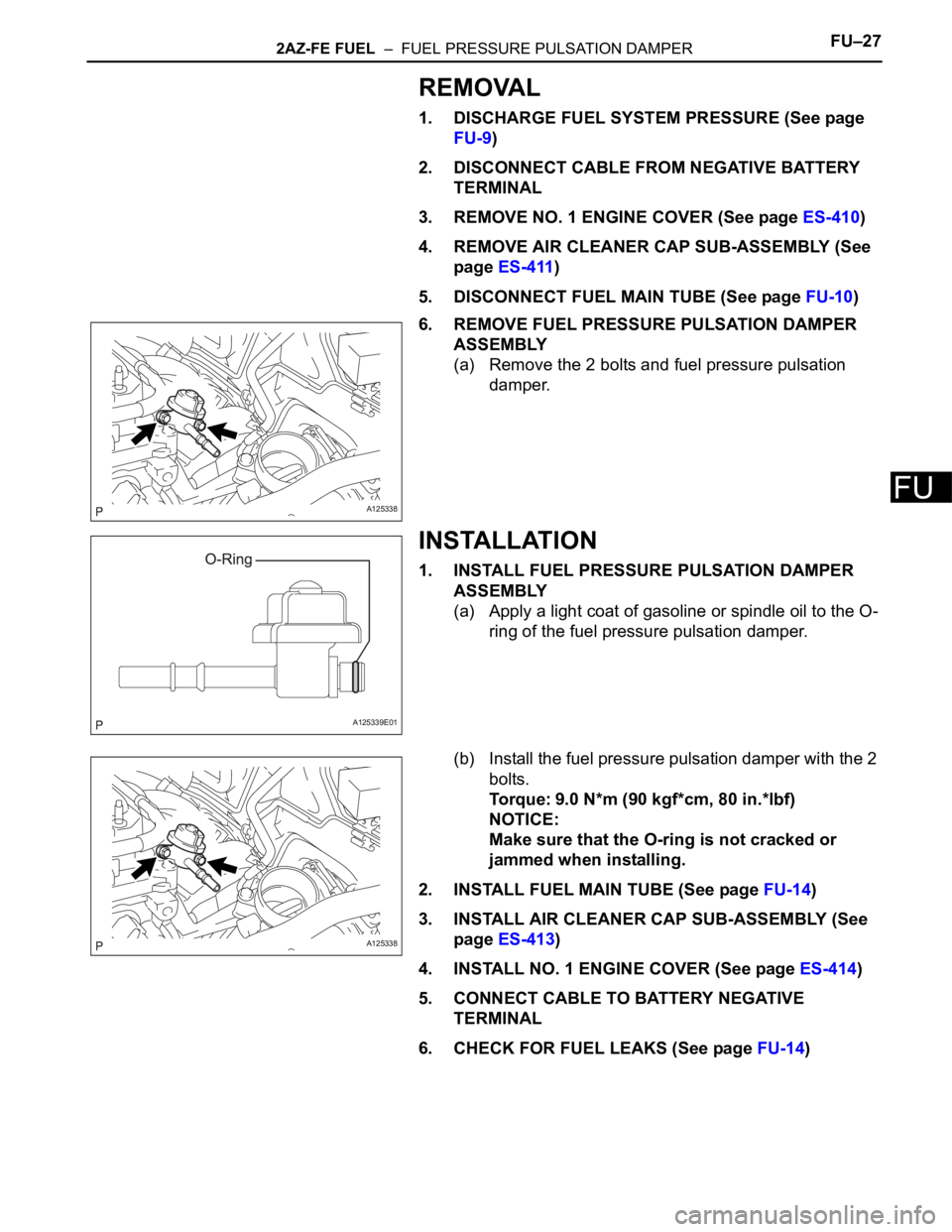

6. REMOVE FUEL PRESSURE PULSATION DAMPER

ASSEMBLY

(a) Remove the 2 bolts and fuel pressure pulsation

damper.

INSTALLATION

1. INSTALL FUEL PRESSURE PULSATION DAMPER

ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the O-

ring of the fuel pressure pulsation damper.

(b) Install the fuel pressure pulsation damper with the 2

bolts.

Torque: 9.0 N*m (90 kgf*cm, 80 in.*lbf)

NOTICE:

Make sure that the O-ring is not cracked or

jammed when installing.

2. INSTALL FUEL MAIN TUBE (See page FU-14)

3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-413)

4. INSTALL NO. 1 ENGINE COVER (See page ES-414)

5. CONNECT CABLE TO BATTERY NEGATIVE

TERMINAL

6. CHECK FOR FUEL LEAKS (See page FU-14)

A125338

A125339E01

A125338

Page 801 of 2000

2GR-FE FUEL – FUEL SYSTEMFU–9

FU

ON-VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

NOTICE:

Do not start the engine.

(c) Select the following tester menus: DIAGNOSIS,

ENHANCED OBD II, ACTIVE TEST and FUEL

PUMP/SPD. Operate the fuel pump.

(d) Touch the fuel hose in the engine compartment to

check the fuel flow, and you will be able to hear the

sound of the fuel pump.

(e) Stop the fuel pump. If there is no fuel flow, the fuel

pump may not be operating. Check the fuel pump

circuit.

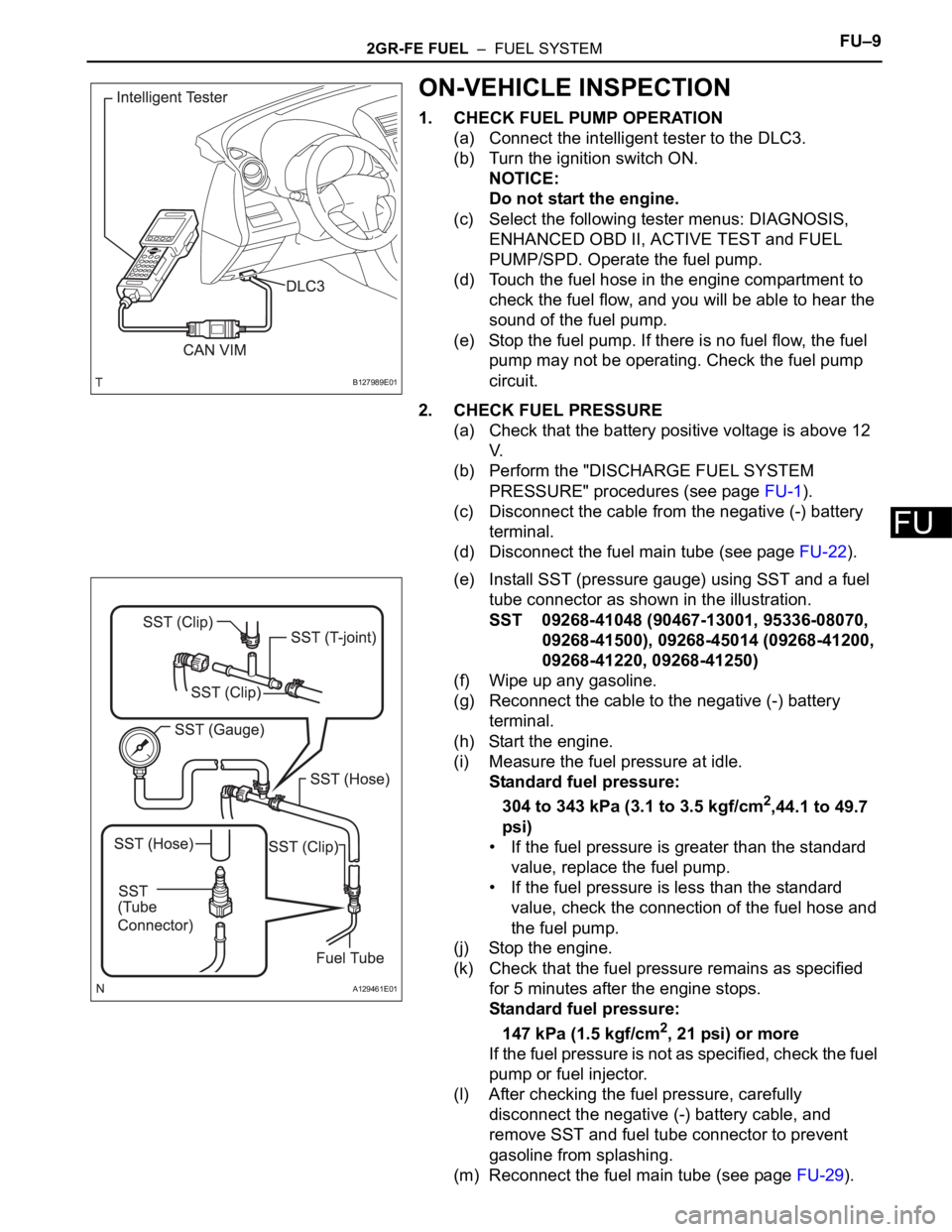

2. CHECK FUEL PRESSURE

(a) Check that the battery positive voltage is above 12

V.

(b) Perform the "DISCHARGE FUEL SYSTEM

PRESSURE" procedures (see page FU-1).

(c) Disconnect the cable from the negative (-) battery

terminal.

(d) Disconnect the fuel main tube (see page FU-22).

(e) Install SST (pressure gauge) using SST and a fuel

tube connector as shown in the illustration.

SST 09268-41048 (90467-13001, 95336-08070,

09268-41500), 09268-45014 (09268-41200,

09268-41220, 09268-41250)

(f) Wipe up any gasoline.

(g) Reconnect the cable to the negative (-) battery

terminal.

(h) Start the engine.

(i) Measure the fuel pressure at idle.

Standard fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm

2,44.1 to 49.7

psi)

• If the fuel pressure is greater than the standard

value, replace the fuel pump.

• If the fuel pressure is less than the standard

value, check the connection of the fuel hose and

the fuel pump.

(j) Stop the engine.

(k) Check that the fuel pressure remains as specified

for 5 minutes after the engine stops.

Standard fuel pressure:

147 kPa (1.5 kgf/cm

2, 21 psi) or more

If the fuel pressure is not as specified, check the fuel

pump or fuel injector.

(l) After checking the fuel pressure, carefully

disconnect the negative (-) battery cable, and

remove SST and fuel tube connector to prevent

gasoline from splashing.

(m) Reconnect the fuel main tube (see page FU-29).

B127989E01

A129461E01

Page 803 of 2000

2GR-FE FUEL – FUEL INJECTORFU–13

FU

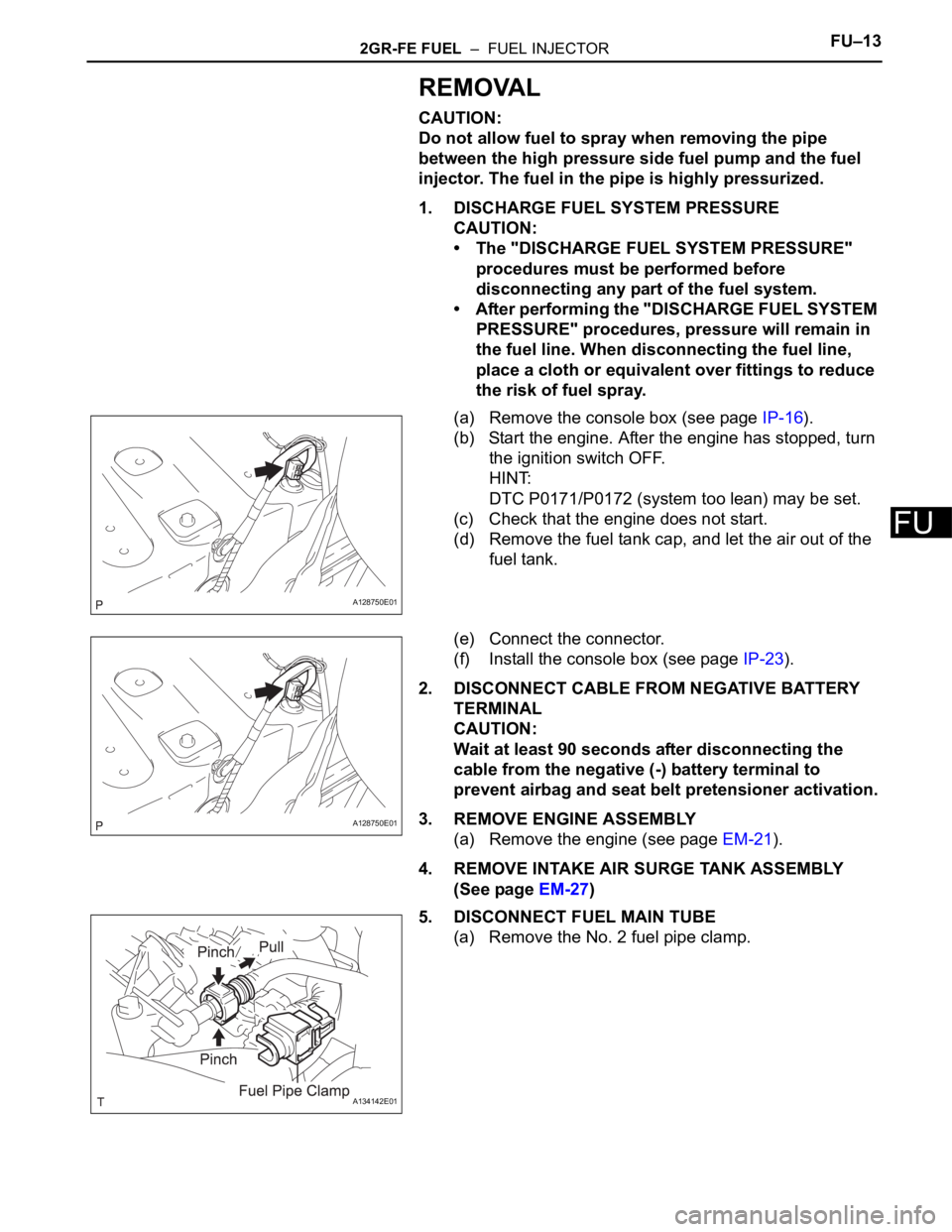

REMOVAL

CAUTION:

Do not allow fuel to spray when removing the pipe

between the high pressure side fuel pump and the fuel

injector. The fuel in the pipe is highly pressurized.

1. DISCHARGE FUEL SYSTEM PRESSURE

CAUTION:

• The "DISCHARGE FUEL SYSTEM PRESSURE"

procedures must be performed before

disconnecting any part of the fuel system.

• After performing the "DISCHARGE FUEL SYSTEM

PRESSURE" procedures, pressure will remain in

the fuel line. When disconnecting the fuel line,

place a cloth or equivalent over fittings to reduce

the risk of fuel spray.

(a) Remove the console box (see page IP-16).

(b) Start the engine. After the engine has stopped, turn

the ignition switch OFF.

HINT:

DTC P0171/P0172 (system too lean) may be set.

(c) Check that the engine does not start.

(d) Remove the fuel tank cap, and let the air out of the

fuel tank.

(e) Connect the connector.

(f) Install the console box (see page IP-23).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE ENGINE ASSEMBLY

(a) Remove the engine (see page EM-21).

4. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(See page EM-27)

5. DISCONNECT FUEL MAIN TUBE

(a) Remove the No. 2 fuel pipe clamp.

A128750E01

A128750E01

A134142E01

Page 808 of 2000

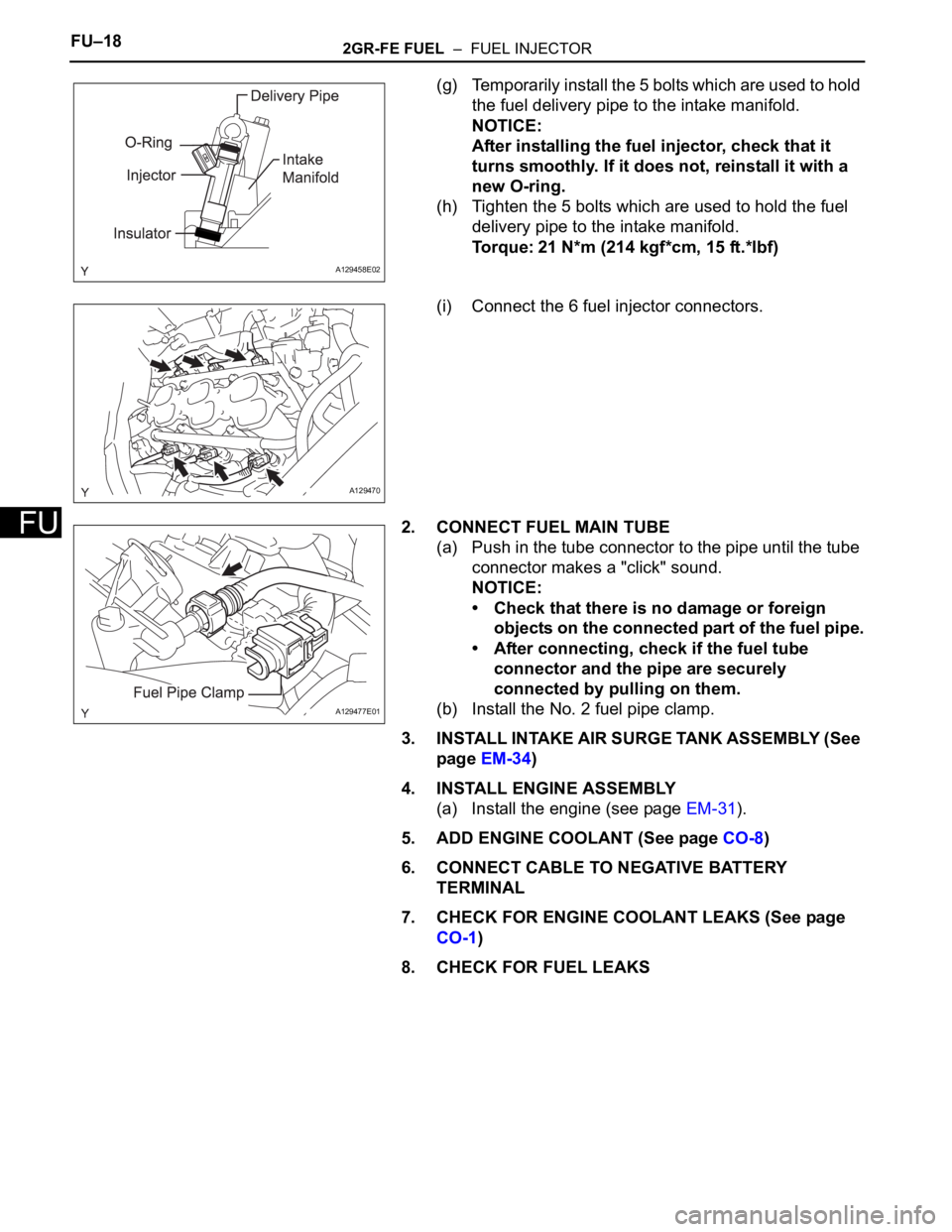

FU–182GR-FE FUEL – FUEL INJECTOR

FU

(g) Temporarily install the 5 bolts which are used to hold

the fuel delivery pipe to the intake manifold.

NOTICE:

After installing the fuel injector, check that it

turns smoothly. If it does not, reinstall it with a

new O-ring.

(h) Tighten the 5 bolts which are used to hold the fuel

delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(i) Connect the 6 fuel injector connectors.

2. CONNECT FUEL MAIN TUBE

(a) Push in the tube connector to the pipe until the tube

connector makes a "click" sound.

NOTICE:

• Check that there is no damage or foreign

objects on the connected part of the fuel pipe.

• After connecting, check if the fuel tube

connector and the pipe are securely

connected by pulling on them.

(b) Install the No. 2 fuel pipe clamp.

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY (See

page EM-34)

4. INSTALL ENGINE ASSEMBLY

(a) Install the engine (see page EM-31).

5. ADD ENGINE COOLANT (See page CO-8)

6. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

7. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

8. CHECK FOR FUEL LEAKS

A129458E02

A129470

A129477E01