check engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 930 of 2000

2GR-FE CHARGING – CHARGING SYSTEMCH–7

CH

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn the high

beam headlights ON and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard

amperage, repair the generator.

HINT:

If the battery is fully charged, the indication will

sometimes be less than the standard amperage.

If this is the case, add more electrical load (operate

the wipers, rear window defogger, etc.) and check

the reading on the ammeter again.

Page 949 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–15

AX

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the normal operating ATF

temperature of 50 to 80

C (122 to 176F).

(a) D position test

Move the shift lever to D and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2, 2 3 and 3 O/D up-

shifts take place at the shift point shown in the

automatic shift schedule (see page SS-55).

HINT:

O/D Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 70 km/h (43

mph) or less.

• ATF temperature is 5

C (41F) or less.

O/D Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Engine coolant temperature is 60

C (140F)

or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3 and

3

O/D up-shifts.

(3) Check for abnormal noise and vibration.

Check for abnormal noise and vibration when

up-shifting from 1

2, 2 3 and 3 O/D while

driving with the shift lever on D, and check while

driving in the lock-up condition.

HINT:

The check for the cause of abnormal noise and

vibration must be done thoroughly as it could

also be due to loss of balance in the differential,

torque converter clutch, etc.

(4) Check kick-down operation.

While driving the vehicle in the 2nd, 3rd and O/D

gears with the shift lever on D, check that the

possible kick-down vehicle speed limits for 2

1, 3

2 and O/D 3 kick-downs conform to

those indicated in the automatic shift schedule

(see page SS-55).

(5) Check for abnormal shock and slip at kick-down.

Page 950 of 2000

AX–16U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(6) Check the lock-up mechanism.

• Drive the vehicl e in the O/D gear with the shift

lever on D. Maintain a steady speed (lock-up

ON).

• Lightly depress the accelerator pedal and

check that the engine speed does not change

abruptly.

HINT:

• There is no lock-up function in the 1st and

2nd gear.

• If there is a sudden increase in engine speed,

there is no lock-up.

(b) 3 position test

Move the shift lever to 3 and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2 and 2 3 up-shifts take

place and that the shift point conforms to the

automatic shift schedule (see page SS-55).

(2) Check engine braking.

While driving the vehicle in the 3rd gear with the

shift lever on 3, release the accelerator pedal

and check the engine braking effect.

(3) Check for abnormal noises during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(c) 2 position test

Move the shift lever to 2 and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2 up-shift takes place and

that the shift point conforms to the automatic

shift schedule (see page SS-55).

HINT:

There is no O/D up-shift and lock-up when the

shift lever is on 2.

(2) Check engine braking.

While driving the vehicle in the 2nd gear with the

shift lever on 2, release the accelerator pedal

and check the engine braking effect.

(3) Check for abnormal noises during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(d) L position test

Move the shift lever to L and fully depress the

accelerator pedal. Check the following:

(1) Check that there is no up-shift.

While driving the vehicle with the shift lever on L,

check that there is no up-shift to 2nd gear.

HINT:

There is no lock-up in L.

Page 951 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–17

AX

(2) Check engine braking.

While driving the vehicle with the shift lever on L,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noises during acceleration

and deceleration.

(e) R position test

Move the shift lever to R and lightly depress the

accelerator pedal. Check that the vehicle moves

backward without any abnormal noise or vibration.

CAUTION:

Before conducting this test, ensure that no

people or obstacles are in the test area.

(f) P position test

Stop the vehicle on an incline (more than 5

). Then

move the shift lever to P and release the parking

brake. Check that the parking lock pawl holds the

vehicle in place.

Page 952 of 2000

AX–18U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MECHANICAL SYSTEM TESTS

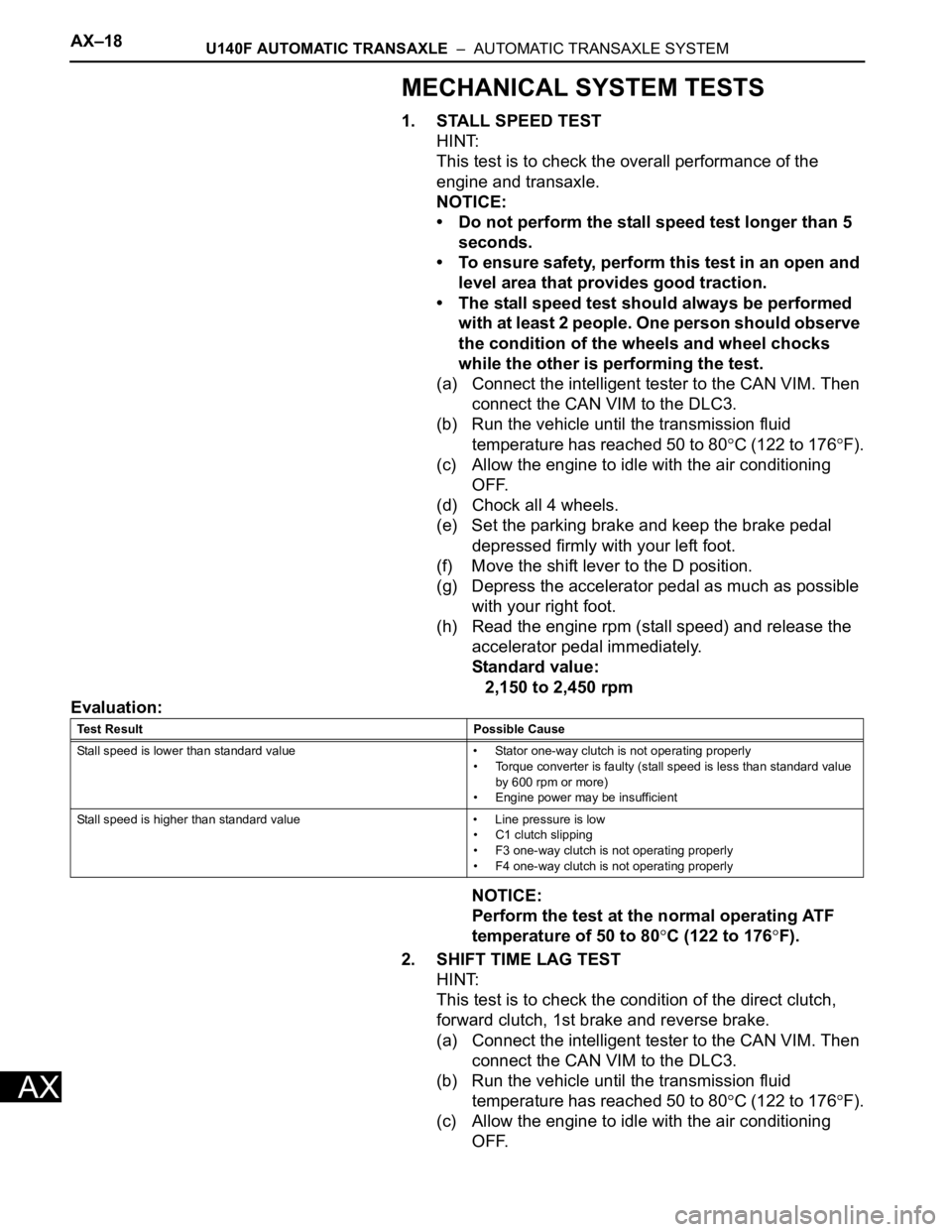

1. STALL SPEED TEST

HINT:

This test is to check the overall performance of the

engine and transaxle.

NOTICE:

• Do not perform the stall speed test longer than 5

seconds.

• To ensure safety, perform this test in an open and

level area that provides good traction.

• The stall speed test should always be performed

with at least 2 people. One person should observe

the condition of the wheels and wheel chocks

while the other is performing the test.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

(c) Allow the engine to idle with the air conditioning

OFF.

(d) Chock all 4 wheels.

(e) Set the parking brake and keep the brake pedal

depressed firmly with your left foot.

(f) Move the shift lever to the D position.

(g) Depress the accelerator pedal as much as possible

with your right foot.

(h) Read the engine rpm (stall speed) and release the

accelerator pedal immediately.

Standard value:

2,150 to 2,450 rpm

Evaluation:

NOTICE:

Perform the test at the normal operating ATF

temperature of 50 to 80

C (122 to 176F).

2. SHIFT TIME LAG TEST

HINT:

This test is to check the condition of the direct clutch,

forward clutch, 1st brake and reverse brake.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

(c) Allow the engine to idle with the air conditioning

OFF.

Test Result Possible Cause

Stall speed is lower than standard value • Stator one-way clutch is not operating properly

• Torque converter is faulty (stall speed is less than standard value

by 600 rpm or more)

• Engine power may be insufficient

Stall speed is higher than standard value • Line pressure is low

• C1 clutch slipping

• F3 one-way clutch is not operating properly

• F4 one-way clutch is not operating properly

Page 953 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–19

AX

(d) Set the parking brake and keep the brake pedal

depressed firmly.

(e) Check the D range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to D and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

(f) Check the R range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to R and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

Standard value:

D range time lag is less than 1.2 seconds

R range time lag is less than 1.5 seconds

Evaluation:

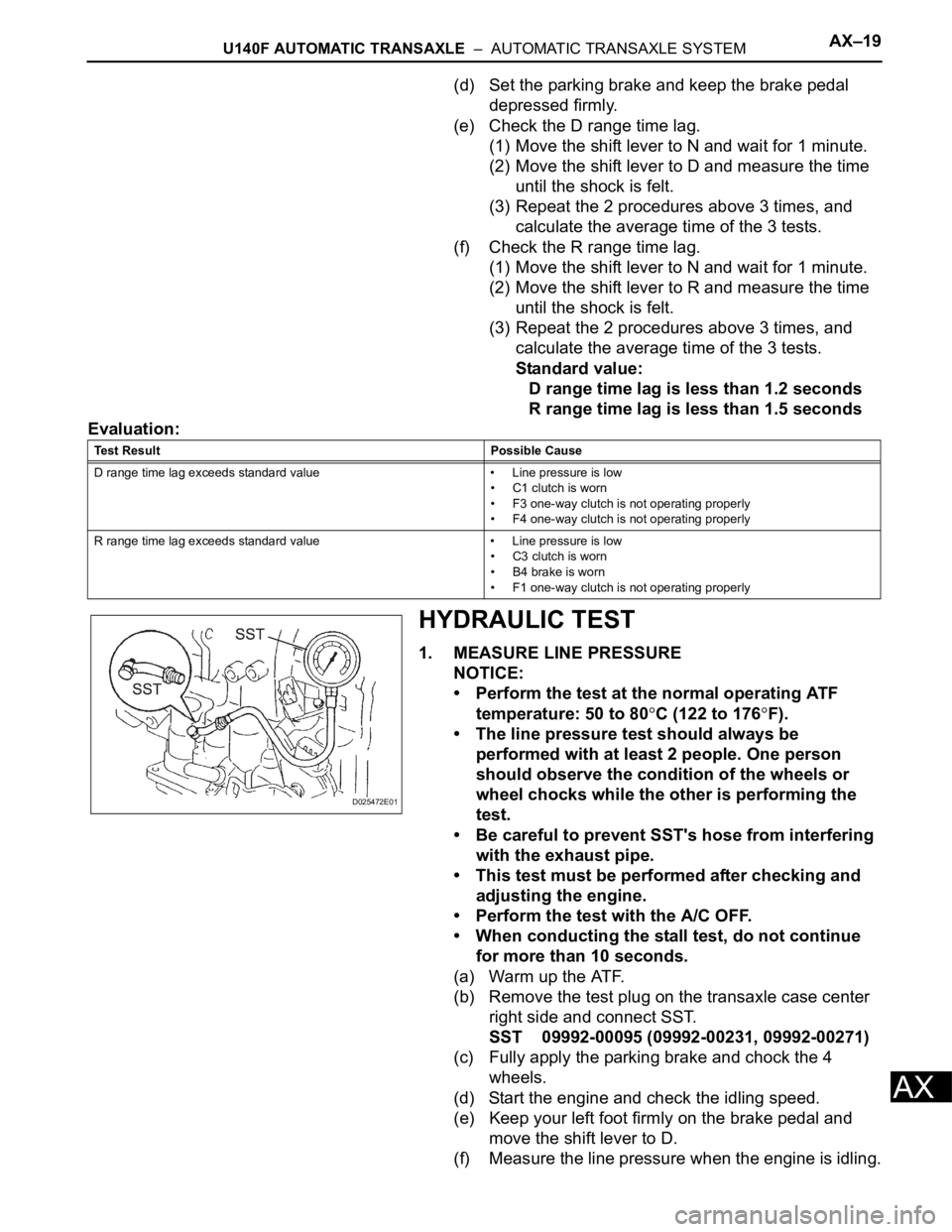

HYDRAULIC TEST

1. MEASURE LINE PRESSURE

NOTICE:

• Perform the test at the normal operating ATF

temperature: 50 to 80

C (122 to 176F).

• The line pressure test should always be

performed with at least 2 people. One person

should observe the condition of the wheels or

wheel chocks while the other is performing the

test.

• Be careful to prevent SST's hose from interfering

with the exhaust pipe.

• This test must be performed after checking and

adjusting the engine.

• Perform the test with the A/C OFF.

• When conducting the stall test, do not continue

for more than 10 seconds.

(a) Warm up the ATF.

(b) Remove the test plug on the transaxle case center

right side and connect SST.

SST 09992-00095 (09992-00231, 09992-00271)

(c) Fully apply the parking brake and chock the 4

wheels.

(d) Start the engine and check the idling speed.

(e) Keep your left foot firmly on the brake pedal and

move the shift lever to D.

(f) Measure the line pressure when the engine is idling.

Test Result Possible Cause

D range time lag exceeds standard value • Line pressure is low

• C1 clutch is worn

• F3 one-way clutch is not operating properly

• F4 one-way clutch is not operating properly

R range time lag exceeds standard value • Line pressure is low

• C3 clutch is worn

• B4 brake is worn

• F1 one-way clutch is not operating properly

D025472E01

Page 960 of 2000

AX–26U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

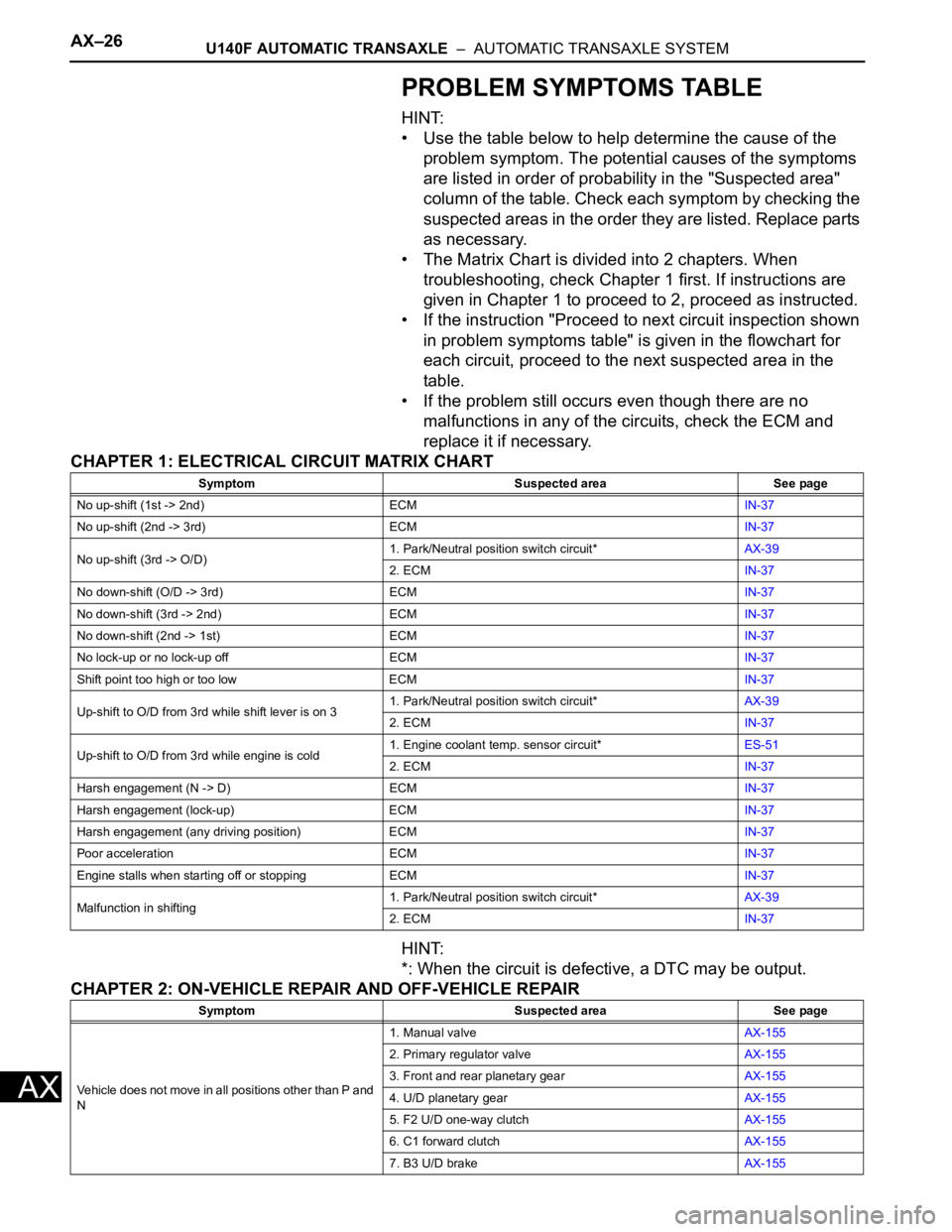

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• The Matrix Chart is divided into 2 chapters. When

troubleshooting, check Chapter 1 first. If instructions are

given in Chapter 1 to proceed to 2, proceed as instructed.

• If the instruction "Proceed to next circuit inspection shown

in problem symptoms table" is given in the flowchart for

each circuit, proceed to the next suspected area in the

table.

• If the problem still occurs even though there are no

malfunctions in any of the circuits, check the ECM and

replace it if necessary.

CHAPTER 1: ELECTRICAL CIRCUIT MATRIX CHART

HINT:

*: When the circuit is defective, a DTC may be output.

CHAPTER 2: ON-VEHICLE REPAIR AND OFF-VEHICLE REPAIR

Symptom Suspected area See page

No up-shift (1st -> 2nd) ECMIN-37

No up-shift (2nd -> 3rd) ECMIN-37

No up-shift (3rd -> O/D)1. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

No down-shift (O/D -> 3rd) ECMIN-37

No down-shift (3rd -> 2nd) ECMIN-37

No down-shift (2nd -> 1st) ECMIN-37

No lock-up or no lock-up off ECMIN-37

Shift point too high or too low ECMIN-37

Up-shift to O/D from 3rd while shift lever is on 31. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

Up-shift to O/D from 3rd while engine is cold1. Engine coolant temp. sensor circuit*ES-51

2. ECMIN-37

Harsh engagement (N -> D) ECMIN-37

Harsh engagement (lock-up) ECMIN-37

Harsh engagement (any driving position) ECMIN-37

Poor acceleration ECMIN-37

Engine stalls when starting off or stopping ECMIN-37

Malfunction in shifting1. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

Symptom Suspected area See page

Vehicle does not move in all positions other than P and

N1. Manual valveAX-155

2. Primary regulator valveAX-155

3. Front and rear planetary gearAX-155

4. U/D planetary gearAX-155

5. F2 U/D one-way clutchAX-155

6. C1 forward clutchAX-155

7. B3 U/D brakeAX-155

Page 965 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–31

AX

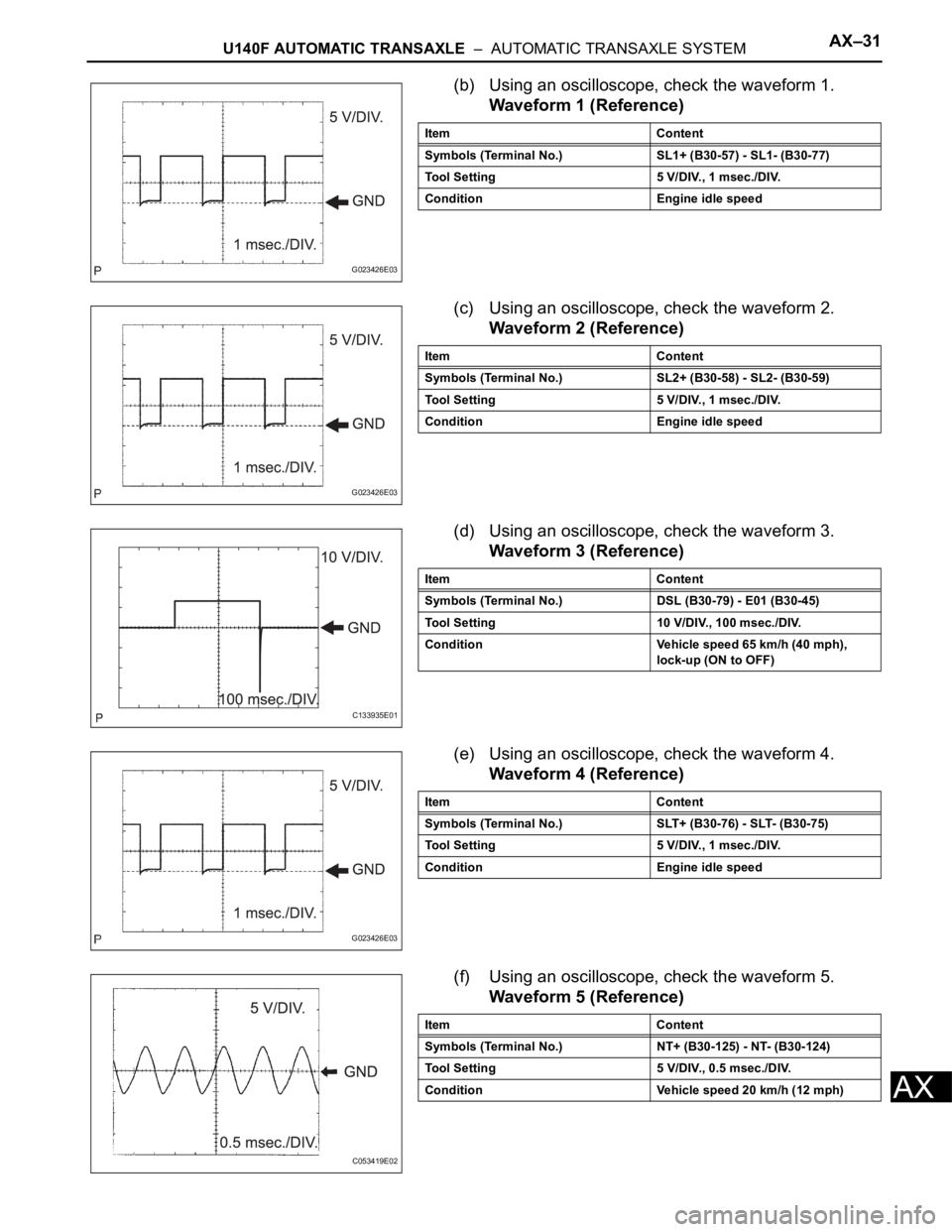

(b) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

(c) Using an oscilloscope, check the waveform 2.

Waveform 2 (Reference)

(d) Using an oscilloscope, check the waveform 3.

Waveform 3 (Reference)

(e) Using an oscilloscope, check the waveform 4.

Waveform 4 (Reference)

(f) Using an oscilloscope, check the waveform 5.

Waveform 5 (Reference)

G023426E03

Item Content

Symbols (Terminal No.) SL1+ (B30-57) - SL1- (B30-77)

Tool Setting 5 V/DIV., 1 msec./DIV.

Condition Engine idle speed

G023426E03

Item Content

Symbols (Terminal No.) SL2+ (B30-58) - SL2- (B30-59)

Tool Setting 5 V/DIV., 1 msec./DIV.

Condition Engine idle speed

C133935E01

Item Content

Symbols (Terminal No.) DSL (B30-79) - E01 (B30-45)

Tool Setting 10 V/DIV., 100 msec./DIV.

Condition Vehicle speed 65 km/h (40 mph),

lock-up (ON to OFF)

G023426E03

Item Content

Symbols (Terminal No.) SLT+ (B30-76) - SLT- (B30-75)

Tool Setting 5 V/DIV., 1 msec./DIV.

Condition Engine idle speed

C053419E02

Item Content

Symbols (Terminal No.) NT+ (B30-125) - NT- (B30-124)

Tool Setting 5 V/DIV., 0.5 msec./DIV.

Condition Vehicle speed 20 km/h (12 mph)

Page 966 of 2000

AX–32U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

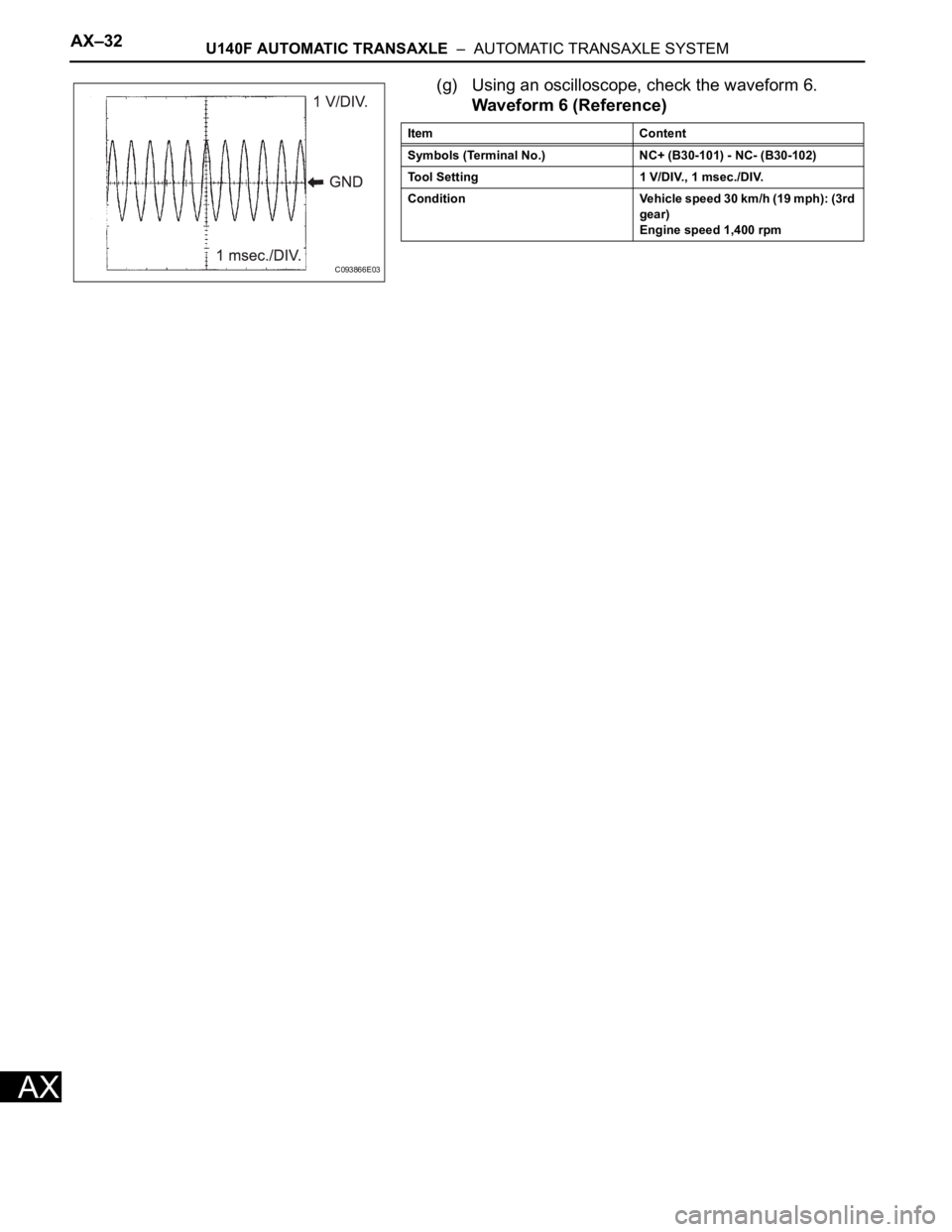

(g) Using an oscilloscope, check the waveform 6.

Waveform 6 (Reference)

C093866E03

Item Content

Symbols (Terminal No.) NC+ (B30-101) - NC- (B30-102)

Tool Setting 1 V/DIV., 1 msec./DIV.

Condition Vehicle speed 30 km/h (19 mph): (3rd

gear)

Engine speed 1,400 rpm

Page 967 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–33

AX

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting On-Board Diagnostic (OBD

II) vehicles, the vehicle must be connected to the

OBD II scan tool (complying with SAE J1987).

Various data output from the vehicle's ECM can

then be read.

(b) OBD II regulations require that the vehicle's on-

board computer illuminates the Malfunction

Indicator Lamp (MIL) on the instrument panel when

the computer detects a malfunction in:

(1) The emission control system/components

(2) The powertrain control components (which affect

vehicle emissions)

(3) The computer

In addition, the applicable Diagnostic Trouble

Codes (DTCs) prescribed by SAE J2012 are

recorded in the ECM memory.

When the malfunction does not reoccur, the MIL

stays illuminated until the ignition switch is

turned OFF, and the MIL turns OFF when the

engine is started. However, the DTCs remain

recorded in the ECM memory.

(c) To check DTCs, connect the intelligent tester to the

Data Link Connector 3 (DLC3) of the vehicle. The

tester displays DTCs, the freeze frame data and a

variety of the engine data.

The DTCs and freeze frame data can be erased

with the tester (see page AX-29).

2. NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in "normal mode"

during normal vehicle use. In normal mode, "2 trip

detection logic" is used to ensure accurate detection

of malfunctions. "Check mode" is also available to

technicians as an option. In check mode, "1 trip

detection logic" is used for simulating malfunction

symptoms and increasing the system's ability to

detect malfunctions, including intermittent

malfunctions.

3. 2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the

malfunction is temporarily stored in the ECM

memory (1st trip). If the same malfunction is

detected during the next drive cycle, the MIL is

illuminated (2nd trip).

FI00534E01

B127989E02