check engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 830 of 2000

2AZ-FE EMISSION CONTROL – VENTILATION VALVEEC–19

EC

INSTALLATION

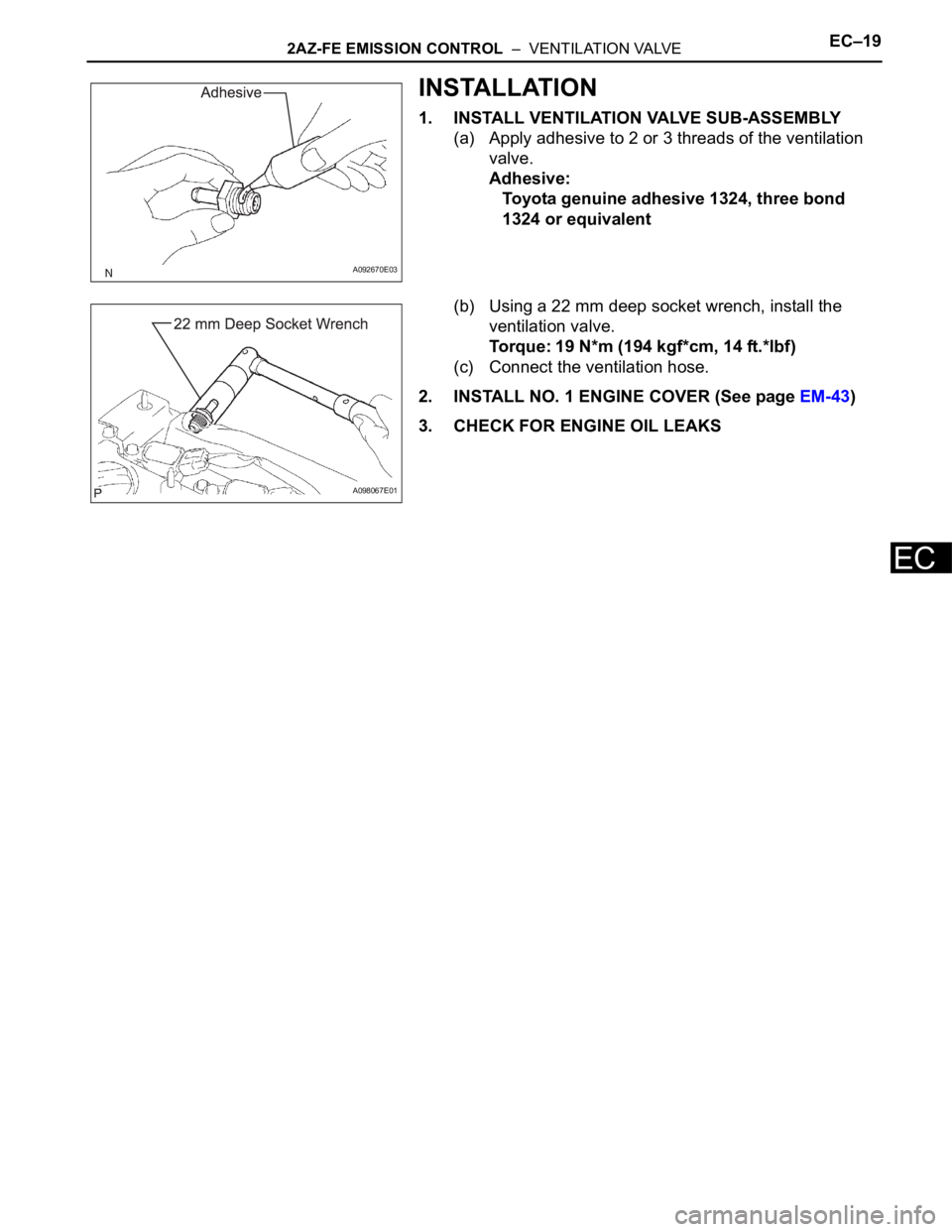

1. INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive to 2 or 3 threads of the ventilation

valve.

Adhesive:

Toyota genuine adhesive 1324, three bond

1324 or equivalent

(b) Using a 22 mm deep socket wrench, install the

ventilation valve.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

(c) Connect the ventilation hose.

2. INSTALL NO. 1 ENGINE COVER (See page EM-43)

3. CHECK FOR ENGINE OIL LEAKS

A092670E03

A098067E01

Page 832 of 2000

EC–82GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

ON-VEHICLE INSPECTION

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

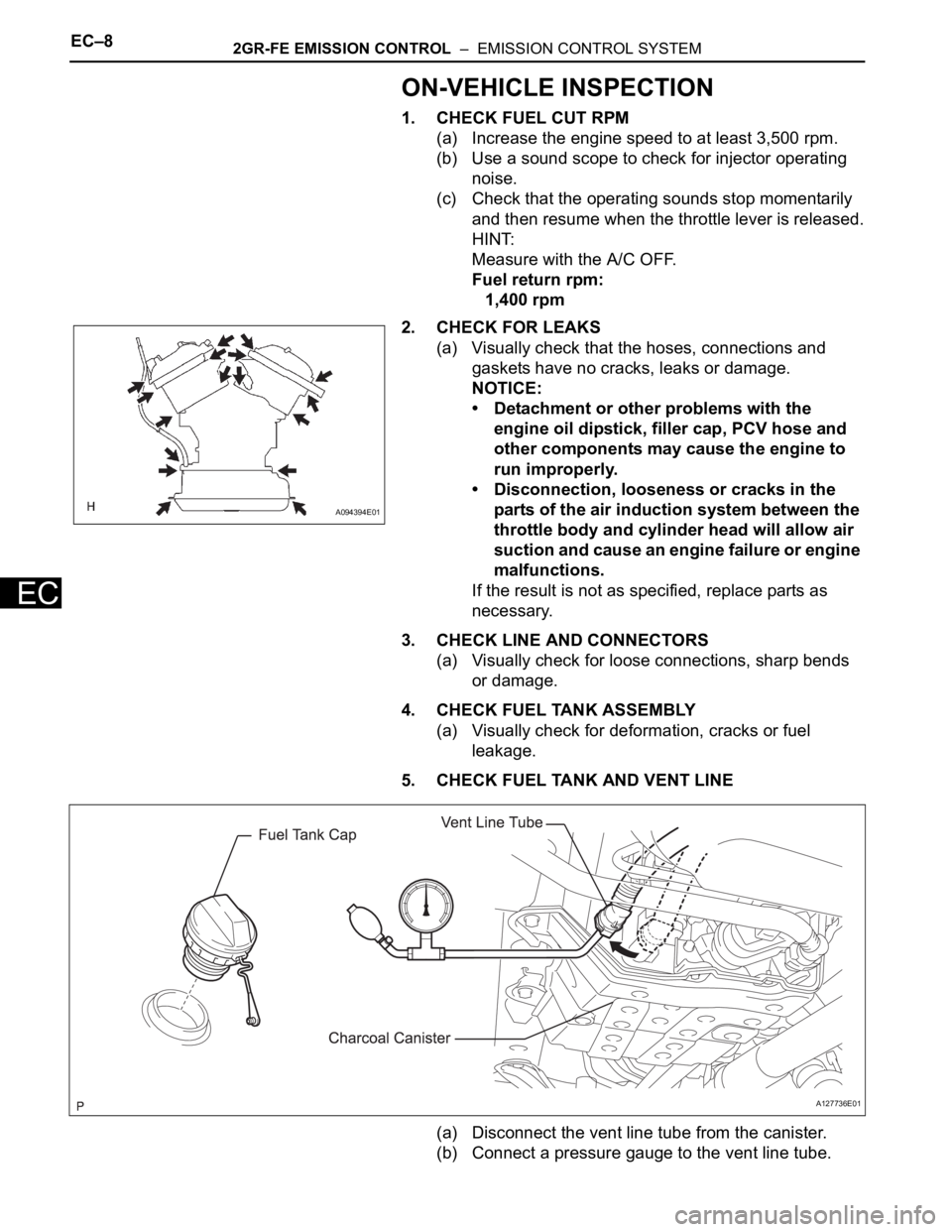

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A094394E01

A127736E01

Page 837 of 2000

EC–202GR-FE EMISSION CONTROL – VENTILATION VALVE

EC

INSTALLATION

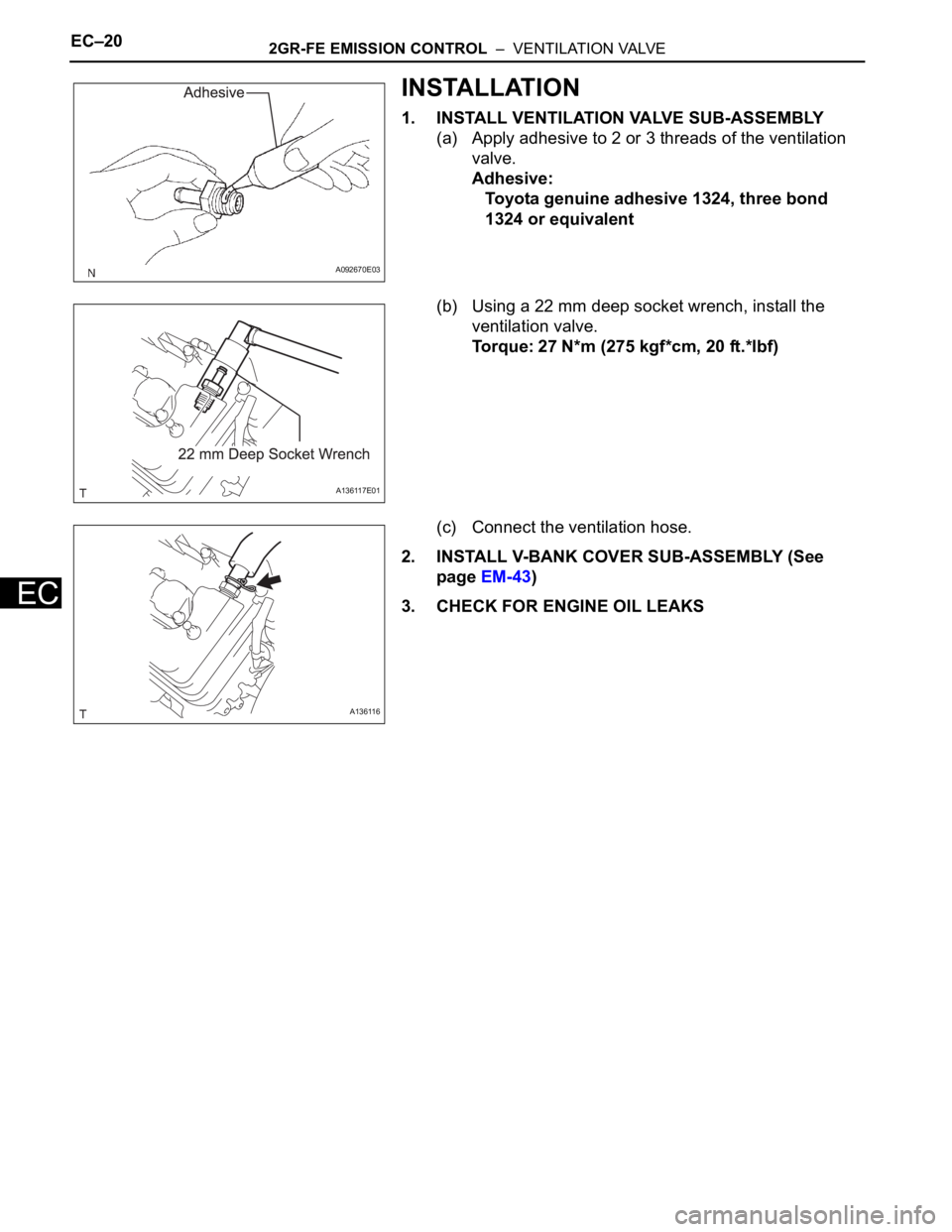

1. INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive to 2 or 3 threads of the ventilation

valve.

Adhesive:

Toyota genuine adhesive 1324, three bond

1324 or equivalent

(b) Using a 22 mm deep socket wrench, install the

ventilation valve.

Torque: 27 N*m (275 kgf*cm, 20 ft.*lbf)

(c) Connect the ventilation hose.

2. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-43)

3. CHECK FOR ENGINE OIL LEAKS

A092670E03

A136117E01

A136116

Page 843 of 2000

2AZ-FE COOLING – WATER PUMPCO–13

CO

INSTALLATION

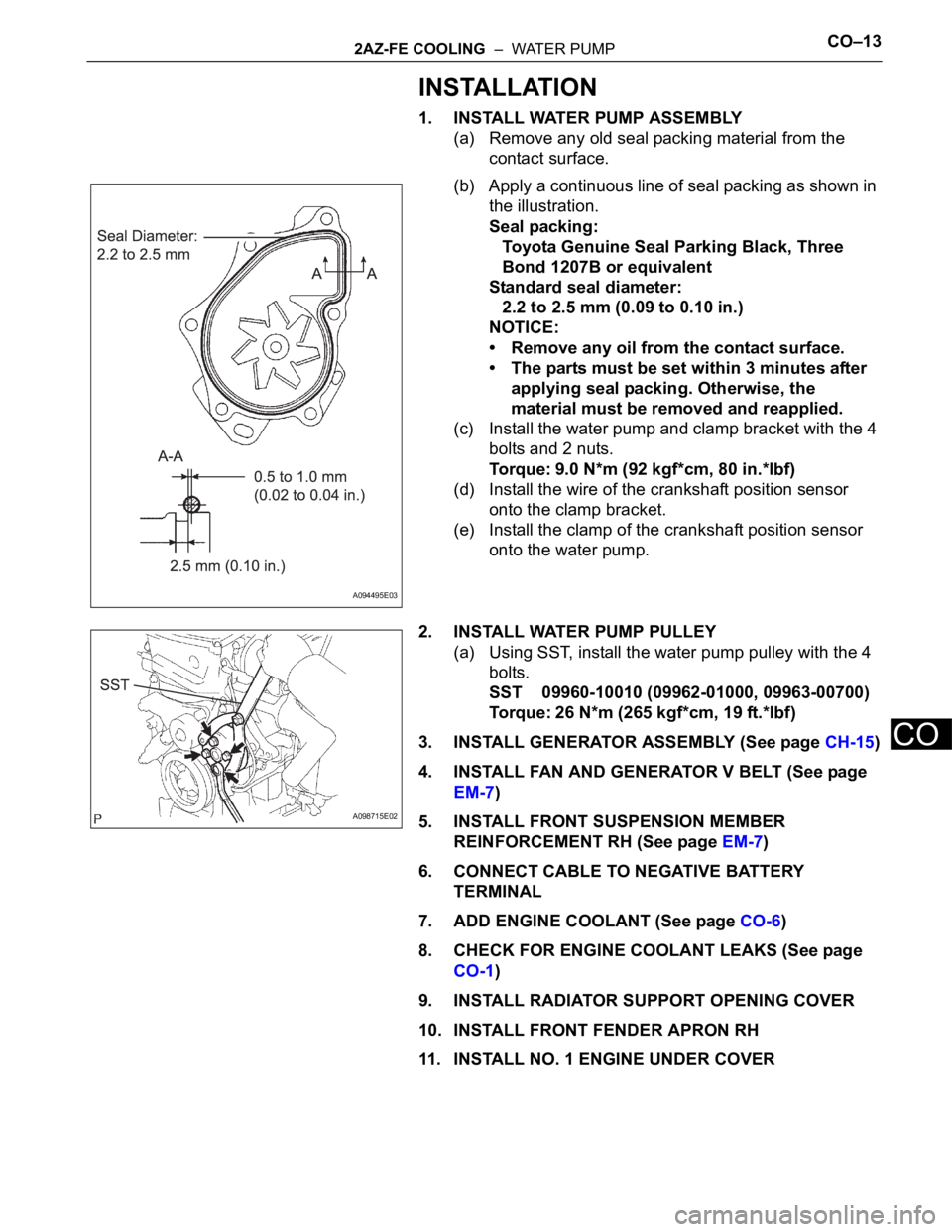

1. INSTALL WATER PUMP ASSEMBLY

(a) Remove any old seal packing material from the

contact surface.

(b) Apply a continuous line of seal packing as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Parking Black, Three

Bond 1207B or equivalent

Standard seal diameter:

2.2 to 2.5 mm (0.09 to 0.10 in.)

NOTICE:

• Remove any oil from the contact surface.

• The parts must be set within 3 minutes after

applying seal packing. Otherwise, the

material must be removed and reapplied.

(c) Install the water pump and clamp bracket with the 4

bolts and 2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(d) Install the wire of the crankshaft position sensor

onto the clamp bracket.

(e) Install the clamp of the crankshaft position sensor

onto the water pump.

2. INSTALL WATER PUMP PULLEY

(a) Using SST, install the water pump pulley with the 4

bolts.

SST 09960-10010 (09962-01000, 09963-00700)

Torque: 26 N*m (265 kgf*cm, 19 ft.*lbf)

3. INSTALL GENERATOR ASSEMBLY (See page CH-15)

4. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

5. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

6. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

7. ADD ENGINE COOLANT (See page CO-6)

8. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

9. INSTALL RADIATOR SUPPORT OPENING COVER

10. INSTALL FRONT FENDER APRON RH

11. INSTALL NO. 1 ENGINE UNDER COVER

A094495E03

A098715E02

Page 844 of 2000

CO–162AZ-FE COOLING – THERMOSTAT

CO

INSTALLATION

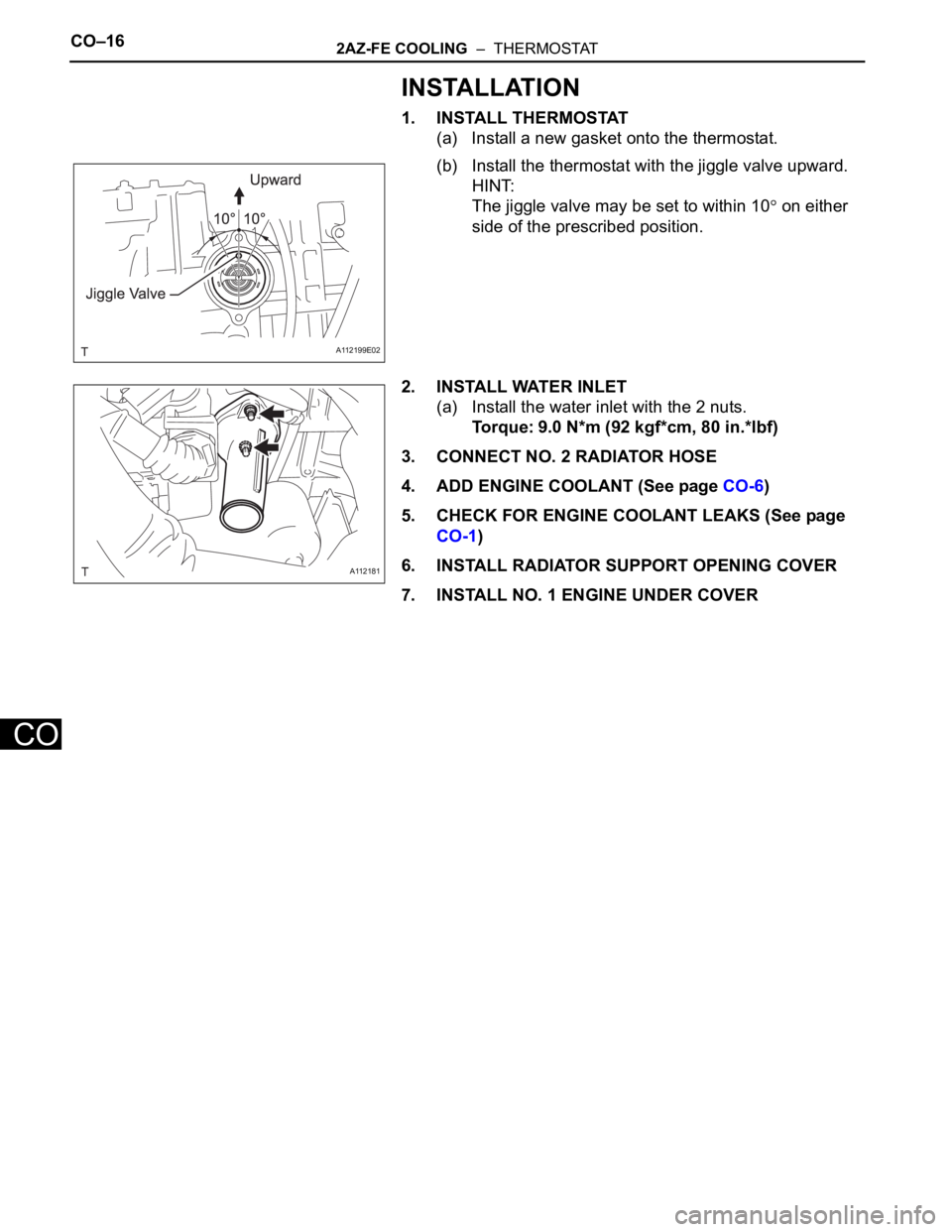

1. INSTALL THERMOSTAT

(a) Install a new gasket onto the thermostat.

(b) Install the thermostat with the jiggle valve upward.

HINT:

The jiggle valve may be set to within 10

on either

side of the prescribed position.

2. INSTALL WATER INLET

(a) Install the water inlet with the 2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

3. CONNECT NO. 2 RADIATOR HOSE

4. ADD ENGINE COOLANT (See page CO-6)

5. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

6. INSTALL RADIATOR SUPPORT OPENING COVER

7. INSTALL NO. 1 ENGINE UNDER COVER

A112199E02

A112181

Page 846 of 2000

2AZ-FE COOLING – COOLING FAN MOTORCO–23

CO

INSTALLATION

1. INSTALL RADIATOR ASSEMBLY

(a) Install the radiator (see page CO-32).

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. ADD ENGINE COOLANT (See page CO-6)

4. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

Page 853 of 2000

2AZ-FE COOLING – RADIATORCO–35

CO

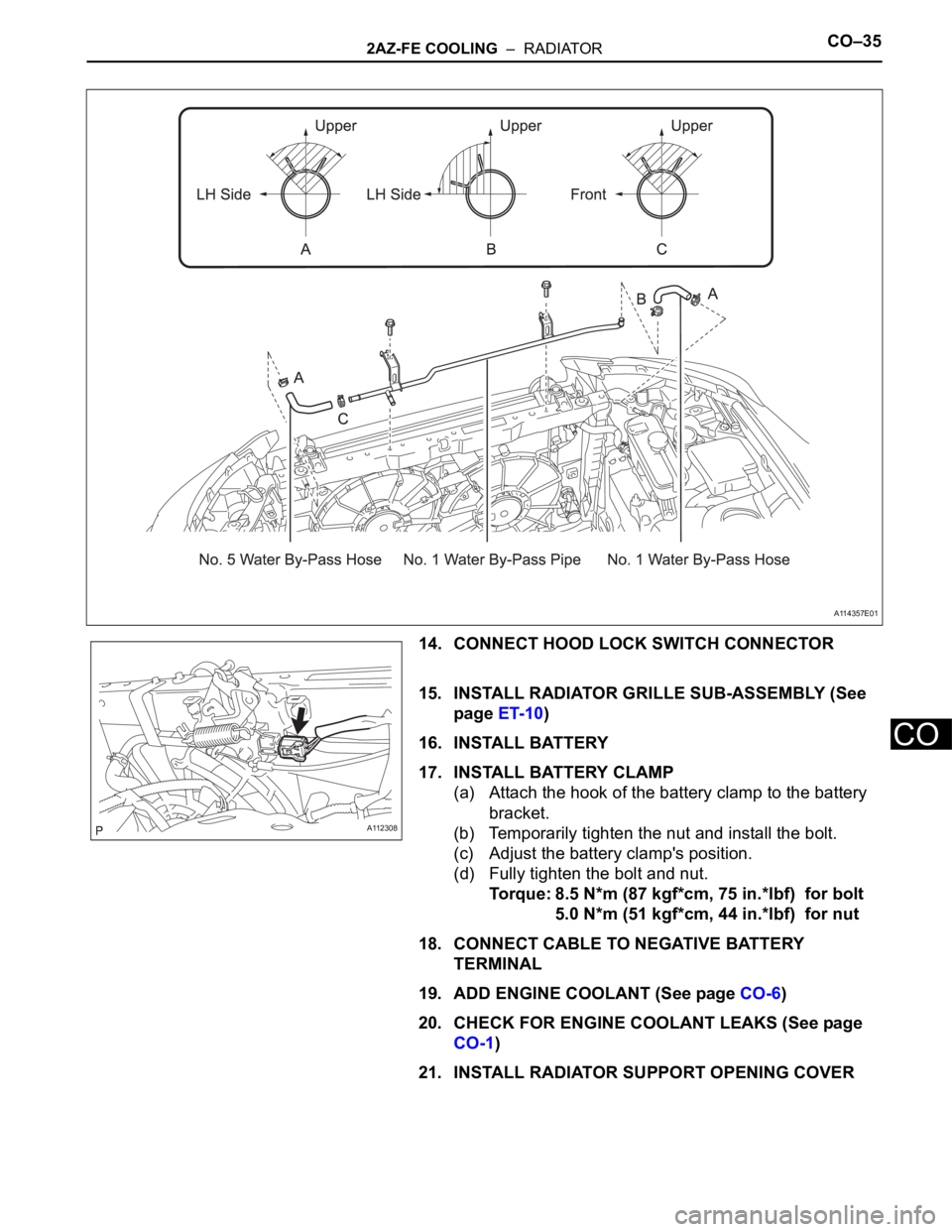

14. CONNECT HOOD LOCK SWITCH CONNECTOR

15. INSTALL RADIATOR GRILLE SUB-ASSEMBLY (See

page ET-10)

16. INSTALL BATTERY

17. INSTALL BATTERY CLAMP

(a) Attach the hook of the battery clamp to the battery

bracket.

(b) Temporarily tighten the nut and install the bolt.

(c) Adjust the battery clamp's position.

(d) Fully tighten the bolt and nut.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf) for bolt

5.0 N*m (51 kgf*cm, 44 in.*lbf) for nut

18. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

19. ADD ENGINE COOLANT (See page CO-6)

20. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

21. INSTALL RADIATOR SUPPORT OPENING COVER

A114357E01

A112308

Page 854 of 2000

CO–62GR-FE COOLING – COOLING FAN SYSTEM

CO

ON-VEHICLE INSPECTION

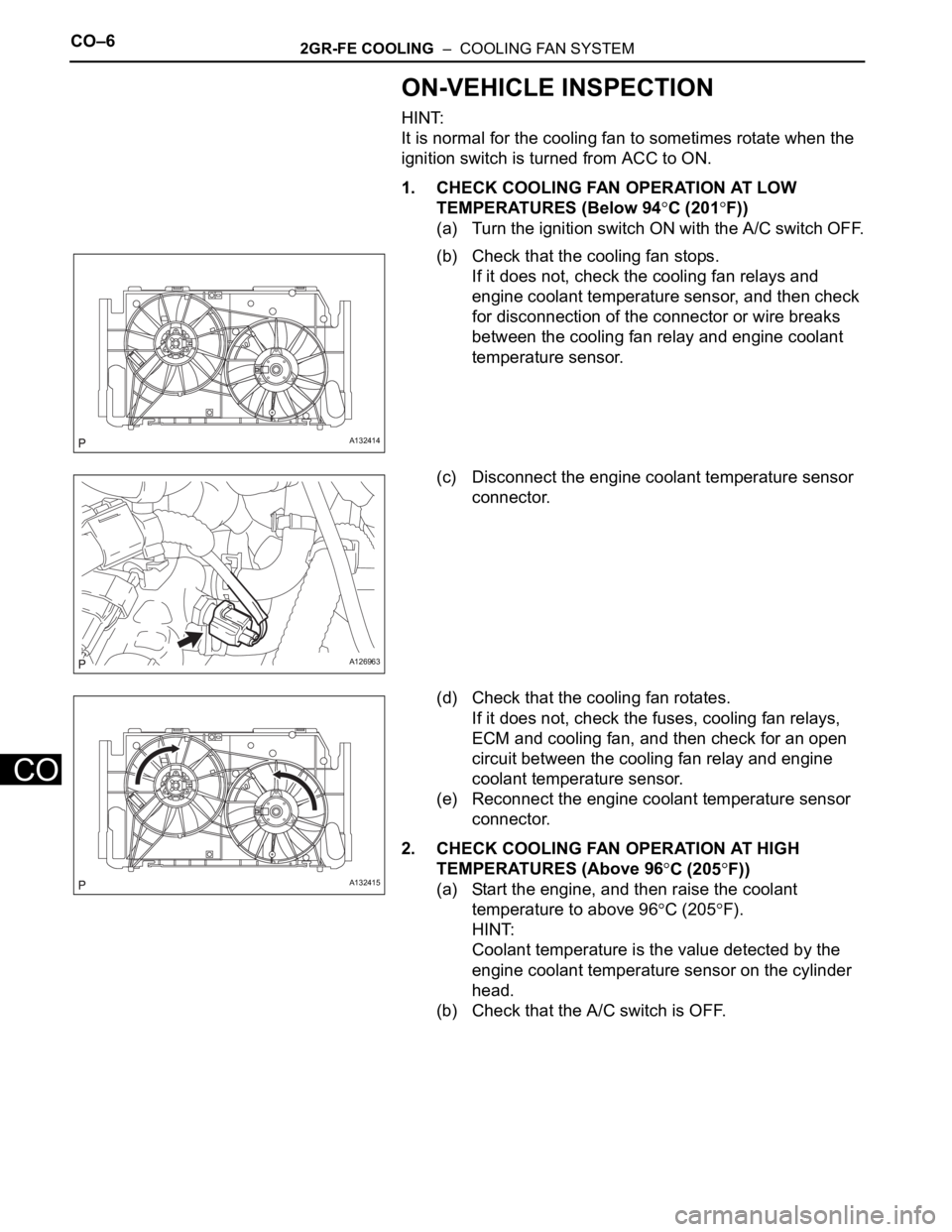

HINT:

It is normal for the cooling fan to sometimes rotate when the

ignition switch is turned from ACC to ON.

1. CHECK COOLING FAN OPERATION AT LOW

TEMPERATURES (Below 94

C (201F))

(a) Turn the ignition switch ON with the A/C switch OFF.

(b) Check that the cooling fan stops.

If it does not, check the cooling fan relays and

engine coolant temperature sensor, and then check

for disconnection of the connector or wire breaks

between the cooling fan relay and engine coolant

temperature sensor.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Check that the cooling fan rotates.

If it does not, check the fuses, cooling fan relays,

ECM and cooling fan, and then check for an open

circuit between the cooling fan relay and engine

coolant temperature sensor.

(e) Reconnect the engine coolant temperature sensor

connector.

2. CHECK COOLING FAN OPERATION AT HIGH

TEMPERATURES (Above 96

C (205F))

(a) Start the engine, and then raise the coolant

temperature to above 96

C (205F).

HINT:

Coolant temperature is the value detected by the

engine coolant temperature sensor on the cylinder

head.

(b) Check that the A/C switch is OFF.

A132414

A126963

A132415

Page 855 of 2000

2GR-FE COOLING – COOLING FAN SYSTEMCO–7

CO

(c) Check that the cooling fan rotates.

If it does not, check the engine coolant temperature

sensor, cooling fan, harness or connector.

A132415

Page 862 of 2000

CO–222GR-FE COOLING – THERMOSTAT

CO

8. INSTALL RADIATOR RESERVOIR TANK

(a) Install the radiator reservoir with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

9. INSTALL RADIATOR SUPPORT OPENING COVER

(See page EM-42)

10. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-42)

11. ADD ENGINE COOLANT (See page CO-8)

12. CHECK FOR ENGINE COOLANT LEAKAGE (See

page CO-1)

13. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-9)

14. INSTALL ENGINE UNDER COVER REAR RH (See

page EM-41)

15. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-41)

16. INSTALL FRONT WHEEL RH

A132441E01