check engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 872 of 2000

2GR-FE COOLING – RADIATORCO–43

CO

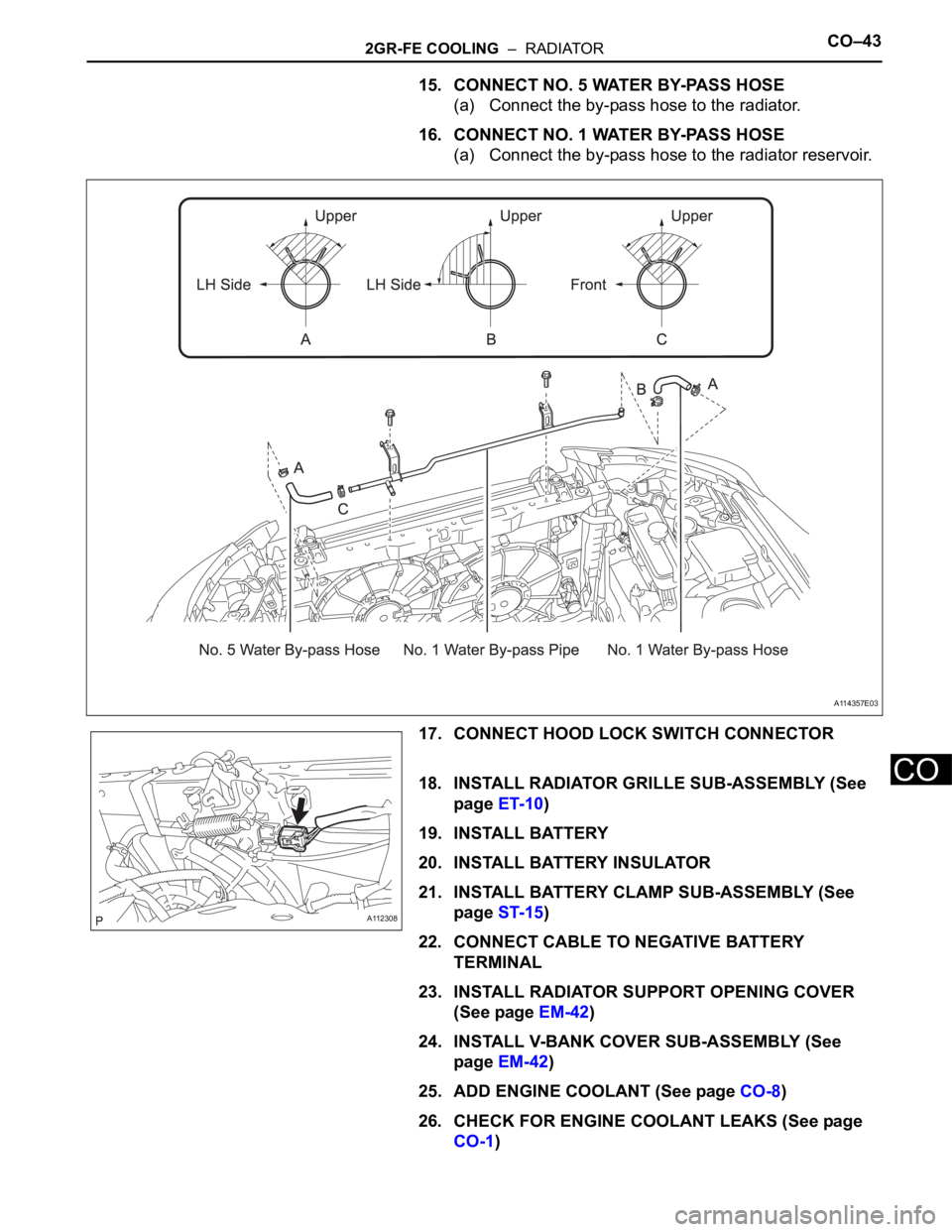

15. CONNECT NO. 5 WATER BY-PASS HOSE

(a) Connect the by-pass hose to the radiator.

16. CONNECT NO. 1 WATER BY-PASS HOSE

(a) Connect the by-pass hose to the radiator reservoir.

17. CONNECT HOOD LOCK SWITCH CONNECTOR

18. INSTALL RADIATOR GRILLE SUB-ASSEMBLY (See

page ET-10)

19. INSTALL BATTERY

20. INSTALL BATTERY INSULATOR

21. INSTALL BATTERY CLAMP SUB-ASSEMBLY (See

page ST-15)

22. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

23. INSTALL RADIATOR SUPPORT OPENING COVER

(See page EM-42)

24. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-42)

25. ADD ENGINE COOLANT (See page CO-8)

26. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

A114357E03

A112308

Page 876 of 2000

LU–162GR-FE LUBRICATION – OIL PUMP

LU

INSPECTION

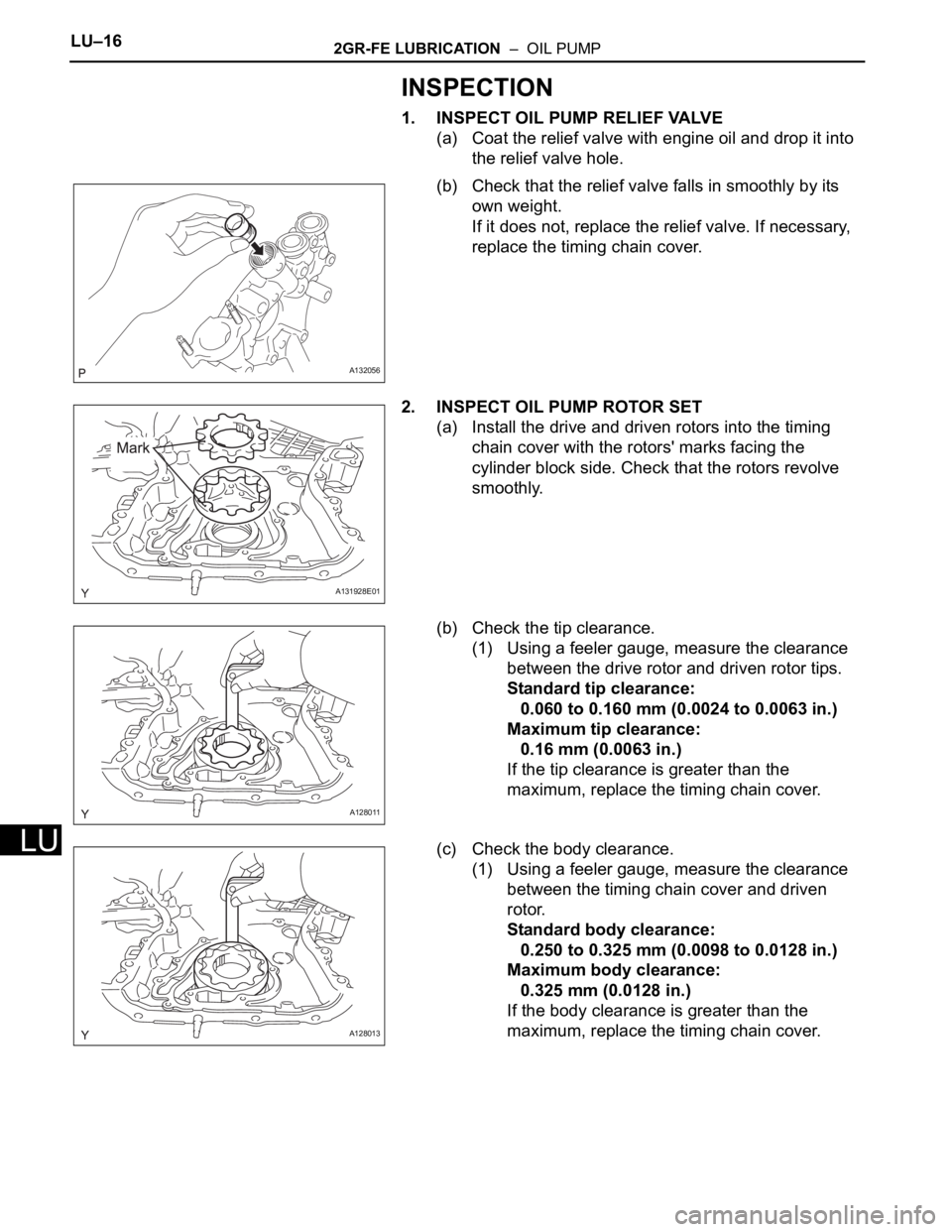

1. INSPECT OIL PUMP RELIEF VALVE

(a) Coat the relief valve with engine oil and drop it into

the relief valve hole.

(b) Check that the relief valve falls in smoothly by its

own weight.

If it does not, replace the relief valve. If necessary,

replace the timing chain cover.

2. INSPECT OIL PUMP ROTOR SET

(a) Install the drive and driven rotors into the timing

chain cover with the rotors' marks facing the

cylinder block side. Check that the rotors revolve

smoothly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive rotor and driven rotor tips.

Standard tip clearance:

0.060 to 0.160 mm (0.0024 to 0.0063 in.)

Maximum tip clearance:

0.16 mm (0.0063 in.)

If the tip clearance is greater than the

maximum, replace the timing chain cover.

(c) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the timing chain cover and driven

rotor.

Standard body clearance:

0.250 to 0.325 mm (0.0098 to 0.0128 in.)

Maximum body clearance:

0.325 mm (0.0128 in.)

If the body clearance is greater than the

maximum, replace the timing chain cover.

A132056

A131928E01

A128011

A128013

Page 877 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–17

LU

(d) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge.

Standard side clearance:

0.030 to 0.090 mm (0.0012 to 0.0035 in.)

Maximum side clearance:

0.090 mm (0.0035 in.)

If the side clearance is greater than the

maximum, replace the timing chain cover.

REPLACEMENT

1. REPLACE TIMING CHAIN COVER OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Do not damage the surface of the oil seal press

fit hole.

(b) Using SST and a hammer, tap in a new oil seal until

its surface is flush with the timing chain cover edge.

SST 09316-60011 (09316-00011)

NOTICE:

• Keep the lip free from foreign matter.

• Do not tap the oil seal at an angle.

• Make sure that the oil seal edge does not

stick out of the timing chain case.

(c) Apply MP grease to the lip of the oil seal.

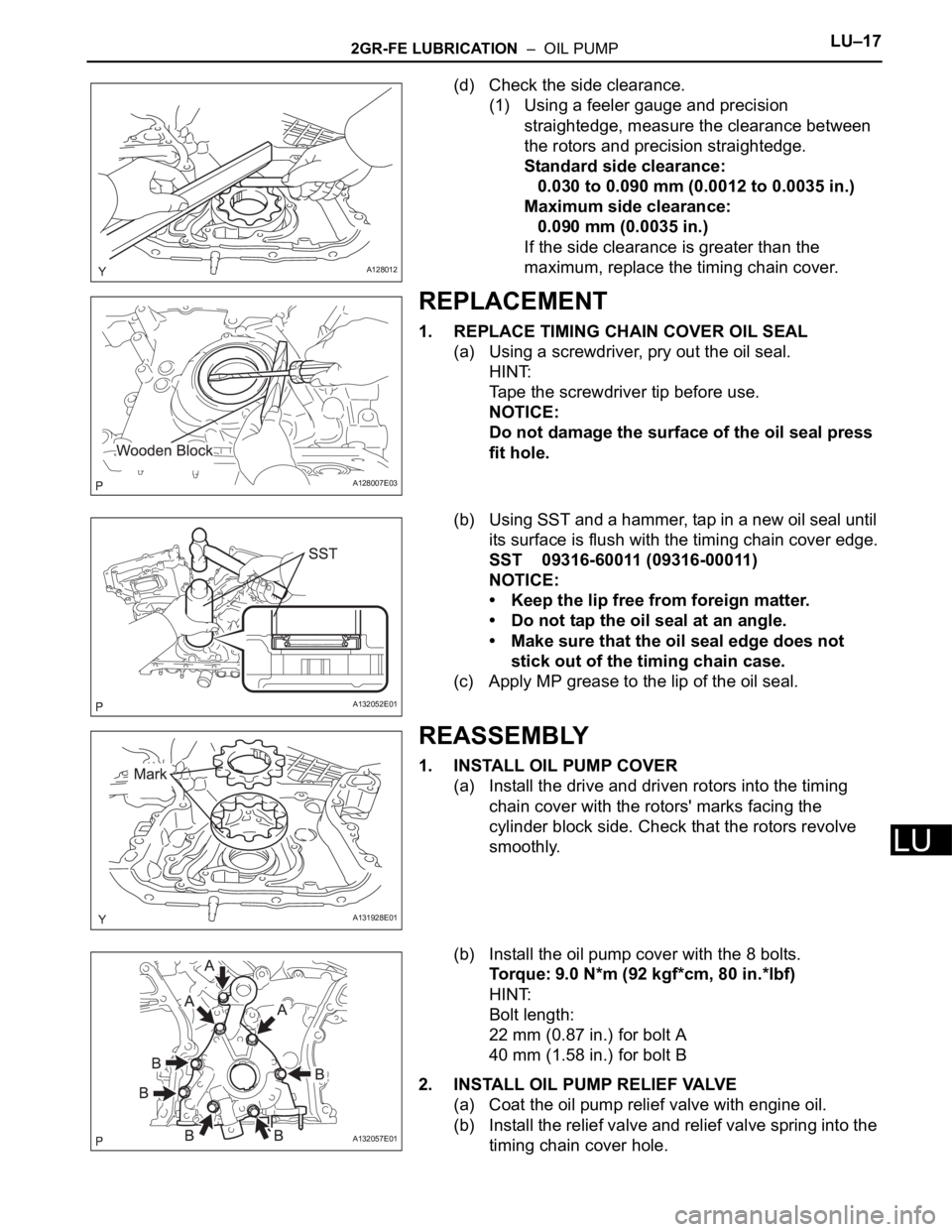

REASSEMBLY

1. INSTALL OIL PUMP COVER

(a) Install the drive and driven rotors into the timing

chain cover with the rotors' marks facing the

cylinder block side. Check that the rotors revolve

smoothly.

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

HINT:

Bolt length:

22 mm (0.87 in.) for bolt A

40 mm (1.58 in.) for bolt B

2. INSTALL OIL PUMP RELIEF VALVE

(a) Coat the oil pump relief valve with engine oil.

(b) Install the relief valve and relief valve spring into the

timing chain cover hole.

A128012

A128007E03

A132052E01

A131928E01

A132057E01

Page 885 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "cold" and "hot" refer to

the temperature of the coils. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the No. 1 engine cover.

(2) Remove the bolt and ignition coil.

(3) Using a 16 mm spark plug wrench, remove the

spark plug.

(4) Disconnect the 4 fuel injector connectors.

(5) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(6) Ground the spark plug.

(7) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, Perform the spark test.

(8) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

A124849E01

A097448E01

A124396

Page 886 of 2000

IG–62AZ-FE IGNITION – IGNITION SYSTEM

IG

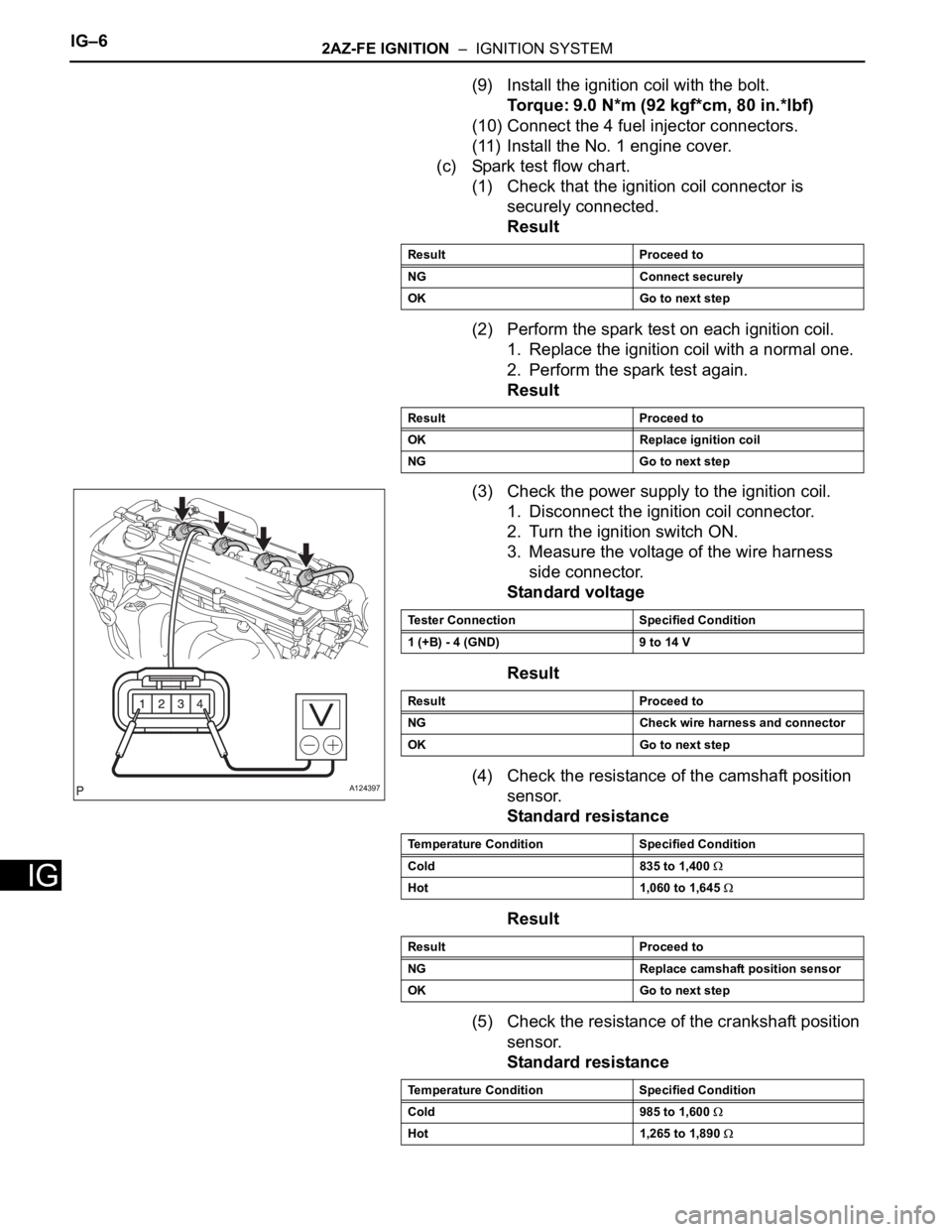

(9) Install the ignition coil with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(10) Connect the 4 fuel injector connectors.

(11) Install the No. 1 engine cover.

(c) Spark test flow chart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the camshaft position

sensor.

Standard resistance

Result

(5) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A124397

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 835 to 1,400

Hot 1,060 to 1,645

Result Proceed to

NG Replace camshaft position sensor

OK Go to next step

Temperature Condition Specified Condition

Cold 985 to 1,600

Hot 1,265 to 1,890

Page 887 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–7

IG

Result

(6) Check the IGT signal from the ECM.

Result

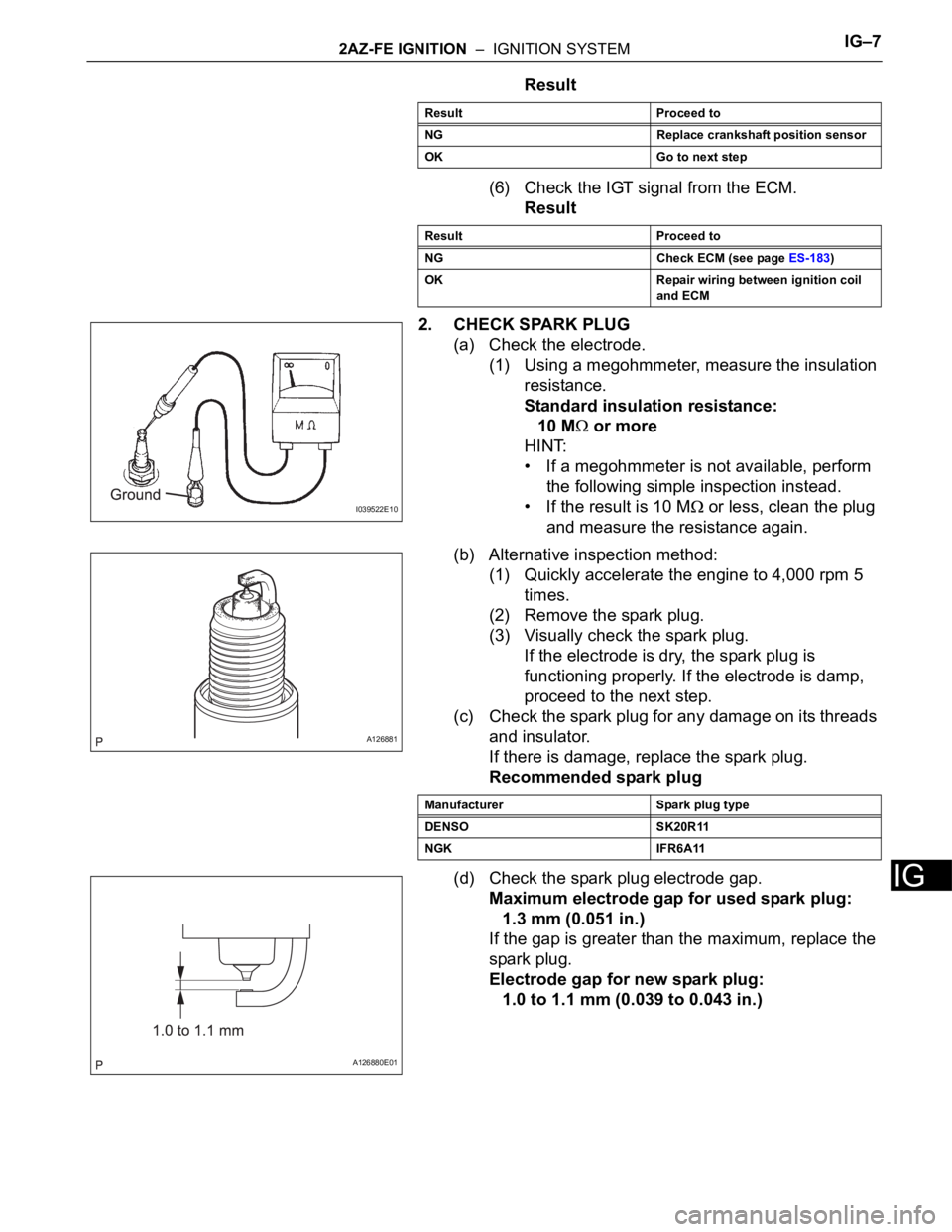

2. CHECK SPARK PLUG

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

HINT:

• If a megohmmeter is not available, perform

the following simple inspection instead.

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its threads

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

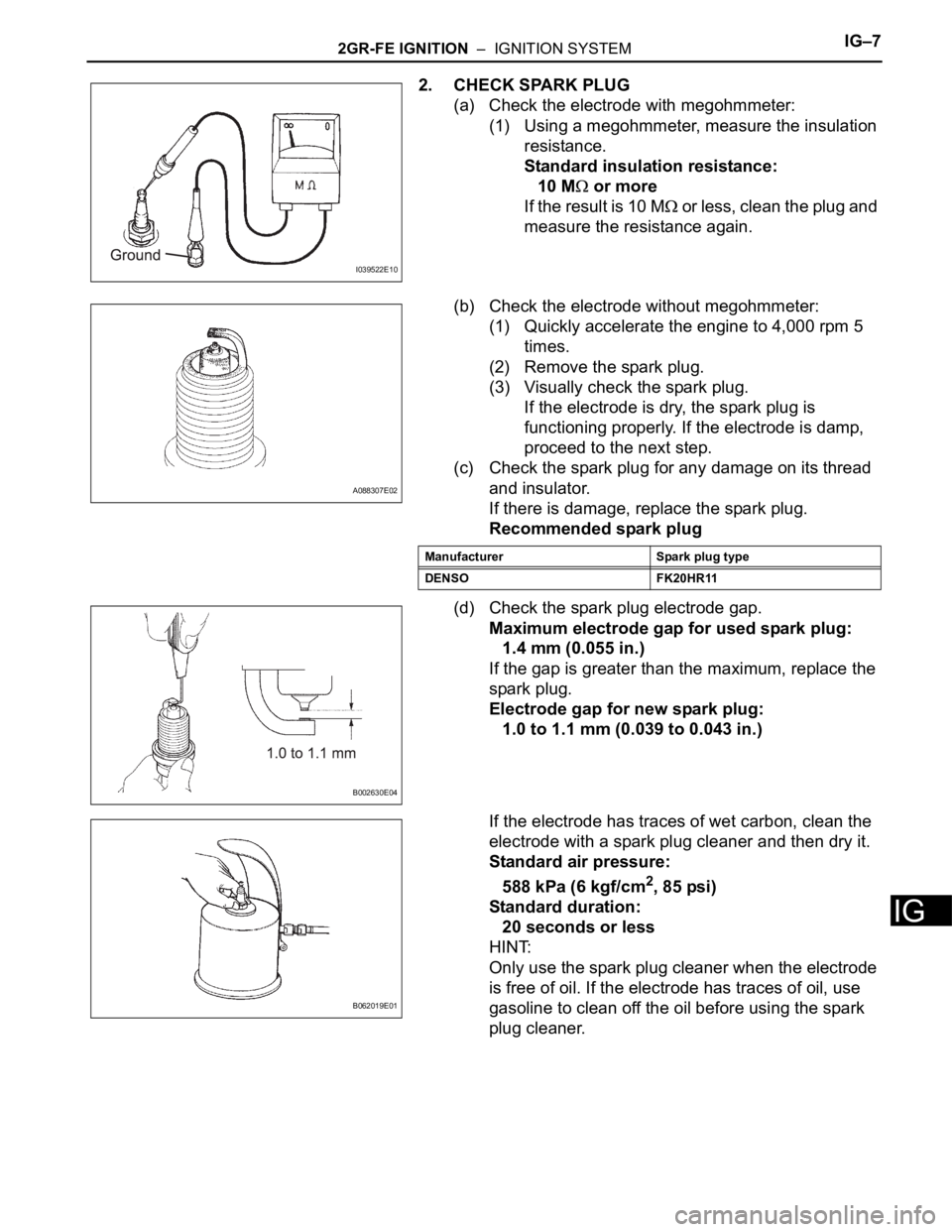

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.3 mm (0.051 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-183)

OK Repair wiring between ignition coil

and ECM

I039522E10

A126881

Manufacturer Spark plug type

DENSO SK20R11

NGK IFR6A11

A126880E01

Page 895 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "Cold" and "Hot" refer to

the temperature of the sensor. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the V-bank cover.

(2) Remove the intake air surge tank (see page

EM-27).

(3) Remove the bolt and ignition coil.

(4) Using a 16 mm spark plug wrench, remove the

spark plug.

(5) Disconnect the 6 fuel injector connectors.

(6) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(7) Ground the spark plug.

(8) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, perform troubleshooting

using the spark test flowchart.

(9) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

(10) Install the ignition coil with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(11) Connect the 6 fuel injector connectors.

(12) Install the intake air surge tank (see page EM-

34).

(13) Install the V-bank cover.

A136823

A136826

Page 897 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–7

IG

2. CHECK SPARK PLUG

(a) Check the electrode with megohmmeter:

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

If the result is 10 M

or less, clean the plug and

measure the resistance again.

(b) Check the electrode without megohmmeter:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its thread

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.4 mm (0.055 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

If the electrode has traces of wet carbon, clean the

electrode with a spark plug cleaner and then dry it.

Standard air pressure:

588 kPa (6 kgf/cm

2, 85 psi)

Standard duration:

20 seconds or less

HINT:

Only use the spark plug cleaner when the electrode

is free of oil. If the electrode has traces of oil, use

gasoline to clean off the oil before using the spark

plug cleaner.

I039522E10

A088307E02

Manufacturer Spark plug type

DENSO FK20HR11

B002630E04

B062019E01

Page 928 of 2000

2GR-FE CHARGING – CHARGING SYSTEMCH–5

CH

ON-VEHICLE INSPECTION

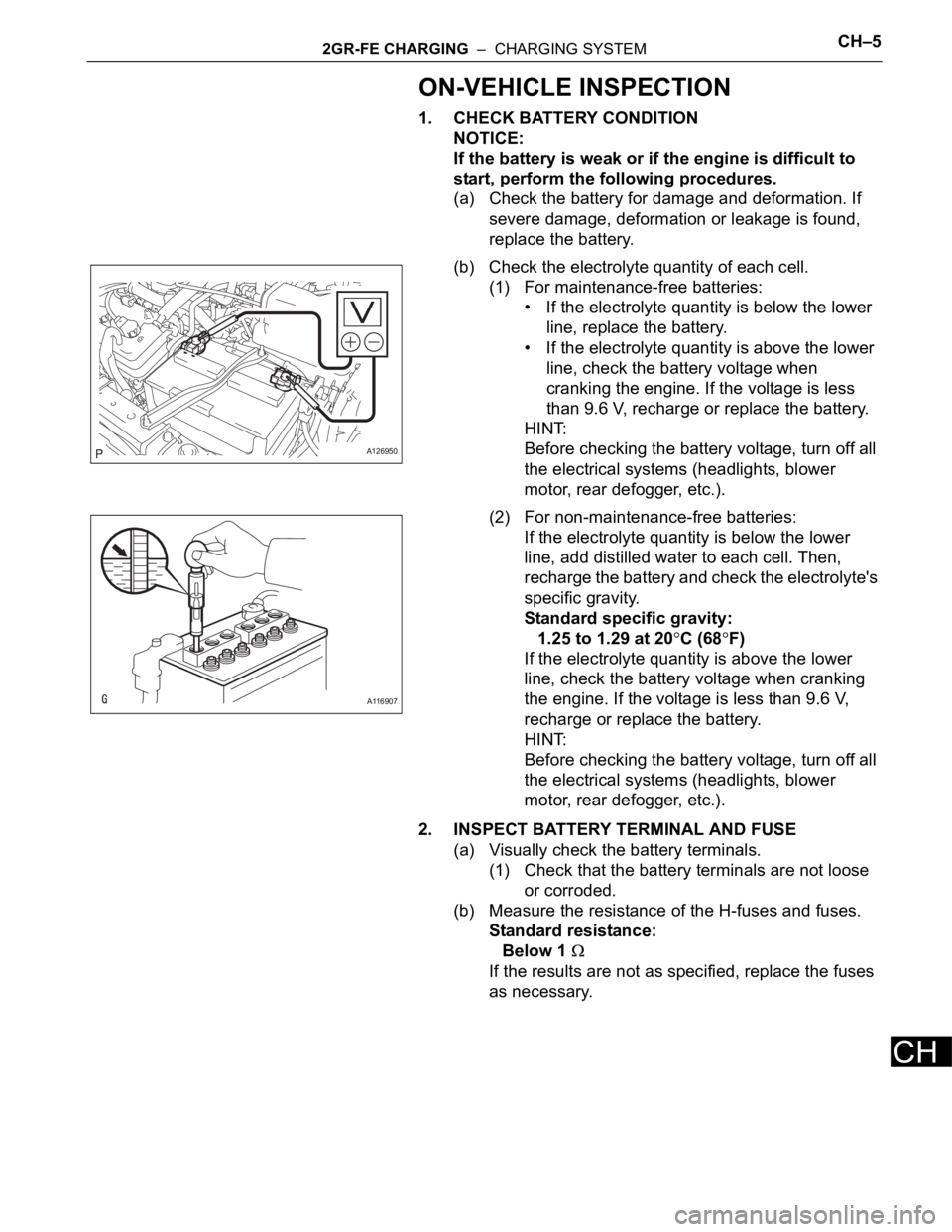

1. CHECK BATTERY CONDITION

NOTICE:

If the battery is weak or if the engine is difficult to

start, perform the following procedures.

(a) Check the battery for damage and deformation. If

severe damage, deformation or leakage is found,

replace the battery.

(b) Check the electrolyte quantity of each cell.

(1) For maintenance-free batteries:

• If the electrolyte quantity is below the lower

line, replace the battery.

• If the electrolyte quantity is above the lower

line, check the battery voltage when

cranking the engine. If the voltage is less

than 9.6 V, recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off all

the electrical systems (headlights, blower

motor, rear defogger, etc.).

(2) For non-maintenance-free batteries:

If the electrolyte quantity is below the lower

line, add distilled water to each cell. Then,

recharge the battery and check the electrolyte's

specific gravity.

Standard specific gravity:

1.25 to 1.29 at 20

C (68F)

If the electrolyte quantity is above the lower

line, check the battery voltage when cranking

the engine. If the voltage is less than 9.6 V,

recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off all

the electrical systems (headlights, blower

motor, rear defogger, etc.).

2. INSPECT BATTERY TERMINAL AND FUSE

(a) Visually check the battery terminals.

(1) Check that the battery terminals are not loose

or corroded.

(b) Measure the resistance of the H-fuses and fuses.

Standard resistance:

Below 1

If the results are not as specified, replace the fuses

as necessary.

A126950

A116907

Page 929 of 2000

CH–62GR-FE CHARGING – CHARGING SYSTEM

CH

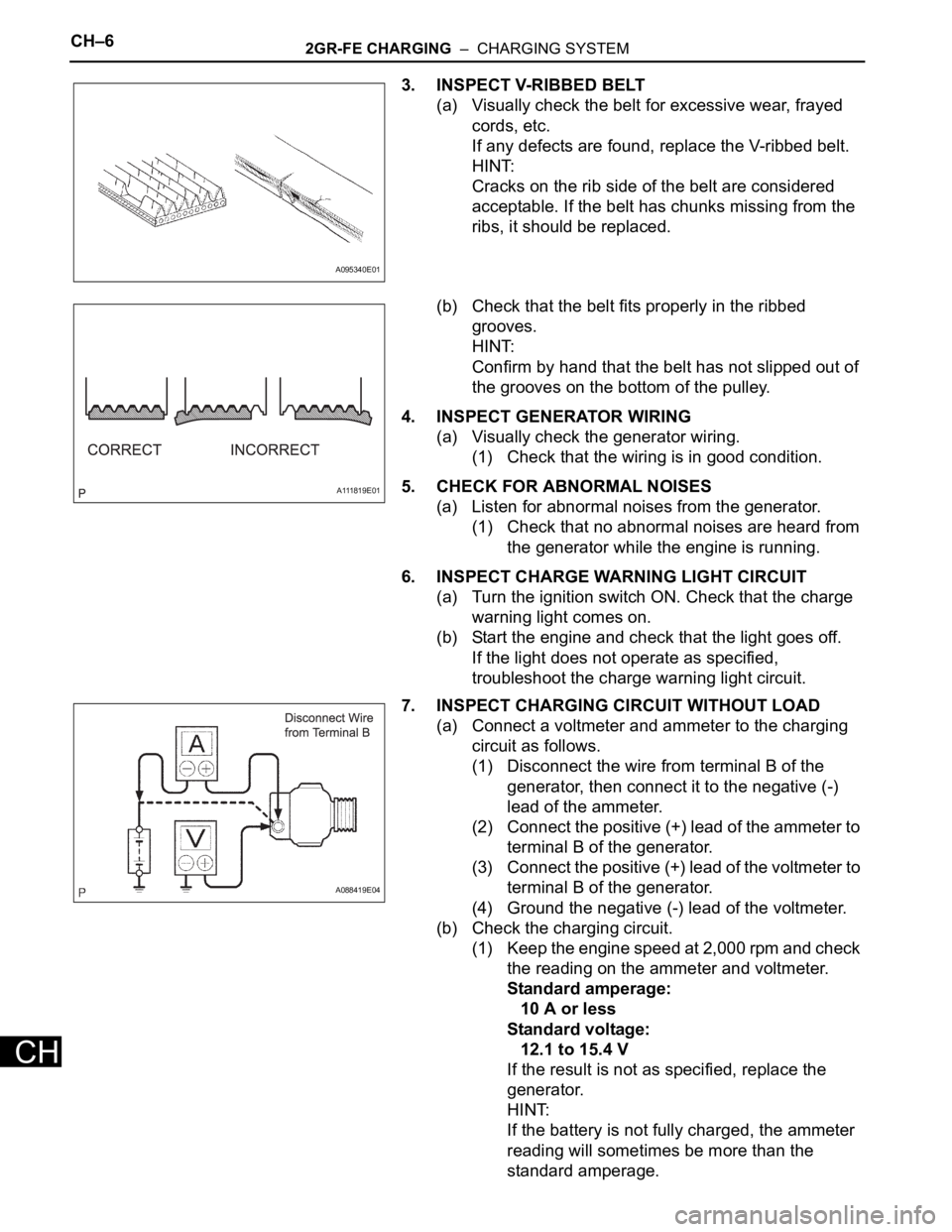

3. INSPECT V-RIBBED BELT

(a) Visually check the belt for excessive wear, frayed

cords, etc.

If any defects are found, replace the V-ribbed belt.

HINT:

Cracks on the rib side of the belt are considered

acceptable. If the belt has chunks missing from the

ribs, it should be replaced.

(b) Check that the belt fits properly in the ribbed

grooves.

HINT:

Confirm by hand that the belt has not slipped out of

the grooves on the bottom of the pulley.

4. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

5. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from

the generator while the engine is running.

6. INSPECT CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch ON. Check that the charge

warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified,

troubleshoot the charge warning light circuit.

7. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) Connect a voltmeter and ammeter to the charging

circuit as follows.

(1) Disconnect the wire from terminal B of the

generator, then connect it to the negative (-)

lead of the ammeter.

(2) Connect the positive (+) lead of the ammeter to

terminal B of the generator.

(3) Connect the positive (+) lead of the voltmeter to

terminal B of the generator.

(4) Ground the negative (-) lead of the voltmeter.

(b) Check the charging circuit.

(1) Keep the engine speed at 2,000 rpm and check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

12.1 to 15.4 V

If the result is not as specified, replace the

generator.

HINT:

If the battery is not fully charged, the ammeter

reading will sometimes be more than the

standard amperage.

A095340E01

A111819E01

A088419E04