TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1011 of 3000

EM–522GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(c) Install the engine mounting insulator RR with the 2

bolts.

Torque: 78 N*m (795 kgf*cm, 58 ft.*lbf)

(d) Connect the connector and clamp.

40. INSTALL POWER STEERING LINK (See page PS-39)

41. INSTALL FRONT STABILIZER BAR

HINT:

(See page SP-36).

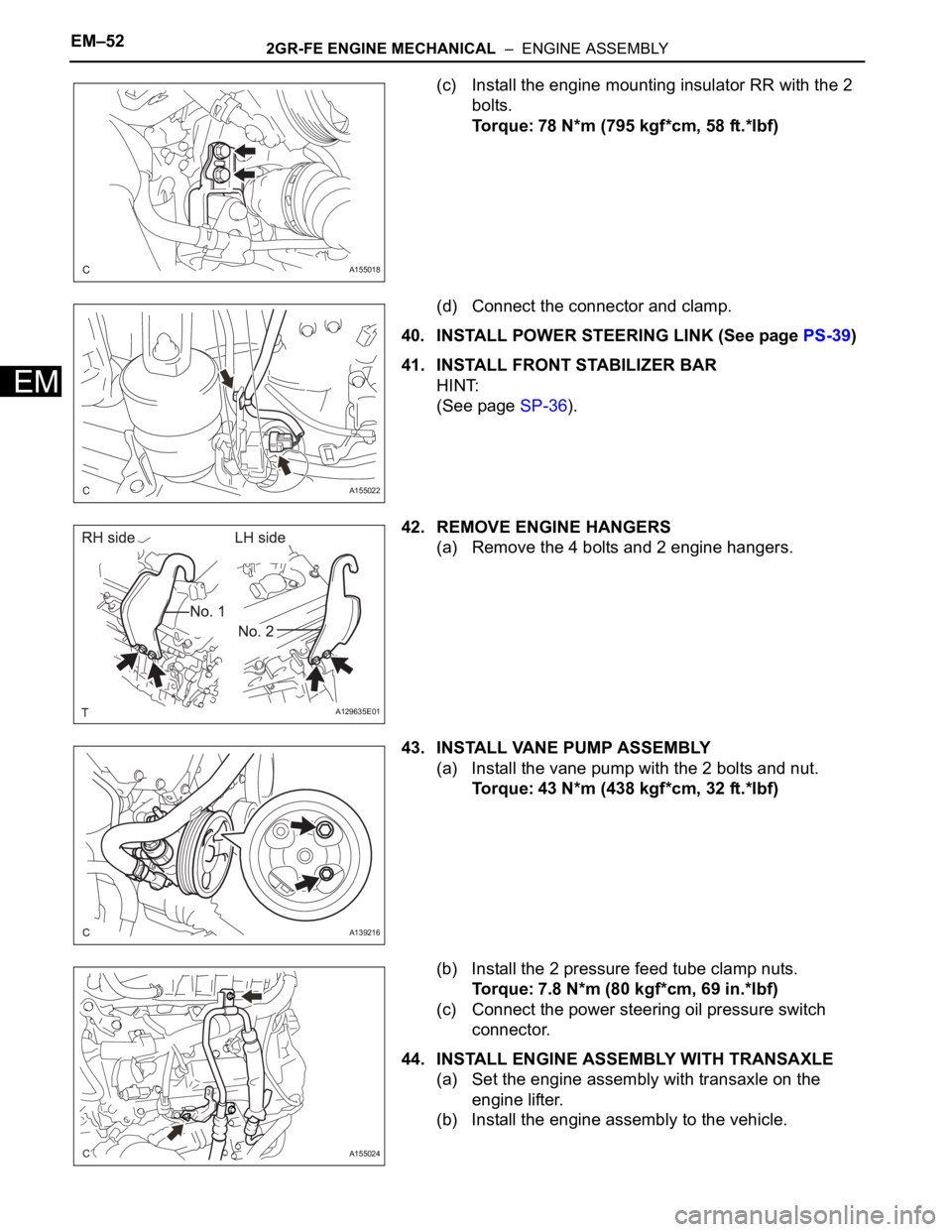

42. REMOVE ENGINE HANGERS

(a) Remove the 4 bolts and 2 engine hangers.

43. INSTALL VANE PUMP ASSEMBLY

(a) Install the vane pump with the 2 bolts and nut.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(b) Install the 2 pressure feed tube clamp nuts.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

(c) Connect the power steering oil pressure switch

connector.

44. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine assembly with transaxle on the

engine lifter.

(b) Install the engine assembly to the vehicle.

A155018

A155022

A129635E01

A139216

A155024

Page 1012 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–53

EM

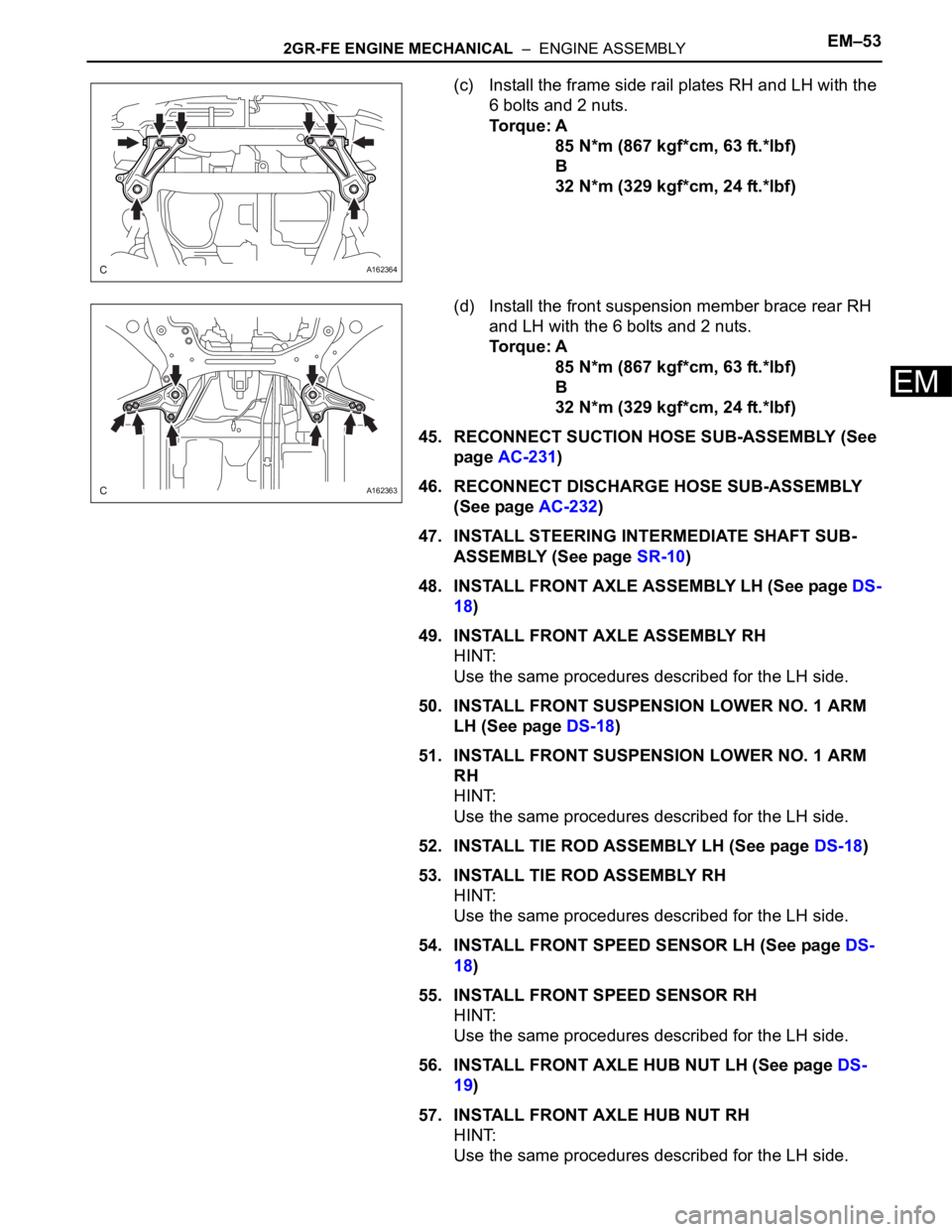

(c) Install the frame side rail plates RH and LH with the

6 bolts and 2 nuts.

Torque: A

85 N*m (867 kgf*cm, 63 ft.*lbf)

B

32 N*m (329 kgf*cm, 24 ft.*lbf)

(d) Install the front suspension member brace rear RH

and LH with the 6 bolts and 2 nuts.

Torque: A

85 N*m (867 kgf*cm, 63 ft.*lbf)

B

32 N*m (329 kgf*cm, 24 ft.*lbf)

45. RECONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-231)

46. RECONNECT DISCHARGE HOSE SUB-ASSEMBLY

(See page AC-232)

47. INSTALL STEERING INTERMEDIATE SHAFT SUB-

ASSEMBLY (See page SR-10)

48. INSTALL FRONT AXLE ASSEMBLY LH (See page DS-

18)

49. INSTALL FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

50. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

LH (See page DS-18)

51. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

RH

HINT:

Use the same procedures described for the LH side.

52. INSTALL TIE ROD ASSEMBLY LH (See page DS-18)

53. INSTALL TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

54. INSTALL FRONT SPEED SENSOR LH (See page DS-

18)

55. INSTALL FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

56. INSTALL FRONT AXLE HUB NUT LH (See page DS-

19)

57. INSTALL FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

A162364

A162363

Page 1013 of 3000

EM–542GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

58. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(See page DS-19)

59. INSTALL FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

60. INSTALL PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY (See page PR-9)

61. FULLY TIGHTEN PROPELLER WITH CENTER

BEARING SHAFT ASSEMBLY (See page PR-10)

62. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for

2WD)

(a) Install the front exhaust pipe assembly (See page

EX-4).

63. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for

4WD)

(a) Install front exhaust pipe assembly (See page EX-

10).

64. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install center exhaust pipe assembly (See page EX-

10).

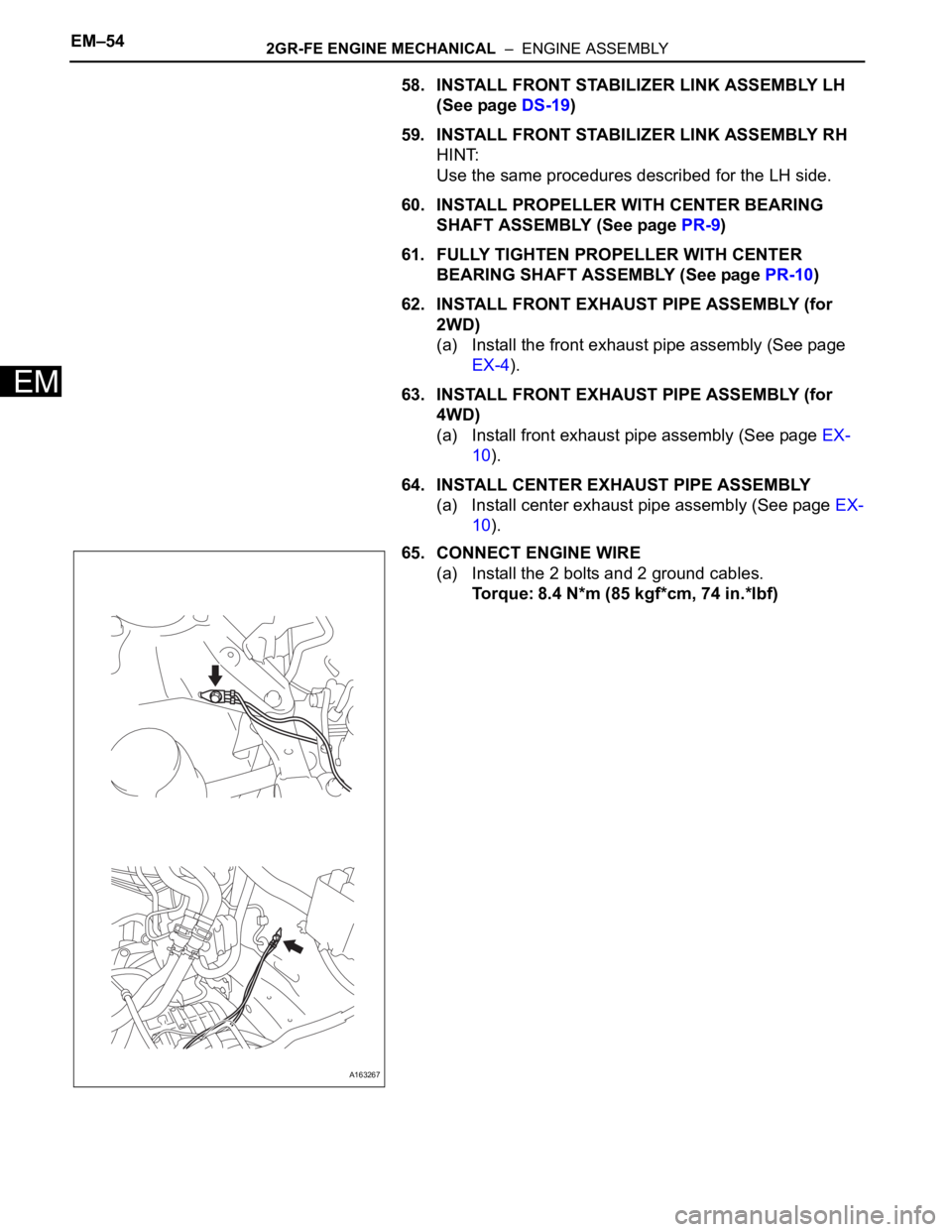

65. CONNECT ENGINE WIRE

(a) Install the 2 bolts and 2 ground cables.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

A163267

Page 1014 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–55

EM

(b) Install the bolt and 2 clamps to the body.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

(c) Connect the wire to the engine room junction block.

Then, install it with the nut.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

(d) Install the engine wire to the body with the 2 nuts.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

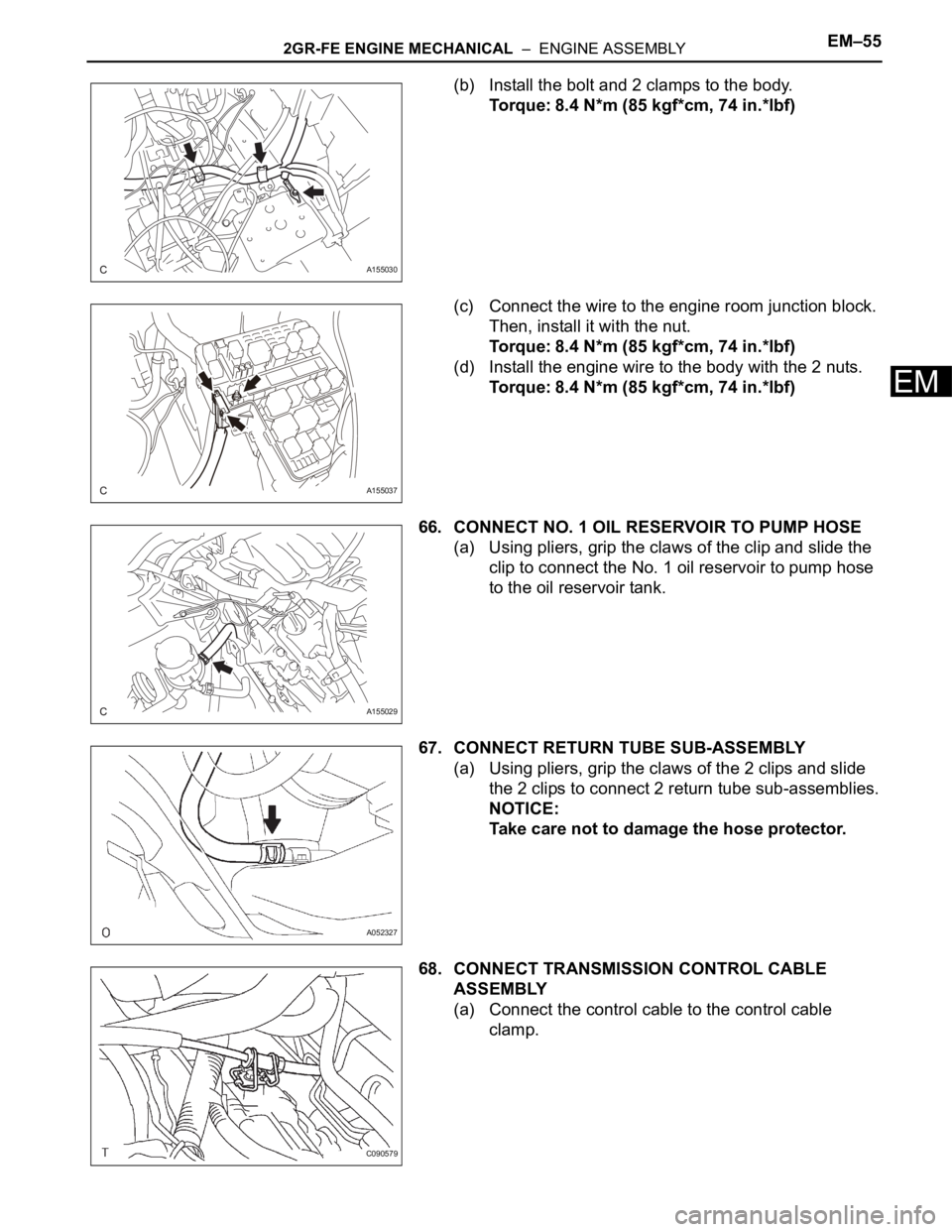

66. CONNECT NO. 1 OIL RESERVOIR TO PUMP HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil reservoir to pump hose

to the oil reservoir tank.

67. CONNECT RETURN TUBE SUB-ASSEMBLY

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to connect 2 return tube sub-assemblies.

NOTICE:

Take care not to damage the hose protector.

68. CONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Connect the control cable to the control cable

clamp.

A155030

A155037

A155029

A052327

C090579

Page 1015 of 3000

EM–562GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

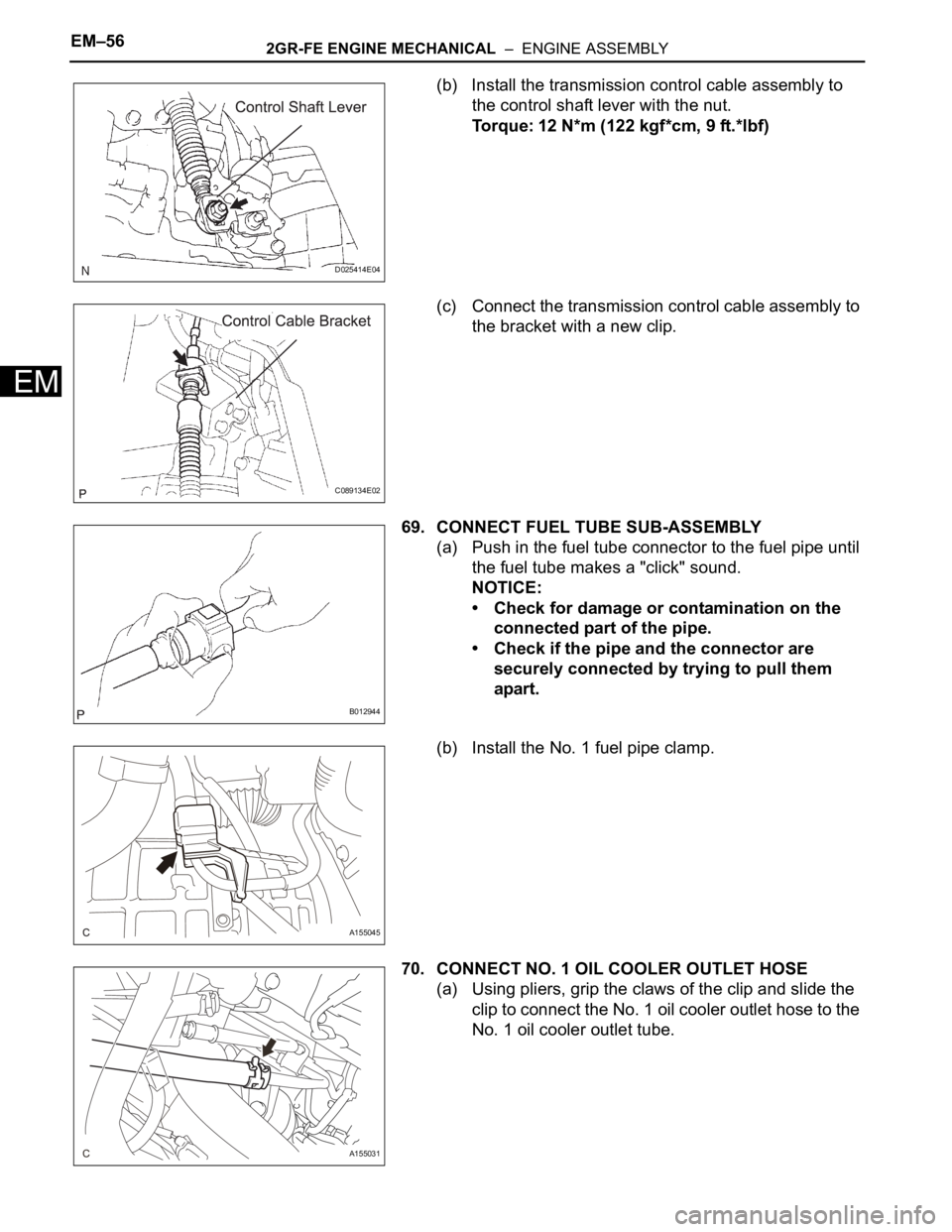

(b) Install the transmission control cable assembly to

the control shaft lever with the nut.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

(c) Connect the transmission control cable assembly to

the bracket with a new clip.

69. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the fuel tube connector to the fuel pipe until

the fuel tube makes a "click" sound.

NOTICE:

• Check for damage or contamination on the

connected part of the pipe.

• Check if the pipe and the connector are

securely connected by trying to pull them

apart.

(b) Install the No. 1 fuel pipe clamp.

70. CONNECT NO. 1 OIL COOLER OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil cooler outlet hose to the

No. 1 oil cooler outlet tube.

D025414E04

C089134E02

B012944

A155045

A155031

Page 1016 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–57

EM

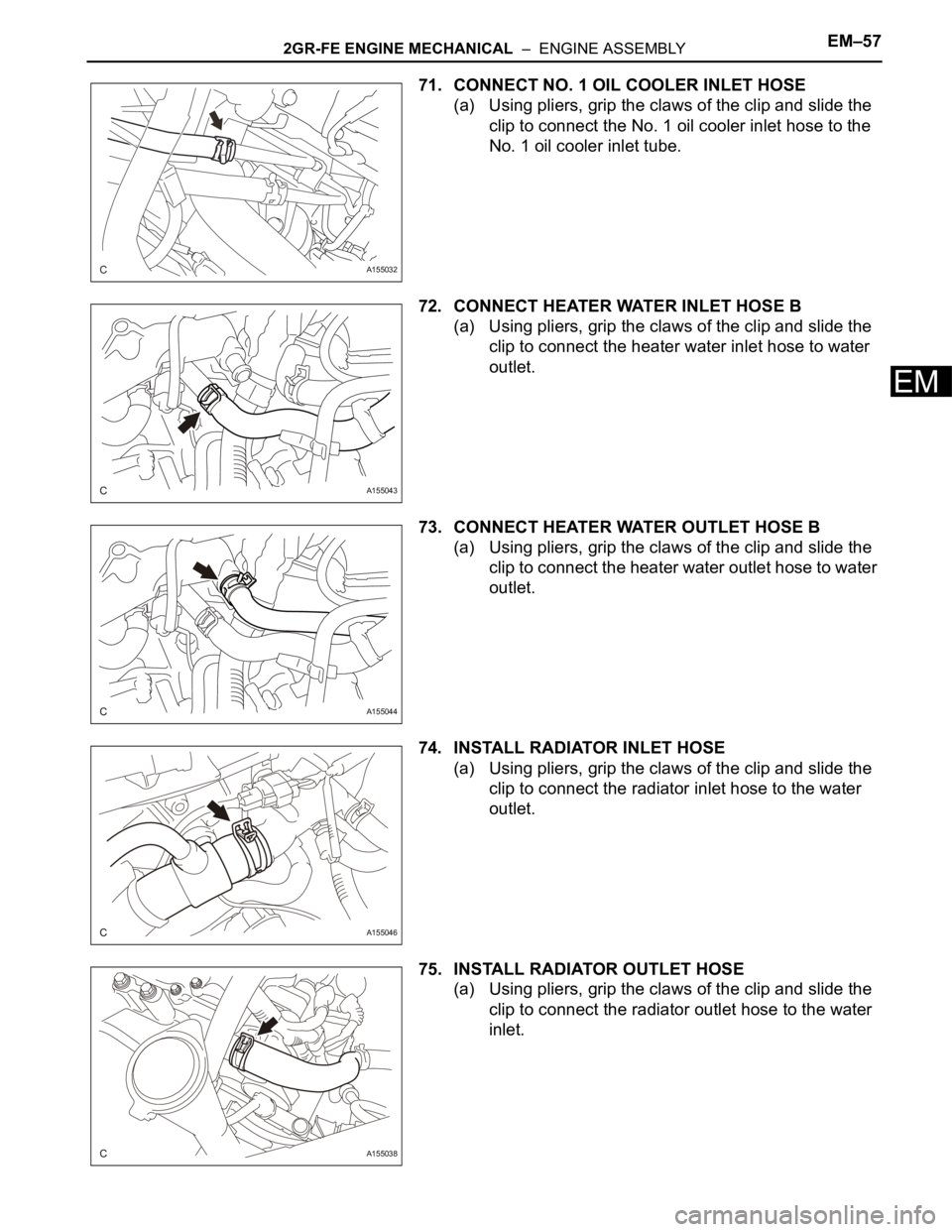

71. CONNECT NO. 1 OIL COOLER INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil cooler inlet hose to the

No. 1 oil cooler inlet tube.

72. CONNECT HEATER WATER INLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the heater water inlet hose to water

outlet.

73. CONNECT HEATER WATER OUTLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the heater water outlet hose to water

outlet.

74. INSTALL RADIATOR INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the radiator inlet hose to the water

outlet.

75. INSTALL RADIATOR OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the radiator outlet hose to the water

inlet.

A155032

A155043

A155044

A155046

A155038

Page 1017 of 3000

EM–582GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

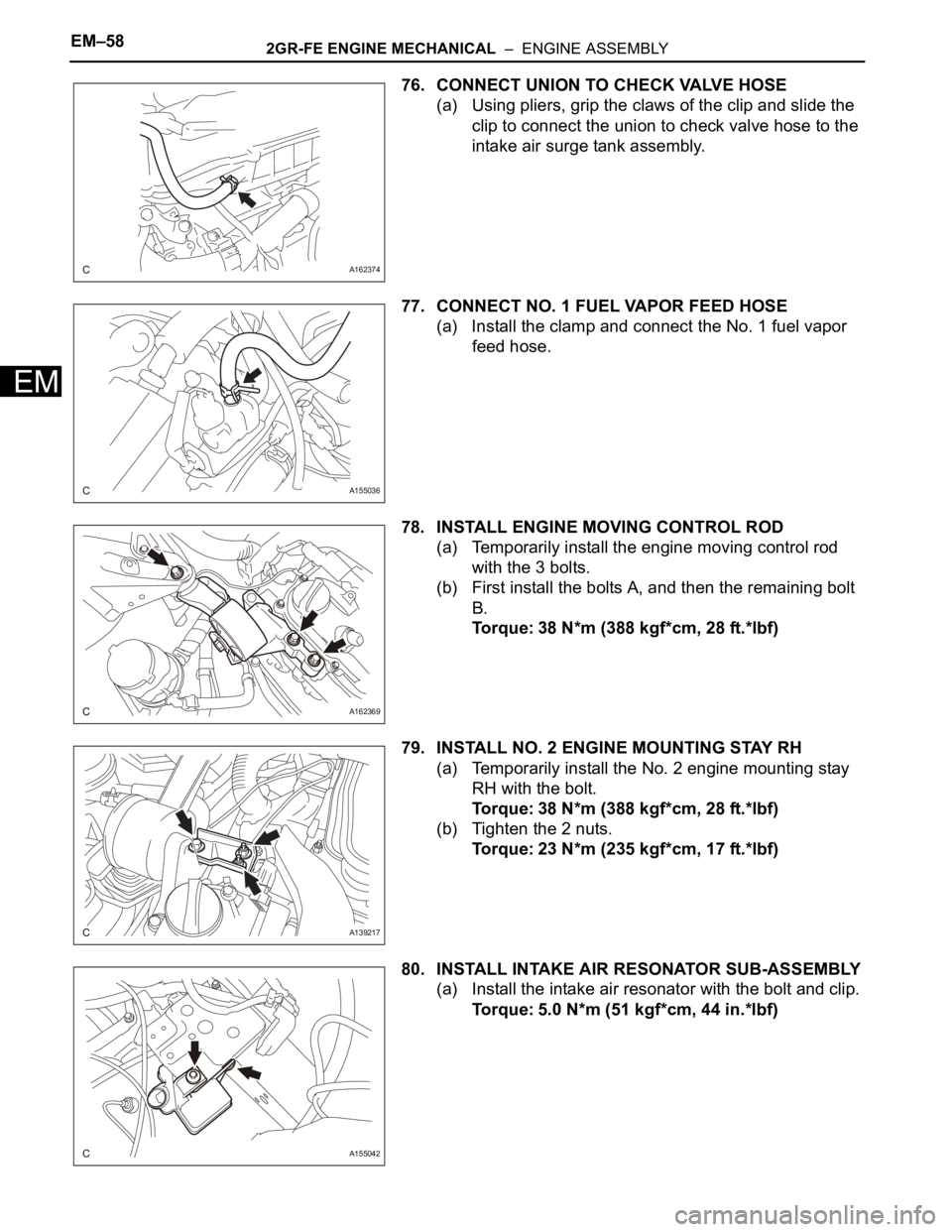

76. CONNECT UNION TO CHECK VALVE HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the union to check valve hose to the

intake air surge tank assembly.

77. CONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Install the clamp and connect the No. 1 fuel vapor

feed hose.

78. INSTALL ENGINE MOVING CONTROL ROD

(a) Temporarily install the engine moving control rod

with the 3 bolts.

(b) First install the bolts A, and then the remaining bolt

B.

Torque: 38 N*m (388 kgf*cm, 28 ft.*lbf)

79. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Temporarily install the No. 2 engine mounting stay

RH with the bolt.

Torque: 38 N*m (388 kgf*cm, 28 ft.*lbf)

(b) Tighten the 2 nuts.

Torque: 23 N*m (235 kgf*cm, 17 ft.*lbf)

80. INSTALL INTAKE AIR RESONATOR SUB-ASSEMBLY

(a) Install the intake air resonator with the bolt and clip.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

A162374

A155036

A162369

A139217

A155042

Page 1018 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–59

EM

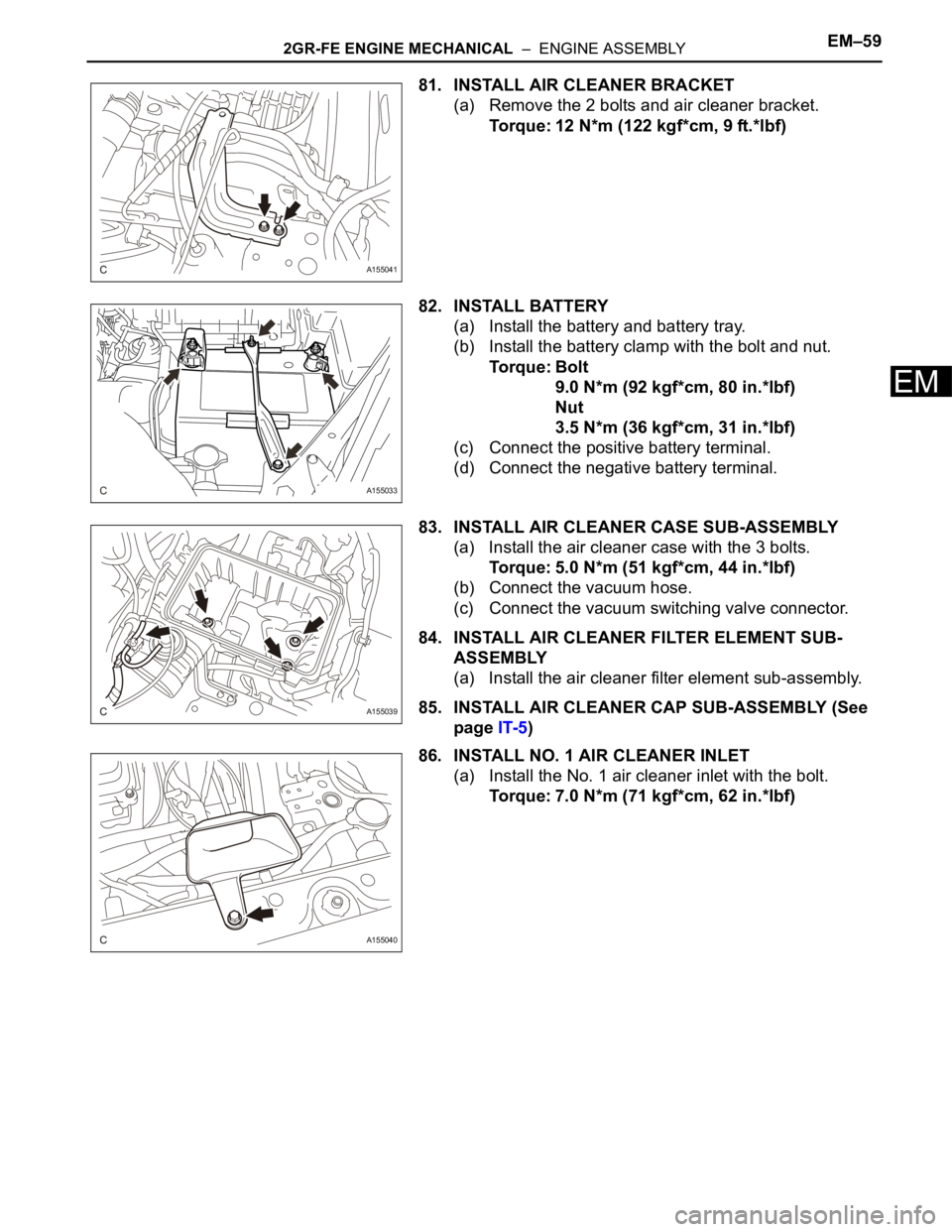

81. INSTALL AIR CLEANER BRACKET

(a) Remove the 2 bolts and air cleaner bracket.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

82. INSTALL BATTERY

(a) Install the battery and battery tray.

(b) Install the battery clamp with the bolt and nut.

Torque: Bolt

9.0 N*m (92 kgf*cm, 80 in.*lbf)

Nut

3.5 N*m (36 kgf*cm, 31 in.*lbf)

(c) Connect the positive battery terminal.

(d) Connect the negative battery terminal.

83. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

(a) Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

(b) Connect the vacuum hose.

(c) Connect the vacuum switching valve connector.

84. INSTALL AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

(a) Install the air cleaner filter element sub-assembly.

85. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page IT-5)

86. INSTALL NO. 1 AIR CLEANER INLET

(a) Install the No. 1 air cleaner inlet with the bolt.

Torque: 7.0 N*m (71 kgf*cm, 62 in.*lbf)

A155041

A155033

A155039

A155040

Page 1019 of 3000

EM–602GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

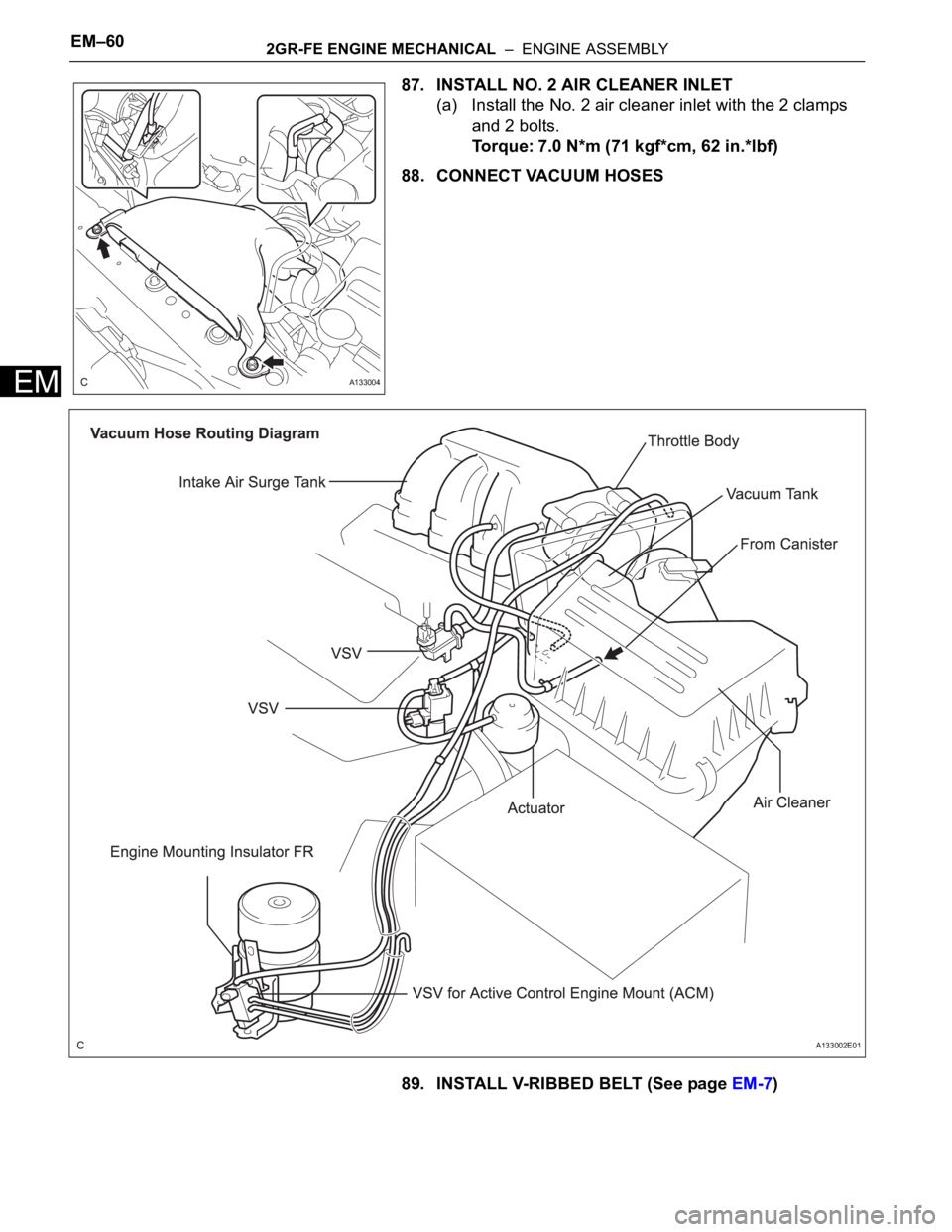

87. INSTALL NO. 2 AIR CLEANER INLET

(a) Install the No. 2 air cleaner inlet with the 2 clamps

and 2 bolts.

Torque: 7.0 N*m (71 kgf*cm, 62 in.*lbf)

88. CONNECT VACUUM HOSES

89. INSTALL V-RIBBED BELT (See page EM-7)

A133004

A133002E01

Page 1020 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–61

EM

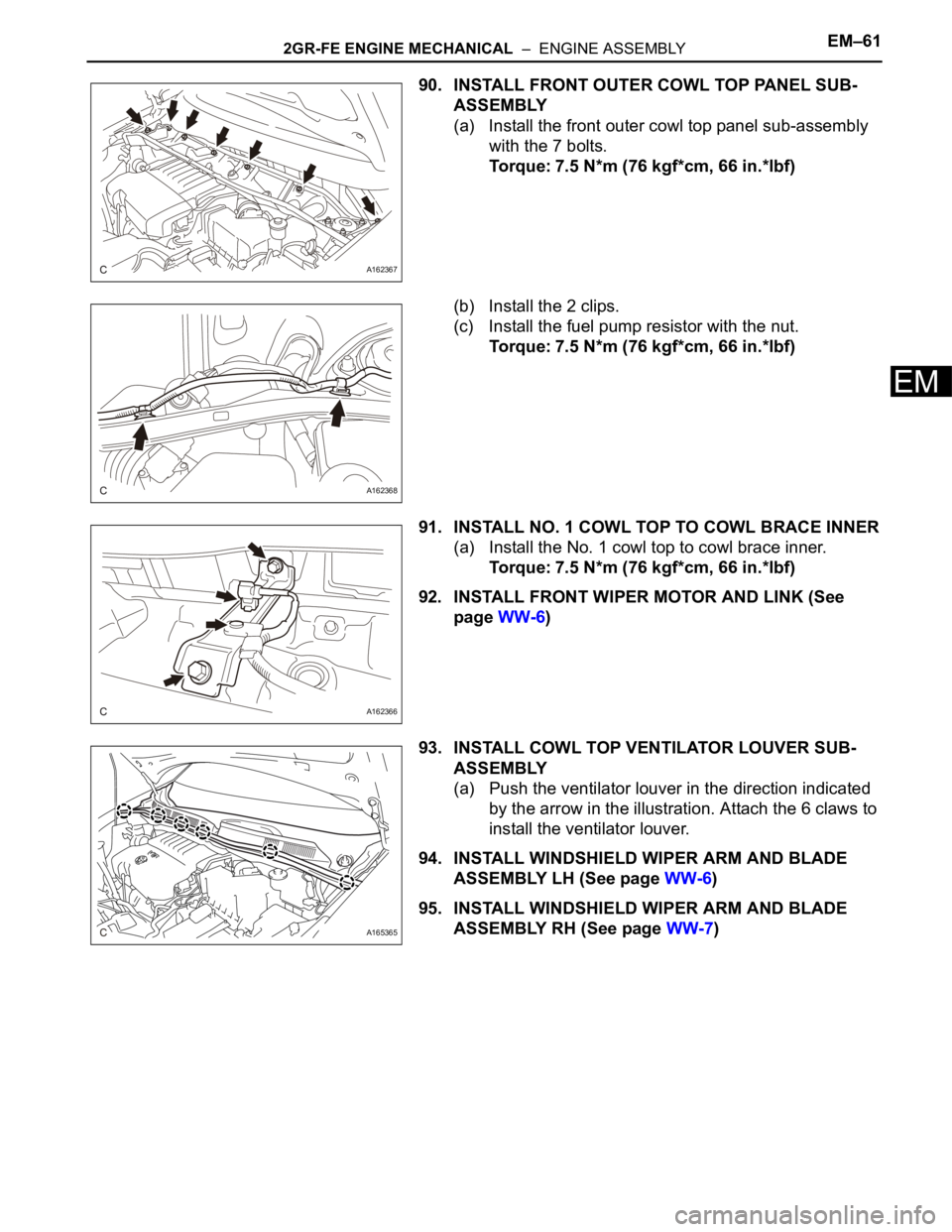

90. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY

(a) Install the front outer cowl top panel sub-assembly

with the 7 bolts.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(b) Install the 2 clips.

(c) Install the fuel pump resistor with the nut.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

91. INSTALL NO. 1 COWL TOP TO COWL BRACE INNER

(a) Install the No. 1 cowl top to cowl brace inner.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

92. INSTALL FRONT WIPER MOTOR AND LINK (See

page WW-6)

93. INSTALL COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY

(a) Push the ventilator louver in the direction indicated

by the arrow in the illustration. Attach the 6 claws to

install the ventilator louver.

94. INSTALL WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY LH (See page WW-6)

95. INSTALL WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-7)

A162367

A162368

A162366

A165365