TOYOTA SIENNA 2007 Service Repair Manual

SIENNA 2007

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57466/w960_57466-0.png

TOYOTA SIENNA 2007 Service Repair Manual

Trending: parking brake, brake fluid, rear view mirror, maintenance, roof, OBD port, coolant reservoir

Page 1201 of 3000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 2WD)EC–33

EC

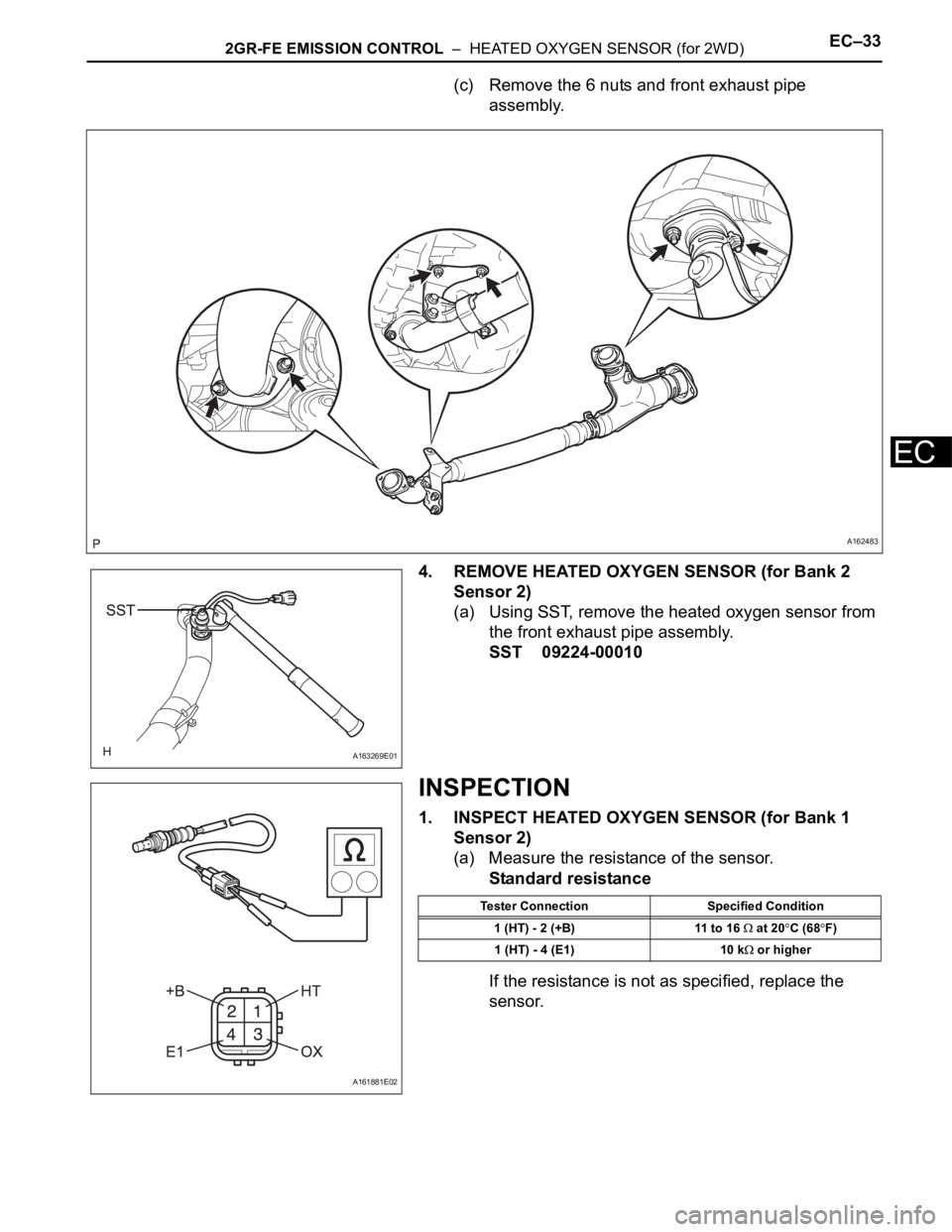

(c) Remove the 6 nuts and front exhaust pipe

assembly.

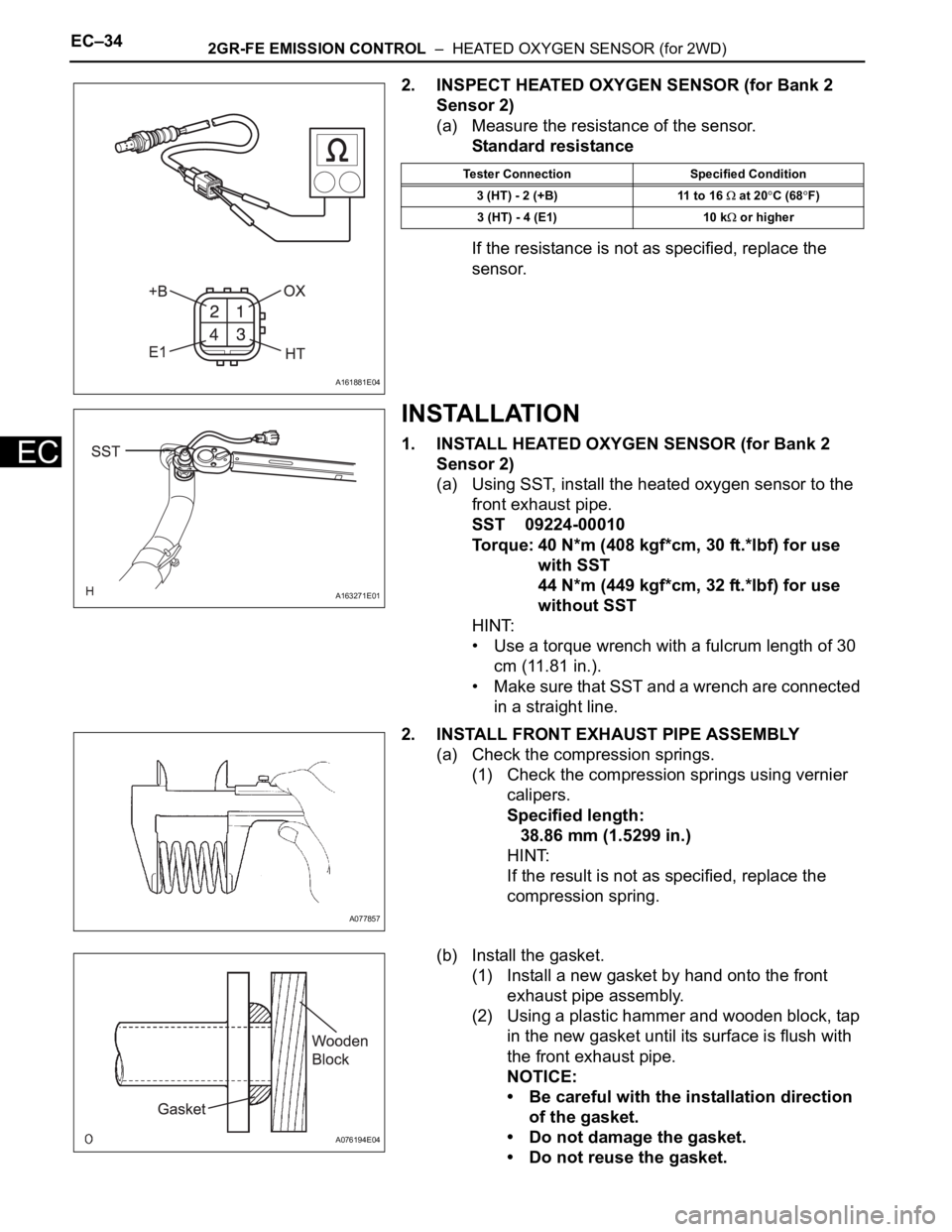

4. REMOVE HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, remove the heated oxygen sensor from

the front exhaust pipe assembly.

SST 09224-00010

INSPECTION

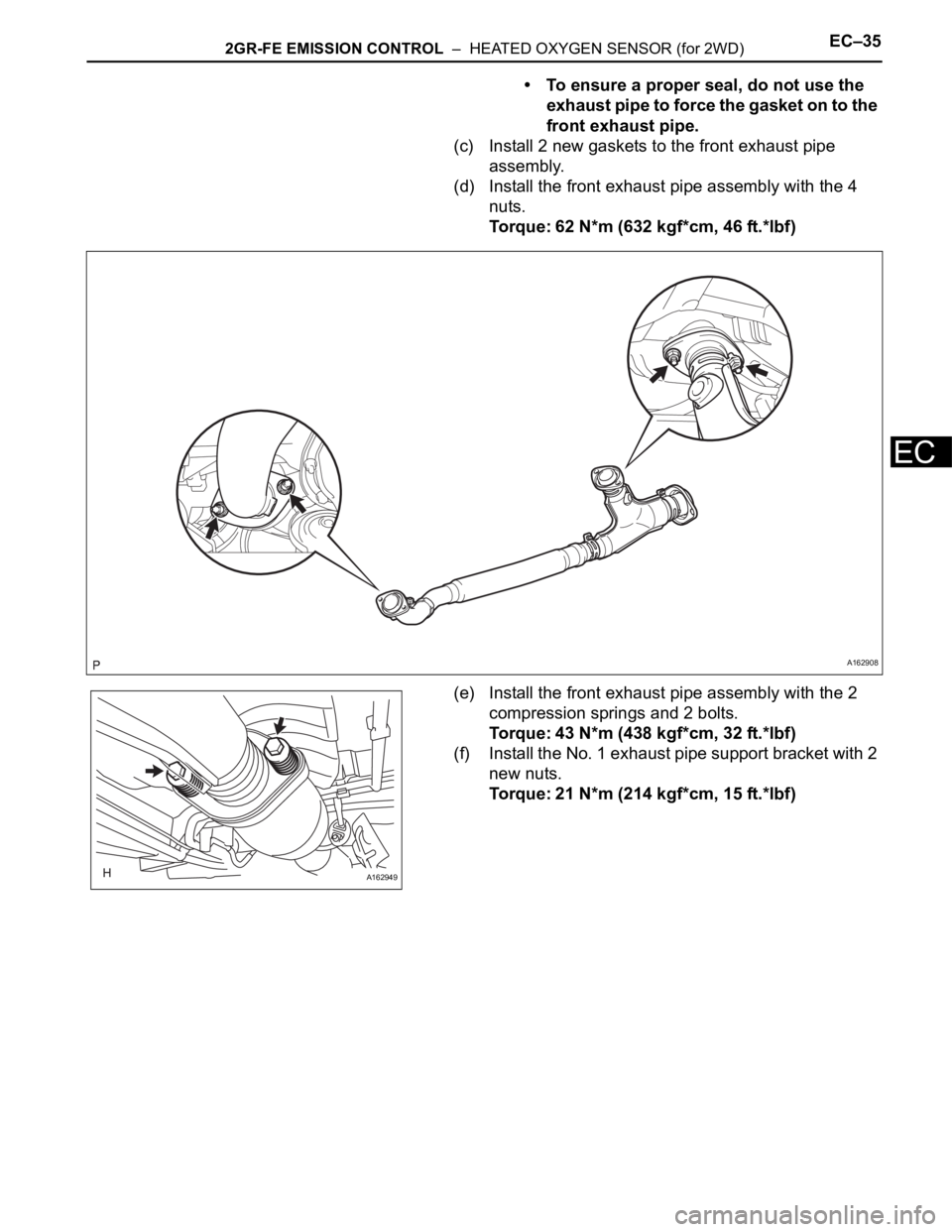

1. INSPECT HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

A162483

A163269E01

A161881E02

Tester Connection Specified Condition

1 (HT) - 2 (+B) 11 to 16

at 20C (68F)

1 (HT) - 4 (E1) 10 k

or higher

Page 1202 of 3000

EC–342GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 2WD)

EC

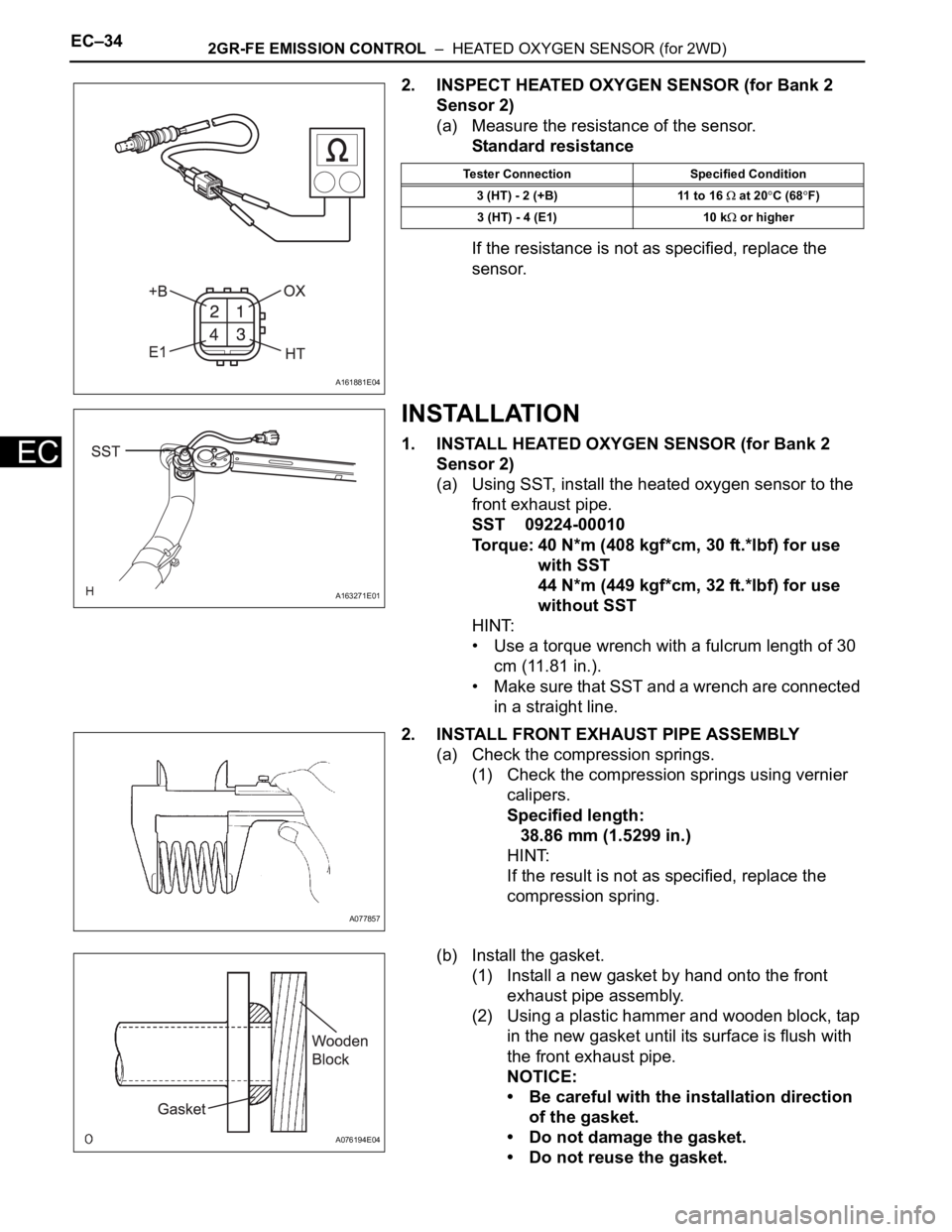

2. INSPECT HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, install the heated oxygen sensor to the

front exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Check the compression springs.

(1) Check the compression springs using vernier

calipers.

Specified length:

38.86 mm (1.5299 in.)

HINT:

If the result is not as specified, replace the

compression spring.

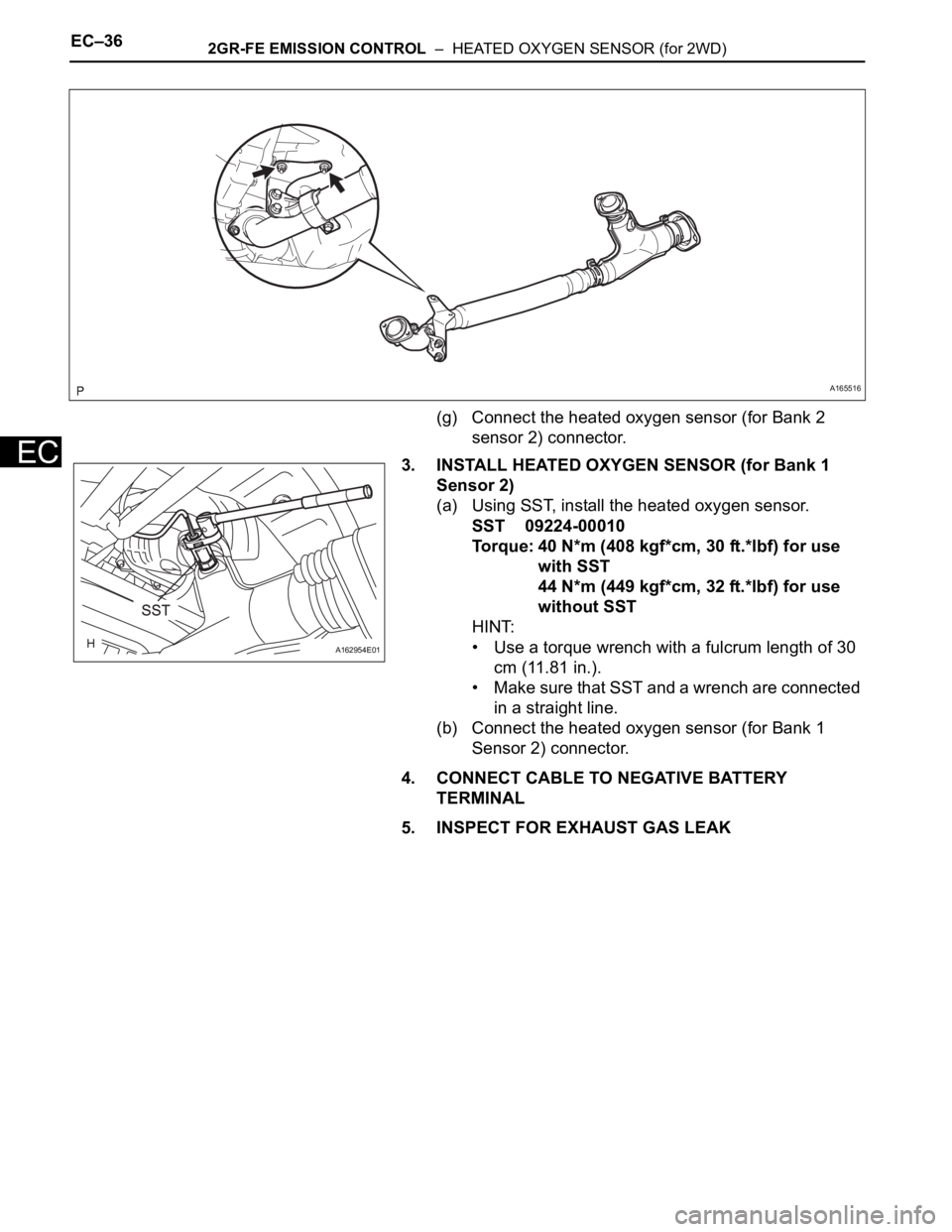

(b) Install the gasket.

(1) Install a new gasket by hand onto the front

exhaust pipe assembly.

(2) Using a plastic hammer and wooden block, tap

in the new gasket until its surface is flush with

the front exhaust pipe.

NOTICE:

• Be careful with the installation direction

of the gasket.

• Do not damage the gasket.

• Do not reuse the gasket.

A161881E04

Tester Connection Specified Condition

3 (HT) - 2 (+B) 11 to 16

at 20C (68F)

3 (HT) - 4 (E1) 10 k

or higher

A163271E01

A077857

A076194E04

Page 1203 of 3000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 2WD)EC–35

EC

• To ensure a proper seal, do not use the

exhaust pipe to force the gasket on to the

front exhaust pipe.

(c) Install 2 new gaskets to the front exhaust pipe

assembly.

(d) Install the front exhaust pipe assembly with the 4

nuts.

Torque: 62 N*m (632 kgf*cm, 46 ft.*lbf)

(e) Install the front exhaust pipe assembly with the 2

compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Install the No. 1 exhaust pipe support bracket with 2

new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A162908

A162949

Page 1204 of 3000

EC–362GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 2WD)

EC

(g) Connect the heated oxygen sensor (for Bank 2

sensor 2) connector.

3. INSTALL HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Using SST, install the heated oxygen sensor.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

(b) Connect the heated oxygen sensor (for Bank 1

Sensor 2) connector.

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. INSPECT FOR EXHAUST GAS LEAK

A165516

A162954E01

Page 1205 of 3000

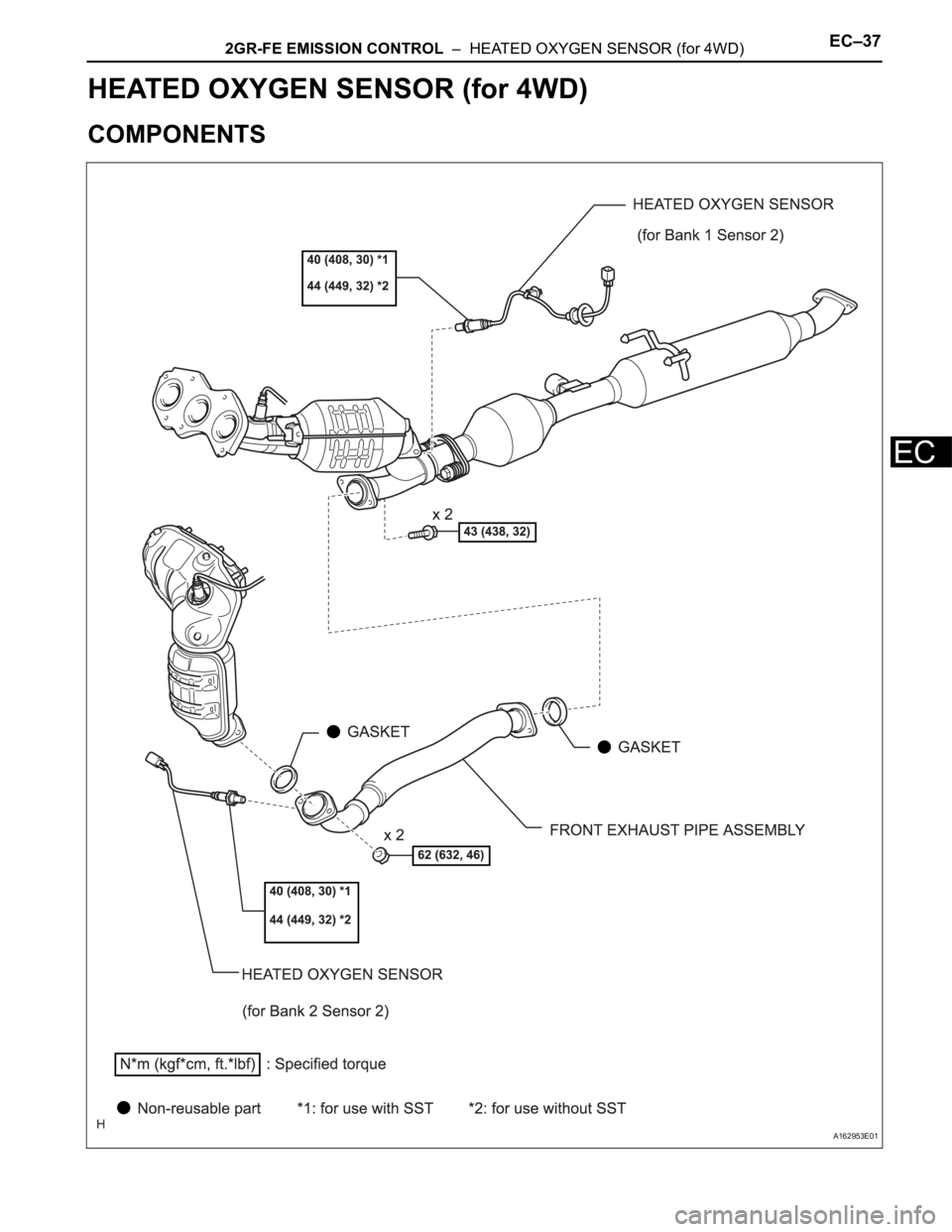

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)EC–37

EC

ENGINE

2GR-FE EMISSION CONTROL

HEATED OXYGEN SENSOR (for 4WD)

COMPONENTS

A162953E01

Page 1206 of 3000

EC–382GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)

EC

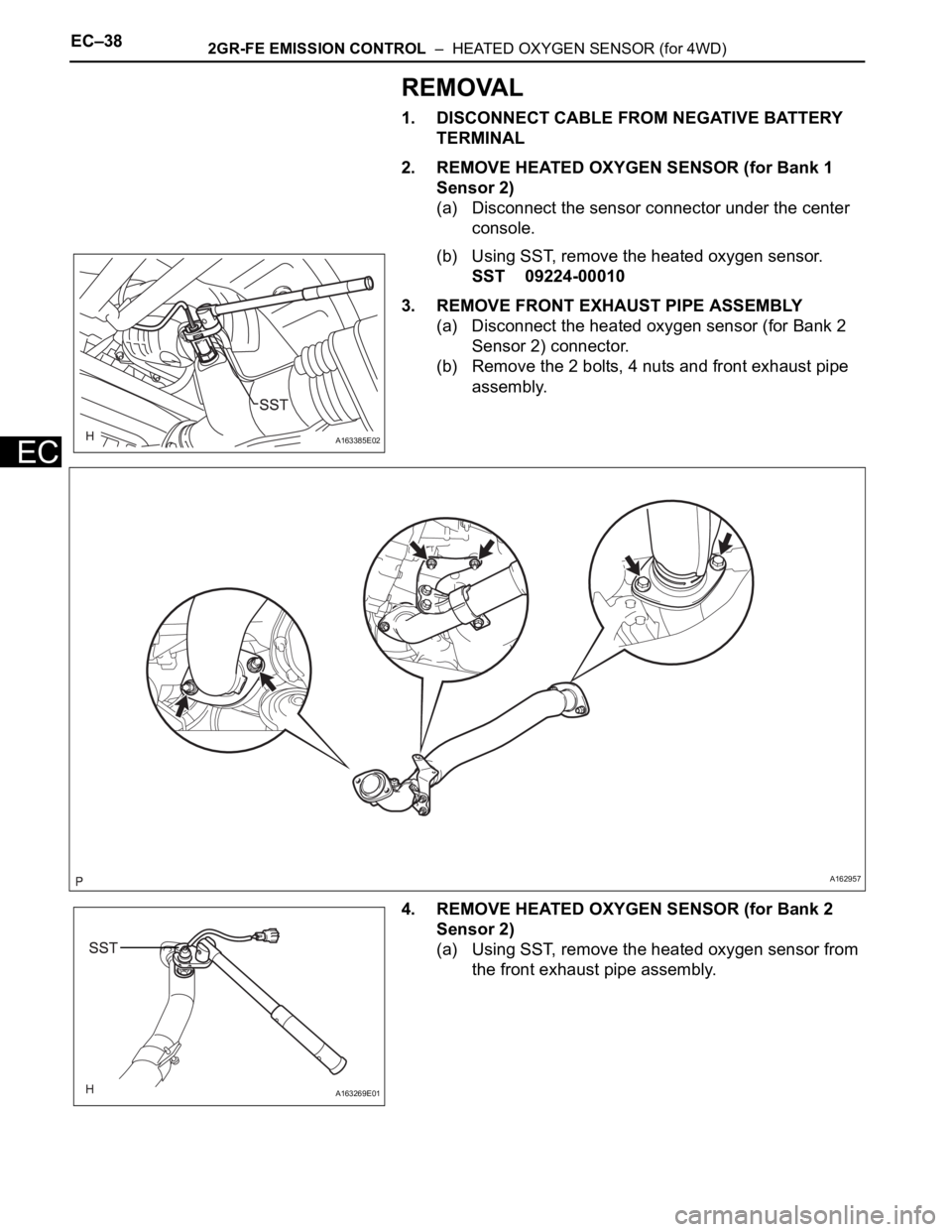

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Disconnect the sensor connector under the center

console.

(b) Using SST, remove the heated oxygen sensor.

SST 09224-00010

3. REMOVE FRONT EXHAUST PIPE ASSEMBLY

(a) Disconnect the heated oxygen sensor (for Bank 2

Sensor 2) connector.

(b) Remove the 2 bolts, 4 nuts and front exhaust pipe

assembly.

4. REMOVE HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, remove the heated oxygen sensor from

the front exhaust pipe assembly.

A163385E02

A162957

A163269E01

Page 1207 of 3000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)EC–39

EC

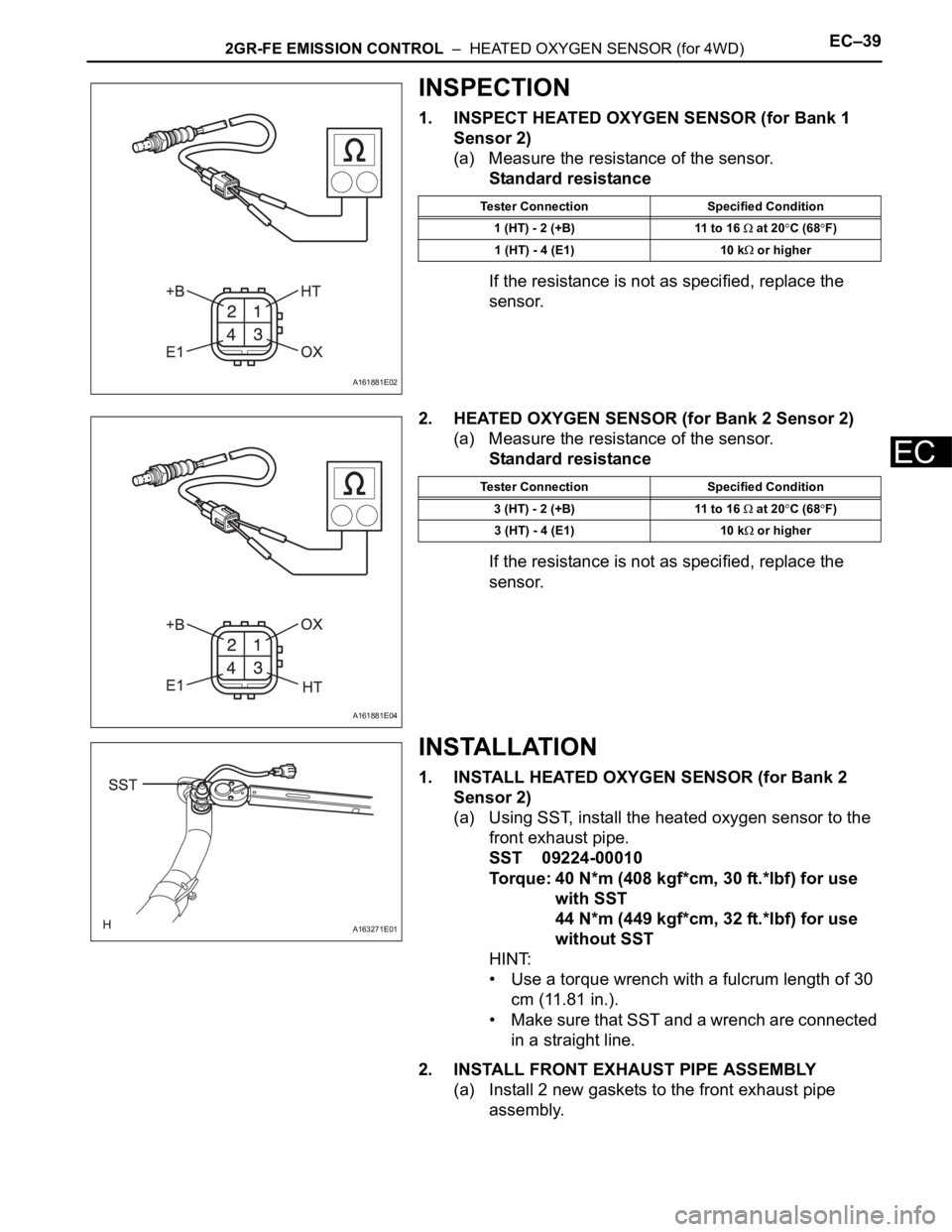

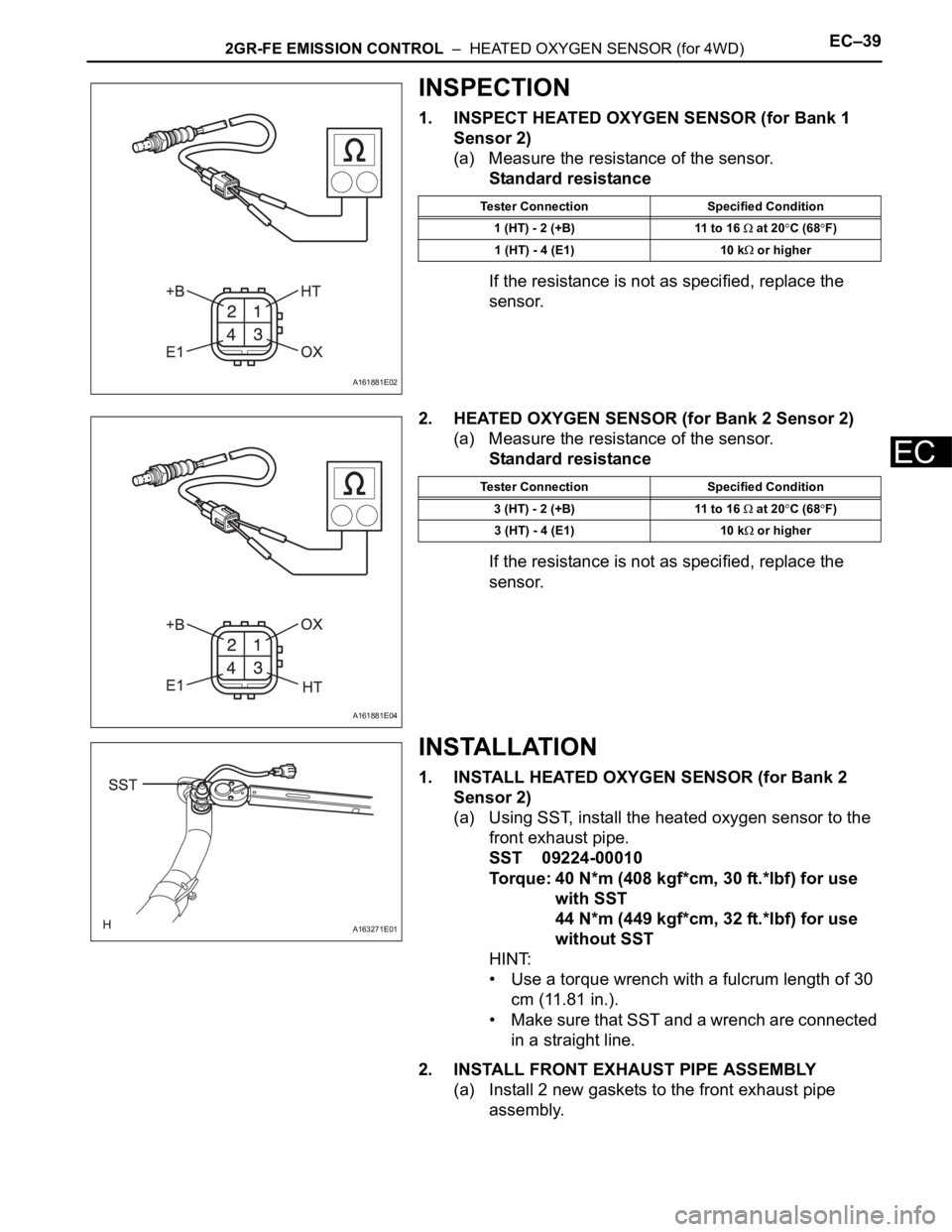

INSPECTION

1. INSPECT HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

2. HEATED OXYGEN SENSOR (for Bank 2 Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, install the heated oxygen sensor to the

front exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Install 2 new gaskets to the front exhaust pipe

assembly.

A161881E02

Tester Connection Specified Condition

1 (HT) - 2 (+B) 11 to 16

at 20C (68F)

1 (HT) - 4 (E1) 10 k

or higher

A161881E04

Tester Connection Specified Condition

3 (HT) - 2 (+B) 11 to 16

at 20C (68F)

3 (HT) - 4 (E1) 10 k

or higher

A163271E01

Page 1208 of 3000

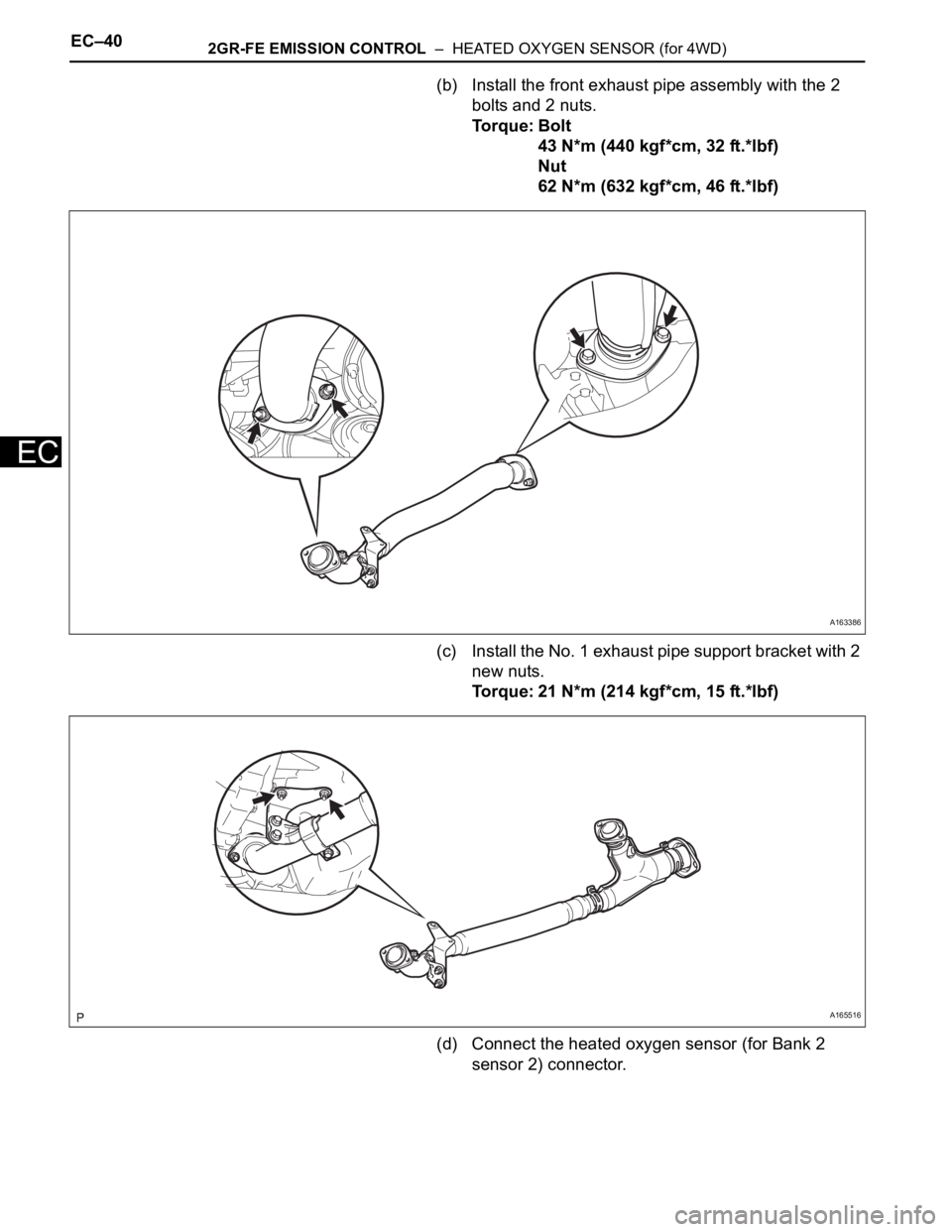

EC–402GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)

EC

(b) Install the front exhaust pipe assembly with the 2

bolts and 2 nuts.

Torque: Bolt

43 N*m (440 kgf*cm, 32 ft.*lbf)

Nut

62 N*m (632 kgf*cm, 46 ft.*lbf)

(c) Install the No. 1 exhaust pipe support bracket with 2

new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the heated oxygen sensor (for Bank 2

sensor 2) connector.

A163386

A165516

Page 1209 of 3000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)EC–41

EC

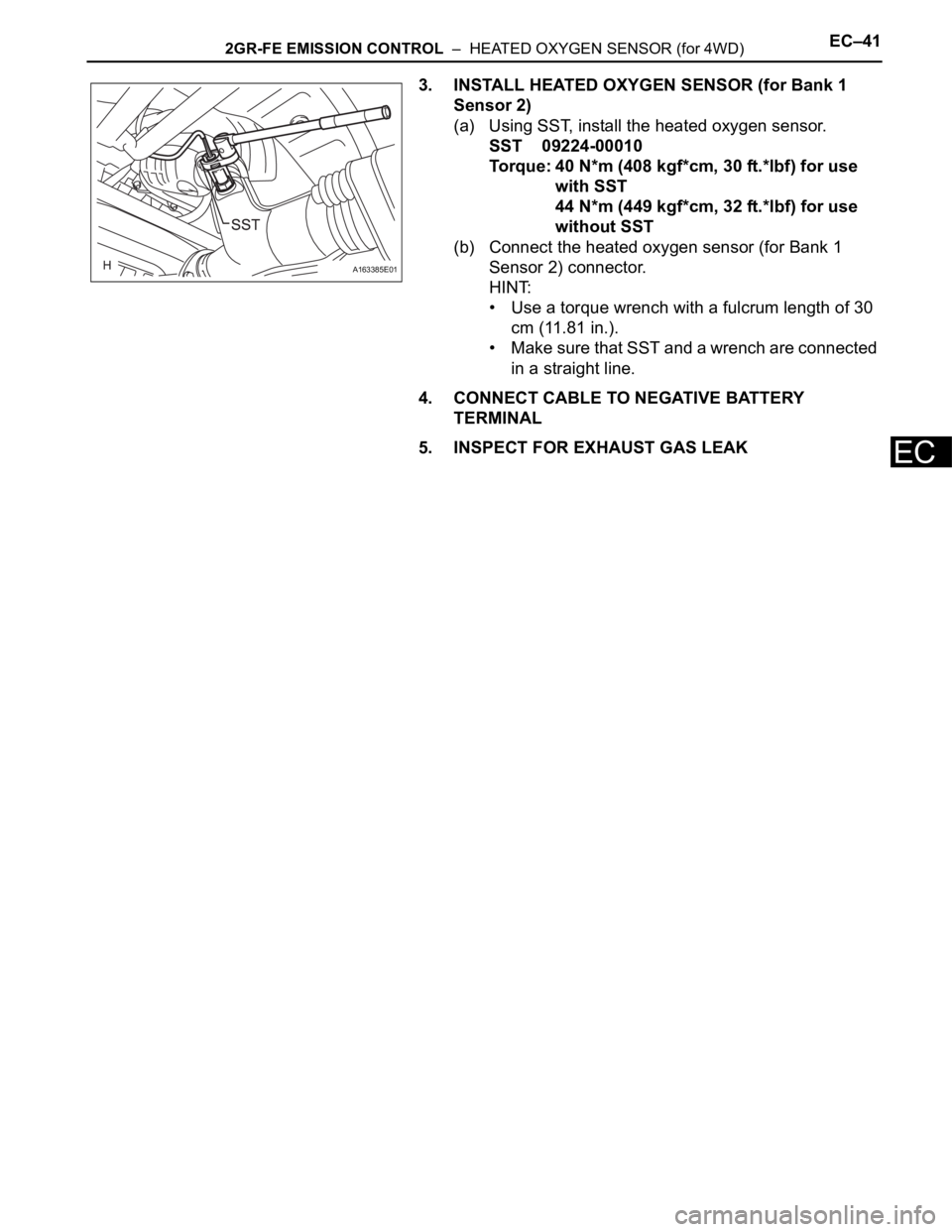

3. INSTALL HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Using SST, install the heated oxygen sensor.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

(b) Connect the heated oxygen sensor (for Bank 1

Sensor 2) connector.

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. INSPECT FOR EXHAUST GAS LEAK

A163385E01

Page 1210 of 3000

EC–422GR-FE EMISSION CONTROL – FUEL TANK CAP

EC

FUEL TANK CAP

INSPECTION

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the cap and gasket are not

deformed or damaged.

If the result is not as specified, replace the cap

assembly or gasket.

A121447E02

Trending: headrest, remote control, fuel cap, display, navigation update, transmission filter, engine overheat