TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1821 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

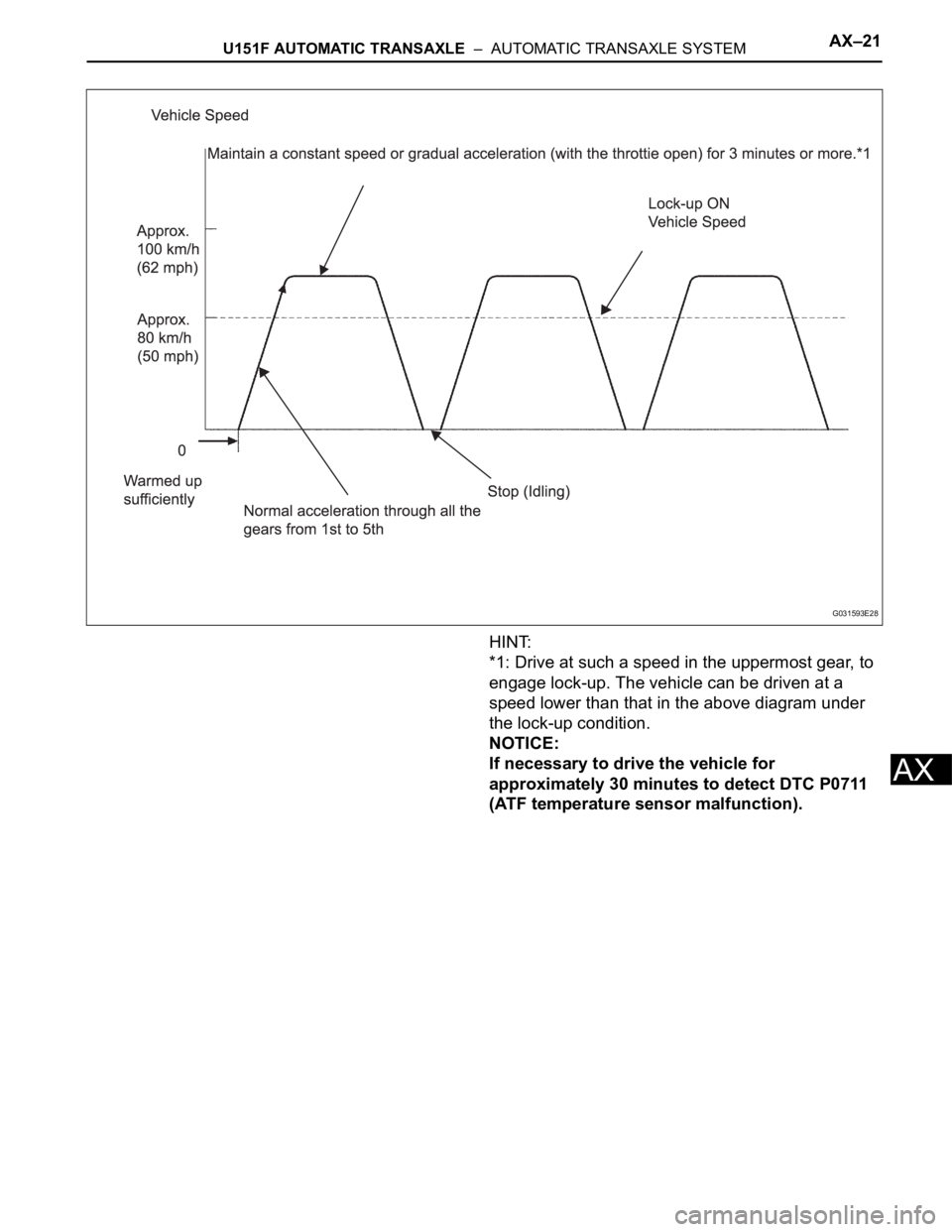

HINT:

*1: Drive at such a speed in the uppermost gear, to

engage lock-up. The vehicle can be driven at a

speed lower than that in the above diagram under

the lock-up condition.

NOTICE:

If necessary to drive the vehicle for

approximately 30 minutes to detect DTC P0711

(ATF temperature sensor malfunction).

G031593E28

Page 1822 of 3000

AX–136U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLY

AX

REMOVAL

1. REMOVE ENGINE UNDER COVER NO.1

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-131)

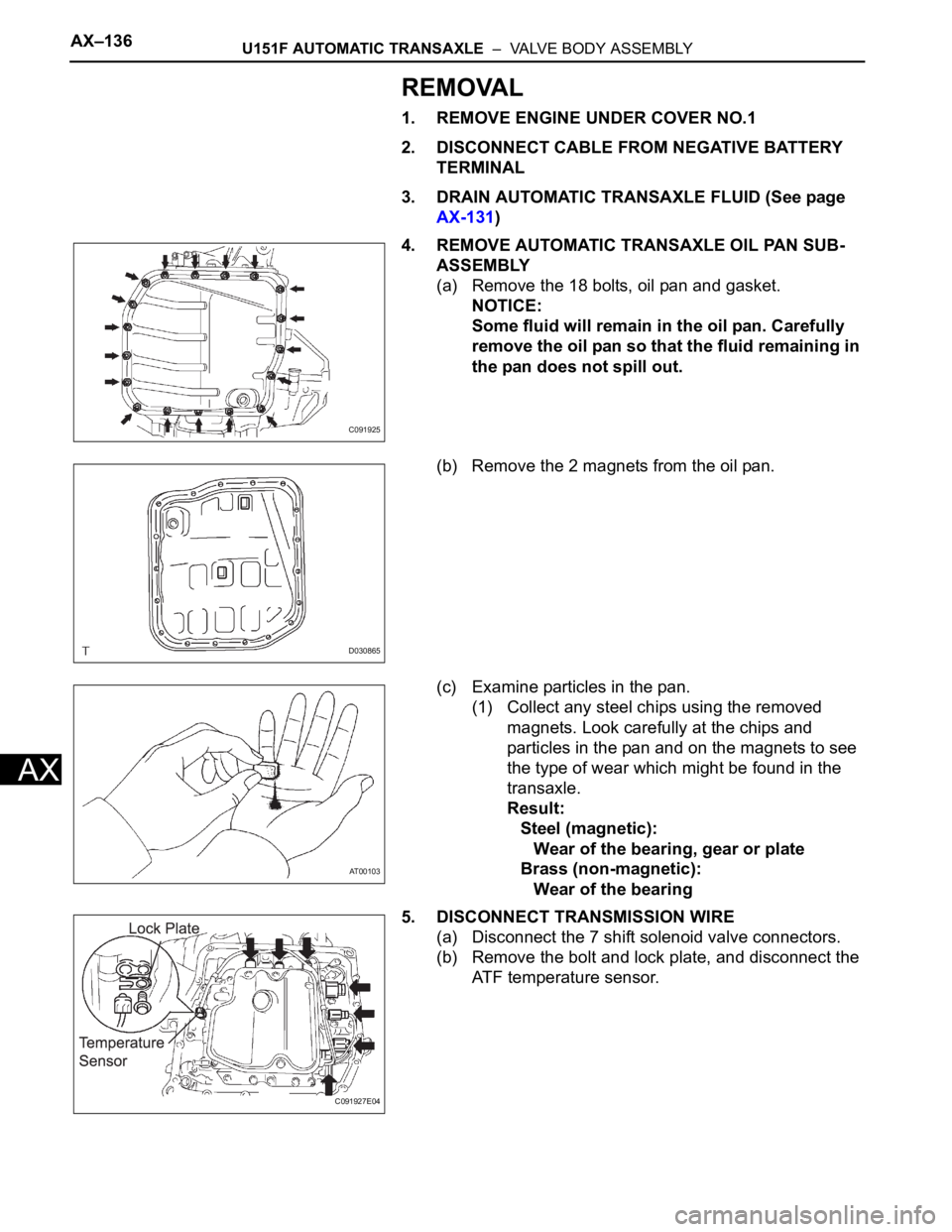

4. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

NOTICE:

Some fluid will remain in the oil pan. Carefully

remove the oil pan so that the fluid remaining in

the pan does not spill out.

(b) Remove the 2 magnets from the oil pan.

(c) Examine particles in the pan.

(1) Collect any steel chips using the removed

magnets. Look carefully at the chips and

particles in the pan and on the magnets to see

the type of wear which might be found in the

transaxle.

Result:

Steel (magnetic):

Wear of the bearing, gear or plate

Brass (non-magnetic):

Wear of the bearing

5. DISCONNECT TRANSMISSION WIRE

(a) Disconnect the 7 shift solenoid valve connectors.

(b) Remove the bolt and lock plate, and disconnect the

ATF temperature sensor.

C091925

D030865

AT00103

C091927E04

Page 1823 of 3000

U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–137

AX

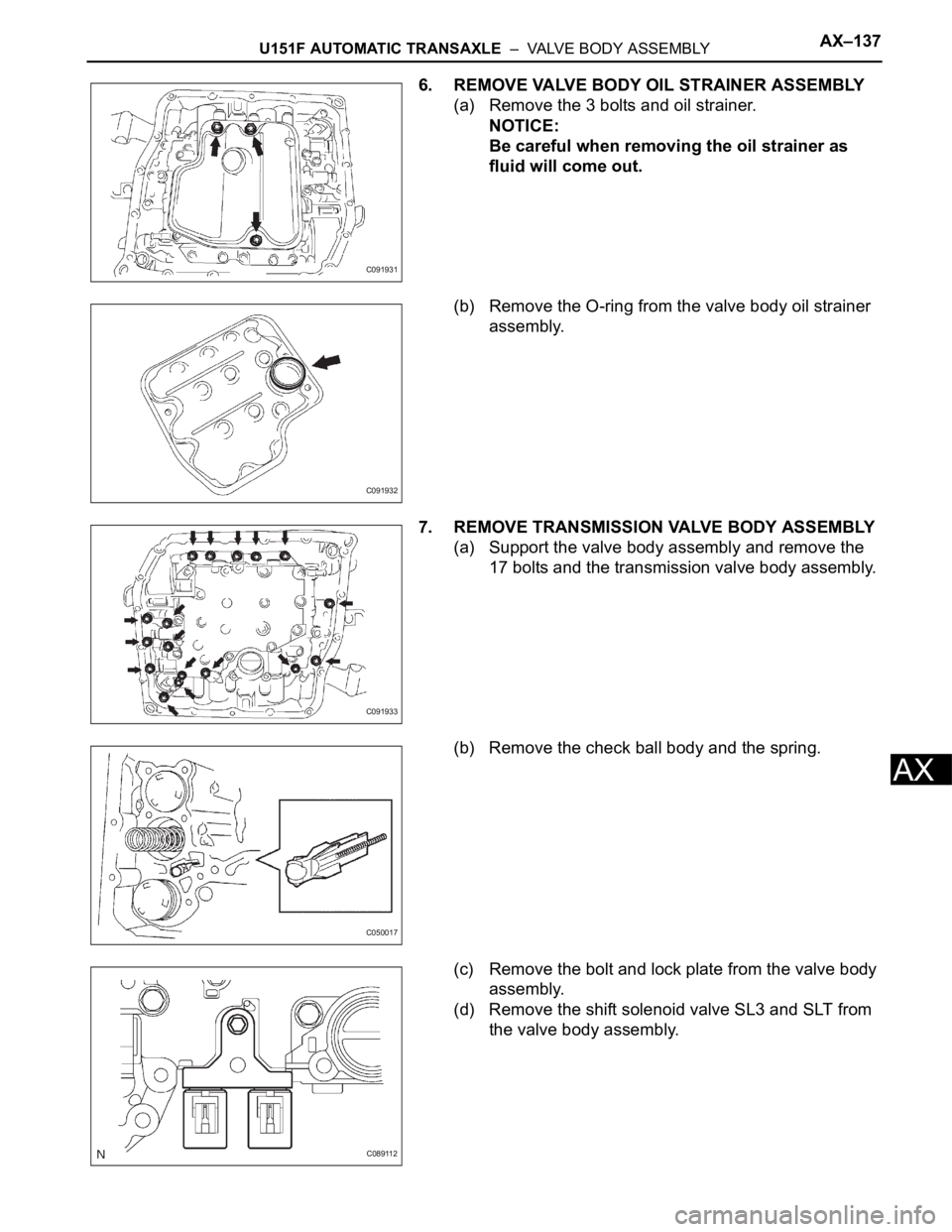

6. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

NOTICE:

Be careful when removing the oil strainer as

fluid will come out.

(b) Remove the O-ring from the valve body oil strainer

assembly.

7. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

(a) Support the valve body assembly and remove the

17 bolts and the transmission valve body assembly.

(b) Remove the check ball body and the spring.

(c) Remove the bolt and lock plate from the valve body

assembly.

(d) Remove the shift solenoid valve SL3 and SLT from

the valve body assembly.

C091931

C091932

C091933

C050017

C089112

Page 1824 of 3000

AX–138U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLY

AX

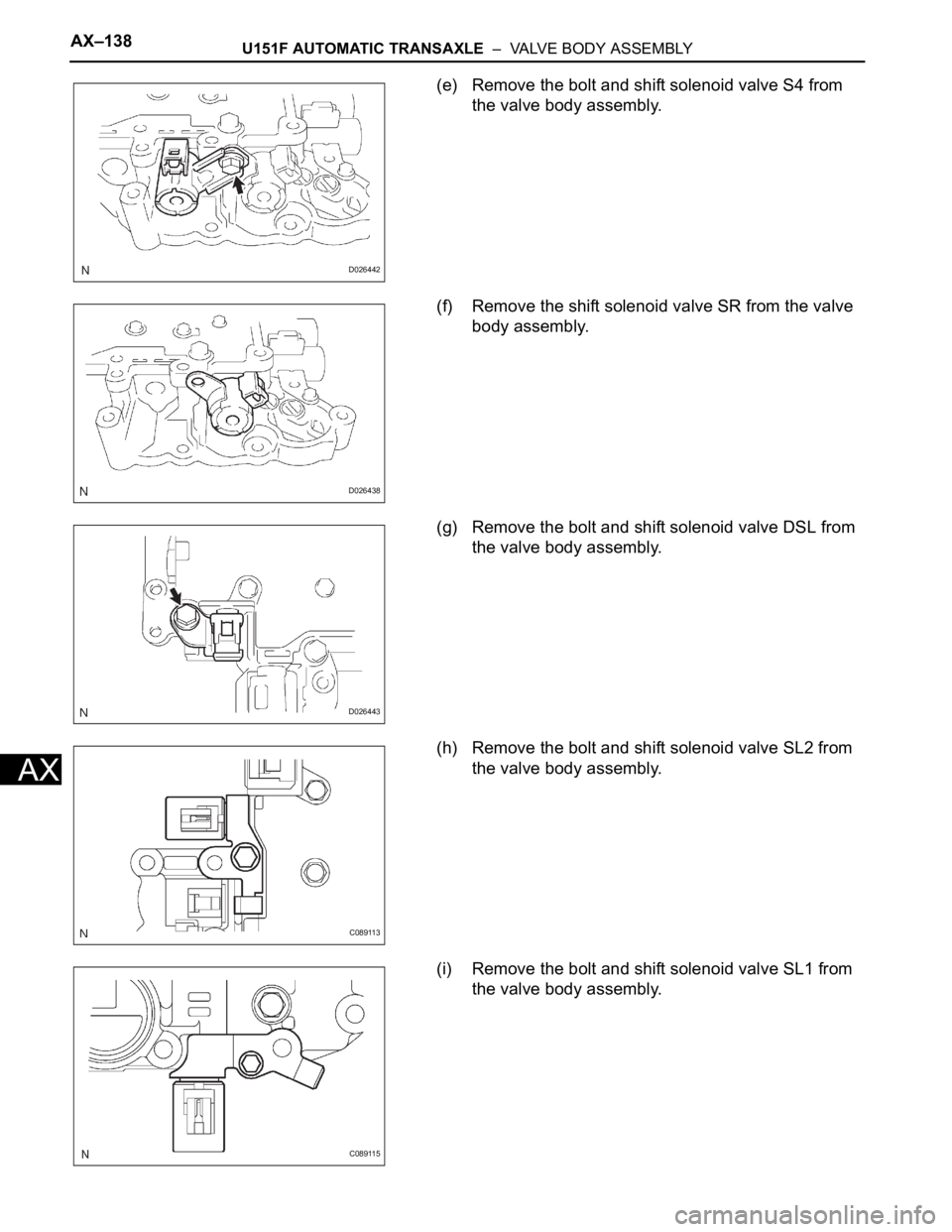

(e) Remove the bolt and shift solenoid valve S4 from

the valve body assembly.

(f) Remove the shift solenoid valve SR from the valve

body assembly.

(g) Remove the bolt and shift solenoid valve DSL from

the valve body assembly.

(h) Remove the bolt and shift solenoid valve SL2 from

the valve body assembly.

(i) Remove the bolt and shift solenoid valve SL1 from

the valve body assembly.

D026442

D026438

D026443

C089113

C089115

Page 1825 of 3000

U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–139

AX

INSTALLATION

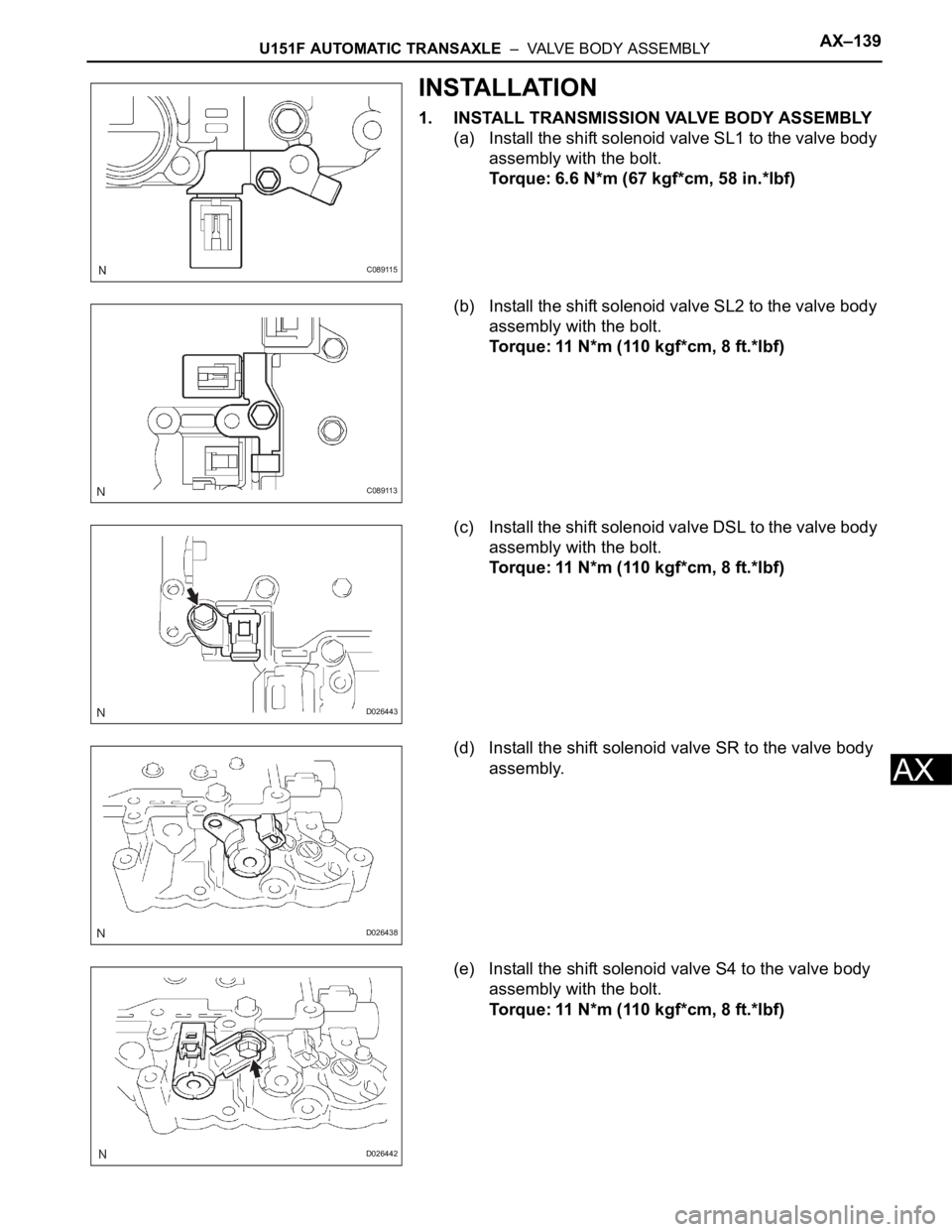

1. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Install the shift solenoid valve SL1 to the valve body

assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shift solenoid valve SL2 to the valve body

assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(c) Install the shift solenoid valve DSL to the valve body

assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(d) Install the shift solenoid valve SR to the valve body

assembly.

(e) Install the shift solenoid valve S4 to the valve body

assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

C089115

C089113

D026443

D026438

D026442

Page 1826 of 3000

AX–140U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLY

AX

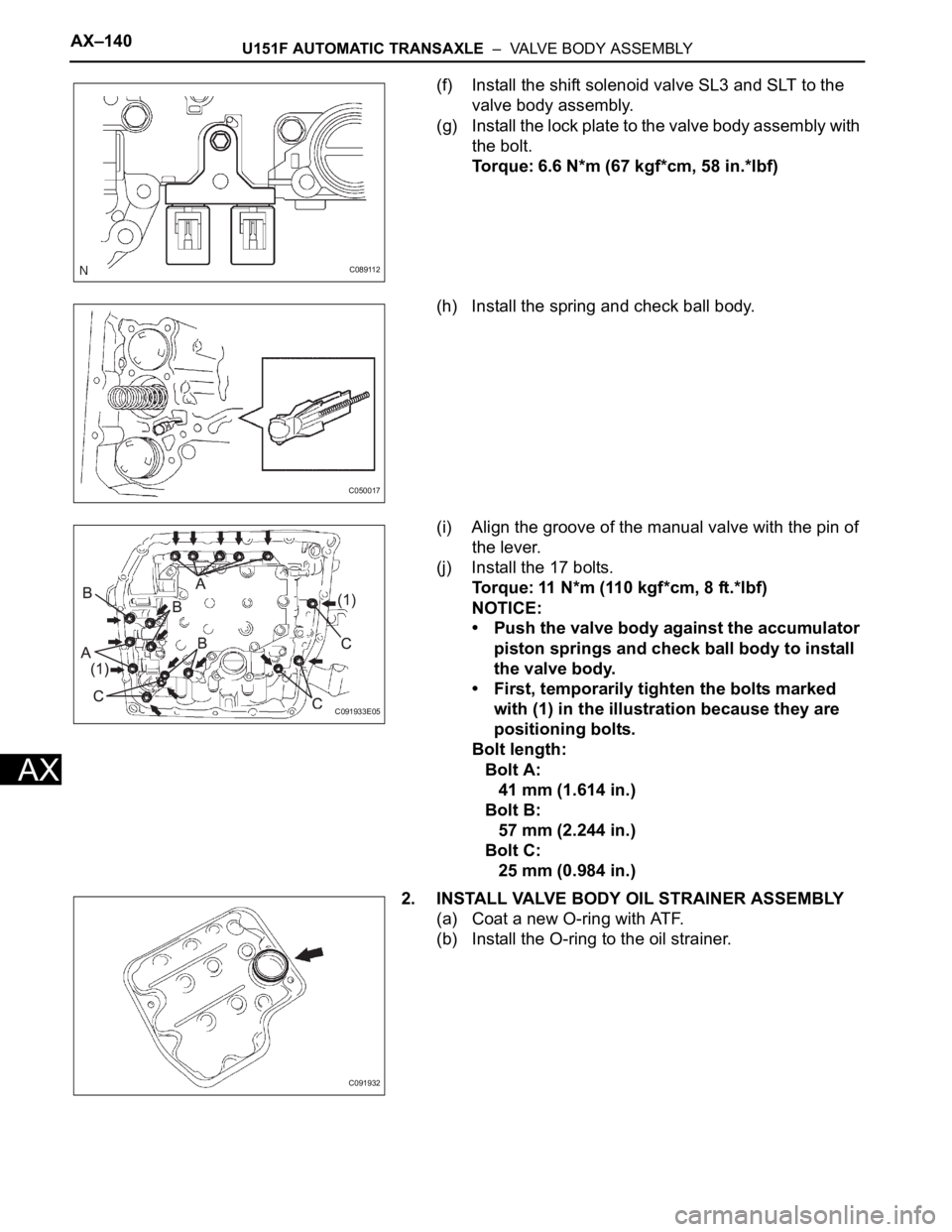

(f) Install the shift solenoid valve SL3 and SLT to the

valve body assembly.

(g) Install the lock plate to the valve body assembly with

the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(h) Install the spring and check ball body.

(i) Align the groove of the manual valve with the pin of

the lever.

(j) Install the 17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

NOTICE:

• Push the valve body against the accumulator

piston springs and check ball body to install

the valve body.

• First, temporarily tighten the bolts marked

with (1) in the illustration because they are

positioning bolts.

Bolt length:

Bolt A:

41 mm (1.614 in.)

Bolt B:

57 mm (2.244 in.)

Bolt C:

25 mm (0.984 in.)

2. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF.

(b) Install the O-ring to the oil strainer.

C089112

C050017

C091933E05

C091932

Page 1827 of 3000

U151F AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–141

AX

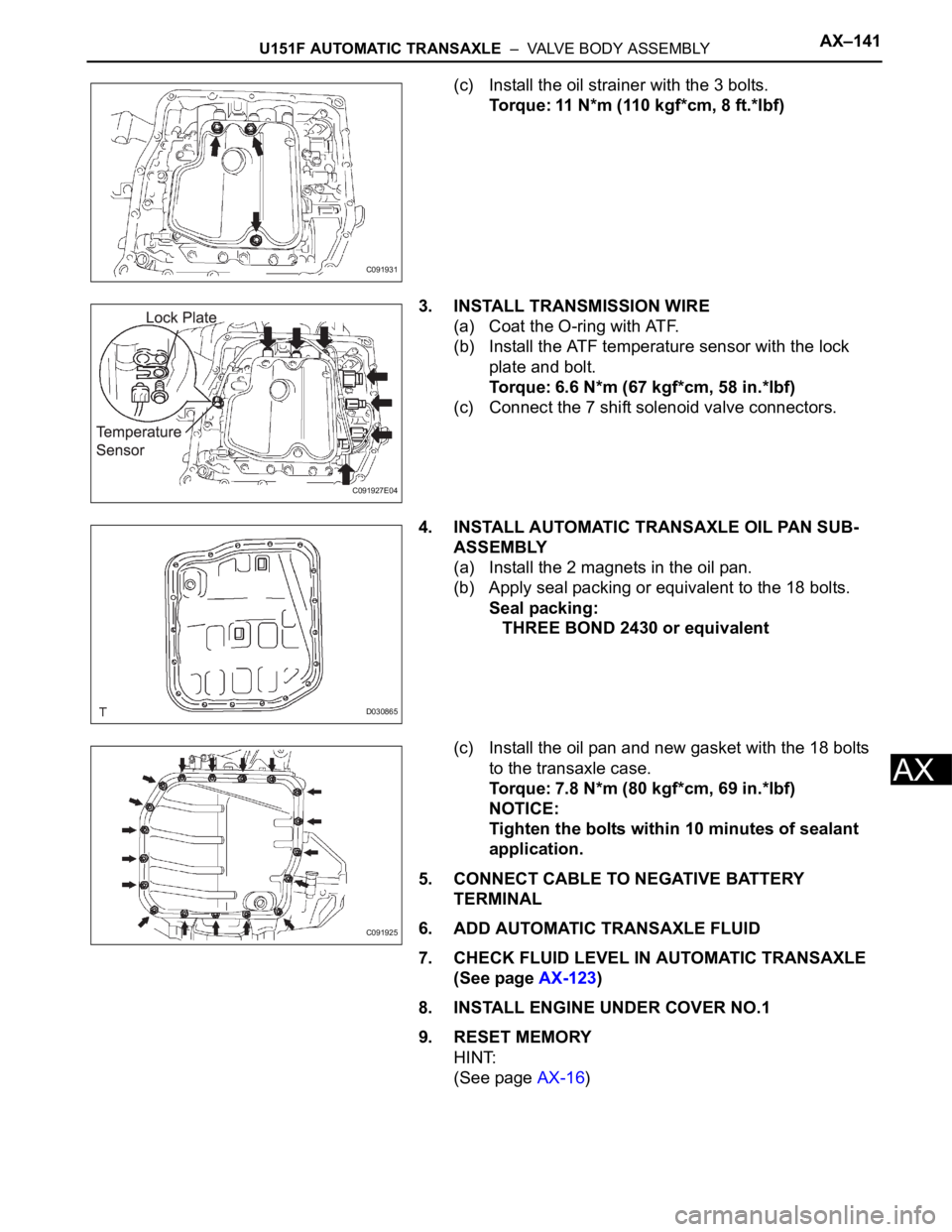

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

3. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(c) Connect the 7 shift solenoid valve connectors.

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing or equivalent to the 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

(c) Install the oil pan and new gasket with the 18 bolts

to the transaxle case.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

Tighten the bolts within 10 minutes of sealant

application.

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. ADD AUTOMATIC TRANSAXLE FLUID

7. CHECK FLUID LEVEL IN AUTOMATIC TRANSAXLE

(See page AX-123)

8. INSTALL ENGINE UNDER COVER NO.1

9. RESET MEMORY

HINT:

(See page AX-16)

C091931

C091927E04

D030865

C091925

Page 1828 of 3000

AX–22U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

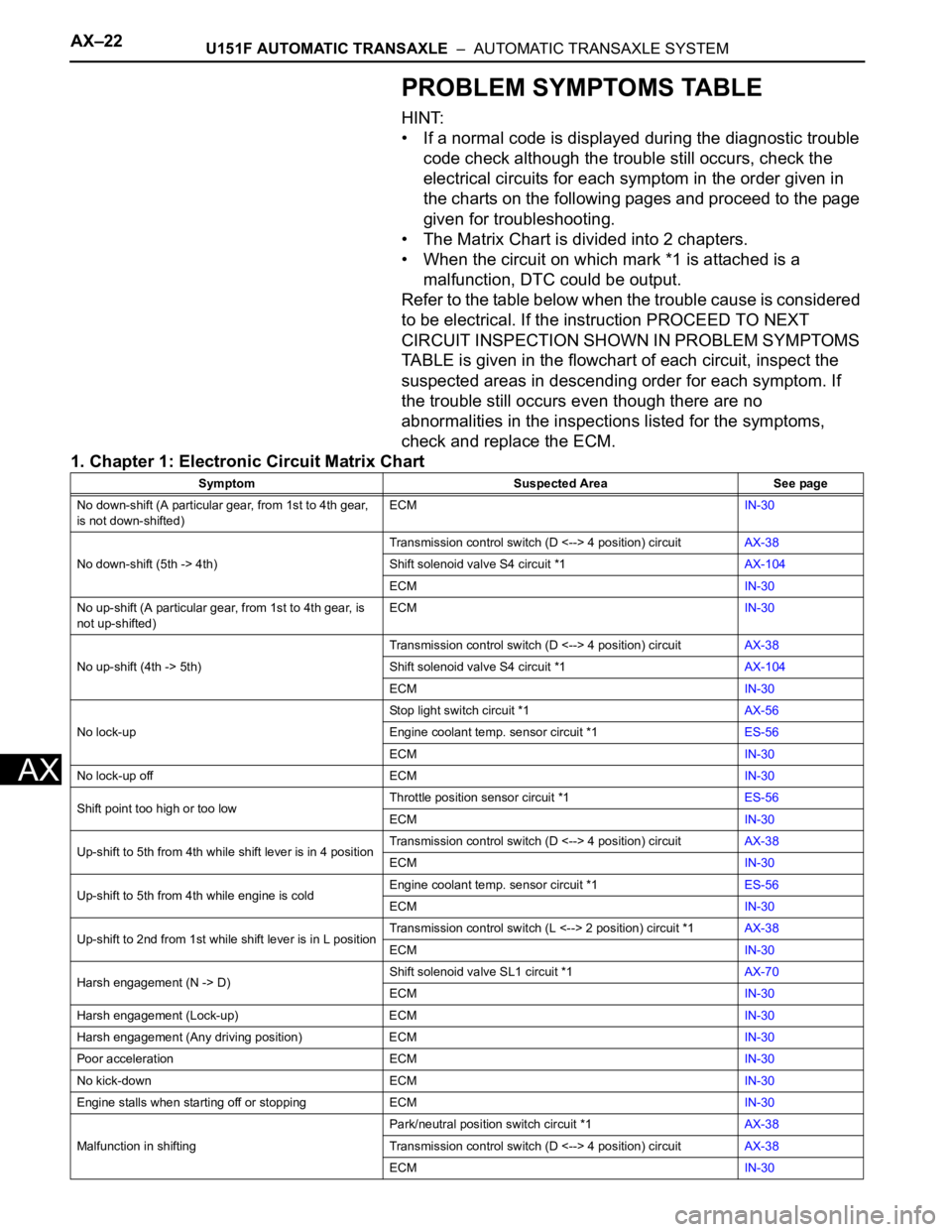

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Page 1829 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–23

AX

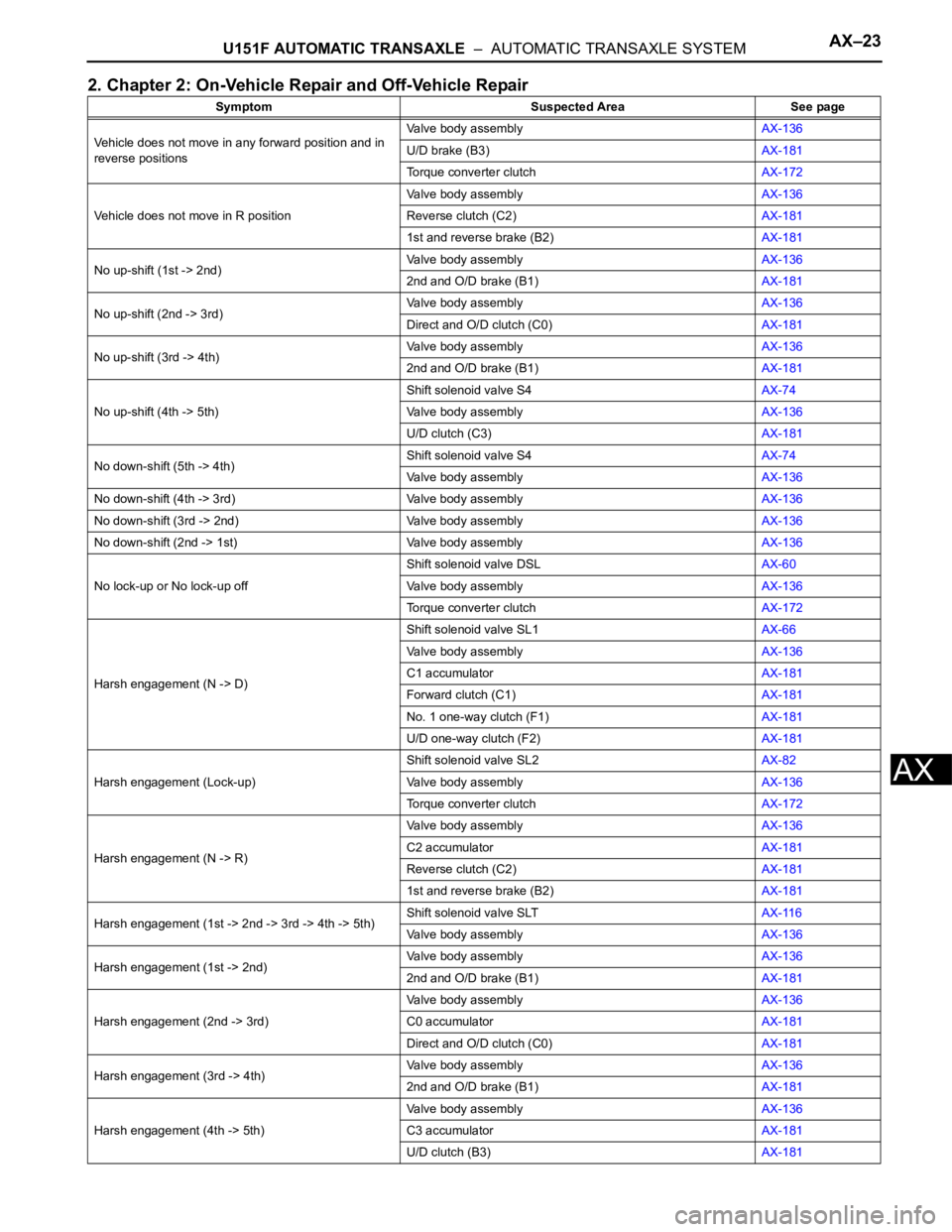

2. Chapter 2: On-Vehicle Repair and Off-Vehicle Repair

Symptom Suspected Area See page

Vehicle does not move in any forward position and in

reverse positionsValve body assemblyAX-136

U/D brake (B3)AX-181

Torque converter clutchAX-172

Vehicle does not move in R positionValve body assemblyAX-136

Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

No up-shift (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No up-shift (2nd -> 3rd)Valve body assemblyAX-136

Direct and O/D clutch (C0)AX-181

No up-shift (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No up-shift (4th -> 5th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

U/D clutch (C3)AX-181

No down-shift (5th -> 4th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

No down-shift (4th -> 3rd) Valve body assemblyAX-136

No down-shift (3rd -> 2nd) Valve body assemblyAX-136

No down-shift (2nd -> 1st) Valve body assemblyAX-136

No lock-up or No lock-up offShift solenoid valve DSLAX-60

Valve body assemblyAX-136

Torque converter clutchAX-172

Harsh engagement (N -> D)Shift solenoid valve SL1AX-66

Valve body assemblyAX-136

C1 accumulatorAX-181

Forward clutch (C1)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Harsh engagement (Lock-up)Shift solenoid valve SL2AX-82

Valve body assemblyAX-136

Torque converter clutchAX-172

Harsh engagement (N -> R)Valve body assemblyAX-136

C2 accumulatorAX-181

Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

Harsh engagement (1st -> 2nd -> 3rd -> 4th -> 5th)Shift solenoid valve SLTAX-116

Valve body assemblyAX-136

Harsh engagement (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

Harsh engagement (2nd -> 3rd)Valve body assemblyAX-136

C0 accumulatorAX-181

Direct and O/D clutch (C0)AX-181

Harsh engagement (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

Harsh engagement (4th -> 5th)Valve body assemblyAX-136

C3 accumulatorAX-181

U/D clutch (B3)AX-181

Page 1830 of 3000

AX–24U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

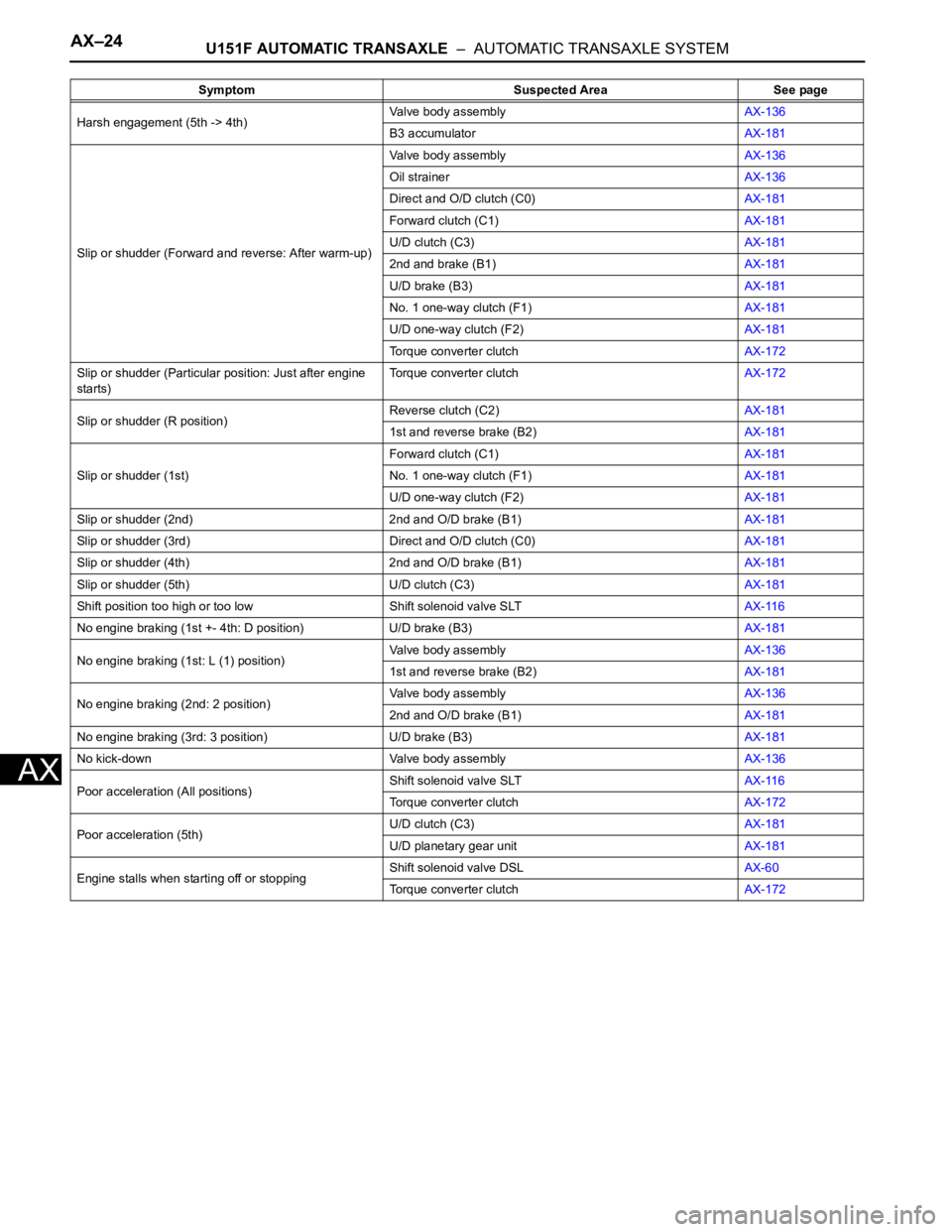

Harsh engagement (5th -> 4th)Valve body assemblyAX-136

B3 accumulatorAX-181

Slip or shudder (Forward and reverse: After warm-up)Valve body assemblyAX-136

Oil strainerAX-136

Direct and O/D clutch (C0)AX-181

Forward clutch (C1)AX-181

U/D clutch (C3)AX-181

2nd and brake (B1)AX-181

U/D brake (B3)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Torque converter clutchAX-172

Slip or shudder (Particular position: Just after engine

starts)Torque converter clutchAX-172

Slip or shudder (R position)Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

Slip or shudder (1st)Forward clutch (C1)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Slip or shudder (2nd) 2nd and O/D brake (B1)AX-181

Slip or shudder (3rd) Direct and O/D clutch (C0)AX-181

Slip or shudder (4th) 2nd and O/D brake (B1)AX-181

Slip or shudder (5th) U/D clutch (C3)AX-181

Shift position too high or too low Shift solenoid valve SLTAX-116

No engine braking (1st +- 4th: D position) U/D brake (B3)AX-181

No engine braking (1st: L (1) position)Valve body assemblyAX-136

1st and reverse brake (B2)AX-181

No engine braking (2nd: 2 position)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No engine braking (3rd: 3 position) U/D brake (B3)AX-181

No kick-down Valve body assemblyAX-136

Poor acceleration (All positions)Shift solenoid valve SLTAX-116

Torque converter clutchAX-172

Poor acceleration (5th)U/D clutch (C3)AX-181

U/D planetary gear unitAX-181

Engine stalls when starting off or stoppingShift solenoid valve DSLAX-60

Torque converter clutchAX-172 Symptom Suspected Area See page