TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1811 of 3000

AX–128U151F AUTOMATIC TRANSAXLE – PARK / NEUTRAL POSITION SWITCH

AX

INSTALLATION

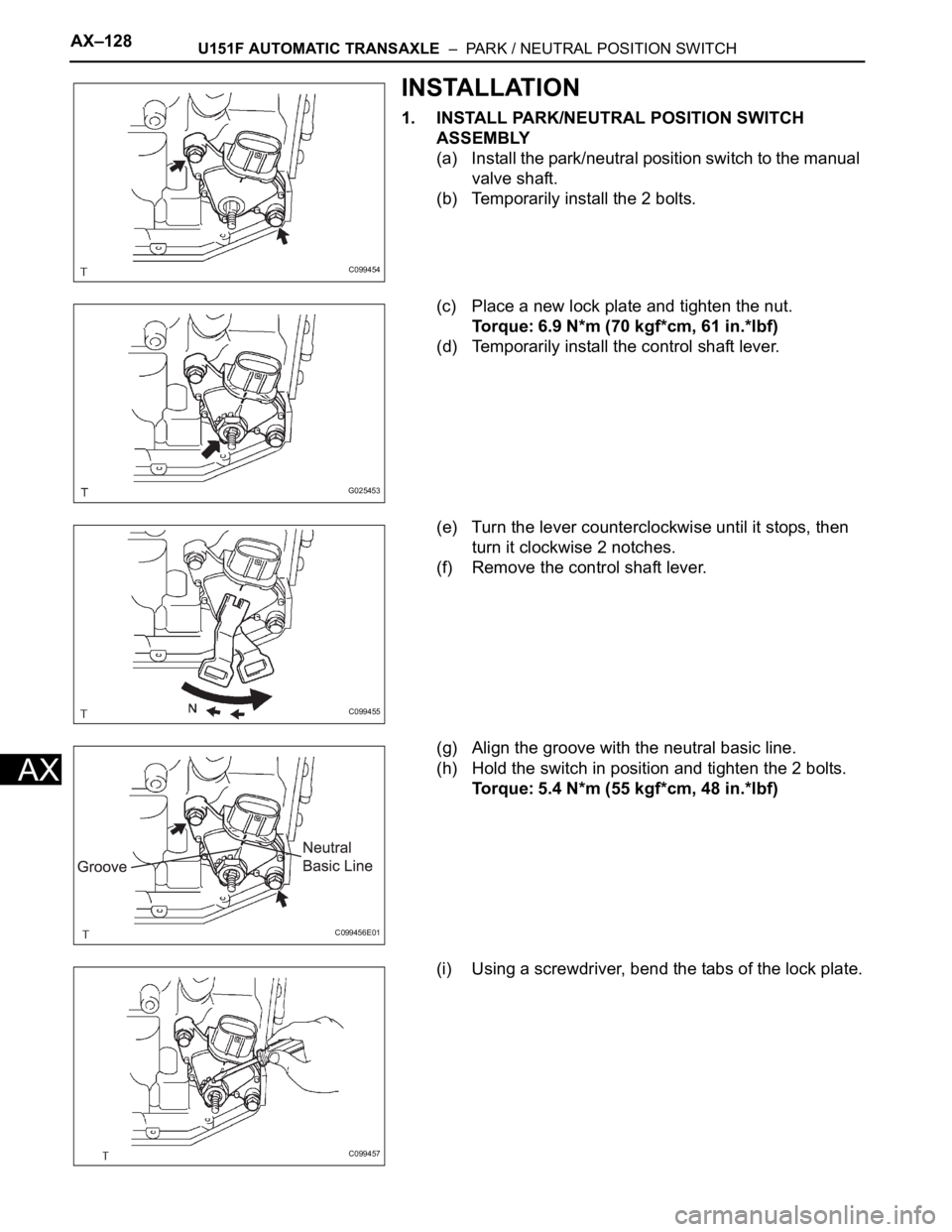

1. INSTALL PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Install the park/neutral position switch to the manual

valve shaft.

(b) Temporarily install the 2 bolts.

(c) Place a new lock plate and tighten the nut.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(d) Temporarily install the control shaft lever.

(e) Turn the lever counterclockwise until it stops, then

turn it clockwise 2 notches.

(f) Remove the control shaft lever.

(g) Align the groove with the neutral basic line.

(h) Hold the switch in position and tighten the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(i) Using a screwdriver, bend the tabs of the lock plate.

C099454

G025453

C099455

C099456E01

C099457

Page 1812 of 3000

U151F AUTOMATIC TRANSAXLE – PARK / NEUTRAL POSITION SWITCHAX–129

AX

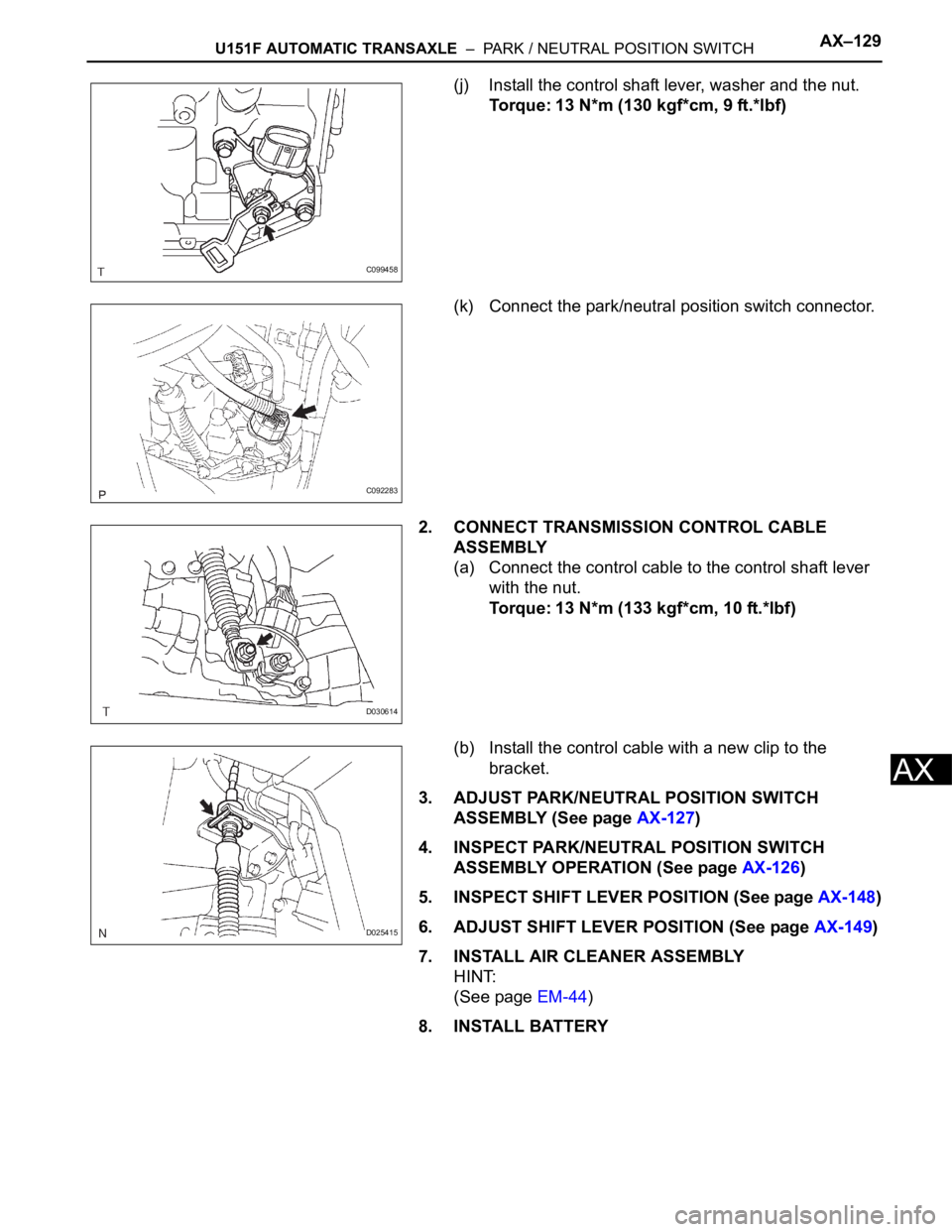

(j) Install the control shaft lever, washer and the nut.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

(k) Connect the park/neutral position switch connector.

2. CONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Connect the control cable to the control shaft lever

with the nut.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

(b) Install the control cable with a new clip to the

bracket.

3. ADJUST PARK/NEUTRAL POSITION SWITCH

ASSEMBLY (See page AX-127)

4. INSPECT PARK/NEUTRAL POSITION SWITCH

ASSEMBLY OPERATION (See page AX-126)

5. INSPECT SHIFT LEVER POSITION (See page AX-148)

6. ADJUST SHIFT LEVER POSITION (See page AX-149)

7. INSTALL AIR CLEANER ASSEMBLY

HINT:

(See page EM-44)

8. INSTALL BATTERY

C099458

C092283

D030614

D025415

Page 1813 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–17

AX

MANUAL SHIFTING TEST

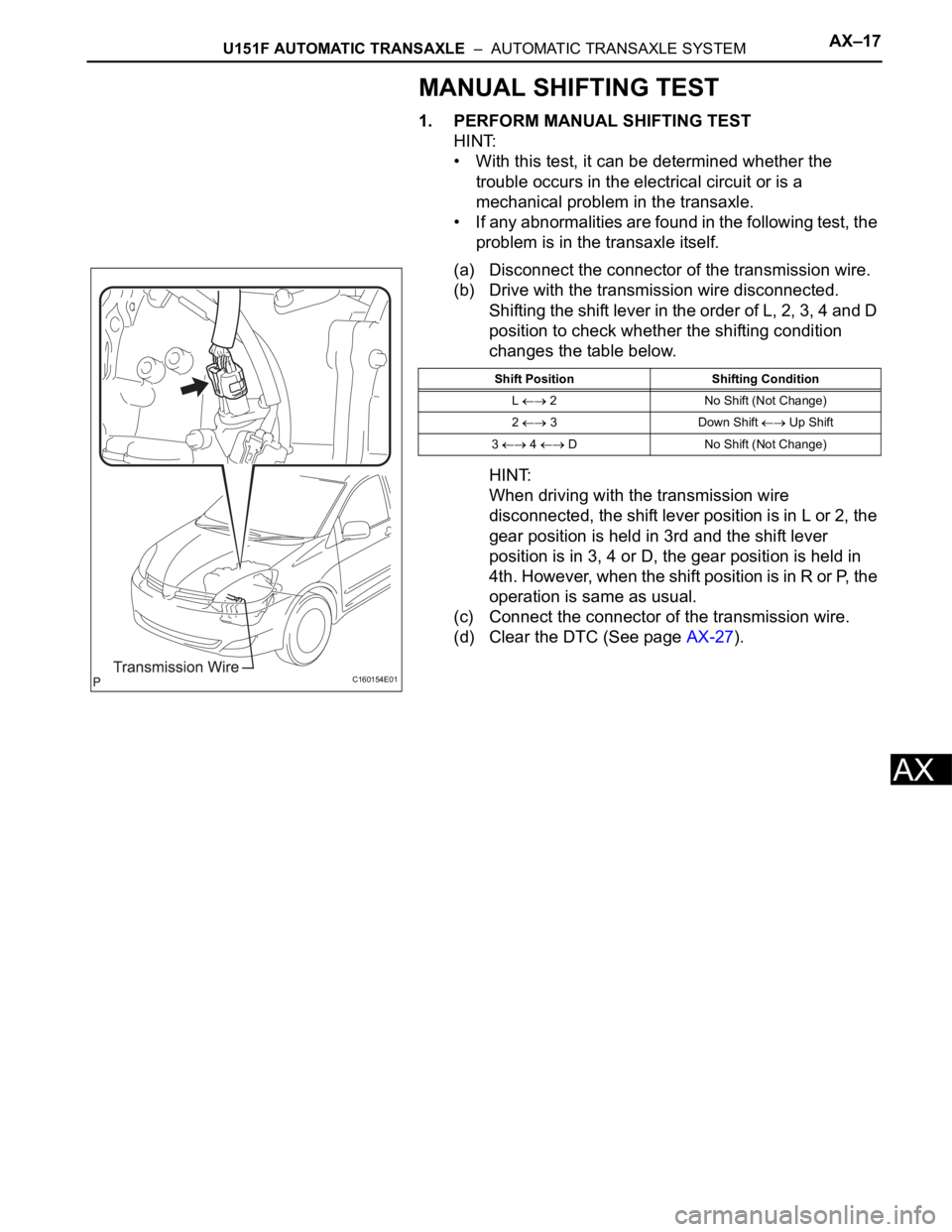

1. PERFORM MANUAL SHIFTING TEST

HINT:

• With this test, it can be determined whether the

trouble occurs in the electrical circuit or is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(a) Disconnect the connector of the transmission wire.

(b) Drive with the transmission wire disconnected.

Shifting the shift lever in the order of L, 2, 3, 4 and D

position to check whether the shifting condition

changes the table below.

HINT:

When driving with the transmission wire

disconnected, the shift lever position is in L or 2, the

gear position is held in 3rd and the shift lever

position is in 3, 4 or D, the gear position is held in

4th. However, when the shift position is in R or P, the

operation is same as usual.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (See page AX-27).

C160154E01

Shift Position Shifting Condition

L

2 No Shift (Not Change)

2

3 Down Shift Up Shift

3

4 D No Shift (Not Change)

Page 1814 of 3000

AX–18U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

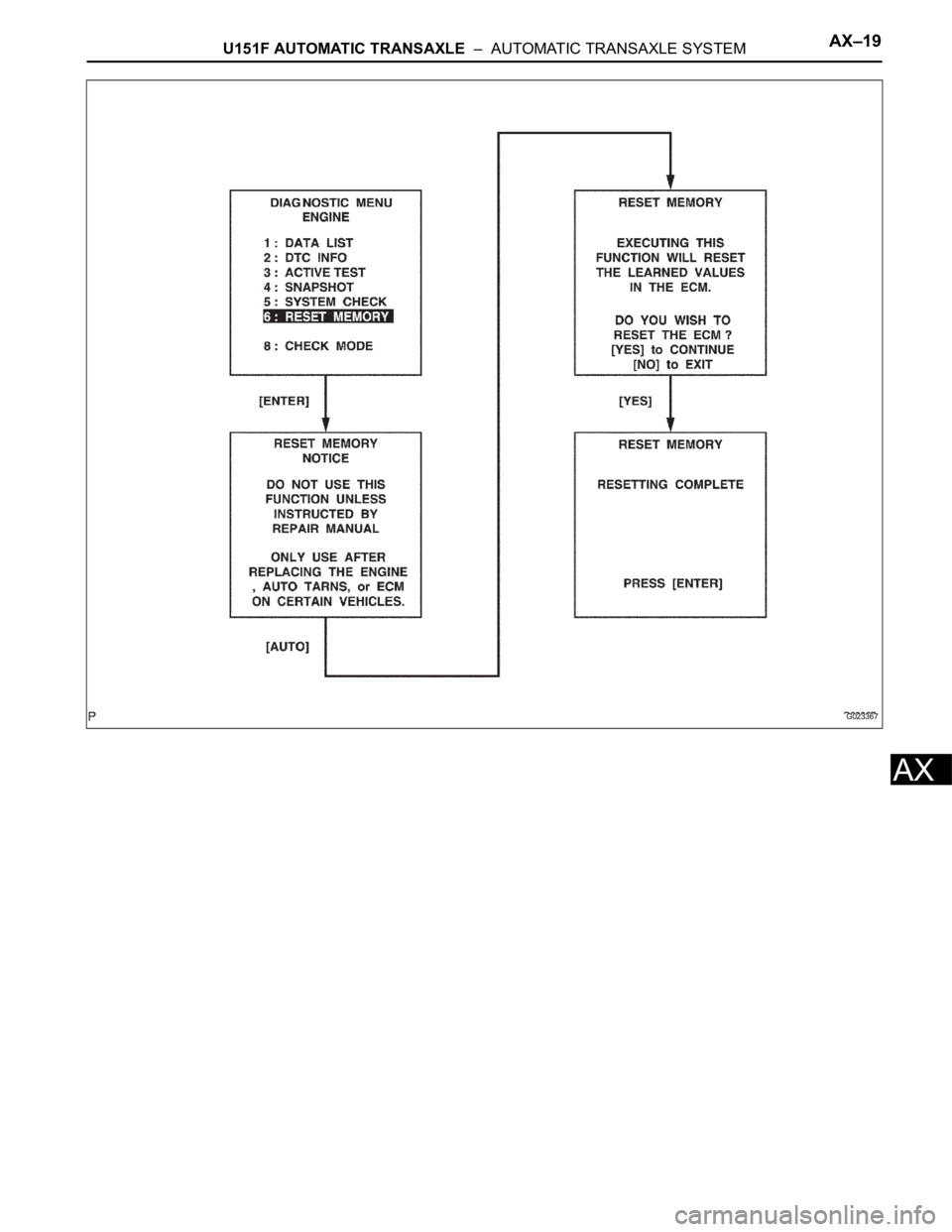

INITIALIZATION

1. RESET MEMORY

NOTICE:

• Perform the RESET MEMORY (AT initialization)

when replacing the automatic transaxle assembly,

engine assembly or ECM.

• The RESET MEMORY can be performed only with

the Intelligent tester.

HINT:

The ECM memorizes the condition that the ECT controls

the automatic transaxle assembly and engine assembly

according to those characteristics. Therefore, when the

automatic transaxle assembly, engine assembly, or ECM

has been replaced, it is necessary to reset the memory

so that the ECM can memorize the new information.

Reset procedure is as follows.

(a) Turn the engine switch off.

(b) Connect the intelligent tester together with the CAN

VIM (controller area network vehicle interface

module) to the DLC3.

(c) Turn the ignition switch to the ON position and push

the intelligent tester main switch on.

(d) Select the item "DIAGNOSIS / ENHANCED OBD

II".

(e) Perform the reset memory procedure from the

ENGINE menu.

CAUTION:

After performing the RESET MEMORY, be sure

to perform the ROAD TEST (See page AX-9)

described earlier.

HINT:

The ECM is learned by performing the ROAD TEST.

(1) Tester menu flow:

Page 1815 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–19

AX

G023367

Page 1816 of 3000

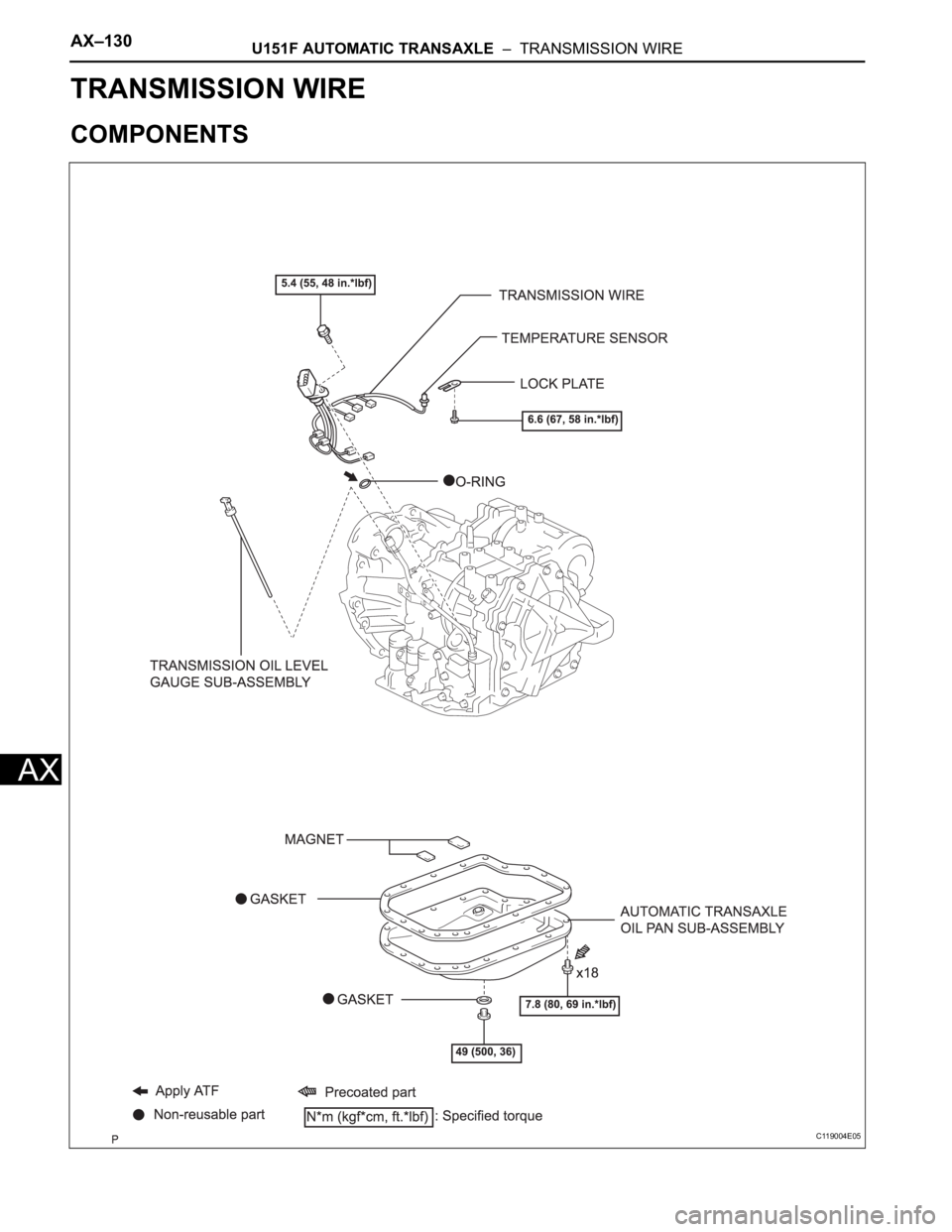

AX–130U151F AUTOMATIC TRANSAXLE – TRANSMISSION WIRE

AX

TRANSMISSION

U151F AUTOMATIC TRANSAXLE

TRANSMISSION WIRE

COMPONENTS

C119004E05

Page 1817 of 3000

U151F AUTOMATIC TRANSAXLE – TRANSMISSION WIREAX–131

AX

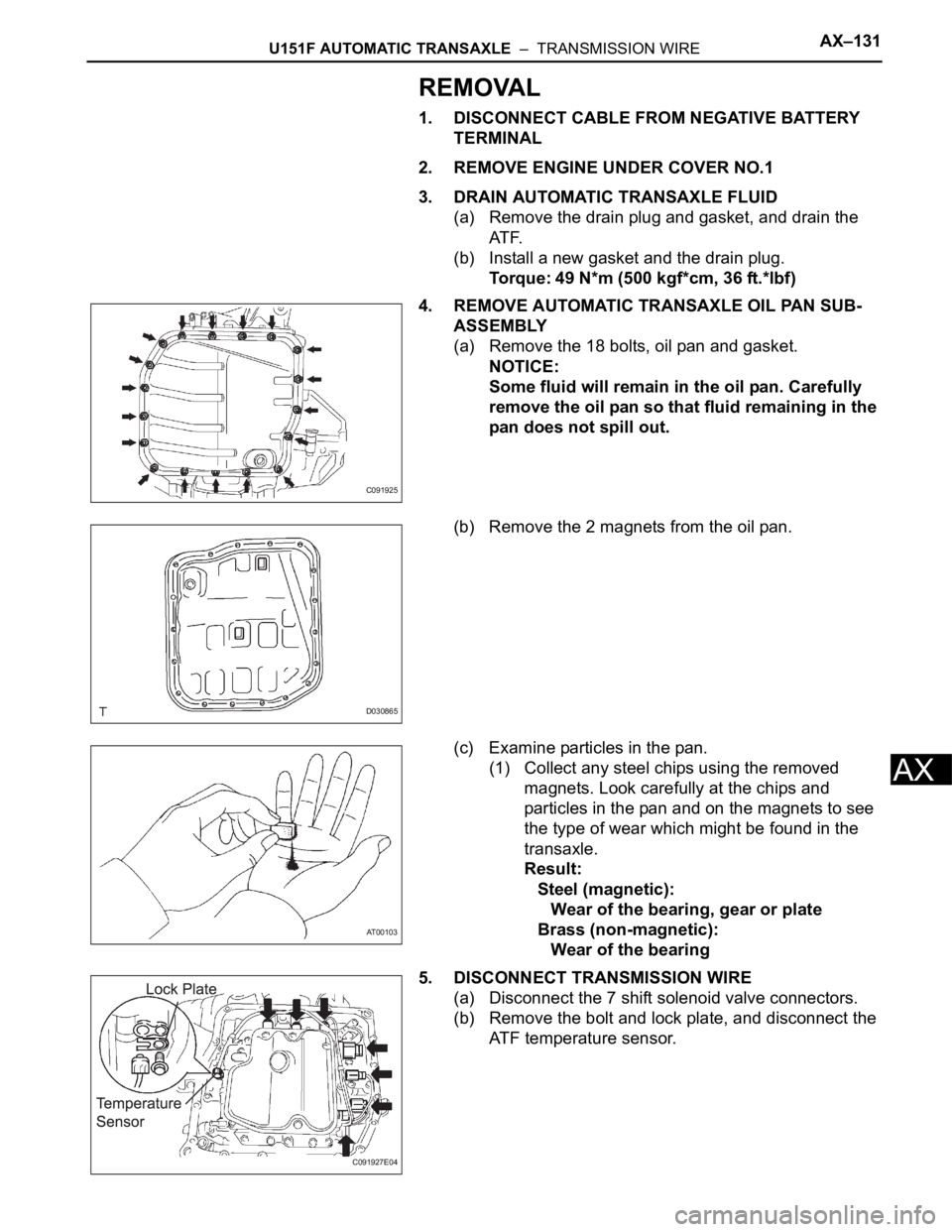

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug and gasket, and drain the

AT F.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

4. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

NOTICE:

Some fluid will remain in the oil pan. Carefully

remove the oil pan so that fluid remaining in the

pan does not spill out.

(b) Remove the 2 magnets from the oil pan.

(c) Examine particles in the pan.

(1) Collect any steel chips using the removed

magnets. Look carefully at the chips and

particles in the pan and on the magnets to see

the type of wear which might be found in the

transaxle.

Result:

Steel (magnetic):

Wear of the bearing, gear or plate

Brass (non-magnetic):

Wear of the bearing

5. DISCONNECT TRANSMISSION WIRE

(a) Disconnect the 7 shift solenoid valve connectors.

(b) Remove the bolt and lock plate, and disconnect the

ATF temperature sensor.

C091925

D030865

AT00103

C091927E04

Page 1818 of 3000

AX–132U151F AUTOMATIC TRANSAXLE – TRANSMISSION WIRE

AX

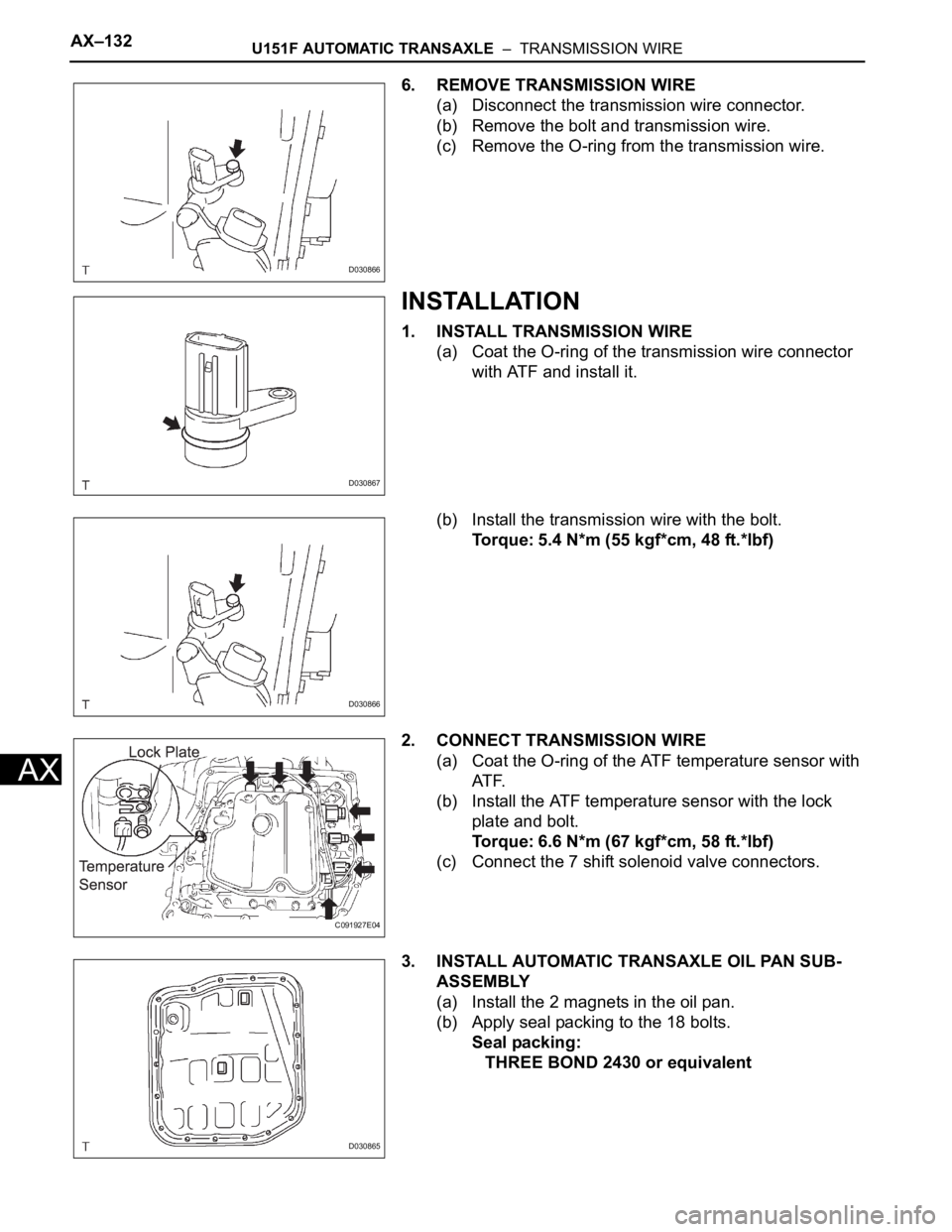

6. REMOVE TRANSMISSION WIRE

(a) Disconnect the transmission wire connector.

(b) Remove the bolt and transmission wire.

(c) Remove the O-ring from the transmission wire.

INSTALLATION

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring of the transmission wire connector

with ATF and install it.

(b) Install the transmission wire with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 ft.*lbf)

2. CONNECT TRANSMISSION WIRE

(a) Coat the O-ring of the ATF temperature sensor with

AT F.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 ft.*lbf)

(c) Connect the 7 shift solenoid valve connectors.

3. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing to the 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

D030866

D030867

D030866

C091927E04

D030865

Page 1819 of 3000

U151F AUTOMATIC TRANSAXLE – TRANSMISSION WIREAX–133

AX

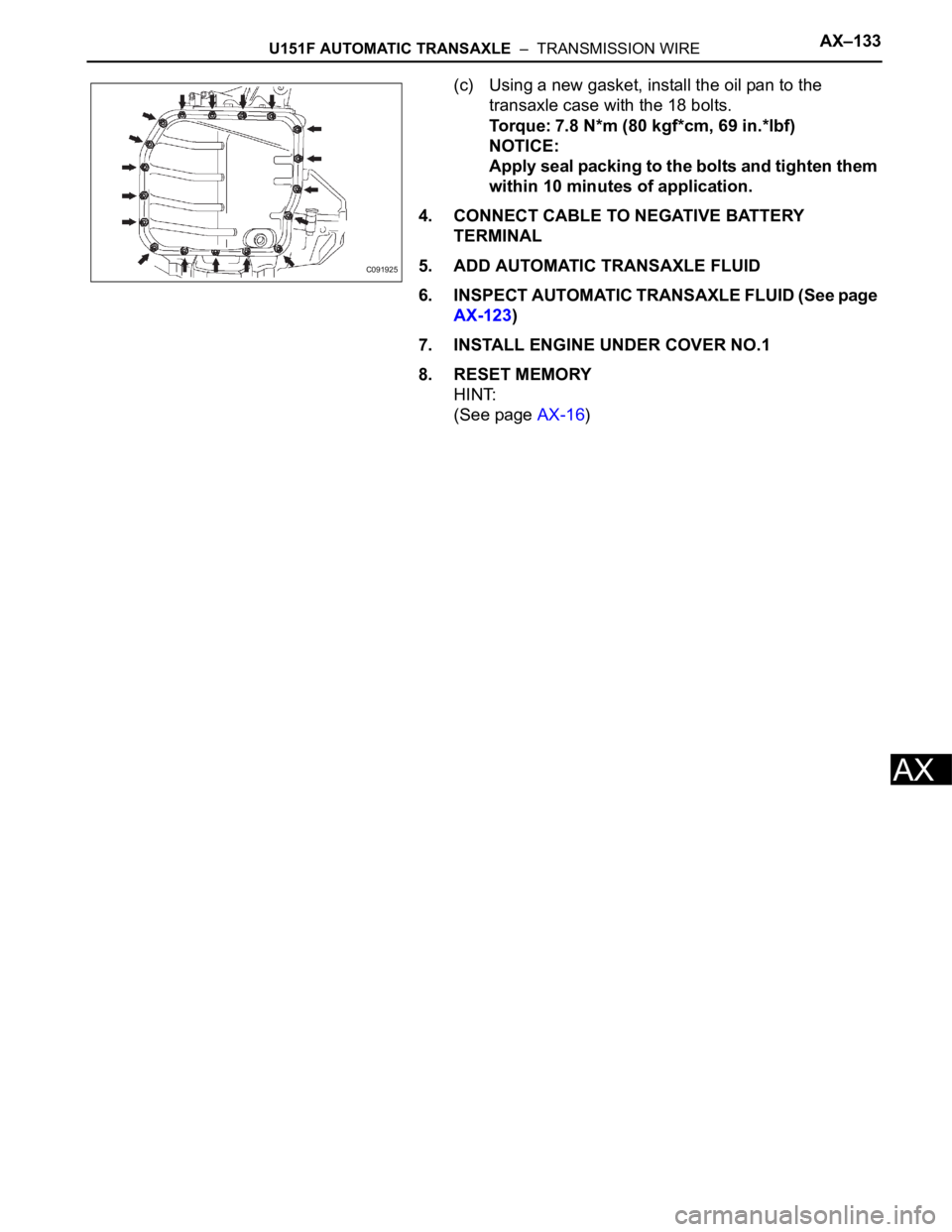

(c) Using a new gasket, install the oil pan to the

transaxle case with the 18 bolts.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

Apply seal packing to the bolts and tighten them

within 10 minutes of application.

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. ADD AUTOMATIC TRANSAXLE FLUID

6. INSPECT AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

7. INSTALL ENGINE UNDER COVER NO.1

8. RESET MEMORY

HINT:

(See page AX-16)

C091925

Page 1820 of 3000

AX–20U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MONITOR DRIVE PATTERN

1. MONITOR DRIVE PATTERN FOR ECT TEST

(a) Perform this drive pattern as one method to

simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due

the actual driving conditions. And some codes may

not be detected through this drive pattern.)

HINT:

Preparation for driving

• Warm up the engine sufficiently. (Engine coolant

temperature is 60

C (140F) or higher)

• Drive the vehicle when the atmospheric

temperature is -10

C (14F) or higher.

(Malfunction is not detected when the

atmospheric temperature is less than -10

C

(14

F))

Driving note

• Drive the vehicle through all gears.

Stop

1st 2nd 3rd 4th 5th 5th

(lock-up ON).

• Repeat the above driving pattern three times or

more.

NOTICE:

• The monitor status can be checked using the

OBD II scan tool or intelligent tester. When

using the intelligent tester, monitor status

can be found in the "ENHANCED OBD II /

DATA LIST" or under "CARB OBD II".

• In the event that the drive pattern must be

interrupted (possibly due to traffic conditions

or other factors), the drive pattern can be

resumed and, in most cases, the monitor can

be completed.

• Perform this drive pattern on a level road as

much as possible and strictly observe the

posted speed limits and traffic laws while

driving.