TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1851 of 3000

AX–156U151F AUTOMATIC TRANSAXLE – TRANSMISSION CONTROL CABLE ASSEMBLY

AX

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated.

(b) When starting engine, make sure that the vehicle

moves forward when shifting from N to D position

and moves rearward when shifting to R position.

2. ADJUST SHIFT LEVER POSITION

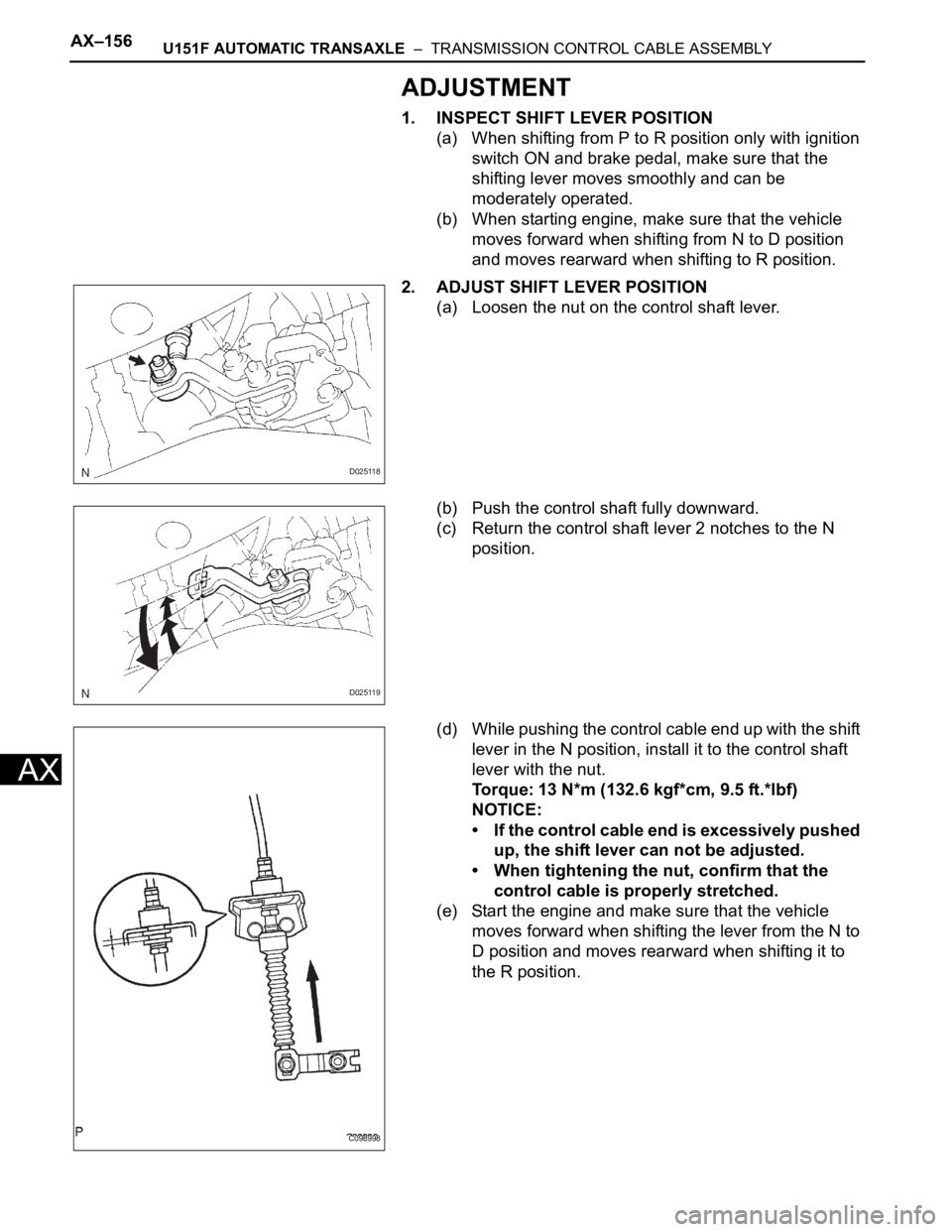

(a) Loosen the nut on the control shaft lever.

(b) Push the control shaft fully downward.

(c) Return the control shaft lever 2 notches to the N

position.

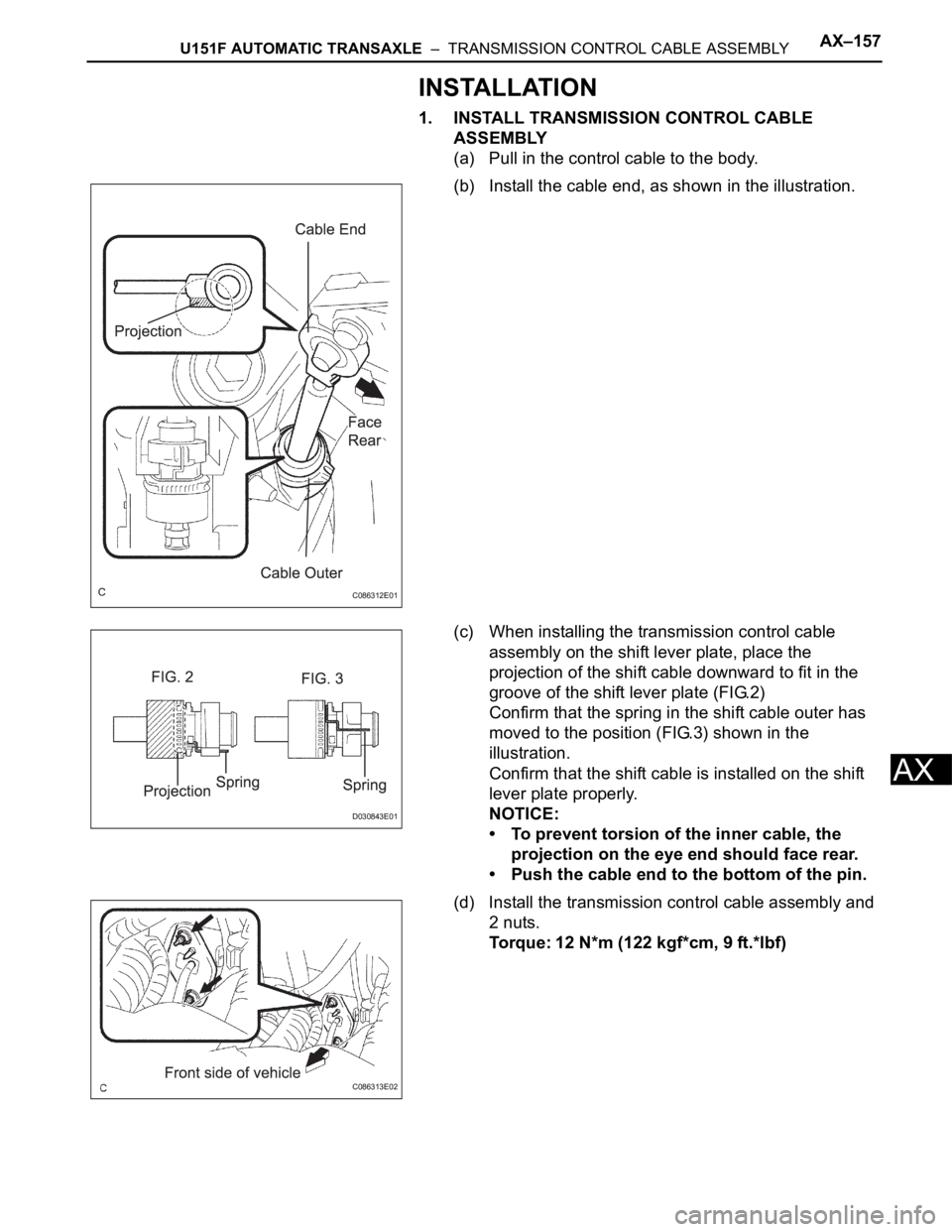

(d) While pushing the control cable end up with the shift

lever in the N position, install it to the control shaft

lever with the nut.

Torque: 13 N*m (132.6 kgf*cm, 9.5 ft.*lbf)

NOTICE:

• If the control cable end is excessively pushed

up, the shift lever can not be adjusted.

• When tightening the nut, confirm that the

control cable is properly stretched.

(e) Start the engine and make sure that the vehicle

moves forward when shifting the lever from the N to

D position and moves rearward when shifting it to

the R position.

D025118

D025119

C098998

Page 1852 of 3000

U151F AUTOMATIC TRANSAXLE – TRANSMISSION CONTROL CABLE ASSEMBLYAX–157

AX

INSTALLATION

1. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY

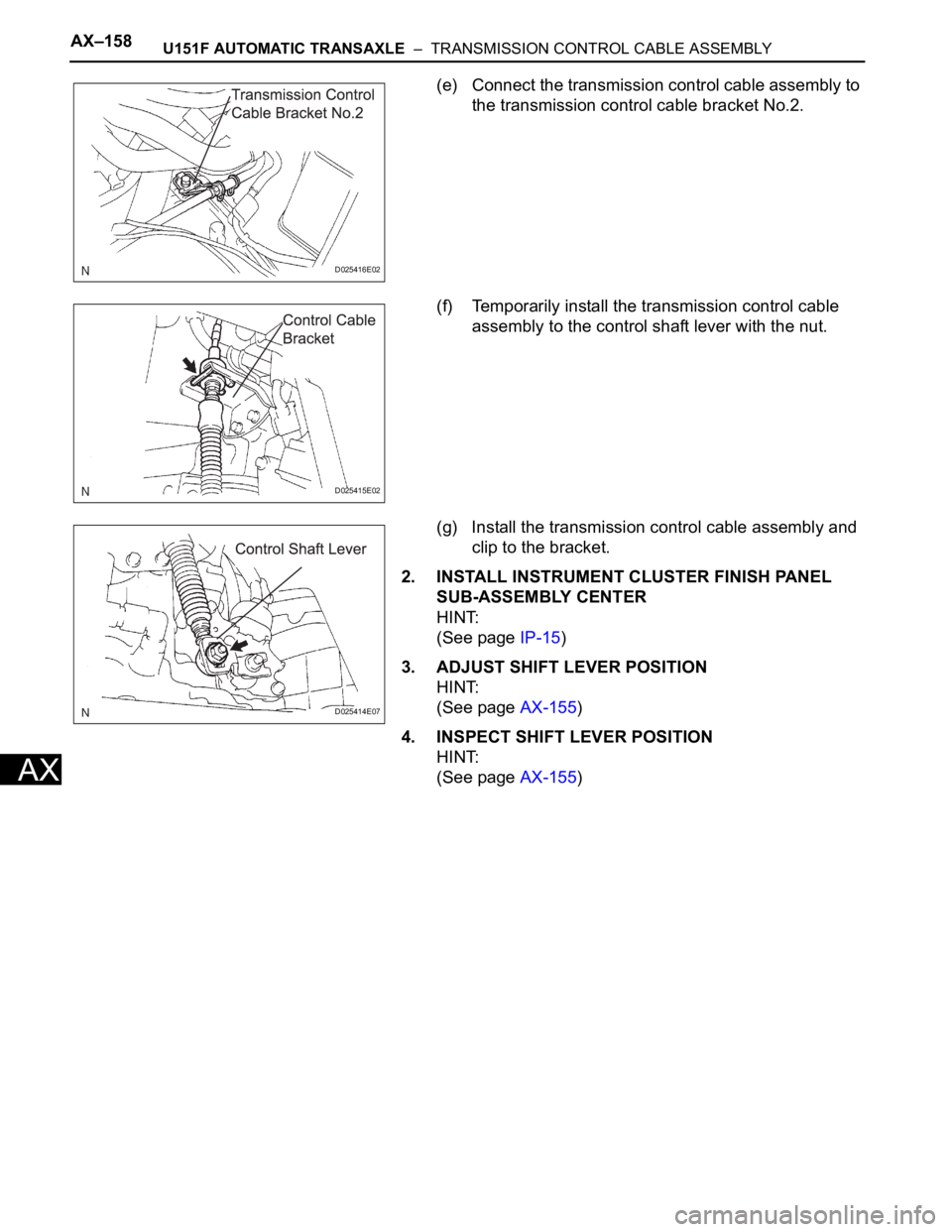

(a) Pull in the control cable to the body.

(b) Install the cable end, as shown in the illustration.

(c) When installing the transmission control cable

assembly on the shift lever plate, place the

projection of the shift cable downward to fit in the

groove of the shift lever plate (FIG.2)

Confirm that the spring in the shift cable outer has

moved to the position (FIG.3) shown in the

illustration.

Confirm that the shift cable is installed on the shift

lever plate properly.

NOTICE:

• To prevent torsion of the inner cable, the

projection on the eye end should face rear.

• Push the cable end to the bottom of the pin.

(d) Install the transmission control cable assembly and

2 nuts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

C086312E01

D030843E01

C086313E02

Page 1853 of 3000

AX–158U151F AUTOMATIC TRANSAXLE – TRANSMISSION CONTROL CABLE ASSEMBLY

AX

(e) Connect the transmission control cable assembly to

the transmission control cable bracket No.2.

(f) Temporarily install the transmission control cable

assembly to the control shaft lever with the nut.

(g) Install the transmission control cable assembly and

clip to the bracket.

2. INSTALL INSTRUMENT CLUSTER FINISH PANEL

SUB-ASSEMBLY CENTER

HINT:

(See page IP-15)

3. ADJUST SHIFT LEVER POSITION

HINT:

(See page AX-155)

4. INSPECT SHIFT LEVER POSITION

HINT:

(See page AX-155)

D025416E02

D025415E02

D025414E07

Page 1854 of 3000

AX–32U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DTC CHECK / CLEAR

1. DTC CHECK (NORMAL MODE)

NOTICE:

When the diagnostic system is switched from the

normal mode to the check mode, all the DTCs and

freeze frame data recorded in the normal mode will

be erased. So before switching modes, always check

the DTCs and freeze frame data, and note them

down.

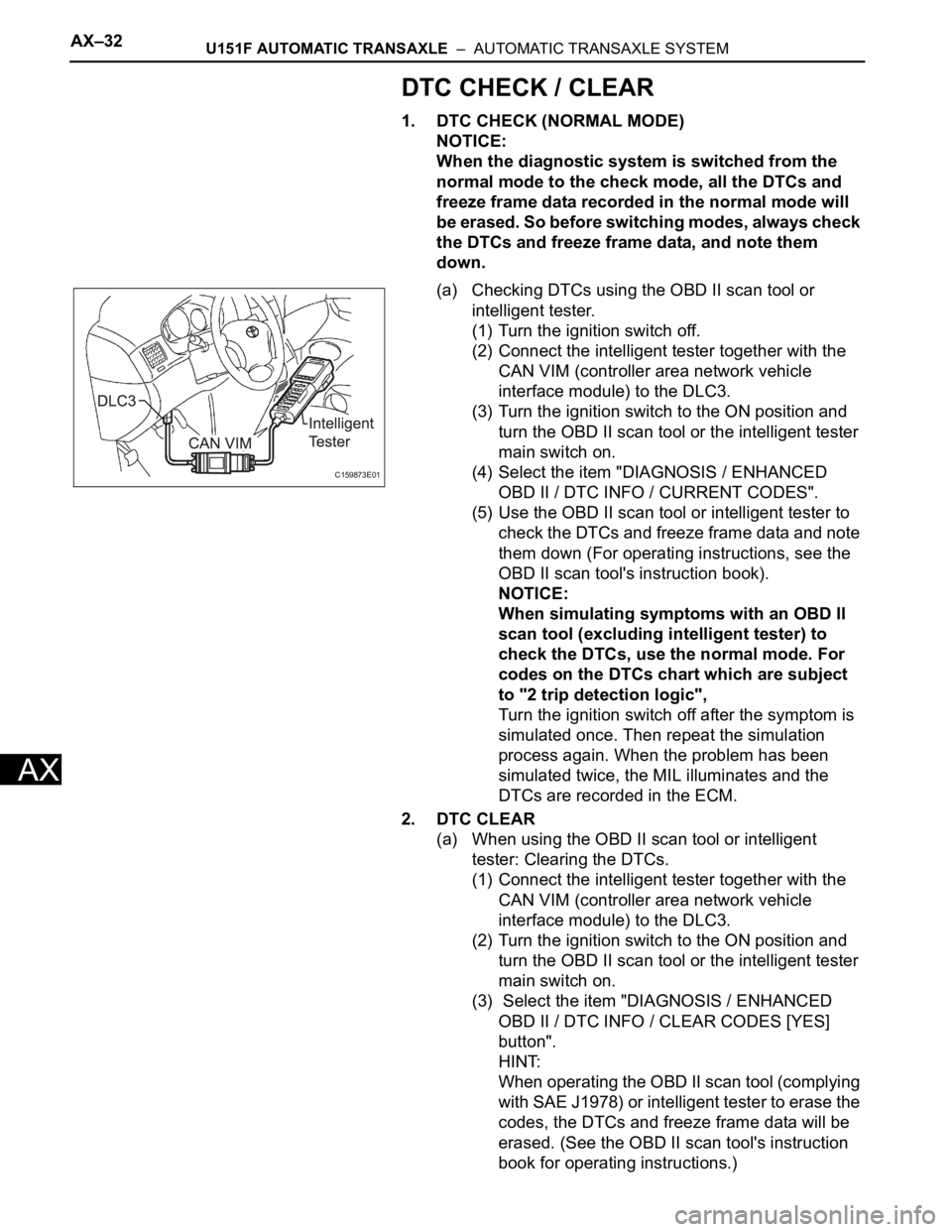

(a) Checking DTCs using the OBD II scan tool or

intelligent tester.

(1) Turn the ignition switch off.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Turn the ignition switch to the ON position and

turn the OBD II scan tool or the intelligent tester

main switch on.

(4) Select the item "DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CURRENT CODES".

(5) Use the OBD II scan tool or intelligent tester to

check the DTCs and freeze frame data and note

them down (For operating instructions, see the

OBD II scan tool's instruction book).

NOTICE:

When simulating symptoms with an OBD II

scan tool (excluding intelligent tester) to

check the DTCs, use the normal mode. For

codes on the DTCs chart which are subject

to "2 trip detection logic",

Turn the ignition switch off after the symptom is

simulated once. Then repeat the simulation

process again. When the problem has been

simulated twice, the MIL illuminates and the

DTCs are recorded in the ECM.

2. DTC CLEAR

(a) When using the OBD II scan tool or intelligent

tester: Clearing the DTCs.

(1) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(2) Turn the ignition switch to the ON position and

turn the OBD II scan tool or the intelligent tester

main switch on.

(3) Select the item "DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CLEAR CODES [YES]

button".

HINT:

When operating the OBD II scan tool (complying

with SAE J1978) or intelligent tester to erase the

codes, the DTCs and freeze frame data will be

erased. (See the OBD II scan tool's instruction

book for operating instructions.)

C159873E01

Page 1855 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–33

AX

(b) When not using the OBD II scan tool or intelligent

tester: Clearing the DTCs.

(1) Disconnect the battery terminal or remove the

EFI and ETCS fuses from the engine room J/B

for 60 seconds or more. However, if you

disconnect the battery terminal, perform do the

"INITIALIZE" procedure.

Page 1856 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–181

AX

DISASSEMBLY

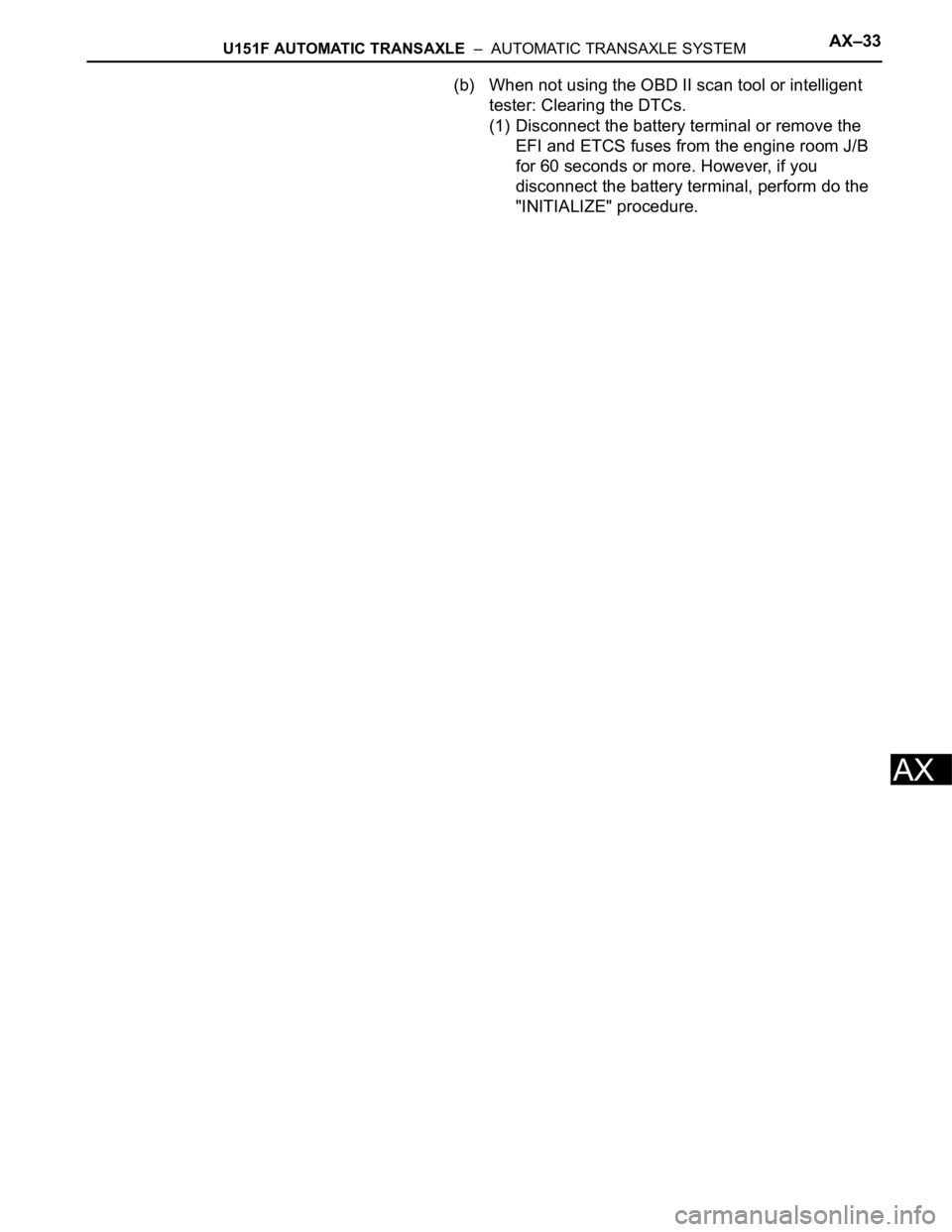

1. REMOVE PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Remove the nut, washer and control shaft lever.

(b) Using a screwdriver, unstake the nut stopper, and

remove the lock nut and nut stopper.

(c) Remove the 2 bolts and pull out the park/neutral

position switch.

2. REMOVE BREATHER PLUG HOSE

(a) Remove the breather plug hose from the transaxle

case.

3. REMOVE OIL COOLER TUBE UNION (INLET OIL

COOLER UNION)

(a) Remove the union.

(b) Remove the O-ring from the union.

4. REMOVE OIL COOLER TUBE UNION (OUTLET OIL

COOLER UNION)

(a) Remove the elbow.

(b) Remove the O-ring from the elbow.

D009644E01

D009643E01

D009639E01

C083143E01

C083144E01

Page 1857 of 3000

AX–182U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

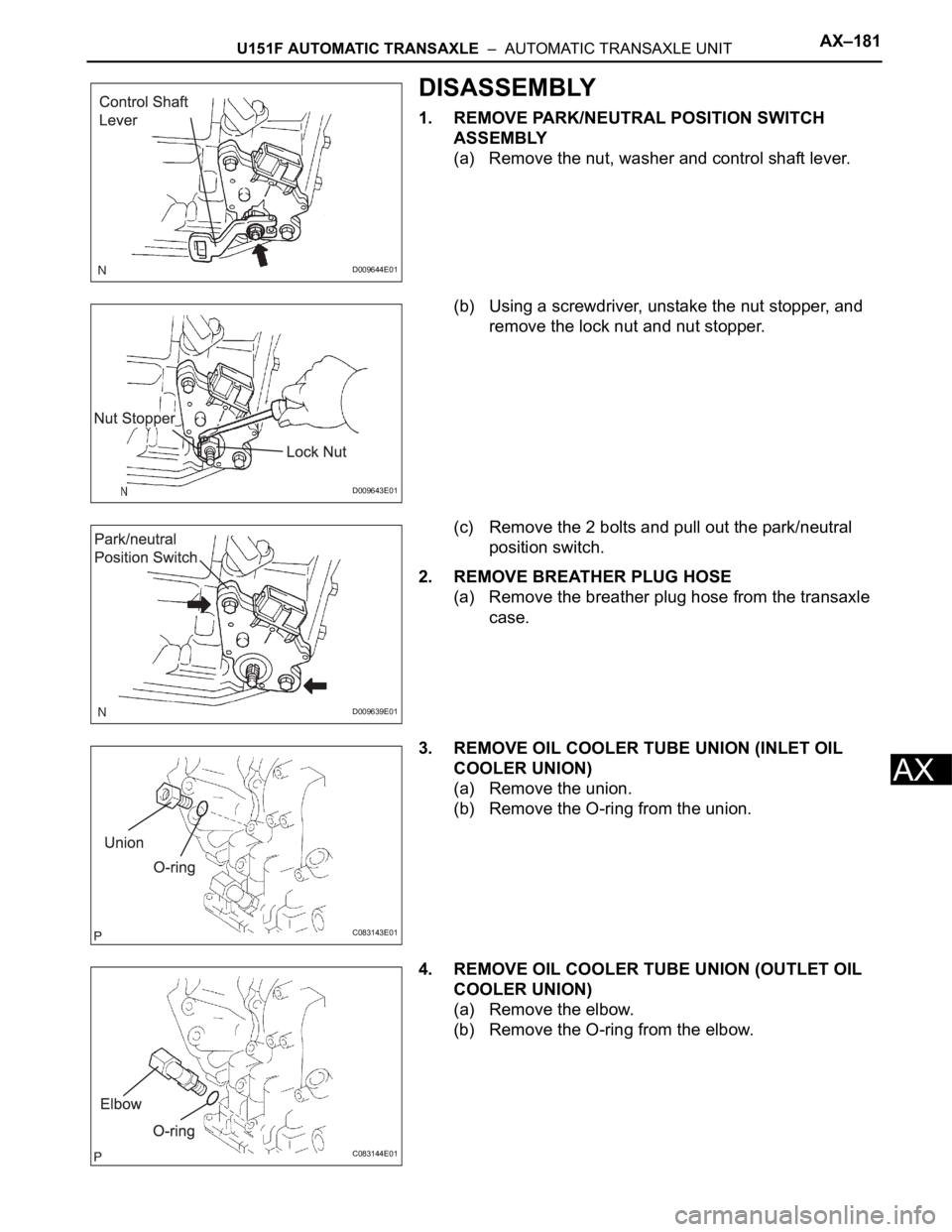

5. REMOVE SPEED SENSOR

(a) Remove the 2 bolts and the 2 speed sensors from

the transaxle assembly.

6. REMOVE TRANSAXLE CASE NO.1 PLUG

(a) Remove the 4 transaxle case No.1 plugs from the

transaxle case.

(b) Remove the 4 O-rings from the 4 transaxle case

No.1 plugs.

7. FIX AUTOMATIC TRANSAXLE ASSEMBLY

(a) Fix the transaxle assembly.

8. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

(b) Remove the 2 magnets from the oil pan.

D030672E01

D026716

D009176

C091925

C086316E02

Page 1858 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–183

AX

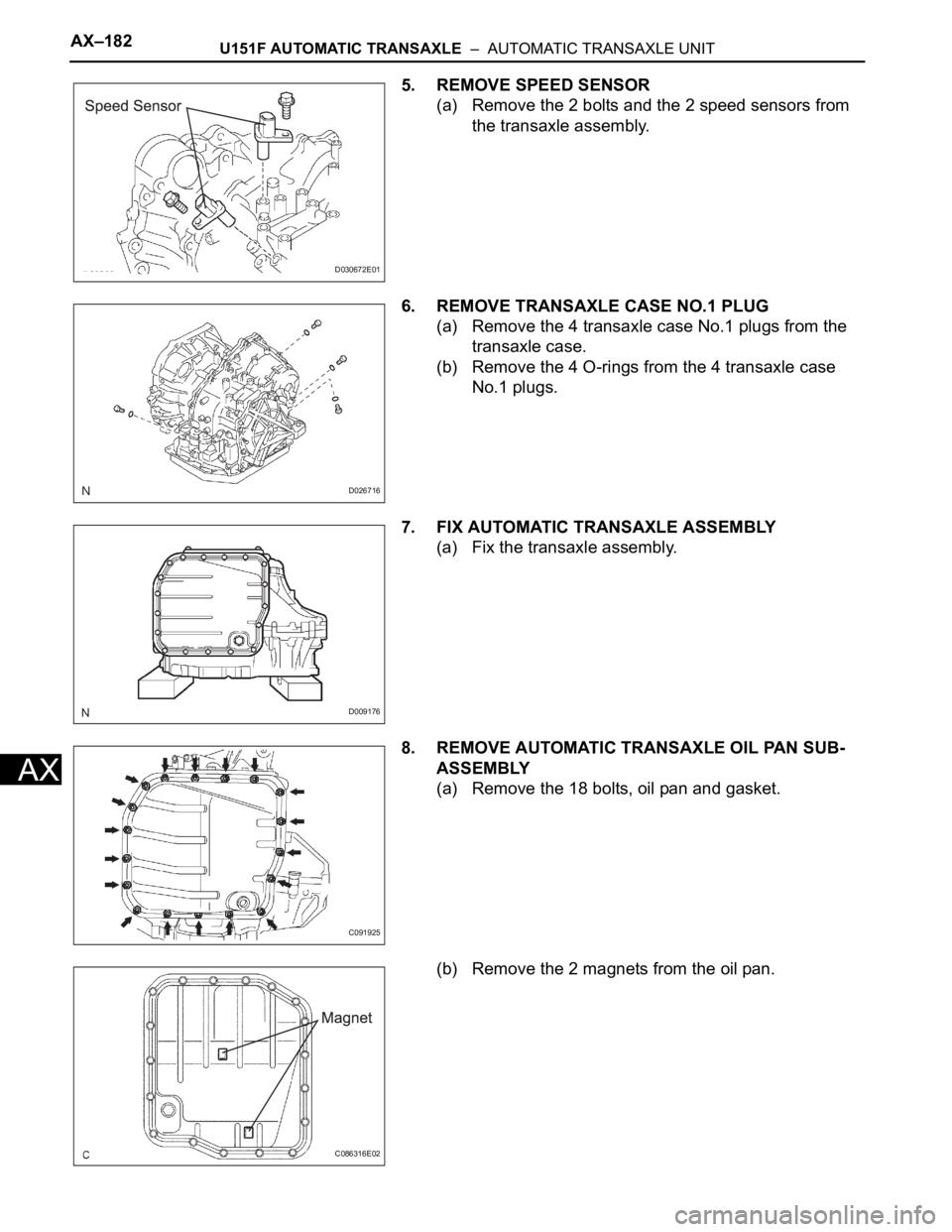

9. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle:

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bushing

10. DISCONNECT TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

11. REMOVE TRANSMISSION WIRE

(a) Remove the bolt and transmission wire from the

transaxle case.

12. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

AT00103E03

C091927E02

D003547E05

C091931

C091932E01

Page 1859 of 3000

AX–184U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

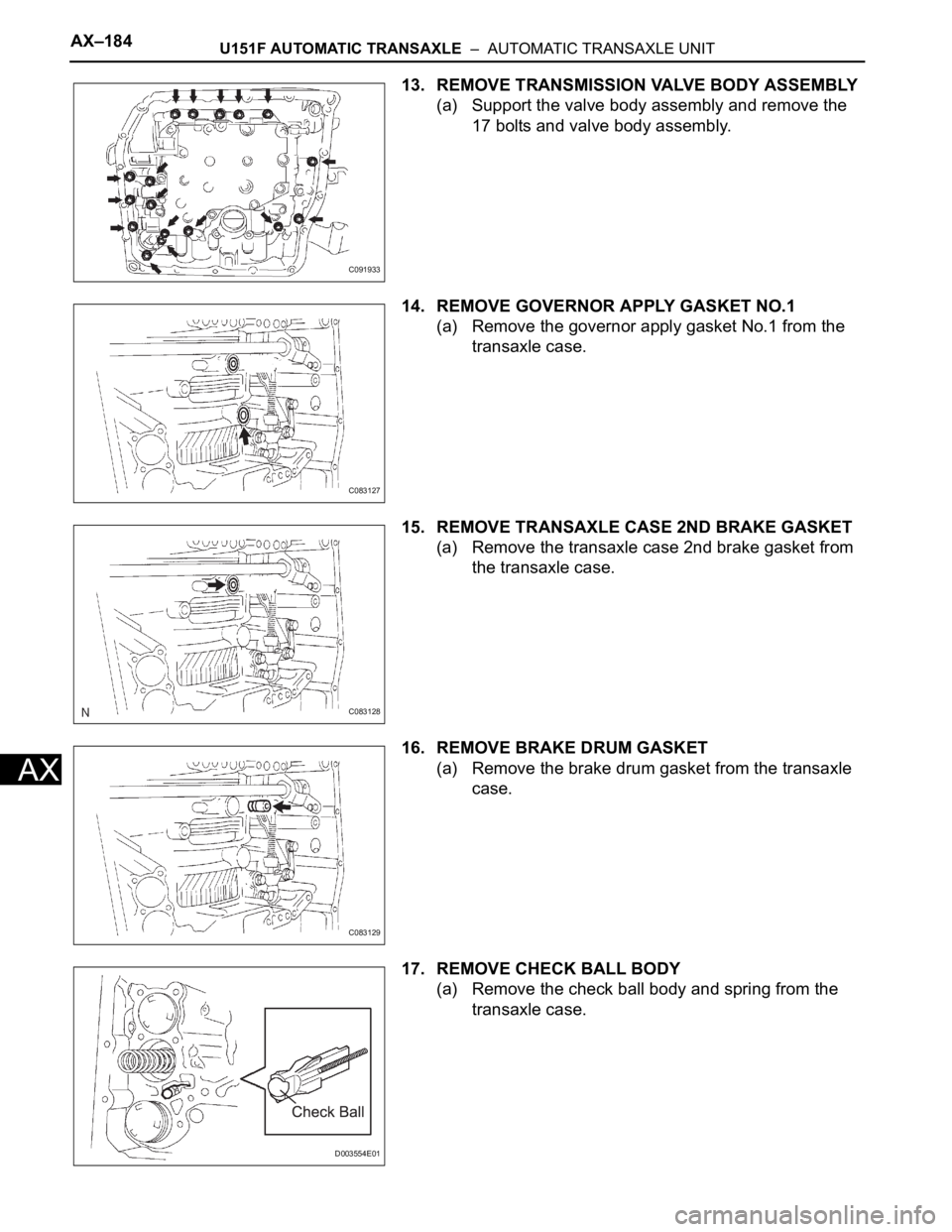

13. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

(a) Support the valve body assembly and remove the

17 bolts and valve body assembly.

14. REMOVE GOVERNOR APPLY GASKET NO.1

(a) Remove the governor apply gasket No.1 from the

transaxle case.

15. REMOVE TRANSAXLE CASE 2ND BRAKE GASKET

(a) Remove the transaxle case 2nd brake gasket from

the transaxle case.

16. REMOVE BRAKE DRUM GASKET

(a) Remove the brake drum gasket from the transaxle

case.

17. REMOVE CHECK BALL BODY

(a) Remove the check ball body and spring from the

transaxle case.

C091933

C083127

C083128

C083129

D003554E01

Page 1860 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–185

AX

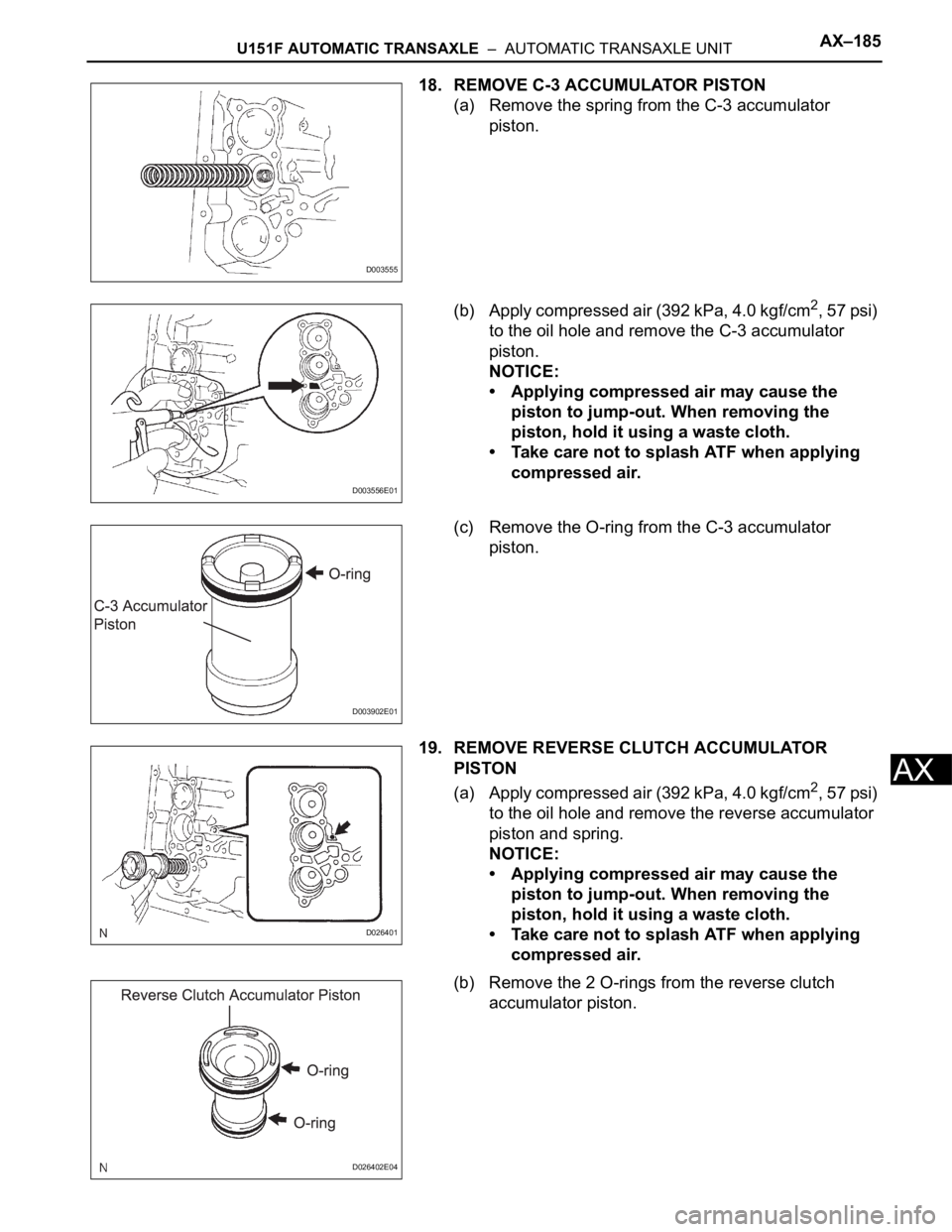

18. REMOVE C-3 ACCUMULATOR PISTON

(a) Remove the spring from the C-3 accumulator

piston.

(b) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the oil hole and remove the C-3 accumulator

piston.

NOTICE:

• Applying compressed air may cause the

piston to jump-out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

(c) Remove the O-ring from the C-3 accumulator

piston.

19. REMOVE REVERSE CLUTCH ACCUMULATOR

PISTON

(a) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the oil hole and remove the reverse accumulator

piston and spring.

NOTICE:

• Applying compressed air may cause the

piston to jump-out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

(b) Remove the 2 O-rings from the reverse clutch

accumulator piston.

D003555

D003556E01

D003902E01

D026401

D026402E04