sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 797 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–25

ES

Rear Oxygen Sensor Heater

$A7 $0C Multiply by 1 TimeMisfire rate for cylinder 6: Misfire counts for last/current driving cycle-

To t a l

Monitor ID Test ID Scaling Unit Description

$42 $91 Multiply by 0.001 Ohm Oxygen sensor heater resistance bank 1 sensor 2

$46 $91 Multiply by 0.004 Ohm Oxygen sensor heater resistance bank 2 sensor 2 Monitor ID Test ID Scaling Unit Description

Page 803 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

Contents:

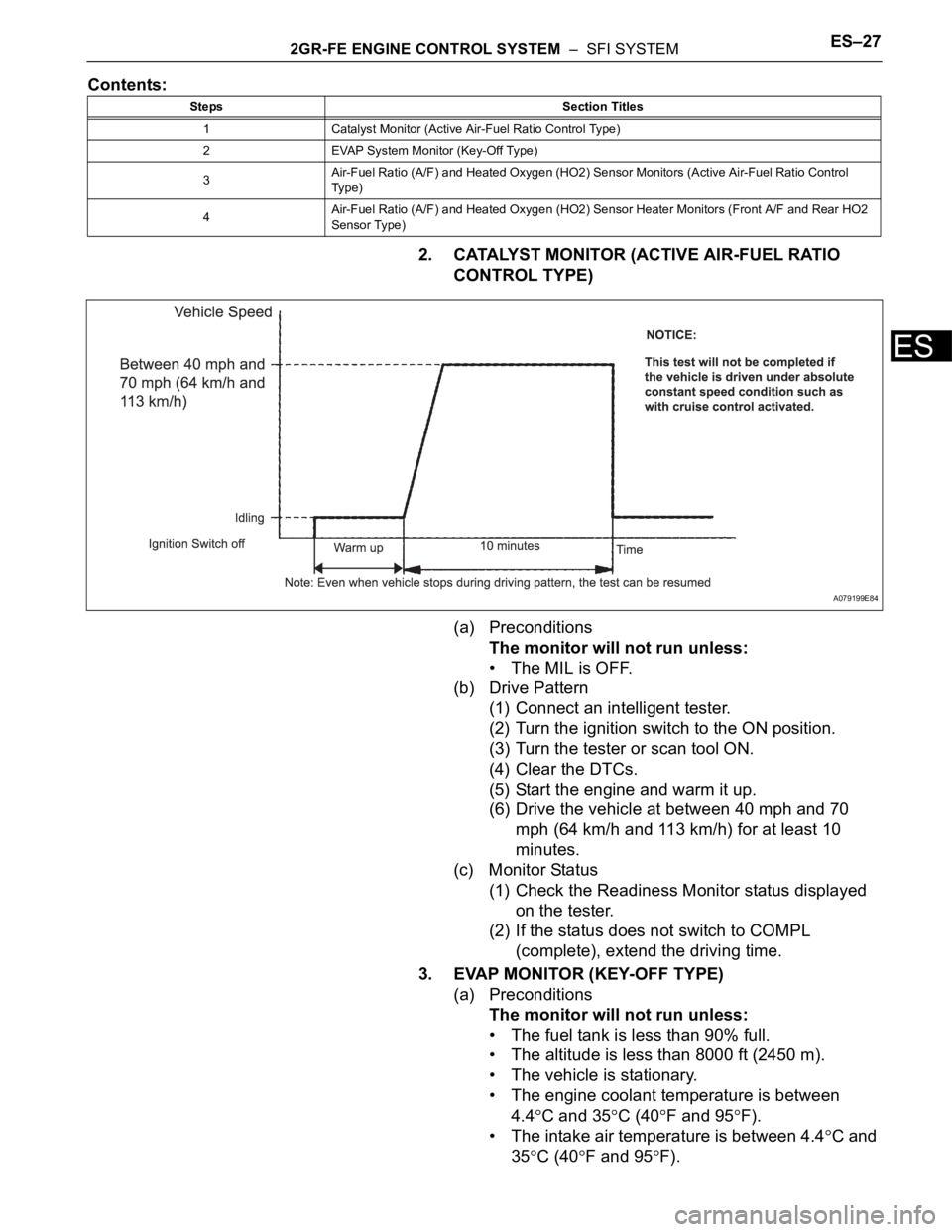

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 804 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

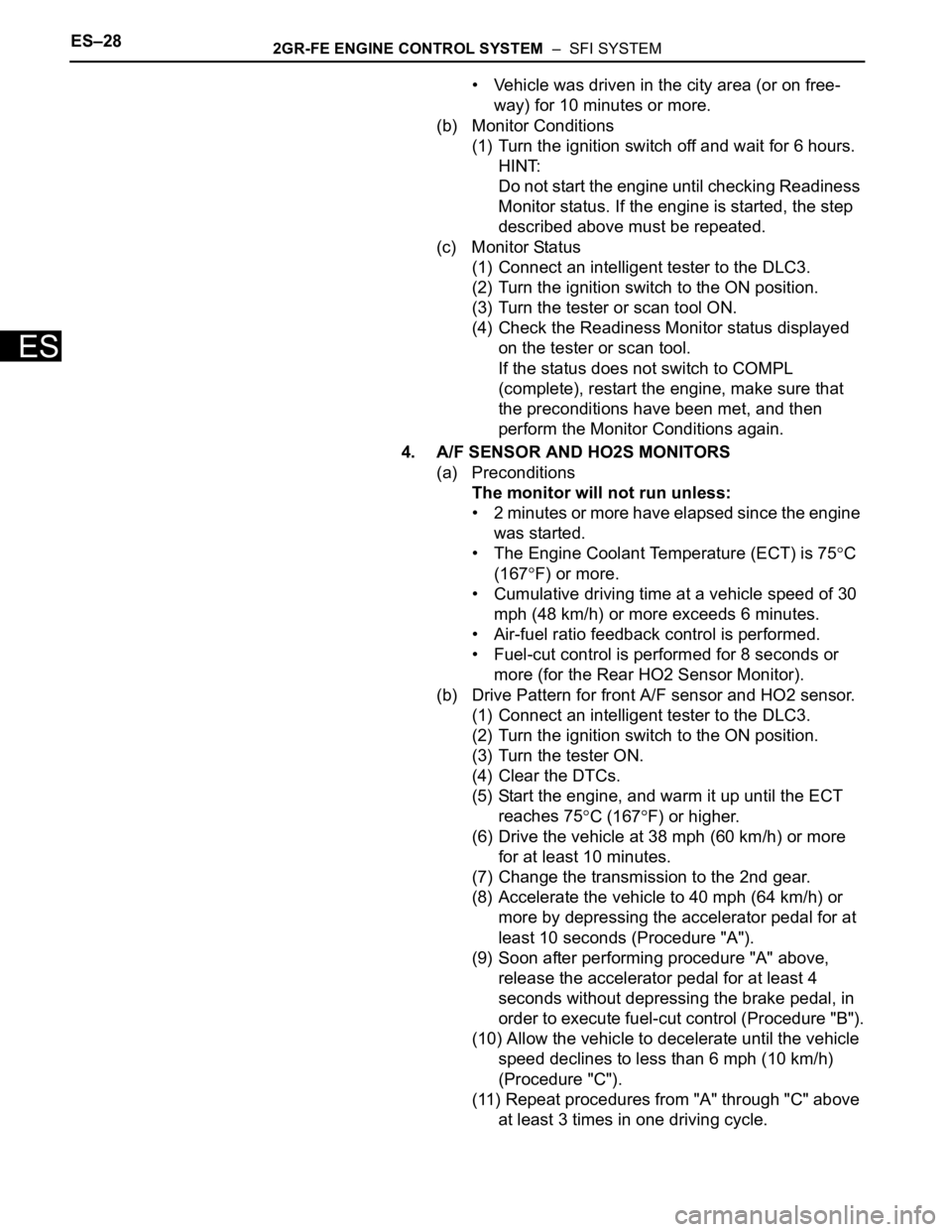

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 805 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–29

ES

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met and then perform the Drive

Pattern again.

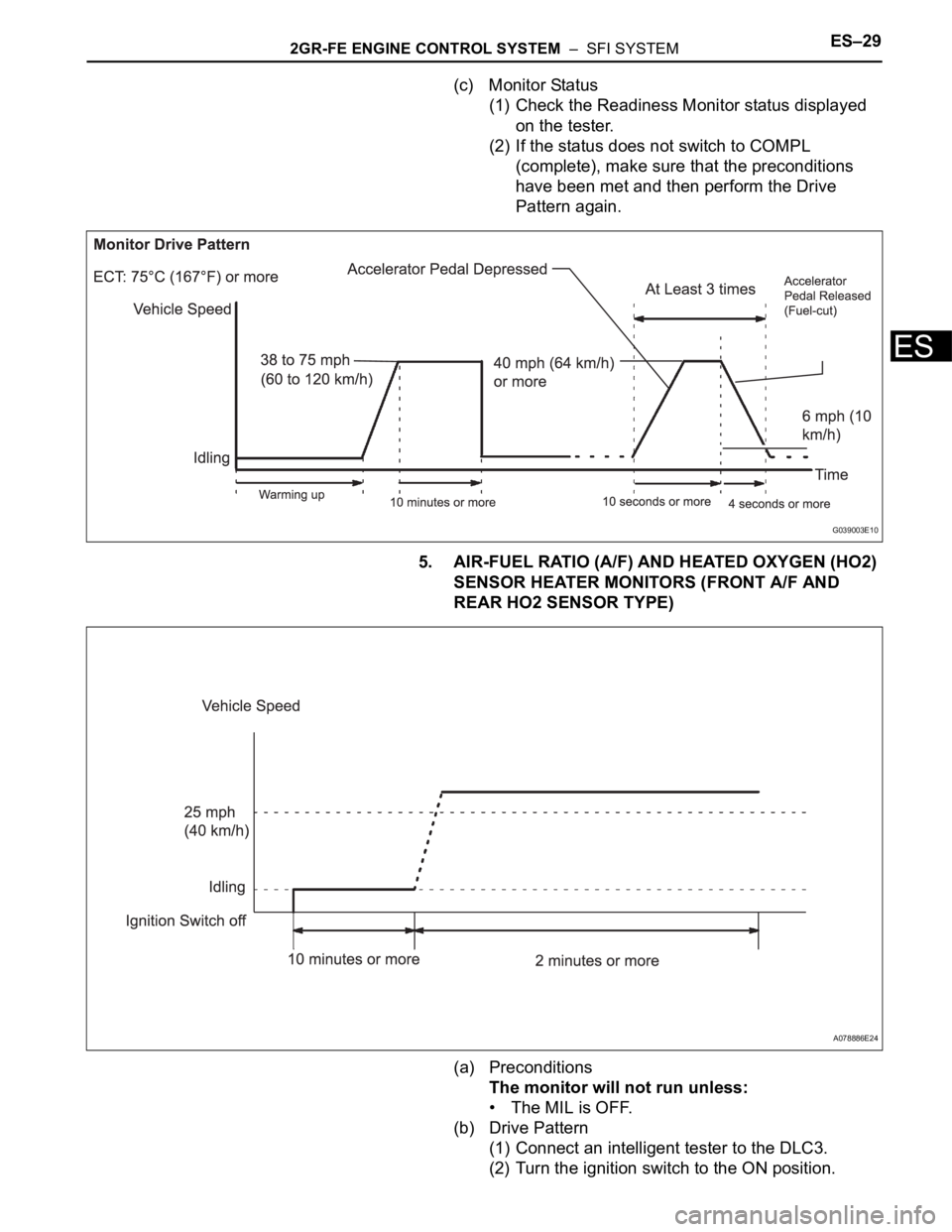

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

G039003E10

A078886E24

Page 808 of 3000

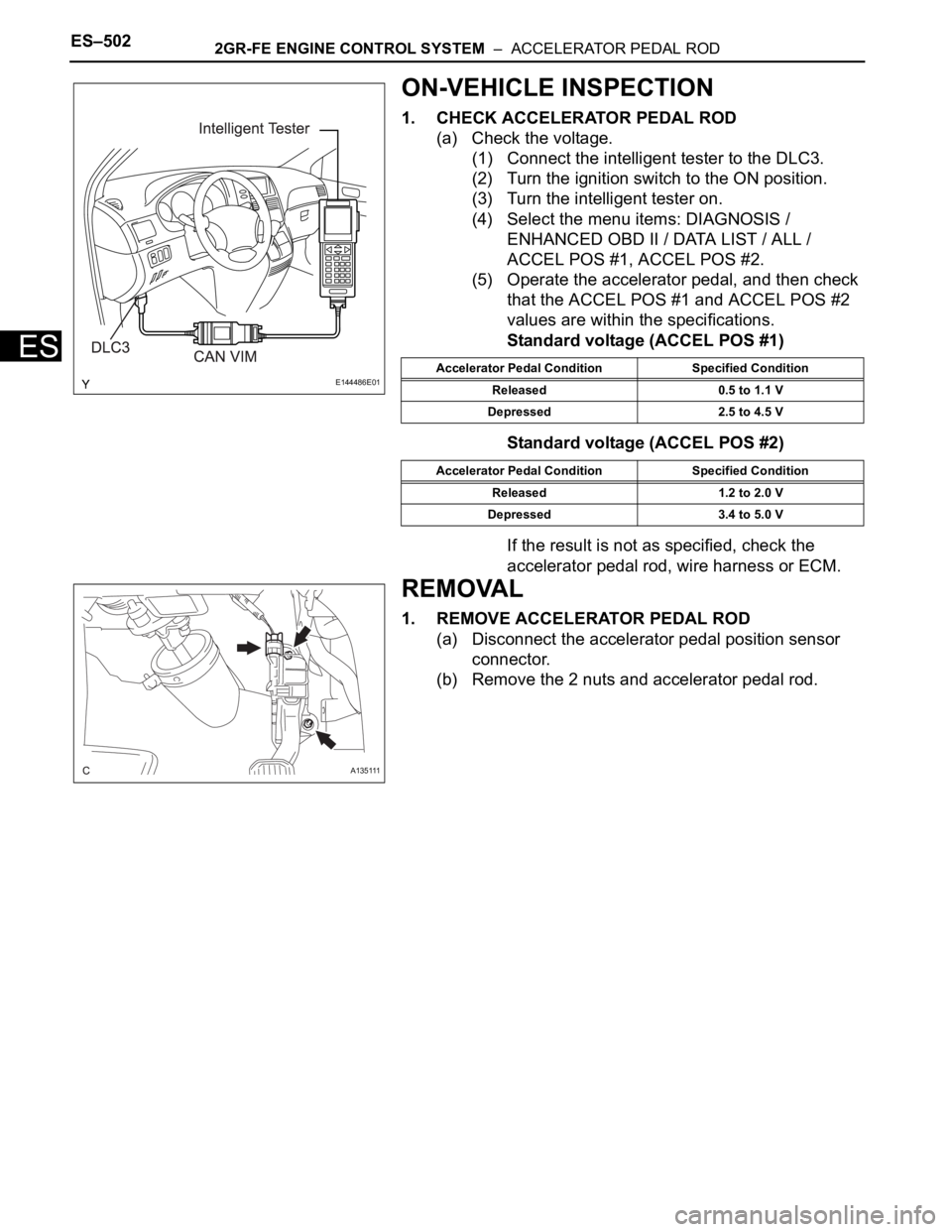

ES–5022GR-FE ENGINE CONTROL SYSTEM – ACCELERATOR PEDAL ROD

ES

ON-VEHICLE INSPECTION

1. CHECK ACCELERATOR PEDAL ROD

(a) Check the voltage.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the intelligent tester on.

(4) Select the menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / ALL /

ACCEL POS #1, ACCEL POS #2.

(5) Operate the accelerator pedal, and then check

that the ACCEL POS #1 and ACCEL POS #2

values are within the specifications.

Standard voltage (ACCEL POS #1)

Standard voltage (ACCEL POS #2)

If the result is not as specified, check the

accelerator pedal rod, wire harness or ECM.

REMOVAL

1. REMOVE ACCELERATOR PEDAL ROD

(a) Disconnect the accelerator pedal position sensor

connector.

(b) Remove the 2 nuts and accelerator pedal rod.

E144486E01Accelerator Pedal Condition Specified Condition

Released 0.5 to 1.1 V

Depressed 2.5 to 4.5 V

Accelerator Pedal Condition Specified Condition

Released 1.2 to 2.0 V

Depressed 3.4 to 5.0 V

A135111

Page 809 of 3000

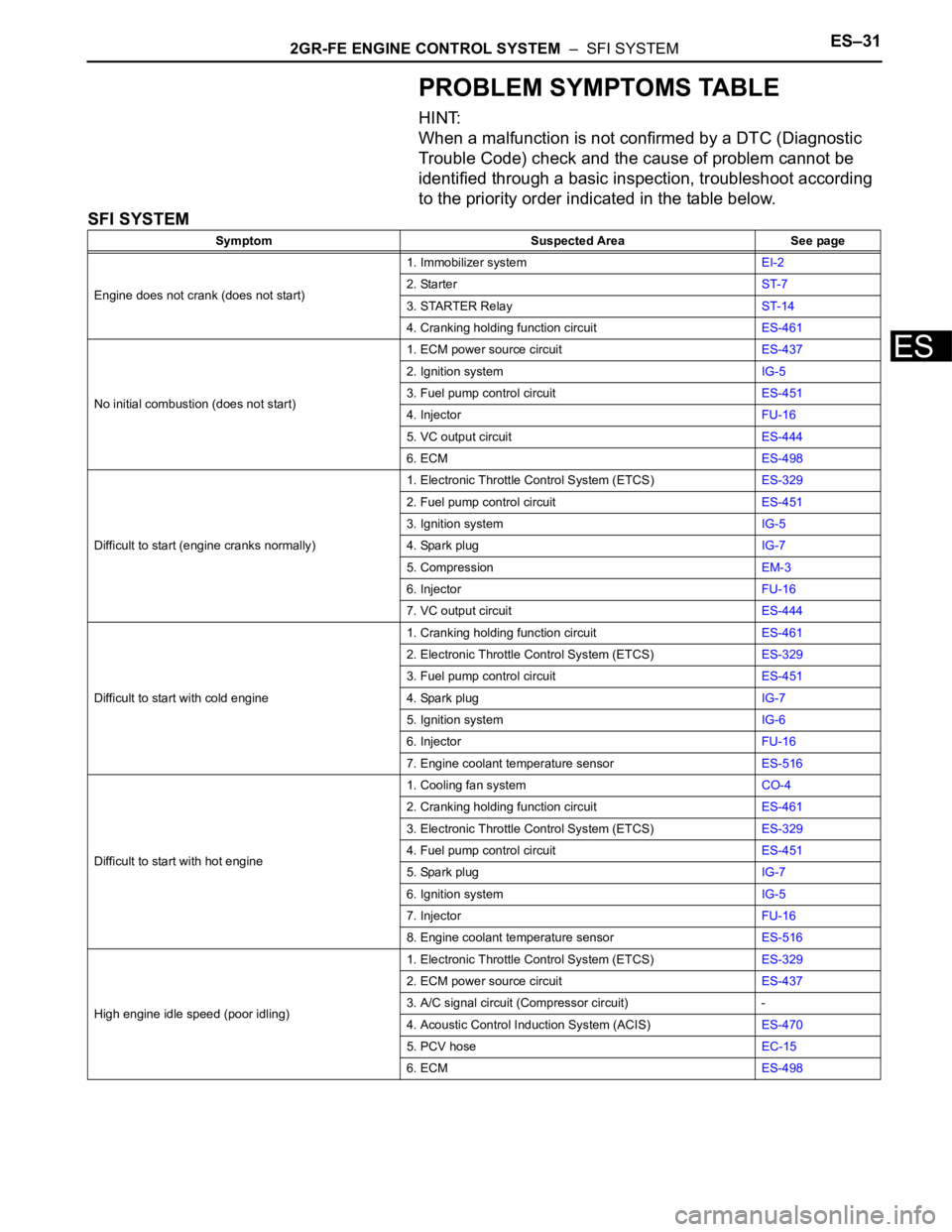

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–31

ES

PROBLEM SYMPTOMS TABLE

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority order indicated in the table below.

SFI SYSTEM

Symptom Suspected Area See page

Engine does not crank (does not start)1. Immobilizer systemEI-2

2. StarterST-7

3. STARTER RelayST-14

4. Cranking holding function circuitES-461

No initial combustion (does not start)1. ECM power source circuitES-437

2. Ignition systemIG-5

3. Fuel pump control circuitES-451

4. InjectorFU-16

5. VC output circuitES-444

6. ECMES-498

Difficult to start (engine cranks normally)1. Electronic Throttle Control System (ETCS)ES-329

2. Fuel pump control circuitES-451

3. Ignition systemIG-5

4. Spark plugIG-7

5. CompressionEM-3

6. InjectorFU-16

7. VC output circuitES-444

Difficult to start with cold engine1. Cranking holding function circuitES-461

2. Electronic Throttle Control System (ETCS)ES-329

3. Fuel pump control circuitES-451

4. Spark plugIG-7

5. Ignition systemIG-6

6. InjectorFU-16

7. Engine coolant temperature sensorES-516

Difficult to start with hot engine1. Cooling fan systemCO-4

2. Cranking holding function circuitES-461

3. Electronic Throttle Control System (ETCS)ES-329

4. Fuel pump control circuitES-451

5. Spark plugIG-7

6. Ignition systemIG-5

7. InjectorFU-16

8. Engine coolant temperature sensorES-516

High engine idle speed (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. ECM power source circuitES-437

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS)ES-470

5. PCV hoseEC-15

6. ECMES-498

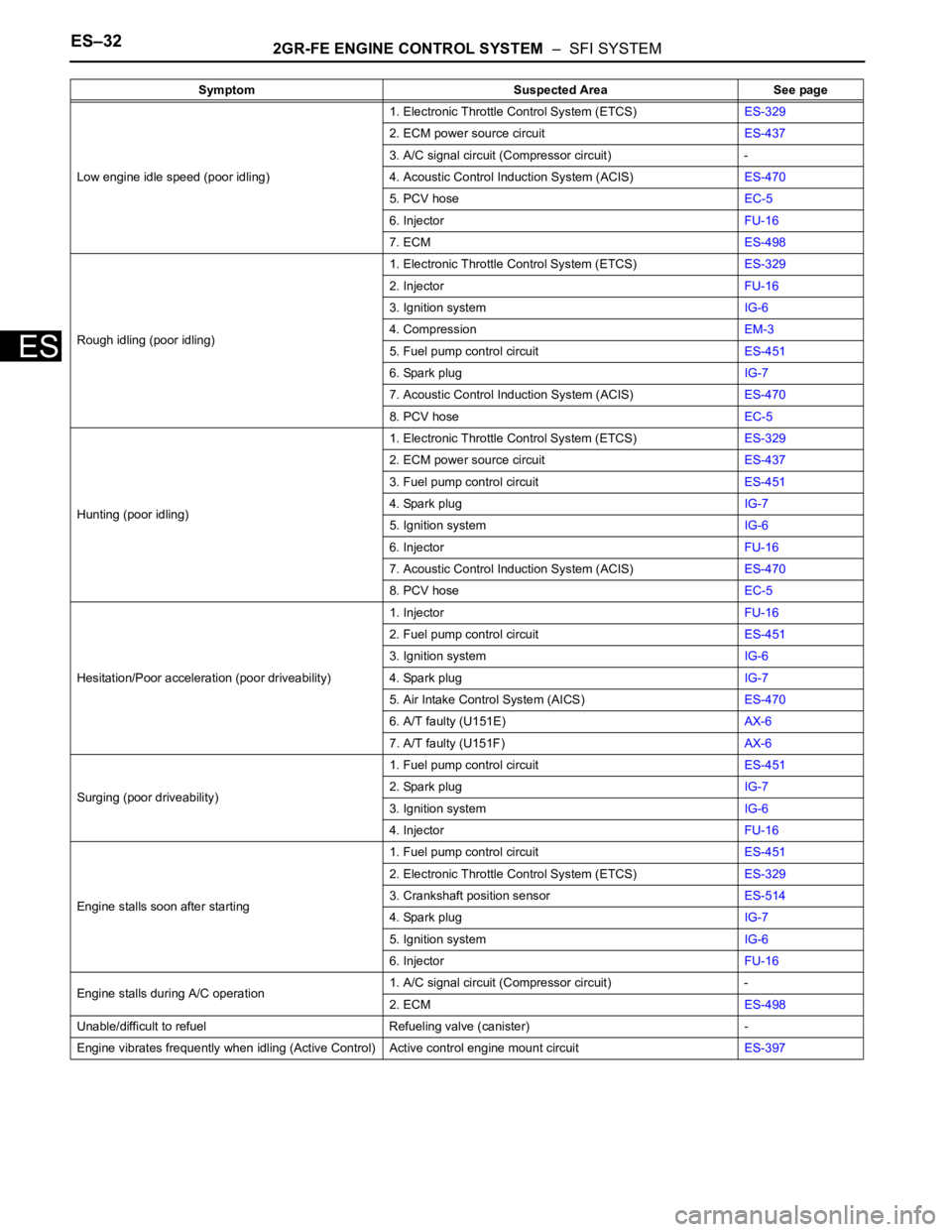

Page 810 of 3000

ES–322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Low engine idle speed (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. ECM power source circuitES-437

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS)ES-470

5. PCV hoseEC-5

6. InjectorFU-16

7. ECMES-498

Rough idling (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. InjectorFU-16

3. Ignition systemIG-6

4. CompressionEM-3

5. Fuel pump control circuitES-451

6. Spark plugIG-7

7. Acoustic Control Induction System (ACIS)ES-470

8. PCV hoseEC-5

Hunting (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. ECM power source circuitES-437

3. Fuel pump control circuitES-451

4. Spark plugIG-7

5. Ignition systemIG-6

6. InjectorFU-16

7. Acoustic Control Induction System (ACIS)ES-470

8. PCV hoseEC-5

Hesitation/Poor acceleration (poor driveability)1. InjectorFU-16

2. Fuel pump control circuitES-451

3. Ignition systemIG-6

4. Spark plugIG-7

5. Air Intake Control System (AICS)ES-470

6. A/T faulty (U151E)AX-6

7. A/T faulty (U151F)AX-6

Surging (poor driveability)1. Fuel pump control circuitES-451

2. Spark plugIG-7

3. Ignition systemIG-6

4. InjectorFU-16

Engine stalls soon after starting1. Fuel pump control circuitES-451

2. Electronic Throttle Control System (ETCS)ES-329

3. Crankshaft position sensorES-514

4. Spark plugIG-7

5. Ignition systemIG-6

6. InjectorFU-16

Engine stalls during A/C operation1. A/C signal circuit (Compressor circuit) -

2. ECMES-498

Unable/difficult to refuel Refueling valve (canister) -

Engine vibrates frequently when idling (Active Control) Active control engine mount circuitES-397 Symptom Suspected Area See page

Page 813 of 3000

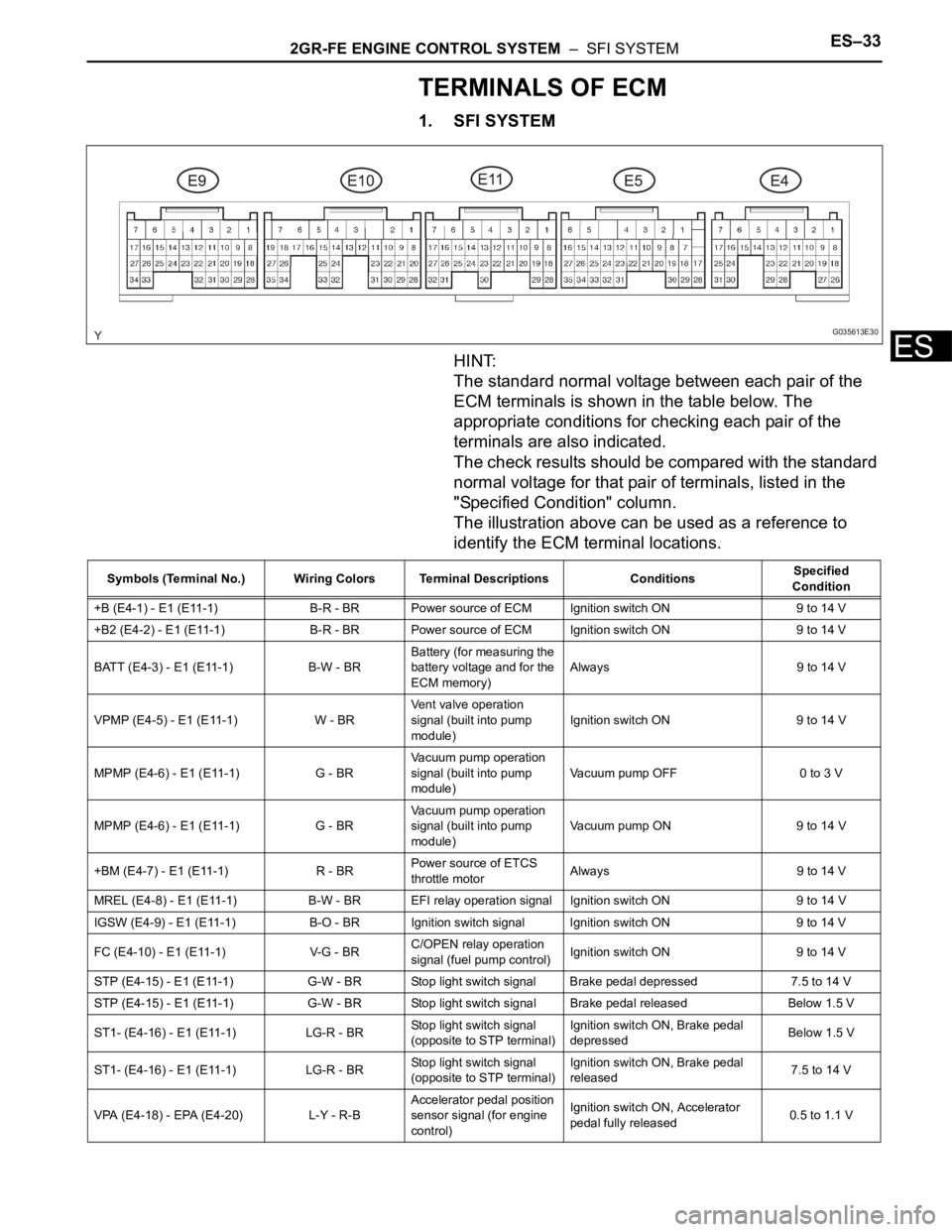

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–33

ES

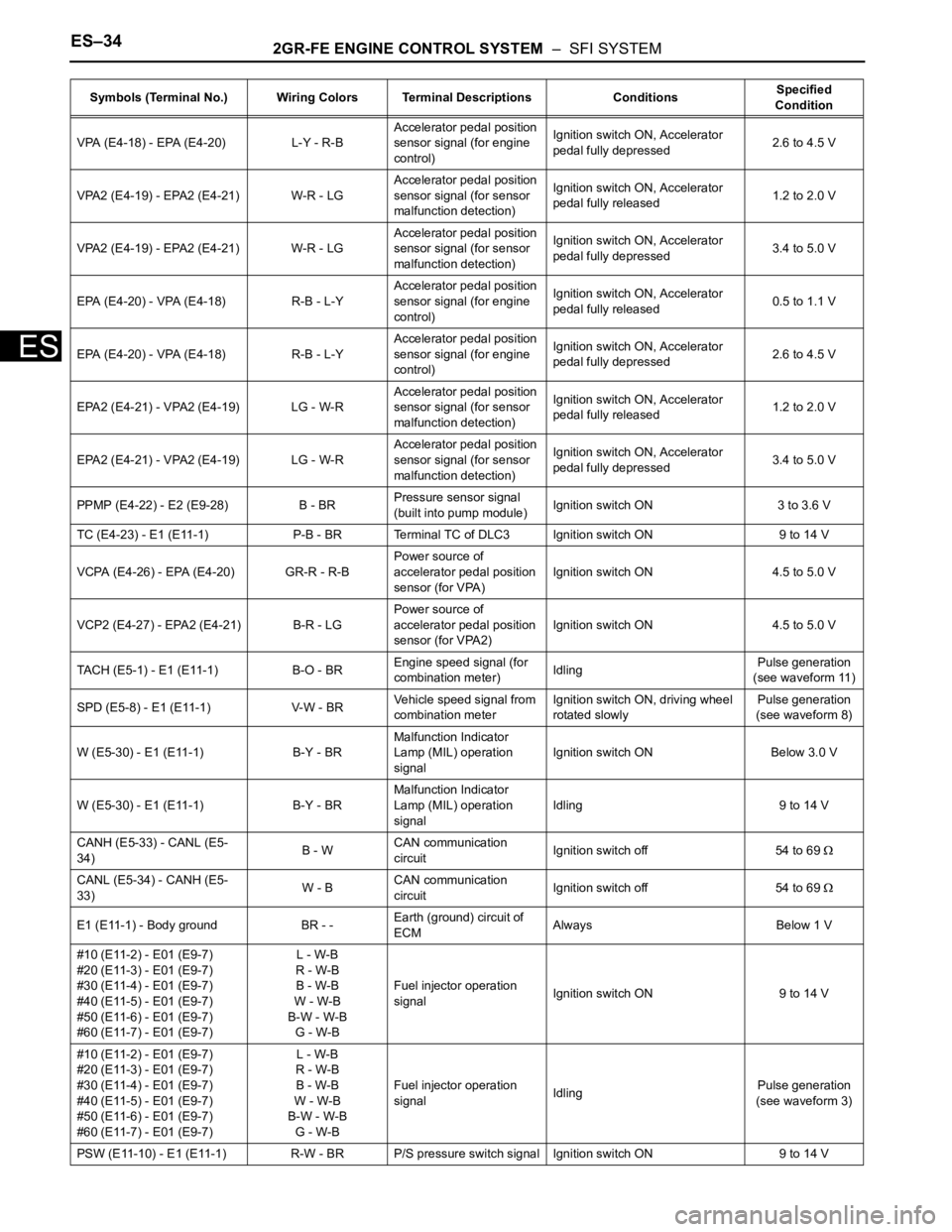

TERMINALS OF ECM

1. SFI SYSTEM

HINT:

The standard normal voltage between each pair of the

ECM terminals is shown in the table below. The

appropriate conditions for checking each pair of the

terminals are also indicated.

The check results should be compared with the standard

normal voltage for that pair of terminals, listed in the

"Specified Condition" column.

The illustration above can be used as a reference to

identify the ECM terminal locations.

G035613E30

Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

+B (E4-1) - E1 (E11-1) B-R - BR Power source of ECM Ignition switch ON 9 to 14 V

+B2 (E4-2) - E1 (E11-1) B-R - BR Power source of ECM Ignition switch ON 9 to 14 V

BATT (E4-3) - E1 (E11-1) B-W - BRBattery (for measuring the

battery voltage and for the

ECM memory)Always 9 to 14 V

VPMP (E4-5) - E1 (E11-1) W - BRVent valve operation

signal (built into pump

module)Ignition switch ON 9 to 14 V

MPMP (E4-6) - E1 (E11-1) G - BRVacuum pump operation

signal (built into pump

module)Vacuum pump OFF 0 to 3 V

MPMP (E4-6) - E1 (E11-1) G - BRVacuum pump operation

signal (built into pump

module)Vacuum pump ON 9 to 14 V

+BM (E4-7) - E1 (E11-1) R - BRPower source of ETCS

throttle motorAlways 9 to 14 V

MREL (E4-8) - E1 (E11-1) B-W - BR EFI relay operation signal Ignition switch ON 9 to 14 V

IGSW (E4-9) - E1 (E11-1) B-O - BRIgnition switch signal Ignition switch ON 9 to 14 V

FC (E4-10) - E1 (E11-1) V-G - BRC/OPEN relay operation

signal (fuel pump control)Ignition switch ON 9 to 14 V

STP (E4-15) - E1 (E11-1) G-W - BR Stop light switch signal Brake pedal depressed 7.5 to 14 V

STP (E4-15) - E1 (E11-1) G-W - BR Stop light switch signal Brake pedal released Below 1.5 V

ST1- (E4-16) - E1 (E11-1) LG-R - BRStop light switch signal

(opposite to STP terminal)Ignition switch ON, Brake pedal

depressedBelow 1.5 V

ST1- (E4-16) - E1 (E11-1) LG-R - BRStop light switch signal

(opposite to STP terminal)Ignition switch ON, Brake pedal

released7.5 to 14 V

VPA (E4-18) - EPA (E4-20) L-Y - R-BAccelerator pedal position

sensor signal (for engine

control)Ignition switch ON, Accelerator

pedal fully released0.5 to 1.1 V

Page 814 of 3000

ES–342GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VPA (E4-18) - EPA (E4-20) L-Y - R-BAccelerator pedal position

sensor signal (for engine

control)Ignition switch ON, Accelerator

pedal fully depressed2.6 to 4.5 V

VPA2 (E4-19) - EPA2 (E4-21) W-R - LGAccelerator pedal position

sensor signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully released1.2 to 2.0 V

VPA2 (E4-19) - EPA2 (E4-21) W-R - LGAccelerator pedal position

sensor signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully depressed3.4 to 5.0 V

EPA (E4-20) - VPA (E4-18) R-B - L-YAccelerator pedal position

sensor signal (for engine

control)Ignition switch ON, Accelerator

pedal fully released0.5 to 1.1 V

EPA (E4-20) - VPA (E4-18) R-B - L-YAccelerator pedal position

sensor signal (for engine

control)Ignition switch ON, Accelerator

pedal fully depressed2.6 to 4.5 V

EPA2 (E4-21) - VPA2 (E4-19) LG - W-RAccelerator pedal position

sensor signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully released1.2 to 2.0 V

EPA2 (E4-21) - VPA2 (E4-19) LG - W-RAccelerator pedal position

sensor signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully depressed3.4 to 5.0 V

PPMP (E4-22) - E2 (E9-28) B - BRPressure sensor signal

(built into pump module)Ignition switch ON 3 to 3.6 V

TC (E4-23) - E1 (E11-1) P-B - BR Terminal TC of DLC3 Ignition switch ON 9 to 14 V

VCPA (E4-26) - EPA (E4-20) GR-R - R-BPower source of

accelerator pedal position

sensor (for VPA)Ignition switch ON 4.5 to 5.0 V

VCP2 (E4-27) - EPA2 (E4-21) B-R - LGPower source of

accelerator pedal position

sensor (for VPA2)Ignition switch ON 4.5 to 5.0 V

TACH (E5-1) - E1 (E11-1) B-O - BREngine speed signal (for

combination meter)IdlingPulse generation

(see waveform 11)

SPD (E5-8) - E1 (E11-1) V-W - BRVehicle speed signal from

combination meterIgnition switch ON, driving wheel

rotated slowlyPulse generation

(see waveform 8)

W (E5-30) - E1 (E11-1) B-Y - BRMalfunction Indicator

Lamp (MIL) operation

signalIgnition switch ON Below 3.0 V

W (E5-30) - E1 (E11-1) B-Y - BRMalfunction Indicator

Lamp (MIL) operation

signalIdling 9 to 14 V

CANH (E5-33) - CANL (E5-

34)B - WCAN communication

circuitIgnition switch off 54 to 69

CANL (E5-34) - CANH (E5-

33)W - BCAN communication

circuitIgnition switch off 54 to 69

E1 (E11-1) - Body ground BR - -Earth (ground) circuit of

ECMAlways Below 1 V

#10 (E11-2) - E01 (E9-7)

#20 (E11-3) - E01 (E9-7)

#30 (E11-4) - E01 (E9-7)

#40 (E11-5) - E01 (E9-7)

#50 (E11-6) - E01 (E9-7)

#60 (E11-7) - E01 (E9-7)L - W-B

R - W-B

B - W-B

W - W-B

B-W - W-B

G - W-BFuel injector operation

signalIgnition switch ON 9 to 14 V

#10 (E11-2) - E01 (E9-7)

#20 (E11-3) - E01 (E9-7)

#30 (E11-4) - E01 (E9-7)

#40 (E11-5) - E01 (E9-7)

#50 (E11-6) - E01 (E9-7)

#60 (E11-7) - E01 (E9-7)L - W-B

R - W-B

B - W-B

W - W-B

B-W - W-B

G - W-BFuel injector operation

signalIdlingPulse generation

(see waveform 3)

PSW (E11-10) - E1 (E11-1) R-W - BR P/S pressure switch signal Ignition switch ON 9 to 14 V Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

Page 815 of 3000

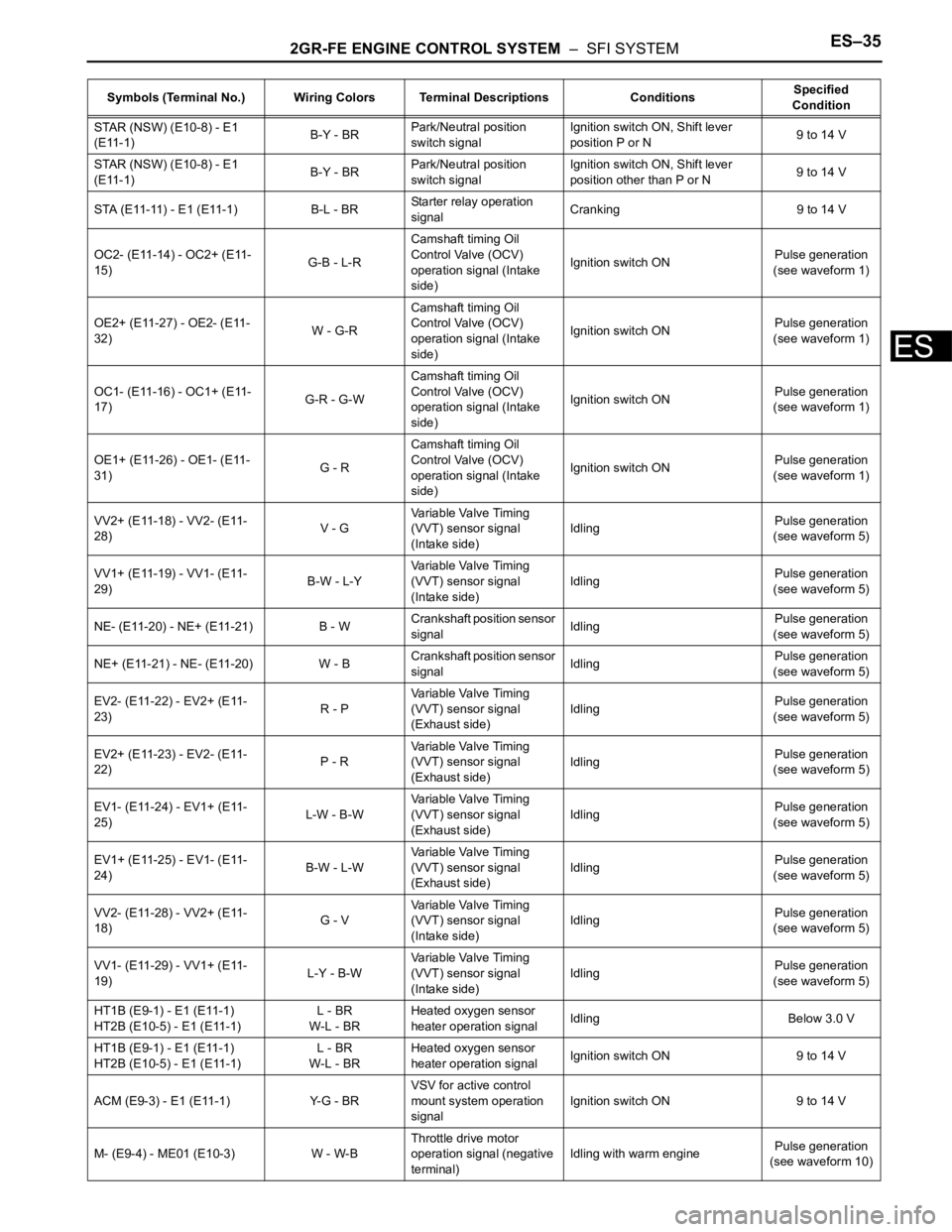

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–35

ES

STAR (NSW) (E10-8) - E1

(E11-1)B-Y - BRPark/Neutral position

switch signalIgnition switch ON, Shift lever

position P or N9 to 14 V

STAR (NSW) (E10-8) - E1

(E11-1)B-Y - BRPark/Neutral position

switch signalIgnition switch ON, Shift lever

position other than P or N9 to 14 V

STA (E11-11) - E1 (E11-1) B-L - BRStarter relay operation

signalCranking 9 to 14 V

OC2- (E11-14) - OC2+ (E11-

15)G-B - L-RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OE2+ (E11-27) - OE2- (E11-

32)W - G-RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OC1- (E11-16) - OC1+ (E11-

17)G-R - G-WCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OE1+ (E11-26) - OE1- (E11-

31)G - RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

VV2+ (E11-18) - VV2- (E11-

28)V - GVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

VV1+ (E11-19) - VV1- (E11-

29)B-W - L-YVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

NE- (E11-20) - NE+ (E11-21) B - WCrankshaft position sensor

signalIdlingPulse generation

(see waveform 5)

NE+ (E11-21) - NE- (E11-20) W - BCrankshaft position sensor

signalIdlingPulse generation

(see waveform 5)

EV2- (E11-22) - EV2+ (E11-

23)R - PVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV2+ (E11-23) - EV2- (E11-

22)P - RVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV1- (E11-24) - EV1+ (E11-

25)L-W - B-WVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV1+ (E11-25) - EV1- (E11-

24)B-W - L-WVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

VV2- (E11-28) - VV2+ (E11-

18)G - VVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

VV1- (E11-29) - VV1+ (E11-

19)L-Y - B-WVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

HT1B (E9-1) - E1 (E11-1)

HT2B (E10-5) - E1 (E11-1)L - BR

W-L - BRHeated oxygen sensor

heater operation signalIdling Below 3.0 V

HT1B (E9-1) - E1 (E11-1)

HT2B (E10-5) - E1 (E11-1)L - BR

W-L - BRHeated oxygen sensor

heater operation signalIgnition switch ON 9 to 14 V

ACM (E9-3) - E1 (E11-1) Y-G - BRVSV for active control

mount system operation

signalIgnition switch ON 9 to 14 V

M- (E9-4) - ME01 (E10-3) W - W-BThrottle drive motor

operation signal (negative

terminal)Idling with warm enginePulse generation

(see waveform 10) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition