sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 710 of 3000

ES–4242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

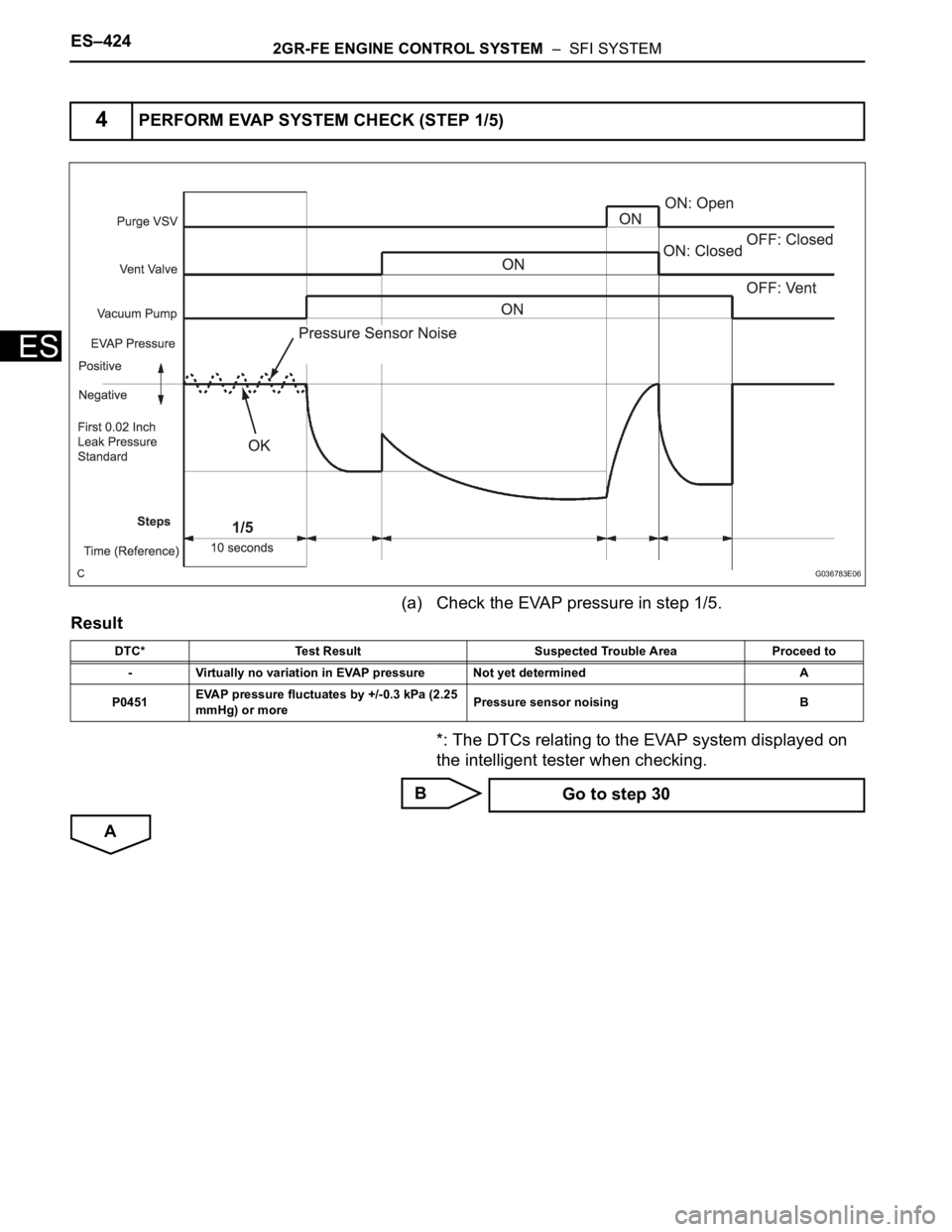

(a) Check the EVAP pressure in step 1/5.

Result

*: The DTCs relating to the EVAP system displayed on

the intelligent tester when checking.

B

A

4PERFORM EVAP SYSTEM CHECK (STEP 1/5)

G036783E06

DTC* Test Result Suspected Trouble Area Proceed to

- Virtually no variation in EVAP pressure Not yet determined A

P0451EVAP pressure fluctuates by +/-0.3 kPa (2.25

mmHg) or morePressure sensor noising B

Go to step 30

Page 713 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–427

ES

A

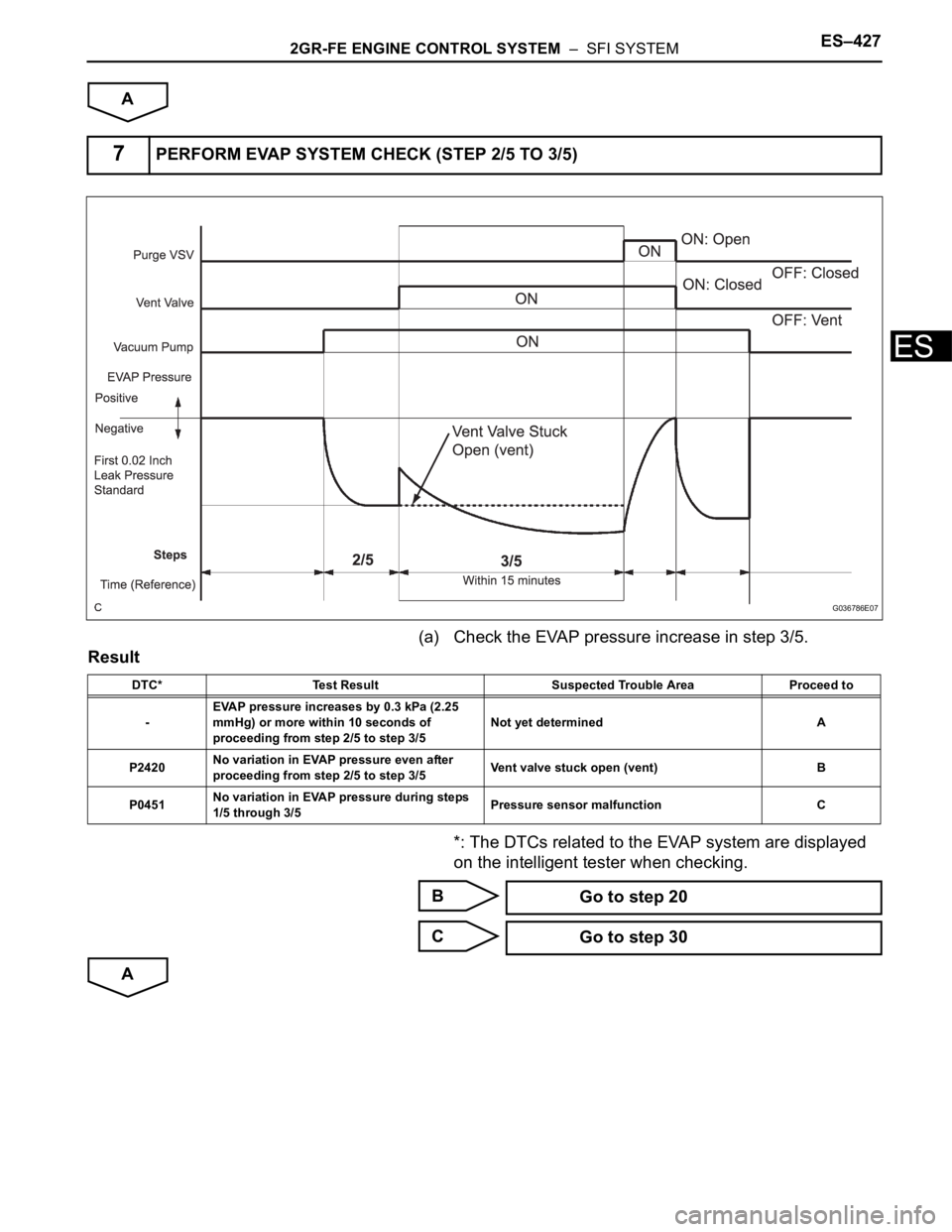

(a) Check the EVAP pressure increase in step 3/5.

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

B

C

A

7PERFORM EVAP SYSTEM CHECK (STEP 2/5 TO 3/5)

G036786E07

DTC* Test Result Suspected Trouble Area Proceed to

-EVAP pressure increases by 0.3 kPa (2.25

mmHg) or more within 10 seconds of

proceeding from step 2/5 to step 3/5Not yet determined A

P2420No variation in EVAP pressure even after

proceeding from step 2/5 to step 3/5Vent valve stuck open (vent) B

P0451No variation in EVAP pressure during steps

1/5 through 3/5Pressure sensor malfunction C

Go to step 20

Go to step 30

Page 738 of 3000

ES–4522GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

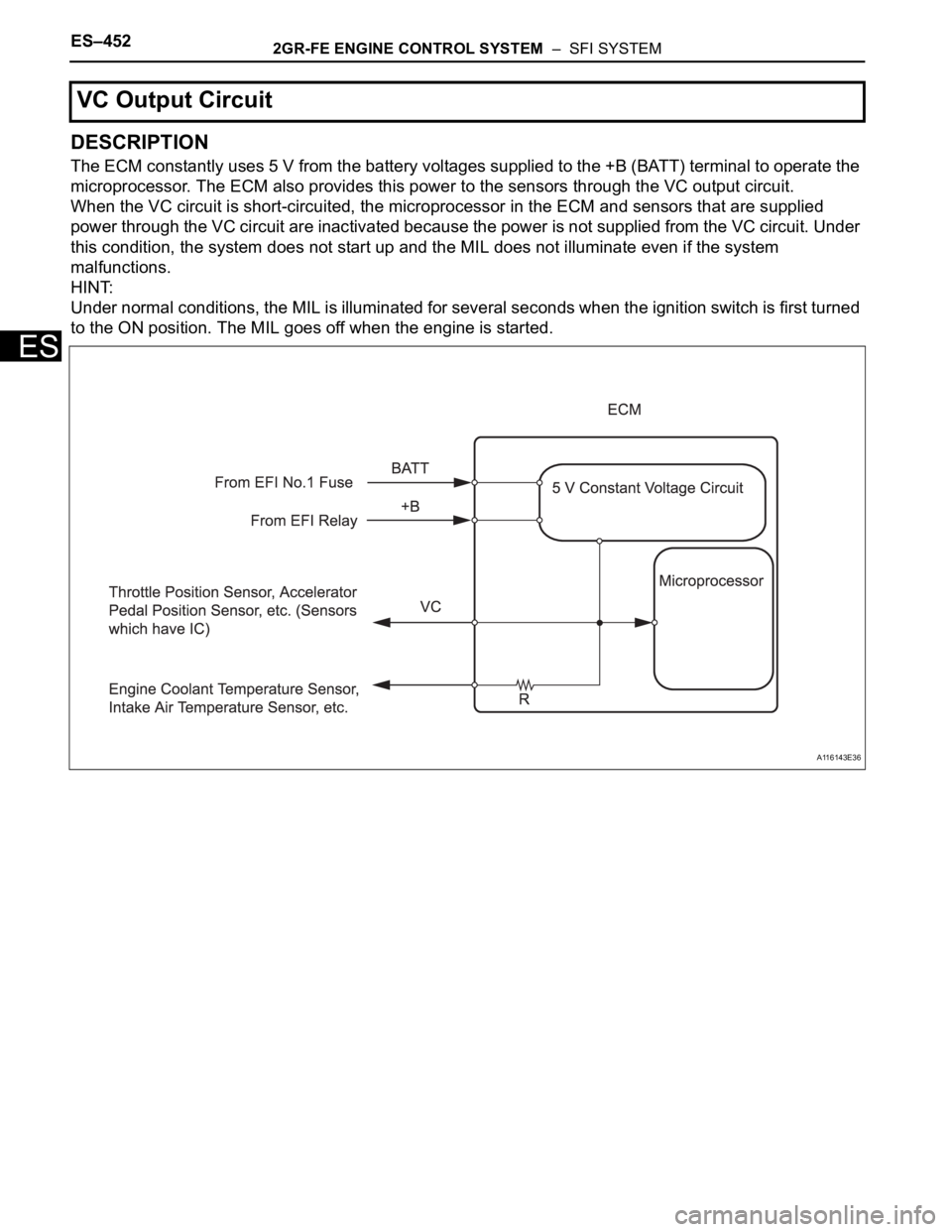

DESCRIPTION

The ECM constantly uses 5 V from the battery voltages supplied to the +B (BATT) terminal to operate the

microprocessor. The ECM also provides this power to the sensors through the VC output circuit.

When the VC circuit is short-circuited, the microprocessor in the ECM and sensors that are supplied

power through the VC circuit are inactivated because the power is not supplied from the VC circuit. Under

this condition, the system does not start up and the MIL does not illuminate even if the system

malfunctions.

HINT:

Under normal conditions, the MIL is illuminated for several seconds when the ignition switch is first turned

to the ON position. The MIL goes off when the engine is started.

VC Output Circuit

A116143E36

Page 741 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–455

ES

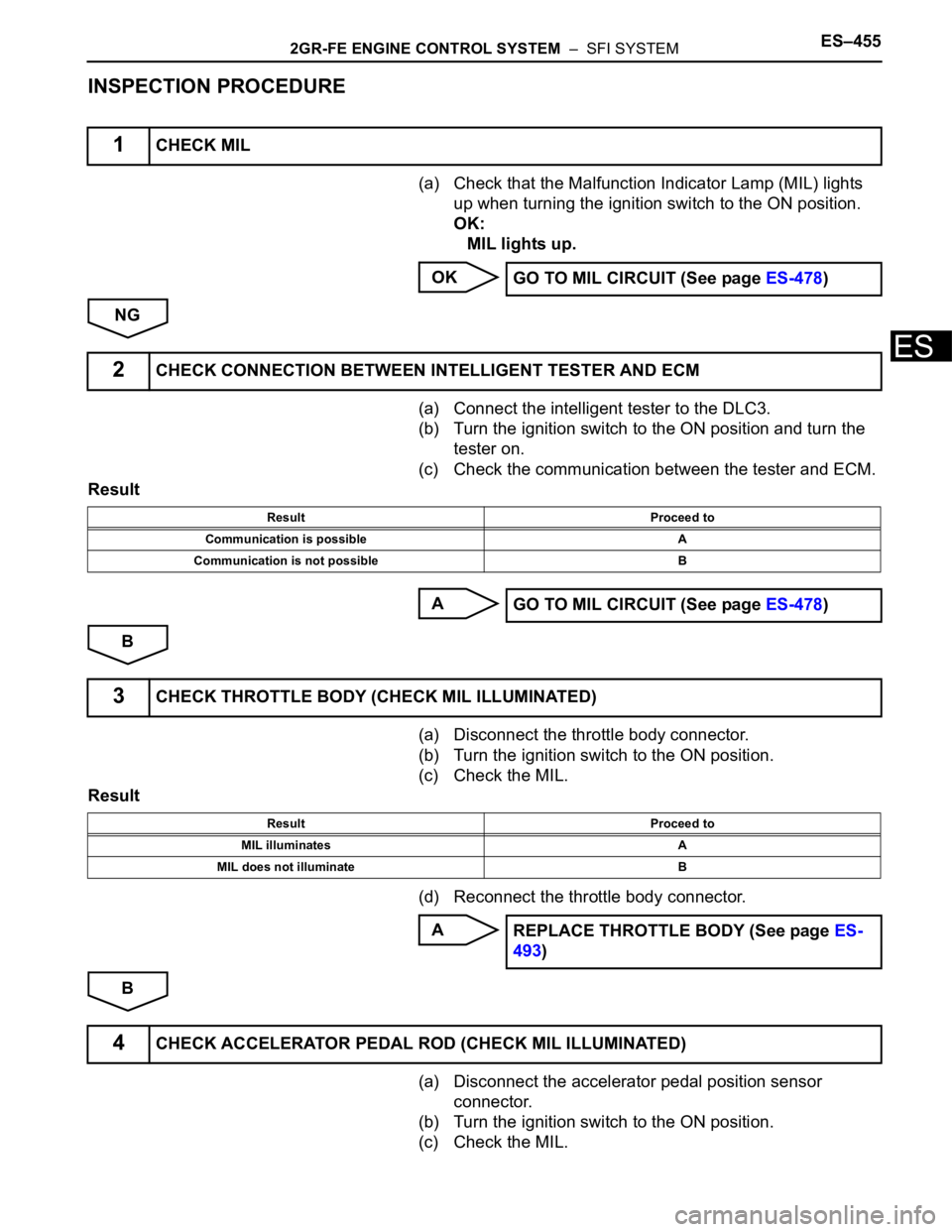

INSPECTION PROCEDURE

(a) Check that the Malfunction Indicator Lamp (MIL) lights

up when turning the ignition switch to the ON position.

OK:

MIL lights up.

OK

NG

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Check the communication between the tester and ECM.

Result

A

B

(a) Disconnect the throttle body connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the throttle body connector.

A

B

(a) Disconnect the accelerator pedal position sensor

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

1CHECK MIL

GO TO MIL CIRCUIT (See page ES-478)

2CHECK CONNECTION BETWEEN INTELLIGENT TESTER AND ECM

Result Proceed to

Communication is possible A

Communication is not possible B

GO TO MIL CIRCUIT (See page ES-478)

3CHECK THROTTLE BODY (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE THROTTLE BODY (See page ES-

493)

4CHECK ACCELERATOR PEDAL ROD (CHECK MIL ILLUMINATED)

Page 742 of 3000

ES–4562GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Result

(d) Reconnect the accelerator pedal position sensor

connector.

A

B

(a) Disconnect the VVT sensor for intake camshaft bank 1

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for intake camshaft bank 1

connector.

A

B

(a) Disconnect the VVT sensor for exhaust camshaft bank 1

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 1

connector.

A

B

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE ACCELERATOR PEDAL ROD (See

page ES-502)

5CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 1 (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR INTAKE

CAMSHAFT BANK 1 (See page ES-509)

6CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 1 (CHECK MIL ILLUMINAT E D )

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR EXHAUST

CAMSHAFT BANK 1 (See page ES-509)

Page 743 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–457

ES

(a) Disconnect the VVT sensor for intake camshaft bank 2

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for intake camshaft bank 2

connector.

A

B

(a) Disconnect the VVT sensor for exhaust camshaft bank 2

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 2

connector.

A

B

(a) Disconnect the canister pump module connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the canister pump module connector.

A

7CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 2 (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR INTAKE

CAMSHAFT BANK 2 (See page ES-509)

8CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 2 (CHECK MIL ILLUMINAT E D )

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR EXHAUST

CAMSHAFT BANK 2 (See page ES-509)

9CHECK CHARCOAL CANISTER ASSEMBLY (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE CHARCOAL CANISTER

ASSEMBLY (See page EC-8)

Page 744 of 3000

ES–4582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

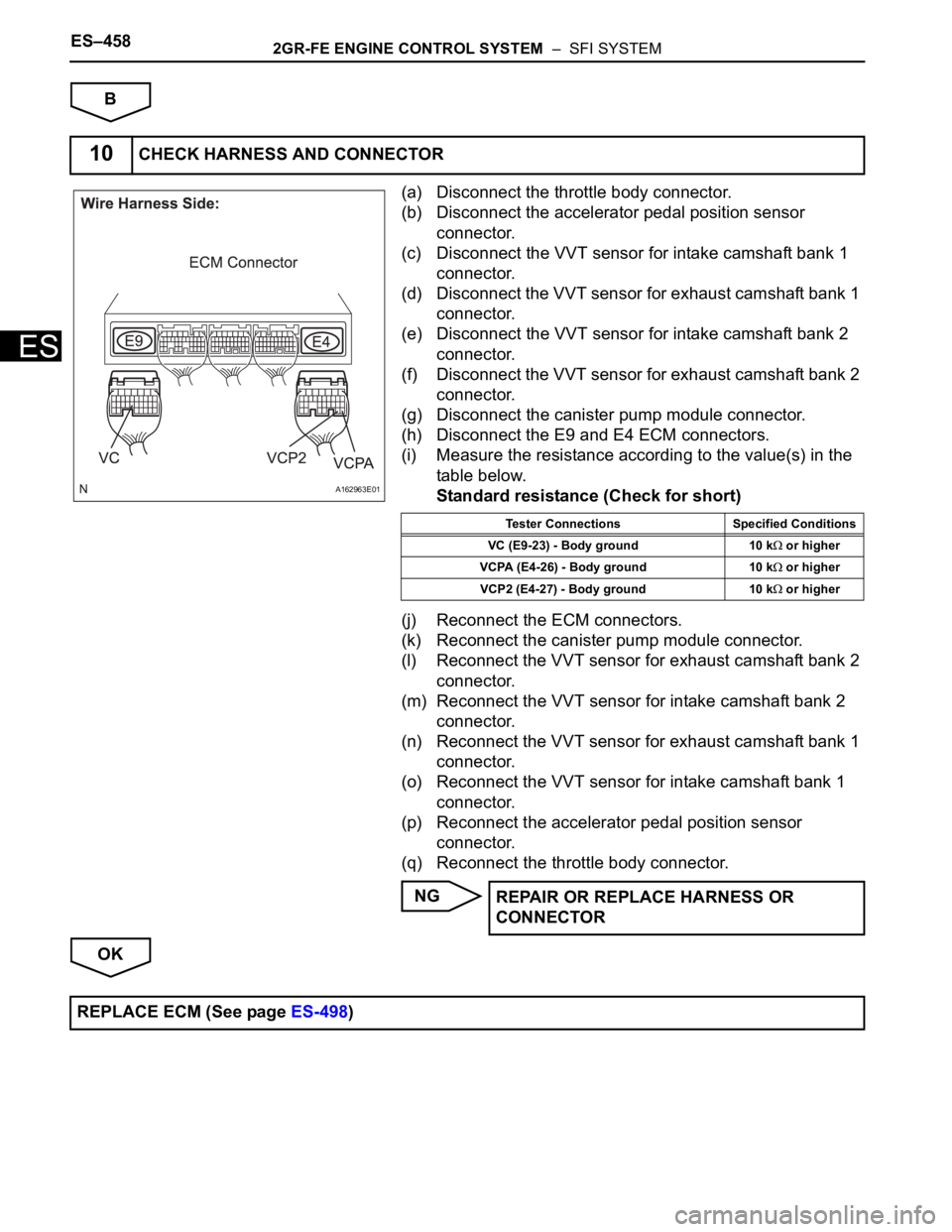

B

(a) Disconnect the throttle body connector.

(b) Disconnect the accelerator pedal position sensor

connector.

(c) Disconnect the VVT sensor for intake camshaft bank 1

connector.

(d) Disconnect the VVT sensor for exhaust camshaft bank 1

connector.

(e) Disconnect the VVT sensor for intake camshaft bank 2

connector.

(f) Disconnect the VVT sensor for exhaust camshaft bank 2

connector.

(g) Disconnect the canister pump module connector.

(h) Disconnect the E9 and E4 ECM connectors.

(i) Measure the resistance according to the value(s) in the

table below.

Standard resistance (Check for short)

(j) Reconnect the ECM connectors.

(k) Reconnect the canister pump module connector.

(l) Reconnect the VVT sensor for exhaust camshaft bank 2

connector.

(m) Reconnect the VVT sensor for intake camshaft bank 2

connector.

(n) Reconnect the VVT sensor for exhaust camshaft bank 1

connector.

(o) Reconnect the VVT sensor for intake camshaft bank 1

connector.

(p) Reconnect the accelerator pedal position sensor

connector.

(q) Reconnect the throttle body connector.

NG

OK

10CHECK HARNESS AND CONNECTOR

A162963E01

Tester Connections Specified Conditions

VC (E9-23) - Body ground 10 k

or higher

VCPA (E4-26) - Body ground 10 k

or higher

VCP2 (E4-27) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM (See page ES-498)

Page 789 of 3000

2GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODYES–493

ES

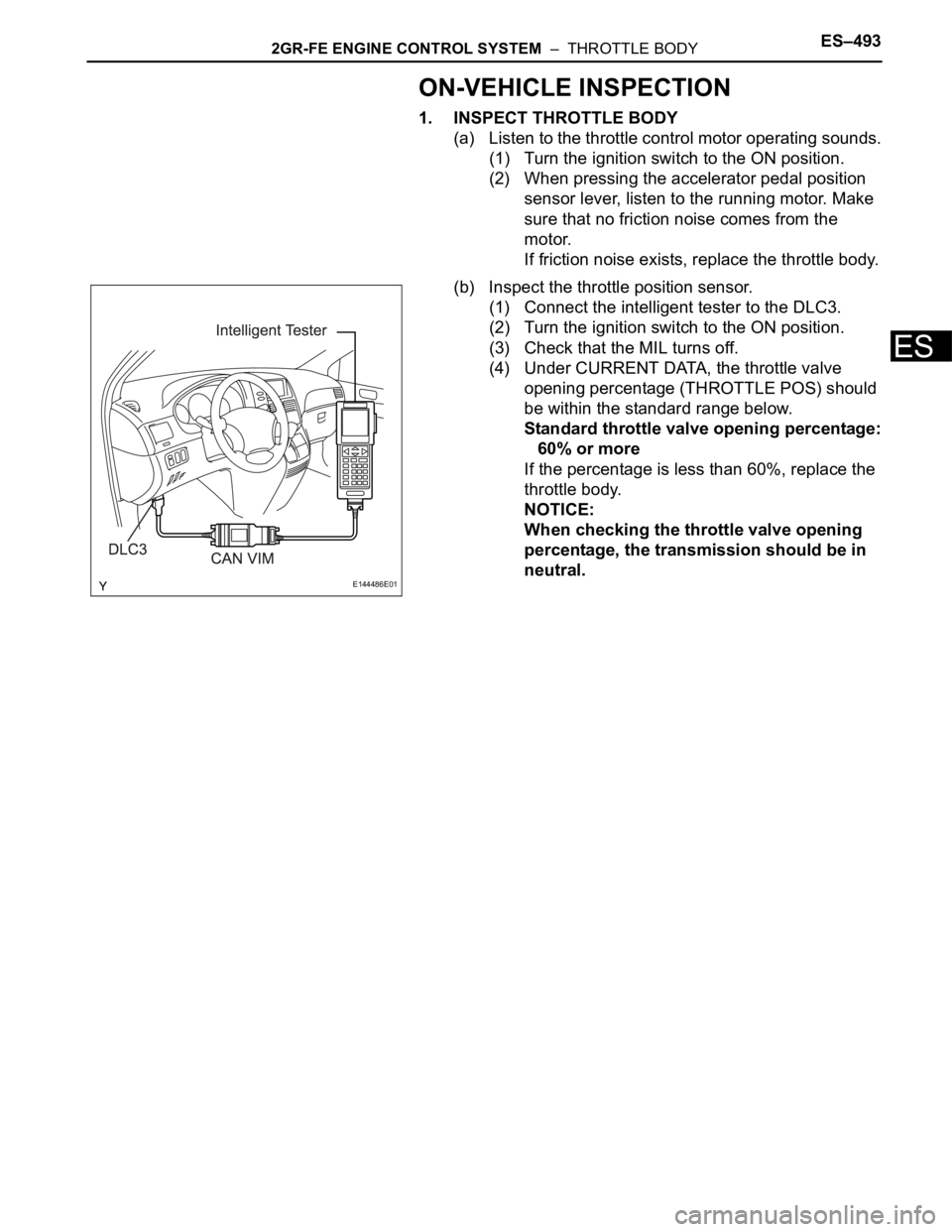

ON-VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Listen to the throttle control motor operating sounds.

(1) Turn the ignition switch to the ON position.

(2) When pressing the accelerator pedal position

sensor lever, listen to the running motor. Make

sure that no friction noise comes from the

motor.

If friction noise exists, replace the throttle body.

(b) Inspect the throttle position sensor.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Check that the MIL turns off.

(4) Under CURRENT DATA, the throttle valve

opening percentage (THROTTLE POS) should

be within the standard range below.

Standard throttle valve opening percentage:

60% or more

If the percentage is less than 60%, replace the

throttle body.

NOTICE:

When checking the throttle valve opening

percentage, the transmission should be in

neutral.

E144486E01

Page 795 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–23

ES

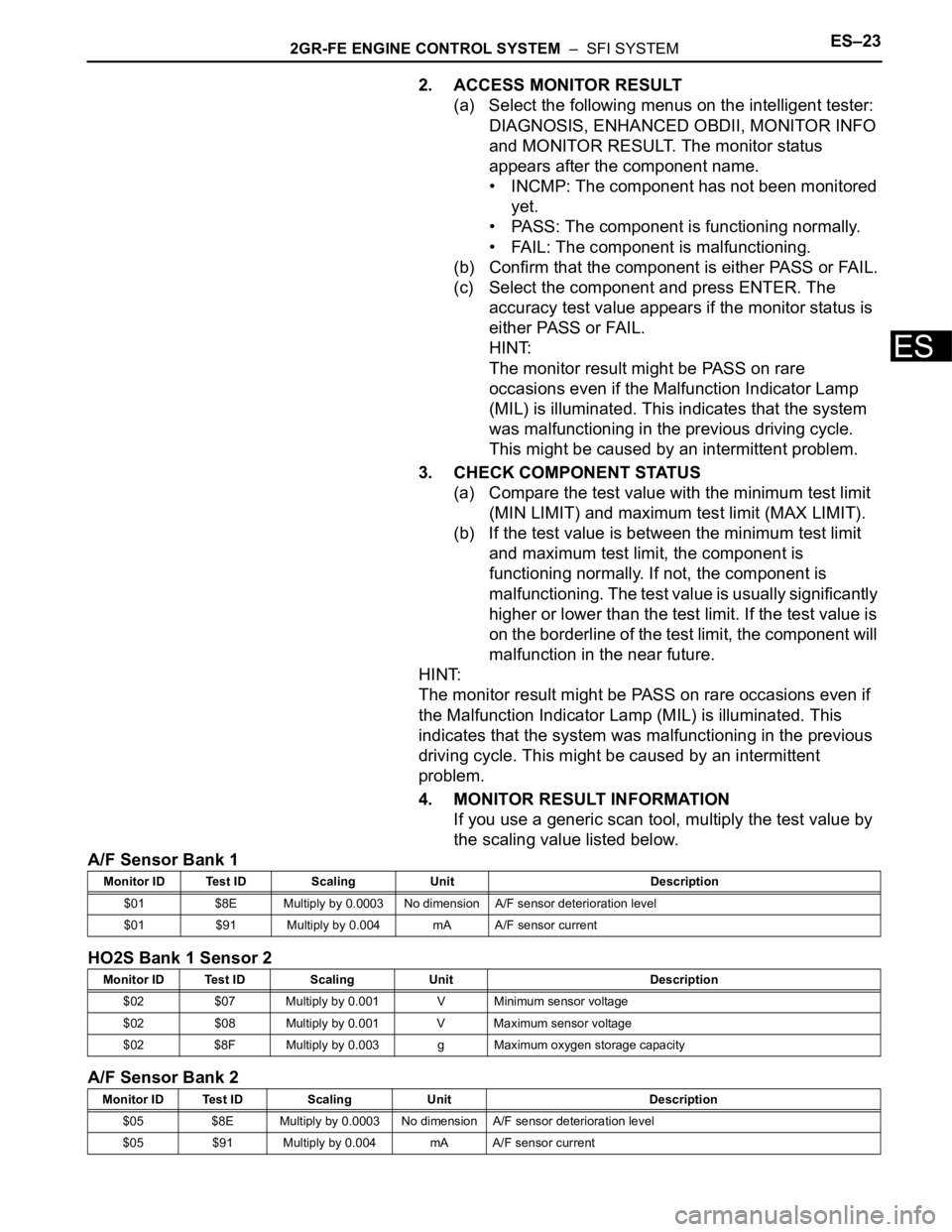

2. ACCESS MONITOR RESULT

(a) Select the following menus on the intelligent tester:

DIAGNOSIS, ENHANCED OBDII, MONITOR INFO

and MONITOR RESULT. The monitor status

appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

HINT:

The monitor result might be PASS on rare

occasions even if the Malfunction Indicator Lamp

(MIL) is illuminated. This indicates that the system

was malfunctioning in the previous driving cycle.

This might be caused by an intermittent problem.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).

(b) If the test value is between the minimum test limit

and maximum test limit, the component is

functioning normally. If not, the component is

malfunctioning. The test value is usually significantly

higher or lower than the test limit. If the test value is

on the borderline of the test limit, the component will

malfunction in the near future.

HINT:

The monitor result might be PASS on rare occasions even if

the Malfunction Indicator Lamp (MIL) is illuminated. This

indicates that the system was malfunctioning in the previous

driving cycle. This might be caused by an intermittent

problem.

4. MONITOR RESULT INFORMATION

If you use a generic scan tool, multiply the test value by

the scaling value listed below.

A/F Sensor Bank 1

HO2S Bank 1 Sensor 2

A/F Sensor Bank 2

Monitor ID Test ID Scaling Unit Description

$01 $8E Multiply by 0.0003 No dimension A/F sensor deterioration level

$01 $91 Multiply by 0.004 mA A/F sensor current

Monitor ID Test ID Scaling Unit Description

$02 $07 Multiply by 0.001 V Minimum sensor voltage

$02 $08 Multiply by 0.001 V Maximum sensor voltage

$02 $8F Multiply by 0.003 g Maximum oxygen storage capacity

Monitor ID Test ID Scaling Unit Description

$05 $8E Multiply by 0.0003 No dimension A/F sensor deterioration level

$05 $91 Multiply by 0.004 mA A/F sensor current

Page 796 of 3000

ES–242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

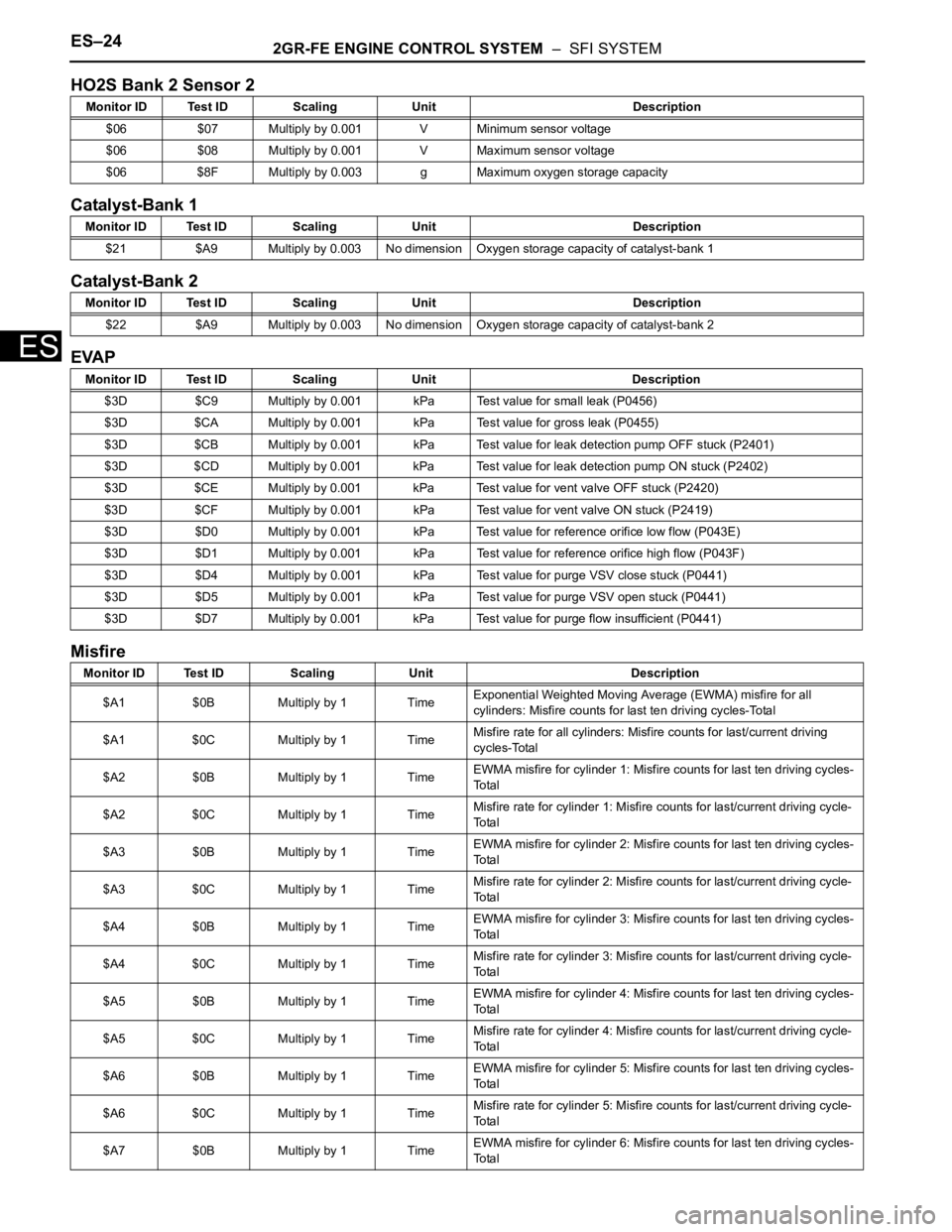

HO2S Bank 2 Sensor 2

Catalyst-Bank 1

Catalyst-Bank 2

EVAP

Misfire

Monitor ID Test ID Scaling Unit Description

$06 $07 Multiply by 0.001 V Minimum sensor voltage

$06 $08 Multiply by 0.001 V Maximum sensor voltage

$06 $8F Multiply by 0.003 g Maximum oxygen storage capacity

Monitor ID Test ID Scaling Unit Description

$21 $A9 Multiply by 0.003 No dimension Oxygen storage capacity of catalyst-bank 1

Monitor ID Test ID Scaling Unit Description

$22 $A9 Multiply by 0.003 No dimension Oxygen storage capacity of catalyst-bank 2

Monitor ID Test ID Scaling Unit Description

$3D $C9 Multiply by 0.001 kPa Test value for small leak (P0456)

$3D $CA Multiply by 0.001 kPa Test value for gross leak (P0455)

$3D $CB Multiply by 0.001 kPa Test value for leak detection pump OFF stuck (P2401)

$3D $CD Multiply by 0.001 kPa Test value for leak detection pump ON stuck (P2402)

$3D $CE Multiply by 0.001 kPa Test value for vent valve OFF stuck (P2420)

$3D $CF Multiply by 0.001 kPa Test value for vent valve ON stuck (P2419)

$3D $D0 Multiply by 0.001 kPa Test value for reference orifice low flow (P043E)

$3D $D1 Multiply by 0.001 kPa Test value for reference orifice high flow (P043F)

$3D $D4 Multiply by 0.001 kPa Test value for purge VSV close stuck (P0441)

$3D $D5 Multiply by 0.001 kPa Test value for purge VSV open stuck (P0441)

$3D $D7 Multiply by 0.001 kPa Test value for purge flow insufficient (P0441)

Monitor ID Test ID Scaling Unit Description

$A1 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for all

cylinders: Misfire counts for last ten driving cycles-Total

$A1 $0C Multiply by 1 TimeMisfire rate for all cylinders: Misfire counts for last/current driving

cycles-Total

$A2 $0B Multiply by 1 TimeEWMA misfire for cylinder 1: Misfire counts for last ten driving cycles-

To t a l

$A2 $0C Multiply by 1 TimeMisfire rate for cylinder 1: Misfire counts for last/current driving cycle-

To t a l

$A3 $0B Multiply by 1 TimeEWMA misfire for cylinder 2: Misfire counts for last ten driving cycles-

To t a l

$A3 $0C Multiply by 1 TimeMisfire rate for cylinder 2: Misfire counts for last/current driving cycle-

To t a l

$A4 $0B Multiply by 1 TimeEWMA misfire for cylinder 3: Misfire counts for last ten driving cycles-

To t a l

$A4 $0C Multiply by 1 TimeMisfire rate for cylinder 3: Misfire counts for last/current driving cycle-

To t a l

$A5 $0B Multiply by 1 TimeEWMA misfire for cylinder 4: Misfire counts for last ten driving cycles-

To t a l

$A5 $0C Multiply by 1 TimeMisfire rate for cylinder 4: Misfire counts for last/current driving cycle-

To t a l

$A6 $0B Multiply by 1 TimeEWMA misfire for cylinder 5: Misfire counts for last ten driving cycles-

To t a l

$A6 $0C Multiply by 1 TimeMisfire rate for cylinder 5: Misfire counts for last/current driving cycle-

To t a l

$A7 $0B Multiply by 1 TimeEWMA misfire for cylinder 6: Misfire counts for last ten driving cycles-

To t a l