TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 941 of 3000

EM–1322GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(h) Install the 8 crankshaft bearing cap bolts to the

outside positions.

(i) Install the crankshaft bearing cap bolts.

HINT:

The crankshaft bearing cap bolts are tightened in 2

progressive steps.

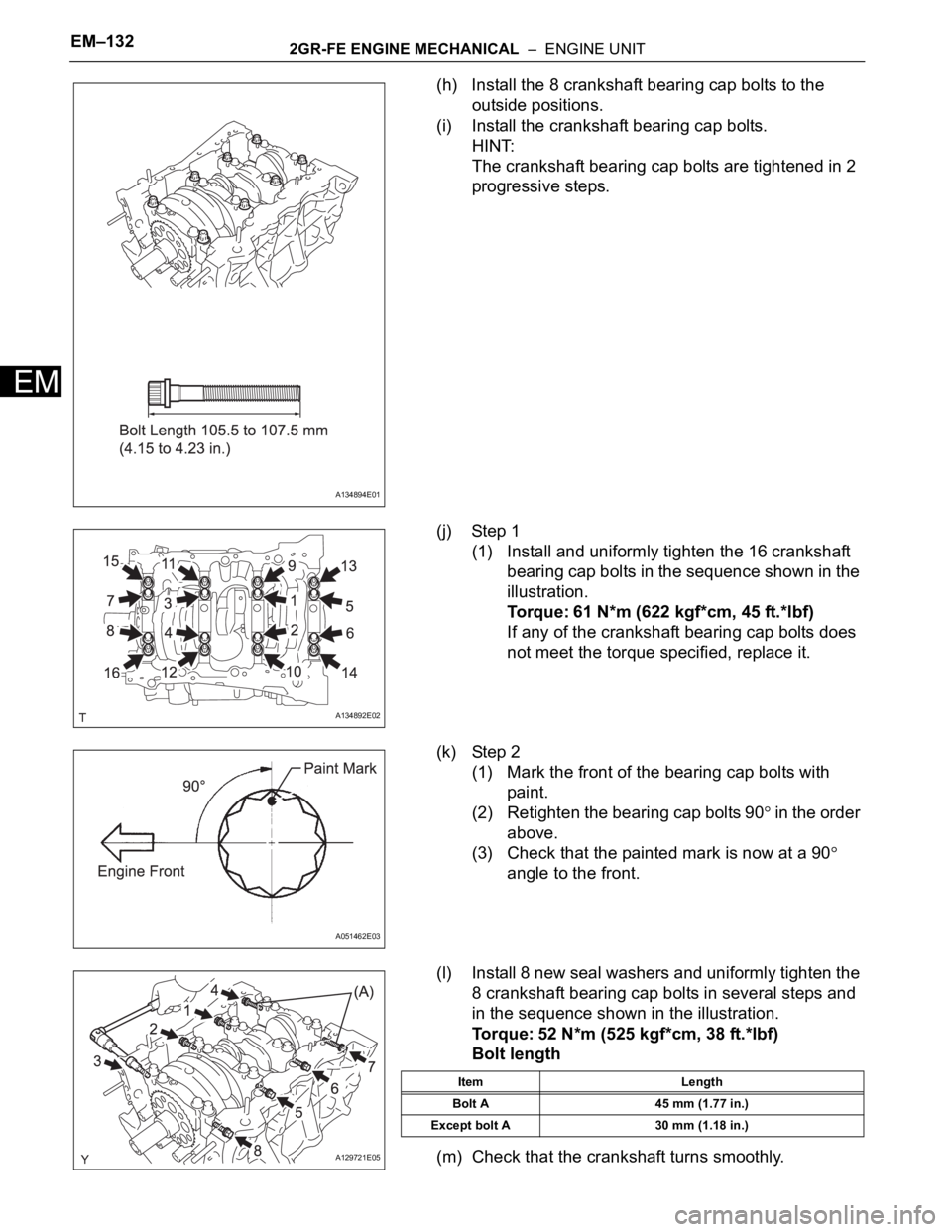

(j) Step 1

(1) Install and uniformly tighten the 16 crankshaft

bearing cap bolts in the sequence shown in the

illustration.

Torque: 61 N*m (622 kgf*cm, 45 ft.*lbf)

If any of the crankshaft bearing cap bolts does

not meet the torque specified, replace it.

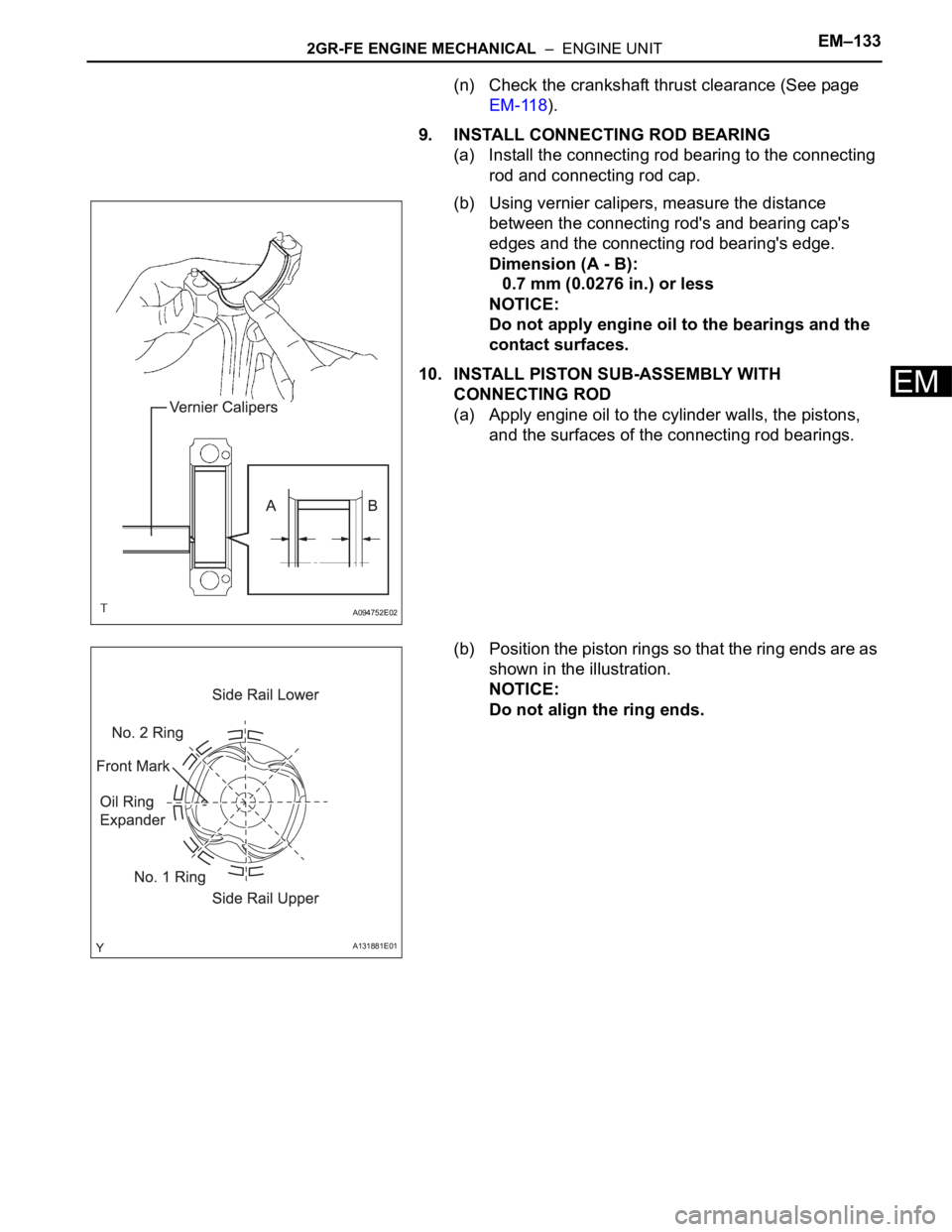

(k) Step 2

(1) Mark the front of the bearing cap bolts with

paint.

(2) Retighten the bearing cap bolts 90

in the order

above.

(3) Check that the painted mark is now at a 90

angle to the front.

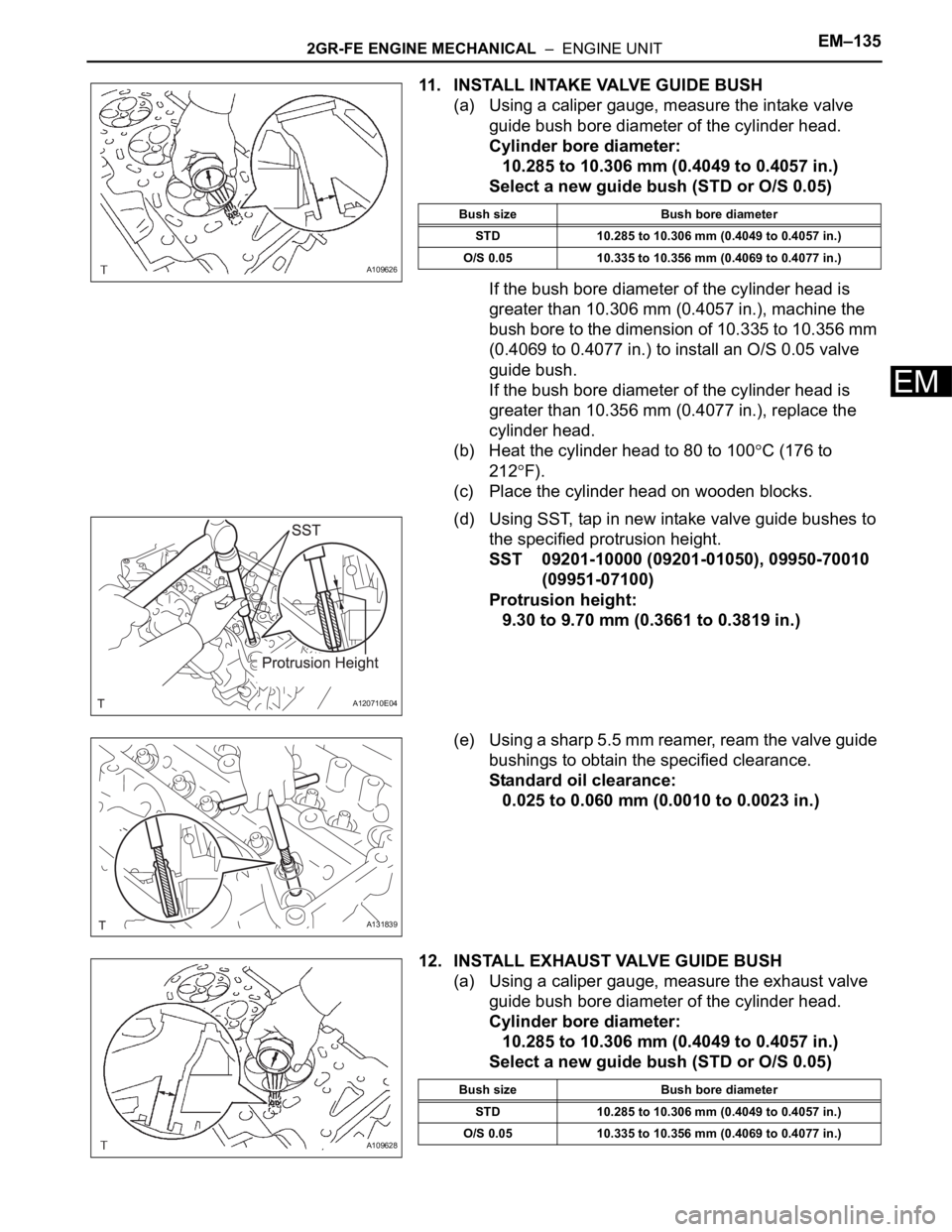

(l) Install 8 new seal washers and uniformly tighten the

8 crankshaft bearing cap bolts in several steps and

in the sequence shown in the illustration.

Torque: 52 N*m (525 kgf*cm, 38 ft.*lbf)

Bolt length

(m) Check that the crankshaft turns smoothly.

A134894E01

A134892E02

A051462E03

A129721E05

Item Length

Bolt A 45 mm (1.77 in.)

Except bolt A 30 mm (1.18 in.)

Page 942 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–133

EM

(n) Check the crankshaft thrust clearance (See page

EM-118).

9. INSTALL CONNECTING ROD BEARING

(a) Install the connecting rod bearing to the connecting

rod and connecting rod cap.

(b) Using vernier calipers, measure the distance

between the connecting rod's and bearing cap's

edges and the connecting rod bearing's edge.

Dimension (A - B):

0.7 mm (0.0276 in.) or less

NOTICE:

Do not apply engine oil to the bearings and the

contact surfaces.

10. INSTALL PISTON SUB-ASSEMBLY WITH

CONNECTING ROD

(a) Apply engine oil to the cylinder walls, the pistons,

and the surfaces of the connecting rod bearings.

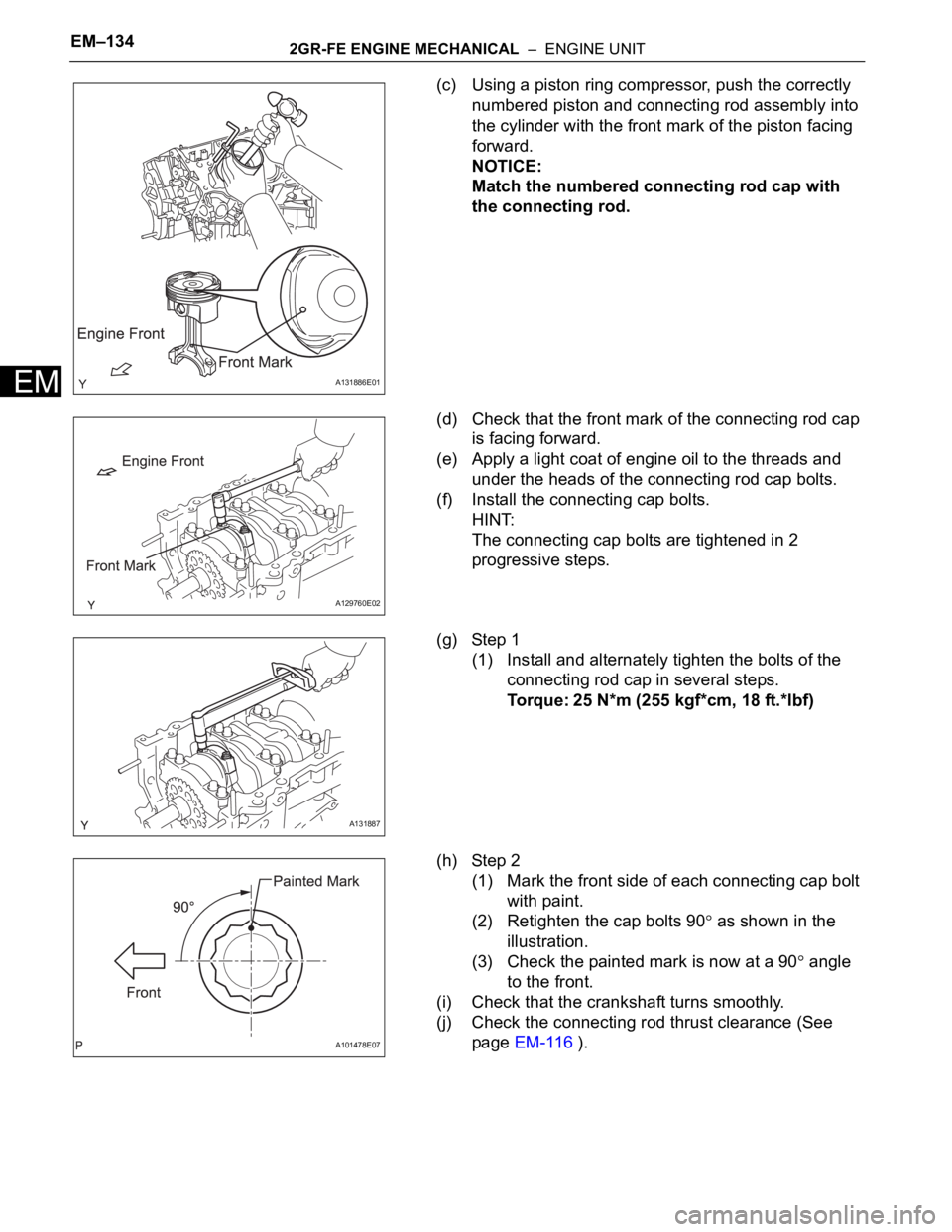

(b) Position the piston rings so that the ring ends are as

shown in the illustration.

NOTICE:

Do not align the ring ends.

A094752E02

A131881E01

Page 943 of 3000

EM–1342GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(c) Using a piston ring compressor, push the correctly

numbered piston and connecting rod assembly into

the cylinder with the front mark of the piston facing

forward.

NOTICE:

Match the numbered connecting rod cap with

the connecting rod.

(d) Check that the front mark of the connecting rod cap

is facing forward.

(e) Apply a light coat of engine oil to the threads and

under the heads of the connecting rod cap bolts.

(f) Install the connecting cap bolts.

HINT:

The connecting cap bolts are tightened in 2

progressive steps.

(g) Step 1

(1) Install and alternately tighten the bolts of the

connecting rod cap in several steps.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

(h) Step 2

(1) Mark the front side of each connecting cap bolt

with paint.

(2) Retighten the cap bolts 90

as shown in the

illustration.

(3) Check the painted mark is now at a 90

angle

to the front.

(i) Check that the crankshaft turns smoothly.

(j) Check the connecting rod thrust clearance (See

page EM-116 ).

A131886E01

A129760E02

A131887

A101478E07

Page 944 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–135

EM

11. INSTALL INTAKE VALVE GUIDE BUSH

(a) Using a caliper gauge, measure the intake valve

guide bush bore diameter of the cylinder head.

Cylinder bore diameter:

10.285 to 10.306 mm (0.4049 to 0.4057 in.)

Select a new guide bush (STD or O/S 0.05)

If the bush bore diameter of the cylinder head is

greater than 10.306 mm (0.4057 in.), machine the

bush bore to the dimension of 10.335 to 10.356 mm

(0.4069 to 0.4077 in.) to install an O/S 0.05 valve

guide bush.

If the bush bore diameter of the cylinder head is

greater than 10.356 mm (0.4077 in.), replace the

cylinder head.

(b) Heat the cylinder head to 80 to 100

C (176 to

212

F).

(c) Place the cylinder head on wooden blocks.

(d) Using SST, tap in new intake valve guide bushes to

the specified protrusion height.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

Protrusion height:

9.30 to 9.70 mm (0.3661 to 0.3819 in.)

(e) Using a sharp 5.5 mm reamer, ream the valve guide

bushings to obtain the specified clearance.

Standard oil clearance:

0.025 to 0.060 mm (0.0010 to 0.0023 in.)

12. INSTALL EXHAUST VALVE GUIDE BUSH

(a) Using a caliper gauge, measure the exhaust valve

guide bush bore diameter of the cylinder head.

Cylinder bore diameter:

10.285 to 10.306 mm (0.4049 to 0.4057 in.)

Select a new guide bush (STD or O/S 0.05)

A109626

Bush size Bush bore diameter

STD 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

O/S 0.05 10.335 to 10.356 mm (0.4069 to 0.4077 in.)

A120710E04

A131839

A109628

Bush size Bush bore diameter

STD 10.285 to 10.306 mm (0.4049 to 0.4057 in.)

O/S 0.05 10.335 to 10.356 mm (0.4069 to 0.4077 in.)

Page 945 of 3000

EM–1362GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

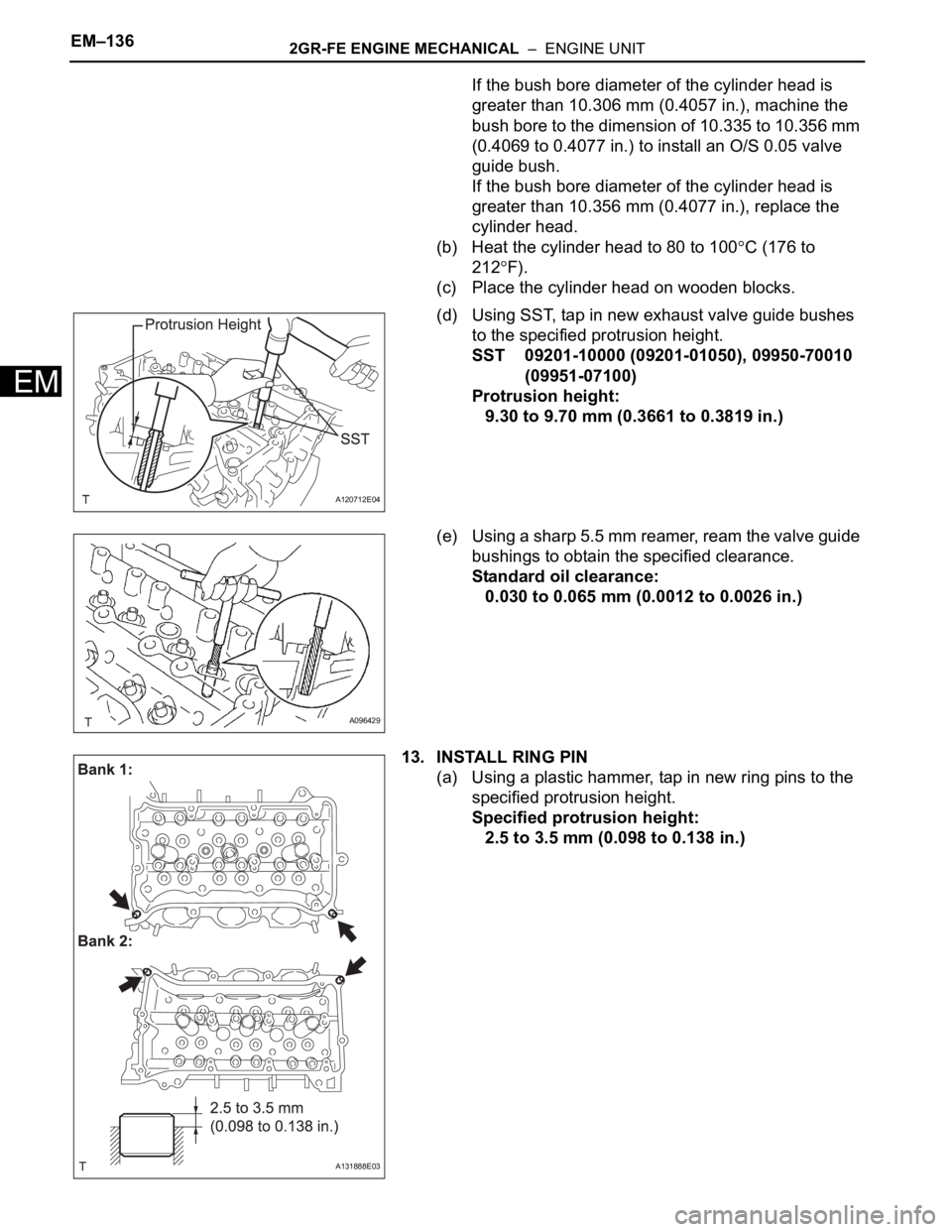

If the bush bore diameter of the cylinder head is

greater than 10.306 mm (0.4057 in.), machine the

bush bore to the dimension of 10.335 to 10.356 mm

(0.4069 to 0.4077 in.) to install an O/S 0.05 valve

guide bush.

If the bush bore diameter of the cylinder head is

greater than 10.356 mm (0.4077 in.), replace the

cylinder head.

(b) Heat the cylinder head to 80 to 100

C (176 to

212

F).

(c) Place the cylinder head on wooden blocks.

(d) Using SST, tap in new exhaust valve guide bushes

to the specified protrusion height.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

Protrusion height:

9.30 to 9.70 mm (0.3661 to 0.3819 in.)

(e) Using a sharp 5.5 mm reamer, ream the valve guide

bushings to obtain the specified clearance.

Standard oil clearance:

0.030 to 0.065 mm (0.0012 to 0.0026 in.)

13. INSTALL RING PIN

(a) Using a plastic hammer, tap in new ring pins to the

specified protrusion height.

Specified protrusion height:

2.5 to 3.5 mm (0.098 to 0.138 in.)

A120712E04

A096429

A131888E03

Page 946 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–137

EM

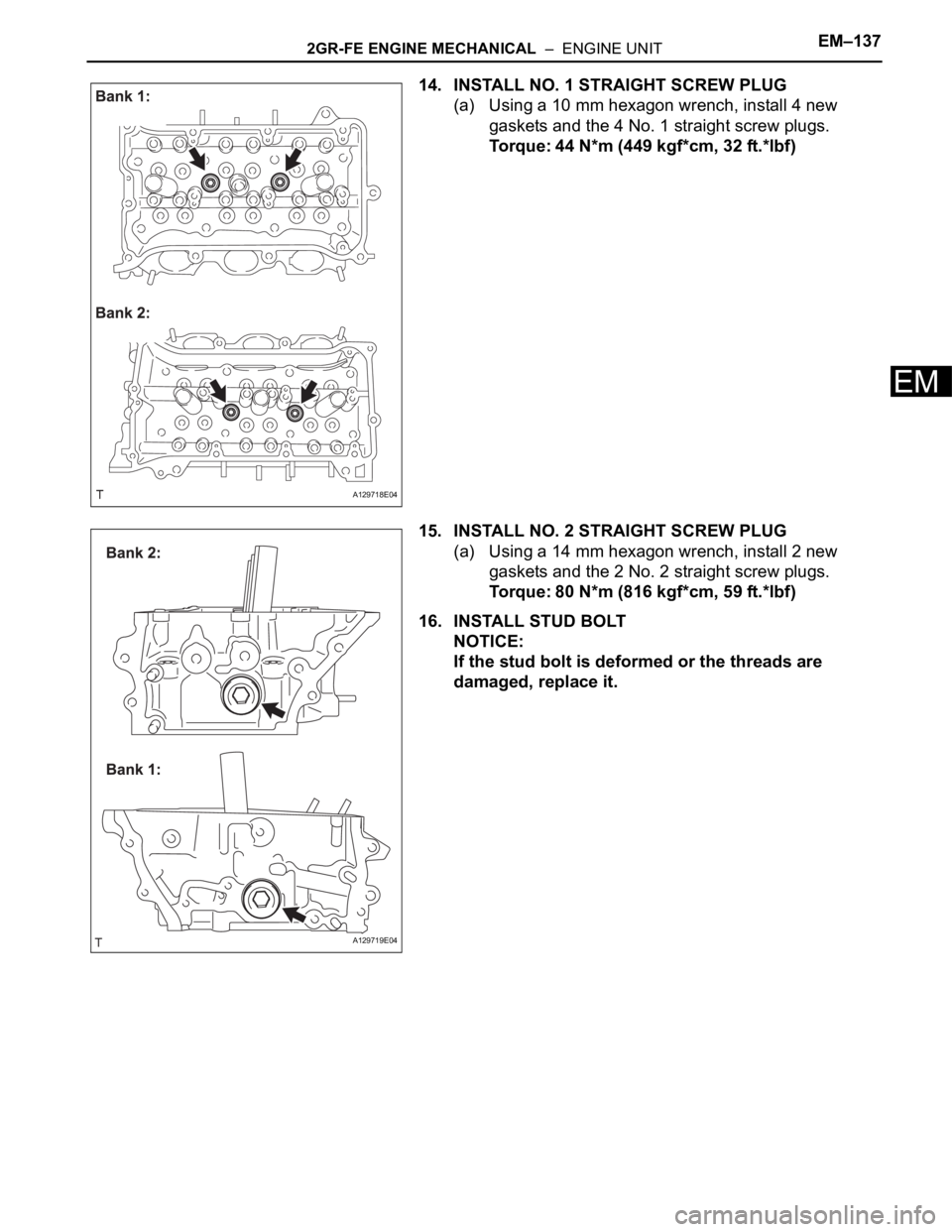

14. INSTALL NO. 1 STRAIGHT SCREW PLUG

(a) Using a 10 mm hexagon wrench, install 4 new

gaskets and the 4 No. 1 straight screw plugs.

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

15. INSTALL NO. 2 STRAIGHT SCREW PLUG

(a) Using a 14 mm hexagon wrench, install 2 new

gaskets and the 2 No. 2 straight screw plugs.

Torque: 80 N*m (816 kgf*cm, 59 ft.*lbf)

16. INSTALL STUD BOLT

NOTICE:

If the stud bolt is deformed or the threads are

damaged, replace it.

A129718E04

A129719E04

Page 947 of 3000

EM–1382GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

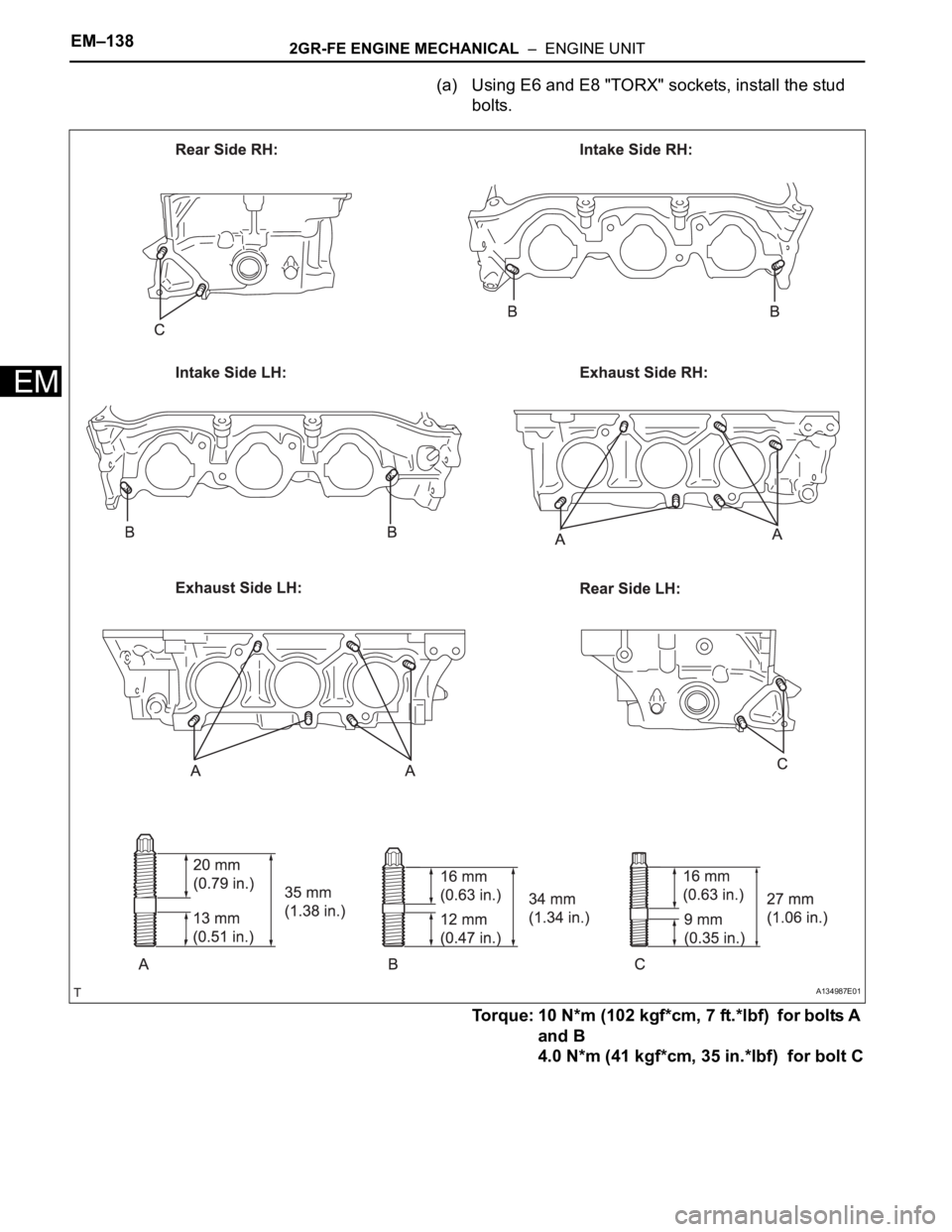

(a) Using E6 and E8 "TORX" sockets, install the stud

bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) for bolts A

and B

4.0 N*m (41 kgf*cm, 35 in.*lbf) for bolt C

A134987E01

Page 948 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–139

EM

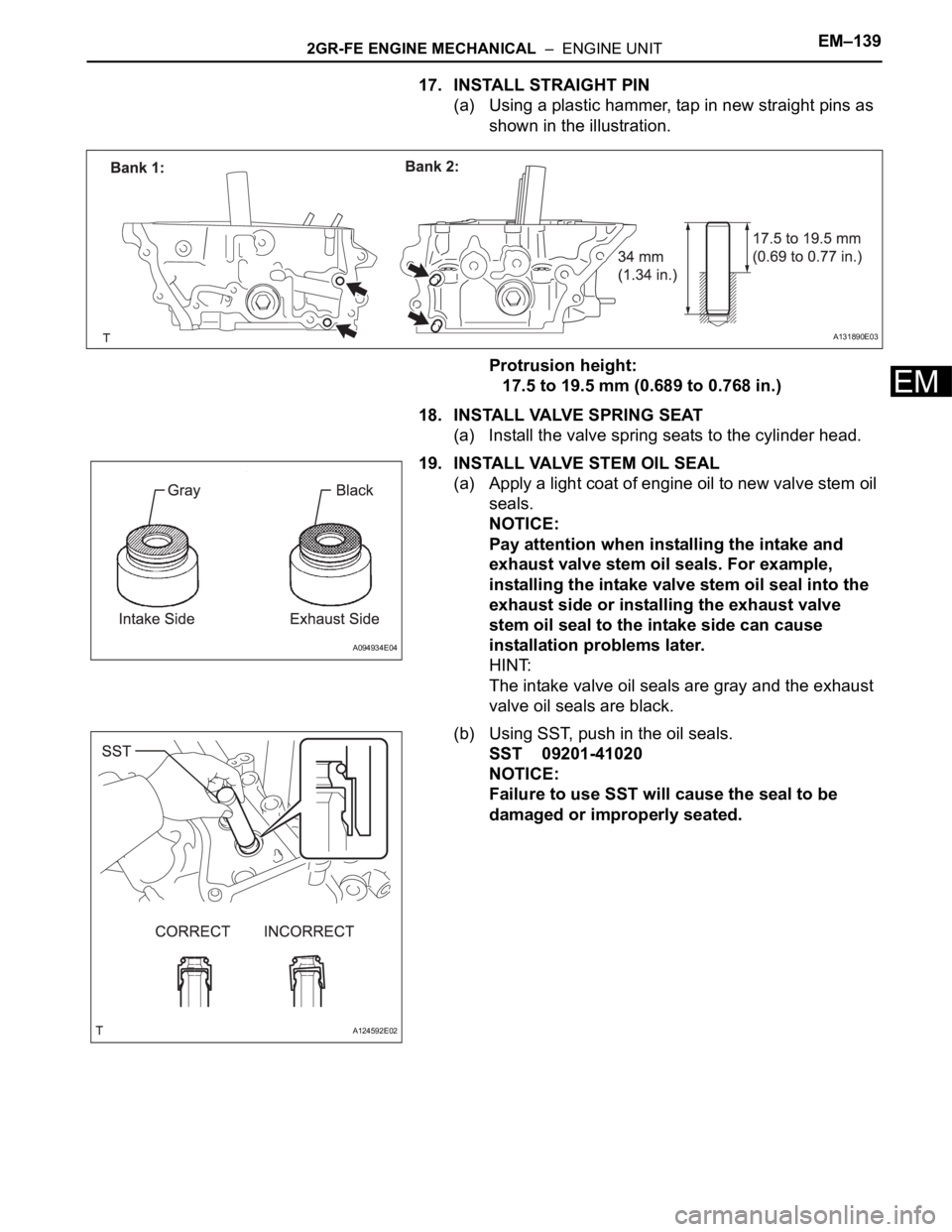

17. INSTALL STRAIGHT PIN

(a) Using a plastic hammer, tap in new straight pins as

shown in the illustration.

Protrusion height:

17.5 to 19.5 mm (0.689 to 0.768 in.)

18. INSTALL VALVE SPRING SEAT

(a) Install the valve spring seats to the cylinder head.

19. INSTALL VALVE STEM OIL SEAL

(a) Apply a light coat of engine oil to new valve stem oil

seals.

NOTICE:

Pay attention when installing the intake and

exhaust valve stem oil seals. For example,

installing the intake valve stem oil seal into the

exhaust side or installing the exhaust valve

stem oil seal to the intake side can cause

installation problems later.

HINT:

The intake valve oil seals are gray and the exhaust

valve oil seals are black.

(b) Using SST, push in the oil seals.

SST 09201-41020

NOTICE:

Failure to use SST will cause the seal to be

damaged or improperly seated.

A131890E03

A094934E04

A124592E02

Page 949 of 3000

EM–1402GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

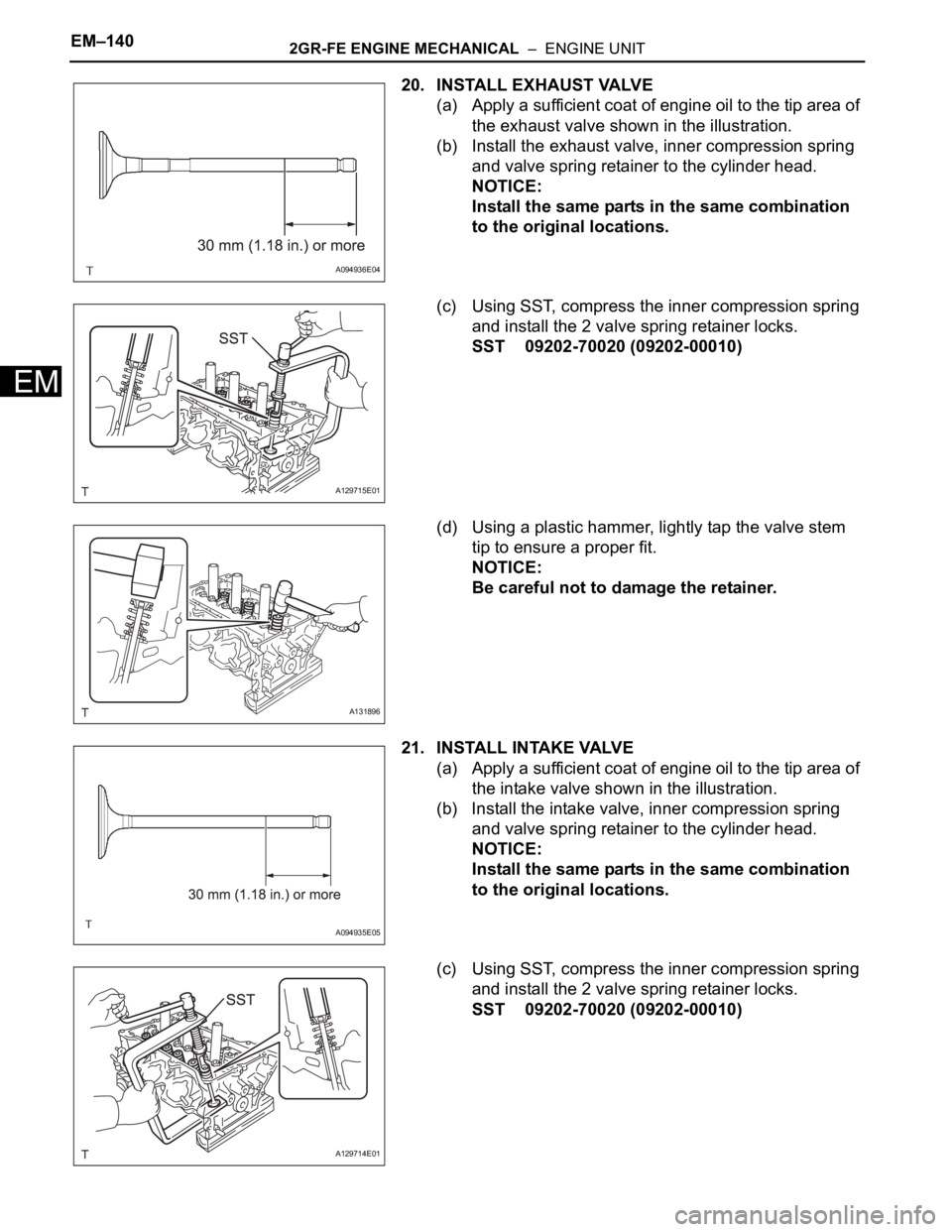

20. INSTALL EXHAUST VALVE

(a) Apply a sufficient coat of engine oil to the tip area of

the exhaust valve shown in the illustration.

(b) Install the exhaust valve, inner compression spring

and valve spring retainer to the cylinder head.

NOTICE:

Install the same parts in the same combination

to the original locations.

(c) Using SST, compress the inner compression spring

and install the 2 valve spring retainer locks.

SST 09202-70020 (09202-00010)

(d) Using a plastic hammer, lightly tap the valve stem

tip to ensure a proper fit.

NOTICE:

Be careful not to damage the retainer.

21. INSTALL INTAKE VALVE

(a) Apply a sufficient coat of engine oil to the tip area of

the intake valve shown in the illustration.

(b) Install the intake valve, inner compression spring

and valve spring retainer to the cylinder head.

NOTICE:

Install the same parts in the same combination

to the original locations.

(c) Using SST, compress the inner compression spring

and install the 2 valve spring retainer locks.

SST 09202-70020 (09202-00010)

A094936E04

A129715E01

A131896

A094935E05

A129714E01

Page 950 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–141

EM

(d) Using a plastic hammer, lightly tap the valve stem

tip to ensure a proper fit.

NOTICE:

Be careful not to damage the retainer.

22. INSTALL VALVE STEM CAP

(a) Apply a light coat of engine oil to the valve stem

caps.

(b) Install the valve stem caps on the valves.

23. INSTALL ENGINE REAR OIL SEAL

(a) Place the oil seal retainer on wooden blocks.

(b) Using SST, tap in a new engine rear oil seal until its

surface is flush with the engine rear oil seal retainer

edge.

SST 09223-15030, 09950-70010 (09951-07100)

NOTICE:

• Keep the lip free of foreign matter.

• Do not tap on the oil seal at an angle.

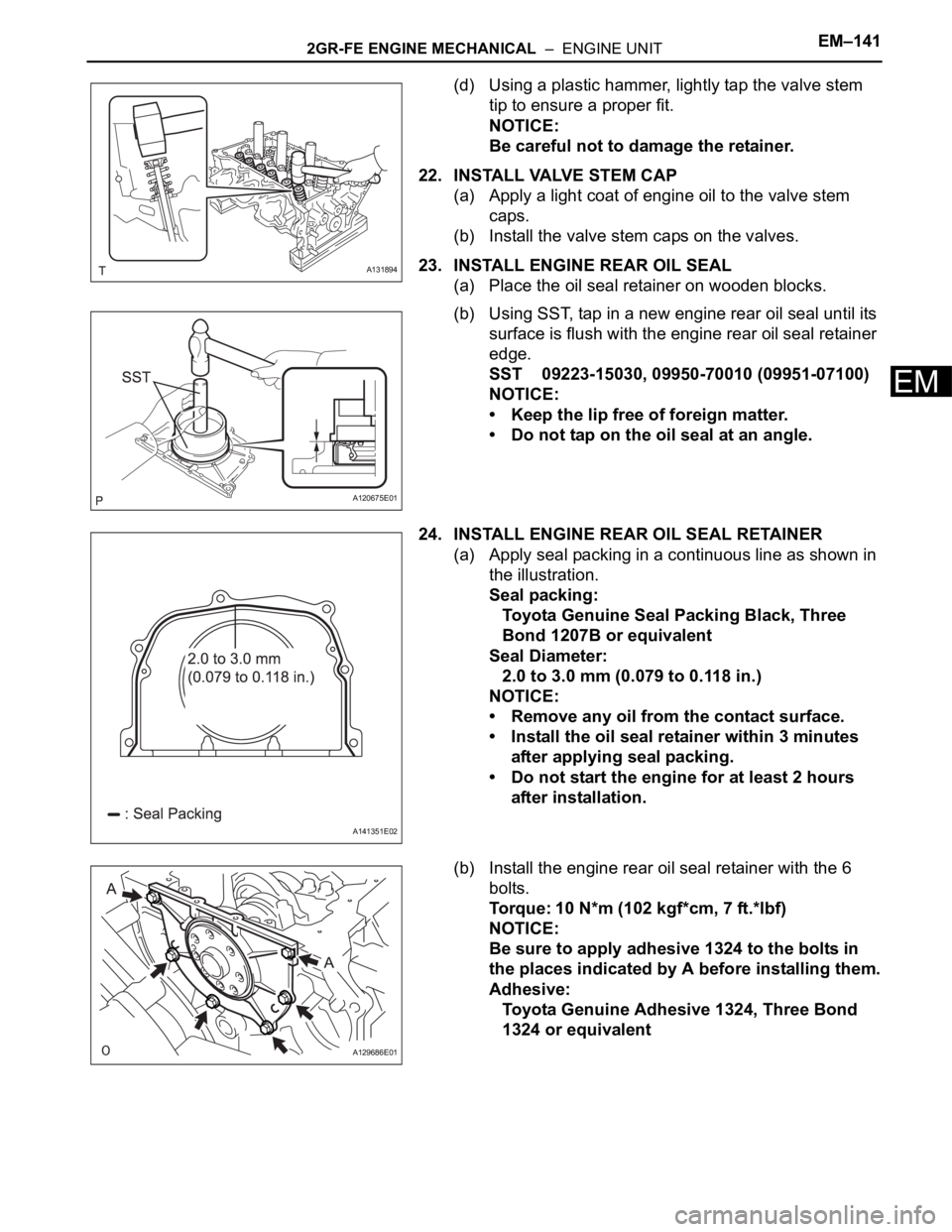

24. INSTALL ENGINE REAR OIL SEAL RETAINER

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or equivalent

Seal Diameter:

2.0 to 3.0 mm (0.079 to 0.118 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the oil seal retainer within 3 minutes

after applying seal packing.

• Do not start the engine for at least 2 hours

after installation.

(b) Install the engine rear oil seal retainer with the 6

bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

NOTICE:

Be sure to apply adhesive 1324 to the bolts in

the places indicated by A before installing them.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

A131894

A120675E01

A141351E02

A129686E01