VOLVO V60 2014 Owners Manual

Manufacturer: VOLVO, Model Year: 2014, Model line: V60, Model: VOLVO V60 2014Pages: 442, PDF Size: 13.85 MB

Page 331 of 442

09 Wheels and tyres

09

* Option/accessory, for more information, see Introduction.329

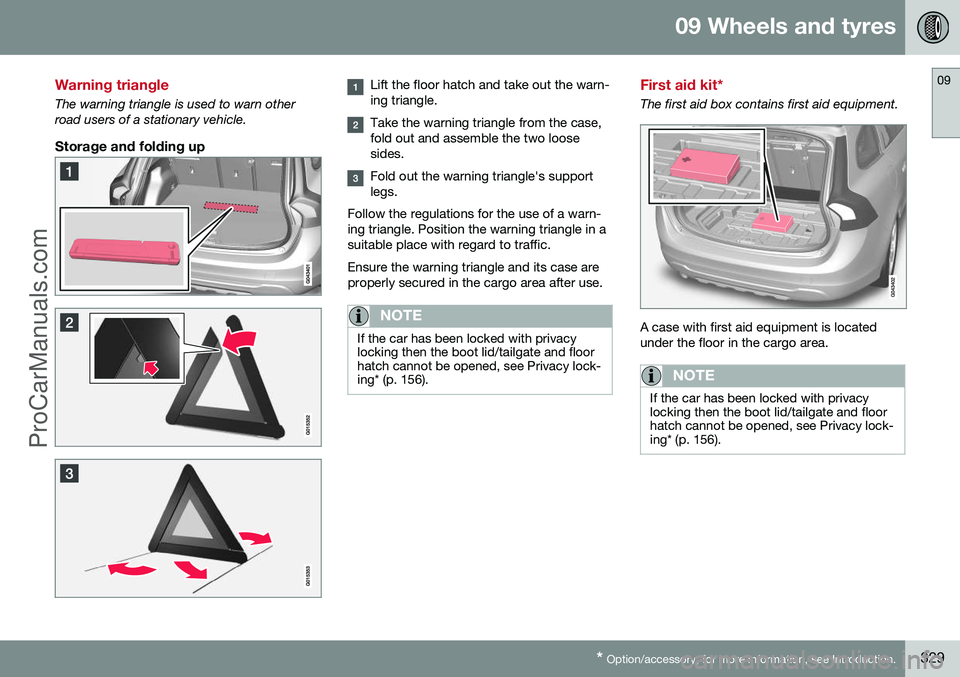

Warning triangle

The warning triangle is used to warn other road users of a stationary vehicle.

Storage and folding up

Lift the floor hatch and take out the warn- ing triangle.

Take the warning triangle from the case, fold out and assemble the two loosesides.

Fold out the warning triangle's support legs.

Follow the regulations for the use of a warn-ing triangle. Position the warning triangle in asuitable place with regard to traffic. Ensure the warning triangle and its case are properly secured in the cargo area after use.

NOTE

If the car has been locked with privacy locking then the boot lid/tailgate and floorhatch cannot be opened, see Privacy lock-ing* (p. 156).

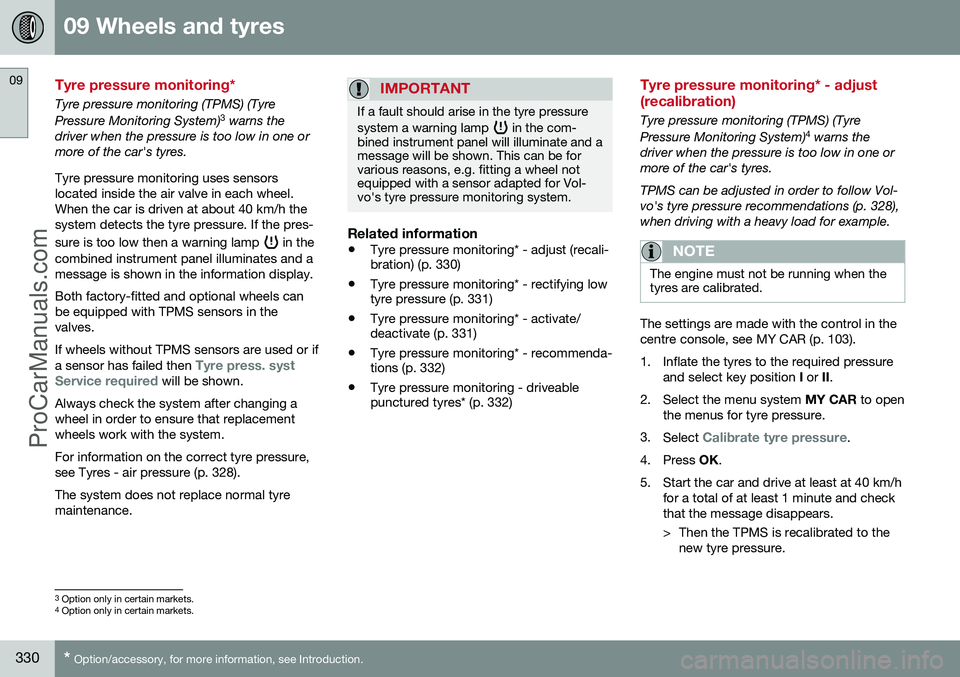

First aid kit*

The first aid box contains first aid equipment.

A case with first aid equipment is located under the floor in the cargo area.

NOTE

If the car has been locked with privacy locking then the boot lid/tailgate and floorhatch cannot be opened, see Privacy lock-ing* (p. 156).

ProCarManuals.co’

Page 332 of 442

09 Wheels and tyres

09

330* Option/accessory, for more information, see Introduction.

Tyre pressure monitoring*

Tyre pressure monitoring (TPMS) (Tyre Pressure Monitoring System) 3

warns the

driver when the pressure is too low in one or more of the car's tyres. Tyre pressure monitoring uses sensors located inside the air valve in each wheel.When the car is driven at about 40 km/h thesystem detects the tyre pressure. If the pres- sure is too low then a warning lamp

in the

combined instrument panel illuminates and a message is shown in the information display. Both factory-fitted and optional wheels can be equipped with TPMS sensors in thevalves. If wheels without TPMS sensors are used or if a sensor has failed then

Tyre press. syst

Service required will be shown.

Always check the system after changing a wheel in order to ensure that replacementwheels work with the system. For information on the correct tyre pressure, see Tyres - air pressure (p. 328). The system does not replace normal tyre maintenance.

IMPORTANT

If a fault should arise in the tyre pressure system a warning lamp

in the com-

bined instrument panel will illuminate and a message will be shown. This can be forvarious reasons, e.g. fitting a wheel notequipped with a sensor adapted for Vol-vo's tyre pressure monitoring system.

Related information

• Tyre pressure monitoring* - adjust (recali- bration) (p. 330)

• Tyre pressure monitoring* - rectifying lowtyre pressure (p. 331)

• Tyre pressure monitoring* - activate/deactivate (p. 331)

• Tyre pressure monitoring* - recommenda-tions (p. 332)

• Tyre pressure monitoring - driveablepunctured tyres* (p. 332)

Tyre pressure monitoring* - adjust (recalibration)

Tyre pressure monitoring (TPMS) (Tyre Pressure Monitoring System) 4

warns the

driver when the pressure is too low in one or more of the car's tyres. TPMS can be adjusted in order to follow Vol- vo's tyre pressure recommendations (p. 328),when driving with a heavy load for example.

NOTE

The engine must not be running when the tyres are calibrated.

The settings are made with the control in the centre console, see MY CAR (p. 103).

1. Inflate the tyres to the required pressure and select key position I or II.

2. Select the menu system MY CAR to open

the menus for tyre pressure.

3. Select

Calibrate tyre pressure.

4. Press OK.

5. Start the car and drive at least at 40 km/h for a total of at least 1 minute and check that the message disappears.

> Then the TPMS is recalibrated to thenew tyre pressure.

3Option only in certain markets.

4 Option only in certain markets.

ProCarManuals.co’

Page 333 of 442

09 Wheels and tyres

09

* Option/accessory, for more information, see Introduction.331

Related information

• Tyre pressure monitoring* (p. 330)

• Tyres - air pressure (p. 328)

Tyre pressure monitoring* - rectifying low tyre pressure

Tyre pressure monitoring TPMS (Tyre Pressure Monitoring System) 5

warns the

driver when the pressure is too low in one or more of the car's tyres. If a message for low tyre pressure is shown in the display:

1. Check the tyre pressure in all four tyres.

2. Inflate the tyre(s) to the correct pressure.

3. Drive at least at 40 km/h for a total of at least 1 minute and check that the mes- sage disappears.

Related information

• Tyre pressure monitoring* (p. 330)

Tyre pressure monitoring* - activate/ deactivate

Tyre pressure monitoring (TPMS) (Tyre Pressure Monitoring System) 6

warns the

driver when the pressure is too low in one or more of the car's tyres.

NOTE

The engine must not be running when tyre pressure monitoring is activated/deacti-vated.

The settings are made with the control in the centre console, see MY CAR (p. 103).

1. Select key position I or II.

2. Select the system MY CAR to open the

menus for tyre pressure.

3. Select Tyre pressure system/Pressure monitoring and press OK.

> An

X is shown in the information dis-

play if the system is activated, the option disappears if the system isdeactivated.

Related information

• Tyre pressure monitoring* (p. 330)

5

Option only in certain markets.

6 Option only in certain markets.

ProCarManuals.co’

Page 334 of 442

09 Wheels and tyres

09

332* Option/accessory, for more information, see Introduction.

Tyre pressure monitoring* - recommendations

Tyre pressure monitoring TPMS (Tyre Pressure Monitoring System) 7

warns the

driver when the pressure is too low in one or more of the car's tyres.

• Volvo recommends that TPMS sensors are fitted to all wheels on the car.

• Volvo recommends that sensors are notmoved between different wheels.

WARNING

When inflating a tyre equipped with TPMS, hold the nozzle of the pump directlyagainst the valve to avoid damaging thevalve.

Related information

• Tyre pressure monitoring* (p. 330)

Tyre pressure monitoring - driveable punctured tyres*

If SST (Self Supporting run flat Tires)* is selected, the car is also equipped with TPMS(p. 330). This type of tyre has a specially reinforced side wall that makes continued driving possi-ble to a limited extent despite the tyre losingall or some of its pressure. These tyres are fit-ted on a special rim. (Normal tyres can alsobe fitted to this rim.) If an SST tyre loses tyre pressure then the yellow TPMS lamp in the combined instru-ment panel illuminates and a message isshown in the information display. If thisoccurs, reduce speed to max. 80 km/h. Thetyre must be replaced as soon as possible. Drive carefully, in some cases it can be diffi- cult to see which tyre is faulty. In order toestablish which tyre needs attention, checkall four tyres.

WARNING

Only people with knowledge of SST tyres should fit them. SST tyres must only be fitted together with TPMS. After an error message about low tyre pressure has been shown, do not drivefaster than 80 km/h. Maximum mileage before tyre replacement is 80 km. Avoid hard driving such as sudden braking or turning. SST tyres must be replaced if they are damaged or punctured.

Related information

•Tyre pressure monitoring* (p. 330)

7

Option only in certain markets.

ProCarManuals.co’

Page 335 of 442

09 Wheels and tyres

09

333

Emergency puncture repair

Emergency puncture repair, where the emer- gency puncture repair kit (TMK - TemporaryMobility Kit) is used to seal a puncture andcheck and adjust the tyre pressure (p. 407). The emergency puncture repair kit (p. 334) consists of a compressor and a bottle of seal-ant. The sealing works as a temporary repair.The sealing fluid bottle must be replacedbefore its expiration date and after use. Thesealing fluid effectively seals tyres puncturedin the tread.

NOTE

The emergency puncture repair kit is only intended for sealing tyres with a puncturein the tread.

The emergency puncture repair kit has limited capacity to seal tyres which have puncturesin the wall. Do not seal tyres with the emer-gency puncture repair kit if they have largerslits, cracks or similar damage. Connect thecompressor to one of the car's 12 V sockets.Choose the socket that is nearest to thepunctured tyre.

IMPORTANT

If the compressor for emergency puncture repair is connected to one of the two sock-ets (p. 141) in the tunnel console then noother current consumer may be connectedto the other one.

NOTE

The compressor for temporary emergency puncture repair has been tested andapproved by Volvo.

Related information

•Emergency puncture repair - operation (p. 335)

• Emergency puncture repair - rechecking(p. 336)

• Emergency puncture repair kit - overview(p. 334)

• Tools (p. 320)

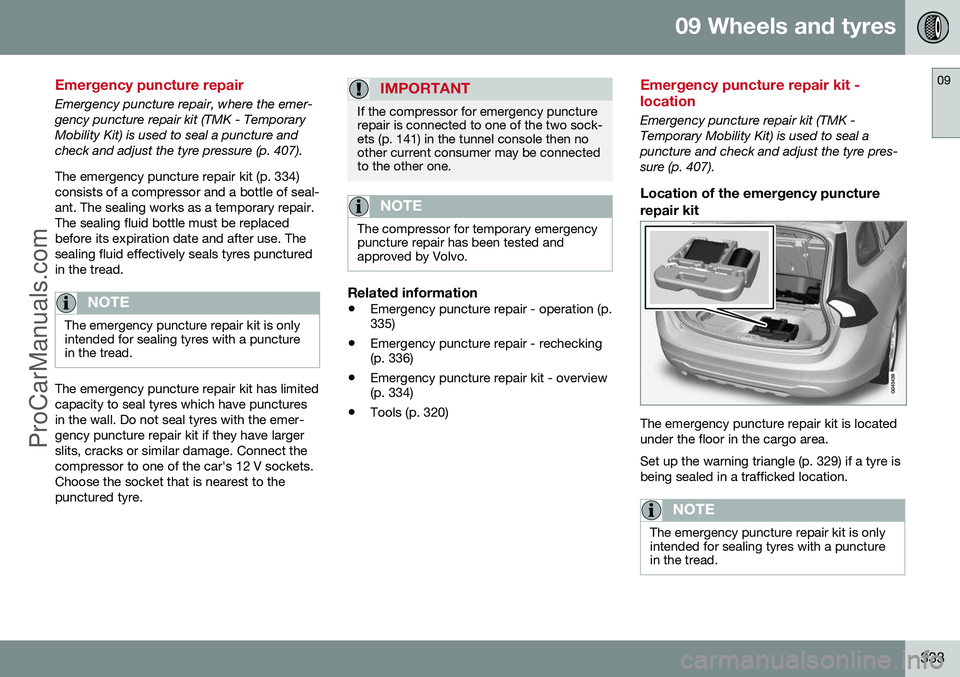

Emergency puncture repair kit - location

Emergency puncture repair kit (TMK - Temporary Mobility Kit) is used to seal apuncture and check and adjust the tyre pres-sure (p. 407).

Location of the emergency puncture

repair kit

The emergency puncture repair kit is located under the floor in the cargo area. Set up the warning triangle (p. 329) if a tyre is being sealed in a trafficked location.

NOTE

The emergency puncture repair kit is only intended for sealing tyres with a puncturein the tread.

ProCarManuals.co’

Page 336 of 442

||

09 Wheels and tyres

09

334

IMPORTANT

If the compressor for emergency puncture repair is connected to one of the two sock-ets (p. 141) in the tunnel console then noother current consumer may be connectedto the other one.

NOTE

The compressor for temporary emergency puncture repair has been tested andapproved by Volvo.

Related information

•Emergency puncture repair kit - overview (p. 334)

• Emergency puncture repair kit - sealant(p. 338)

• Emergency puncture repair (p. 333)

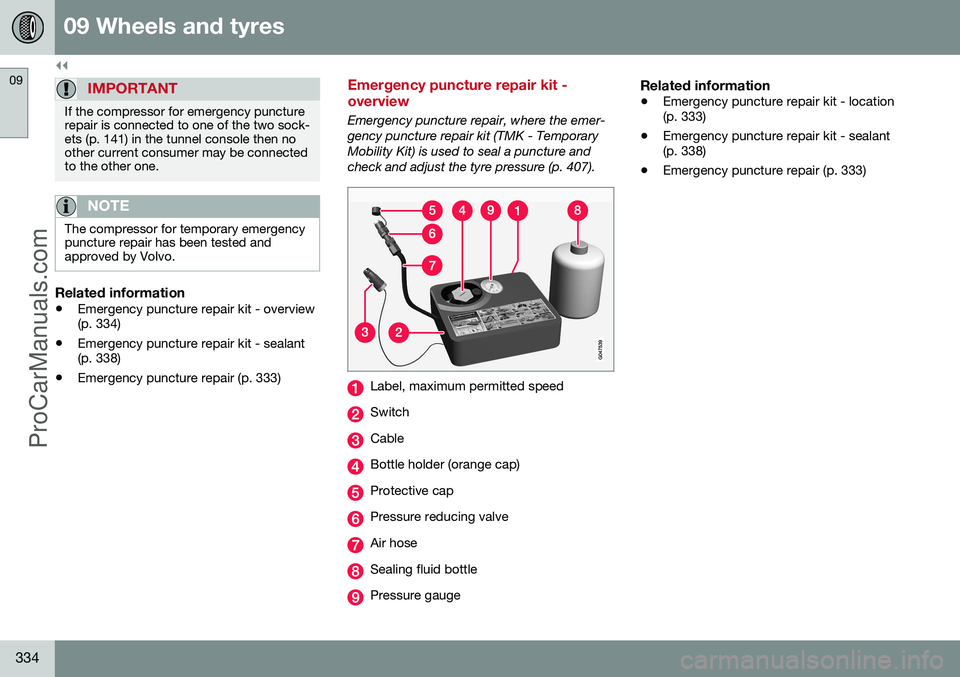

Emergency puncture repair kit - overview

Emergency puncture repair, where the emer- gency puncture repair kit (TMK - Temporary

Mobility Kit) is used to seal a puncture andcheck and adjust the tyre pressure (p. 407).

Label, maximum permitted speed

Switch

Cable

Bottle holder (orange cap)

Protective cap

Pressure reducing valve

Air hose

Sealing fluid bottle

Pressure gauge

Related information

•

Emergency puncture repair kit - location (p. 333)

• Emergency puncture repair kit - sealant(p. 338)

• Emergency puncture repair (p. 333)

ProCarManuals.co’

Page 337 of 442

09 Wheels and tyres

09

}}

335

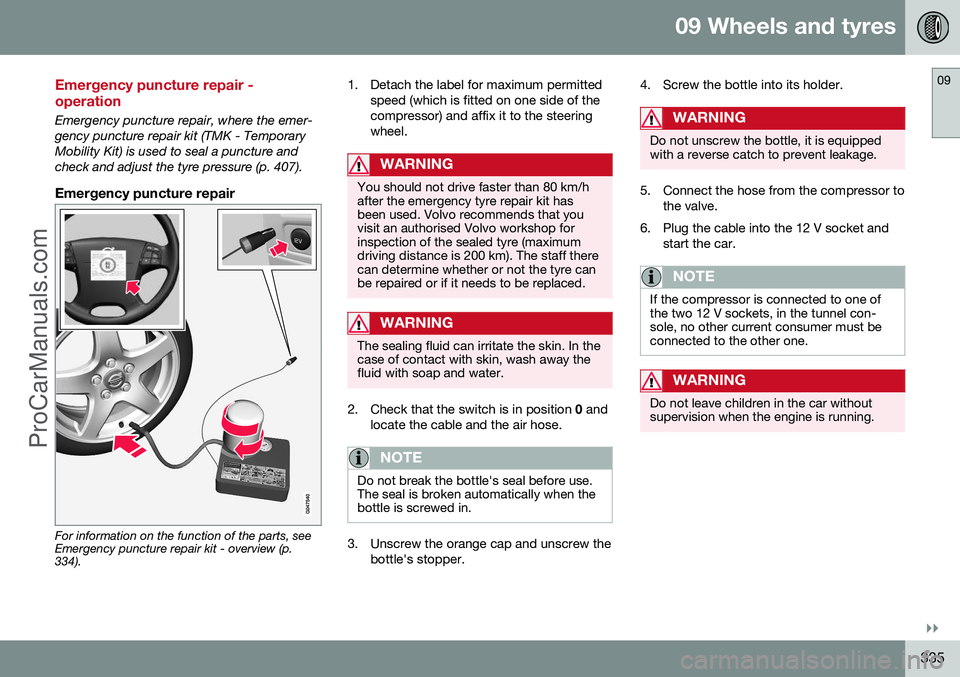

Emergency puncture repair - operation

Emergency puncture repair, where the emer- gency puncture repair kit (TMK - TemporaryMobility Kit) is used to seal a puncture andcheck and adjust the tyre pressure (p. 407).

Emergency puncture repair

For information on the function of the parts, see Emergency puncture repair kit - overview (p.334).1. Detach the label for maximum permitted

speed (which is fitted on one side of the compressor) and affix it to the steeringwheel.

WARNING

You should not drive faster than 80 km/h after the emergency tyre repair kit hasbeen used. Volvo recommends that youvisit an authorised Volvo workshop forinspection of the sealed tyre (maximumdriving distance is 200 km). The staff therecan determine whether or not the tyre canbe repaired or if it needs to be replaced.

WARNING

The sealing fluid can irritate the skin. In the case of contact with skin, wash away thefluid with soap and water.

2. Check that the switch is in position 0 and

locate the cable and the air hose.

NOTE

Do not break the bottle's seal before use. The seal is broken automatically when thebottle is screwed in.

3. Unscrew the orange cap and unscrew the bottle's stopper. 4. Screw the bottle into its holder.

WARNING

Do not unscrew the bottle, it is equipped with a reverse catch to prevent leakage.

5. Connect the hose from the compressor to

the valve.

6. Plug the cable into the 12 V socket and start the car.

NOTE

If the compressor is connected to one of the two 12 V sockets, in the tunnel con-sole, no other current consumer must beconnected to the other one.

WARNING

Do not leave children in the car without supervision when the engine is running.

ProCarManuals.co’

Page 338 of 442

||

09 Wheels and tyres

09

336

7. Flick the switch to position I.

WARNING

Never stand next to the tyre when the compressor is running. If cracks orunevenness arise then the compressormust be switched off immediately. Thejourney should not be continued. Contact-ing an authorised tyre centre is recom-mended.

NOTE

When the compressor starts, the pressure can increase up to 6 bar but the pressuredrops after approximately 30 seconds.

8. Inflate the tyre for 7 minutes.

IMPORTANT

Risk of overheating. The compressor must not run for more than 10 minutes.

9. Switch off the compressor to check the

pressure on the pressure gauge. Mini- mum pressure is 1.8 bar and maximum3.5 bar. (Release air with the pressurereducing valve if the tyre pressure is toohigh.)

WARNING

If the pressure is below 1.8 bar then the hole in the tyre is too big. The journeyshould not be continued. Contacting anauthorised tyre centre is recommended.

10. Switch off the compressor and unplug thecable from the 12 V socket.

11. Detach the hose from the tyre valve and fit the valve cap.

12. As soon as possible, drive approximately 3 km at a maximum speed of 80 km/h so that the sealing fluid can seal the tyre.

Related information

• Emergency puncture repair (p. 333)

• Emergency puncture repair - rechecking (p. 336)

• Emergency puncture repair kit - overview(p. 334)

Emergency puncture repair - rechecking

Emergency puncture repair, where the emer- gency puncture repair kit (TMK - TemporaryMobility Kit) is used to seal a puncture andcheck and adjust the tyre pressure (p. 407).

Check tyre pressure1. Reconnect the equipment.

2. Read the tyre pressure on the pressure

gauge.

• If it is below 1.3 bar 8

then the tyre is

insufficiently sealed. The journey should not be continued. Contact atyre centre.

• If the tyre pressure is higher than 1.3 bar 8

, the tyre must be inflated to the

pressure specified in accordance with the tyre pressure table, see Tyres -approved tyre pressures (p. 407).Release air using the pressure reduc-ing valve if the tyre pressure is toohigh.

8 1 bar = 100 kPa.

ProCarManuals.co’

Page 339 of 442

09 Wheels and tyres

09

337

WARNING

Do not unscrew the bottle, it is equipped with a reverse catch to prevent leakage.

3. Make sure the compressor is switchedoff. Detach the air hose and cable. Fit the valve cap.

NOTE

•After a tyre has been inflated, always refit the dust cap in order to avoiddamage to the valve from gravel, dirt,etc.

• Only use plastic dust caps. Metal dustcaps can rust and become difficult tounscrew.

NOTE

The sealing fluid bottle and the hose must be replaced after use. Volvo recommendsthat this replacement is performed by anauthorised Volvo workshop.

WARNING

Check the tyre pressure regularly.

Volvo recommends that you drive to the near- est authorised Volvo workshop for thereplacement/repair of the damaged tyre. Advise the workshop that the tyre containssealing fluid.

WARNING

You should not drive faster than 80 km/h after the emergency tyre repair kit hasbeen used. Volvo recommends that youvisit an authorised Volvo workshop forinspection of the sealed tyre (maximumdriving distance is 200 km). The staff therecan determine whether or not the tyre canbe repaired or if it needs to be replaced.

Related information

•

Emergency puncture repair (p. 333)

• Emergency puncture repair - operation (p. 335)

• Emergency puncture repair kit - overview(p. 334)

Emergency puncture repair kit - inflating the tyres

The car's original tyres can be inflated using the compressor in the emergency puncturerepair kit (p. 334).

1. The compressor must be switched off.

Make sure that the switch is in position 0

and locate the cable and air hose.

2. Unscrew the wheel's dust cap and screw in the air hose valve connection to the bottom of the thread on the tyre's airvalve.

WARNING

Inhaling car exhaust fumes could result in danger to life. Never leave the engine run-ning in sealed areas or areas that lack suf-ficient ventilation.

WARNING

Do not leave children in the car without supervision when the engine is running.

3. Connect the cable to one of the car's 12 V sockets and start the car.

4. Start the compressor by flicking the switch to position I.

ProCarManuals.co’

Page 340 of 442

||

09 Wheels and tyres

09

338

IMPORTANT

Risk of overheating. The compressor must not run for more than 10 minutes.

5. Inflate the tyre to the pressure specified inaccordance with the tyre pressure table, Tyres - approved tyre pressures (p. 407).Release air using the pressure reducingvalve if the tyre pressure is too high.

6. Switch off the compressor Detach the air hose and cable.

7. Refit the dust cap.

Related information

• Emergency puncture repair (p. 333)

• Emergency puncture repair kit - overview (p. 334)

• Emergency puncture repair - rechecking(p. 336)

Emergency puncture repair kit - sealant

The container (bottle) with the emergency puncture repair kit (p. 334) contains sealantand it can be replaced. Replace the bottle when the expiration date has passed. Treat the old bottle as environ-mentally hazardous waste.

WARNING

The bottle contains 1.2-Ethanol and natu- ral rubber-latex. Harmful if ingested. Could result in allergic reaction in the event of skin contact. Avoid contact with the skin and eyes.Store out of the reach of children.

Related information

•

Emergency puncture repair (p. 333)

ProCarManuals.co’