check engine YAMAHA WR 250F 2015 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 124 of 430

ENGINE

3-20

TIP

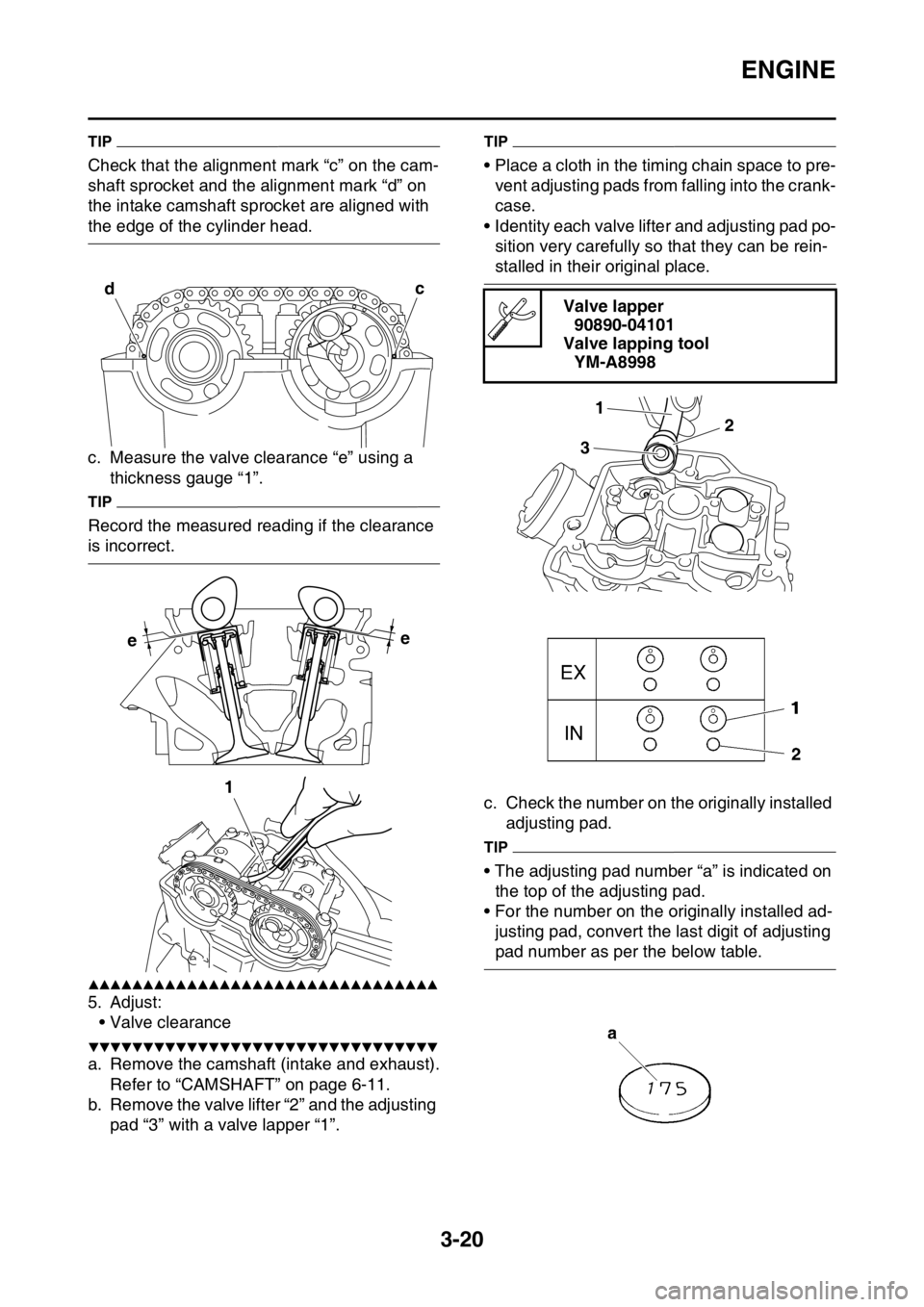

Check that the alignment mark “c” on the cam-

shaft sprocket and the alignment mark “d” on

the intake camshaft sprocket are aligned with

the edge of the cylinder head.

c. Measure the valve clearance “e” using a

thickness gauge “1”.

TIP

Record the measured reading if the clearance

is incorrect.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Adjust:

• Valve clearance

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the camshaft (intake and exhaust).

Refer to “CAMSHAFT” on page 6-11.

b. Remove the valve lifter “2” and the adjusting

pad “3” with a valve lapper “1”.

TIP

• Place a cloth in the timing chain space to pre-

vent adjusting pads from falling into the crank-

case.

• Identity each valve lifter and adjusting pad po-

sition very carefully so that they can be rein-

stalled in their original place.

c. Check the number on the originally installed

adjusting pad.

TIP

• The adjusting pad number “a” is indicated on

the top of the adjusting pad.

• For the number on the originally installed ad-

justing pad, convert the last digit of adjusting

pad number as per the below table.

dc

ee

1

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

1

32

Page 125 of 430

ENGINE

3-21

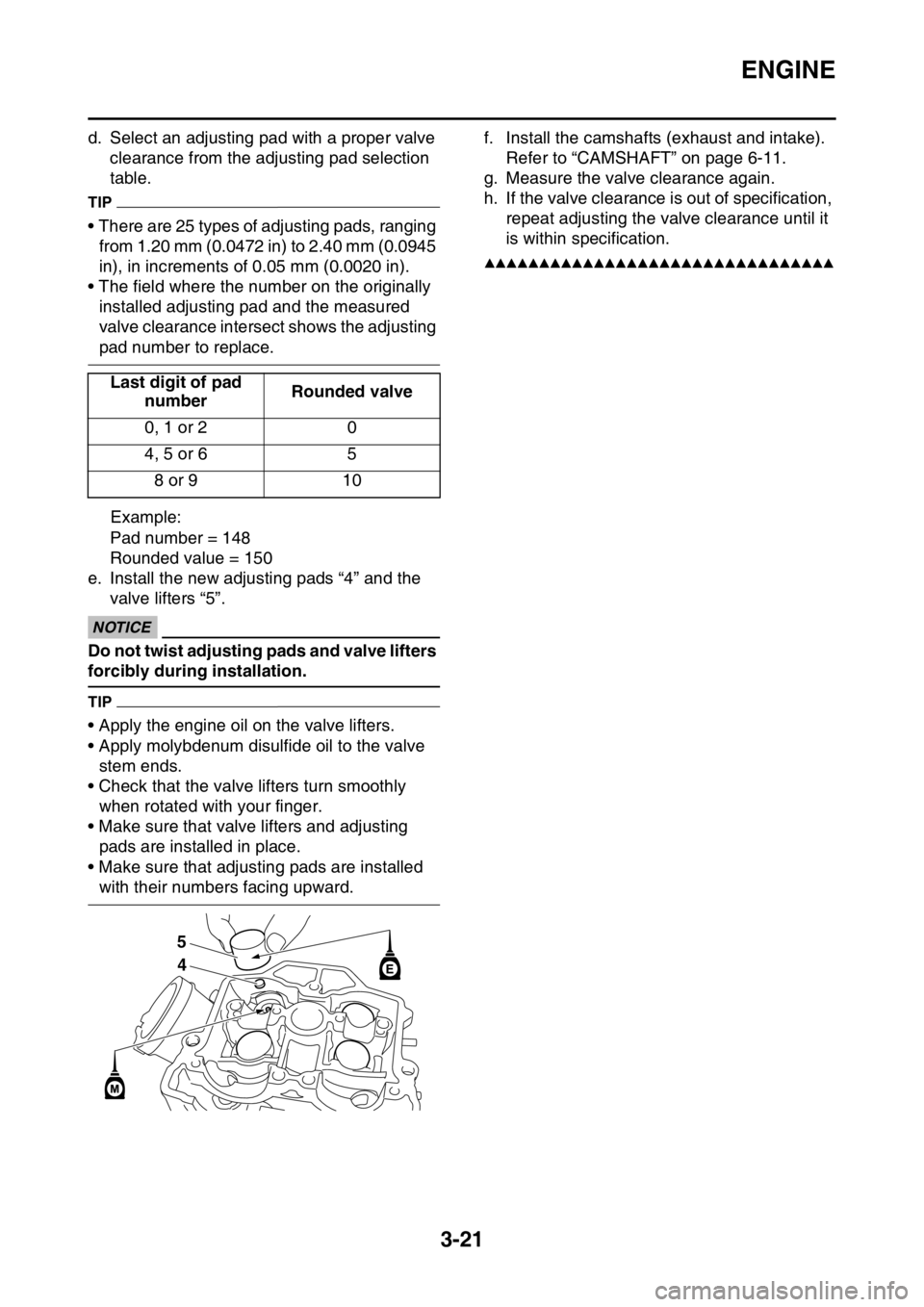

d. Select an adjusting pad with a proper valve

clearance from the adjusting pad selection

table.

TIP

• There are 25 types of adjusting pads, ranging

from 1.20 mm (0.0472 in) to 2.40 mm (0.0945

in), in increments of 0.05 mm (0.0020 in).

• The field where the number on the originally

installed adjusting pad and the measured

valve clearance intersect shows the adjusting

pad number to replace.

Example:

Pad number = 148

Rounded value = 150

e. Install the new adjusting pads “4” and the

valve lifters “5”.

ECA

NOTICE

Do not twist adjusting pads and valve lifters

forcibly during installation.

TIP

• Apply the engine oil on the valve lifters.

• Apply molybdenum disulfide oil to the valve

stem ends.

• Check that the valve lifters turn smoothly

when rotated with your finger.

• Make sure that valve lifters and adjusting

pads are installed in place.

• Make sure that adjusting pads are installed

with their numbers facing upward.f. Install the camshafts (exhaust and intake).

Refer to “CAMSHAFT” on page 6-11.

g. Measure the valve clearance again.

h. If the valve clearance is out of specification,

repeat adjusting the valve clearance until it

is within specification.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Last digit of pad

numberRounded valve

0, 1 or 2 0

4, 5 or 6 5

8 or 9 10

4 5

Page 134 of 430

CHASSIS

3-30

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

EAS2GB2112ADJUSTING THE DRIVE CHAIN SLACKECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or

“b” until the specified drive chain slack is ob-

tained.

TIP

• To maintain the proper wheel alignment, ad-

just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the locknut.

e. Tighten the wheel axle nut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Drive chain slack

50–60 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

Locknut

21 Nm (2.1 m·kgf, 15 ft·lbf)

Wheel axle nut

125 Nm (12.5 m·kgf, 90 ft·lbf)

a

1

32

a

b

T R..

T R..

Page 141 of 430

CHASSIS

3-37

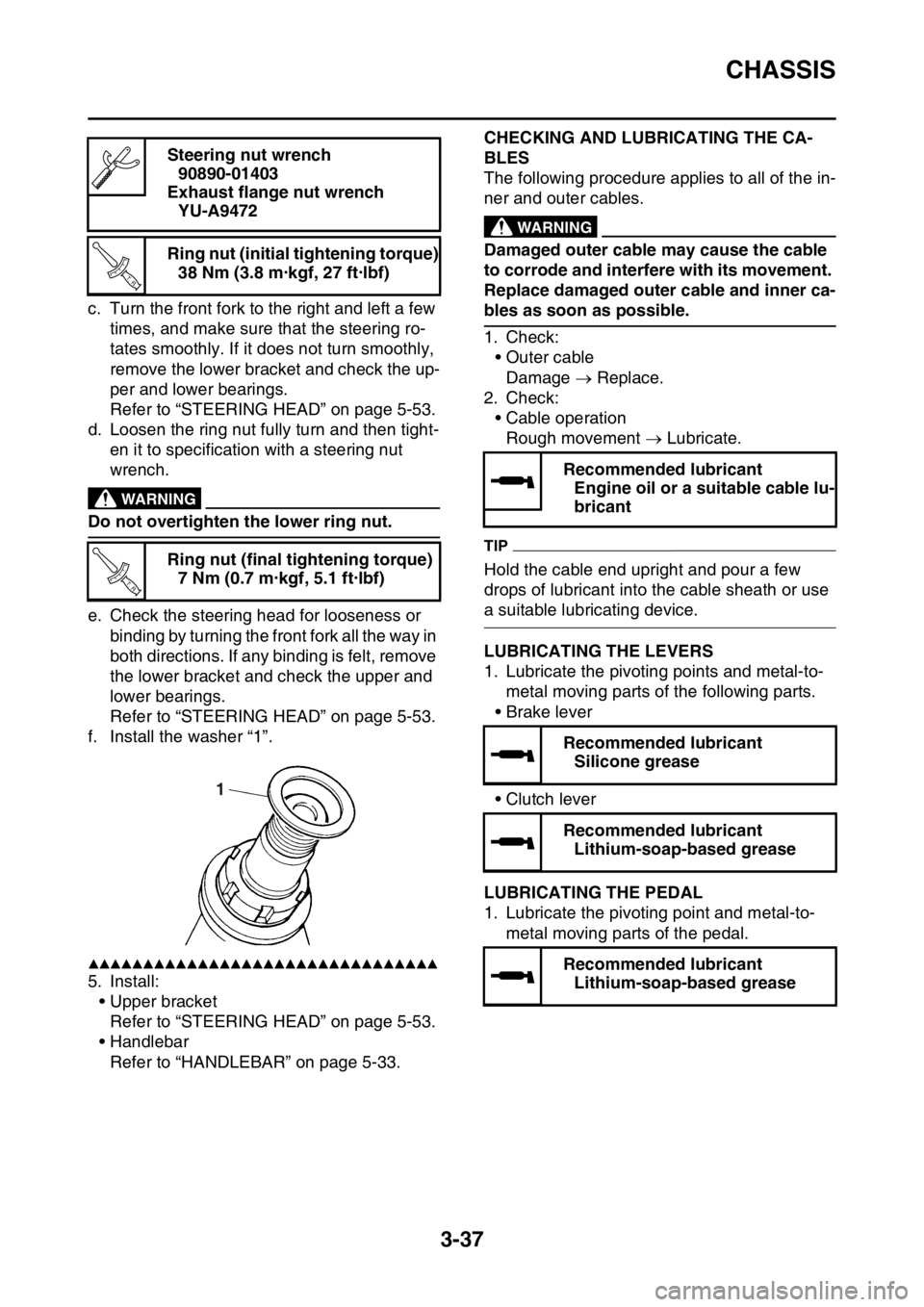

c. Turn the front fork to the right and left a few

times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 5-53.

d. Loosen the ring nut fully turn and then tight-

en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or

binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 5-53.

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Upper bracket

Refer to “STEERING HEAD” on page 5-53.

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

EAS2GB2126

CHECKING AND LUBRICATING THE CA-

BLES

The following procedure applies to all of the in-

ner and outer cables.

EWA

WARNING

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner ca-

bles as soon as possible.

1. Check:

• Outer cable

Damage Replace.

2. Check:

• Cable operation

Rough movement Lubricate.

TIP

Hold the cable end upright and pour a few

drops of lubricant into the cable sheath or use

a suitable lubricating device.

EAS2GB2127LUBRICATING THE LEVERS

1. Lubricate the pivoting points and metal-to-

metal moving parts of the following parts.

•Brake lever

• Clutch lever

EAS2GB2128LUBRICATING THE PEDAL

1. Lubricate the pivoting point and metal-to-

metal moving parts of the pedal. Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

Ring nut (initial tightening torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

T R..

1

Recommended lubricant

Engine oil or a suitable cable lu-

bricant

Recommended lubricant

Silicone grease

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

Page 142 of 430

CHASSIS

3-38

EAS2GB2129LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between each side plate. Steam clean-

ing, high-pressure washing, certain solvents,

and the use of a coarse brush can damage

these O-rings. Therefore, use only kerosene to

clean the drive chain. Wipe the drive chain dry

and thoroughly lubricate it with engine oil or

chain lubricant that is suitable for O-ring chains.

Do not use any other lubricants on the drive

chain since they may contain solvents that

could damage the O-rings.

EAS2GB2130LUBRICATING THE SIDESTAND

Lubricate the pivoting point and metal-to-metal

moving parts of the sidestand.

EAS2GB2131CHECKING THE CHASSIS FASTENERS

Make sure that all nuts, bolts, and screws are

properly tightened.

Refer to “CHASSIS TIGHTENING TORQUES”

on page 2-17.Recommended lubricant

Chain lubricant suitable for O-

ring chains

Recommended lubricant

Lithium-soap-based grease

Page 144 of 430

ELECTRICAL SYSTEM

3-40

2. Attach:

• Timing light “1”

• Digital tachometer “2”

To the high tension code “3”.

3. Adjust:

• Engine idling speed

Refer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-18.

4. Check:

• Ignition timing

Check whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install:

• Timing mark accessing screw

EAS2GB2135

CHECKING AND CHARGING THE BATTERY

Refer to “CHECKING AND CHARGING THE

BATTERY” on page 9-69.

EAS2GB2136REPLACING THE HEADLIGHT BULBEWA

WARNING

Since the headlight bulb gets extremely hot,

keep flammable products and your hands

away from the bulb until it has cooled down.

1. Remove:

• Headlight unit bolt “1”

TIP

After you have removed the headlight unit

bolts, lift and remove the headlight unit.

2. Remove:

• Headlight coupler “1”

• Bulb cover “2”

3. Remove:

• Headlight bulb “1” Timing light

90890-03141

Timing light

YU-03141

Digital tachometer

90890-06760

Digital tachometer

YU-39951-B

Timing mark accessing screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

ba

T R..

11

1

2

1

Page 229 of 430

6

ENGINE

ENGINE REMOVAL......................................................................................... 6-1

REMOVING THE SILENCER ..................................................................... 6-6

REMOVING THE EXHAUST PIPE 2.......................................................... 6-6

REMOVING THE DRIVE SPROCKET ....................................................... 6-6

REMOVING THE ENGINE ......................................................................... 6-7

CLEANING THE SPARK ARRESTER ....................................................... 6-7

CHECKING THE SILENCER AND EXHAUST PIPE.................................. 6-8

INSTALLING THE ENGINE........................................................................ 6-8

INSTALLING THE BRAKE PEDAL ............................................................ 6-9

INSTALLING THE DRIVE SPROCKET...................................................... 6-9

INSTALLING THE EXHAUST PIPE AND MUFFLER................................. 6-9

CAMSHAFT.................................................................................................... 6-11

REMOVING THE CAMSHAFT ................................................................. 6-13

CHECKING THE CAMSHAFT.................................................................. 6-14

CHECKING THE TIMING CHAIN AND CAMSHAFT SPROCKET .......... 6-15

CHECKING THE TIMING CHAIN TENSIONERS .................................... 6-15

CHECKING THE DECOMPRESSION SYSTEM...................................... 6-16

INSTALLING THE CAMSHAFTS ............................................................. 6-16

CYLINDER HEAD........................................................................................... 6-18

REMOVING THE CYLINDER HEAD........................................................ 6-20

CHECKING THE TIMING CHAIN GUIDE (INTAKE SIDE) ...................... 6-20

CHECKING THE CYLINDER HEAD ........................................................ 6-20

INSTALLING THE CYLINDER HEAD ...................................................... 6-21

VALVES AND VALVE SPRINGS................................................................... 6-22

REMOVING THE VALVES ....................................................................... 6-23

CHECKING THE VALVES AND VALVE GUIDES ................................... 6-24

CHECKING THE VALVE SEATS ............................................................. 6-26

CHECKING THE VALVE SPRINGS......................................................... 6-27

CHECKING THE VALVE LIFTERS .......................................................... 6-28

INSTALLING THE VALVES ..................................................................... 6-28

CYLINDER AND PISTON............................................................................... 6-30

REMOVING THE PISTON ....................................................................... 6-31

CHECKING THE CYLINDER AND PISTON ............................................ 6-31

CHECKING THE PISTON RINGS............................................................ 6-32

CHECKING THE PISTON PIN ................................................................. 6-33

INSTALLING THE PISTON AND CYLINDER .......................................... 6-33

ELECTRIC STARTER.................................................................................... 6-35

CHECKING THE STARTER MOTOR ...................................................... 6-37

ASSEMBLING THE STARTER MOTOR .................................................. 6-38

Page 239 of 430

ENGINE REMOVAL

6-8

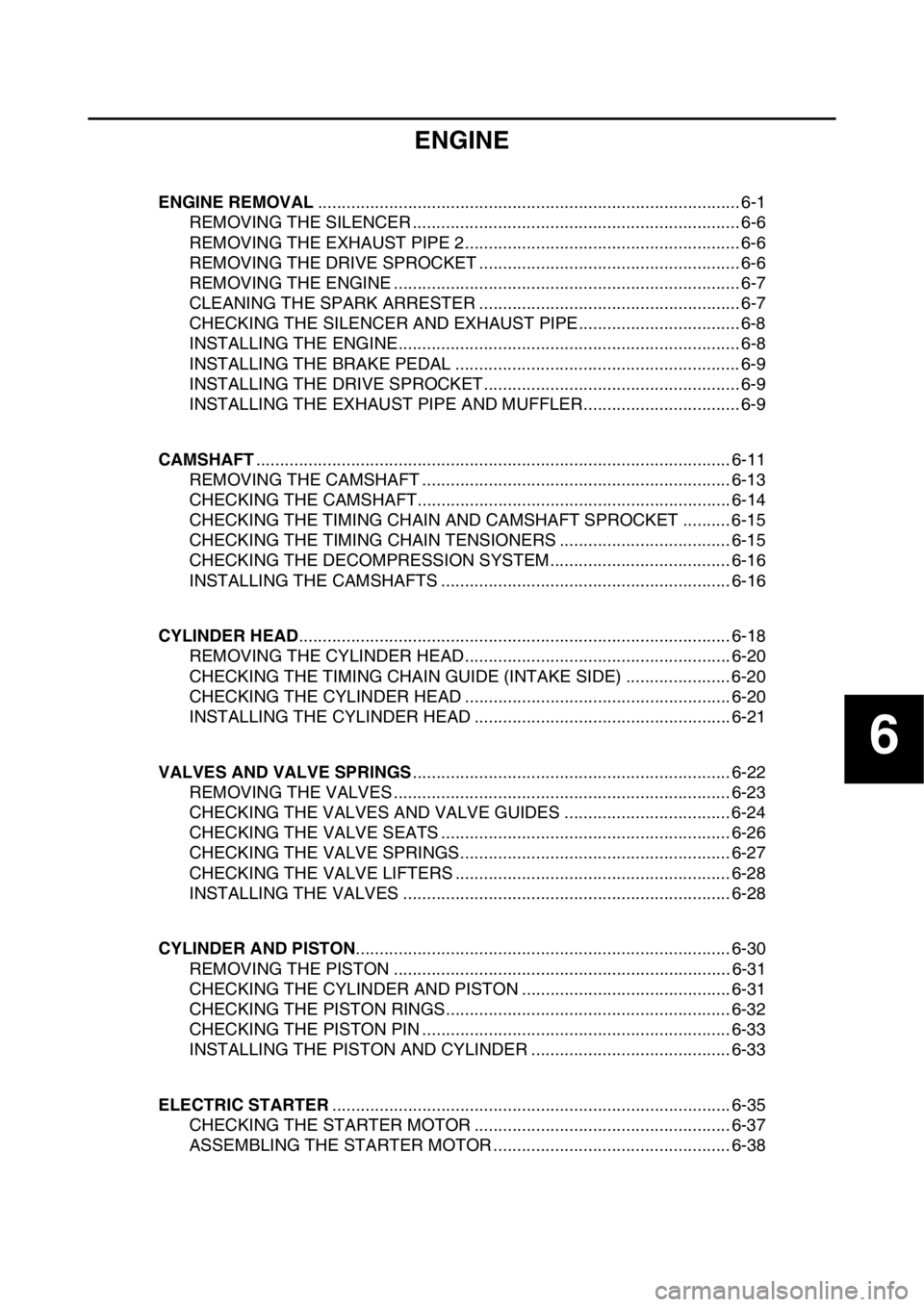

5. Install:

• Spark arrester gasket

• Spark arrester

Insert the spark arrester into the muffler and

align the bolt holes.

• Tail pipe gasket

• Spark arrester bolts

6. Install:

• Muffler cap

TIP

First tighten the two screws “a” located horizon-

tally apart, and then tighten the others.

EAS2GB2234CHECKING THE SILENCER AND EXHAUST

PIPE

1. Check:

•Gasket “1”

Damage Replace.

EAS2GB2235INSTALLING THE ENGINE

1. Install:

• Engine “1”

Install the engine from the right side.

• Pivot shaft “2”• Engine mounting bolt (lower side) “3”

• Front engine bracket “4”

• Engine bracket bolt (front side) “5”

• Engine mounting bolt (front side) “6”

• Upper engine bracket “7”

• Engine bracket bolt (upper side) “8”

• Engine mounting bolt (upper side) “9”

TIP

Apply molybdenum disulfide grease to the pivot

shaft. Spark arrester bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Muffler cap screw

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Pivot shaft

85 Nm (8.5 m·kgf, 61 ft·lbf)

New

New

T R..

T R..

1

1

T R..

Engine mounting bolt (lower side)

53 Nm (5.3 m·kgf, 38 ft·lbf)

Engine bracket bolt (front side)

34 Nm (3.4 m·kgf, 25 ft·lbf)

Engine mounting bolt (front side)

55 Nm (5.5 m·kgf, 40 ft·lbf)

Engine bracket bolt (upper side)

34 Nm (3.4 m·kgf, 25 ft·lbf)

Engine mounting bolt (upper

side)

45 Nm (4.5 m·kgf, 33 ft·lbf)

T R..

T R..

T R..

T R..

T R..

M

78

9

9 8

7

4 1

2

43

5

56

Page 241 of 430

ENGINE REMOVAL

6-10

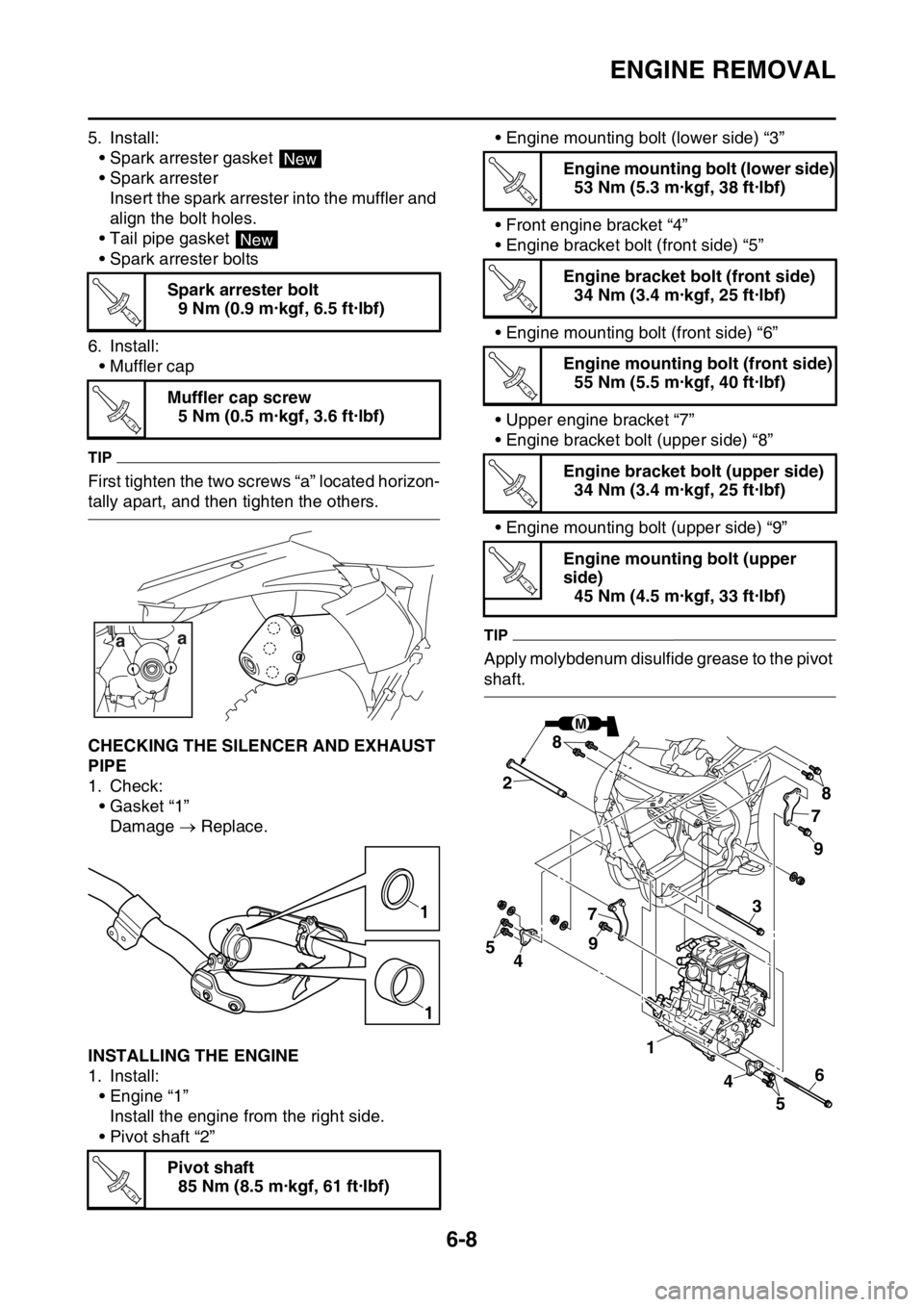

2. Install:

•Clamp

• Exhaust pipe 2 “1”

• Bolt (exhaust pipe 2) “2”

TIP

Install and temporarily tighten the exhaust pipe

2 with its end positioned as shown with respect

to the exhaust pipe 1.

3. Install:

•Clamp

• Silencer “1”

• Bolt (silencer) “2”

TIP

Install and temporarily tighten the silencer so

that its joint is positioned as shown with respect

to the exhaust pipe 2.

4. Tighten:

• Bolt (exhaust pipe 2)

•Clamp

TIP

Tighten while checking that their front and rear

joints are inserted in position.

Bolt (silencer)

30 Nm (3.0 m·kgf, 22 ft·lbf)

1

22

1

2

2mm (0.08in)

T R..

Bolt (exhaust pipe 2)

20 Nm (2.0 m·kgf, 14 ft·lbf)

Clamp

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

1

22

2mm (0.08in)

T R..

T R..

Page 247 of 430

CAMSHAFT

6-16

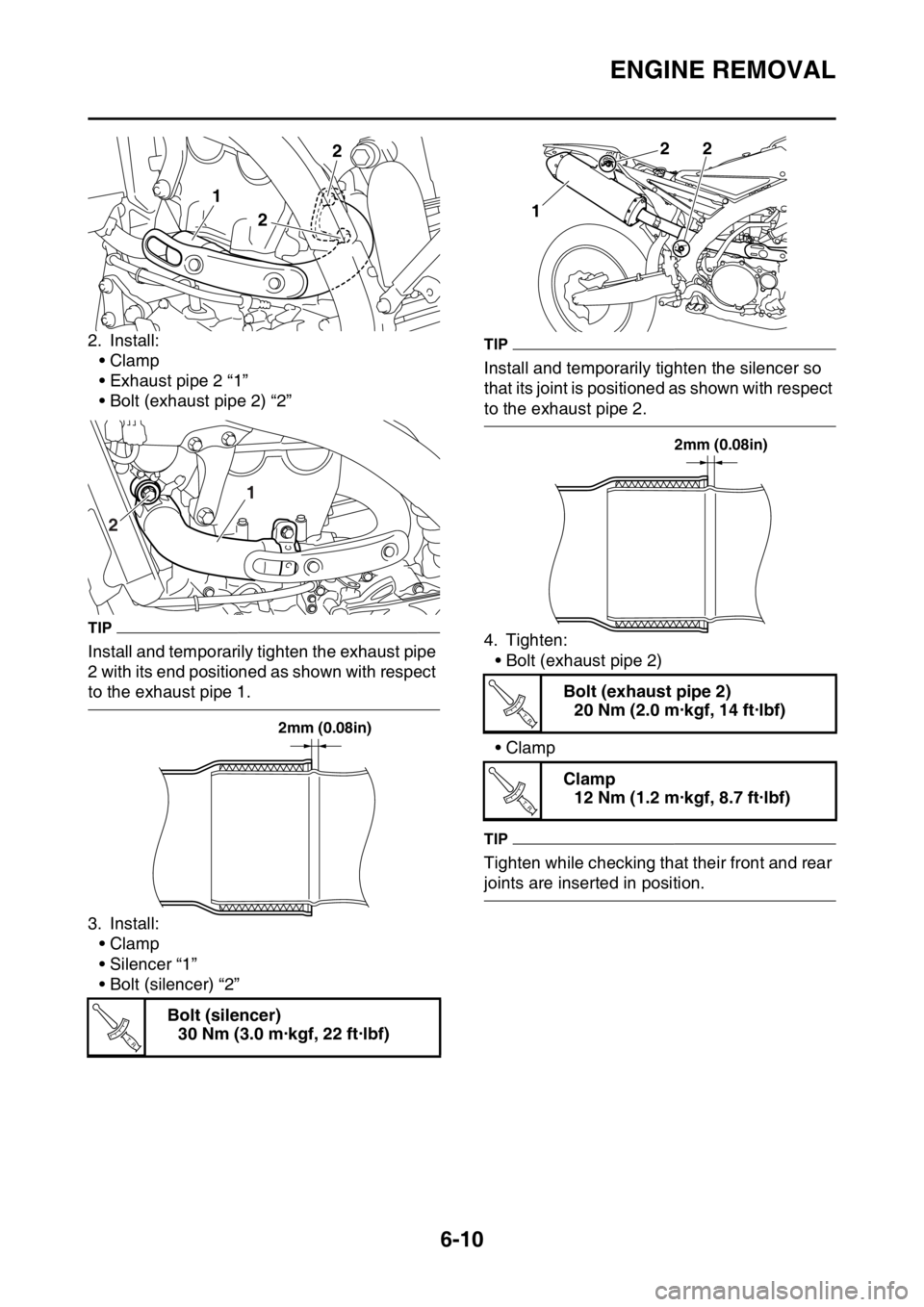

EAS2GB2244CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:

• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2”

projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

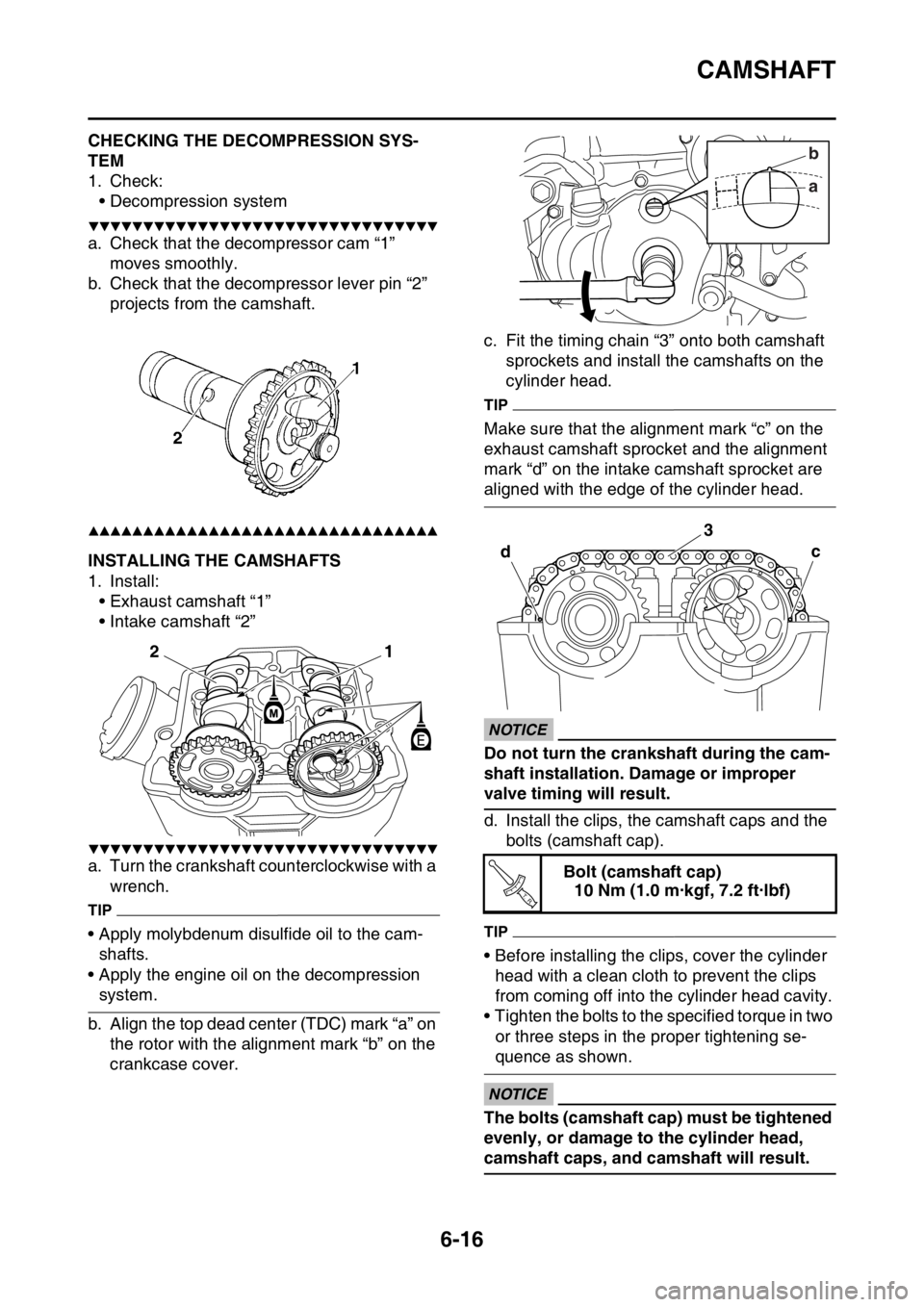

EAS2GB2245INSTALLING THE CAMSHAFTS

1. Install:

• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-

shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the

bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder

head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

ECA

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

ab

dc

3

T R..