check engine YAMAHA WR 250F 2015 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 249 of 430

CYLINDER HEAD

6-18

EAS2GB2246

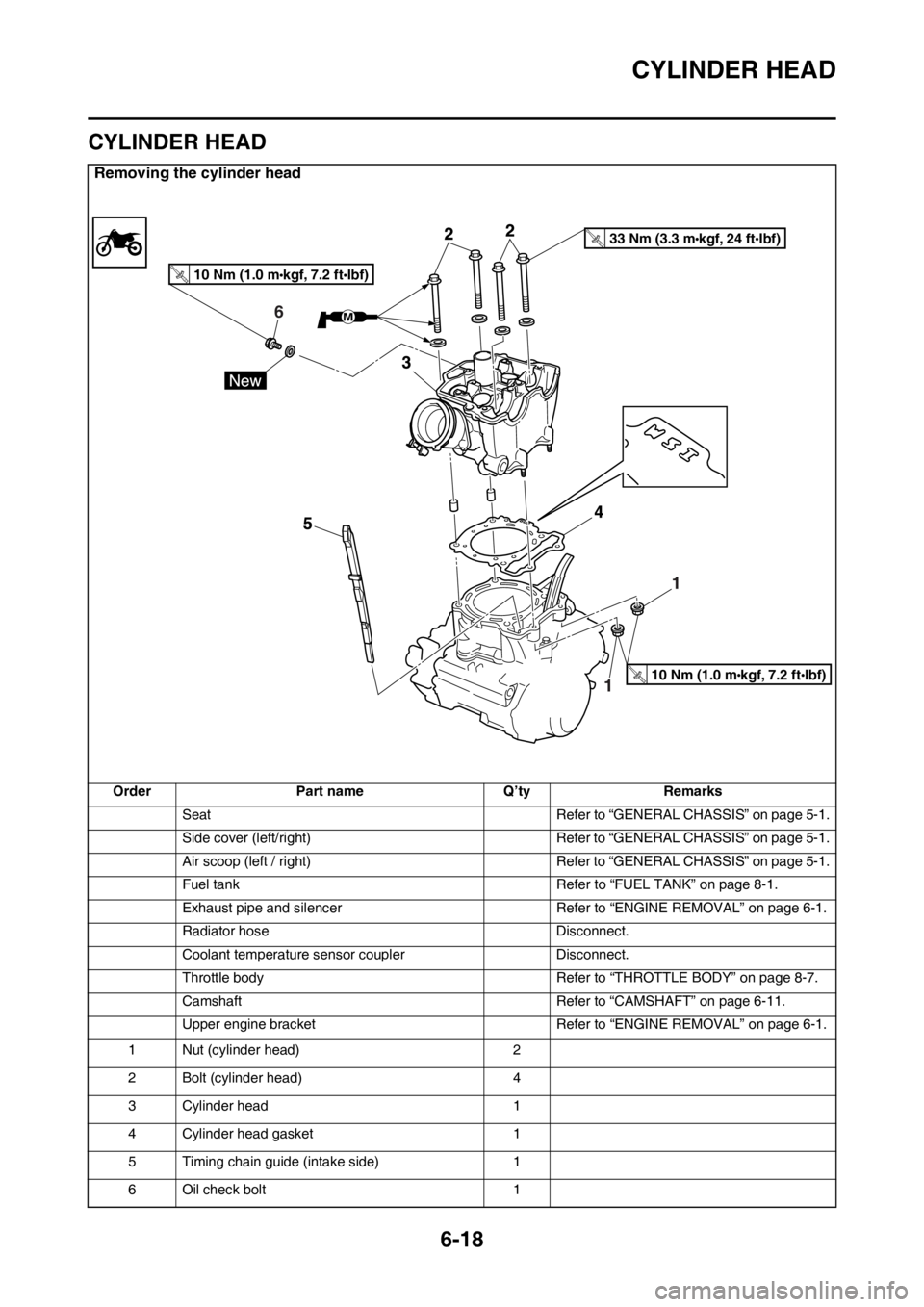

CYLINDER HEAD

Removing the cylinder head

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Exhaust pipe and silencer Refer to “ENGINE REMOVAL” on page 6-1.

Radiator hose Disconnect.

Coolant temperature sensor coupler Disconnect.

Throttle body Refer to “THROTTLE BODY” on page 8-7.

Camshaft Refer to “CAMSHAFT” on page 6-11.

Upper engine bracket Refer to “ENGINE REMOVAL” on page 6-1.

1 Nut (cylinder head) 2

2 Bolt (cylinder head) 4

3 Cylinder head 1

4 Cylinder head gasket 1

5 Timing chain guide (intake side) 1

6 Oil check bolt 1

6

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

33 Nm (3.3 m kgf, 24 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 264 of 430

CYLINDER AND PISTON

6-33

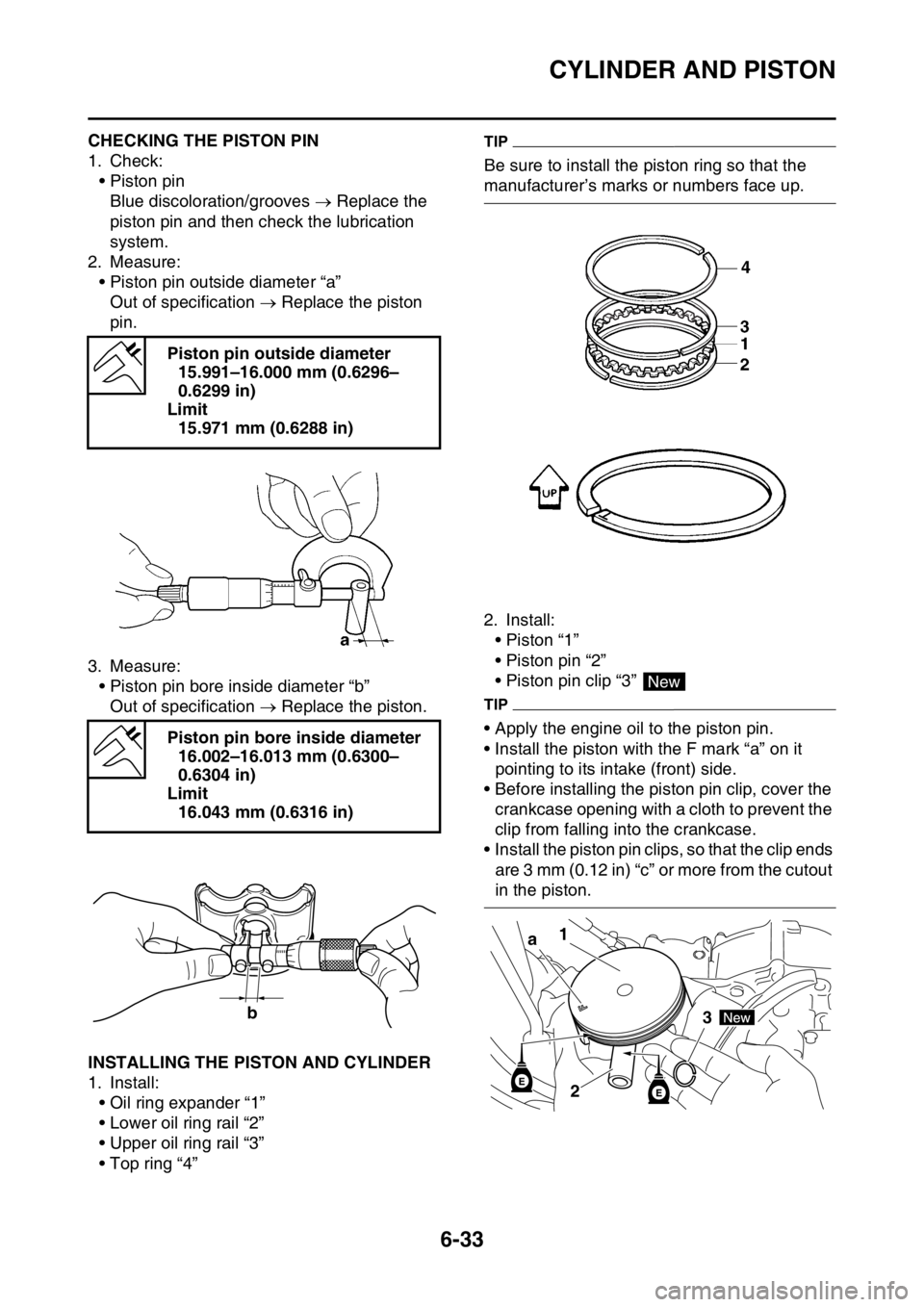

EAS2GB2262CHECKING THE PISTON PIN

1. Check:

• Piston pin

Blue discoloration/grooves Replace the

piston pin and then check the lubrication

system.

2. Measure:

• Piston pin outside diameter “a”

Out of specification Replace the piston

pin.

3. Measure:

• Piston pin bore inside diameter “b”

Out of specification Replace the piston.

EAS2GB2263INSTALLING THE PISTON AND CYLINDER

1. Install:

• Oil ring expander “1”

• Lower oil ring rail “2”

• Upper oil ring rail “3”

• Top ring “4”

TIP

Be sure to install the piston ring so that the

manufacturer’s marks or numbers face up.

2. Install:

• Piston “1”

• Piston pin “2”

• Piston pin clip “3”

TIP

• Apply the engine oil to the piston pin.

• Install the piston with the F mark “a” on it

pointing to its intake (front) side.

• Before installing the piston pin clip, cover the

crankcase opening with a cloth to prevent the

clip from falling into the crankcase.

• Install the piston pin clips, so that the clip ends

are 3 mm (0.12 in) “c” or more from the cutout

in the piston. Piston pin outside diameter

15.991–16.000 mm (0.6296–

0.6299 in)

Limit

15.971 mm (0.6288 in)

Piston pin bore inside diameter

16.002–16.013 mm (0.6300–

0.6304 in)

Limit

16.043 mm (0.6316 in)

b

4

New

1

3

2 a

Page 276 of 430

CLUTCH

6-45

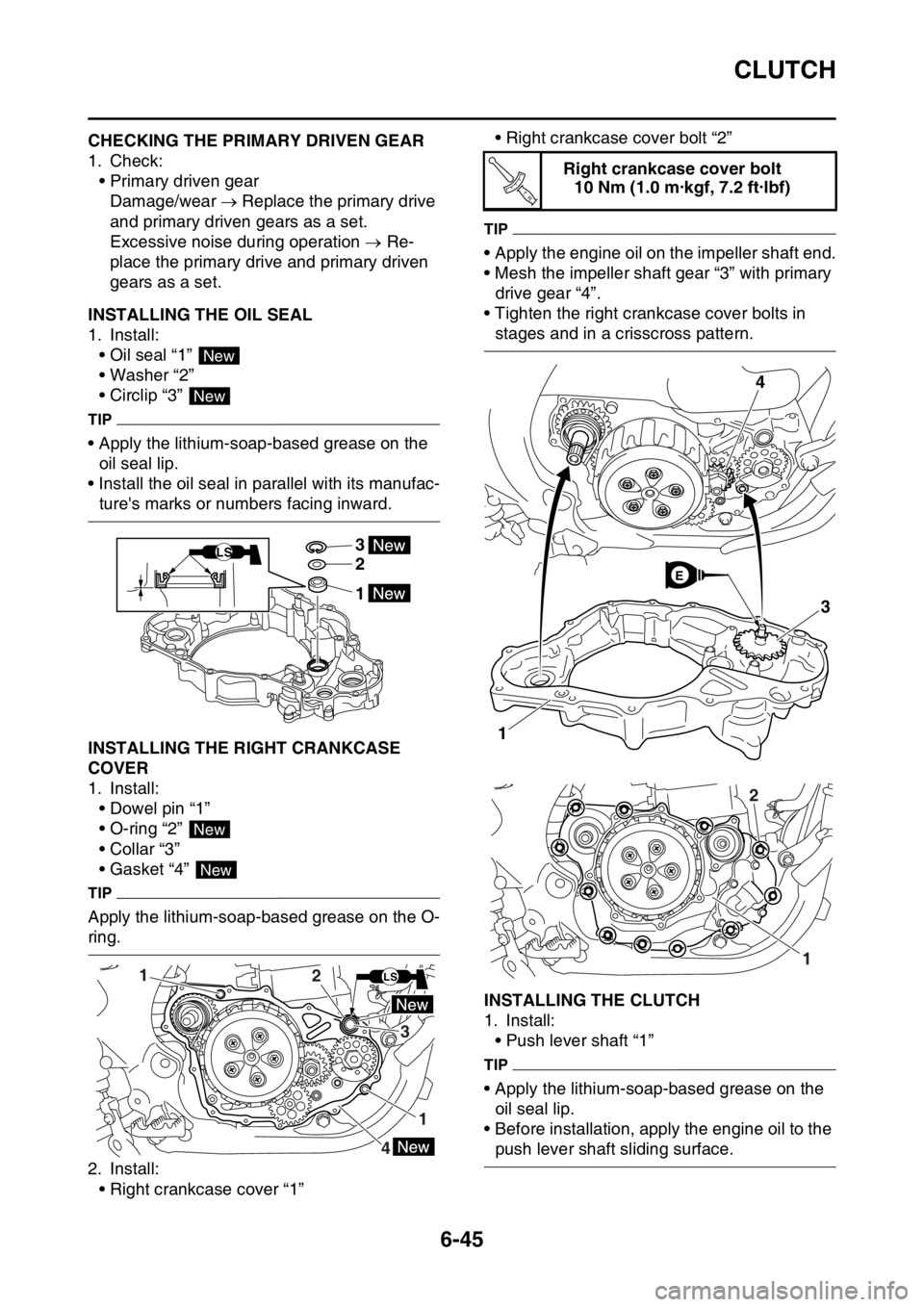

EAS2GB2278CHECKING THE PRIMARY DRIVEN GEAR

1. Check:

• Primary driven gear

Damage/wear Replace the primary drive

and primary driven gears as a set.

Excessive noise during operation Re-

place the primary drive and primary driven

gears as a set.

EAS2GB2279INSTALLING THE OIL SEAL

1. Install:

• Oil seal “1”

• Washer “2”

• Circlip “3”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal in parallel with its manufac-

ture's marks or numbers facing inward.

EAS2GB2280INSTALLING THE RIGHT CRANKCASE

COVER

1. Install:

• Dowel pin “1”

• O-ring “2”

• Collar “3”

• Gasket “4”

TIP

Apply the lithium-soap-based grease on the O-

ring.

2. Install:

• Right crankcase cover “1”• Right crankcase cover bolt “2”

TIP

• Apply the engine oil on the impeller shaft end.

• Mesh the impeller shaft gear “3” with primary

drive gear “4”.

• Tighten the right crankcase cover bolts in

stages and in a crisscross pattern.

EAS2GB2281INSTALLING THE CLUTCH

1. Install:

• Push lever shaft “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Before installation, apply the engine oil to the

push lever shaft sliding surface.

New

New

3

2

1

LS

New

New

1

1

3

2

4

LS

Right crankcase cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

3

1

4

E

1

2

Page 290 of 430

OIL PUMP AND BALANCER GEAR

6-59

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS2GB2305ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2”

EAS2GB2306INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

21

3

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

1

E

T R..

2

1

T R..

1

2

LT

Page 302 of 430

CRANKCASE

6-71

EAS2GB2313DISASSEMBLING THE CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1”.

TIP

• Place the crankcase with its left side down-

ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force.c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2314REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by

pressing its inner race.

• Do not use the removed bearing.

EAS2GB2315CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:

• Timing chain

Stiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check:

• Timing chain guide

Damage/wear Replace

EAS2GB2316CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

2. Check:

• Crankcase

Crack/damage Replace.

1

a

Page 311 of 430

TRANSMISSION

6-80

6. Install:

• Shift fork 1 (L) “1”

• Shift fork 2 (C) “2”

• Shift fork 3 (R) “3”

• Shift cam “4”

(to the main axle and the drive axle)

TIP

• Apply engine oil to the shift fork grooves.

• Apply engine oil to the shift cam groove and

the bearing contact surface.

• Mesh the shift fork 1 (L) with the 5th wheel

gear “5” and “3” (R) with the 6th wheel gear “7”

on the drive axle.

• Mesh the shift fork 2 (C) with the 3rd/4th pin-

ion gear “6” on the main axle.7. Install:

• Long shift fork guide bar “1”

• Short shift fork guide bar “2”

• Spring “3”

TIP

• Screw the spring into the shift fork guide bar

lightly beforehand.

• Apply the engine oil on the shift fork guide

bars.

8. Check:

• Operation of shift cam and shift fork

• Transmission operation

Unsmooth operation Repair.

3

12

6

2

4

5

3

7

1

E

E

E

2 13

E

Page 319 of 430

WATER PUMP

7-6

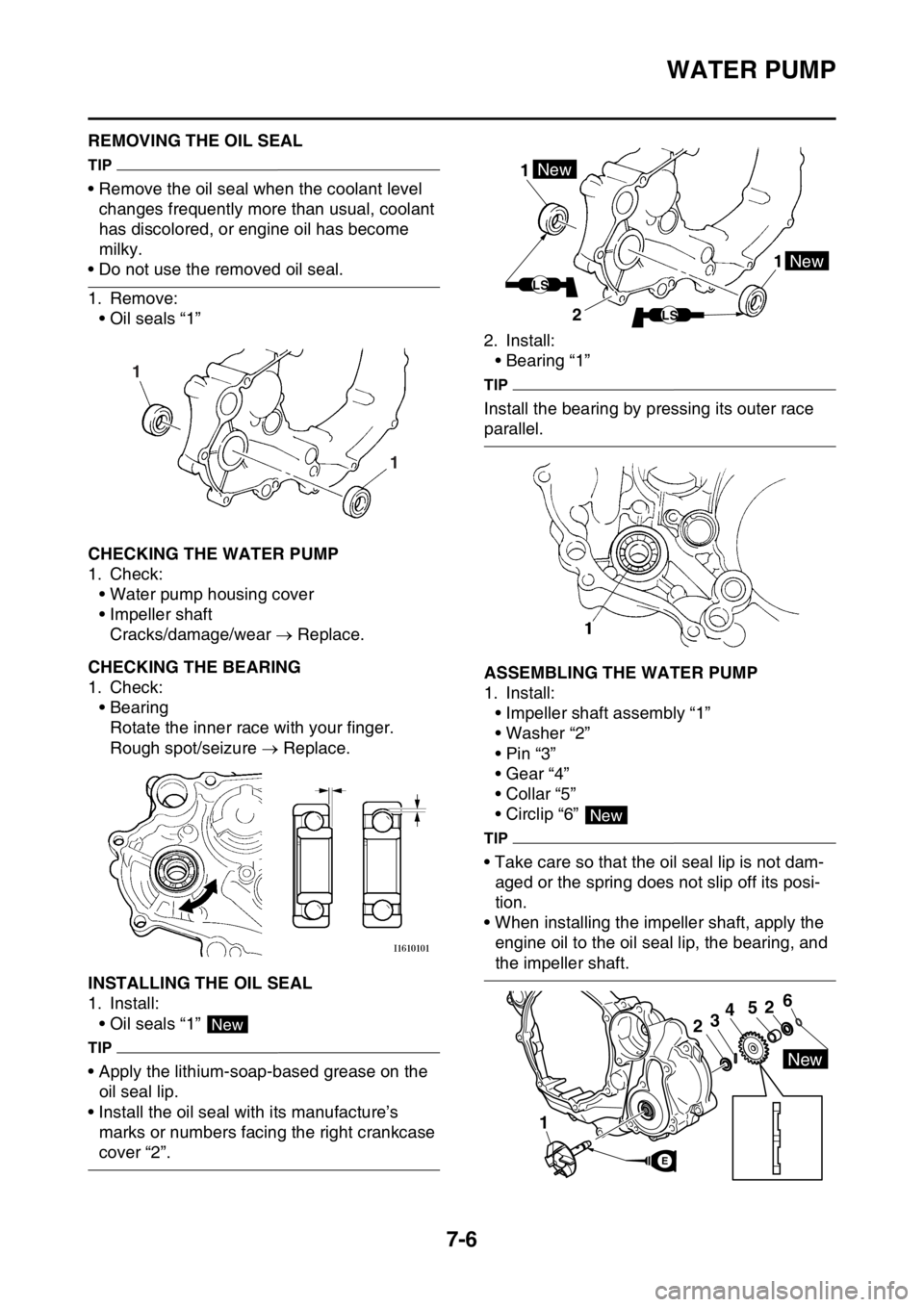

EAS2GB2335REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS2GB2336CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS2GB2337CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS2GB2338INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover “2”.2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS2GB2339ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

• Washer “2”

•Pin “3”

• Gear “4”

• Collar “5”

• Circlip “6”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• When installing the impeller shaft, apply the

engine oil to the oil seal lip, the bearing, and

the impeller shaft.

1 1

New

1 1New

New

LS

LS2

New

1

2

52346

New

E

Page 326 of 430

FUEL TANK

8-5

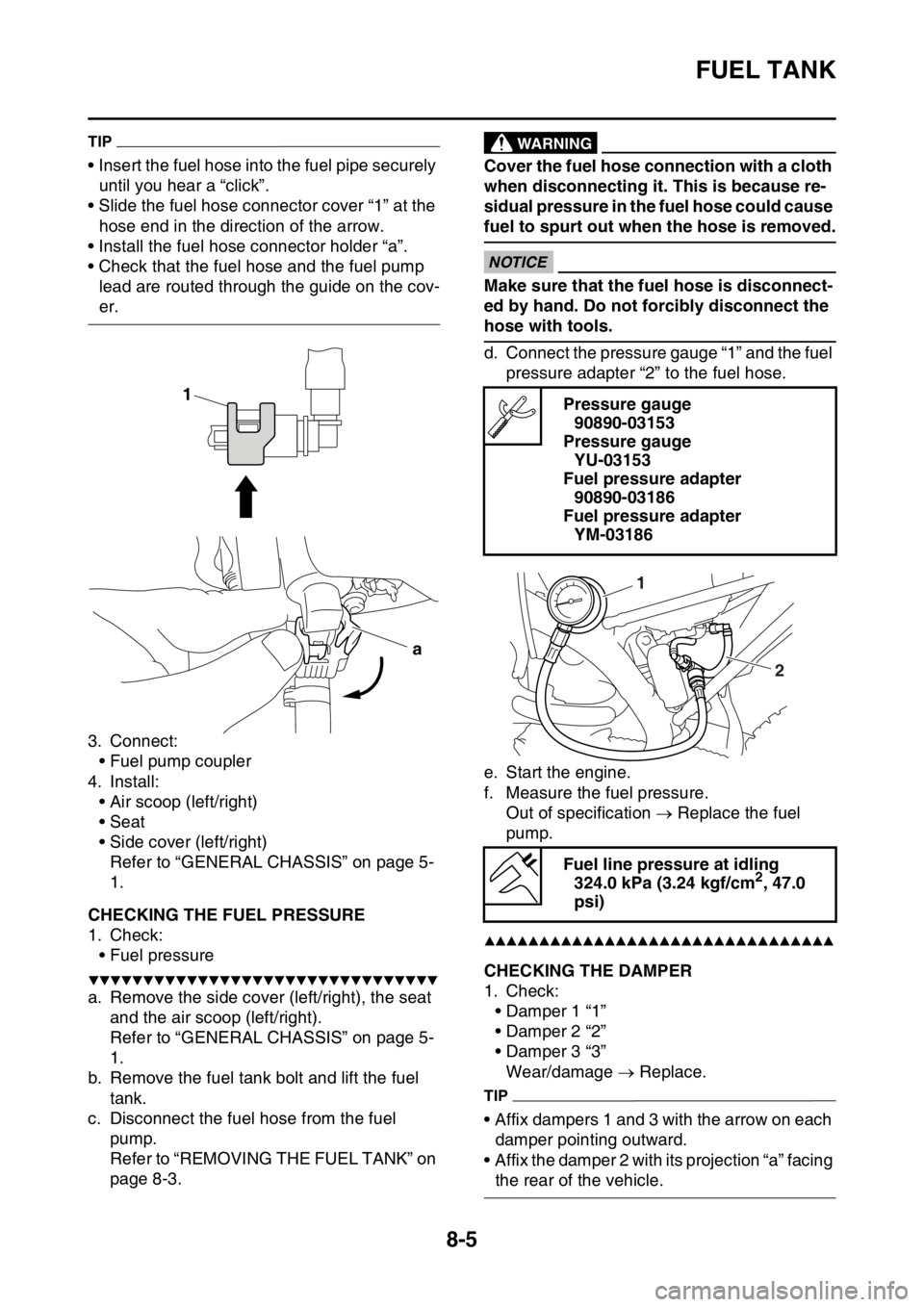

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click”.

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a”.

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov-

er.

3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GB2350CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 5-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 8-3.

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

d. Connect the pressure gauge “1” and the fuel

pressure adapter “2” to the fuel hose.

e. Start the engine.

f. Measure the fuel pressure.

Out of specification Replace the fuel

pump.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2351CHECKING THE DAMPER

1. Check:

• Damper 1 “1”

• Damper 2 “2”

• Damper 3 “3”

Wear/damage Replace.

TIP

• Affix dampers 1 and 3 with the arrow on each

damper pointing outward.

• Affix the damper 2 with its projection “a” facing

the rear of the vehicle.

1

a

Pressure gauge

90890-03153

Pressure gauge

YU-03153

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186

Fuel line pressure at idling

324.0 kPa (3.24 kgf/cm

2, 47.0

psi)

1

2

Page 331 of 430

THROTTLE BODY

8-10

EAS2GB2354CHECKING THE INJECTOR

1. Check:

• Injectors

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 9-28.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 9-81.

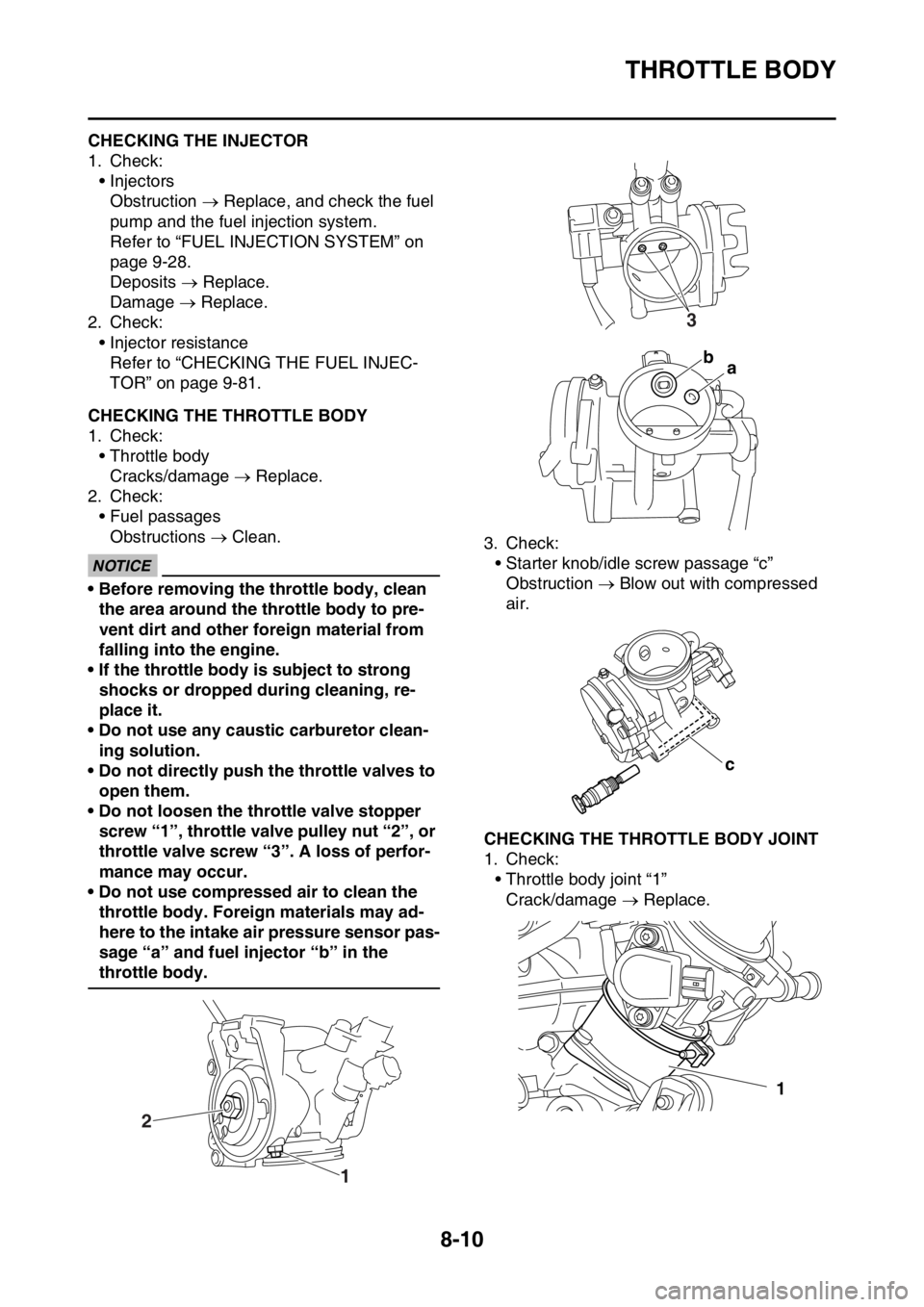

EAS2GB2355CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS2GB2356CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 338 of 430

IGNITION SYSTEM

9-4

EAS2GB2361TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73.OK

The ignition system is normal.

NG

5. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74.NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-74.NG

Replace the stator assembly.

OK

7. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK