engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 779 of 1640

Radiator and Condenser Fan Controls

Description

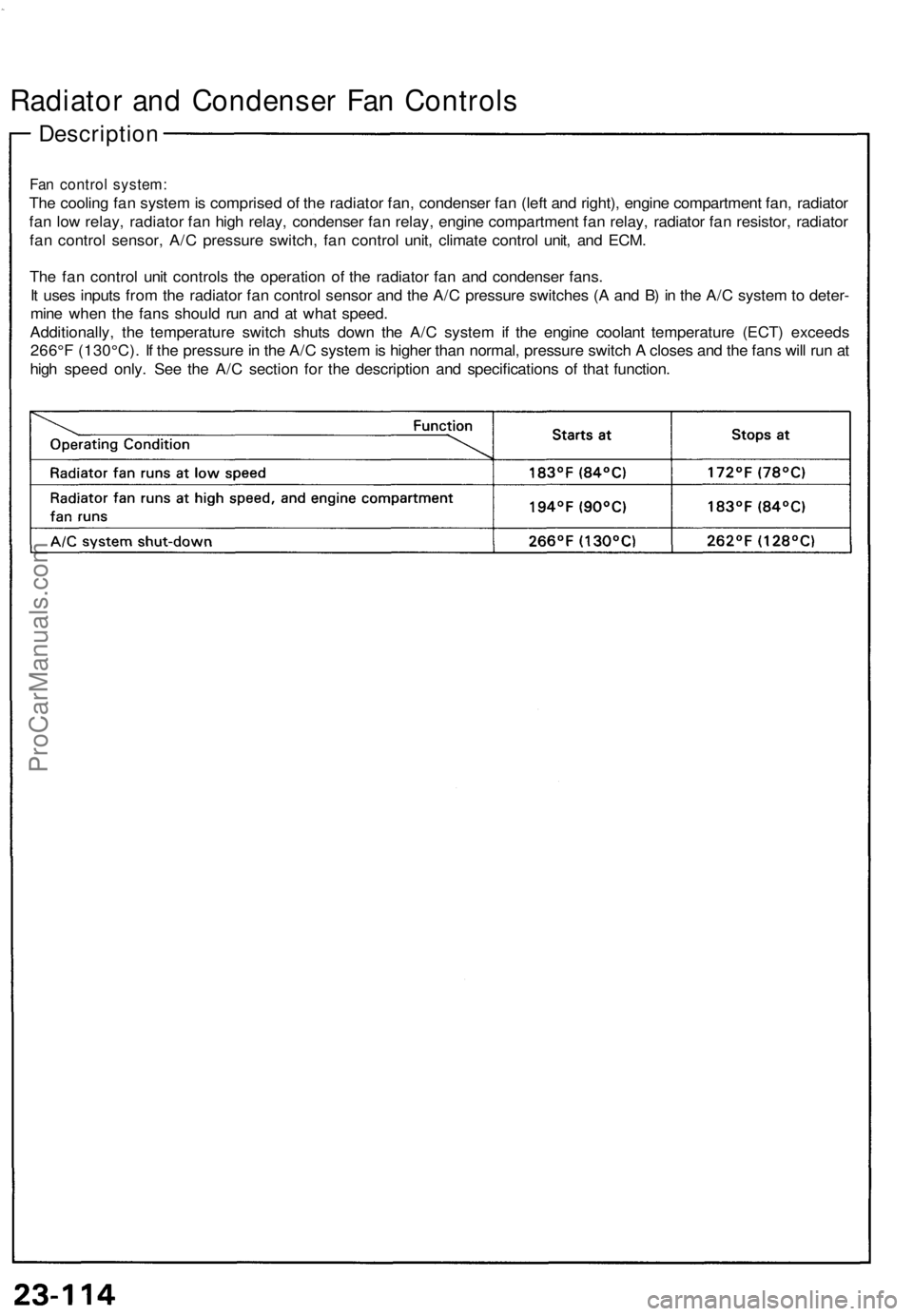

Fan control system:

The cooling fan system is comprised of the radiator fan, condenser fan (left and right), engine compartment fan, radiator

fan low relay, radiator fan high relay, condenser fan relay, engine compartment fan relay, radiator fan resistor, radiator

fan control sensor, A/C pressure switch, fan control unit, climate control unit, and ECM.

The fan control unit controls the operation of the radiator fan and condenser fans.

It uses inputs from the radiator fan control sensor and the A/C pressure switches (A and B) in the A/C system to deter-

mine when the fans should run and at what speed.

Additionally, the temperature switch shuts down the A/C system if the engine coolant temperature (ECT) exceeds

266°F (130°C). If the pressure in the A/C system is higher than normal, pressure switch A closes and the fans will run at

high speed only. See the A/C section for the description and specifications of that function.ProCarManuals.com

Page 783 of 1640

Radiator an d Condense r Fa n Control s

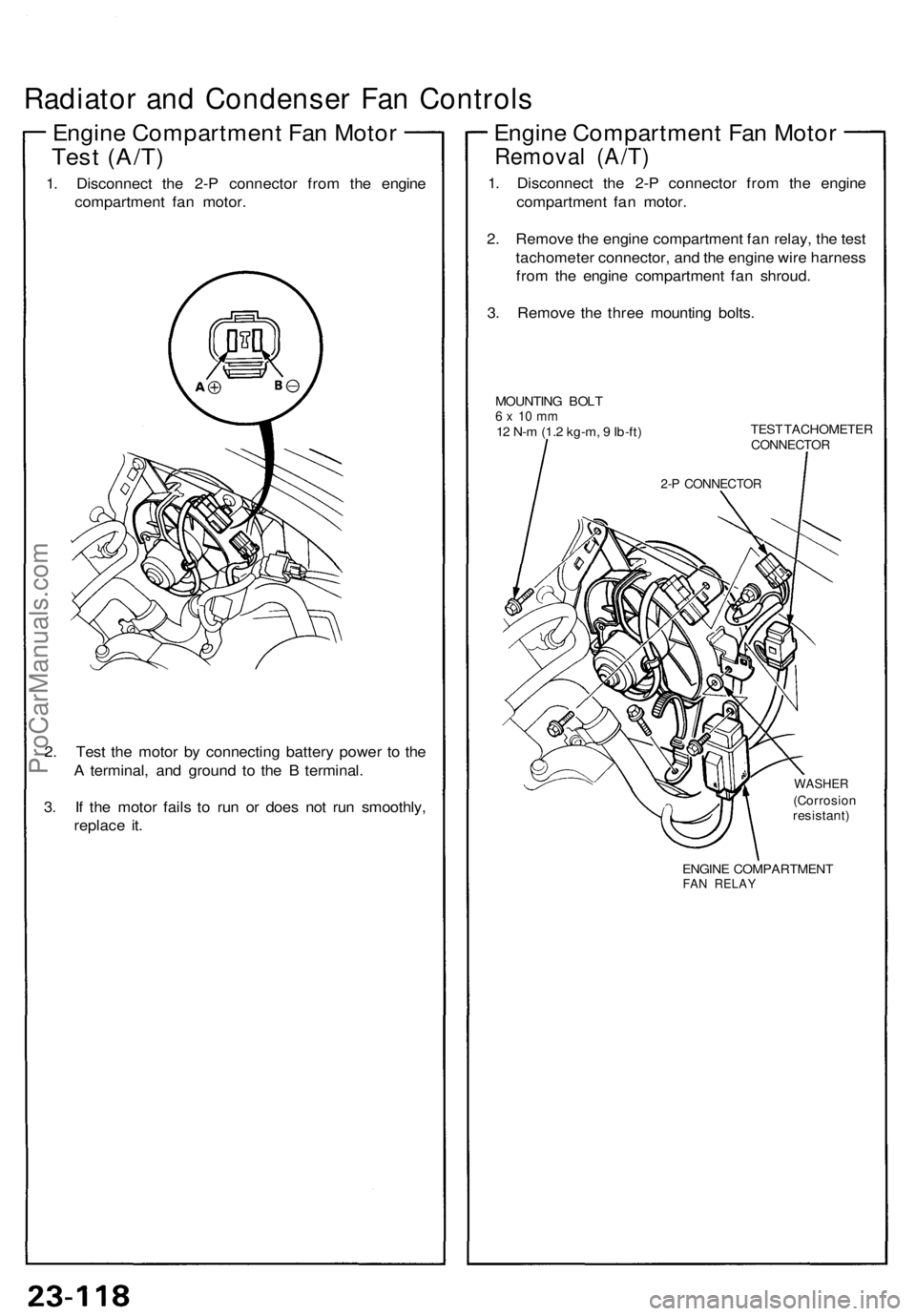

Engine Compartmen t Fa n Moto r

Tes t (A/T )

1. Disconnec t th e 2- P connecto r fro m th e engin e

compartmen t fa n motor .

2 . Tes t th e moto r b y connectin g batter y powe r t o th e

A terminal , an d groun d t o th e B terminal .

3 . I f th e moto r fail s t o ru n o r doe s no t ru n smoothly ,

replac e it .

Engin e Compartmen t Fa n Moto r

Remova l (A/T )

1. Disconnec t th e 2- P connecto r fro m th e engin e

compartmen t fa n motor .

2 . Remov e th e engin e compartmen t fa n relay, the tes t

tachomete r connector , an d th e engin e wir e harnes s

fro m th e engin e compartmen t fa n shroud .

3 . Remov e th e thre e mountin g bolts .

MOUNTIN G BOL T6 x 1 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft ) TES

T TACHOMETE RCONNECTOR

WASHER(Corrosio nresistant)

ENGIN E COMPARTMEN T

FAN RELA Y

2-P CONNECTO R

ProCarManuals.com

Page 784 of 1640

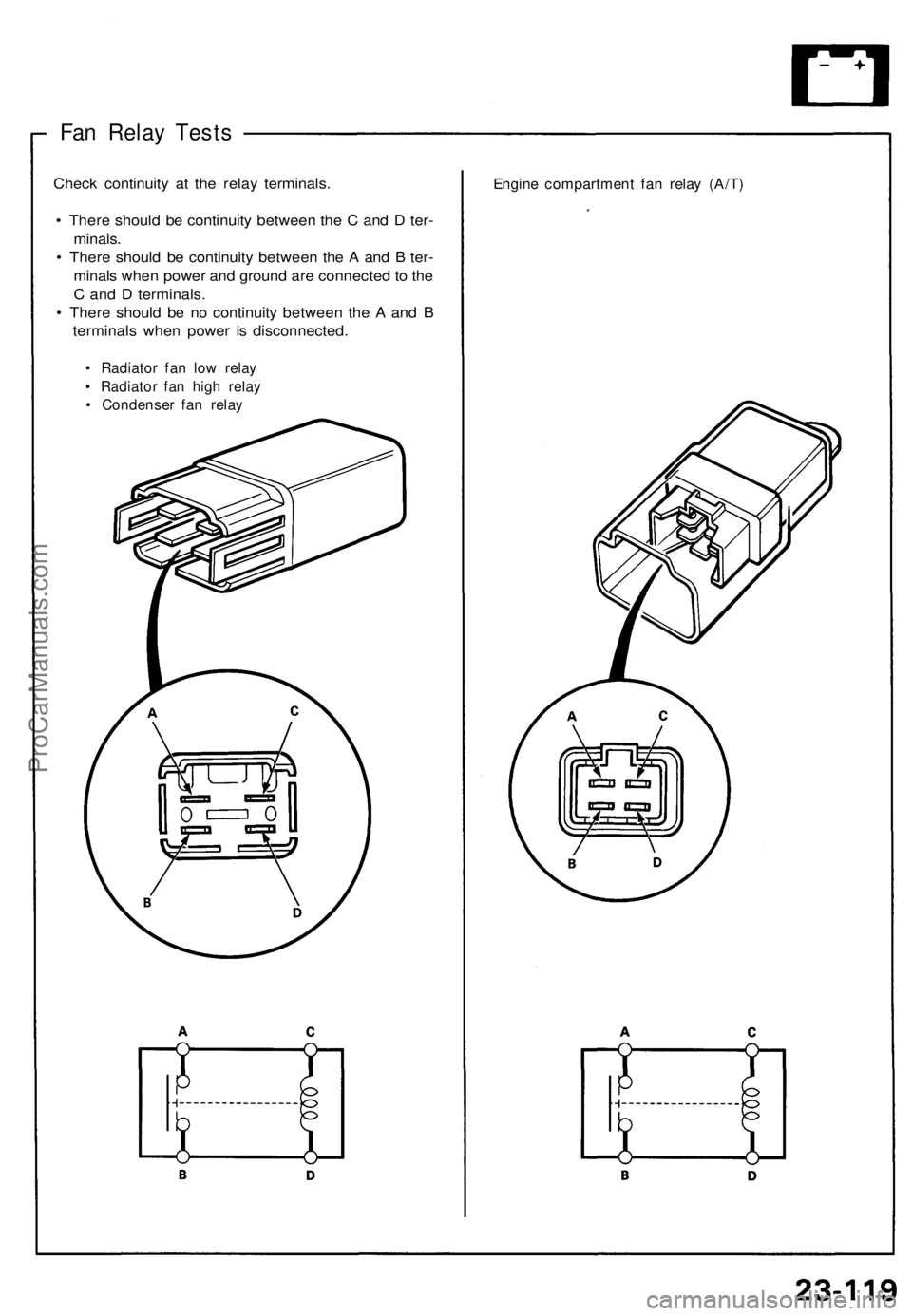

Fan Relay Tests

Check continuity at the relay terminals.

• There should be continuity between the C and D ter-

minals.

• There should be continuity between the A and B ter-

minals when power and ground are connected to the

C and D terminals.

• There should be no continuity between the A and B

terminals when power is disconnected.

• Radiator fan low relay

• Radiator fan high relay

• Condenser fan relay

Engine compartment fan relay (A/T)ProCarManuals.com

Page 786 of 1640

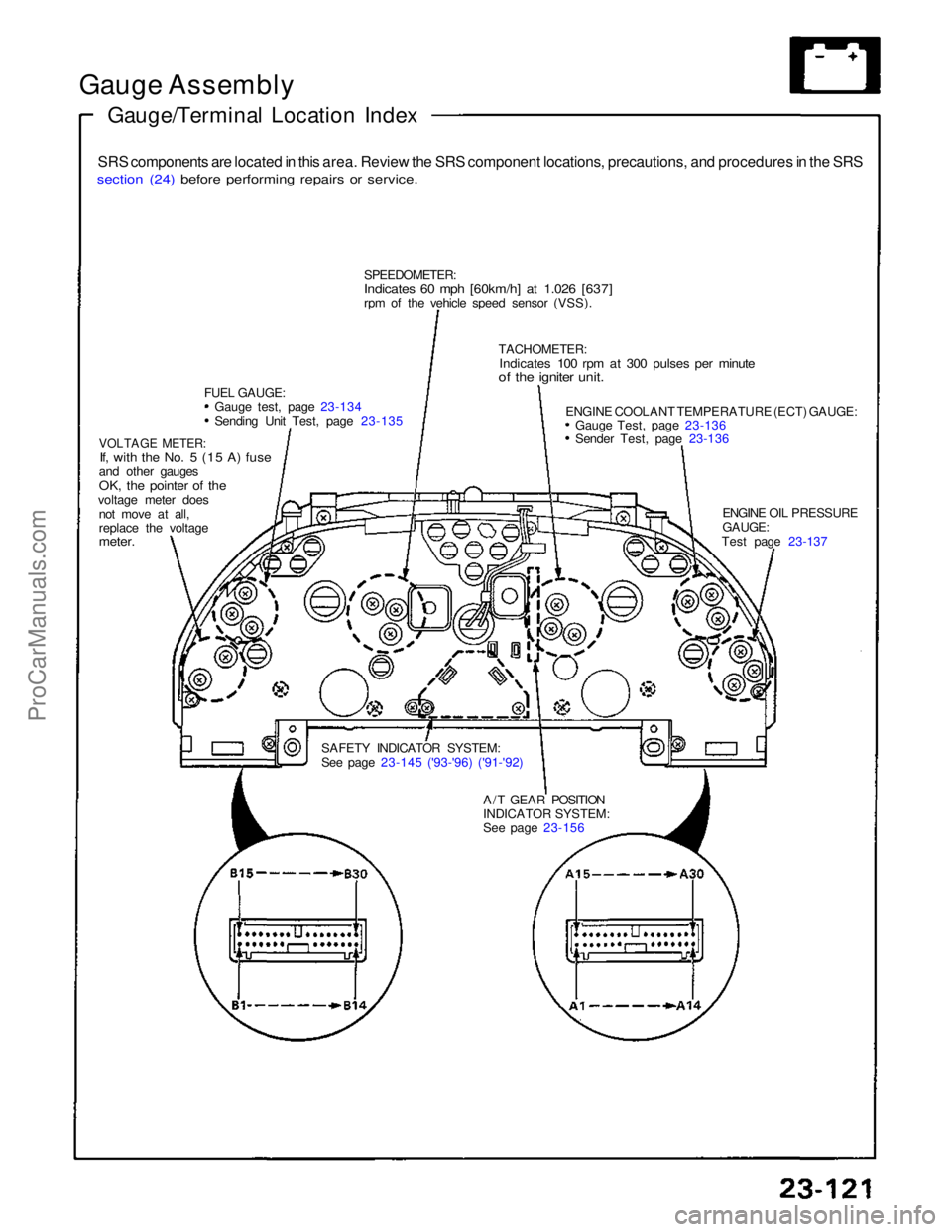

Gauge Assembly

Gauge/Terminal Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

SPEEDOMETER:

Indicates 60 mph [60km/h] at 1.026 [637]

rpm of the vehicle speed sensor (VSS).

FUEL GAUGE: Gauge test, page 23-134 Sending Unit Test, page 23-135

VOLTAGE METER:

If, with the No. 5 (15 A) fuse

and other gauges

OK, the pointer of the

voltage meter does not move at all,

replace the voltage

meter.

SAFETY INDICATOR SYSTEM:

See page 23-145 ('93-'96) ('91-'92)A/T GEAR POSITION

INDICATOR SYSTEM:

See page 23-156 ENGINE OIL PRESSURE

GAUGE:

Test page 23-137

ENGINE COOLANT TEMPERATURE (ECT) GAUGE:

Gauge Test, page 23-136 Sender Test, page 23-136

TACHOMETER:

Indicates 100 rpm at 300 pulses per minute

of the igniter unit.ProCarManuals.com

Page 790 of 1640

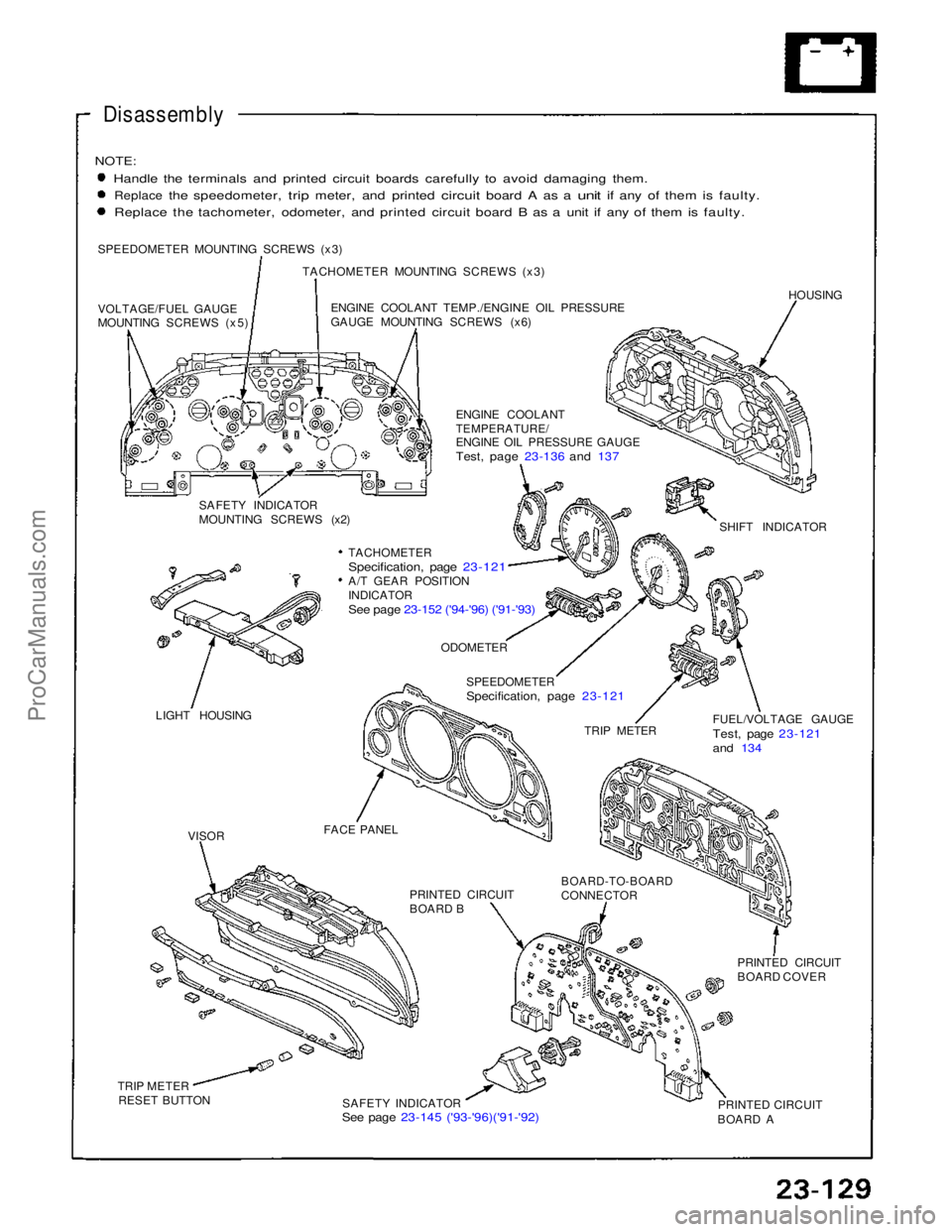

Disassembly

NOTE:

Handle the terminals and printed circuit boards carefully to avoid damaging them.

Replace

the

speedometer,

trip

meter,

and

printed

circuit

board

A as a

unit

if any of

them

is

faulty. Replace the tachometer, odometer, and printed circuit board B as a unit if any of them is faulty.

SPEEDOMETER MOUNTING SCREWS (x3) TACHOMETER MOUNTING SCREWS (x3)

VOLTAGE/FUEL GAUGE

MOUNTING SCREWS (x5) ENGINE COOLANT TEMP./ENGINE OIL PRESSURE

GAUGE MOUNTING SCREWS (x6)

HOUSING

ENGINE COOLANT

TEMPERATURE/

ENGINE OIL PRESSURE GAUGE

Test, page 23-136 and 137

SAFETY INDICATOR

MOUNTING SCREWS (x2) SHIFT INDICATOR

TACHOMETER

Specification, page 23-121

A/T GEAR POSITION

INDICATOR

See page 23-152 ('94-'96) ('91-'93)

LIGHT HOUSING

ODOMETER

SPEEDOMETER

Specification, page 23-121

TRIP METER FUEL/VOLTAGE GAUGE

Test, page 23-121

and 134

FACE PANEL PRINTED CIRCUIT

BOARD B

BOARD-TO-BOARD

CONNECTOR

PRINTED CIRCUIT

BOARD COVER

PRINTED CIRCUIT

BOARD A

SAFETY INDICATOR

See page 23-145 ('93-'96)('91-'92)

TRIP METER

RESET BUTTON

VISORProCarManuals.com

Page 797 of 1640

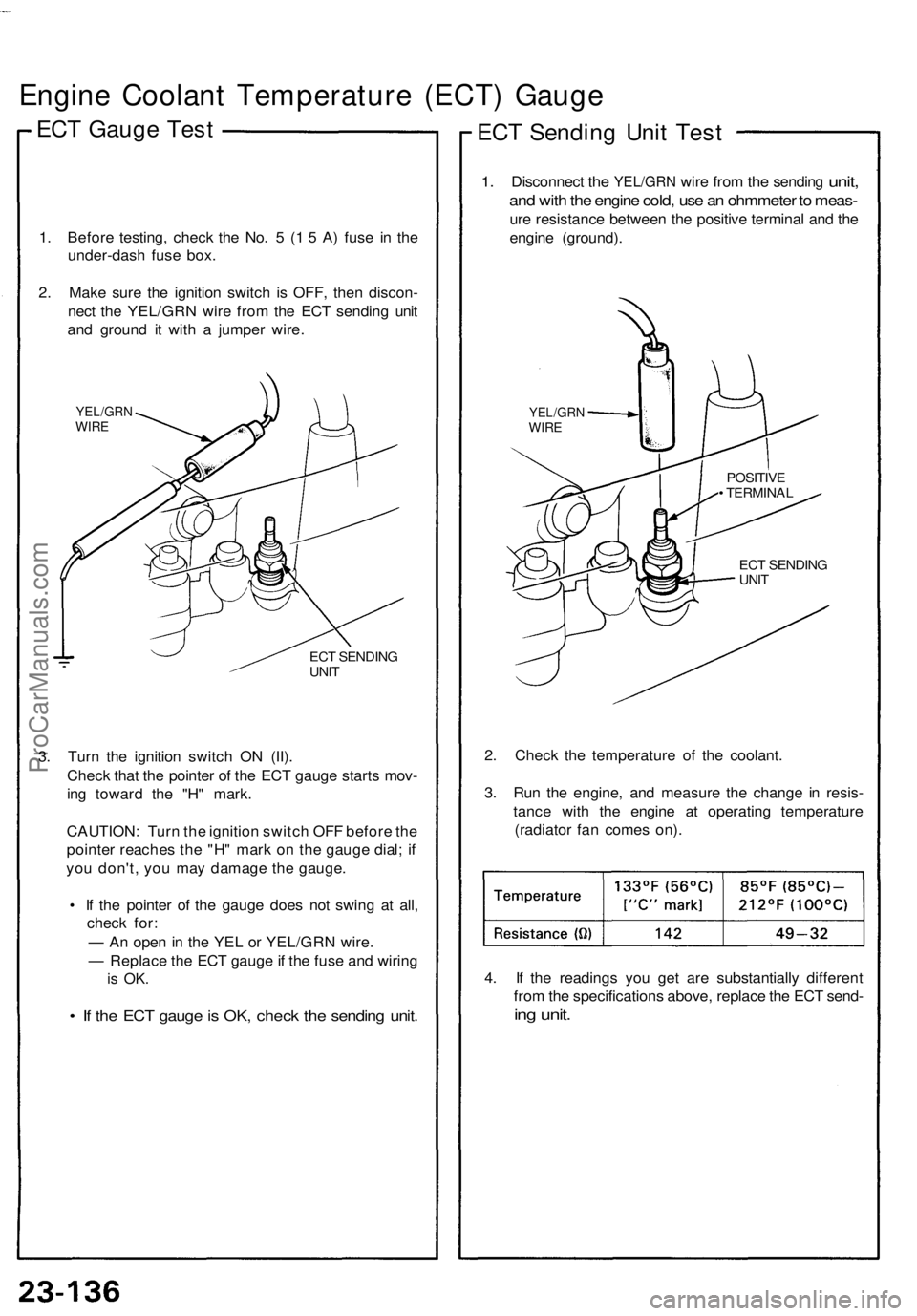

Engine Coolan t Temperatur e (ECT ) Gaug e

ECT Gaug e Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e EC T sendin g uni t

an d groun d i t wit h a jumpe r wire .

YEL/GR NWIRE

ECT SENDIN G

UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e EC T gaug e start s mov -

in g towar d th e "H " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "H " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y damag e th e gauge .

• I f th e pointe r o f th e gaug e doe s no t swin g a t all ,

chec k for :

— A n ope n in th e YE L o r YEL/GR N wire .

— Replac e th e EC T gaug e if th e fus e an d wirin g

is OK .

• I f th e EC T gaug e is OK , chec k th e sendin g unit .

ECT Sendin g Uni t Tes t

1. Disconnec t the YEL/GR N wire fro m the sendin g unit,

and wit h th e engin e cold , us e a n ohmmete r t o meas -

ure resistanc e betwee n th e positiv e termina l an d th e

engin e (ground) .

2 . Chec k th e temperatur e o f th e coolant .

3 . Ru n th e engine , an d measur e th e chang e i n resis -

tanc e wit h th e engin e a t operatin g temperatur e

(radiato r fa n come s on) .

4 . I f th e reading s yo u ge t ar e substantiall y differen t

fro m th e specification s above , replac e th e EC T send -

ing unit .

YEL/GR NWIRE

POSITIV E

• TERMINA L

EC T SENDIN G

UNI T

ProCarManuals.com

Page 798 of 1640

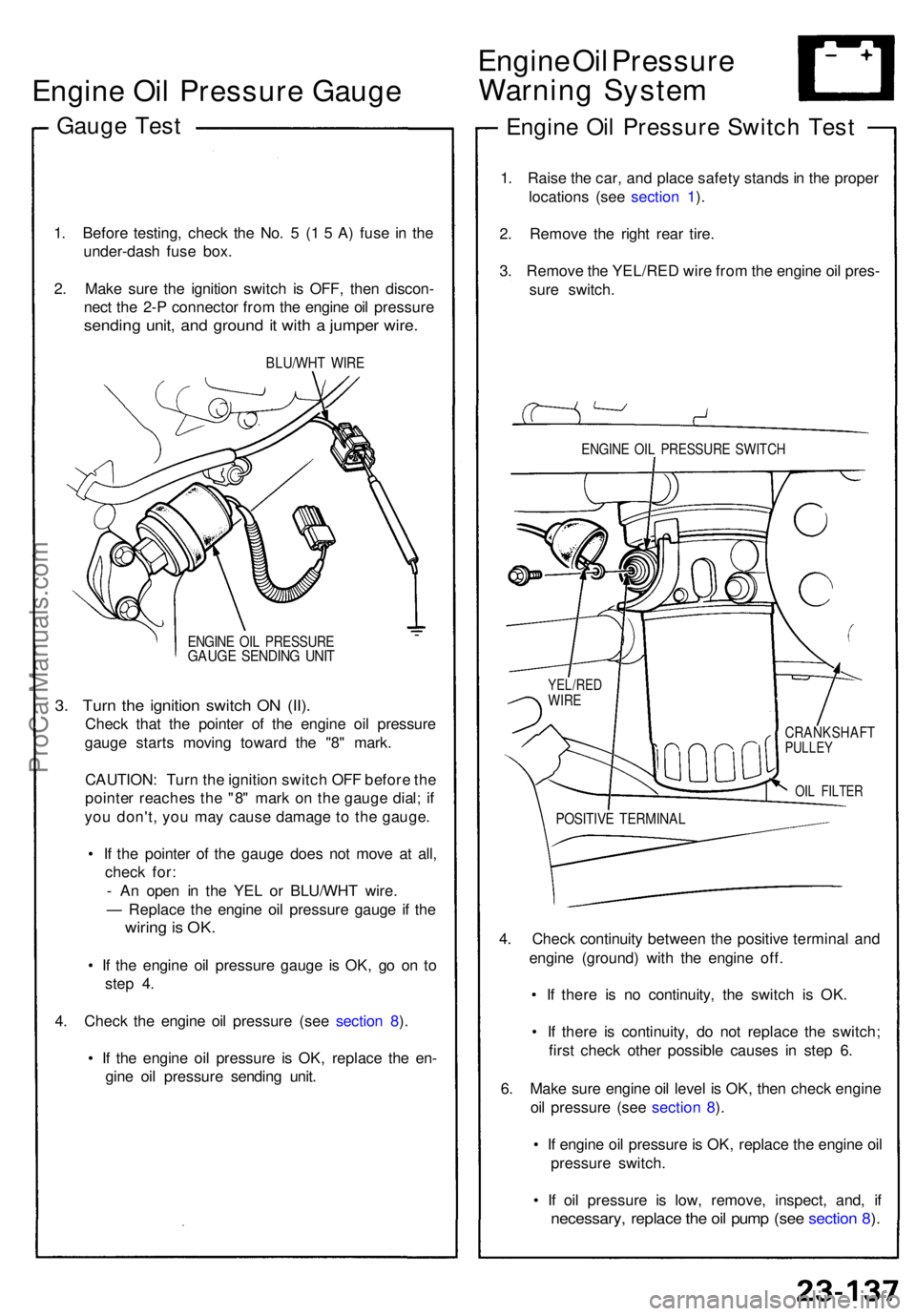

Engine Oi l Pressur e Gaug e

Gauge Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e 2- P connecto r fro m th e engin e oi l pressur e

sending unit , an d groun d it wit h a jumpe r wire .

BLU/WH T WIR E

ENGIN E OI L PRESSUR EGAUGE SENDIN G UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e engin e oi l pressur e

gaug e start s movin g towar d th e "8 " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "8 " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y caus e damag e t o th e gauge .

• I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k for :

- A n ope n i n th e YE L o r BLU/WH T wire .

— Replac e th e engin e oi l pressur e gaug e i f th e

wirin g is OK .

• I f th e engin e oi l pressur e gaug e i s OK , g o o n t o

ste p 4 .

4 . Chec k th e engin e oi l pressur e (se e sectio n 8 ).

• I f th e engin e oi l pressur e i s OK , replac e th e en -

gin e oi l pressur e sendin g unit .

Engin e Oi l Pressur e

Warnin g Syste m

Engine Oi l Pressur e Switc h Tes t

1. Rais e th e car , an d plac e safet y stand s in th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e righ t rea r tire .

3 . Remov e th e YEL/RE D wir e fro m th e engin e oi l pres -

sur e switch .

ENGINE OI L PRESSUR E SWITC H

CRANKSHAF TPULLEY

4. Chec k continuit y betwee n th e positiv e termina l an d

engin e (ground ) wit h th e engin e off .

• I f ther e i s n o continuity , th e switc h i s OK .

• I f ther e i s continuity , d o no t replac e th e switch ;

firs t chec k othe r possibl e cause s i n ste p 6 .

6 . Mak e sur e engin e oi l leve l i s OK , the n chec k engine

oi l pressur e (se e sectio n 8 ).

• I f engin e oi l pressur e is OK , replac e th e engin e oi l

pressur e switch .

• I f oi l pressur e i s low , remove , inspect , and , i f

necessary , replac e th e oi l pum p (se e sectio n 8 ).

YEL/RE DWIRE

POSITIV E TERMINA L

OIL FILTE R

ProCarManuals.com

Page 805 of 1640

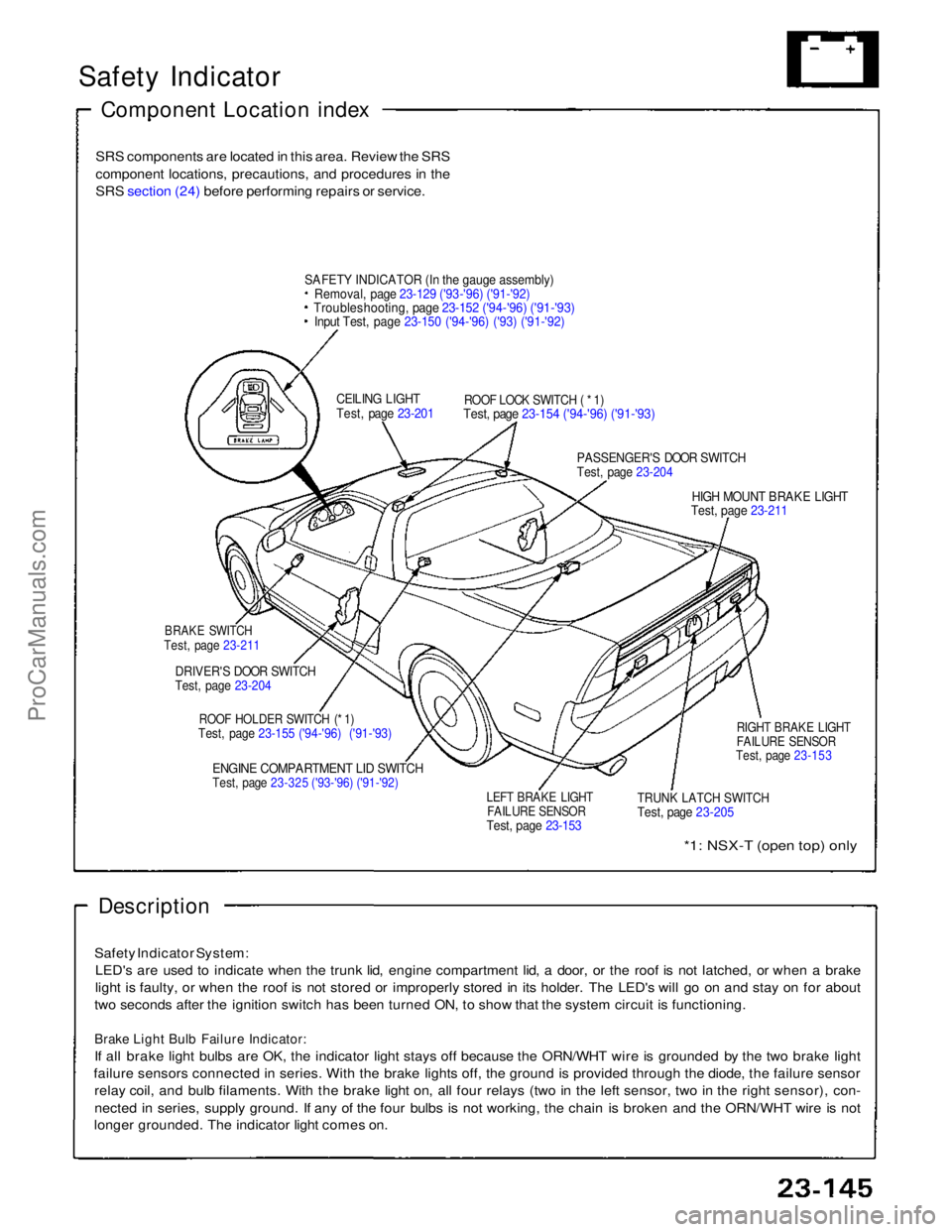

Safety Indicator

Component Location index

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

SAFET

Y

INDICATOR (In the gauge assembly)

Removal, page 23-129 ('93-'96) ('91-'92)

Troubleshooting, page 23-152 ('94-'96) ('91-'93)

Input Test, page 23-150 ('94-'96) ('93) ('91-'92)

CEILING LIGHT

Test, page 23-201

ROOF LOCK SWITCH ( * 1)

Test, page 23-154 ('94-'96) ('91-'93)

PASSENGER'S DOOR SWITCH

Test, page 23-204

HIGH MOUNT BRAKE LIGHT

Test, page 23-211

BRAKE SWITCH

Test, page 23-211

DRIVER'S DOOR SWITCH

Test, page 23-204

ROOF HOLDER SWITCH (* 1)

Test, page 23-155 ('94-'96) ('91-'93)

ENGINE COMPARTMENT LID SWITCH

Test, page 23-325 ('93-'96) ('91-'92)

LEFT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

TRUNK LATCH SWITCH

Test, page 23-205

RIGHT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

*1: NSX-T (open top) only

Description

Safety Indicator System: LED's are used to indicate when the trunk lid, engine compartment lid, a door, or the roof is not latched, or when a brake

light is faulty, or when the roof is not stored or improperly stored in its holder. The LED's will go on and stay on for about

two seconds after the ignition switch has been turned ON, to show that the system circuit is functioning.

Brake Light Bulb Failure Indicator:

If all brake light bulbs are OK, the indicator light stays off because the ORN/WHT wire is grounded by the two brake light

failure sensors connected in series. With the brake lights off, the ground is provided through the diode, the failure sensor relay coil, and bulb filaments. With the brake light on, all four relays (two in the left sensor, two in the right sensor), con-

nected in series, supply ground. If any of the four bulbs is not working, the chain is broken and the ORN/WHT wire is not

longer grounded. The indicator light comes on.ProCarManuals.com

Page 811 of 1640

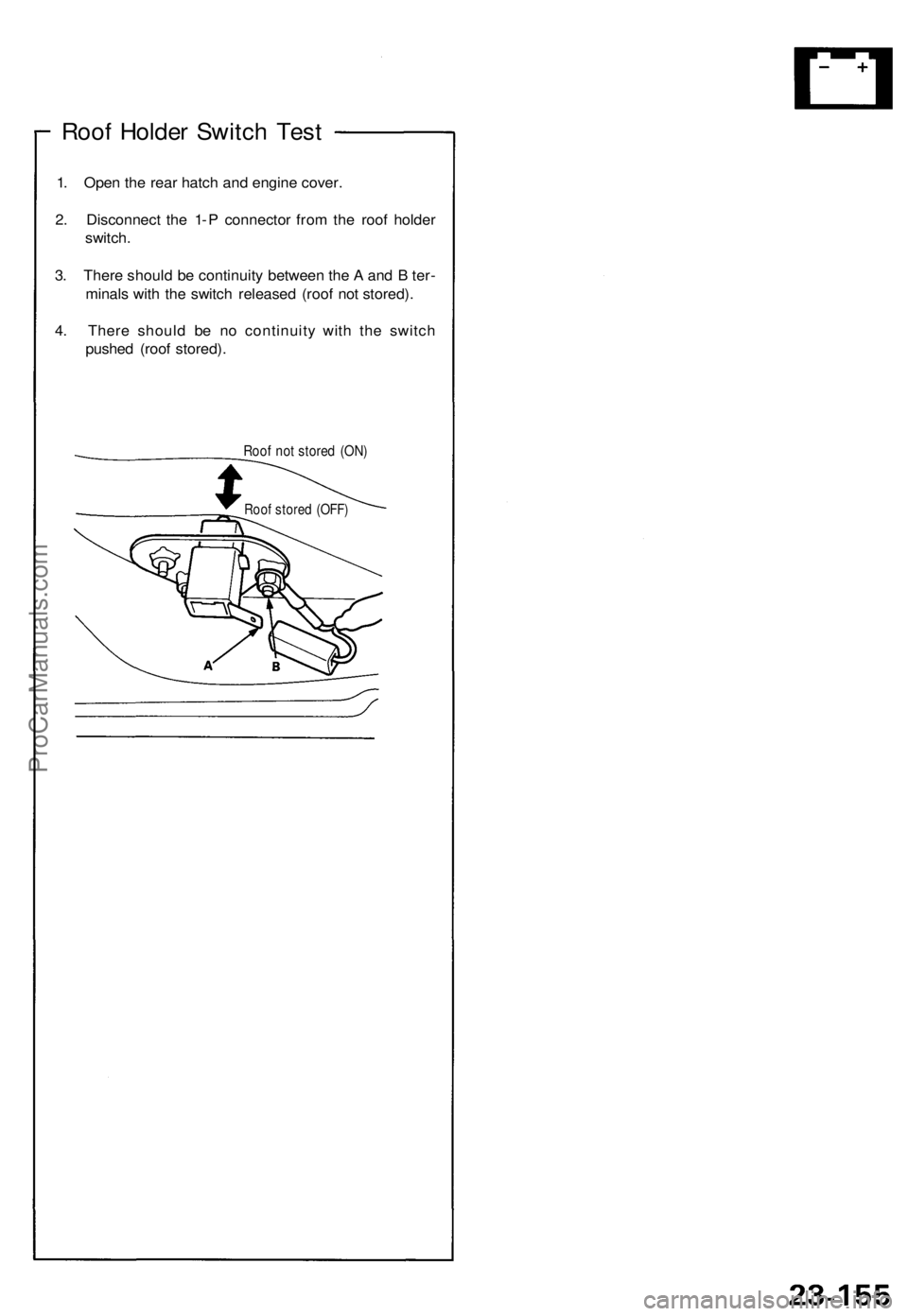

Roof Holder Switch Test

1. Open the rear hatch and engine cover.

2. Disconnect the 1- P connector from the roof holder

switch.

3. There should be continuity between the A and B ter-

minals with the switch released (roof not stored).

4. There should be no continuity with the switch

pushed (roof stored).

Roof not stored (ON)

Roof stored (OFF)ProCarManuals.com

Page 816 of 1640

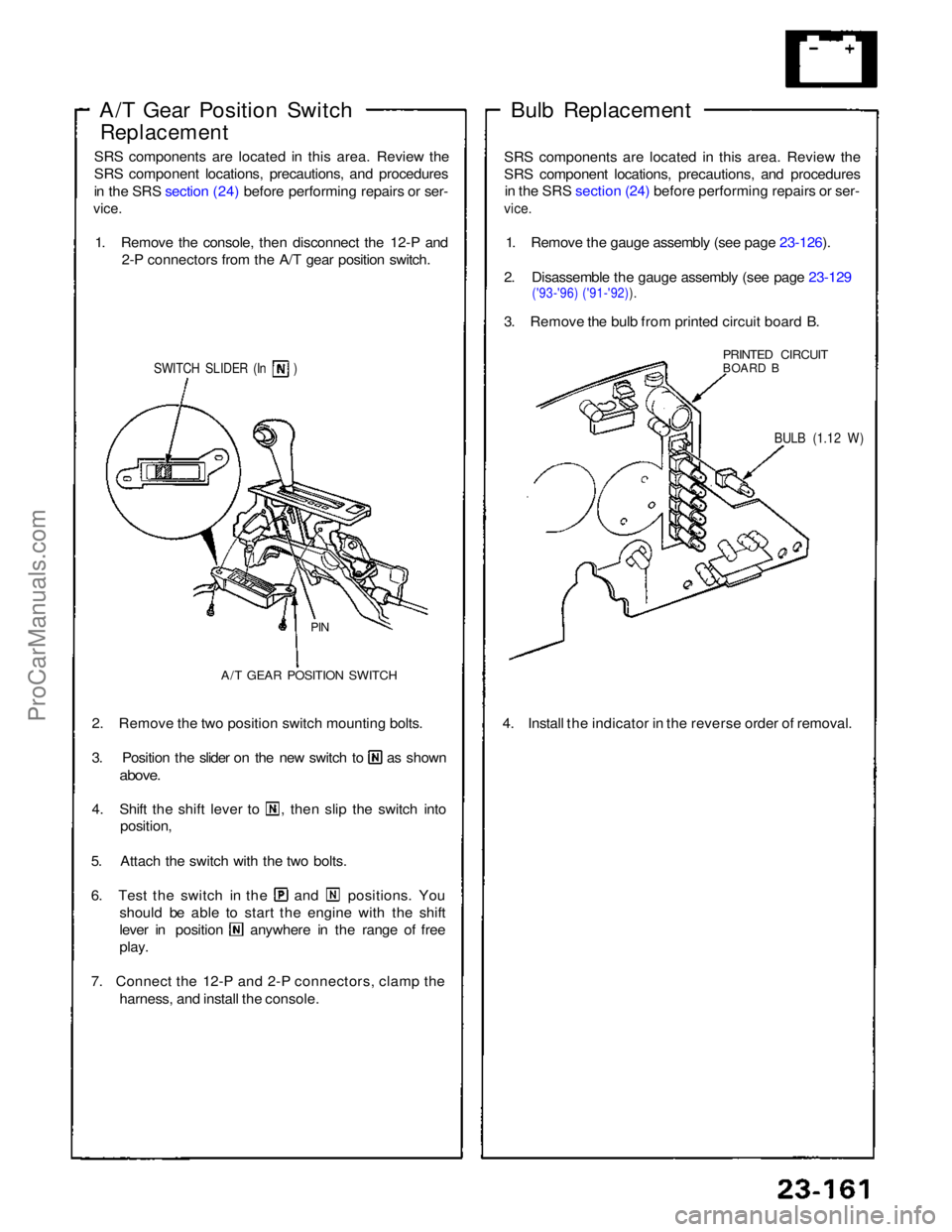

A/T Gear Position Switch

Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

1. Remove the console, then disconnect the 12-P and 2-P connectors from the A/T gear position switch.

SWITCH SLIDER (In )

PIN

A/T GEAR POSITION SWITCH

2. Remove the two position switch mounting bolts. 3. Position the slider on the new switch to as shown

above.

4. Shift the shift lever to , then slip the switch into

position,

5. Attach the switch with the two bolts. 6. Test the switch in the and positions. You

should be able to start the engine with the shift lever in position anywhere in the range of free

play.

7. Connect the 12-P and 2-P connectors, clamp the harness, and install the console. Bulb Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures in the SRS section (24) before performing repairs or ser-

vice.

1. Remove the gauge assembly (see page 23-126).

2. Disassemble the gauge assembly (see page 23-129

('93-'96) ('91-'92)).

3. Remove the bulb from printed circuit board B.

PRINTED CIRCUIT

BOARD B

BULB (1.12 W)

4. Install the indicator in the reverse order of removal.ProCarManuals.com