engine ACURA NSX 1991 Service Manual Online

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 307 of 1640

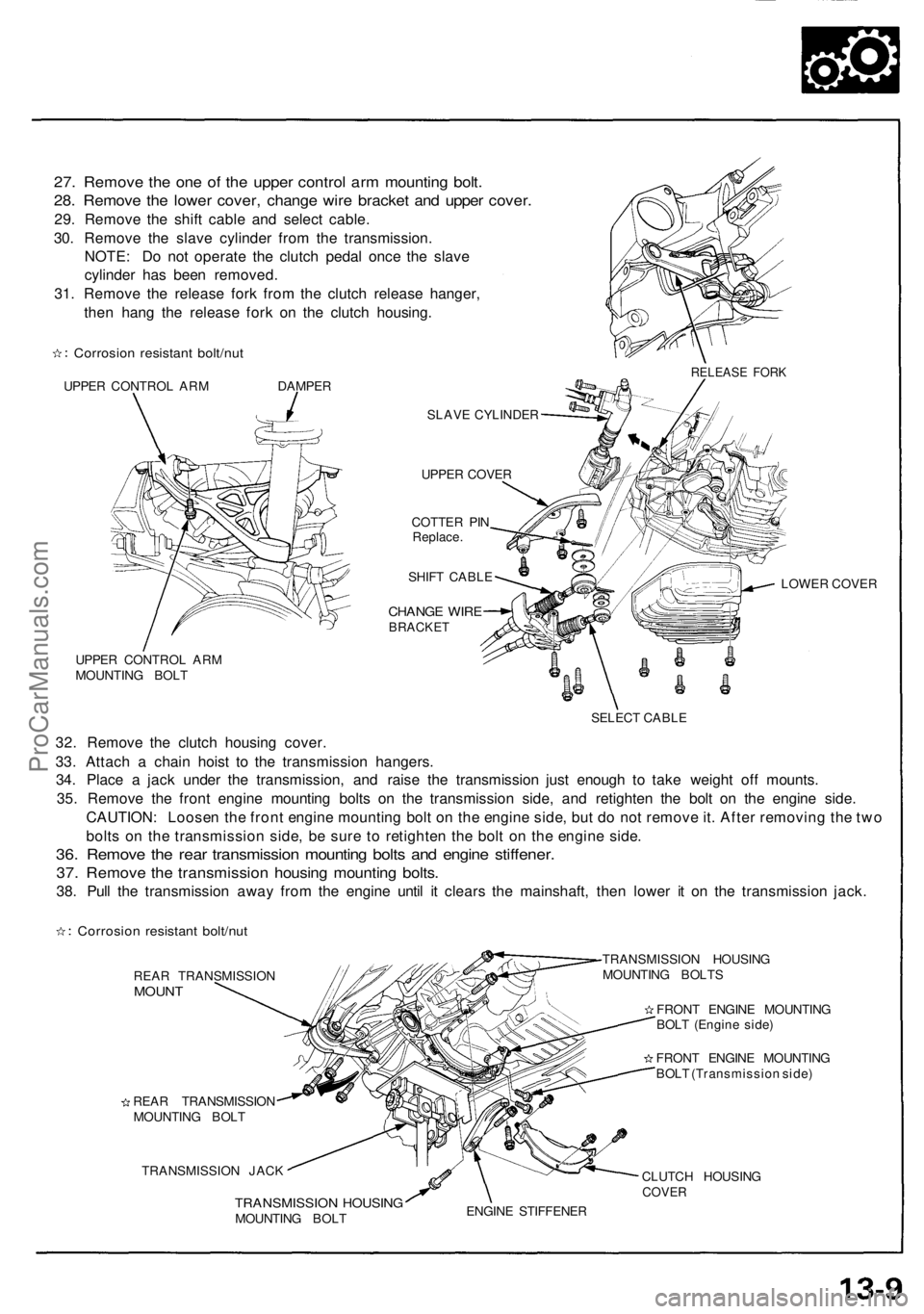

27. Remove the one of the upper control arm mounting bolt.

28. Remove the lower cover, change wire bracket and upper cover.

29. Remove the shift cable and select cable.

30. Remove the slave cylinder from the transmission.

NOTE: Do not operate the clutch pedal once the slave

cylinder has been removed.

31. Remove the release fork from the clutch release hanger,

then hang the release fork on the clutch housing.

Corrosion resistant bolt/nut

UPPER CONTROL ARM DAMPER

SLAVE CYLINDER

UPPER COVER

COTTER PIN

Replace.

SHIFT CABLE

CHANGE WIRE

BRACKET

UPPER CONTROL ARM

MOUNTING BOLT

LOWER COVER

SELECT CABLE

32. Remove the clutch housing cover.

33. Attach a chain hoist to the transmission hangers.

34. Place a jack under the transmission, and raise the transmission just enough to take weight off mounts.

35. Remove the front engine mounting bolts on the transmission side, and retighten the bolt on the engine side.

CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the two

bolts on the transmission side, be sure to retighten the bolt on the engine side.

36. Remove the rear transmission mounting bolts and engine stiffener.

37. Remove the transmission housing mounting bolts.

38. Pull the transmission away from the engine until it clears the mainshaft, then lower it on the transmission jack.

Corrosion resistant bolt/nut

REAR TRANSMISSION

MOUNT

REAR TRANSMISSION

MOUNTING BOLT

TRANSMISSION JACK

TRANSMISSION HOUSING

MOUNTING BOLTS

FRONT ENGINE MOUNTING

BOLT (Engine side)

FRONT ENGINE MOUNTING

BOLT (Transmission side)

TRANSMISSION HOUSING

MOUNTING BOLT

CLUTCH HOUSING

COVER

ENGINE STIFFENER

RELEASE FORKProCarManuals.com

Page 407 of 1640

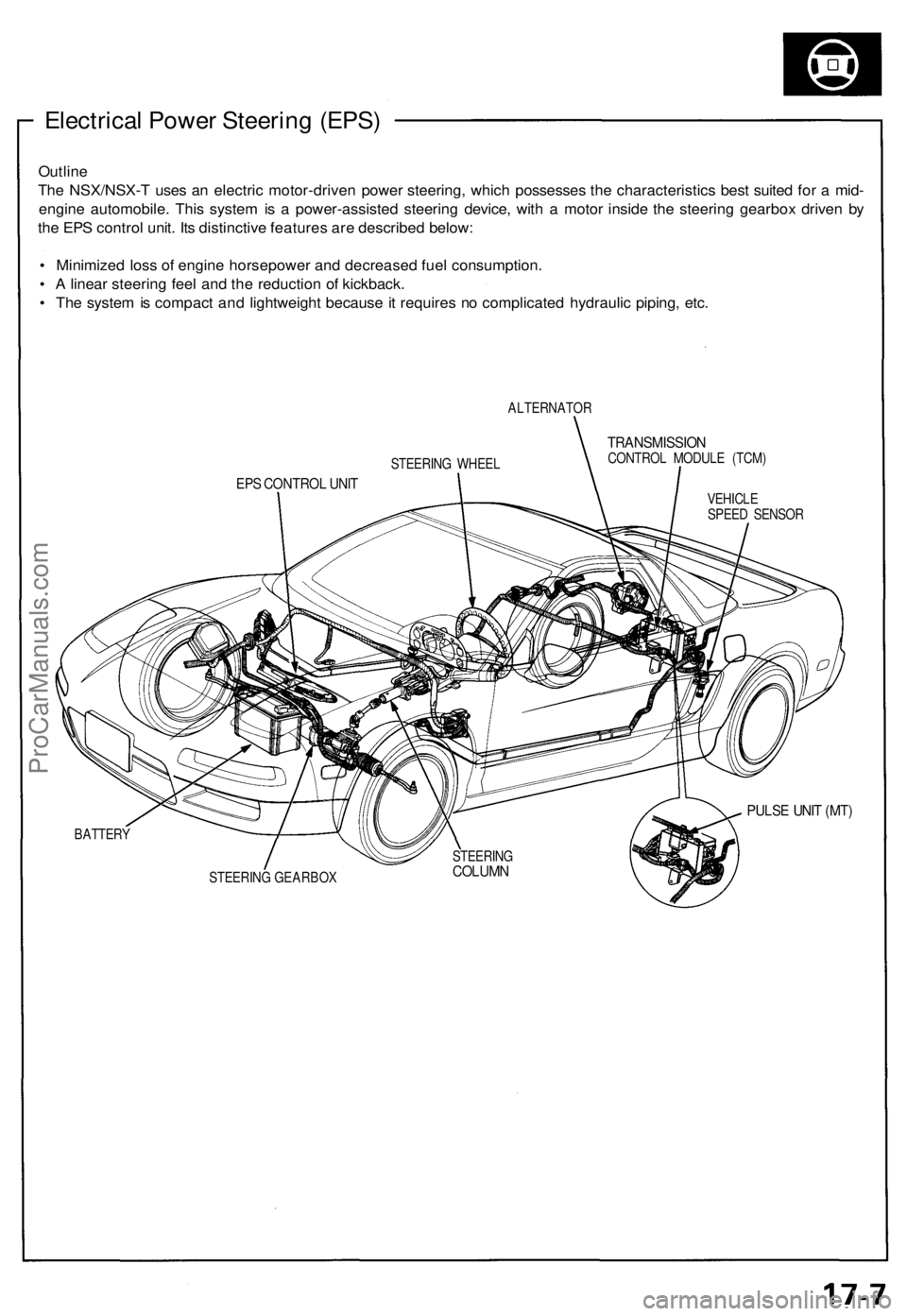

Electrical Power Steering (EPS)

Outline

The NSX/NSX-T uses an electric motor-driven power steering, which possesses the characteristics best suited for a mid-

engine automobile. This system is a power-assisted steering device, with a motor inside the steering gearbox driven by

the EPS control unit. Its distinctive features are described below:

• Minimized loss of engine horsepower and decreased fuel consumption.

• A linear steering feel and the reduction of kickback.

• The system is compact and lightweight because it requires no complicated hydraulic piping, etc.

ALTERNATOR

TRANSMISSION

CONTROL MODULE (TCM)

EPS CONTROL UNIT

VEHICLE

SPEED SENSOR

PULSE UNIT (MT)

BATTERY

STEERING GEARBOX

STEERING WHEEL

STEERING

COLUMNProCarManuals.com

Page 412 of 1640

System Description

Function and Operation

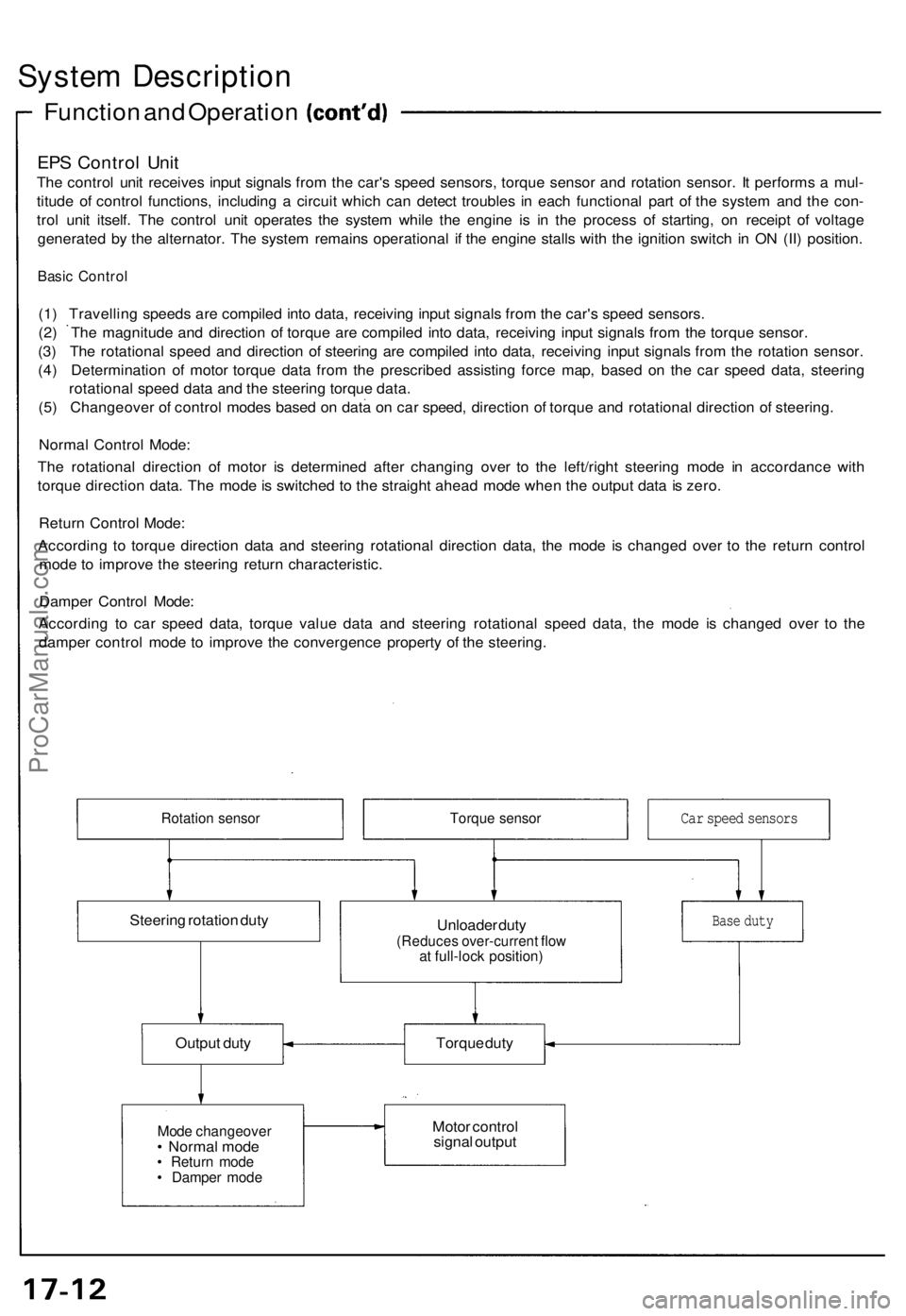

EPS Control Unit

The control unit receives input signals from the car's speed sensors, torque sensor and rotation sensor. It performs a mul-

titude of control functions, including a circuit which can detect troubles in each functional part of the system and the con-

trol unit itself. The control unit operates the system while the engine is in the process of starting, on receipt of voltage

generated by the alternator. The system remains operational if the engine stalls with the ignition switch in ON (II) position.

Basic Control

(1) Travelling speeds are compiled into data, receiving input signals from the car's speed sensors.

(2) The magnitude and direction of torque are compiled into data, receiving input signals from the torque sensor.

(3) The rotational speed and direction of steering are compiled into data, receiving input signals from the rotation sensor.

(4) Determination of motor torque data from the prescribed assisting force map, based on the car speed data, steering

rotational speed data and the steering torque data.

(5) Changeover of control modes based on data on car speed, direction of torque and rotational direction of steering.

Normal Control Mode:

The rotational direction of motor is determined after changing over to the left/right steering mode in accordance with

torque direction data. The mode is switched to the straight ahead mode when the output data is zero.

Return Control Mode:

According to torque direction data and steering rotational direction data, the mode is changed over to the return control

mode to improve the steering return characteristic.

Damper Control Mode:

According to car speed data, torque value data and steering rotational speed data, the mode is changed over to the

damper control mode to improve the convergence property of the steering.

Rotation sensor

Torque sensor

Steering rotation duty

Unloader duty

(Reduces over-current flow

at full-lock position)

Output duty

Torque duty

Mode changeover

• Normal mode

• Return mode

• Damper mode

Motor control

signal output

Base duty

Car speed sensorsProCarManuals.com

Page 420 of 1640

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 21 and DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot. If the problem is an

intermittent problem, the system does not become active after the engine starts even though the problem is solved.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 421 of 1640

Diagnostic Troubl e Cod e (DTC ) Indicatio n

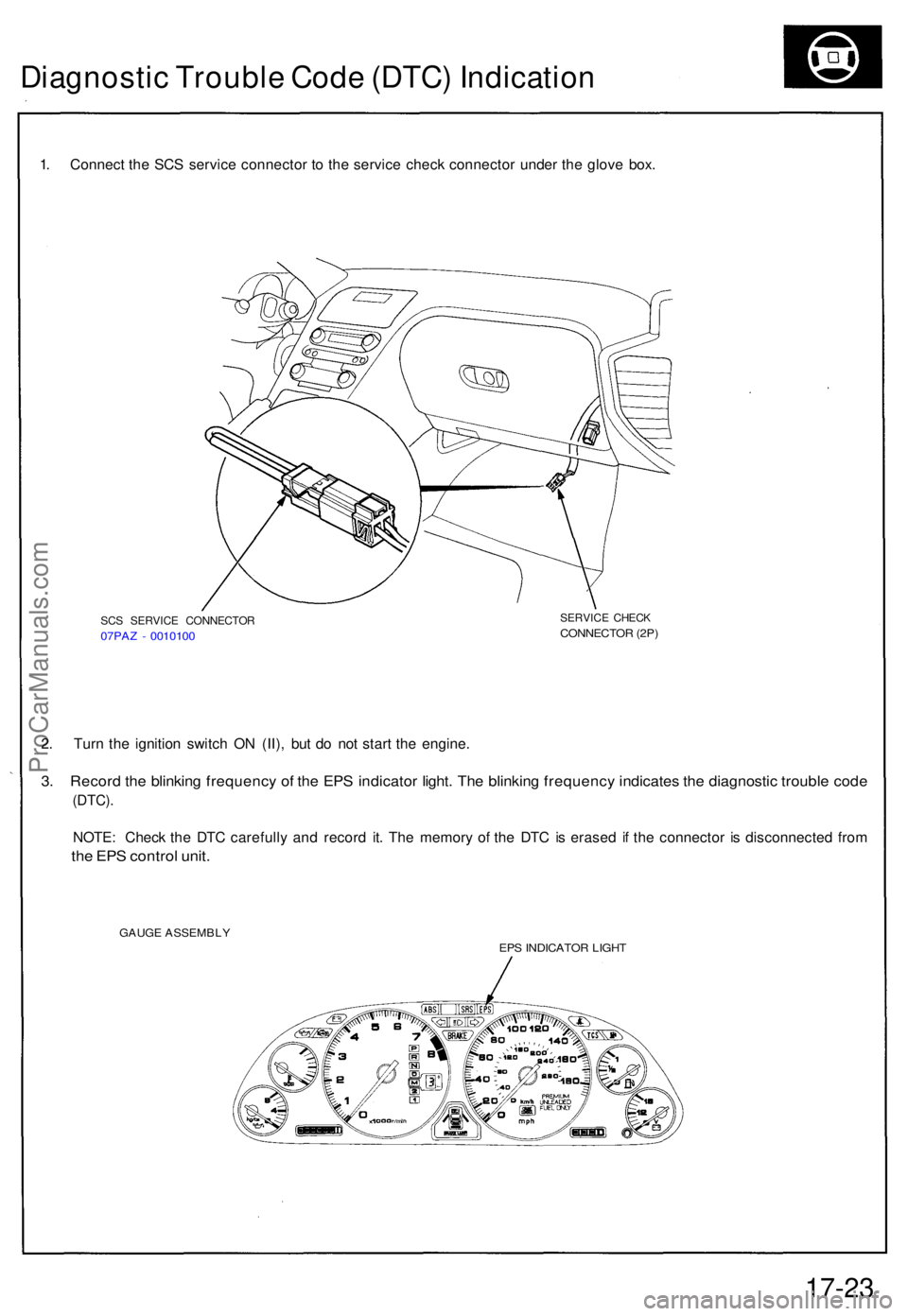

1. Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r unde r th e glov e box .

SCS SERVIC E CONNECTO R07PAZ - 001010 0

SERVIC E CHEC KCONNECTO R (2P )

2. Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

3. Recor d th e blinkin g frequenc y o f th e EP S indicato r light . Th e blinkin g frequenc y indicate s th e diagnosti c troubl e cod e

(DTC) .

NOTE: Chec k th e DT C carefull y an d recor d it . Th e memor y o f th e DT C is erase d i f th e connecto r i s disconnecte d fro m

the EP S contro l unit .

GAUG E ASSEMBL YEPS INDICATO R LIGH T

17-23

ProCarManuals.com

Page 422 of 1640

Diagnostic Trouble Code (DTC) Indication

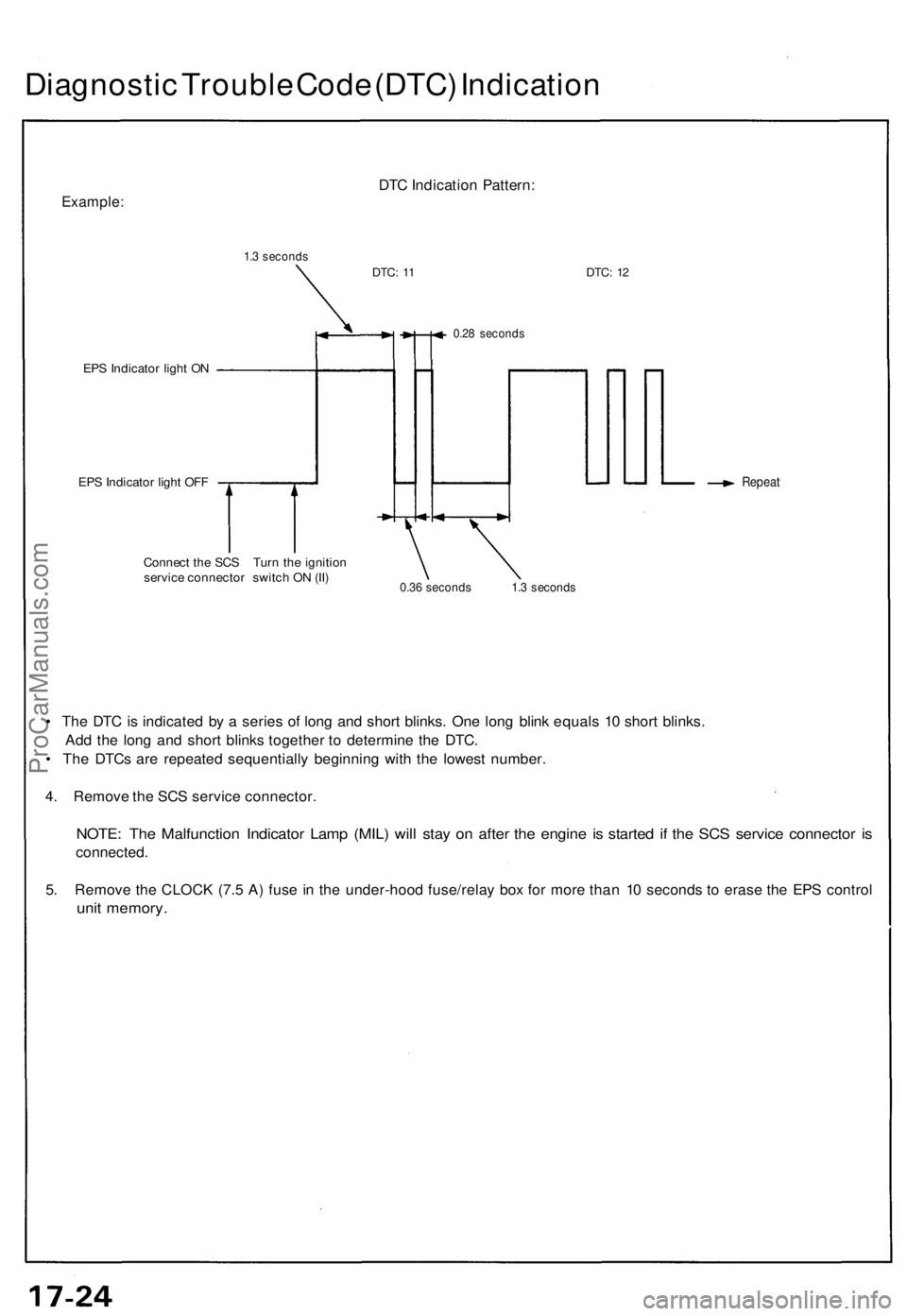

Example:

1.3 seconds

DTC Indication Pattern:

DTC:

11

DTC:

12

EPS Indicator light ON

EPS Indicator light OFF

0.28 seconds

Repeat

Connect the SCS Turn the ignition

service connector switch ON (II)

0.36 seconds 1.3 seconds

• The DTC is indicated by a series of long and short blinks. One long blink equals 10 short blinks.

Add the long and short blinks together to determine the DTC.

• The DTCs are repeated sequentially beginning with the lowest number.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the CLOCK (7.5 A) fuse in the under-hood fuse/relay box for more than 10 seconds to erase the EPS control

unit memory.ProCarManuals.com

Page 485 of 1640

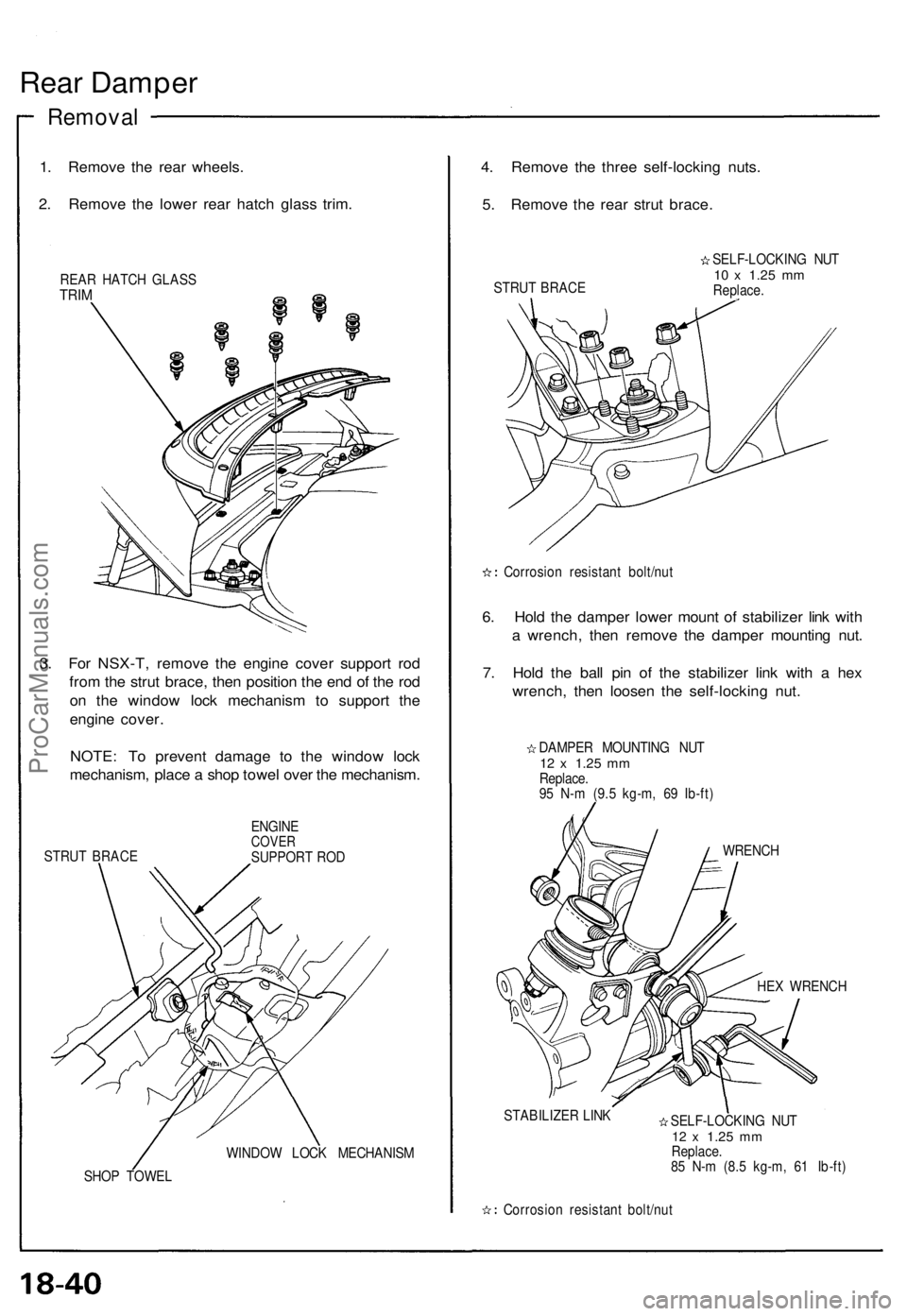

Rear Damper

Removal

1. Remove the rear wheels.

2. Remove the lower rear hatch glass trim.

REAR HATCH GLASS

TRIM

3. For NSX-T, remove the engine cover support rod

from the strut brace, then position the end of the rod

on the window lock mechanism to support the

engine cover.

NOTE: To prevent damage to the window lock

mechanism, place a shop towel over the mechanism.

STRUT BRACE

ENGINE

COVER

SUPPORT ROD

WINDOW LOCK MECHANISM

SHOP TOWEL

4. Remove the three self-locking nuts.

5. Remove the rear strut brace.

STRUT BRACE

SELF-LOCKING NUT

10 x

1.25

mm

Replace.

Corrosion resistant bolt/nut

6. Hold the damper lower mount of stabilizer link with

a wrench, then remove the damper mounting nut.

7. Hold the ball pin of the stabilizer link with a hex

wrench, then loosen the self-locking nut.

DAMPER MOUNTING NUT

12 x

1.25

mm

Replace.

95 N-m (9.5 kg-m, 69 Ib-ft)

WRENCH

HEX WRENCH

STABILIZER LINK

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

85 N-m (8.5 kg-m, 61 Ib-ft)

Corrosion resistant bolt/nutProCarManuals.com

Page 490 of 1640

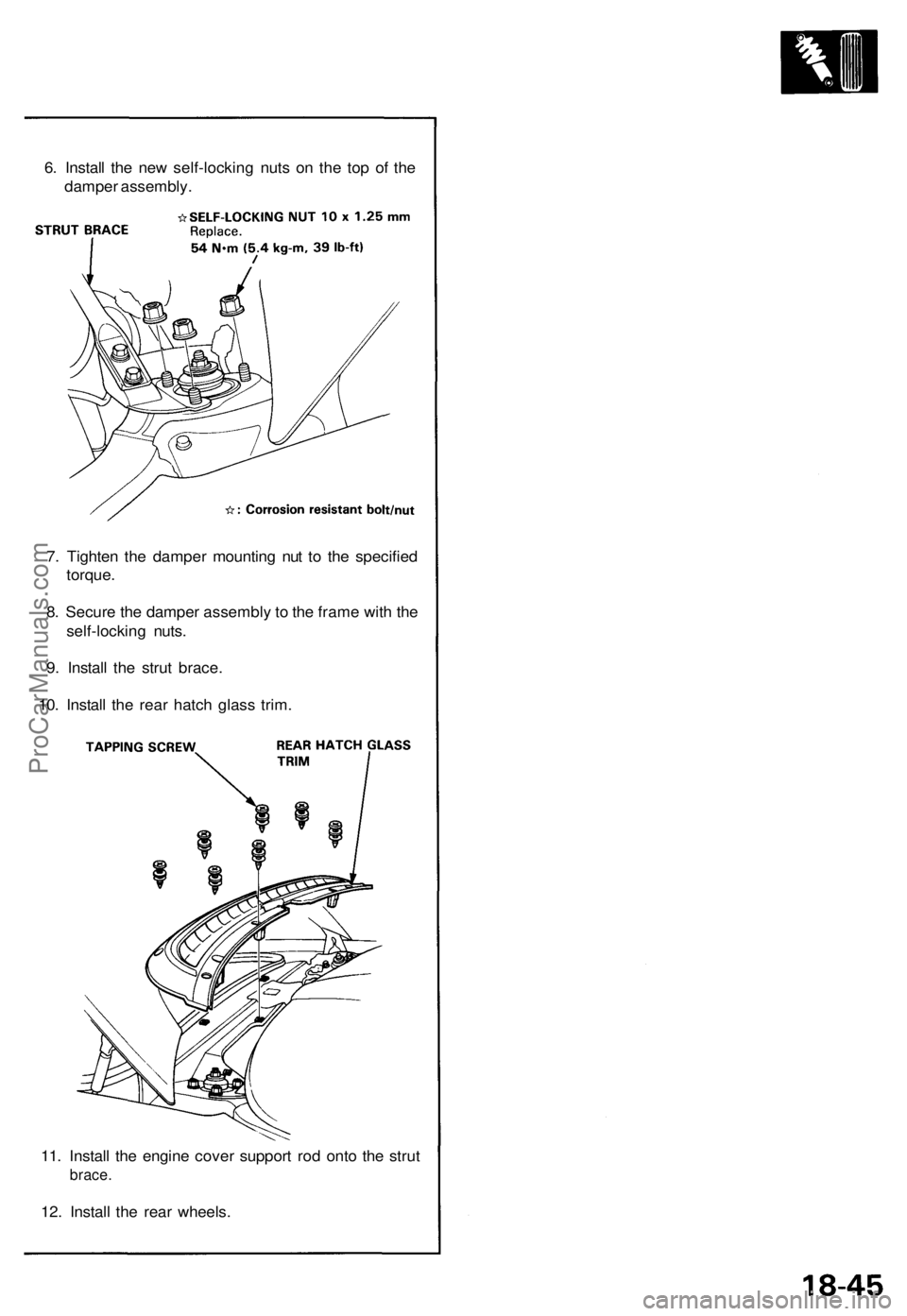

6. Install the new self-locking nuts on the top of the

damper assembly.

7. Tighten the damper mounting nut to the specified

torque.

8. Secure the damper assembly to the frame with the

self-locking nuts.

9. Install the strut brace.

10. Install the rear hatch glass trim.

11. Install the engine cover support rod onto the strut

brace.

12. Install the rear wheels.ProCarManuals.com

Page 493 of 1640

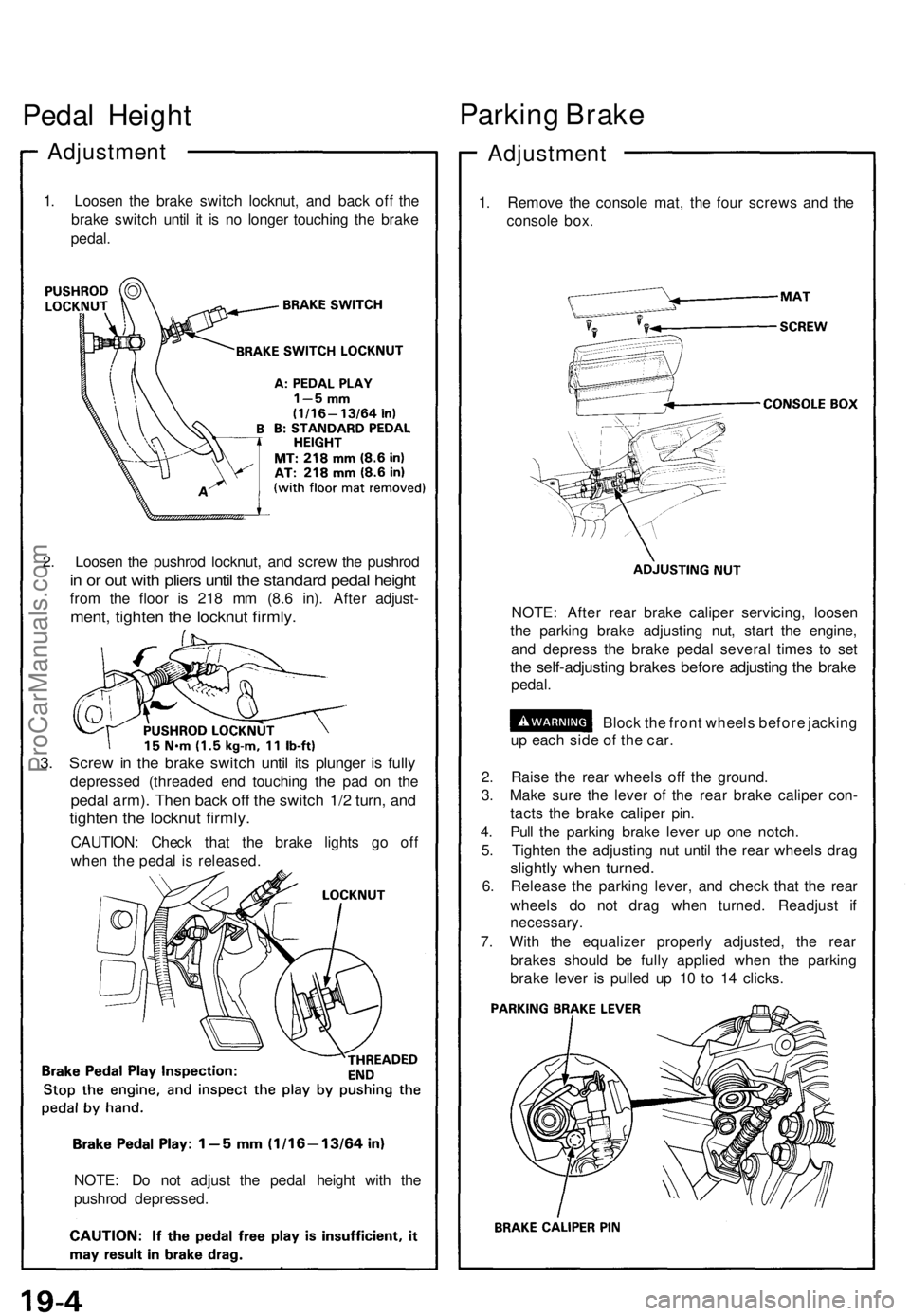

Pedal Heigh t

Adjustmen t

1. Loose n th e brak e switc h locknut , an d bac k of f th e

brak e switc h unti l i t i s n o longe r touchin g th e brak e

pedal .

2 . Loose n th e pushro d locknut , an d scre w th e pushro d

in o r ou t wit h plier s unti l th e standar d peda l heigh t

from th e floo r i s 21 8 m m (8. 6 in) . Afte r adjust -

ment, tighte n th e locknu t firmly .

3. Scre w in th e brak e switc h unti l it s plunge r i s full y

depresse d (threade d en d touchin g th e pa d o n th e

peda l arm) . The n bac k of f th e switc h 1/ 2 turn , an d

tighte n th e locknu t firmly .

CAUTION : Chec k tha t th e brak e light s g o of f

whe n th e peda l i s released .

NOTE : D o no t adjus t th e peda l heigh t wit h th e

pushro d depressed .

Parking Brak e

Adjustmen t

1. Remov e th e consol e mat , th e fou r screw s an d th e

consol e box .

NOTE : Afte r rea r brak e calipe r servicing , loose n

th e parkin g brak e adjustin g nut , star t th e engine ,

an d depres s th e brak e peda l severa l time s t o se t

the self-adjustin g brake s befor e adjustin g th e brak e

pedal .

Block th e fron t wheel s befor e jackin g

u p eac h sid e o f th e car .

2 . Rais e th e rea r wheel s of f th e ground .

3 . Mak e sur e th e leve r o f th e rea r brak e calipe r con -

tact s th e brak e calipe r pin .

4 . Pul l th e parkin g brak e leve r u p on e notch .

5 . Tighte n th e adjustin g nu t unti l th e rea r wheel s dra g

slightl y whe n turned .

6. Releas e th e parkin g lever , an d chec k tha t th e rea r

wheel s d o no t dra g whe n turned . Readjus t i f

necessary .

7. Wit h th e equalize r properl y adjusted , th e rea r

brake s shoul d b e full y applie d whe n th e parkin g

brak e leve r i s pulle d u p 1 0 t o 1 4 clicks .

ProCarManuals.com

Page 502 of 1640

Brake Booste r

Tests

Functiona l Tes t

1. Wit h th e engin e stopped , depres s th e brak e peda l

severa l time s t o deplet e th e vacuu m reservoir , the n

depres s th e peda l har d an d hol d i t fo r 1 5 seconds .

I f th e peda l sinks , eithe r th e maste r cylinde r i s

bypassin g internally , o r th e brak e syste m (maste r

cylinder , lines , modulator , proportionin g valve , o r

calipers ) ar e leaking .

2 . Star t th e engin e wit h th e peda l depressed . I f th e pe -

da l sink s slightly , th e vacuu m booste r i s operatin g

normally , i f th e peda l heigh t doe s no t vary , th e

booste r o r chec k valv e i s faulty .

3 . Wit h th e engin e running , depres s th e brak e peda l

lightly . Appl y jus t enoug h pressur e t o hol d bac k au -

tomati c transmissio n creep . I f th e brak e peda l sink s

mor e tha n 2 5 m m (1. 0 in. ) i n thre e minutes , th e

maste r cylinde r i s faulty . A sligh t chang e i n peda l

heigh t whe n th e A/ C compresso r cycle s o n an d of f

i f normal . (Th e A/ C compresso r loa d change s th e

vacuu m availabl e t o th e booster. )

Leak Tes t

1. Depres s th e brak e peda l wit h th e engin e running ,

the n sto p th e engine . I f th e peda l heigh t doe s no t

var y whil e depresse d fo r 3 0 seconds , th e vacuu m

booste r i s OK . I f th e peda l rises , th e booste r i s faulty .

2 . Wit h th e engin e stopped , depres s th e brak e peda l

severa l time s usin g norma l pressure . Whe n th e pe -

da l i s firs t depressed , i t shoul d b e low . O n consecu -

tiv e applications , th e peda l heigh t shoul d graduall y

rise . I f th e peda l positio n doe s no t vary , chec k th e

booste r chec k valve .

Booste r Chec k Valv e Tes t

1. Disconnec t th e brak e booste r vacuu m hos e a t th e

booste r o r a t th e booste r sid e o f th e valve .

2 . Star t th e engin e an d le t i t idle . Ther e shoul d b e vacu -

um . I f n o vacuu m is available , th e chec k valv e is no t

workin g properly . Replac e th e chec k valv e an d

retest .

ProCarManuals.com