engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 747 of 1640

Starting System

Description

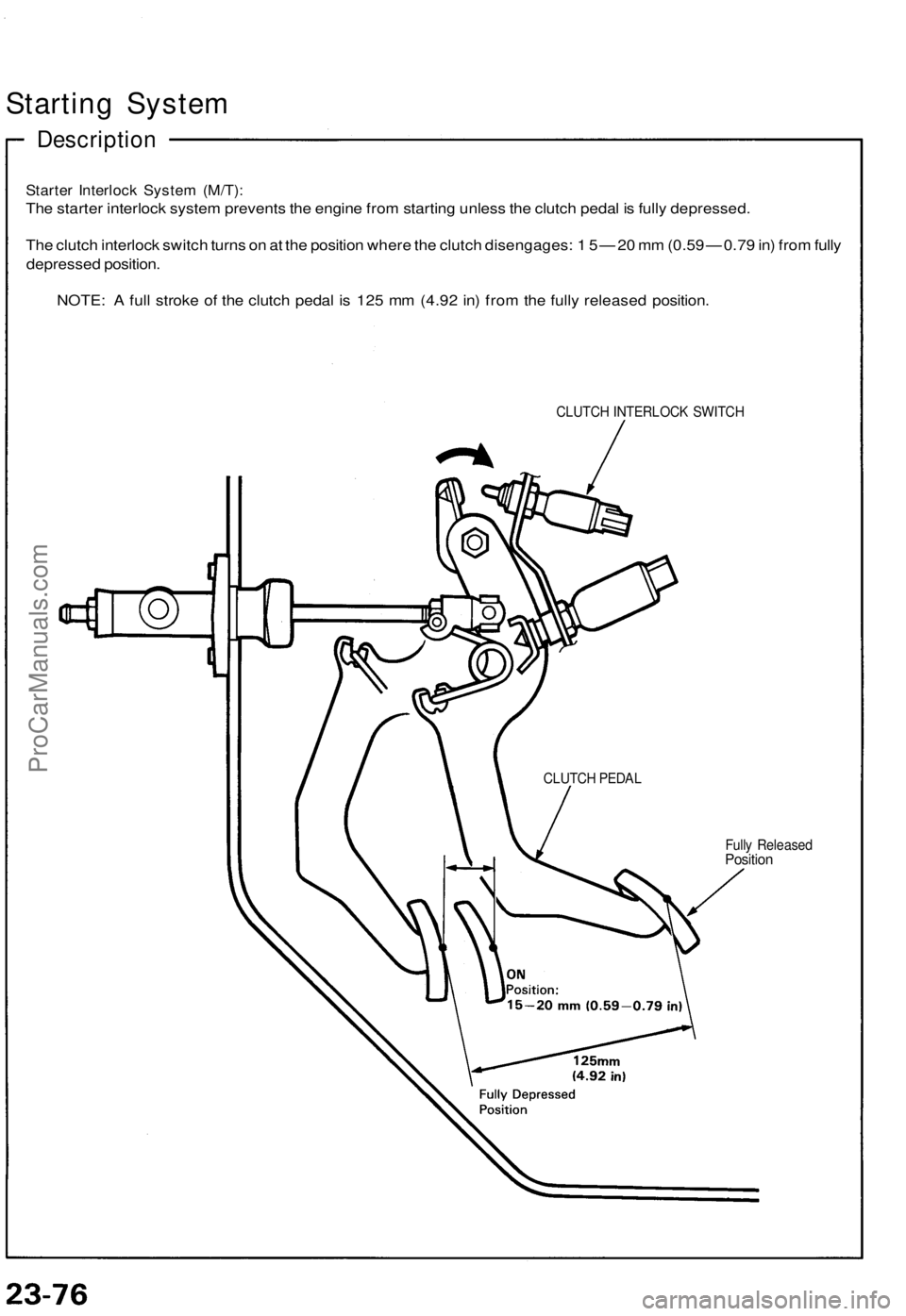

Starter Interlock System (M/T):

The starter interlock system prevents the engine from starting unless the clutch pedal is fully depressed.

The clutch interlock switch turns on at the position where the clutch disengages: 1 5 — 20 mm (0.59 — 0.79 in) from fully

depressed position.

NOTE: A full stroke of the clutch pedal is 125 mm (4.92 in) from the fully released position.

CLUTCH INTERLOCK SWITCH

Fully Released

Position

CLUTCH PEDALProCarManuals.com

Page 748 of 1640

Starting Syste m

Starter Tes t

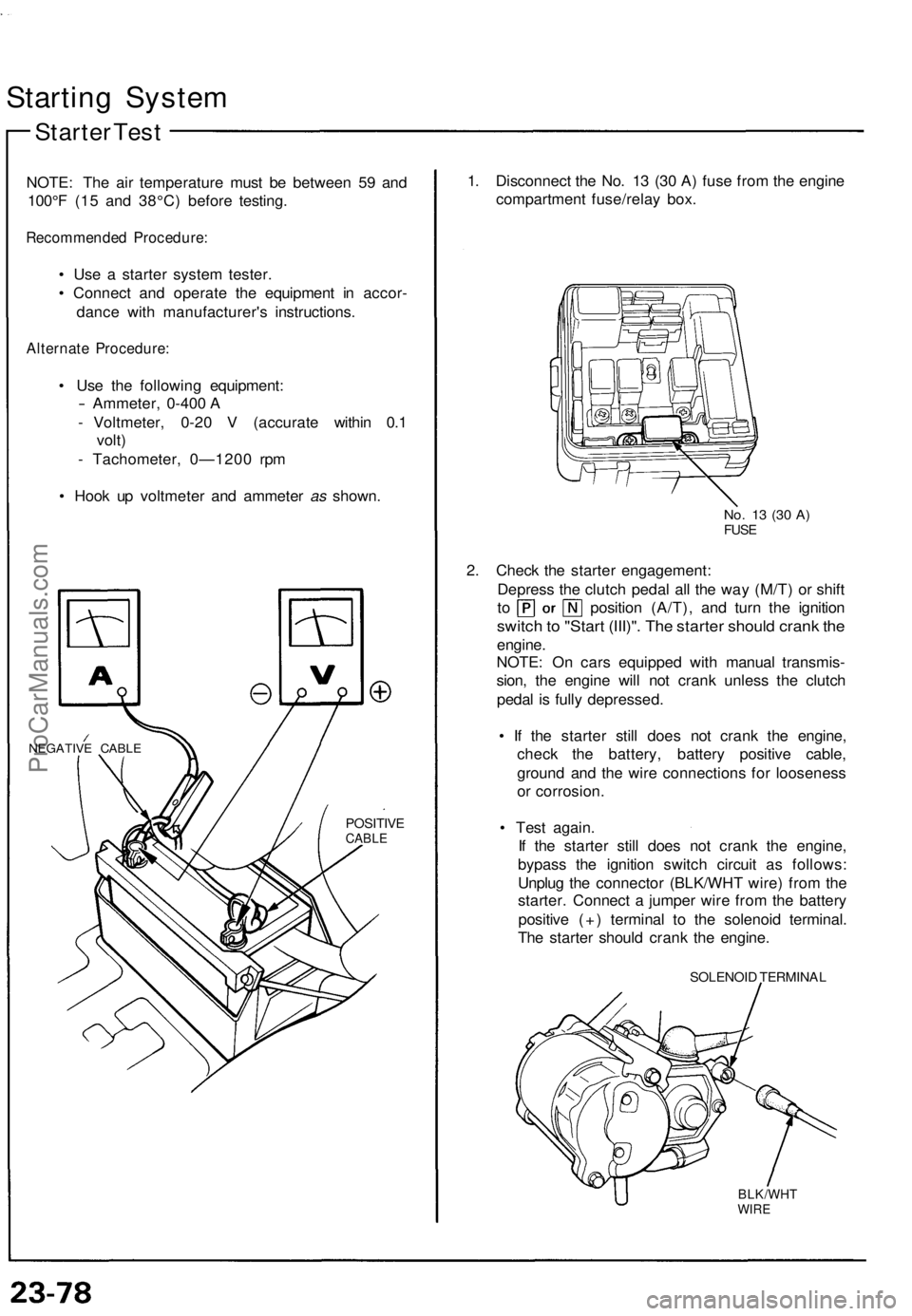

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

• Us e a starte r syste m tester .

• Connec t an d operat e th e equipmen t i n accor -

danc e wit h manufacturer' s instructions .

Alternate Procedure :

• Us e th e followin g equipment :

- Ammeter, 0-400 A

- Voltmeter , 0-2 0 V (accurat e withi n 0. 1

volt )

- Tachometer , 0—120 0 rp m

• Hoo k u p voltmete r an d ammete r as shown .

NEGATIV E CABL E

POSITIV ECABLE

1. Disconnec t th e No . 1 3 (3 0 A ) fus e fro m th e engin e

compartmen t fuse/rela y box .

No. 1 3 (3 0 A )FUS E

2. Chec k th e starte r engagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , an d tur n th e ignitio n

switch to "Star t (III)" . Th e starte r shoul d cran k th e

engine .

NOTE : O n car s equippe d wit h manua l transmis -

sion , th e engin e wil l no t cran k unles s th e clutc h

peda l i s full y depressed .

• I f th e starte r stil l doe s no t cran k th e engine ,

chec k th e battery , batter y positiv e cable ,

groun d an d th e wir e connection s fo r loosenes s

o r corrosion .

• Tes t again .

I f th e starte r stil l doe s no t cran k th e engine ,

bypas s th e ignitio n switc h circui t a s follows :

Unplu g th e connecto r (BLK/WH T wire ) fro m th e

starter . Connec t a jumpe r wir e fro m th e batter y

positiv e (+ ) termina l t o th e solenoi d terminal .

Th e starte r shoul d cran k th e engine .

SOLENOI D TERMINA L

BLK/WHTWIRE

ProCarManuals.com

Page 749 of 1640

- I f th e starte r stil l doe s no t cran k th e engine ,

remov e th e starte r an d diagnos e it s interna l

problems .

- I f th e starte r crank s th e engine , chec k fo r a n

ope n i n th e BLK/WH T wir e an d connector s be -

twee n th e starte r an d ignitio n switch . Chec k th e

ignitio n switch .

On car s wit h automati c transmission , chec k th e

A/ T gea r positio n switc h (neutra l positio n

switch ) an d connector .

O n car s with manua l transmission , chec k th e

starte r cu t relay , clutc h interloc k switc h an d

connectors .

NOTE : Chec k th e No . 2 9 (5 0 A ) fus e an d th e

starte r cu t relay , an d inspec t th e securit y alar m

system .

3 . Chec k fo r wea r o r damage :

Th e starte r shoul d cran k th e engin e smoothl y an d

steadily .

If th e starte r engages , bu t crank s th e engin e er -

ratically , remov e th e starte r motor . Inspec t th e

starter , driv e gea r an d flywhee l rin g gea r fo r

damage .

Check th e driv e gea r overrunnin g clutc h fo r bindin g

or slippin g whe n th e armatur e i s rotated with th e

driv e gea r held . Replac e th e gear s i f damaged .

4 . Chec k crankin g voltag e an d curren t draw :

Voltag e shoul d b e n o les s tha n 8. 5 volts .

Curren t shoul d b e n o mor e tha n 35 0 amperes .

I f voltag e i s to o low , o r curren t dra w to o high ,

chec k for :

• Lo w battery .

• Ope n circui t i n starte r armatur e commutato r

segments .

• Starte r armatur e dragging .

• Shorte d armatur e winding .

• Excessiv e dra g i n engine . 5

. Chec k crankin g rpm :

Engin e spee d durin g crankin g shoul d b e abov e 10 0

rpm .

If spee d i s to o low , chec k for :

Loos e batter y o r starte r terminals .

Excessivel y wor n starte r brushes .

Ope n circui t i n commutato r segments .

Dirt y o r damage d helica l splin e o r driv e gear .

Defectiv e driv e gea r overrunnin g clutch .

6 . Chec k th e starte r disengagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , tur n th e ignitio n switc h

to "Star t (III) " an d releas e to O N (II) .

The starter drive gea r shoul d disengag e fro m th e

flywhee l rin g gear .

I f th e driv e gea r hang s u p o n th e flywhee l rin g gear ,

check :

• Solenoi d plunge r an d switc h fo r malfunction .

• Driv e gea r assembl y fo r dir t o r damage d over -

runnin g clutch .

ProCarManuals.com

Page 751 of 1640

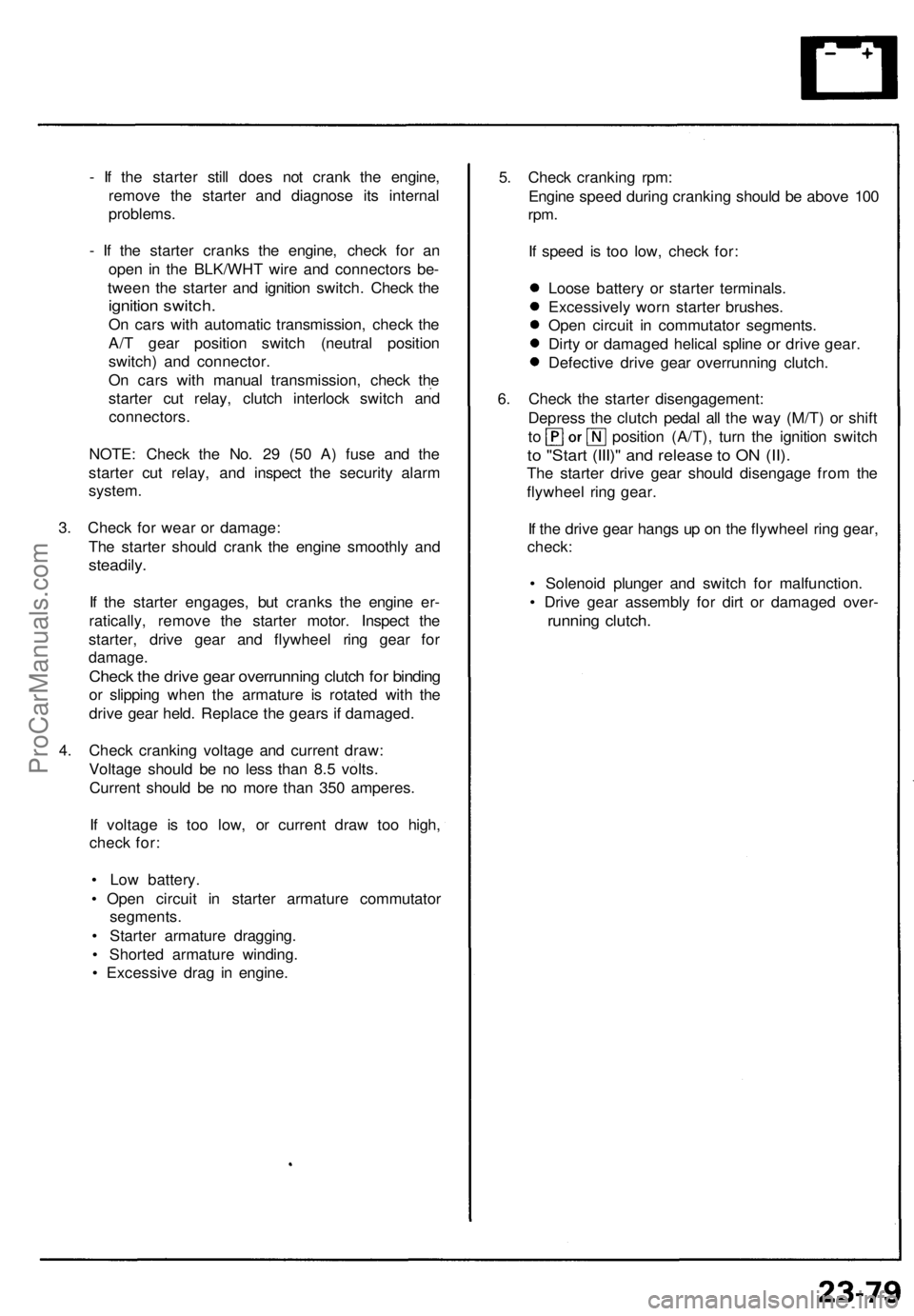

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

PULL - IN COIL HOLD - IN COIL

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

B-TERMINAL MOUNTING NUT

9 N-m (0.9 kg-m. 6.5 Ib-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

BLK/WHT WIREProCarManuals.com

Page 760 of 1640

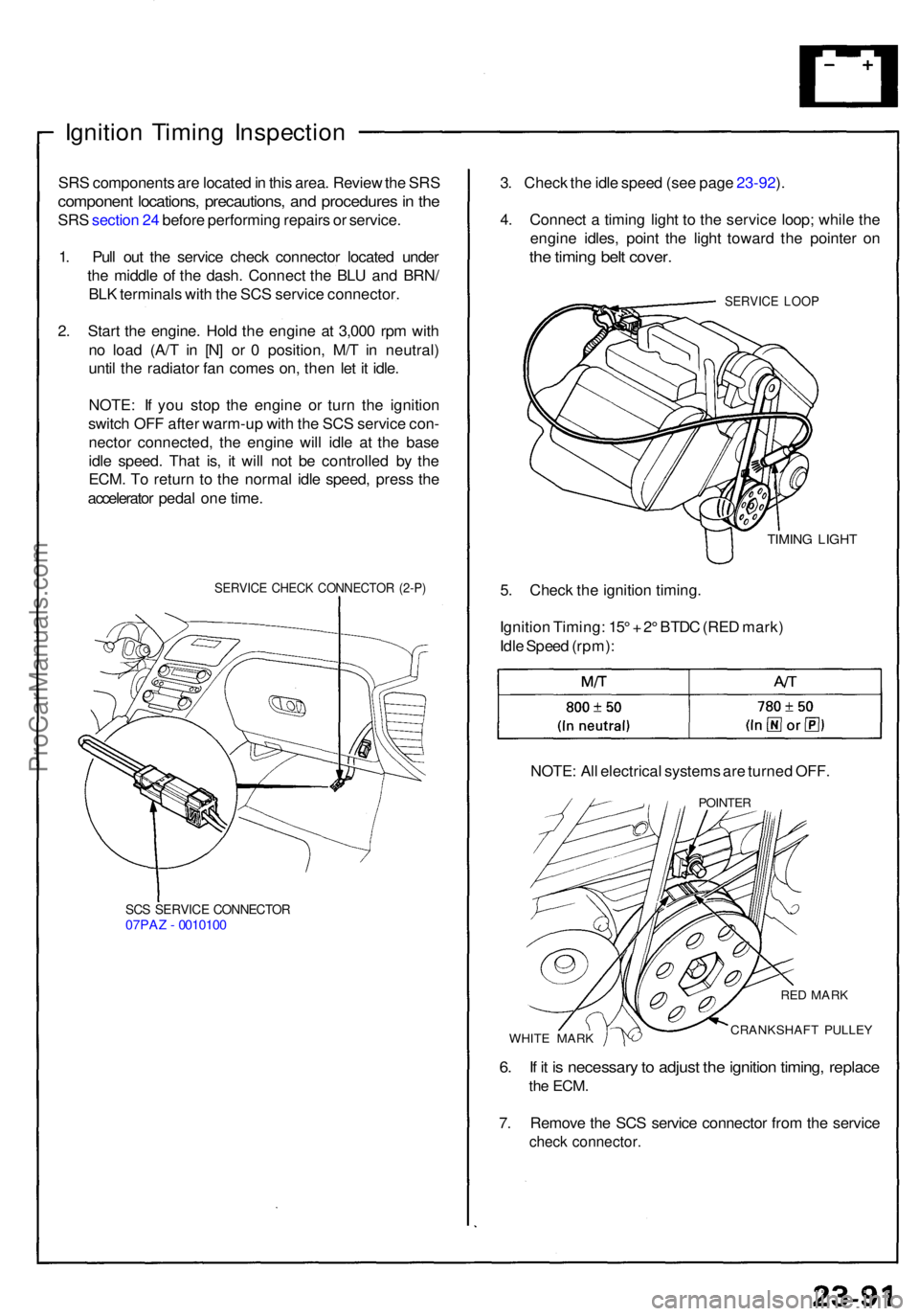

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s in th e

SR S sectio n 24 befor e performin g repair s o r service .

1 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e middl e o f th e dash . Connec t th e BL U an d BRN /

BL K terminal s wit h th e SC S servic e connector .

2 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

n o loa d (A/ T i n [N ] o r 0 position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

NOTE : I f yo u sto p th e engin e o r tur n th e ignitio n

switc h OF F afte r warm-u p wit h th e SC S servic e con -

necto r connected , th e engin e wil l idl e a t th e bas e

idl e speed . Tha t is , i t wil l no t b e controlle d b y th e

ECM . T o retur n t o th e norma l idl e speed , pres s th e

accelerato r peda l on e time .

SERVIC E CHEC K CONNECTO R (2-P )

SCS SERVIC E CONNECTO R07PAZ - 001010 0

3. Chec k th e idl e spee d (se e pag e 23-92 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

the timin g bel t cover .

SERVIC E LOO P

TIMIN G LIGH T

5. Chec k th e ignitio n timing .

Ignitio n Timing : 15 ° + 2° BTD C (RE D mark )

Idl e Spee d (rpm) :

NOTE : Al l electrica l system s ar e turne d OFF .

POINTE R

WHITE MAR K

RED MAR K

CRANKSHAF T PULLE Y

6. I f i t i s necessar y to adjus t th e ignitio n timing , replac e

the ECM .

7. Remov e th e SC S servic e connecto r fro m th e servic e

check connector .

ProCarManuals.com

Page 761 of 1640

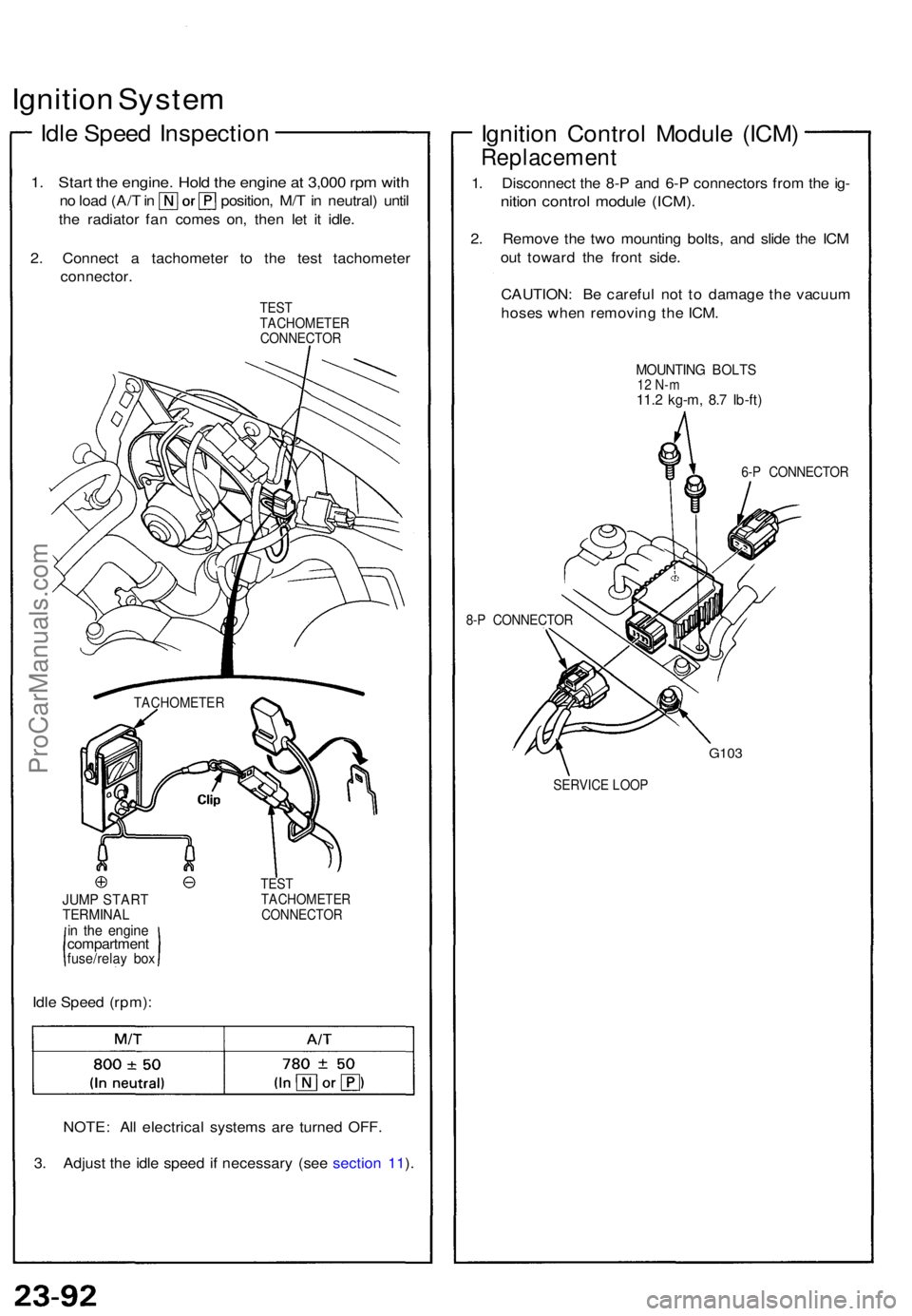

Ignition Syste m

Idle Spee d Inspectio n

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in position , M/ T in neutral ) unti l

th e radiator fan come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r

connector .

TEST

TACHOMETE R

CONNECTO R

JUMP STAR TTERMINA Lin th e engin ecompartmen tfuse/relay bo x

Idle Spee d (rpm) :

TEST

TACHOMETE R

CONNECTO R

NOTE: Al l electrica l system s ar e turne d OFF .

3 . Adjus t th e idl e spee d i f necessar y (se e sectio n 11 ).

Ignitio n Contro l Modul e (ICM )

Replacemen t

1. Disconnec t th e 8- P an d 6- P connector s fro m th e ig -

nitio n contro l modul e (ICM) .

2. Remov e th e tw o mountin g bolts , an d slid e th e IC M

ou t towar d th e fron t side .

CAUTION : B e carefu l no t t o damag e th e vacuu m

hose s whe n removin g th e ICM .

MOUNTIN G BOLT S12 N- m11.2 kg-m , 8. 7 Ib-ft )

6-P CONNECTO R

8- P CONNECTO R

G103

SERVIC E LOO P

TACHOMETE

R

ProCarManuals.com

Page 765 of 1640

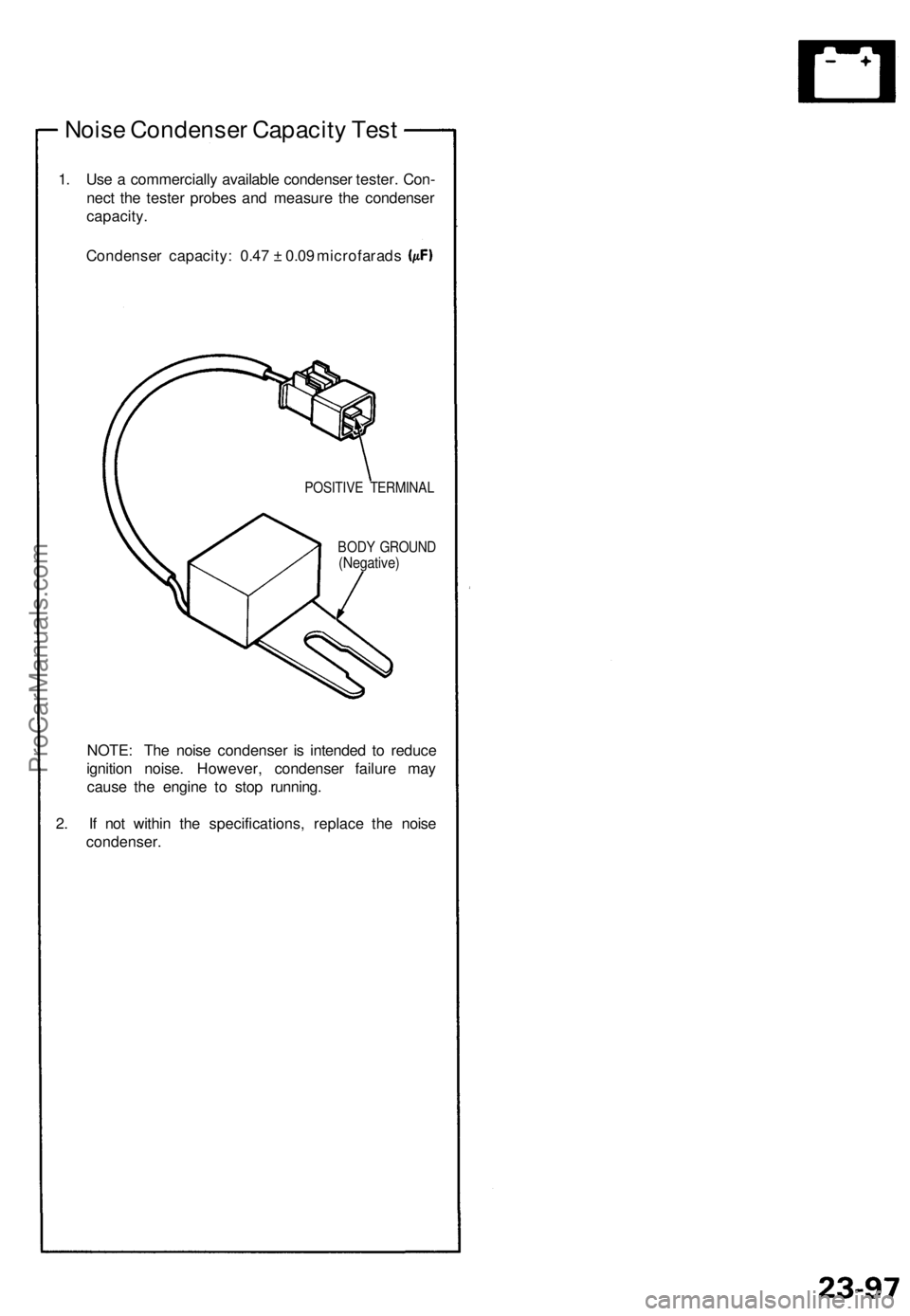

Noise Condenser Capacity Test

1. Use a commercially available condenser tester. Con-

nect the tester probes and measure the condenser

capacity.

Condenser capacity: 0.47 ± 0.09 microfarads

POSITIVE TERMINAL

BODY GROUND

(Negative)

NOTE: The noise condenser is intended to reduce

ignition noise. However, condenser failure may

cause the engine to stop running.

2. If not within the specifications, replace the noise

condenser.ProCarManuals.com

Page 767 of 1640

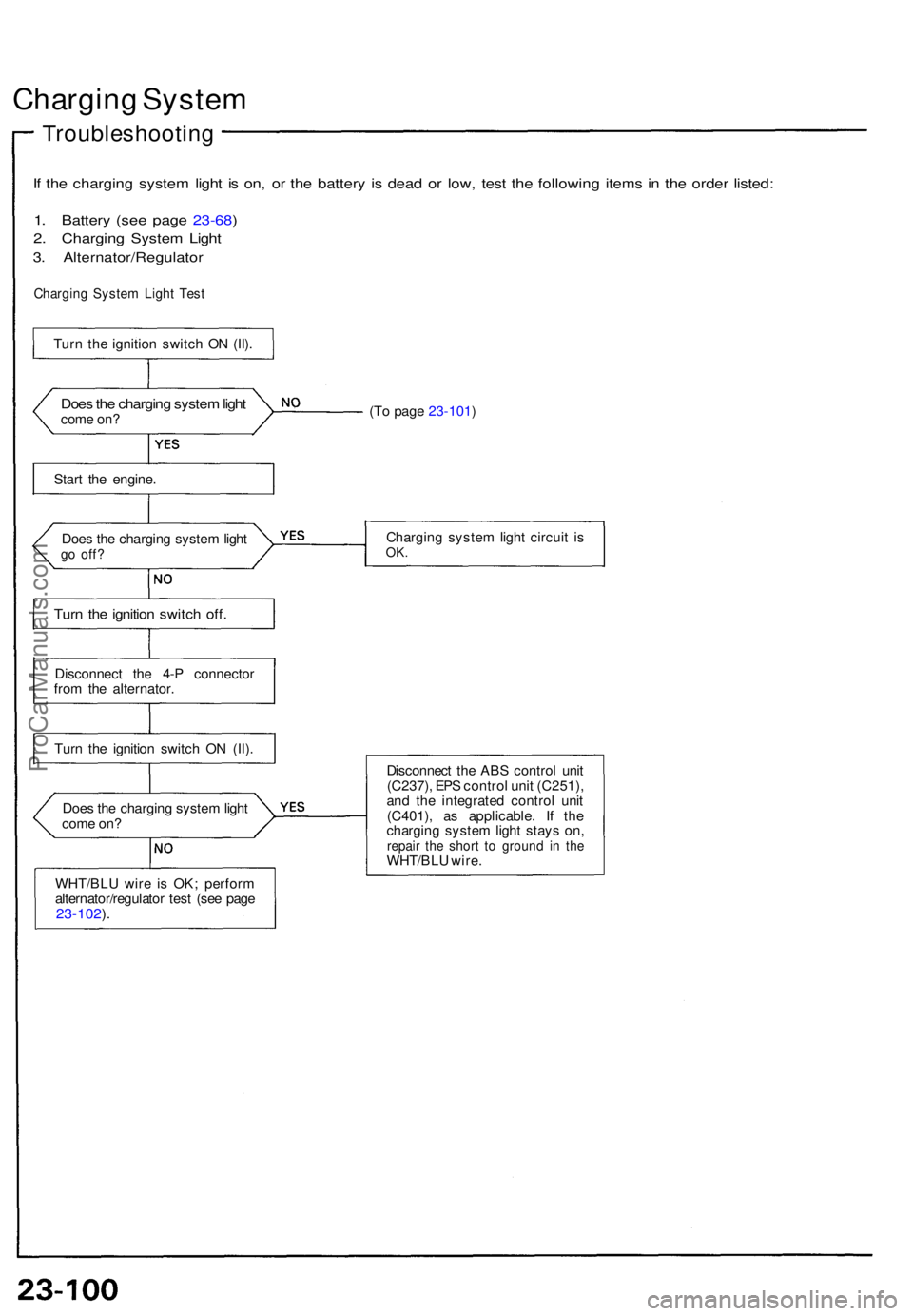

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t i s on , o r th e batter y i s dea d o r low , tes t th e followin g item s i n th e orde r listed :

1. Batter y (se e pag e 23-68 )

2. Chargin g Syste m Ligh t

3. Alternator/Regulato r

Charging Syste m Ligh t Tes t

Does th e chargin g syste m ligh tcom e on ?

Star t th e engine .

Doe s th e chargin g syste m ligh t

go off ?

Turn th e ignitio n switc h off .

Disconnec t th e 4- P connecto r

fro m th e alternator .

Tur n th e ignitio n switc h O N (II) .

WHT/BL U wir e i s OK ; perfor m

alternator/regulato r tes t (se e pag e

23-102 ).

Doe s th e chargin g syste m ligh t

com e on ? (T

o pag e 23-101 )

Chargin g syste m ligh t circui t i s

OK .

Disconnec t th e AB S contro l uni t

(C237) , EP S contro l uni t (C251) ,

an d th e integrate d contro l uni t

(C401) , a s applicable . I f th e

chargin g syste m ligh t stay s on ,

repai r th e shor t t o groun d i n th eWHT/BL U wire .

Tur

n th e ignitio n switc h O N (II) .

ProCarManuals.com

Page 769 of 1640

Charging System

Troubleshooting

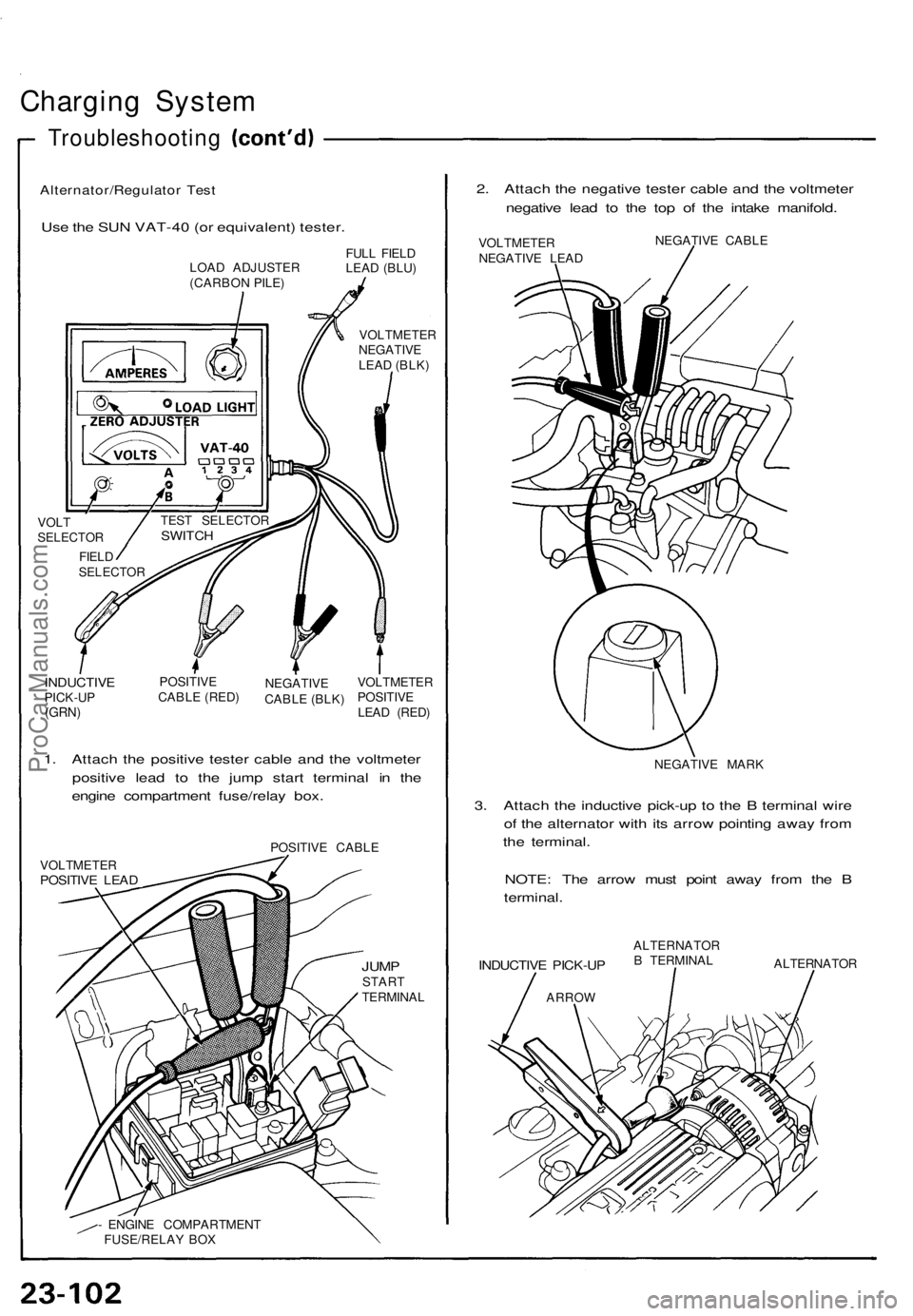

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

VOLT

SELECTOR

FIELD

SELECTOR

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

- ENGINE COMPARTMENT

FUSE/RELAY BOX

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATOR

TEST SELECTOR

SWITCHProCarManuals.com

Page 776 of 1640

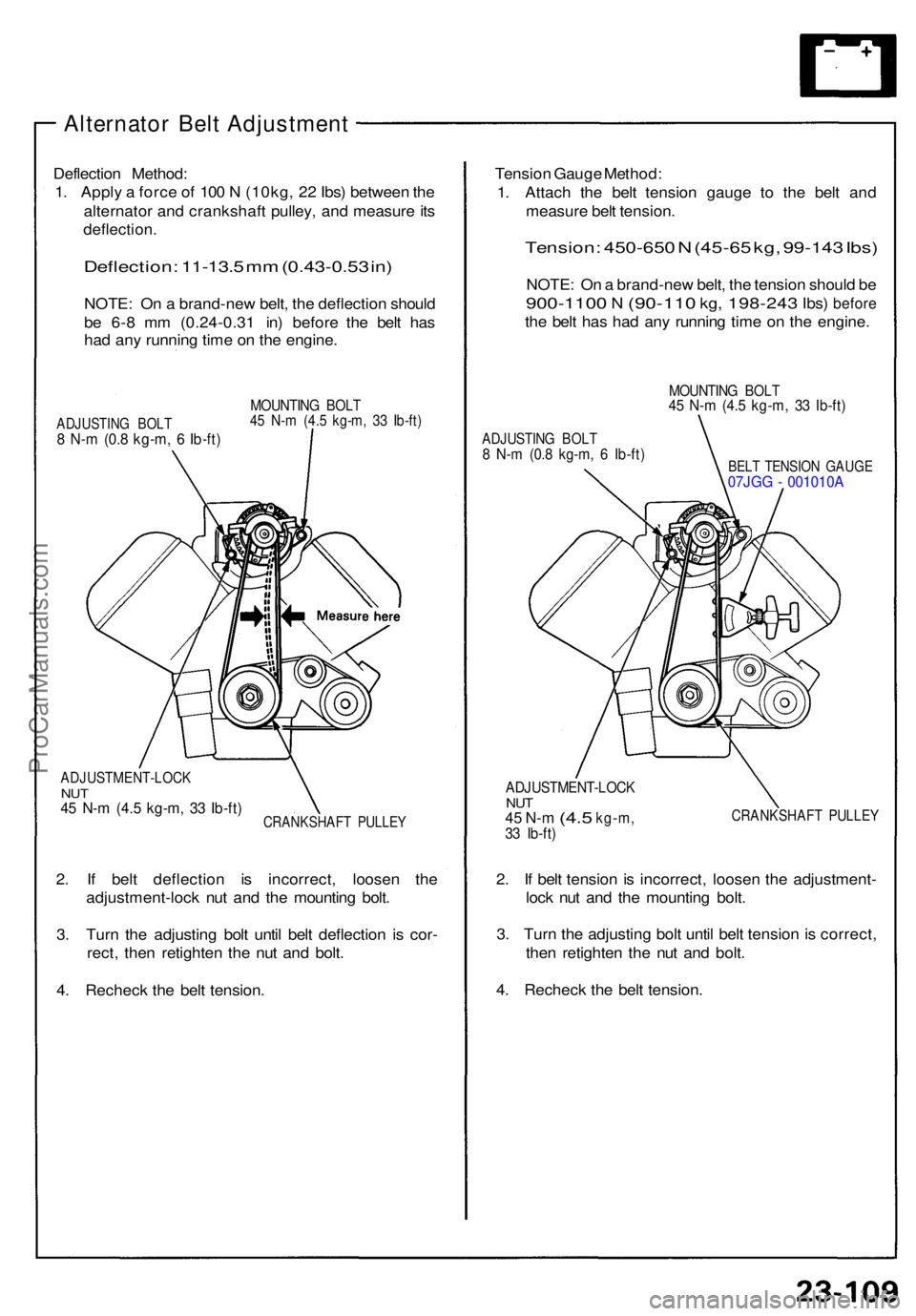

Alternator Belt Adjustment

Deflectio n Method :

1 . Appl y a forc e o f 10 0 N (10kg , 2 2 Ibs ) betwee n th e

alternato r an d crankshaf t pulley , an d measur e it s

deflection .

Deflection : 11-13. 5 m m (0.43-0.5 3 in )

NOTE : O n a brand-ne w belt , th e deflectio n shoul d

b e 6- 8 m m (0.24-0.3 1 in ) befor e th e bel t ha s

ha d an y runnin g tim e o n th e engine .

ADJUSTIN G BOL T8 N- m (0. 8 kg-m , 6 Ib-ft )

MOUNTIN G BOL T45 N- m (4. 5 kg-m , 3 3 Ib-ft )

ADJUSTMENT-LOC KNUT45 N- m (4. 5 kg-m , 3 3 Ib-ft )CRANKSHAF T PULLE Y

2. I f bel t deflectio n i s incorrect , loose n th e

adjustment-loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t deflectio n i s cor -

rect , the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension . Tensio

n Gaug e Method :

1 . Attac h th e bel t tensio n gaug e t o th e bel t an d

measur e bel t tension .

Tension : 450-65 0 N (45-6 5 kg , 99-14 3 Ibs )

NOTE : O n a brand-ne w belt , th e tensio n shoul d b e

900-110 0 N (90-110 kg, 198-24 3 Ibs) befor e

the bel t ha s ha d an y runnin g tim e o n th e engine .

MOUNTIN G BOL T45 N- m (4. 5 kg-m , 3 3 Ib-ft )

ADJUSTIN G BOL T8 N- m (0. 8 kg-m , 6 Ib-ft )BELT TENSIO N GAUG E07JGG - 001010 A

ADJUSTMENT-LOC KNUT45 N- m (4. 5 kg-m ,33 Ib-ft )

CRANKSHAF T PULLE Y

2. I f bel t tensio n is incorrect , loose n th e adjustment -

loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t tensio n is correct ,

the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension .

ProCarManuals.com