engine ACURA NSX 1991 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 521 of 1640

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

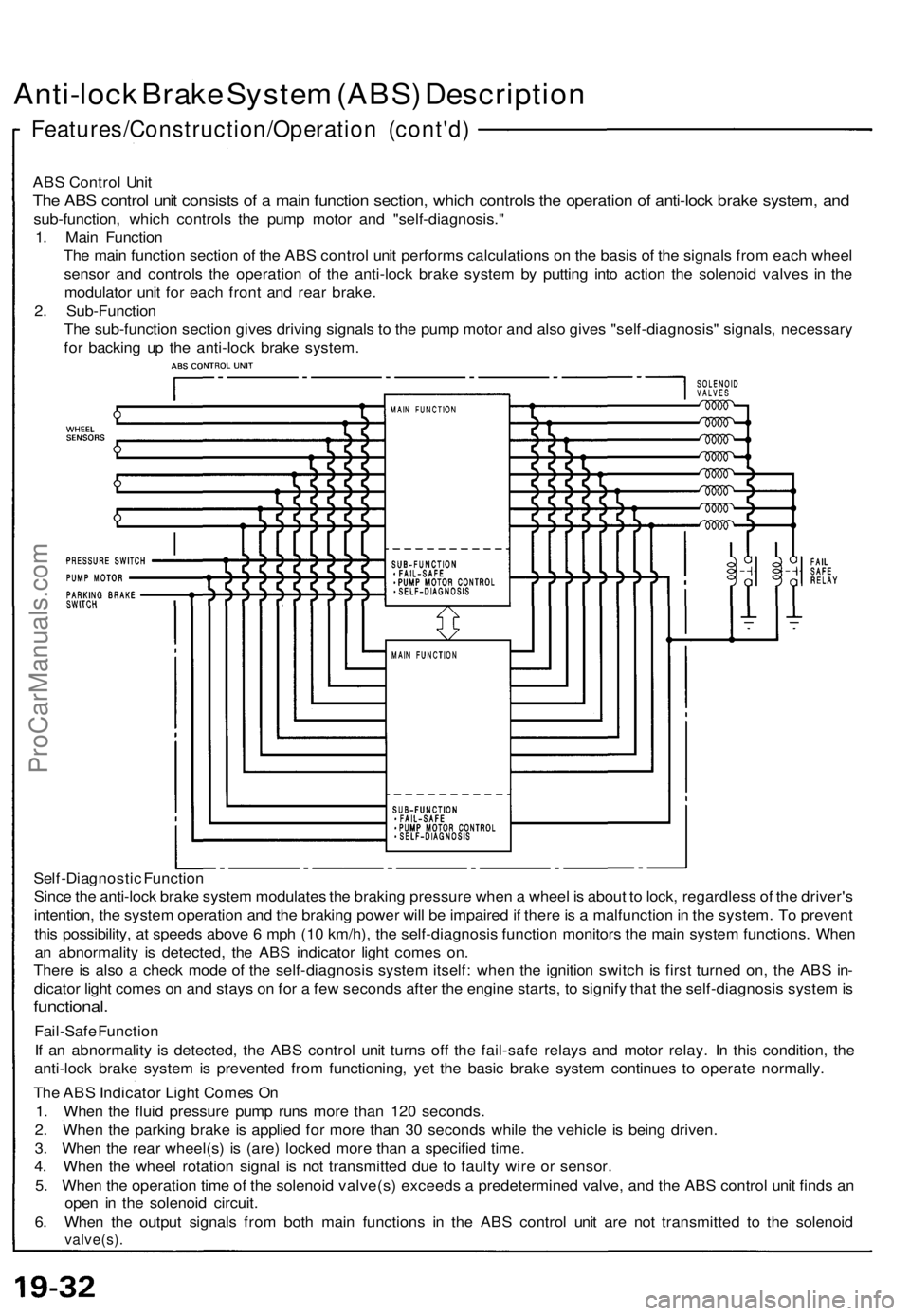

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and

sub-function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the

modulator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary

for backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS in-

dicator light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is

functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the

anti-lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid

valve(s).ProCarManuals.com

Page 531 of 1640

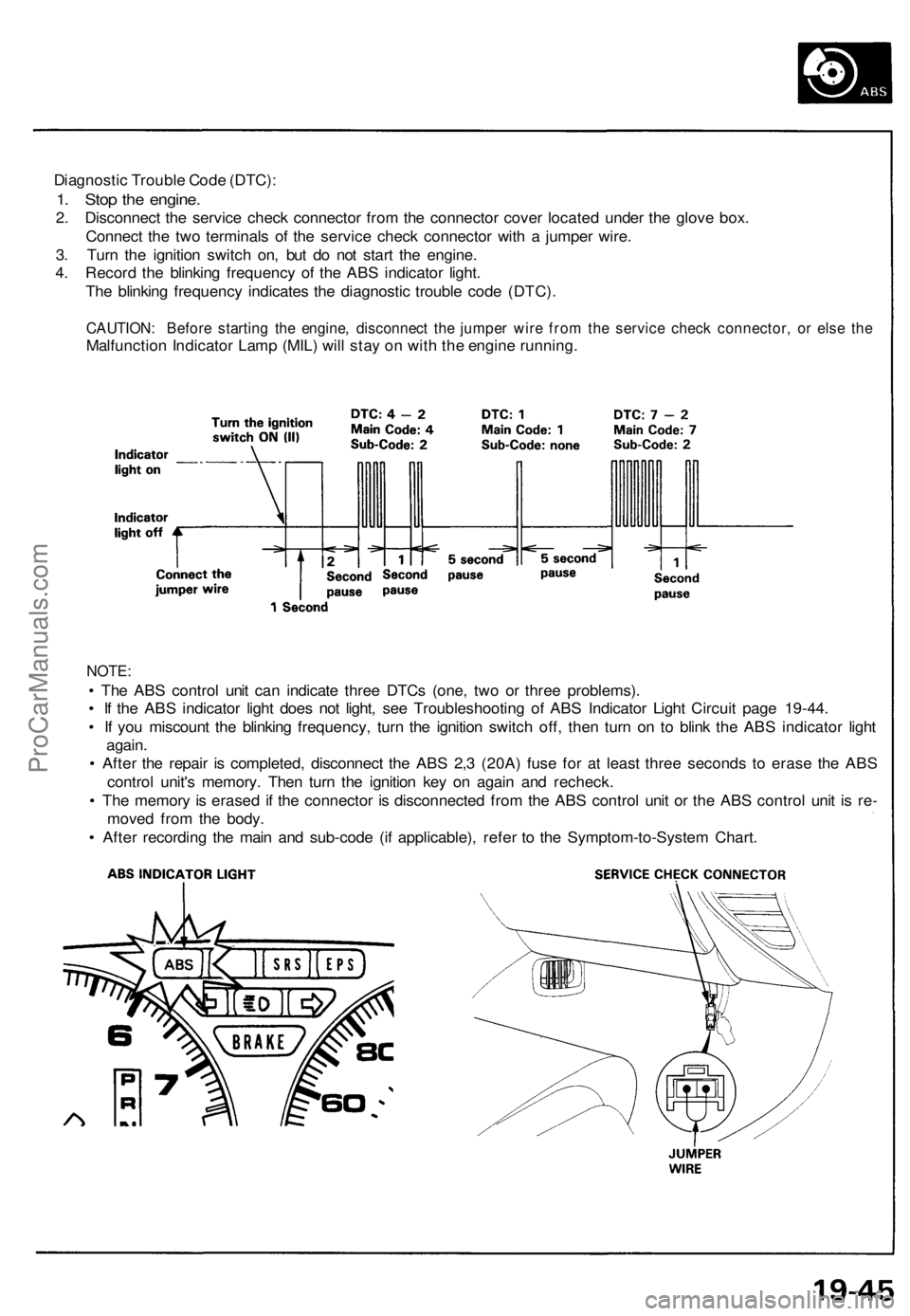

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 546 of 1640

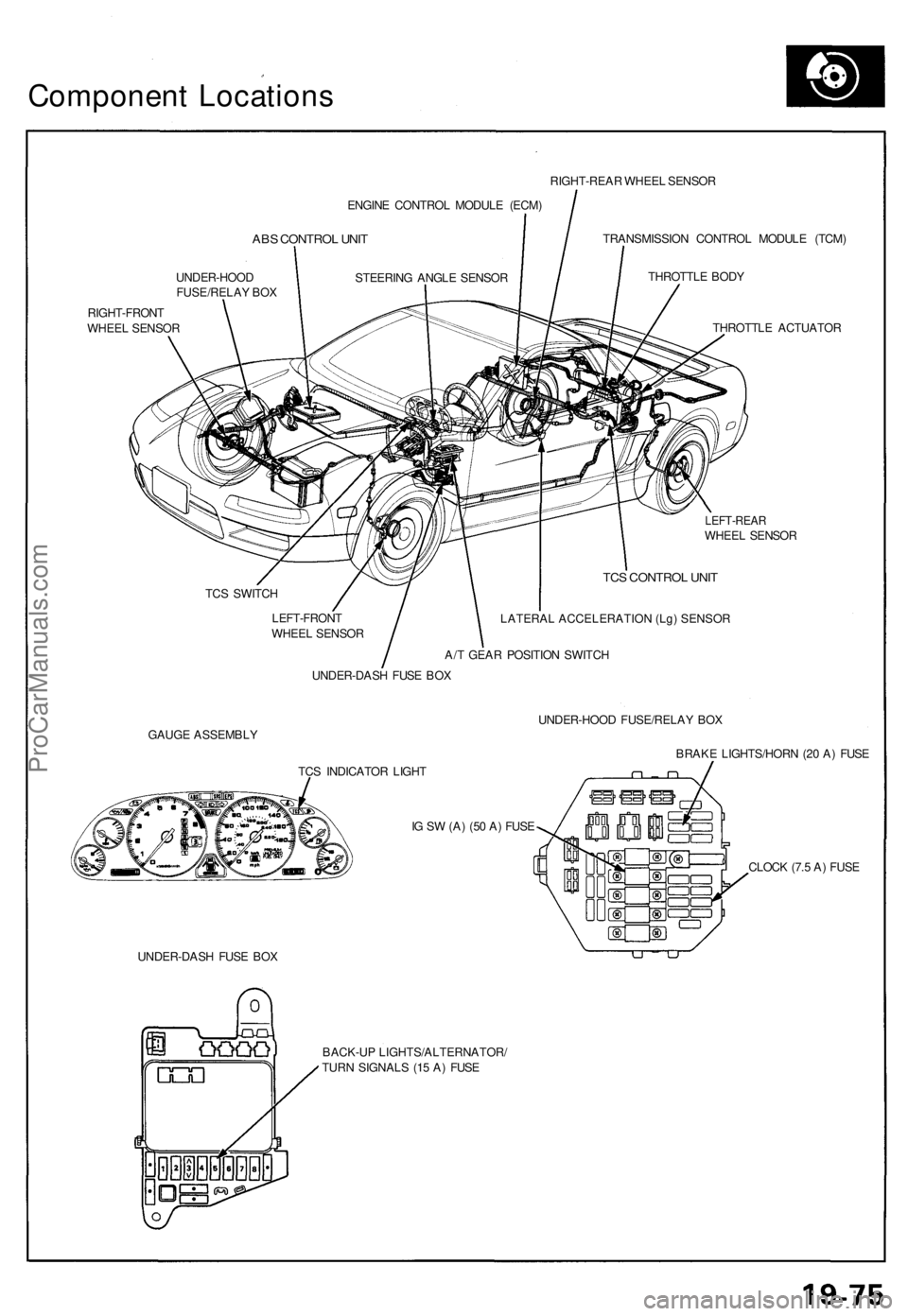

Component Location s

ENGINE CONTRO L MODUL E (ECM )

ABS CONTRO L UNI T

UNDER-HOO D

FUSE/RELA Y BO X

RIGHT-FRON T

WHEE L SENSO R RIGHT-REA

R WHEE L SENSO R

TRANSMISSIO N CONTRO L MODUL E (TCM )

THROTTL E BOD Y

THROTTL E ACTUATO R

LEFT-REARWHEEL SENSO R

TC S SWITC H

LEFT-FRON T

WHEE L SENSO R

TCS CONTRO L UNI T

LATERAL ACCELERATION (Lg) SENSOR

A/T GEA R POSITIO N SWITC H

UNDER-DAS H FUS E BO X

GAUG E ASSEMBL Y UNDER-HOO

D FUSE/RELA Y BO X

BRAK E LIGHTS/HOR N (2 0 A ) FUS E

TC S INDICATO R LIGH T

I G S W (A ) (5 0 A ) FUS E

UNDER-DAS H FUS E BO X CLOC

K (7. 5 A ) FUS E

BACK-U P LIGHTS/ALTERNATOR /

TUR N SIGNAL S (1 5 A ) FUS E

STEERIN

G ANGL E SENSO R

ProCarManuals.com

Page 547 of 1640

System Descriptio n

Outline

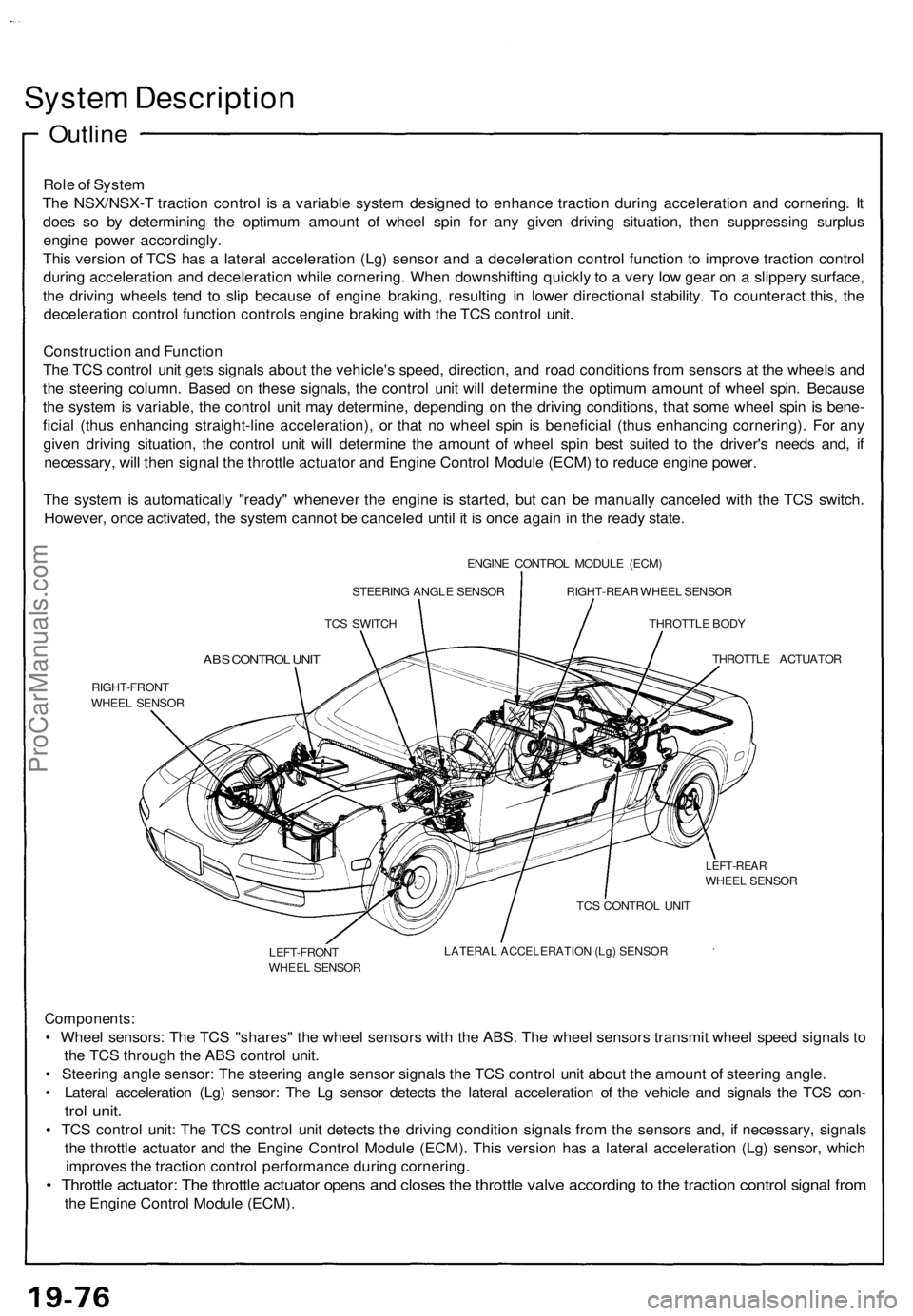

Role o f Syste m

Th e NSX/NSX- T tractio n contro l i s a variabl e syste m designe d t o enhanc e tractio n durin g acceleratio n an d cornering . I t

doe s s o b y determinin g th e optimu m amoun t o f whee l spi n fo r an y give n drivin g situation , the n suppressin g surplu s

engin e powe r accordingly .

Thi s versio n o f TC S ha s a latera l acceleratio n (Lg ) senso r an d a deceleratio n contro l functio n t o improv e tractio n contro l

durin g acceleratio n an d deceleratio n whil e cornering . Whe n downshiftin g quickl y t o a ver y lo w gea r o n a slipper y surface ,

th e drivin g wheel s ten d t o sli p becaus e o f engin e braking , resultin g i n lowe r directiona l stability . T o counterac t this , th e

deceleratio n contro l functio n control s engine braking wit h th e TC S contro l unit .

Constructio n an d Functio n

Th e TC S contro l uni t get s signal s abou t th e vehicle' s speed , direction , an d roa d condition s fro m sensor s a t th e wheel s an d

th e steerin g column . Base d o n thes e signals , th e contro l uni t wil l determin e th e optimu m amoun t o f whee l spin . Becaus e

th e syste m is variable , th e contro l uni t ma y determine , dependin g o n th e drivin g conditions , tha t som e whee l spi n i s bene -

ficia l (thu s enhancin g straight-lin e acceleration) , o r tha t n o whee l spi n i s beneficia l (thu s enhancin g cornering) . Fo r an y

give n drivin g situation , th e contro l uni t wil l determin e th e amoun t o f whee l spi n bes t suite d t o th e driver' s need s and , i f

necessary , wil l the n signa l th e throttl e actuato r an d Engin e Contro l Modul e (ECM ) t o reduc e engin e power .

Th e syste m is automaticall y "ready " wheneve r th e engin e i s started , bu t ca n b e manuall y cancele d wit h th e TC S switch .

However , onc e activated , th e syste m canno t b e cancele d unti l i t i s onc e agai n in th e read y state .

ENGIN E CONTRO L MODUL E (ECM )

STEERIN G ANGL E SENSO R

TC S SWITC H RIGHT-REA

R WHEE L SENSO R

THROTTL E BOD Y

ABS CONTRO L UNI T

RIGHT-FRON T

WHEE L SENSO R THROTTL

E ACTUATO R

LEFT-REARWHEEL SENSO R

LEFT-FRON T

WHEE L SENSO R TC

S CONTRO L UNI T

LATERAL ACCELERATION (Lg) SENSOR

Components :

• Whee l sensors : Th e TC S "shares " th e whee l sensor s wit h th e ABS . Th e whee l sensor s transmi t whee l spee d signal s t o

th e TC S throug h th e AB S contro l unit .

• Steerin g angl e sensor : Th e steerin g angl e senso r signal s th e TC S contro l uni t abou t th e amoun t o f steerin g angle .

• Latera l acceleratio n (Lg ) sensor : Th e L g senso r detect s th e latera l acceleratio n o f th e vehicl e an d signal s th e TC S con -

trol unit .

• TC S contro l unit : Th e TC S contro l uni t detect s th e drivin g conditio n signal s fro m th e sensor s and , i f necessary , signal s

th e throttl e actuato r an d th e Engin e Contro l Modul e (ECM) . Thi s versio n ha s a latera l acceleratio n (Lg ) sensor , whic h

improve s th e tractio n contro l performanc e durin g cornering .

• Throttl e actuator : Th e throttl e actuato r open s an d close s th e throttl e valv e accordin g to th e tractio n contro l signa l fro m

the Engin e Contro l Modul e (ECM) .

ProCarManuals.com

Page 548 of 1640

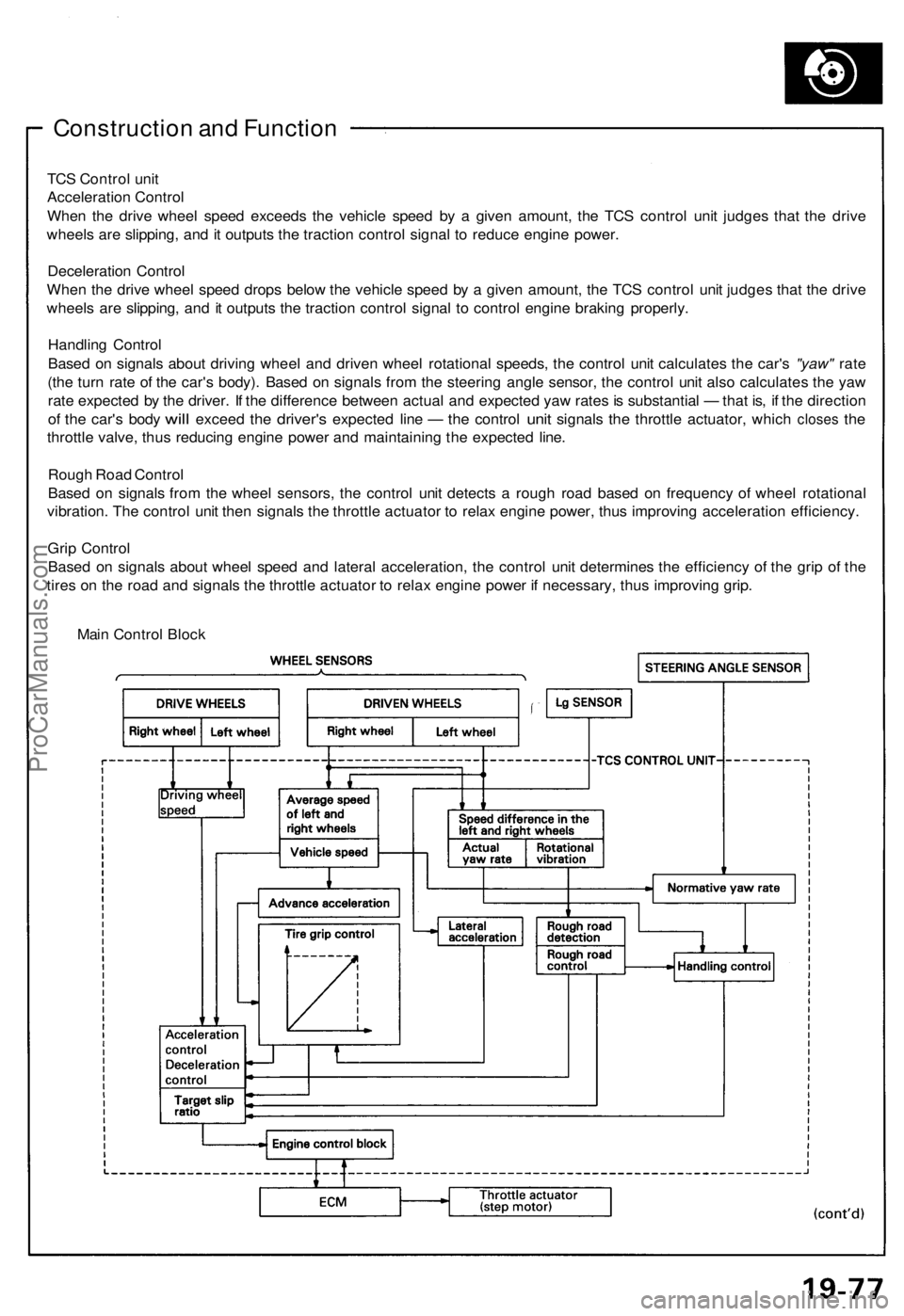

Construction an d Functio n

TCS Contro l uni t

Acceleratio n Contro l

Whe n th e driv e whee l spee d exceed s th e vehicl e spee d b y a give n amount , th e TC S contro l uni t judge s tha t th e driv e

wheel s ar e slipping , an d it output s th e tractio n contro l signa l t o reduc e engin e power .

Deceleratio n Contro l

Whe n th e driv e whee l spee d drop s belo w th e vehicl e spee d b y a give n amount , th e TC S contro l uni t judge s tha t th e driv e

wheel s ar e slipping , an d it output s th e tractio n contro l signa l t o contro l engin e brakin g properly .

Handlin g Contro l

Base d o n signal s abou t drivin g whee l an d drive n whee l rotationa l speeds , th e contro l uni t calculate s th e car' s "yaw" rate

(th e tur n rat e o f th e car' s body) . Base d o n signal s fro m th e steerin g angl e sensor , th e contro l uni t als o calculate s th e ya w

rat e expecte d b y th e driver . I f th e differenc e betwee n actua l an d expecte d ya w rate s is substantia l — tha t is , i f th e directio n

of th e car' s bod y will excee d the driver' s expecte d lin e — the contro l unit signal s the throttl e actuator , whic h close s the

throttl e valve , thu s reducin g engin e powe r an d maintainin g th e expecte d line .

Roug h Roa d Contro l

Base d o n signal s fro m th e whee l sensors , th e contro l uni t detect s a roug h roa d base d o n frequenc y o f whee l rotationa l

vibration . Th e contro l uni t the n signal s th e throttl e actuato r t o rela x engine power, thu s improvin g acceleratio n efficiency .

Gri p Contro l

Base d o n signal s abou t whee l spee d an d latera l acceleration , th e contro l uni t determine s th e efficienc y o f th e gri p o f th e

tire s o n th e roa d an d signal s th e throttl e actuato r t o rela x engine power i f necessary , thu s improvin g grip .

Mai n Contro l Bloc k

ProCarManuals.com

Page 553 of 1640

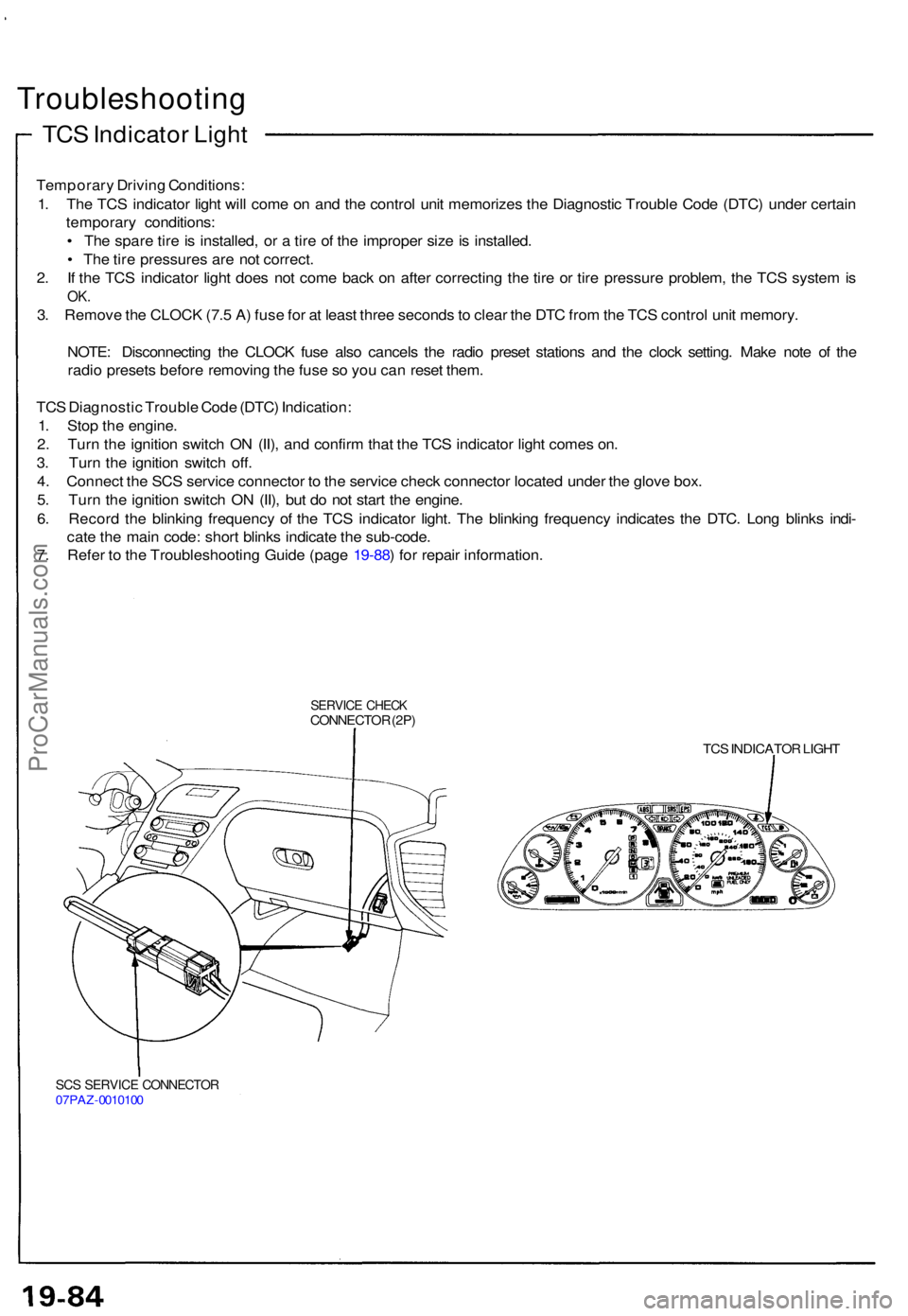

Troubleshooting

TCS Indicato r Ligh t

Temporar y Drivin g Conditions :

1 . Th e TC S indicato r ligh t wil l com e o n an d th e contro l uni t memorize s th e Diagnosti c Troubl e Cod e (DTC ) unde r certai n

temporar y conditions :

• Th e spar e tir e is installed , o r a tir e o f th e imprope r siz e is installed .

• Th e tir e pressure s ar e no t correct .

2 . I f th e TC S indicato r ligh t doe s no t com e bac k o n afte r correctin g th e tir e o r tir e pressur e problem , th e TC S syste m is

OK .

3. Remov e th e CLOC K (7. 5 A ) fus e fo r a t leas t thre e second s to clea r th e DT C fro m th e TC S contro l uni t memory .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

TC S Diagnosti c Troubl e Cod e (DTC ) Indication :

1 . Sto p th e engine .

2 . Tur n th e ignitio n switc h O N (II) , an d confir m tha t th e TC S indicato r ligh t come s on .

3 . Tur n th e ignitio n switc h off .

4 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r locate d unde r th e glov e box .

5 . Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

6 . Recor d th e blinkin g frequenc y o f th e TC S indicato r light . Th e blinkin g frequenc y indicate s th e DTC . Lon g blink s indi -

cat e th e mai n code : shor t blink s indicat e th e sub-code .

7 . Refe r t o th e Troubleshootin g Guid e (pag e 19-88 ) fo r repai r information .

SERVICE CHEC KCONNECTO R (2P )

TCS INDICATO R LIGH T

SCS SERVIC E CONNECTO R07PAZ-001010 0

ProCarManuals.com

Page 558 of 1640

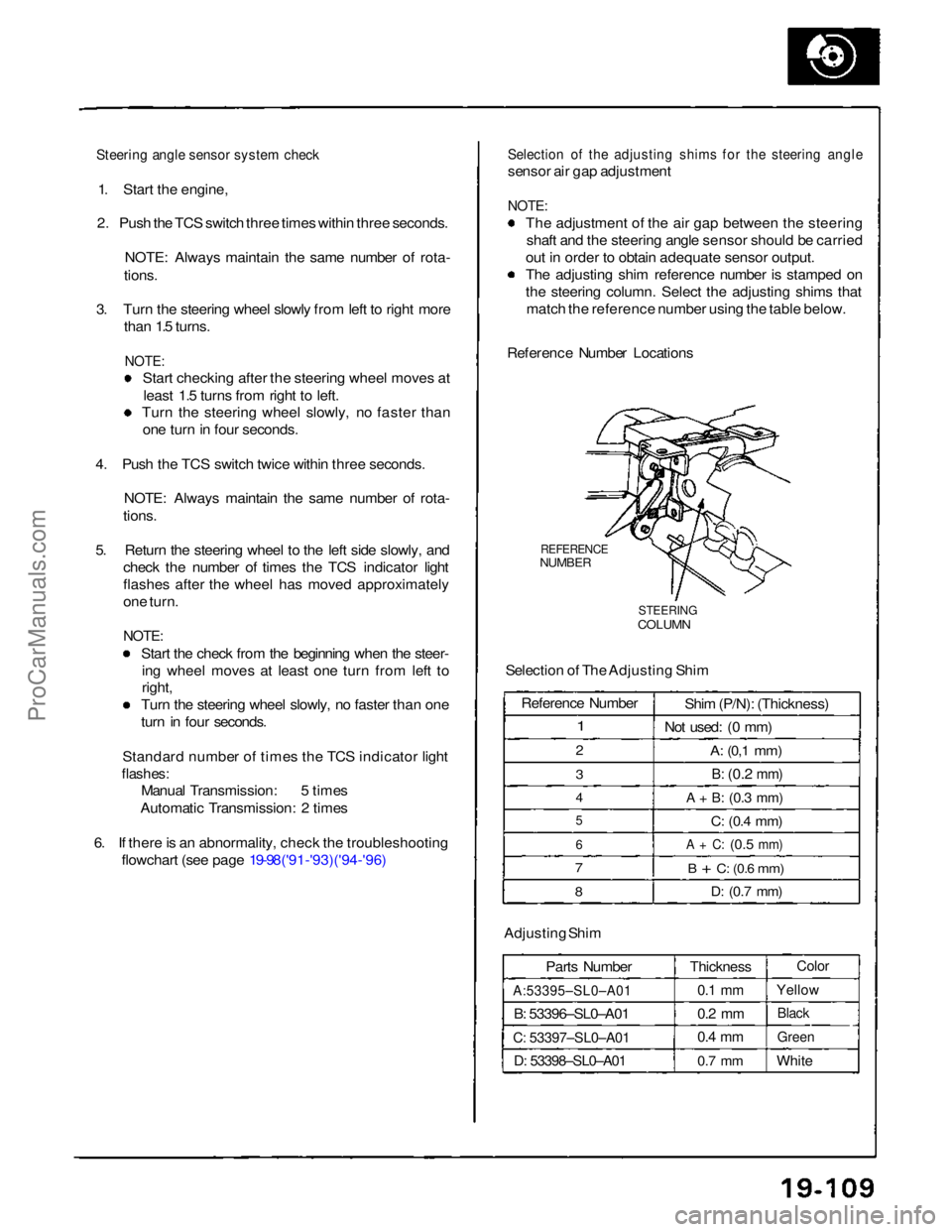

Steering angle sensor system check

1. Start the engine,

2. Push the TCS switch three times within three seconds.

NOTE: Always maintain the same number of rota-

tions.

3. Turn the steering wheel slowly from left to right more than 1.5 turns.

NOTE:

Start checking after the steering wheel moves at

least 1.5 turns from right to left.

Turn the steering wheel slowly, no faster than

one turn in four seconds.

4. Push the TCS switch twice within three seconds. NOTE: Always maintain the same number of rota-

tions.

5. Return the steering wheel to the left side slowly, and check the number of times the TCS indicator light

flashes after the wheel has moved approximately

one turn.

NOTE:

Start the check from the beginning when the steer-ing wheel moves at least one turn from left to

right, Turn the steering wheel slowly, no faster than one

turn in four seconds.

Standard number of times the TCS indicator light

flashes:

Manual Transmission: 5 times

Automatic Transmission: 2 times

6. If there is an abnormality, check the troubleshooting flowchart (see page 19-98('91-'93)('94-'96)

Selection of the adjusting shims for the steering angle

sensor air gap adjustment

NOTE:

The adjustment of the air gap between the steeringshaft and the steering angle sensor should be carried

out in order to obtain adequate sensor output.

The adjusting shim reference number is stamped on

the steering column. Select the adjusting shims that match the reference number using the table below.

Reference Number Locations

REFERENCE

NUMBER

STEERING

COLUMN

Selection of The Adjusting Shim

Adjusting Shim Parts Number

A:53395–SL0–A01

B: 53396–SL0–A01

C: 53397–SL0–A01

D: 53398–SL0–A01

Thickness

0.1 mm

0.2 mm

0.4 mm

0.7 mm

Color

Yellow

Black

Green

White

Reference Number

1

2

3

4

5

6

7

8

Shim (P/N): (Thickness)

Not used: (0 mm)

A:

(0,1

mm)

B:

(0.2

mm)

A + B:

(0.3

mm)

C:

(0.4

mm)

A + C:

(0.5

mm)

B + C:

(0.6

mm)

D:

(0.7

mm)ProCarManuals.com

Page 621 of 1640

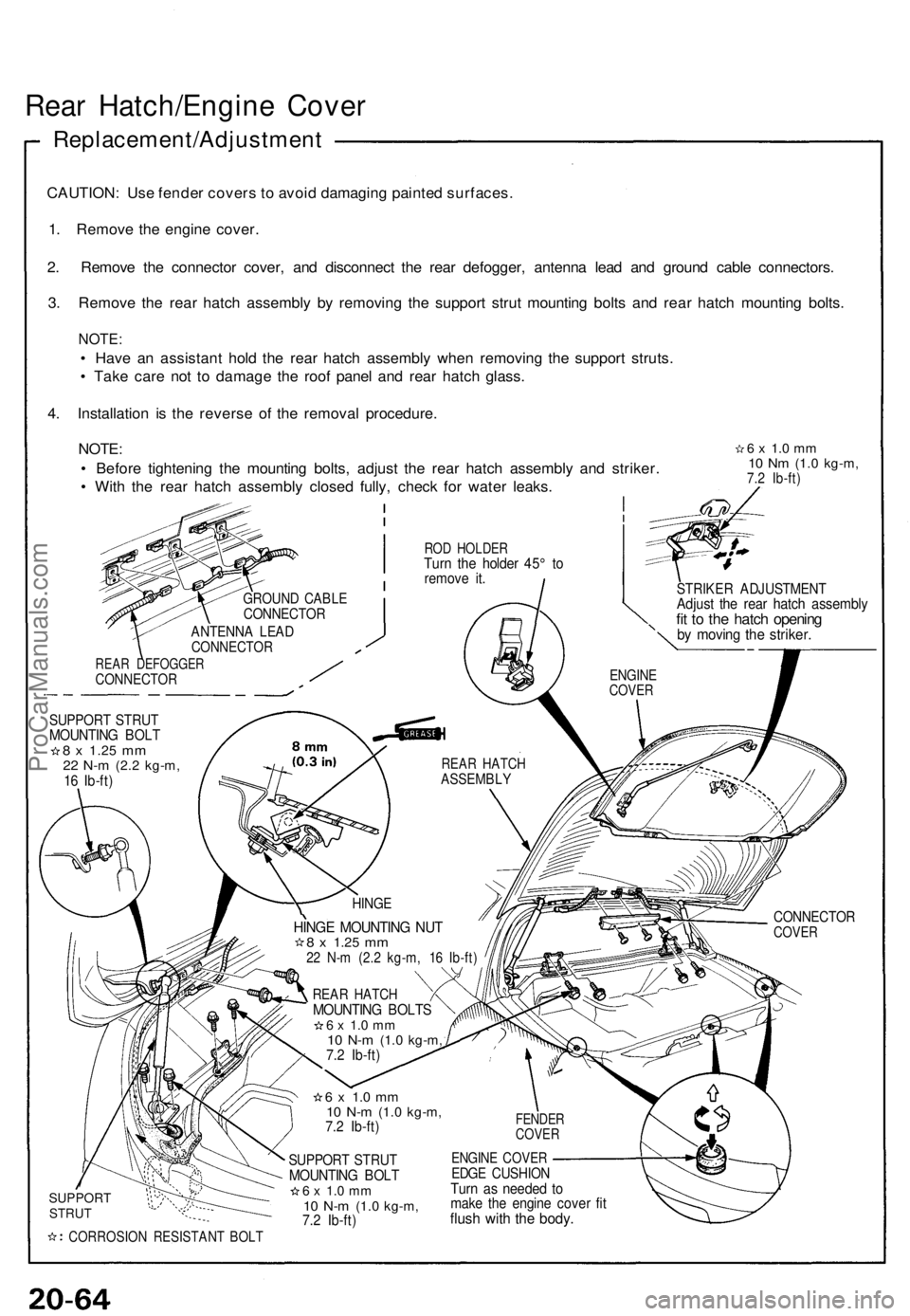

Rear Hatch/Engin e Cove r

Replacement/Adjustmen t

CAUTION: Us e fende r cover s t o avoi d damagin g painte d surfaces .

1 . Remov e th e engin e cover .

2 . Remov e th e connecto r cover , an d disconnec t th e rea r defogger , antenn a lea d an d groun d cabl e connectors .

3 . Remov e th e rea r hatc h assembl y b y removin g th e suppor t stru t mountin g bolt s an d rea r hatc h mountin g bolts .

NOTE :

• Hav e a n assistan t hol d th e rea r hatc h assembl y whe n removin g th e suppor t struts .

• Tak e car e no t t o damag e th e roo f pane l an d rea r hatc h glass .

4 . Installatio n i s th e revers e o f th e remova l procedure .

NOTE :

• Befor e tightenin g th e mountin g bolts , adjus t th e rea r hatc h assembl y an d striker .

• Wit h th e rea r hatc h assembl y close d fully , chec k fo r wate r leaks .

ROD HOLDE RTurn th e holde r 45 ° t oremov e it .

6 x 1. 0 m m10 N m (1. 0 kg-m ,7.2 Ib-ft )

GROUN D CABL ECONNECTO R

ANTENNA LEA DCONNECTO R

STRIKER ADJUSTMEN TAdjust th e rea r hatc h assembl yfit t o th e hatc h openin gby movin g th e striker .

REAR DEFOGGE RCONNECTO R

SUPPORT STRU TMOUNTIN G BOL T8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7.2 Ib-ft )

SUPPOR TSTRUT

CORROSIO N RESISTAN T BOL T

SUPPOR T STRU TMOUNTIN G BOL T6 x 1. 0 m m10 N- m (1. 0 kg-m ,7.2 Ib-ft )

CONNECTO RCOVER

ENGIN E COVE REDGE CUSHIO NTurn a s neede d t omak e th e engin e cove r fi tflus h wit h th e body .

HINGE MOUNTIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

HING E

REAR HATC HASSEMBL Y

ENGINECOVER

FENDE RCOVER

REAR HATC HMOUNTIN G BOLT S6 x 1. 0 m m10 N- m (1. 0 kg-m ,7.2 Ib-ft )

ProCarManuals.com

Page 673 of 1640

Engine Cover/Roo f Cove r

Remova l

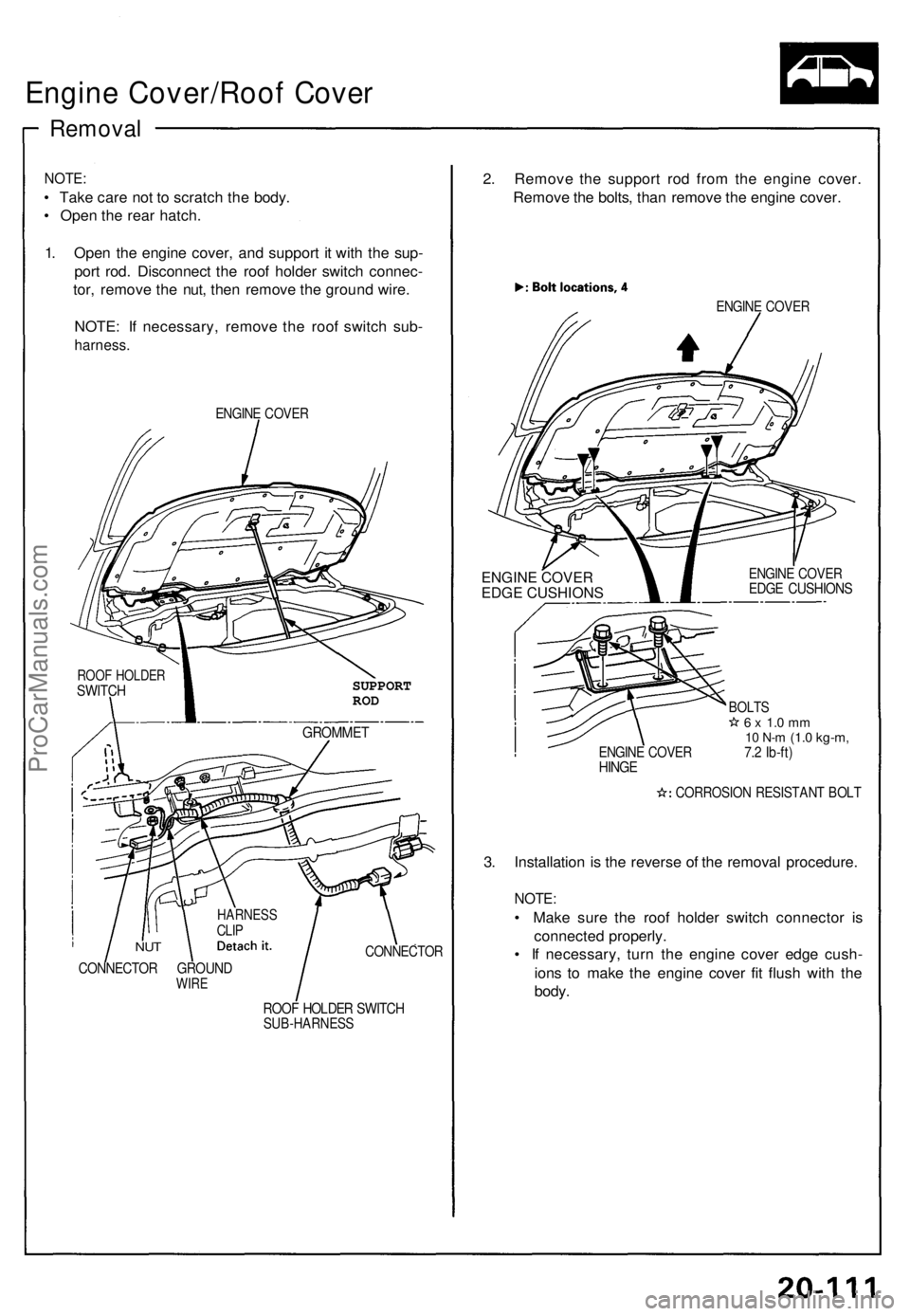

NOTE:

• Tak e car e no t t o scratc h th e body .

• Ope n th e rea r hatch .

1 . Ope n th e engin e cover , an d suppor t i t wit h th e sup -

por t rod . Disconnec t th e roo f holde r switc h connec -

tor , remov e th e nut , the n remov e th e groun d wire .

NOTE : I f necessary , remov e th e roo f switc h sub -

harness .

ENGINE COVE R

CONNECTO R

CONNECTO R GROUN DWIRE

ROO F HOLDE R SWITC HSUB-HARNES S

2. Remov e th e suppor t ro d fro m th e engin e cover .

Remov e th e bolts , tha n remov e th e engin e cover .

ENGIN E COVE R

ENGIN E COVE R

EDGE CUSHION S

ENGINE COVE RHINGE

BOLT S6 x 1. 0 m m10 N- m (1. 0 kg-m ,7.2 Ib-ft )

CORROSIO N RESISTAN T BOL T

3. Installatio n i s th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e roo f holde r switc h connecto r i s

connecte d properly .

• I f necessary , tur n th e engin e cove r edg e cush -

ion s t o mak e th e engine cover fi t flus h wit h th e

body .

SUPPOR TROD

ENGINE COVER

EDGE CUSHIONS

GROMME T

ROOF HOLDE RSWITCH

HARNES SCLIPNUT

ProCarManuals.com

Page 674 of 1640

Engine Cover/Roo f Cove r

Replacemen t

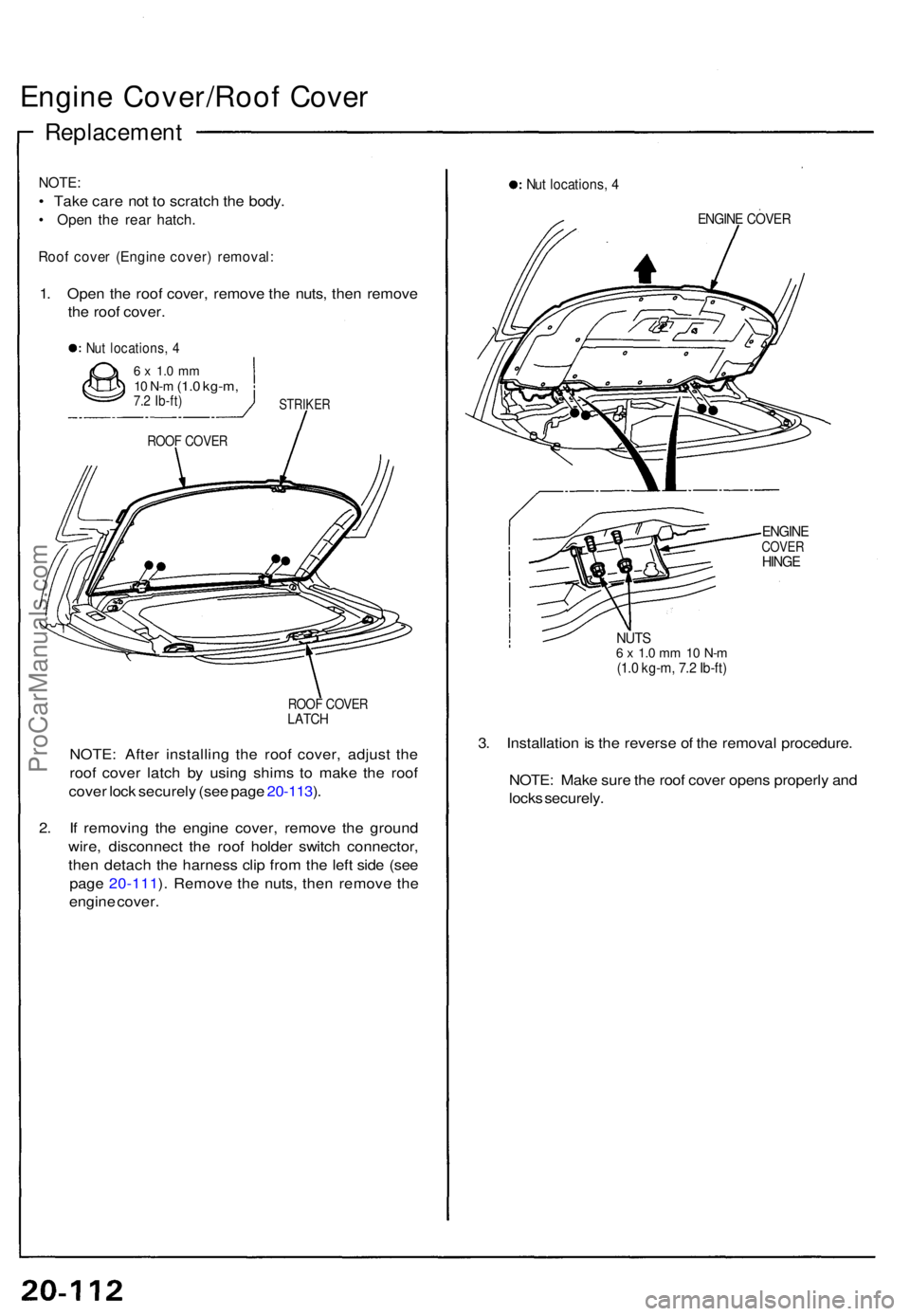

NOTE:

• Tak e car e no t t o scratc h th e body .

• Ope n th e rea r hatch .

Roof cove r (Engin e cover ) removal :

1. Ope n th e roo f cover , remov e th e nuts , the n remov e

th e roo f cover .

Nut locations , 4

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7.2 Ib-ft )STRIKE R

ROOF COVE RLATCH

NOTE : Afte r installin g th e roo f cover , adjus t th e

roo f cove r latc h b y usin g shim s t o mak e th e roo f

cove r loc k securel y (se e pag e 20-113 ).

2 . I f removin g th e engin e cover , remov e th e groun d

wire , disconnec t th e roo f holde r switc h connector ,

the n detac h th e harnes s cli p fro m th e lef t sid e (se e

pag e 20-111 ). Remov e th e nuts , the n remov e th e

engin e cover .

Nut locations , 4

ENGIN E COVE R

ENGINECOVERHINGE

NUTS6 x 1. 0 m m 10 N- m(1.0 kg-m , 7. 2 Ib-ft )

3. Installatio n is th e revers e o f th e remova l procedure .

NOTE : Mak e sur e th e roo f cove r open s properl y an d

lock s securely .

ROOF COVE R

ProCarManuals.com