ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1331 of 1640

System Description

Power Unit

The power unit consists of a driving circuit, current sensor, field effect transistor (FET) bridge circuit, and two relays.

It receives control signals from the CPU and controls the driving current of the motor. The driving circuit controls the

rotational direction and speed of the motor by driving the FET bridge circuit with a pulse width modulation (PWM) method

on receipt of an input of driving signals from the EPS control unit.

< Rotational Speed Control >

The PWM driving signal is a digital signal repeating the process of voltage ON/OFF at a constant frequency, which changes the ratio of ON time per one cycle of this signal. The ratio is called the duty ratio. When there is a change in duty ratio,

the average voltage changes as smoothly as an analog type. The ratio of digital signal voltage (E) and the average voltage

(Motor rotational speed fast)

ONE CYCLE

AVERAGE

VOLTAGE (60%)

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 60%

CURRENT

SENSOR

POWER

RELAY

FROM

BATTERY

RELAY

CONTROL

SIGNALS

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 40%

AVERAGE

VOLTAGE (40%)

(Motor rotational speed slow)

DIGITAL VOLTAGE

ONE CYCLE

CURRENT

FEED BACK

DRIVE

SIGNAL

< Rotational Direction Control >

Normal Mode Control:

The table below shows the normal control mode to con-

trol the flow of current from the battery:

("PWM" in the table indicates PWM control based on

torque sensor data). Return Control Mode:

Return control mode improves the steering return charac-

teristics. ("PWM" in the table denotes PWM control based on torque sensor data while "PWM-r" PWM con-

trol based on rotation sensor).

POWER UNIT

FET DRIVE

CIRCUIT

GROND

FAIL SAFE

RELAY

Damper Control Mode:

The damper mode control which improves the convergence of steering, is performed with damper mode signals from

the control unit. In this mode, a short current circuit is formed on the motor side by turning off FET (1) and (2), and on FET (3) and (4), which suppresses the returning speed of the steering. < Motor Driving Current Control >

A current sensor, power relay and fail-safe relay are built into the power unit. The current sensor detects motor driving

current and transmits data to the EPS control unit. If there is a problem in the system, a cut-off signal is sent from the EPS

control unit to relay, then the relay cuts off motor current to switch to manual steering operation. (V) is called the duty ratio

of motor is slow. As the duty ratio increases, the rotational speed increases to increase the torque. When the duty ratio is low, the rotational speed

Its relationship is expressed by V = E x

Steering

condition Steering to

rightStraight

ahead

Steering to

left

OFFOFF

ON

FET

(1)

FET

(2)

FET

(3)

FET

(4)

OFF

OFF

OFF

ON

OFF

PWM

OFF

OFF

PWM

Motor operation

Stops

Operates in direction

steering to the left Operates in direction

steering to the right

Steering condition

Return from right steering

to straight ahead

Return from left steering

to straight ahead

FET (1)

PWM-r

OFF

FET (2)

OFF

PWM-r

FET (3)

OFF

PWM

OFF

PWM

FET (4)

MOTORProCarManuals.com

Page 1332 of 1640

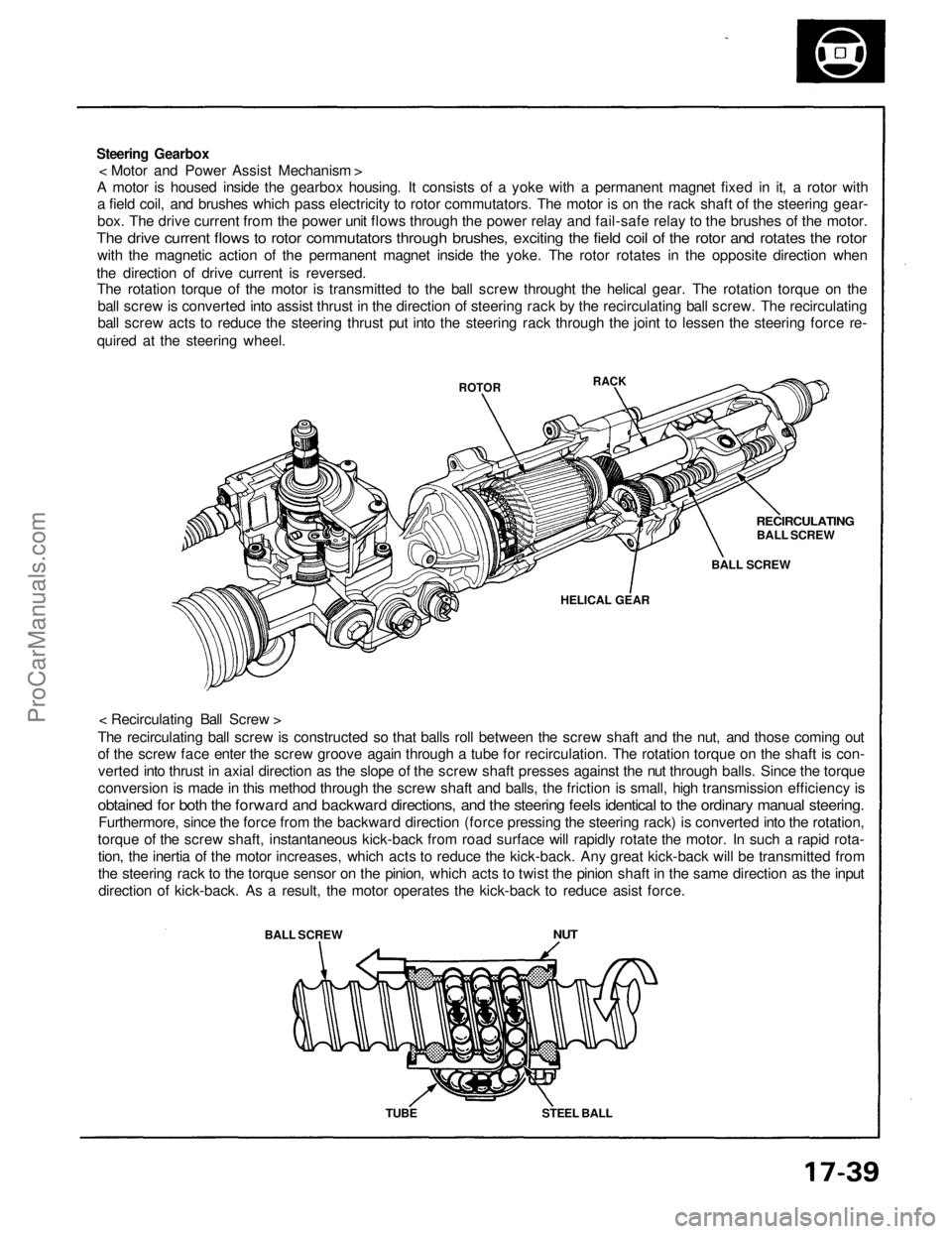

Steering Gearbox

< Motor and Power Assist Mechanism >

A motor is housed inside the gearbox housing. It consists of a yoke with a permanent magnet fixed in it, a rotor with

a field coil, and brushes which pass electricity to rotor commutators. The motor is on the rack shaft of the steering gear-

box. The drive current from the power unit flows through the power relay and fail-safe relay to the brushes of the motor.

The drive current flows to rotor commutators through brushes, exciting the field coil of the rotor and rotates the rotor

with the magnetic action of the permanent magnet inside the yoke. The rotor rotates in the opposite direction when

the direction of drive current is reversed.

The rotation torque of the motor is transmitted to the ball screw throught the helical gear. The rotation torque on the

ball screw is converted into assist thrust in the direction of steering rack by the recirculating ball screw. The recirculating

ball screw acts to reduce the steering thrust put into the steering rack through the joint to lessen the steering force re-

quired at the steering wheel.

< Recirculating Ball Screw >

The recirculating ball screw is constructed so that balls roll between the screw shaft and the nut, and those coming out

of the screw face enter the screw groove again through a tube for recirculation. The rotation torque on the shaft is con-

verted into thrust in axial direction as the slope of the screw shaft presses against the nut through balls. Since the torque

conversion is made in this method through the screw shaft and balls, the friction is small, high transmission efficiency is

obtained for both the forward and backward directions, and the steering feels identical to the ordinary manual steering.

Furthermore, since the force from the backward direction (force pressing the steering rack) is converted into the rotation,

torque of the screw shaft, instantaneous kick-back from road surface will rapidly rotate the motor. In such a rapid rota-

tion, the inertia of the motor increases, which acts to reduce the kick-back. Any great kick-back will be transmitted from

the steering rack to the torque sensor on the pinion, which acts to twist the pinion shaft in the same direction as the input

direction of kick-back. As a result, the motor operates the kick-back to reduce asist force.

BALL SCREW

ROTOR

NUT

TUBE

STEEL BALL

HELICAL GEAR

BALL SCREW

RECIRCULATING

BALL SCREW

RACKProCarManuals.com

Page 1333 of 1640

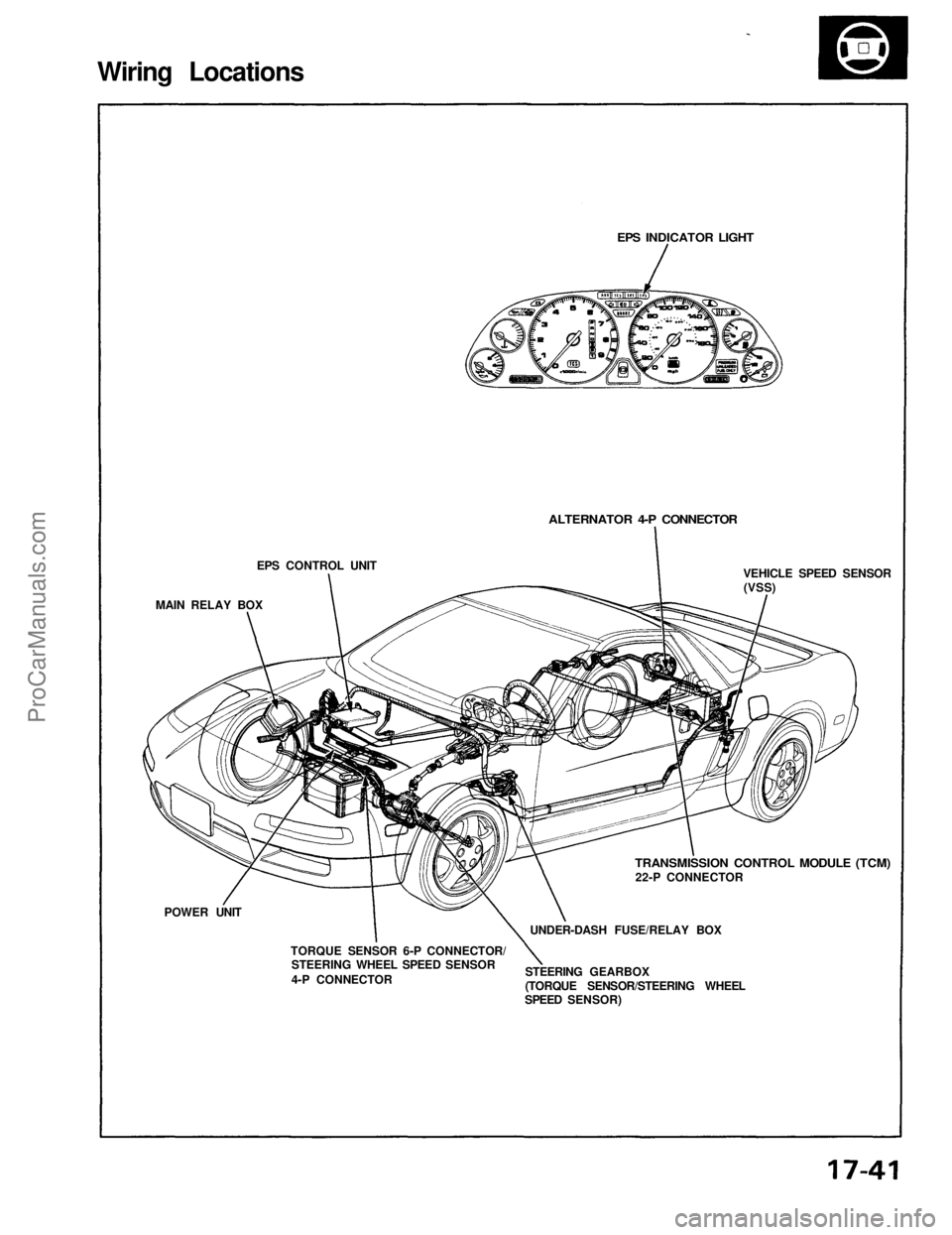

Wiring Locations

EPS CONTROL UNIT

MAIN RELAY BOX

POWER UNIT

TORQUE SENSOR 6-P CONNECTOR/

STEERING WHEEL SPEED SENSOR

4-P CONNECTOR

STEERING GEARBOX

(TORQUE SENSOR/STEERING WHEEL

SPEED SENSOR)

UNDER-DASH FUSE/RELAY BOX

TRANSMISSION CONTROL MODULE (TCM)

22-P CONNECTOR

VEHICLE SPEED SENSOR

(VSS)

ALTERNATOR 4-P CONNECTOR

EPS INDICATOR LIGHTProCarManuals.com

Page 1334 of 1640

Troubleshooting

Troubleshooting Precautions

Always use the test harness to verify the resistance, voltage, current and other electrical characteristics for the EPS

control unit, torque sensor, steering wheel speed sensor, power unit, and their connectors.

The test probe must not make direct contact with the connector terminals. Make sure that the terminals are not bent or damaged in any way when a test harness is installed.

A digital circuit tester must be used to perform the inspections.

An analog circuit tester must be used only when this procedure is indicated in the specification figures.

The EPS system connector should not be disconnected except when necessary.

Inspect the connection condition and ground of each EPS system connector before peforming the troubleshooting

procedures.ProCarManuals.com

Page 1335 of 1640

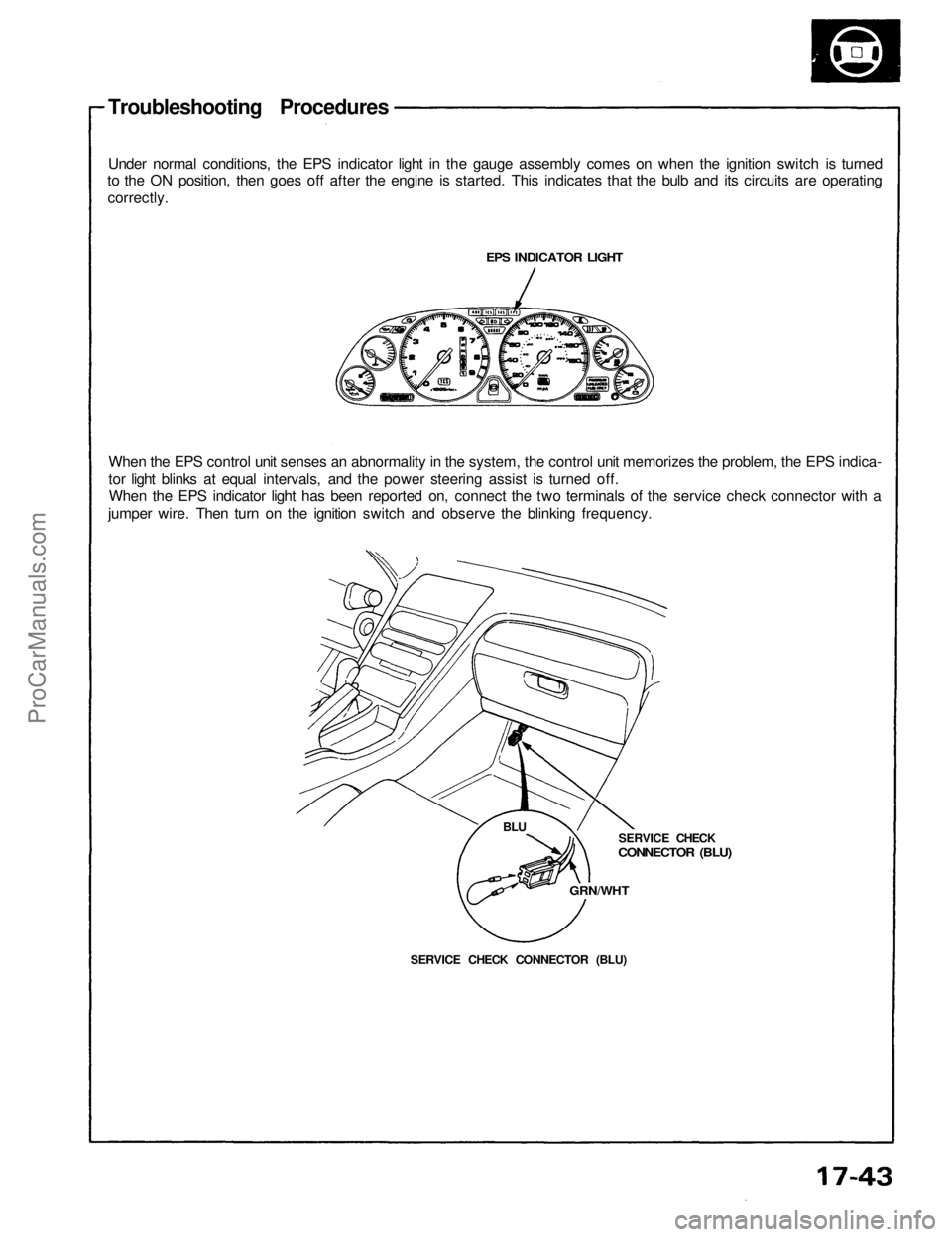

Troubleshooting Procedures

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned

to the ON position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating

correctly.

EPS INDICATOR LIGHT

When the EPS control unit senses an abnormality in the system, the control unit memorizes the problem, the EPS indica-

tor light blinks at equal intervals, and the power steering assist is turned off.

When the EPS indicator light has been reported on, connect the two terminals of the service check connector with a

jumper wire. Then turn on the ignition switch and observe the blinking frequency.

SERVICE CHECK

CONNECTOR (BLU)

GRN/WHT

SERVICE CHECK CONNECTOR (BLU)

BLUProCarManuals.com

Page 1336 of 1640

Troubleshooting

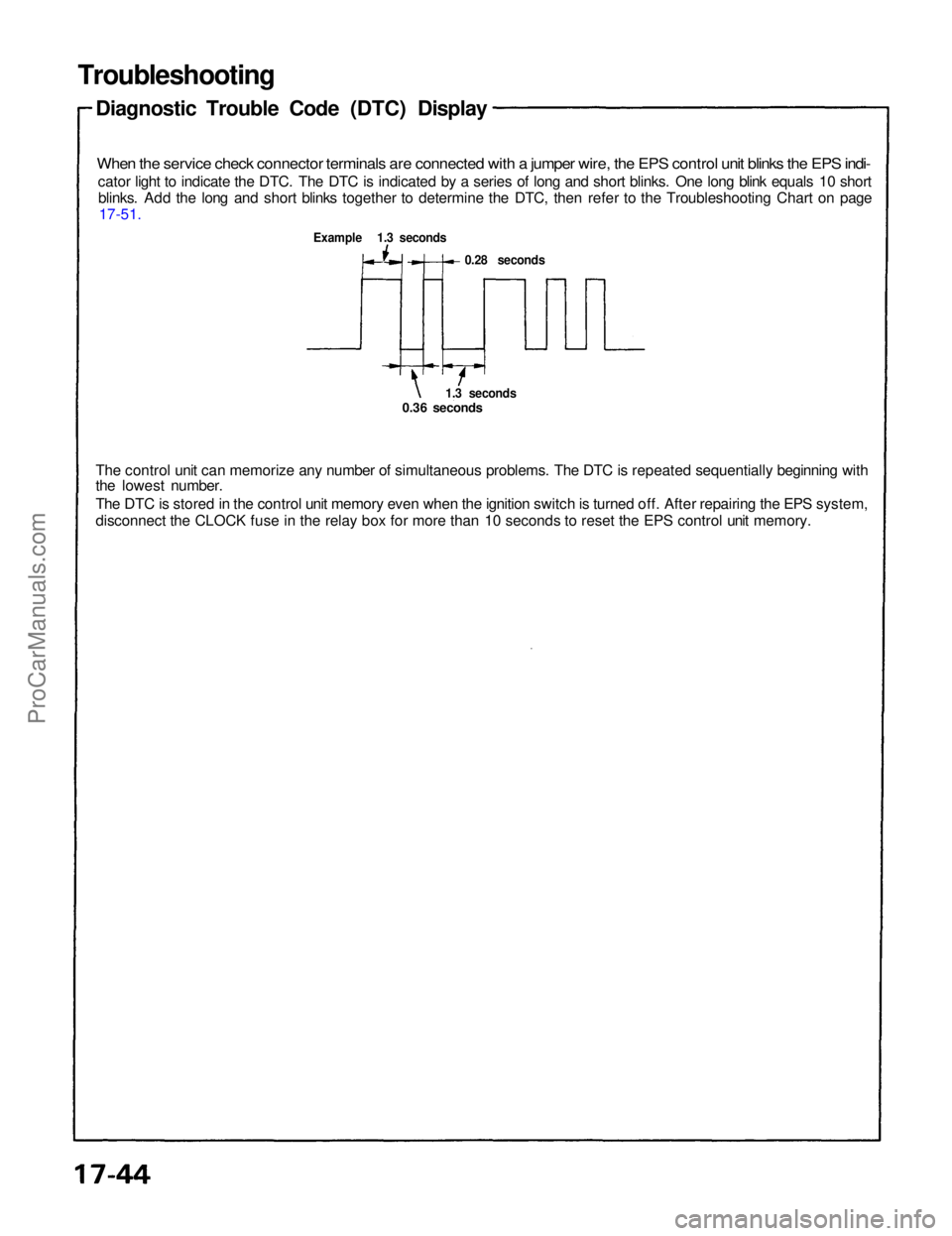

Diagnostic Trouble Code (DTC) Display

When the service check connector terminals are connected with a jumper wire, the EPS control unit blinks the EPS indi-

cator light to indicate the DTC. The DTC is indicated by a series of long and short blinks. One long blink equals 10 shortblinks. Add the long and short blinks together to determine the DTC, then refer to the Troubleshooting Chart on page 17-51.

Example 1.3 seconds

0.28 seconds

1.3 seconds

0.36 seconds

The control unit can memorize any number of simultaneous problems. The DTC is repeated sequentially beginning with

the lowest number.

The DTC is stored in the control unit memory even when the ignition switch is turned off. After repairing the EPS system,

disconnect the CLOCK fuse in the relay box for more than 10 seconds to reset the EPS control unit memory.ProCarManuals.com

Page 1337 of 1640

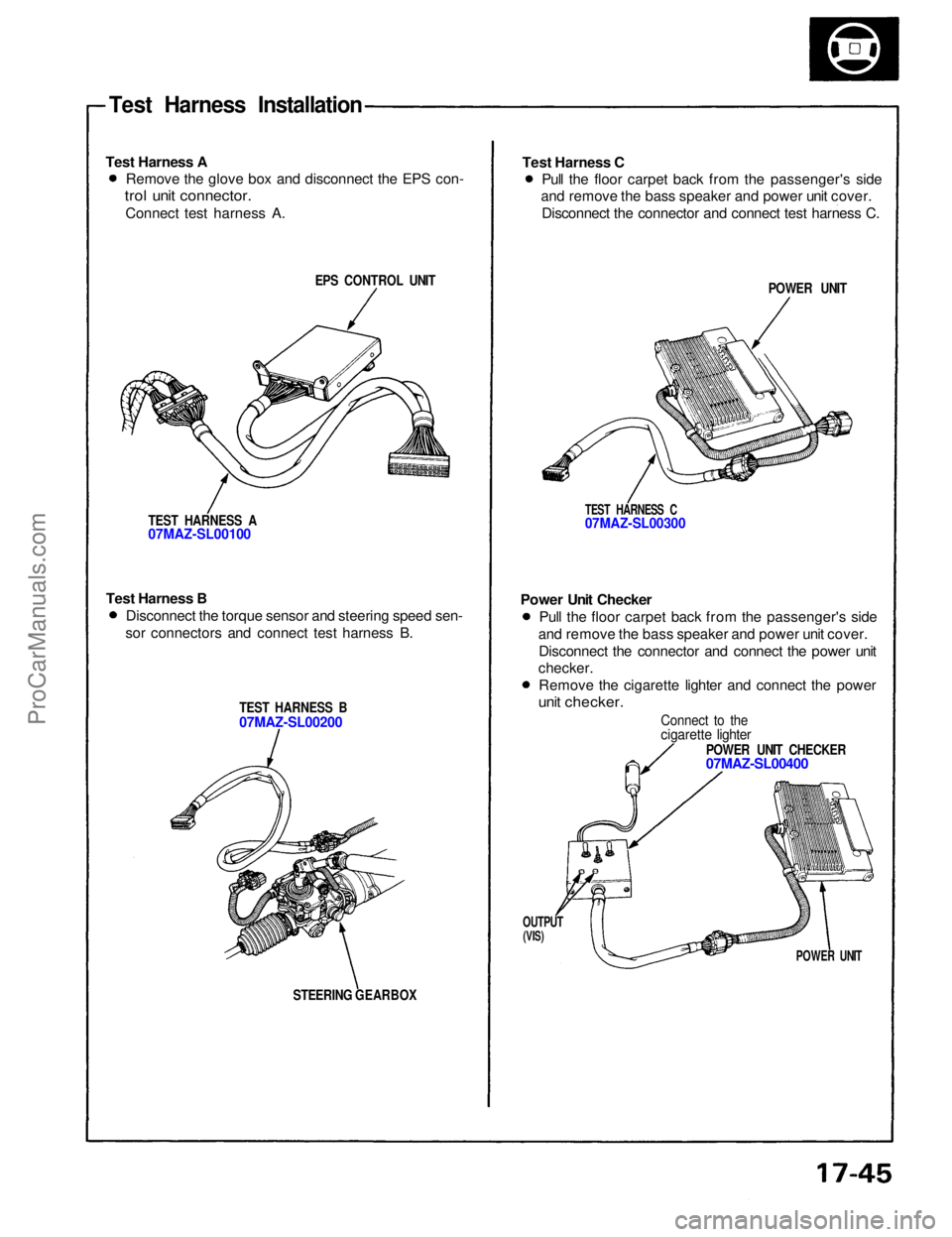

Test Harness Installation

Test Harness A

EPS CONTROL UNIT

TEST HARNESS A

07MAZ-SL00100

Test Harness B

TEST HARNESS B

07MAZ-SL00200

STEERING GEARBOX

Test Harness C

POWER UNIT

TEST HARNESS C

07MAZ-SL00300

Power Unit Checker

Connect to the

cigarette lighter

POWER UNIT CHECKER

07MAZ-SL00400

POWER UNIT

OUTPUT

(VIS)

Remove the glove box and disconnect the EPS con-

trol unit connector.

Connect test harness A.

Disconnect the torque sensor and steering speed sen-

sor connectors and connect test harness B. Pull the floor carpet back from the passenger's side

and remove the bass speaker and power unit cover.

Disconnect the connector and connect test harness C.

Pull the floor carpet back from the passenger's side

and remove the bass speaker and power unit cover. Disconnect the connector and connect the power unit

checker.

Remove the cigarette lighter and connect the power

unit checker.ProCarManuals.com

Page 1338 of 1640

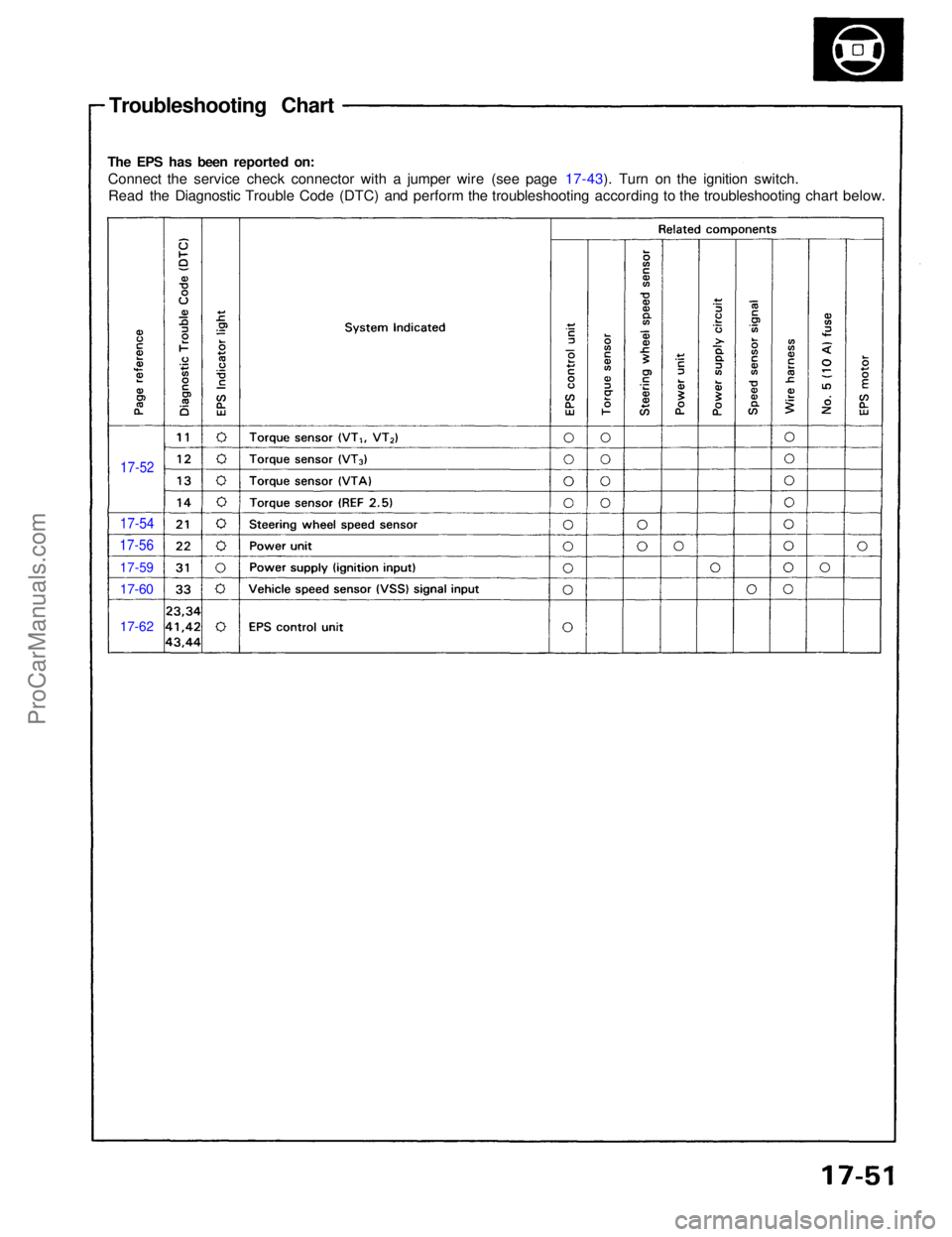

Troubleshooting Chart

The EPS has been reported on: Connect the service check connector with a jumper wire (see page 17-43). Turn on the ignition switch.Read the Diagnostic Trouble Code (DTC) and perform the troubleshooting according to the troubleshooting chart below.

17-52

17-54

17-56

17-59

17-60

17-62ProCarManuals.com

Page 1339 of 1640

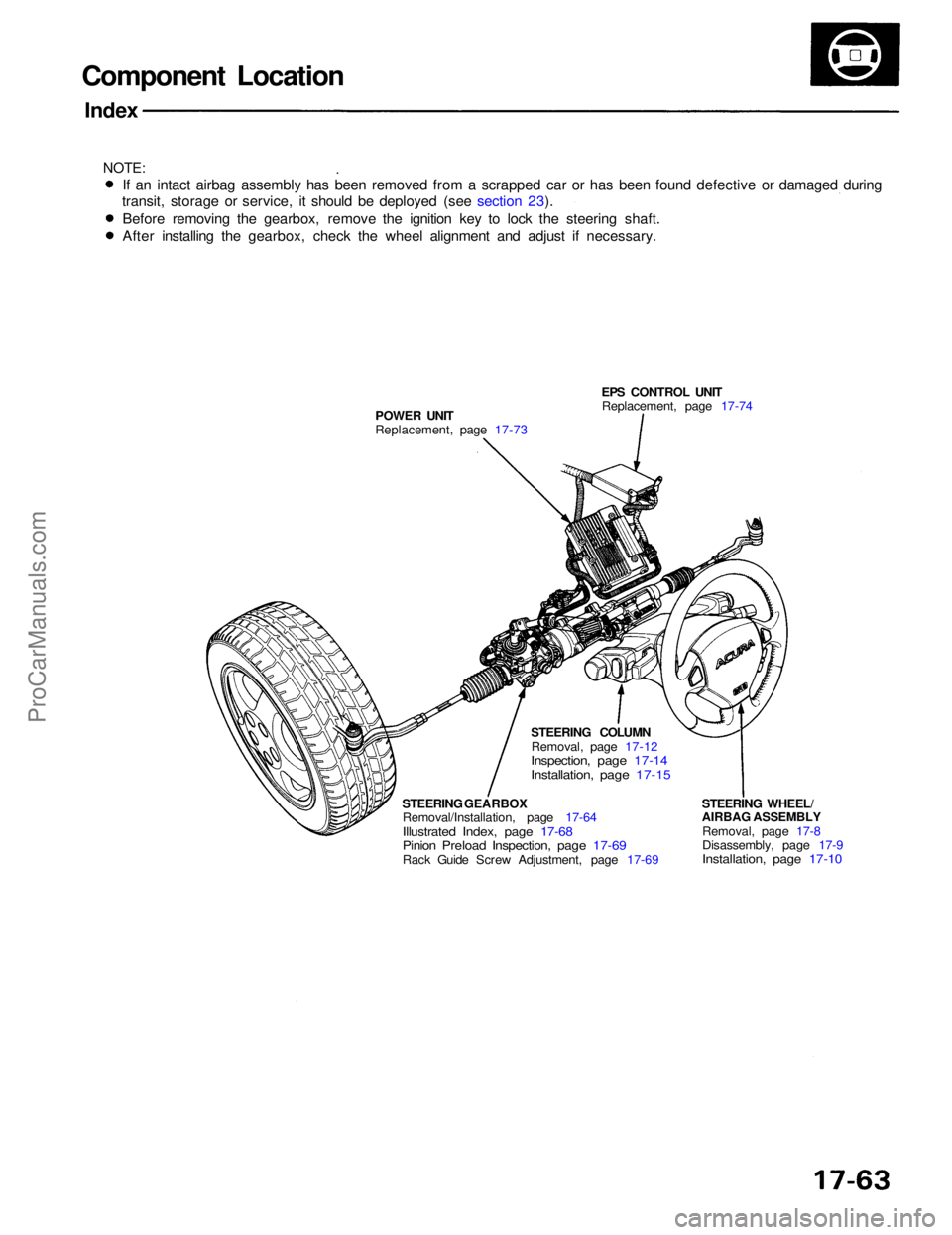

Component Location

Index

NOTE:

EPS CONTROL UNITReplacement, page 17-74

POWER UNIT

Replacement, page 17-73

STEERING WHEEL/

AIRBAG ASSEMBLYRemoval, page 17-8

Disassembly, page 17-9

Installation, page 17-10

STEERING COLUMN

Removal, page 17-12

Inspection, page 17-14

Installation, page 17-15

STEERING GEARBOX Removal/Installation, page 17-64

Illustrated Index, page 17-68

Pinion Preload Inspection, page 17-69

Rack Guide Screw Adjustment, page 17-69

If an intact airbag assembly has been removed from a scrapped car or has been found defective or damaged during

transit, storage or service, it should be deployed (see section 23).

Before removing the gearbox, remove the ignition key to lock the steering shaft.

After installing the gearbox, check the wheel alignment and adjust if necessary.ProCarManuals.com

Page 1340 of 1640

Power Steering

Gearbox Removal/Installation

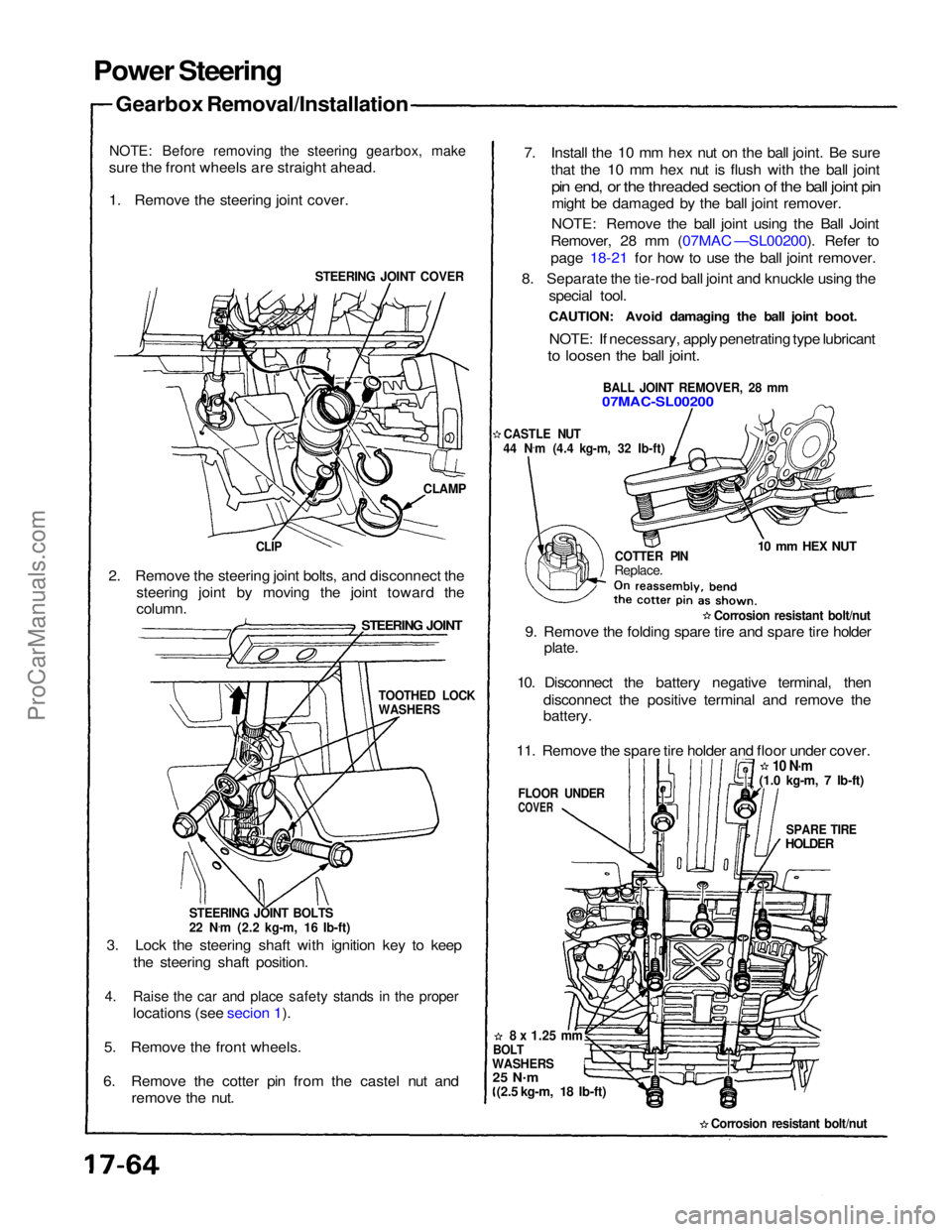

NOTE: Before removing the steering gearbox, make

sure the front wheels are straight ahead.

1. Remove the steering joint cover.

STEERING JOINT COVER

CLAMP

CLIP

2. Remove the steering joint bolts, and disconnect the steering joint by moving the joint toward the

STEERING JOINT

column.

STEERING JOINT BOLTS

22 N.

m (2.2 kg-m, 16 Ib-ft)

3. Lock the steering shaft with ignition key to keep the steering shaft position.

4. Raise the car and place safety stands in the proper

locations (see secion 1).

5. Remove the front wheels.

6. Remove the cotter pin from the castel nut and remove the nut. 7. Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm (07MAC —SL00200). Refer to

page 18-21 for how to use the ball joint remover.

8. Separate the tie-rod ball joint and knuckle using the special tool.

CAUTION: Avoid damaging the ball joint boot.

NOTE: If necessary, apply penetrating type lubricant

to loosen the ball joint.

BALL JOINT REMOVER, 28 mm

07MAC-SL00200

CASTLE NUT

44 N .

m (4.4 kg-m, 32 Ib-ft)

COTTER PIN

Replace.

10 mm HEX NUT

Corrosion resistant bolt/nut

9. Remove the folding spare tire and spare tire holder plate.

10. Disconnect the battery negative terminal, then disconnect the positive terminal and remove the

battery.

11. Remove the spare tire holder and floor under cover.

10 N·m

SPARE TIRE

HOLDER

FLOOR UNDER

COVER

8 x

1.25

mm

BOLT

WASHERS

25 N .

m

(2.5 kg-m, 18 Ib-ft)

Corrosion resistant bolt/nut

TOOTHED LOCK

WASHERS

(1.0 kg-m, 7 Ib-ft)ProCarManuals.com