ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1291 of 1640

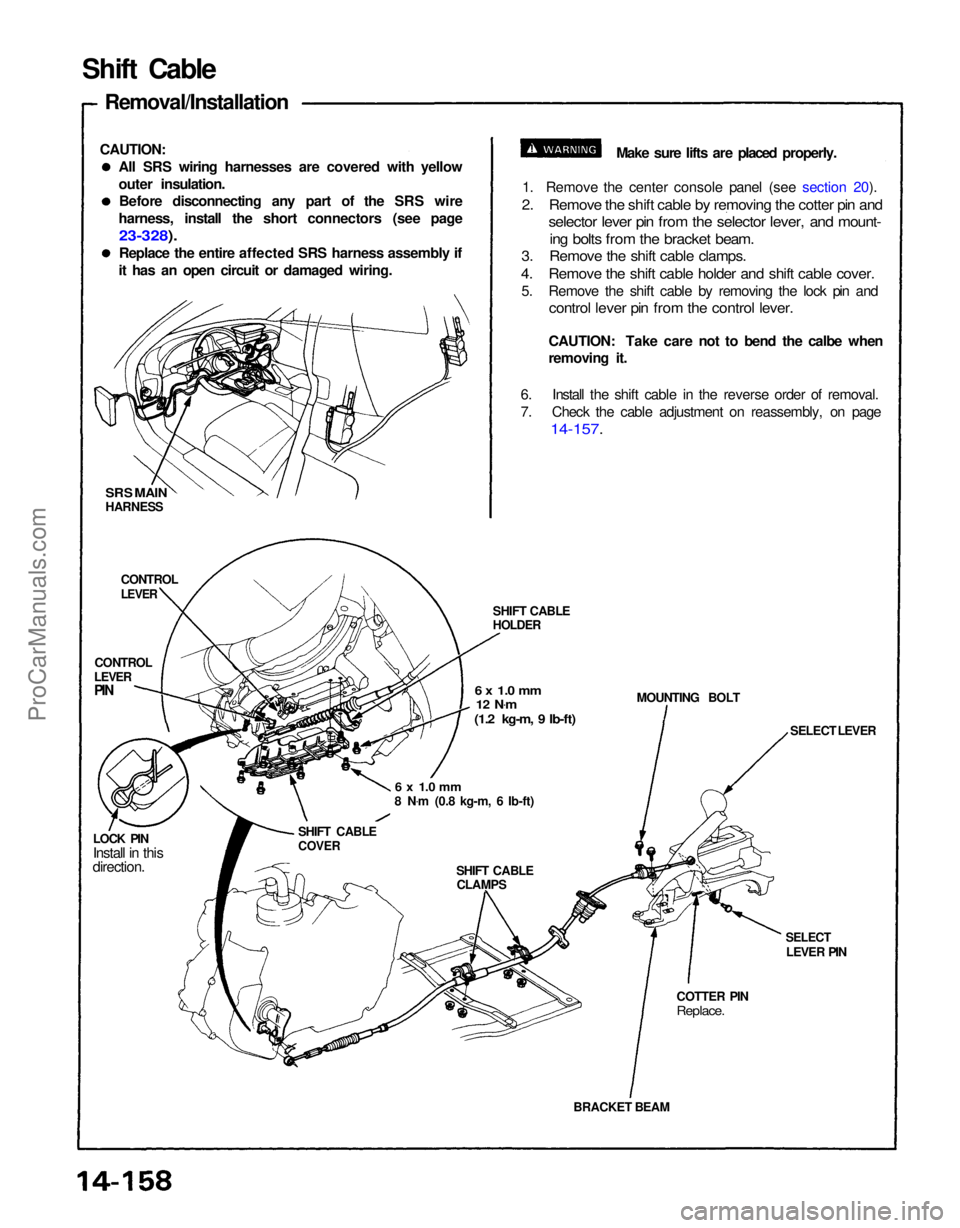

BRACKET BEAM

COTTER PIN

Replace.

SELECT

LEVER PIN SELECT LEVER

MOUNTING BOLT

SHIFT CABLE

HOLDER

6 x 1.0 mm

12 N .

m

(1.2 kg-m, 9 Ib-ft)

6 x 1.0 mm

8 N .

m (0.8 kg-m, 6 Ib-ft)

SHIFT CABLECLAMPS

SHIFT CABLE

COVER

LOCK PIN

Install in this

direction. CONTROL

LEVER

LEVER

CONTROL

SRS MAIN

HARNESS Make sure lifts are placed properly.

1. Remove the center console panel (see section 20).

2. Remove the shift cable by removing the cotter pin and

selector lever pin from the selector lever, and mount-

ing bolts from the bracket beam.

3. Remove the shift cable clamps.

4. Remove the shift cable holder and shift cable cover.

5. Remove the shift cable by removing the lock pin and

control lever pin from the control lever.

CAUTION: Take care not to bend the calbe when

removing it.

6. Install the shift cable in the reverse order of removal.

7. Check the cable adjustment on reassembly, on page

14-157.

Shift Cable

Removal/Installation

All SRS wiring harnesses are covered with yellow

outer insulation.Before disconnecting any part of the SRS wire

harness, install the short connectors (see page

23-328).

Replace the entire affected SRS harness assembly if

it has an open circuit or damaged wiring.

CAUTION:

PINProCarManuals.com

Page 1292 of 1640

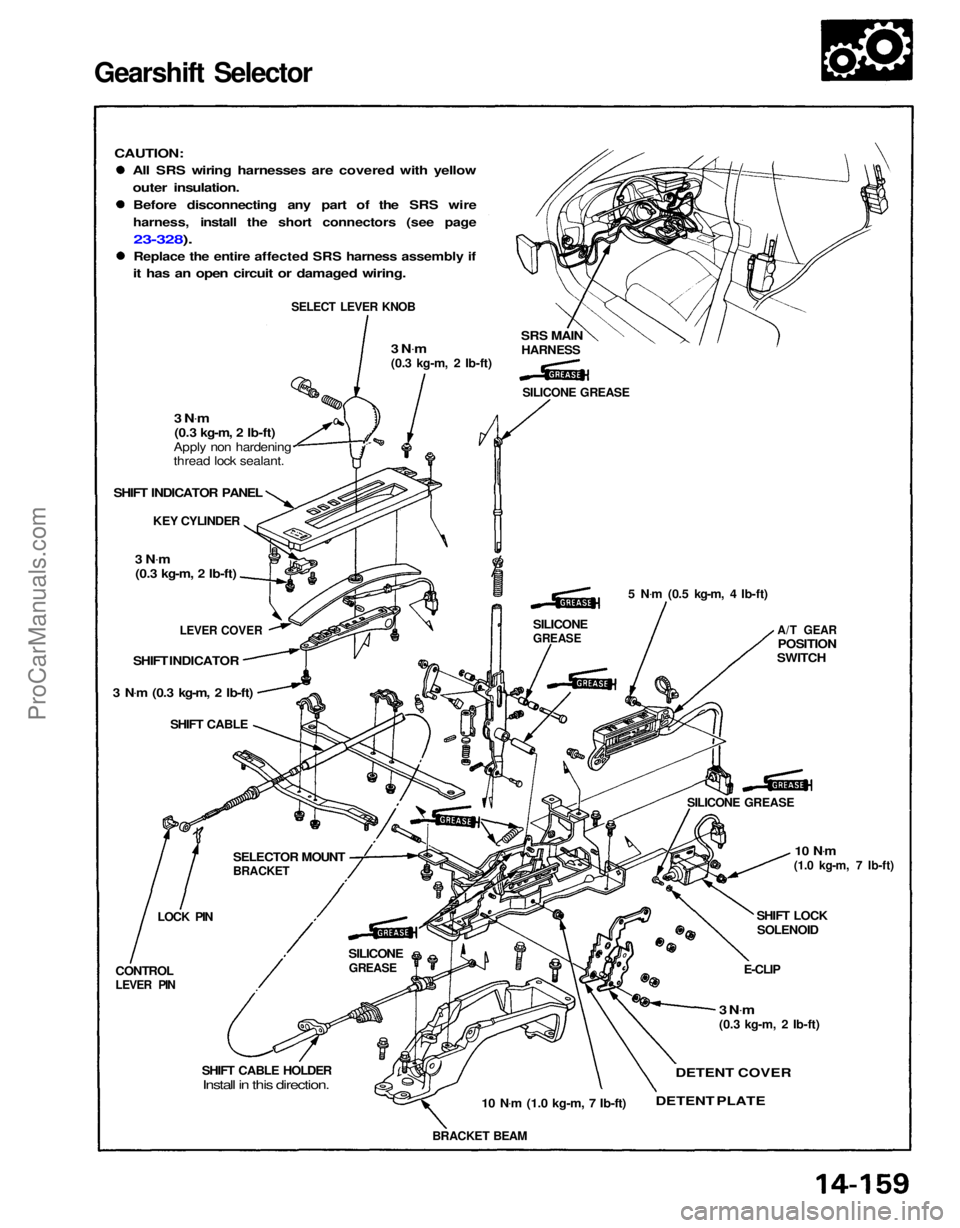

Gearshift Selector

All SRS wiring harnesses are covered with yellow

outer insulation.

Before disconnecting any part of the SRS wire

harness, install the short connectors (see page

23-328).

Replace the entire affected SRS harness assembly if

it has an open circuit or damaged wiring.

CAUTION:

SELECT LEVER KNOB

3 N.

m

(0.3 kg-m, 2 Ib-ft)

SRS MAIN

HARNESS

SILICONE GREASE

3 N .

m

(0.3 kg-m, 2 Ib-ft)

Apply non hardening

thread lock sealant.

SHIFT INDICATOR PANEL

KEY CYLINDER

3 N .

m

(0.3 kg-m, 2 Ib-ft)

5 N.

m (0.5 kg-m, 4 Ib-ft)

A/T GEAR

POSITION

SWITCH

SILICONE

GREASE

LEVER COVER

SHIFT INDICATOR

3 N .

m (0.3 kg-m, 2 Ib-ft)

SHIFT CABLE

SILICONE GREASE

10 N.

m

(1.0 kg-m, 7 Ib-ft)

SHIFT LOCK

SOLENOID

E-CLIP

3 N .

m

(0.3 kg-m, 2 Ib-ft)

DETENT COVER

DETENT

PLATE

10 N

.

m (1.0 kg-m, 7 Ib-ft)

BRACKET BEAM

SHIFT CABLE HOLDER

Install in this direction.

CONTROL

LEVER PIN

LOCK PIN

SELECTOR MOUNT

BRACKET

SILICONE

GREASEProCarManuals.com

Page 1293 of 1640

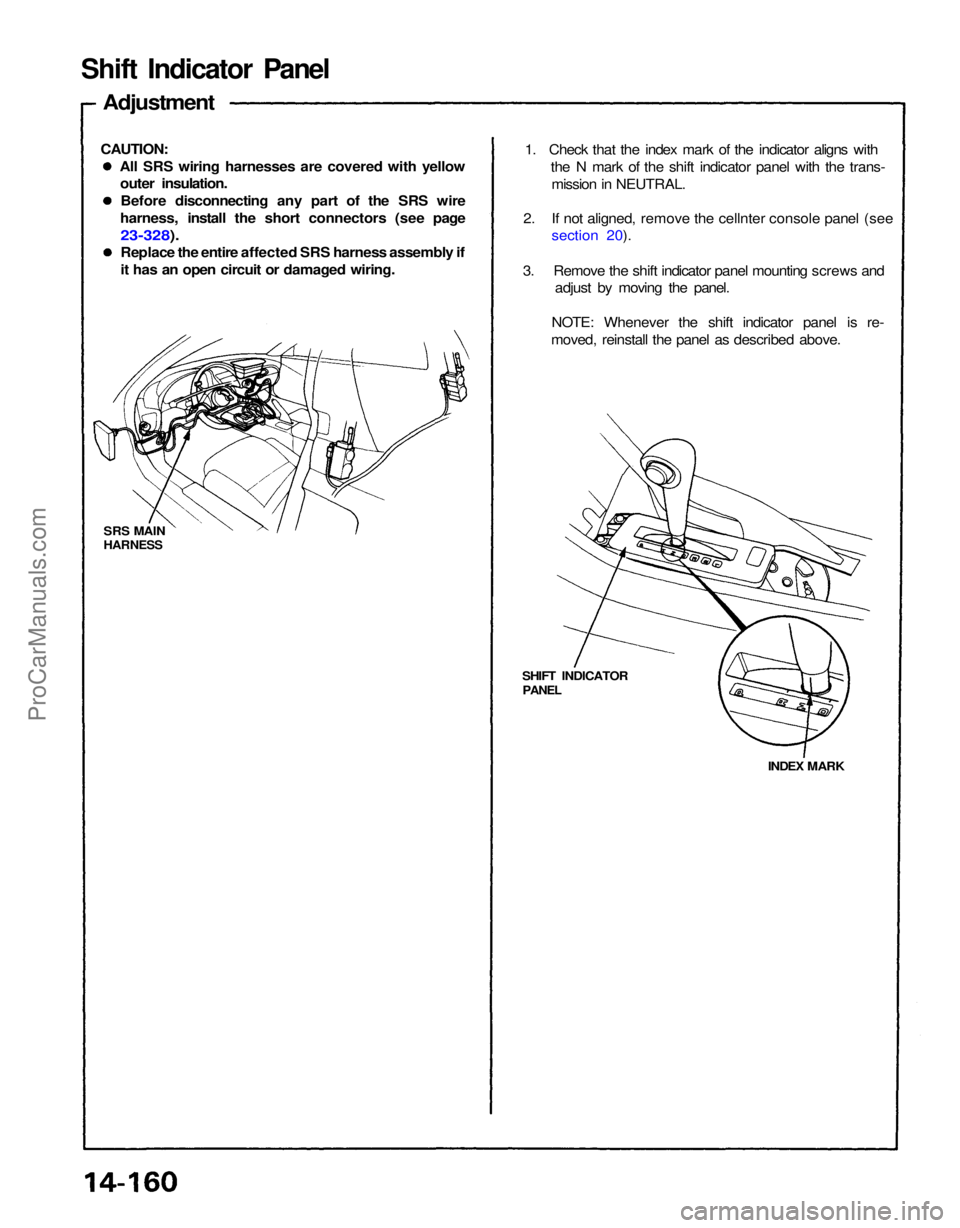

INDEX MARK

SHIFT INDICATOR

PANEL

SRS MAIN

HARNESS

1. Check that the index mark of the indicator aligns with

the N mark of the shift indicator panel with the trans-mission in NEUTRAL.

2. If not aligned, remove the cellnter console panel (see section 20).

3. Remove the shift indicator panel mounting screws and adjust by moving the panel.

NOTE: Whenever the shift indicator panel is re-

moved, reinstall the panel as described above.

All SRS wiring harnesses are covered with yellow

outer insulation.

Before disconnecting any part of the SRS wire

harness, install the short connectors (see page

23-328).

Replace the entire affected SRS harness assembly if

it has an open circuit or damaged wiring.

CAUTION:

Adjustment

Shift Indicator PanelProCarManuals.com

Page 1294 of 1640

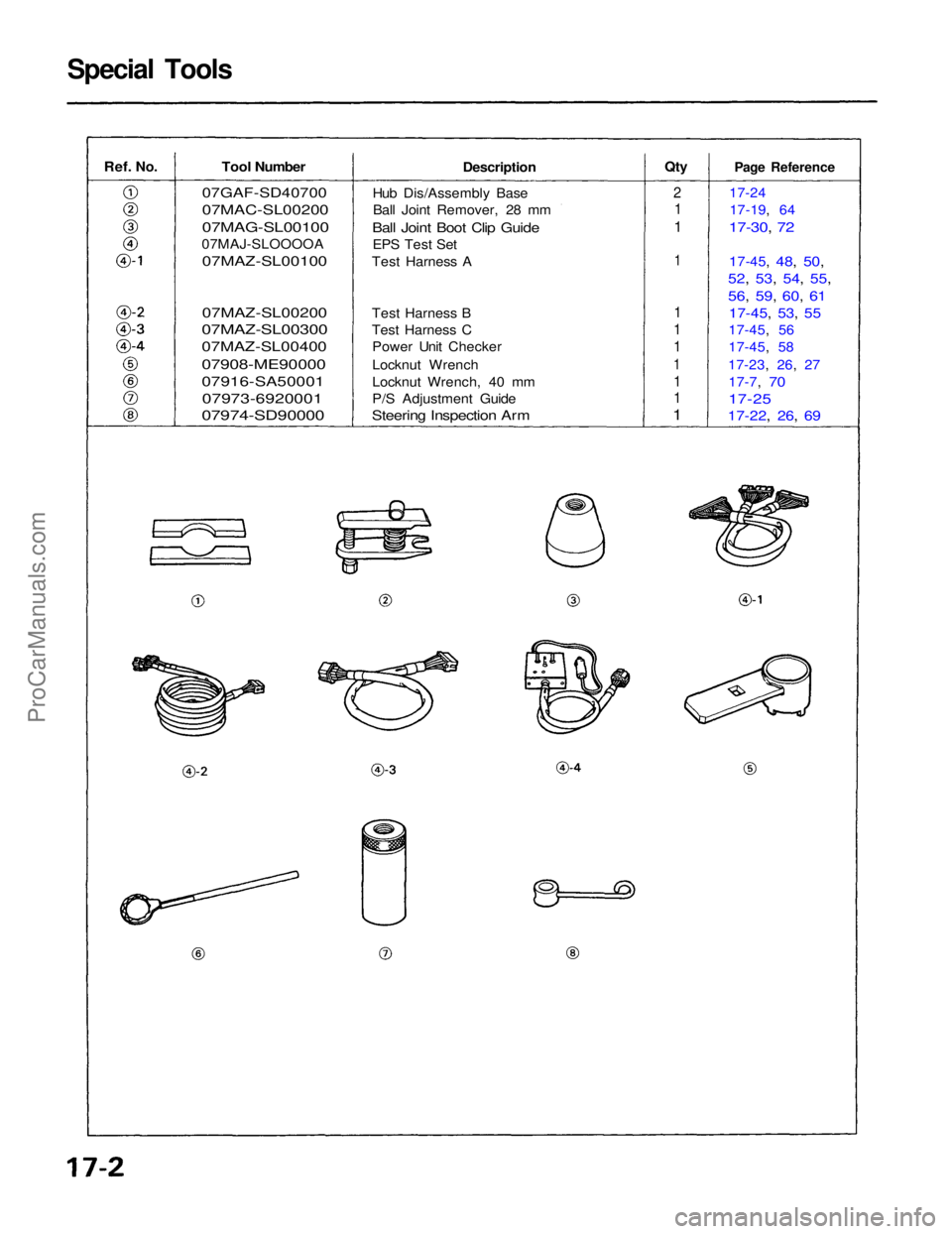

Special Tools

Ref.

No.

Tool Number

07GAF-SD40700

07MAC-SL00200

07MAG-SL00100

07MAJ-SLOOOOA

07MAZ-SL00100

07MAZ-SL00200

07MAZ-SL00300

07MAZ-SL00400

07908-ME90000

07916-SA50001

07973-6920001

07974-SD90000

Description

Hub Dis/Assembly Base Ball Joint Remover, 28 mm

Ball Joint Boot Clip Guide

EPS Test Set

Test Harness A

Test Harness B

Test Harness C Power Unit Checker

Locknut Wrench

Locknut Wrench, 40 mm

P/S Adjustment Guide

Steering Inspection Arm

Qty

2

1

1

1

1

1

1

1

1

1

1

Page Reference

17-24 17-19, 64

17-30, 72

1

7-45,

48, 50,

52, 53, 54, 55,

56, 59, 60, 61

17-45, 53, 55

17-45, 56

17-45, 58

17-23, 26, 27 17-7,

70

17-25

17-22, 26, 69ProCarManuals.com

Page 1295 of 1640

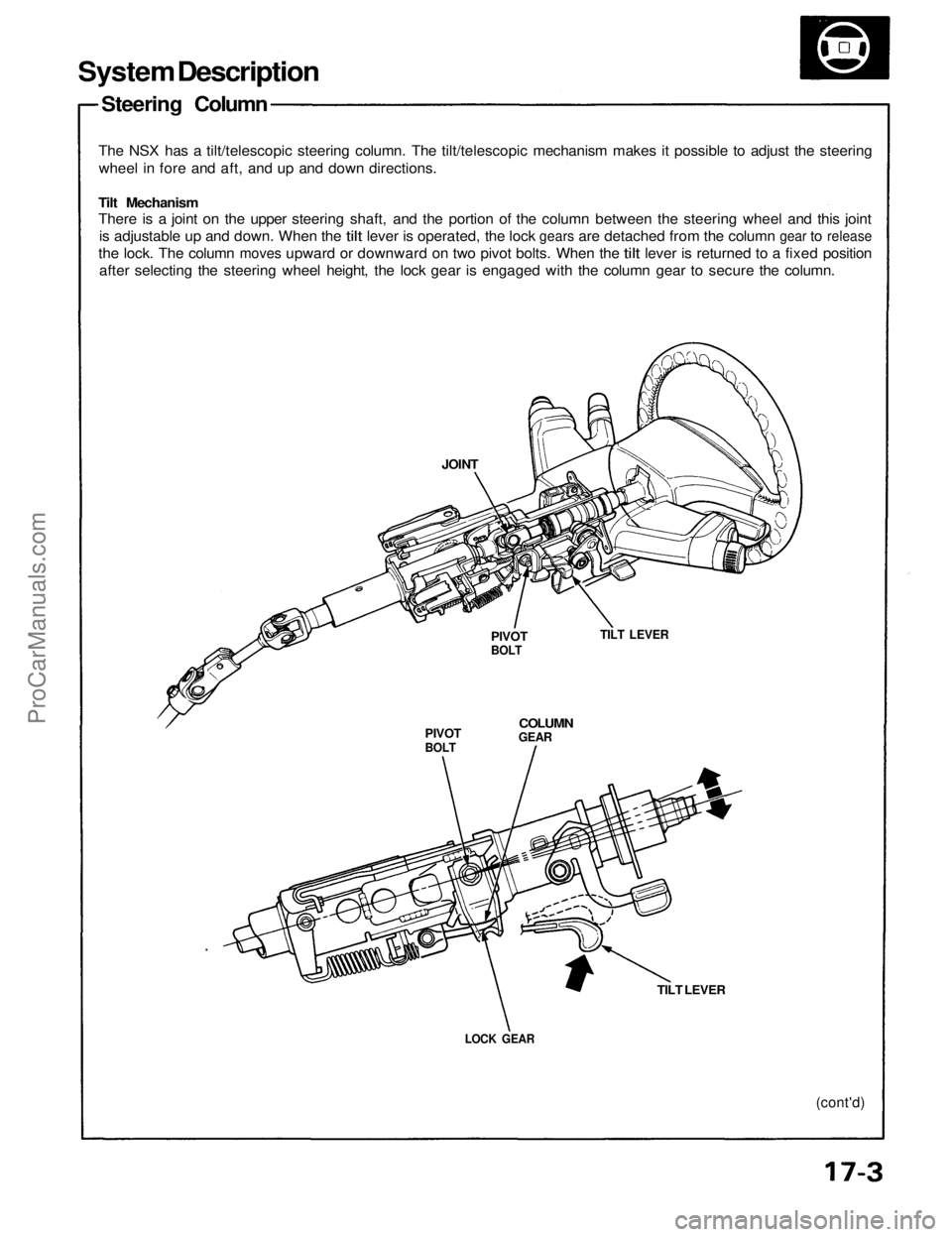

System Description

Steering Column

The NSX has a tilt/telescopic steering column. The tilt/telescopic mechanism makes it possible to adjust the steering

wheel in fore and aft, and up and down directions.

Tilt Mechanism

There is a joint on the upper steering shaft, and the portion of the column between the steering wheel and this joint

is

adjustable

up and

down. When

the

tilt

lever

is

operated,

the

lock

gears

are

detached from

the

column

gear

to

release

the

lock.

The

column

moves

upward

or

downward

on two

pivot bolts. When

the

tilt

lever

is

returned

to a

fixed position

after selecting the steering wheel height, the lock gear is engaged with the column gear to secure the column.

PIVOT

BOLT

TILT LEVER

COLUMN

GEAR

PIVOT

BOLT

LOCK GEAR

TILT LEVER

(cont'd)

JOINTProCarManuals.com

Page 1296 of 1640

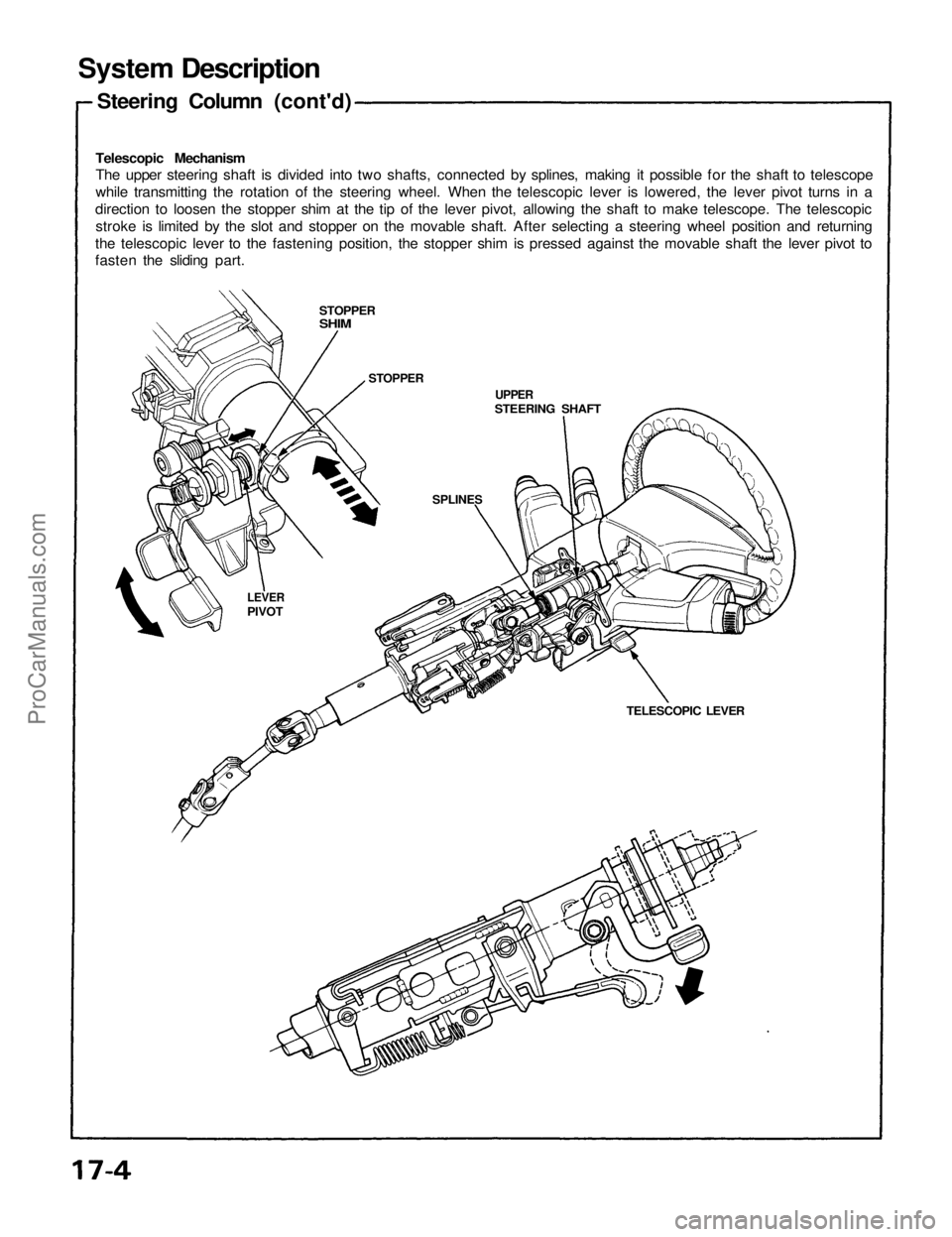

System Description

Steering Column (cont'd)

Telescopic Mechanism

The upper steering shaft is divided into two shafts, connected by splines, making it possible for the shaft to telescope

while transmitting the rotation of the steering wheel. When the telescopic lever is lowered, the lever pivot turns in a

direction to loosen the stopper shim at the tip of the lever pivot, allowing the shaft to make telescope. The telescopic

stroke is limited by the slot and stopper on the movable shaft. After selecting a steering wheel position and returning

the telescopic lever to the fastening position, the stopper shim is pressed against the movable shaft the lever pivot to

fasten the sliding part.

STOPPER

SHIM

STOPPER

UPPER

STEERING SHAFT

SPLINES

LEVER

PIVOT

TELESCOPIC LEVERProCarManuals.com

Page 1297 of 1640

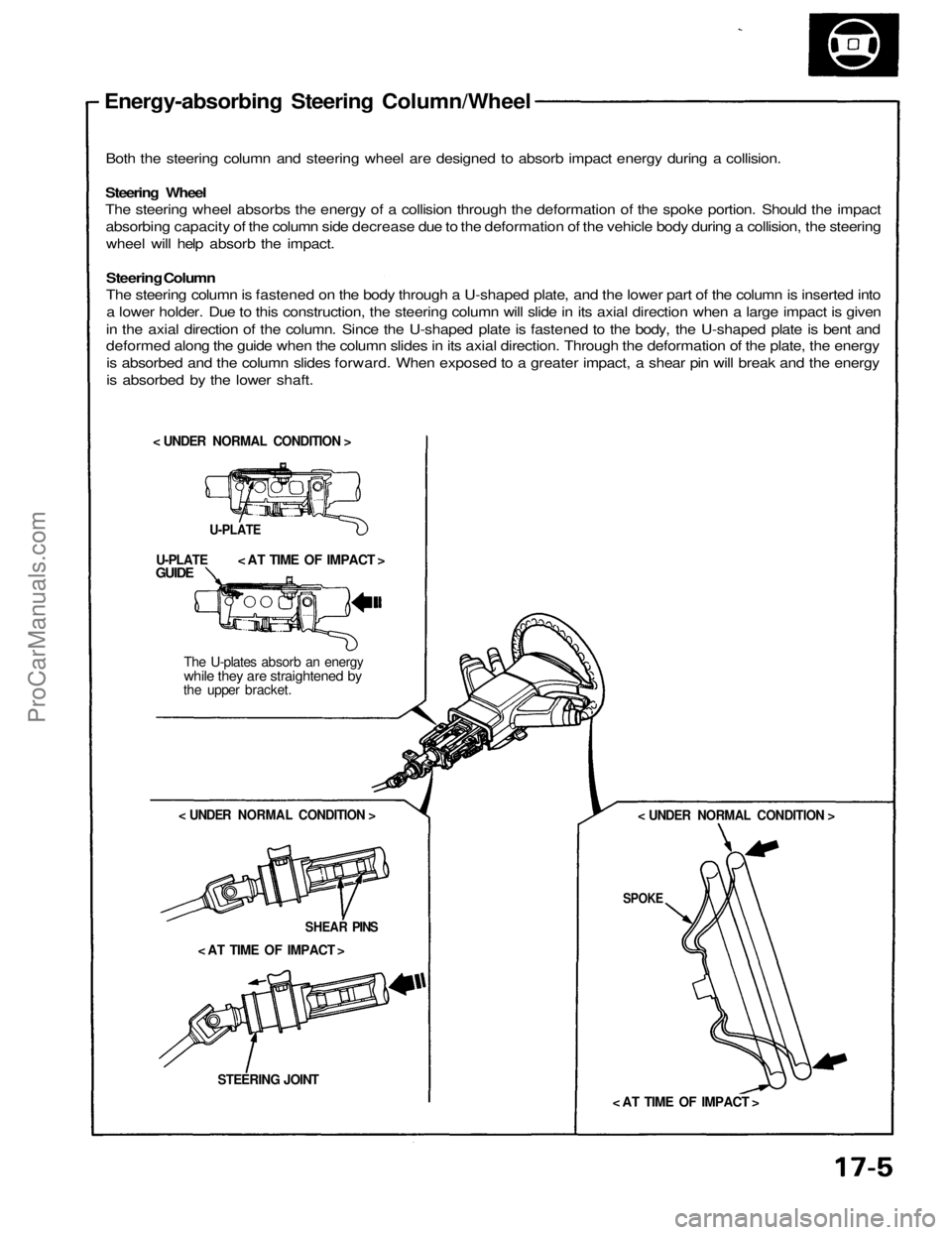

Energy-absorbing Steering Column/Wheel

Both the steering column and steering wheel are designed to absorb impact energy during a collision.

Steering Wheel

The steering wheel absorbs the energy of a collision through the deformation of the spoke portion. Should the impact

absorbing capacity of the column side decrease due to the deformation of the vehicle body during a collision, the steering

wheel will help absorb the impact.

Steering Column

The steering column is fastened on the body through a U-shaped plate, and the lower part of the column is inserted into

a lower holder. Due to this construction, the steering column will slide in its axial direction when a large impact is given

in the axial direction of the column. Since the U-shaped plate is fastened to the body, the U-shaped plate is bent and

deformed along the guide when the column slides in its axial direction. Through the deformation of the plate, the energy

is absorbed and the column slides forward. When exposed to a greater impact, a shear pin will break and the energy

is absorbed by the lower shaft.

< UNDER NORMAL CONDITION >

U-PLATE

< AT TIME OF IMPACT >

U-PLATE

GUIDE

The U-plates absorb an energy

while they are straightened by

the upper bracket.

< UNDER NORMAL CONDITION >

SHEAR PINS

< AT TIME OF IMPACT >

STEERING JOINT

< UNDER NORMAL CONDITION >

SPOKE

< AT TIME OF IMPACT >ProCarManuals.com

Page 1298 of 1640

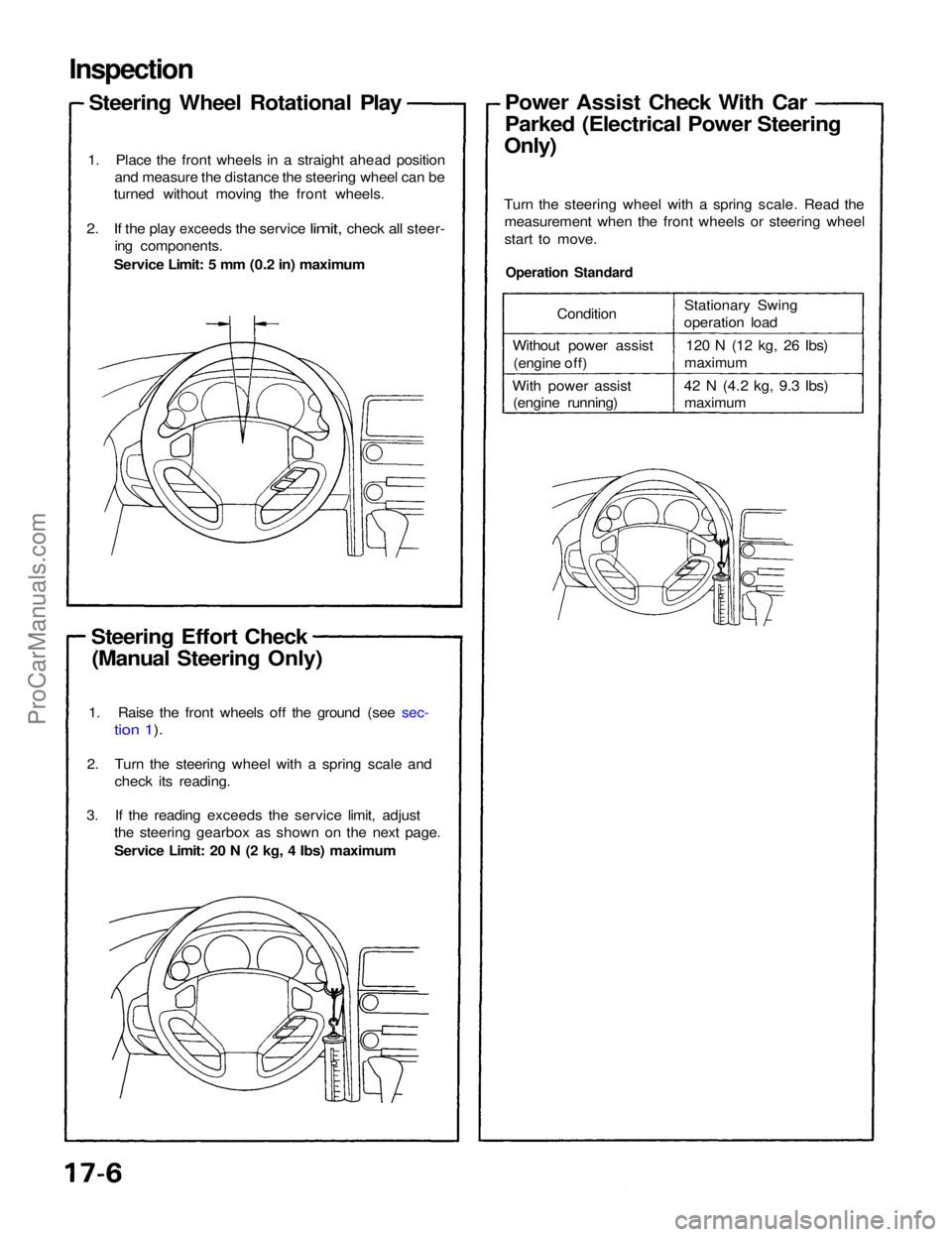

Inspection

Steering Wheel Rotational Play

1. Place the front wheels in a straight ahead position and measure the distance the steering wheel can be

turned without moving the front wheels.

2. If the

play

exceeds

the

service

limit,

check

all

steer- ing components.

Service Limit: 5 mm (0.2 in) maximum

Steering Effort Check (Manual Steering Only)

Operation Standard

Turn the steering wheel with a spring scale. Read the

measurement when the front wheels or steering wheel

start to move.Power Assist Check With Car

Parked (Electrical Power Steering

Only)

1. Raise the front wheels off the ground (see sec-

tion 1).

2. Turn the steering wheel with a spring scale and check its reading.

3. If the reading exceeds the service limit, adjust the steering gearbox as shown on the next page.

Service Limit: 20 N (2 kg, 4 Ibs) maximum Condition

Without power assist (engine off)

With power assist (engine running) Stationary Swing

operation load

120 N (12 kg, 26

Ibs)

maximum

42 N

(4.2

kg, 9.3

Ibs) maximumProCarManuals.com

Page 1299 of 1640

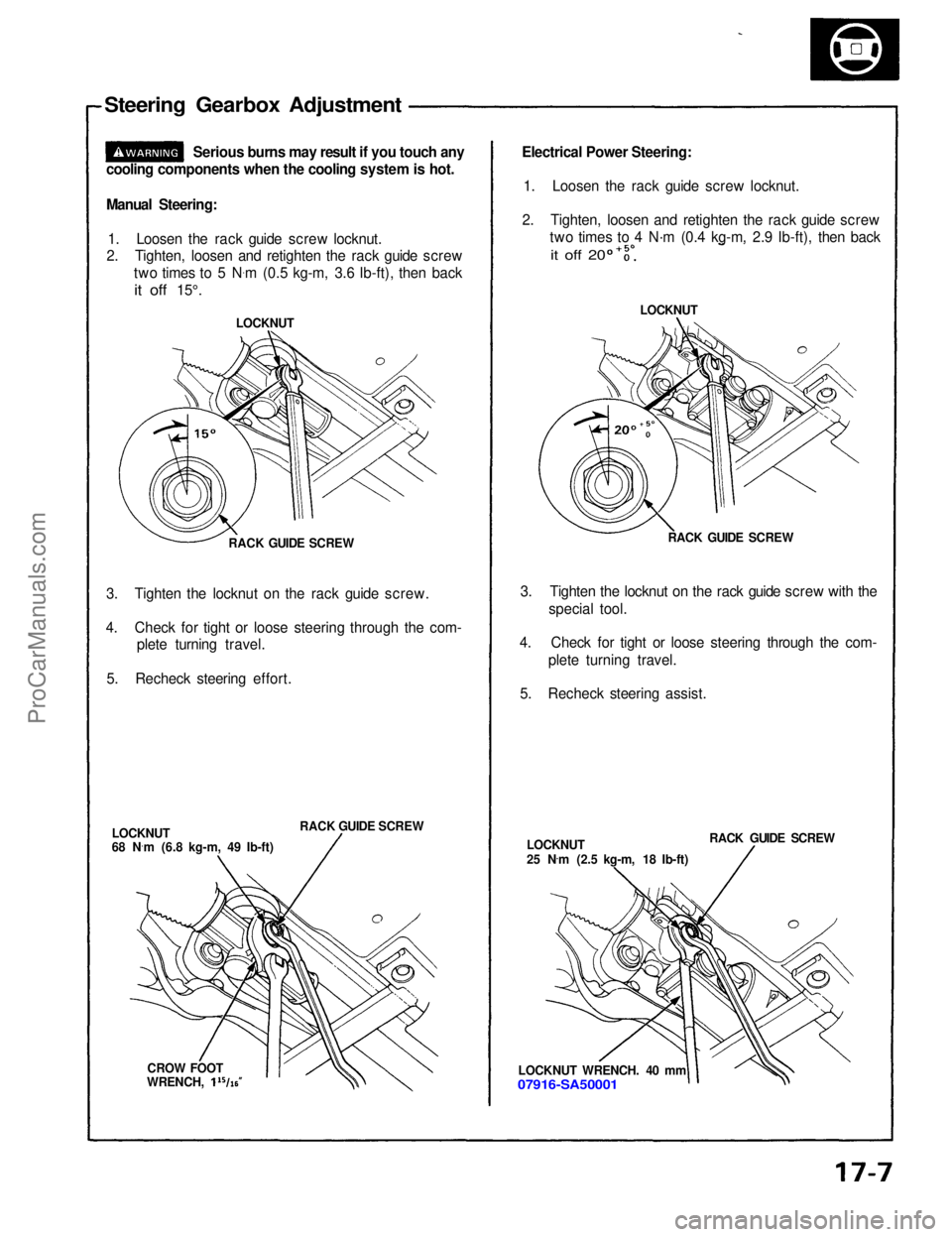

Steering Gearbox Adjustment

Serious burns may result if you touch any

cooling components when the cooling system is hot.

Manual Steering:

1. Loosen the rack guide screw locknut.

2. Tighten, loosen and retighten the rack guide screw

two times to 5 N .

m (0.5 kg-m, 3.6 Ib-ft), then back

it off

15°.

RACK GUIDE SCREW

3. Tighten the locknut on the rack guide screw.

4. Check for tight or loose steering through the com- plete turning travel.

5. Recheck steering effort.

RACK GUIDE SCREW

LOCKNUT

68 N ·

m (6.8 kg-m, 49 Ib-ft)

CROW FOOT LOCKNUT

Electrical Power Steering:

1. Loosen the rack guide screw locknut.

2. Tighten, loosen and retighten the rack guide screw two times to 4 N·m (0.4 kg-m, 2.9 Ib-ft), then back

LOCKNUT

RACK GUIDE SCREW

3. Tighten the locknut on the rack guide screw with the special tool.

4. Check for tight or loose steering through the com- plete turning travel.

5. Recheck steering assist.

LOCKNUT

25 N .

m (2.5 kg-m, 18 Ib-ft) RACK GUIDE SCREW

LOCKNUT WRENCH. 40 mm

07916-SA50001

it off 20

WRENCH,ProCarManuals.com

Page 1300 of 1640

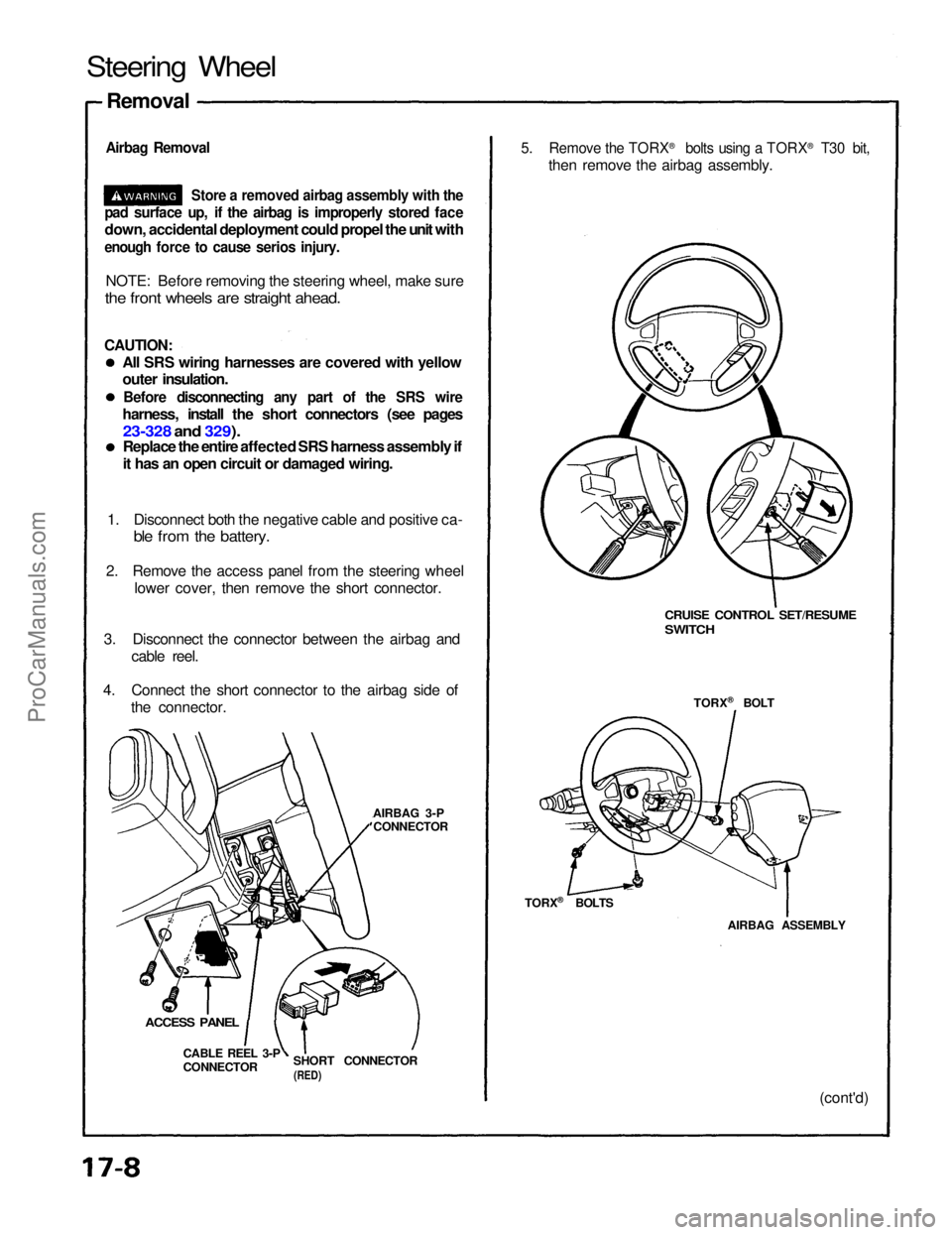

Steering Wheel

Removal

Airbag Removal

Store a removed airbag assembly with the

pad surface up, if the airbag is improperly stored face

down, accidental deployment could propel the unit with

enough force to cause serios injury.

NOTE: Before removing the steering wheel, make sure

the front wheels are straight ahead.

CAUTION:

All SRS wiring harnesses are covered with yellow

outer insulation.

Before disconnecting any part of the SRS wire

harness, install the short connectors (see pages

23-328 and 329).

Replace the entire affected SRS harness assembly if

it has an open circuit or damaged wiring.

1. Disconnect both the negative cable and positive ca-

ble from the battery.

2. Remove the access panel from the steering wheel lower cover, then remove the short connector.

3. Disconnect the connector between the airbag and cable reel.

4. Connect the short connector to the airbag side of the connector.

AIRBAG 3-PCONNECTOR

SHORT CONNECTOR

(RED)

CABLE REEL 3-P

CONNECTOR

ACCESS PANEL

CRUISE CONTROL SET/RESUME

SWITCH

TORX ®

BOLT

AIRBAG ASSEMBLY (cont'd)

5. Remove the TORX

®

bolts using a TORX ®

T30 bit,

then remove the airbag assembly.

TORX ®

BOLTSProCarManuals.com