ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1311 of 1640

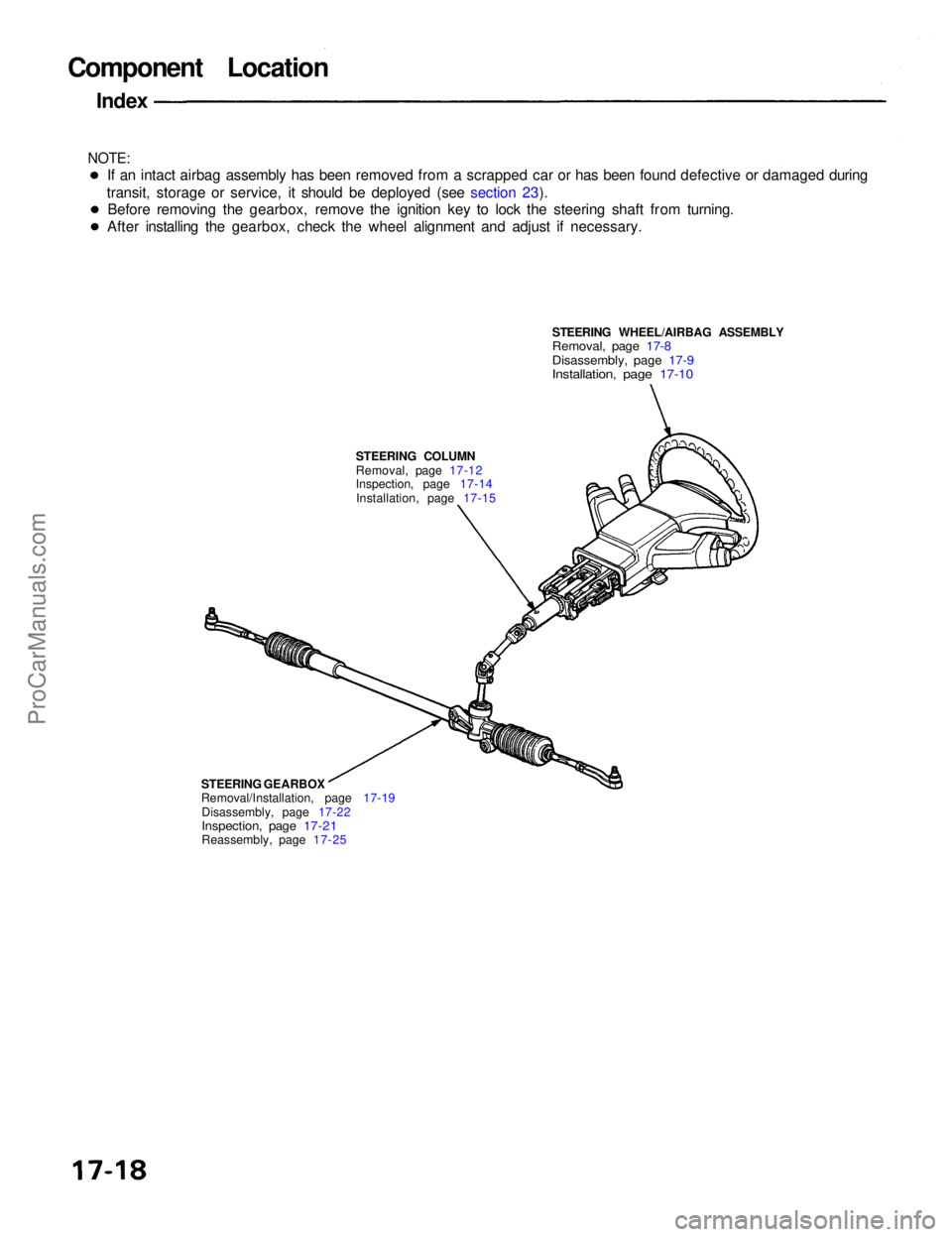

Component Location

Index

NOTE:

If an intact airbag assembly has been removed from a scrapped car or has been found defective or damaged during

transit, storage or service, it should be deployed (see section 23). Before removing the gearbox, remove the ignition key to lock the steering shaft from turning.

After installing the gearbox, check the wheel alignment and adjust if necessary.

STEERING WHEEL/AIRBAG ASSEMBLY

Removal, page 17-8

Disassembly, page 17-9

Installation, page 17-10

STEERING COLUMN

Removal, page 17-12

Inspection, page 17-14 Installation, page 17-15

STEERING GEARBOX

Removal/Installation, page 17-19 Disassembly, page 17-22

Inspection, page 17-21

Reassembly, page 17-25ProCarManuals.com

Page 1312 of 1640

Manual Steering

Gearbox Removal/Installation

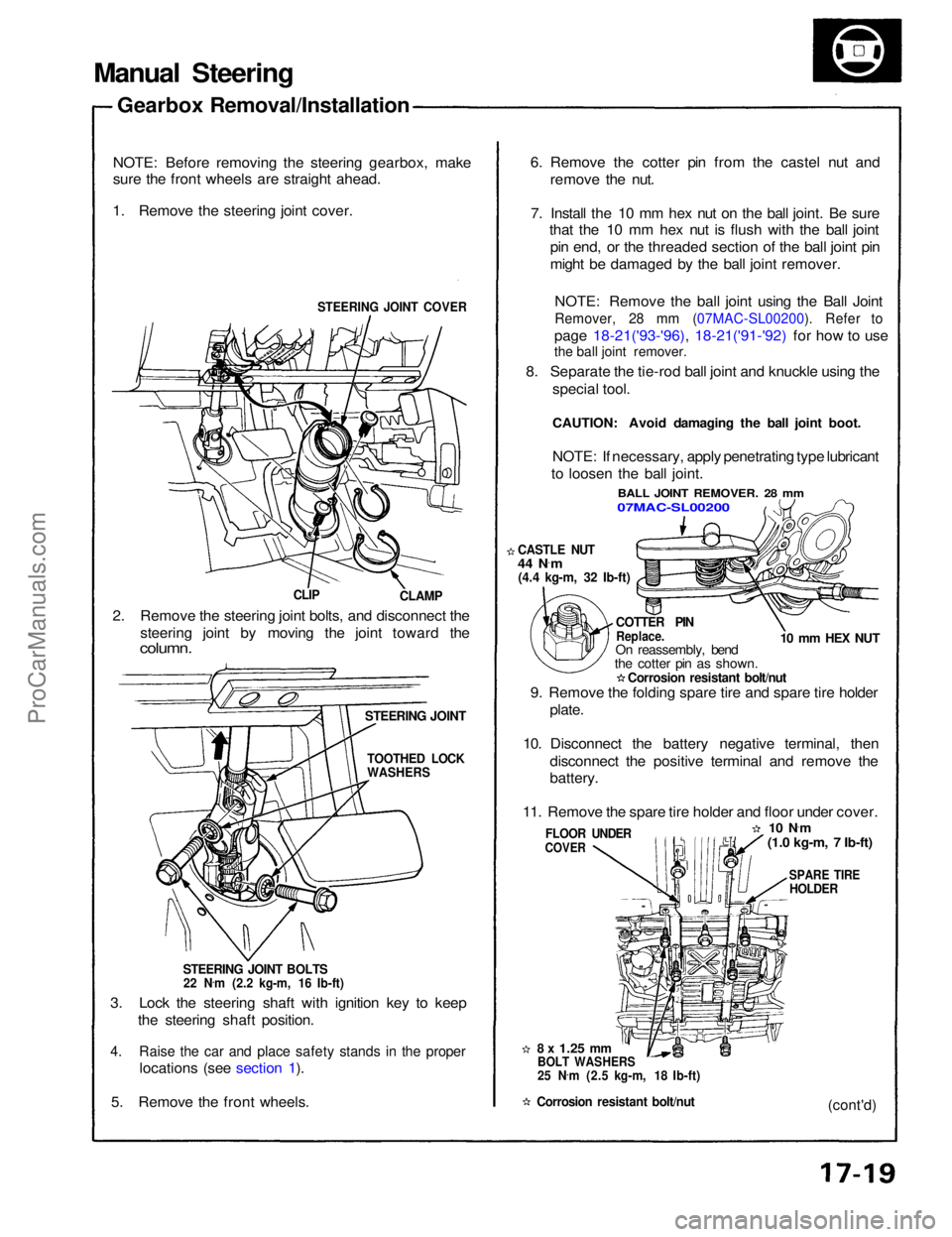

NOTE: Before removing the steering gearbox, make

sure the front wheels are straight ahead.

1. Remove the steering joint cover.

STEERING JOINT COVER

CLAMP

CLIP

2. Remove the steering joint bolts, and disconnect the steering joint by moving the joint toward the

column.

STEERING JOINT

STEERING JOINT BOLTS

22 N .

m (2.2 kg-m, 16 Ib-ft)

3. Lock the steering shaft with ignition key to keep the steering shaft position.

4. Raise the car and place safety stands in the proper

locations (see section 1).

5. Remove the front wheels.

8 x

1.25

mm

BOLT WASHERS

25 N .

m (2.5 kg-m, 18 Ib-ft)

Corrosion resistant bolt/nut

FLOOR UNDER

COVER

9. Remove the folding spare tire and spare tire holder

plate.

10. Disconnect the battery negative terminal, then disconnect the positive terminal and remove the

battery.

11. Remove the spare tire holder and floor under cover.

10 N·

m

(1.0 kg-m, 7 Ib-ft)

SPARE TIRE

HOLDER

(cont'd)

COTTER PIN

Replace.

On reassembly, bend

the cotter pin as shown.

Corrosion resistant bolt/nut

CASTLE NUT

44 N

·

m

(4.4 kg-m, 32 Ib-ft)

10 mm HEX NUT

NOTE: If necessary, apply penetrating type lubricant

to loosen the ball joint.

BALL JOINT REMOVER. 28 mm

07MAC-SL00200

6. Remove the cotter pin from the castel nut and

remove the nut.

7. Install the 10 mm hex nut on the ball joint. Be sure that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm (07MAC-SL00200). Refer to

page 18-21('93-'96), 18-21('91-'92) for how to use

8. Separate the tie-rod ball joint and knuckle using the special tool.

CAUTION: Avoid damaging the ball joint boot.

TOOTHED LOCK

WASHERSProCarManuals.com

Page 1313 of 1640

Manual Steering

Gearbox Removal/Installation (Cont'd)

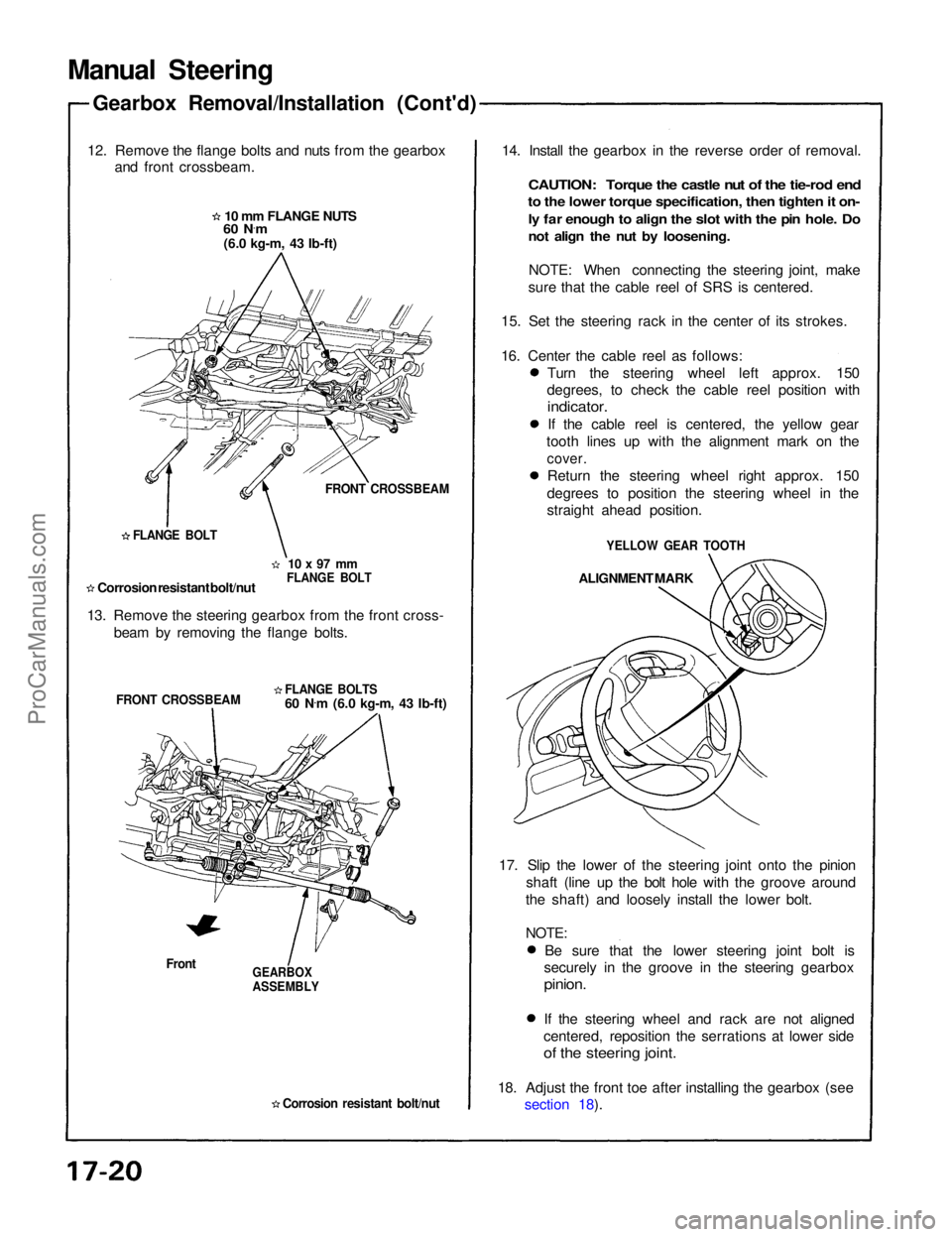

12. Remove the flange bolts and nuts from the gearbox and front crossbeam.

10 mm FLANGE NUTS

60 N ·

m

(6.0 kg-m, 43 Ib-ft)

FRONT CROSSBEAM

10 x 97 mm

FLANGE BOLT

FLANGE BOLT

Corrosion resistant bolt/nut

13. Remove the steering gearbox from the front cross- beam by removing the flange bolts.

FLANGE BOLTS

60 N.

m (6.0 kg-m, 43 Ib-ft)

FRONT CROSSBEAM

Front

GEARBOX

ASSEMBLY

Corrosion resistant bolt/nut

14. Install the gearbox in the reverse order of removal.

CAUTION: Torque the castle nut of the tie-rod end

to the lower torque specification, then tighten it on-

ly far enough to align the slot with the pin hole. Do

not align the nut by loosening.

NOTE: When connecting the steering joint, make

sure that the cable reel of SRS is centered.

15. Set the steering rack in the center of its strokes.

16. Center the cable reel as follows: Turn the steering wheel left approx. 150

degrees, to check the cable reel position with

indicator.

If the cable reel is centered, the yellow gear

tooth lines up with the alignment mark on the

cover.

Return the steering wheel right approx. 150

degrees to position the steering wheel in the

straight ahead position.

YELLOW GEAR TOOTH

ALIGNMENT MARK

17. Slip the lower of the steering joint onto the pinion shaft (line up the bolt hole with the groove around

the shaft) and loosely install the lower bolt.

NOTE:

Be sure that the lower steering joint bolt is

securely in the groove in the steering gearbox

pinion.

If the steering wheel and rack are not aligned

centered, reposition the serrations at lower side

of the steering joint.

18. Adjust the front toe after installing the gearbox (see section 18).ProCarManuals.com

Page 1314 of 1640

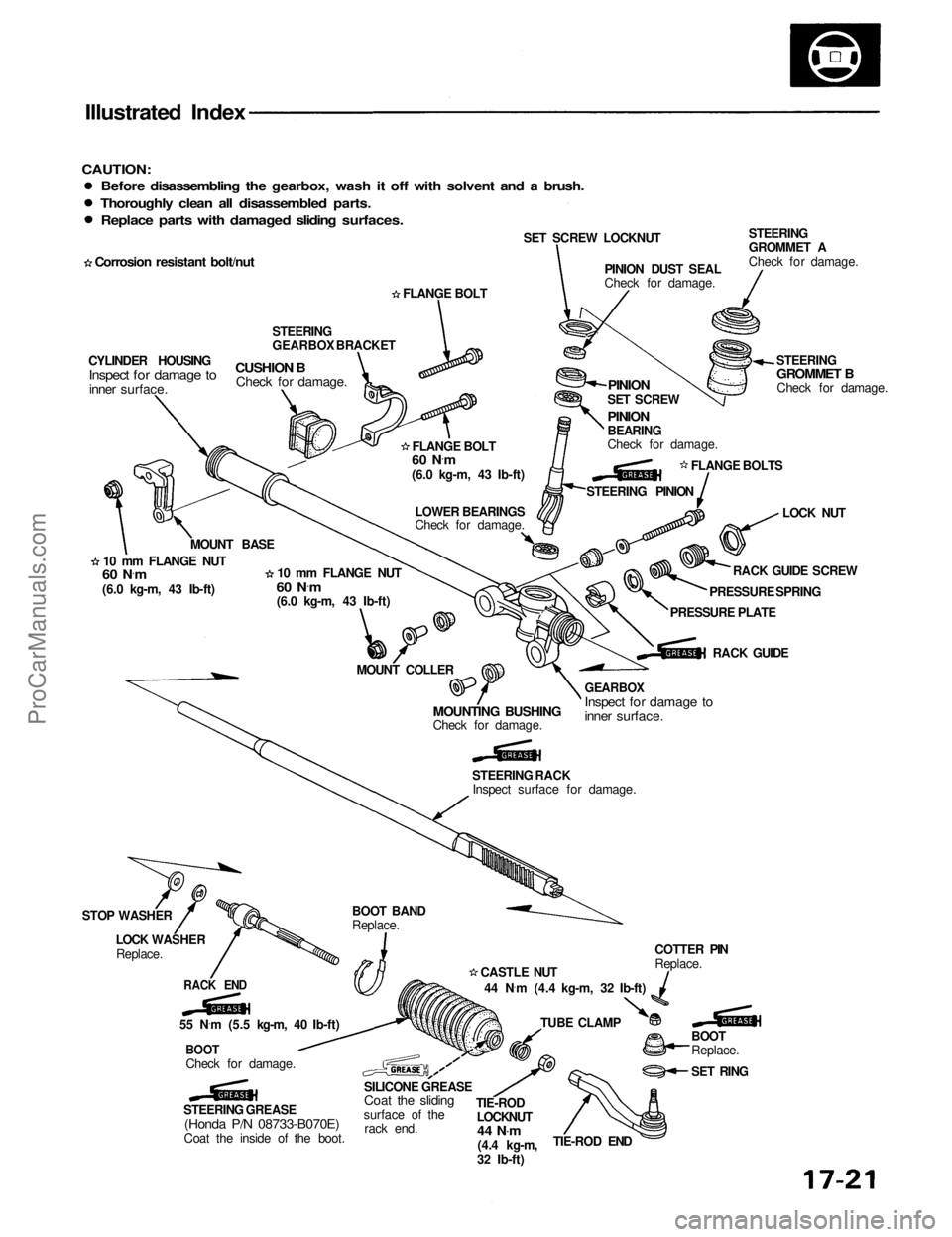

Illustrated Index

CAUTION:

Before disassembling the gearbox, wash it off with solvent and a brush.

Thoroughly clean all disassembled parts.

Replace parts with damaged sliding surfaces.

SET SCREW LOCKNUT

FLANGE BOLT PINION DUST SEAL

Check for damage.STEERING

GROMMET A

Check for damage.

STEERING

GROMMET B

Check for damage.

PINION

SET SCREW

PINION

BEARING

Check for damage.

FLANGE BOLTS

Corrosion resistant bolt/nut

CYLINDER HOUSING

Inspect for damage to

inner surface.

STEERING

GEARBOX BRACKET

CUSHION B

Check for damage.

FLANGE BOLT

60 N ·

m

(6.0 kg-m, 43 Ib-ft)

10 mm FLANGE NUT

60 N ·

m

(6.0 kg-m, 43 Ib-ft) MOUNT BASE

10 mm FLANGE NUT

60 N ·

m

(6.0 kg-m, 43 Ib-ft) LOWER BEARINGS

Check for damage.

STEERING PINION

LOCK NUT

RACK GUIDE SCREW

PRESSURE SPRING

PRESSURE PLATE

RACK GUIDE

GEARBOX

Inspect for damage to

inner surface.

MOUNT COLLER

MOUNTING BUSHING

Check for damage.

STEERING RACKInspect surface for damage.

BOOT BAND

Replace.

STOP WASHER

LOCK WASHERReplace.

RACK END

55 N ·

m (5.5 kg-m, 40 Ib-ft)

BOOT

Check for damage.

STEERING GREASE

(Honda P/N 08733-B070E)

Coat the inside of the boot. SILICONE GREASE

Coat the sliding

surface of the rack end. TIE-ROD

LOCKNUT

44 N .

m

(4.4 kg-m,

32 Ib-ft) TIE-ROD END BOOT

Replace.

SET RING

TUBE CLAMP COTTER PIN

Replace.

CASTLE NUT

44 N ·

m (4.4 kg-m, 32 Ib-ft)ProCarManuals.com

Page 1315 of 1640

Manual Steering

Overhaul

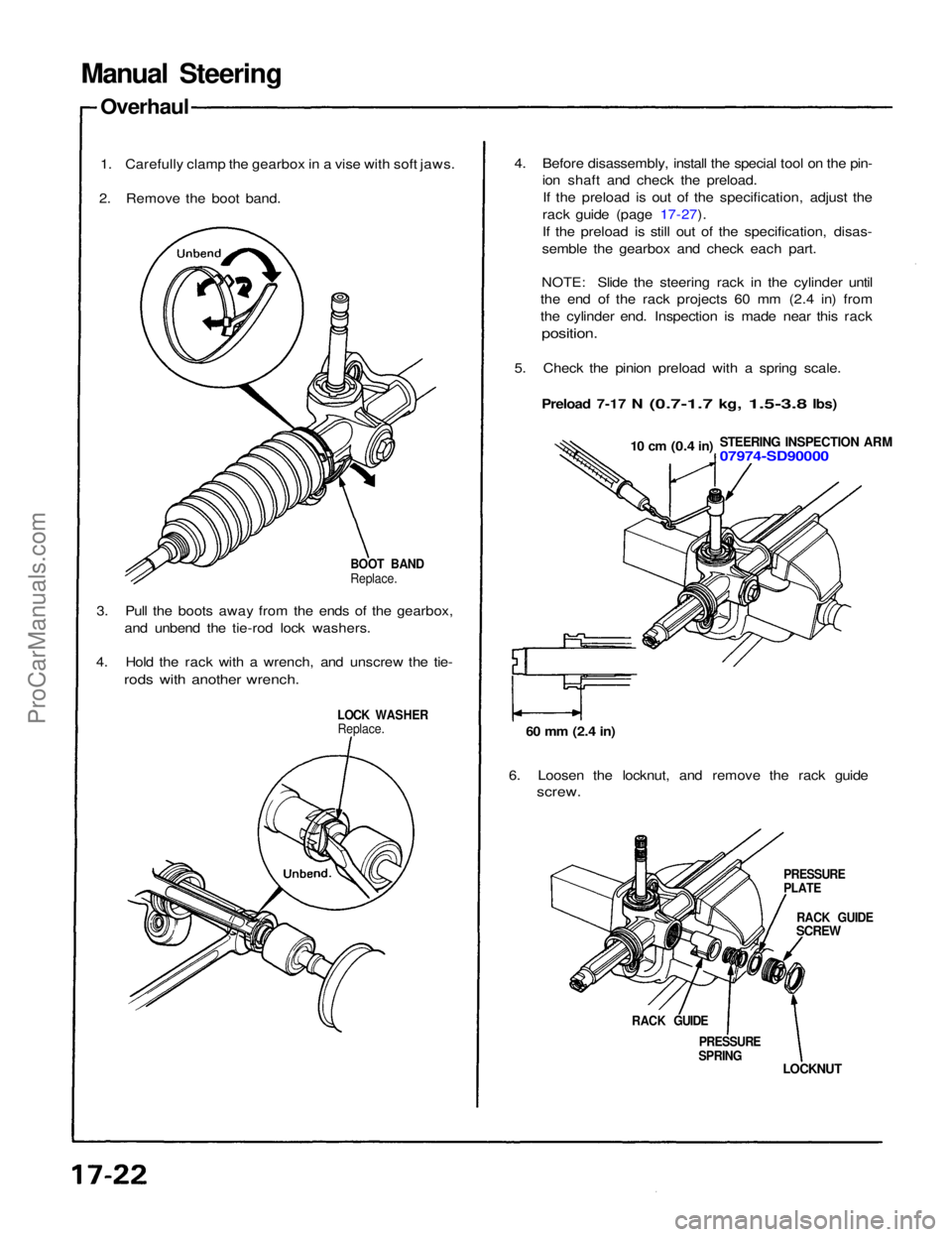

1. Carefully clamp the gearbox in a vise with soft jaws.

2. Remove the boot band.

BOOT BAND

Replace.

3. Pull the boots away from the ends of the gearbox, and unbend the tie-rod lock washers.

4. Hold the rack with a wrench, and unscrew the tie-

rods with another wrench.

LOCK WASHERReplace.

4. Before disassembly, install the special tool on the pin-

ion shaft and check the preload.

If the preload is out of the specification, adjust the

rack guide (page 17-27).

If the preload is still out of the specification, disas-

semble the gearbox and check each part.

NOTE: Slide the steering rack in the cylinder until

the end of the rack projects 60 mm (2.4 in) from

the cylinder end. Inspection is made near this rack

position.

5. Check the pinion preload with a spring scale.

Preload 7-17

N

(0.7-1.7

kg,

1.5-3.8

Ibs)

10 cm

(0.4

in)

STEERING INSPECTION ARM

07974-SD90000

PRESSURE

PLATERACK GUIDE

SCREW

LOCKNUT

PRESSURE

SPRING

RACK GUIDE

60 mm

(2.4

in)

6. Loosen the locknut, and remove the rack guide

screw.ProCarManuals.com

Page 1316 of 1640

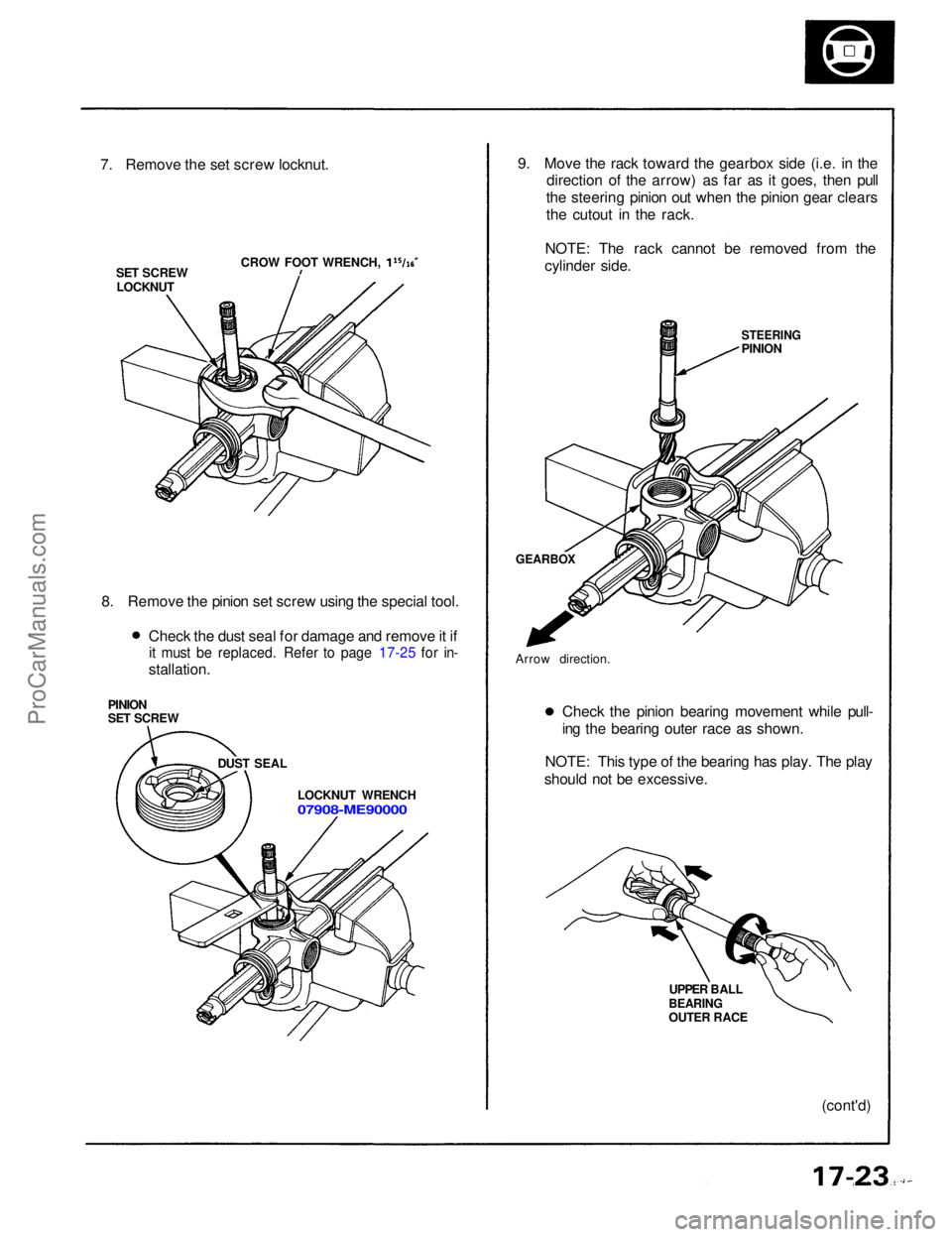

7. Remove the set screw locknut.

CROW FOOT WRENCH,

SET SCREW

LOCKNUT

8. Remove the pinion set screw using the special tool. Check the dust seal for damage and remove it if

it must be replaced. Refer to page 17-25 for in-

stallation.

PINION

SET SCREW

LOCKNUT WRENCH

07908-ME90000

9. Move the rack toward the gearbox side (i.e. in the

direction of the arrow) as far as it goes, then pull

the steering pinion out when the pinion gear clears

the cutout in the rack.

NOTE: The rack cannot be removed from the

cylinder side.

STEERING

PINION

GEARBOX

Arrow direction. Check the pinion bearing movement while pull-

ing the bearing outer race as shown.

NOTE: This type of the bearing has play. The play

should not be excessive.

UPPER BALL

BEARING

OUTER RACE

(cont'd)

DUST SEALProCarManuals.com

Page 1317 of 1640

Manual Steering

Overhaul (Cont'd)

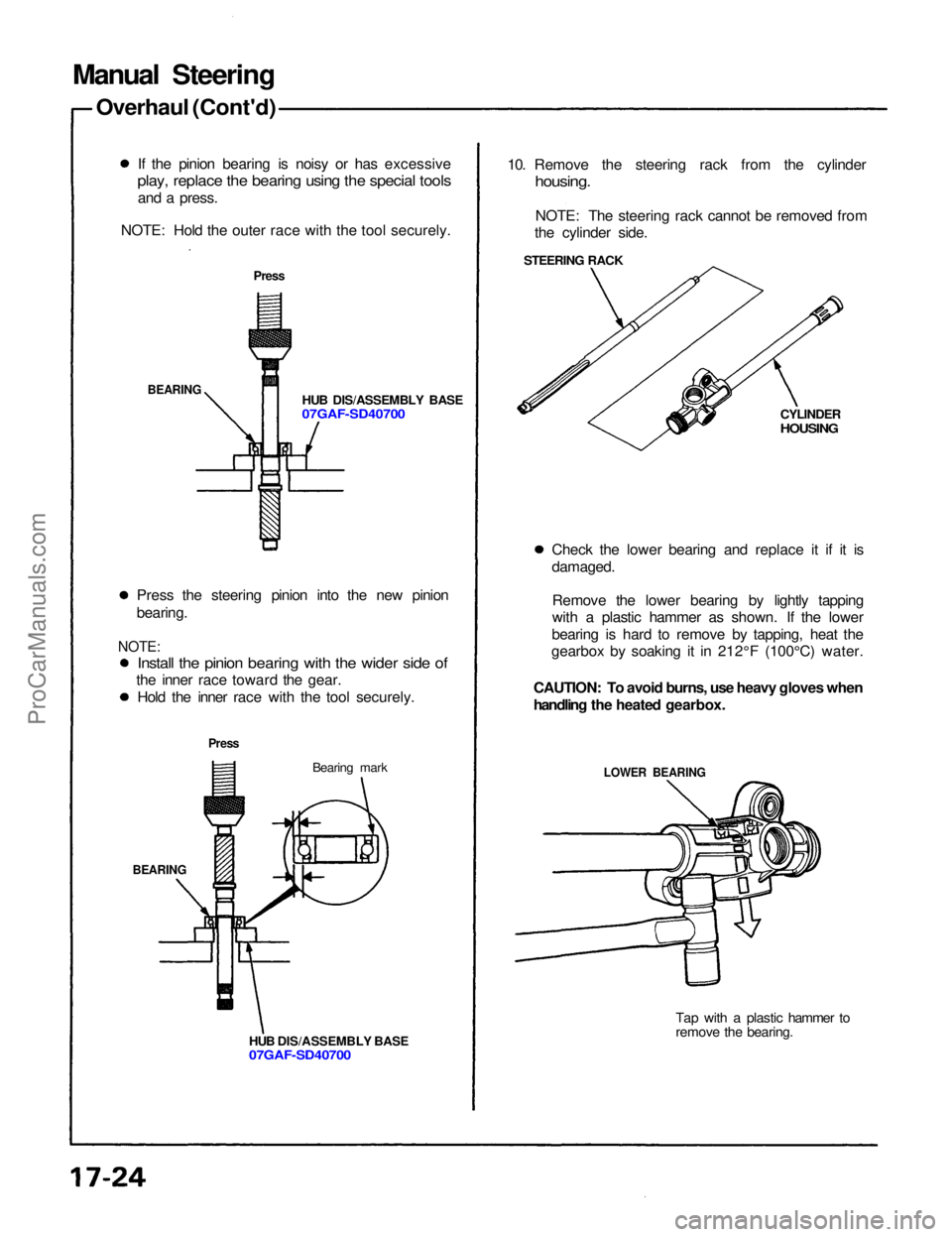

If the pinion bearing is noisy or has excessive

play, replace the bearing using the special tools

and a press.

NOTE: Hold the outer race with the tool securely.

Press

HUB DIS/ASSEMBLY BASE

07GAF-SD40700

BEARING

Press the steering pinion into the new pinion

bearing.

NOTE:

Install the pinion bearing with the wider side of

the inner race toward the gear.

Hold the inner race with the tool securely.

Press

Bearing mark

BEARING

HUB DIS/ASSEMBLY BASE

07GAF-SD40700

10. Remove the steering rack from the cylinder

housing.

NOTE: The steering rack cannot be removed from

the cylinder side.

STEERING RACK

CYLINDER

HOUSING

Check the lower bearing and replace it if it is

damaged. Remove the lower bearing by lightly tapping

with a plastic hammer as shown. If the lower

bearing is hard to remove by tapping, heat the

gearbox by soaking it in 212°F (100°C) water.

CAUTION: To avoid burns, use heavy gloves when

handling the heated gearbox.

LOWER BEARING

Tap with a plastic hammer to

remove the bearing.ProCarManuals.com

Page 1318 of 1640

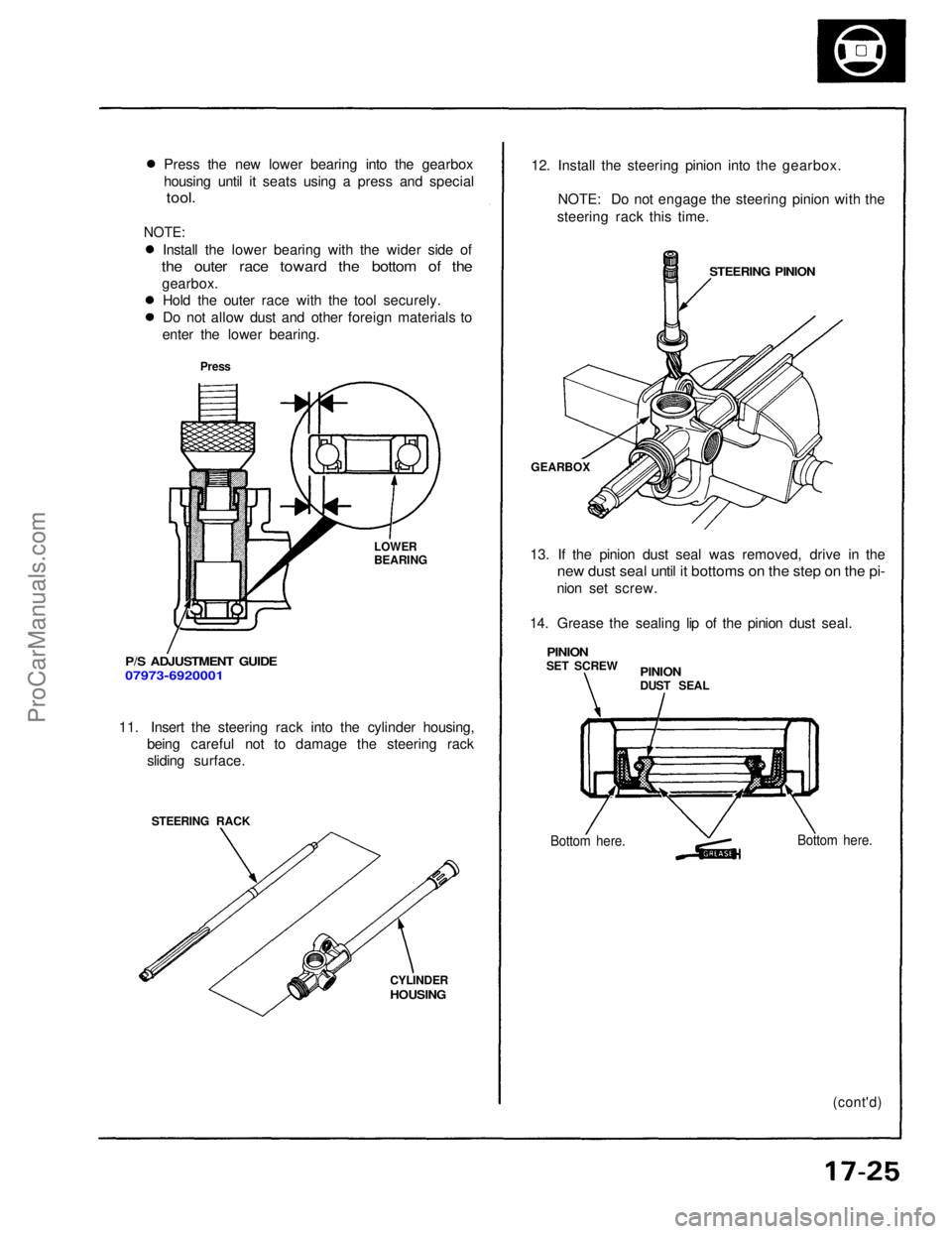

Press the new lower bearing into the gearbox

housing until it seats using a press and special

tool.

NOTE:

Install the lower bearing with the wider side of

the outer race toward the bottom of the

gearbox. Hold the outer race with the tool securely.

Do not allow dust and other foreign materials to

enter the lower bearing.

Press

LOWER

BEARING

P/S ADJUSTMENT GUIDE

07973-6920001

11. Insert the steering rack into the cylinder housing, being careful not to damage the steering rack

sliding surface.

STEERING RACK

CYLINDER

HOUSING

12. Install the steering pinion into the gearbox.

NOTE: Do not engage the steering pinion with the

steering rack this time.

STEERING PINION

GEARBOX

13. If the pinion dust seal was removed, drive in the

new dust seal until it bottoms on the step on the pi-

nion set screw.

14. Grease the sealing lip of the pinion dust seal.

PINION

SET SCREW

PINION

DUST SEAL

Bottom here.

Bottom here.

(cont'd)ProCarManuals.com

Page 1319 of 1640

Manual Steering

Overhaul (Cont'd)

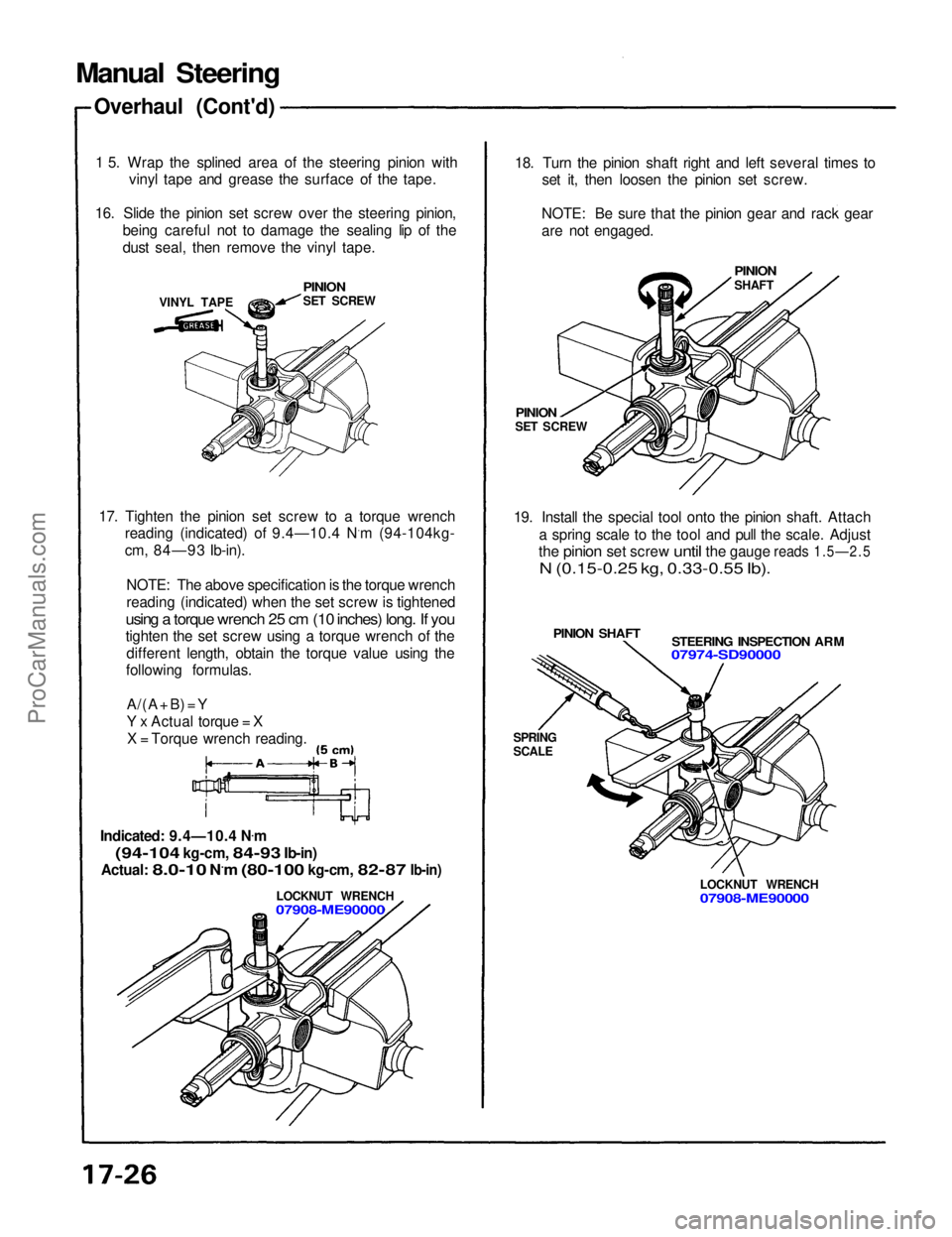

1 5. Wrap the splined area of the steering pinion with vinyl tape and grease the surface of the tape.

16. Slide the pinion set screw over the steering pinion, being careful not to damage the sealing lip of the

dust seal, then remove the vinyl tape.

PINION

SET SCREW

VINYL TAPE

17. Tighten the pinion set screw to a torque wrench reading (indicated) of 9.4—10.4 N.m (94-104kg-

cm, 84—93 Ib-in).

NOTE: The above specification is the torque wrench

reading (indicated) when the set screw is tightened

using a torque wrench 25 cm (10 inches) long. If you

tighten the set screw using a torque wrench of the different length, obtain the torque value using the

following formulas.

A/(A

+ B) = Y

Y x Actual torque = XX = Torque wrench reading.

Indicated: 9.4—10.4 N .

m

(94-104

kg-cm,

84-93

Ib-in)

Actual:

8.0-10

N.m

(80-100

kg-cm,

82-87

Ib-in)

LOCKNUT WRENCH

07908-ME90000

18. Turn the pinion shaft right and left several times to

set it, then loosen the pinion set screw.

NOTE: Be sure that the pinion gear and rack gear

are not engaged.

PINION

SHAFT

PINION

SET SCREW

19. Install the special tool onto the pinion shaft. Attach a spring scale to the tool and pull the scale. Adjust

the

pinion

set

screw

until

the

gauge

reads

1.5—2.5

N (0.15-0.25 kg, 0.33-0.55 Ib).

STEERING INSPECTION ARM

07974-SD90000

PINION SHAFT

SPRING

SCALE

LOCKNUT WRENCH

07908-ME90000ProCarManuals.com

Page 1320 of 1640

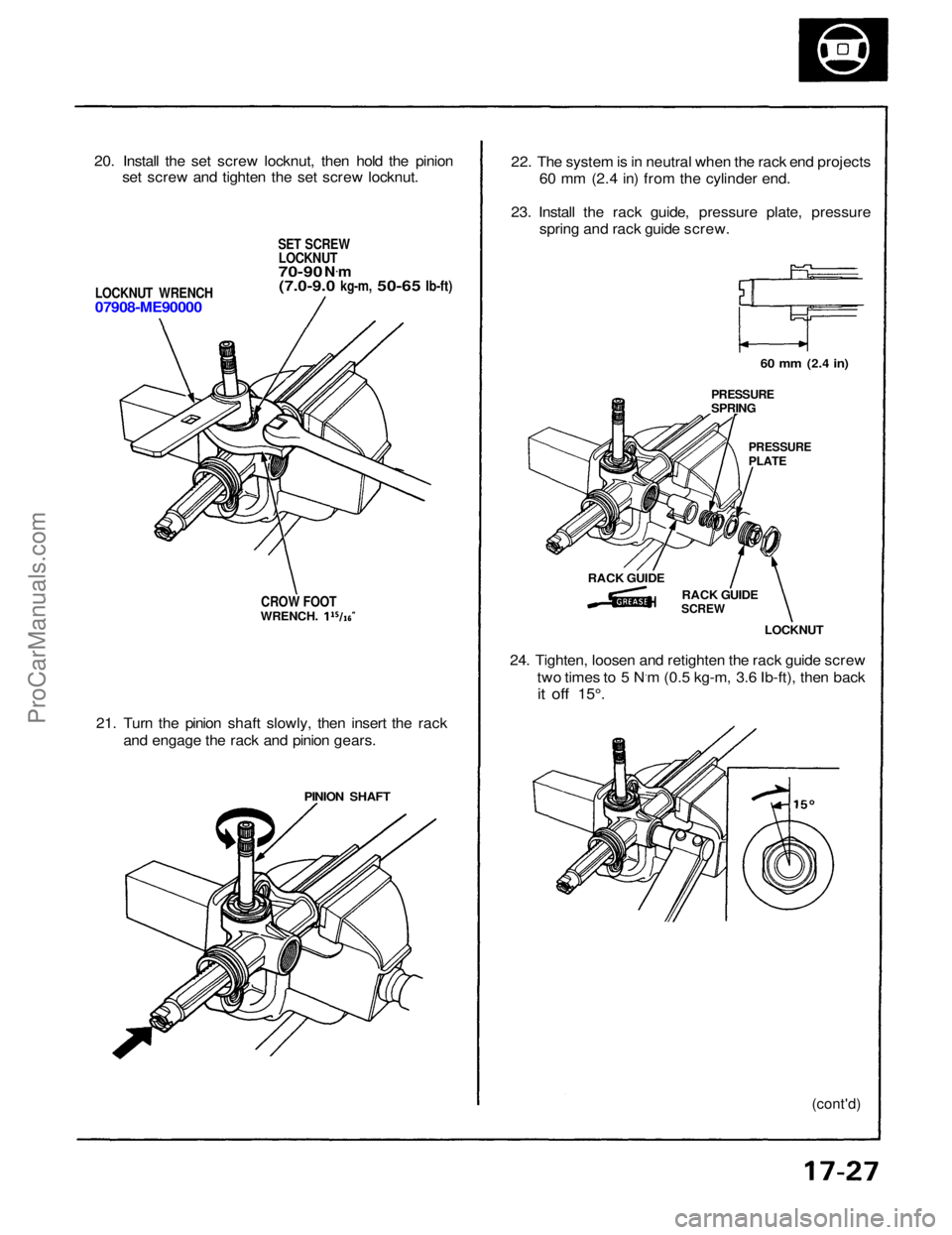

20. Install the set screw locknut, then hold the pinion

set screw and tighten the set screw locknut.

SET SCREW

LOCKNUT

70-90

N .

m

(7.0-9.0

kg-m,

50-65

Ib-ft)

LOCKNUT WRENCH

07908-ME90000

CROW FOOT

21. Turn the pinion shaft slowly, then insert the rack and engage the rack and pinion gears.

PINION SHAFT 22. The system is in neutral when the rack end projects

60 mm (2.4 in) from the cylinder end.

23. Install the rack guide, pressure plate, pressure spring and rack guide screw.

60 mm

(2.4

in)

PRESSURE

SPRING

PRESSURE

PLATE

RACK GUIDE

SCREW

LOCKNUT

24. Tighten, loosen and retighten the rack guide screw two times to 5 N ·

m (0.5 kg-m, 3.6 Ib-ft), then back

it off

15°. RACK GUIDE

(cont'd)

WRENCH.ProCarManuals.com