engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1200 of 1640

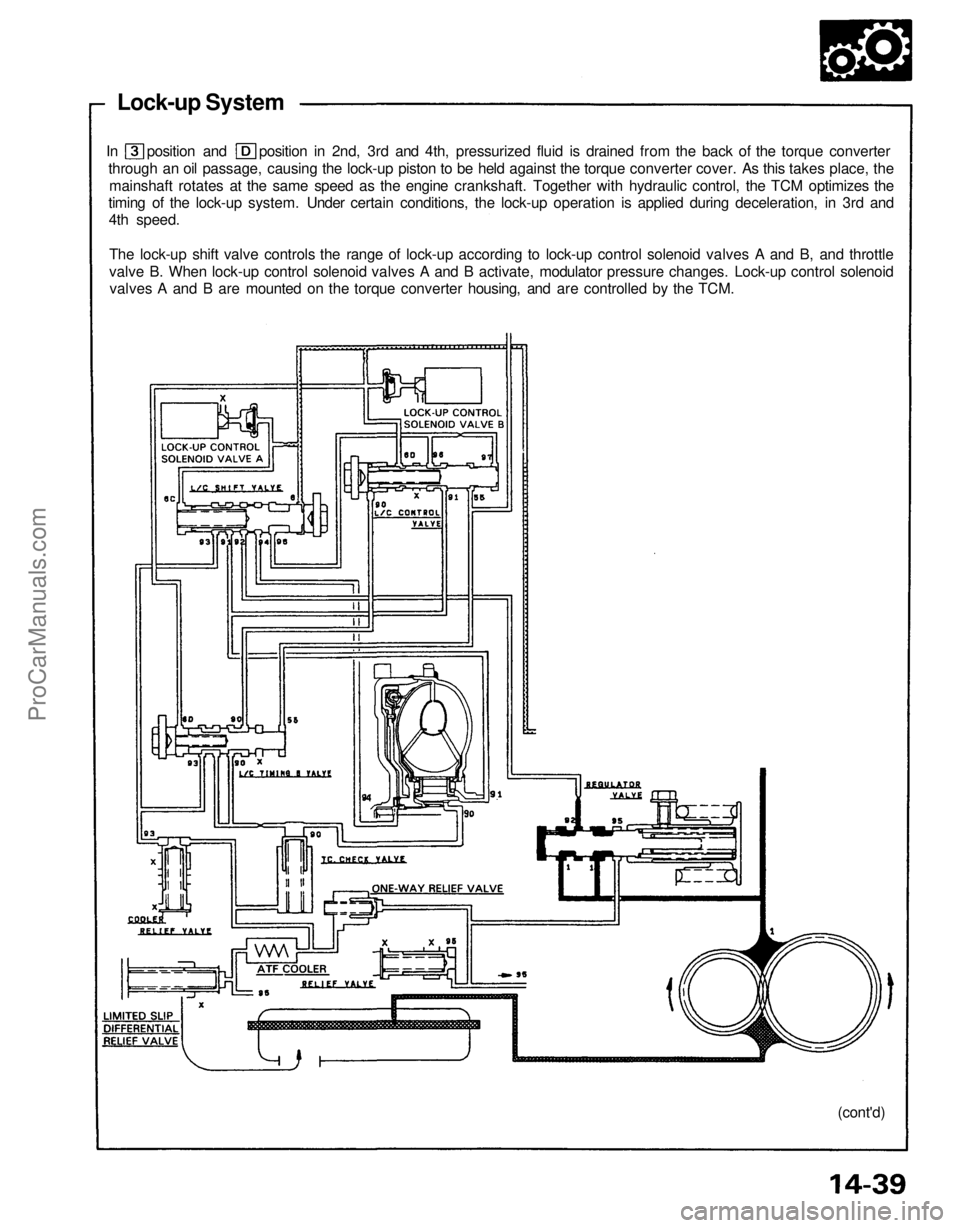

Lock-up System

In position and position in 2nd, 3rd and 4th, pressurized fluid is drained from the back of the torque converter

through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, themainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up system. Under certain conditions, the lock-up operation is applied during deceleration, in 3rd and 4th speed.

The lock-up shift valve controls the range of lock-up according to lock-up control solenoid valves A and B, and throttle

valve B. When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoidvalves A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 1206 of 1640

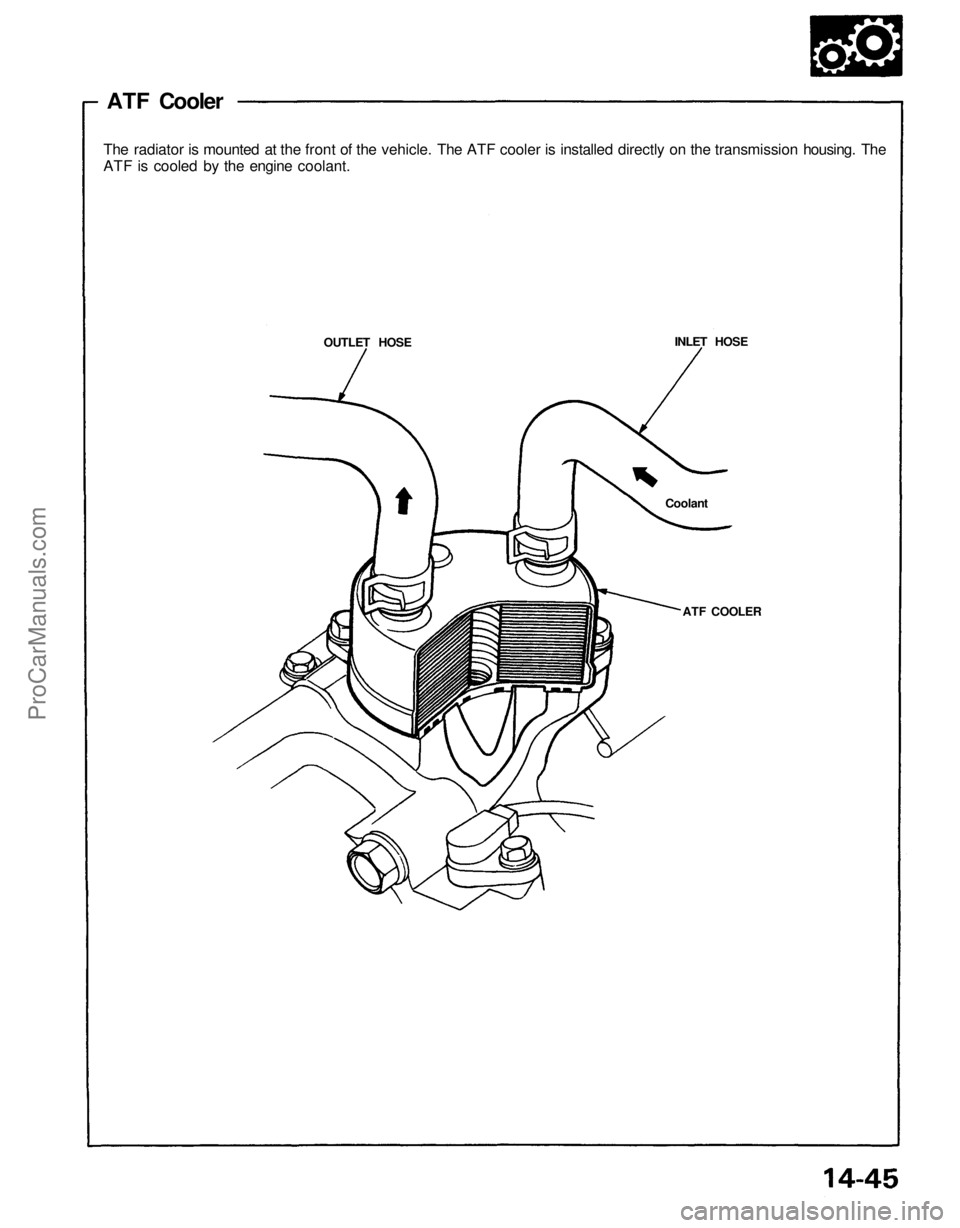

ATF Cooler

The radiator is mounted at the front of the vehicle. The ATF cooler is installed directly on the transmission housing. The

ATF is cooled by the engine coolant.

OUTLET HOSE

INLET HOSE

Coolant

ATF COOLERProCarManuals.com

Page 1207 of 1640

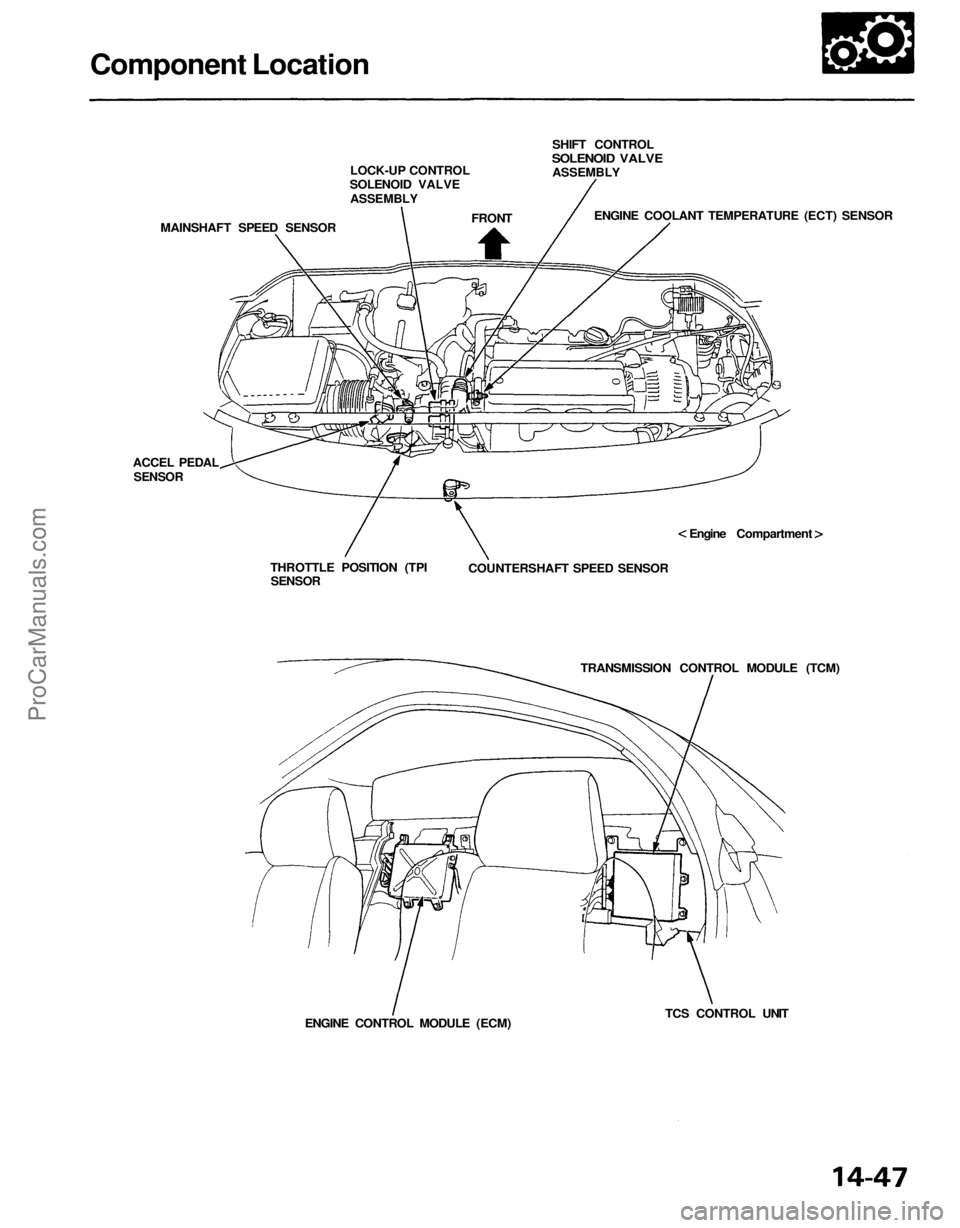

Component Location

LOCK-UP CONTROL

SOLENOID VALVE

ASSEMBLY

MAINSHAFT SPEED SENSOR

FRONT

SHIFT CONTROL

SOLENOID VALVE

ASSEMBLY

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Engine Compartment

COUNTERSHAFT SPEED SENSOR

TRANSMISSION CONTROL MODULE (TCM)

TCS CONTROL UNIT

ENGINE CONTROL MODULE (ECM)

THROTTLE POSITION (TPI

SENSOR

ACCEL PEDAL

SENSORProCarManuals.com

Page 1210 of 1640

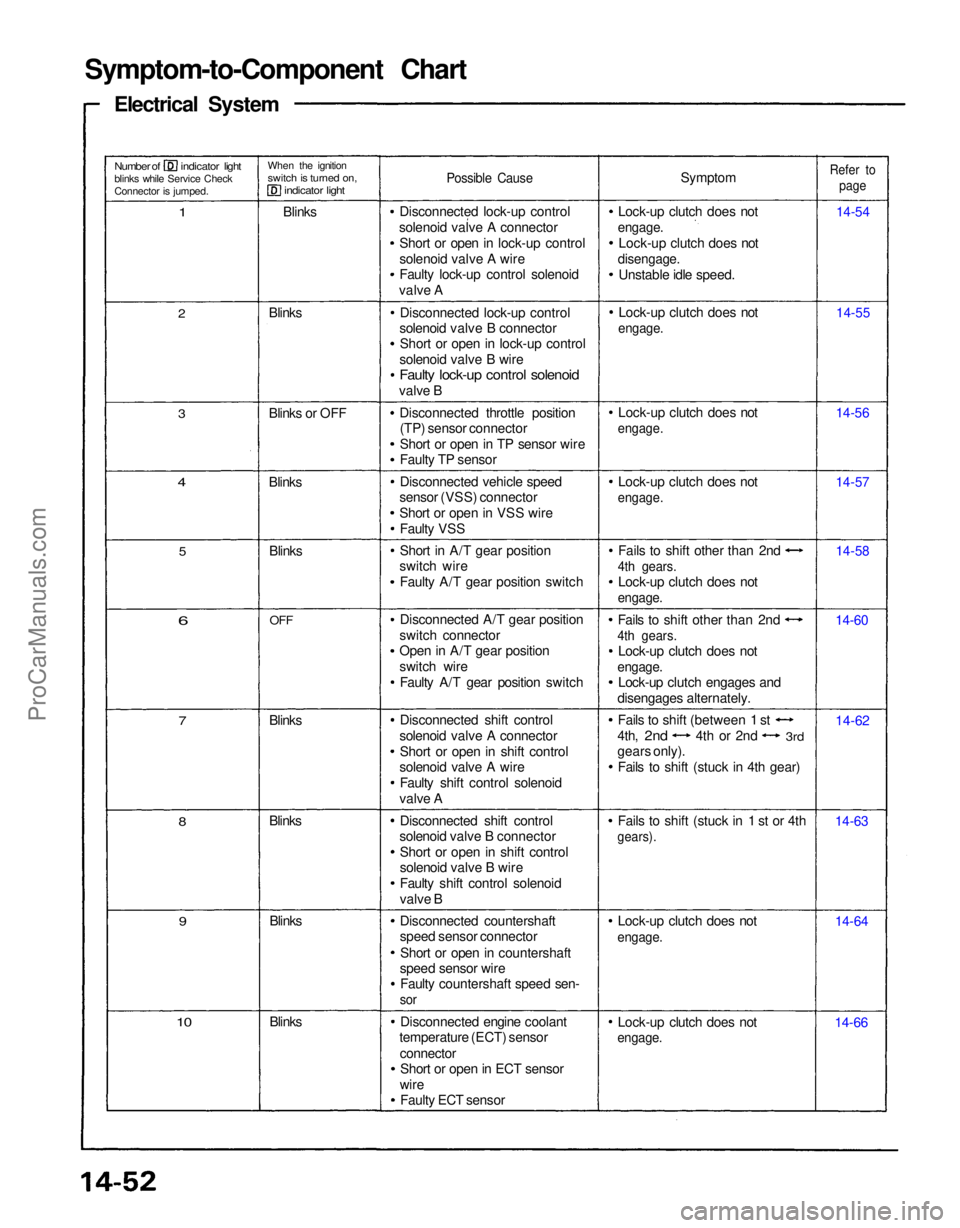

Symptom-to-Component Chart

Electrical System

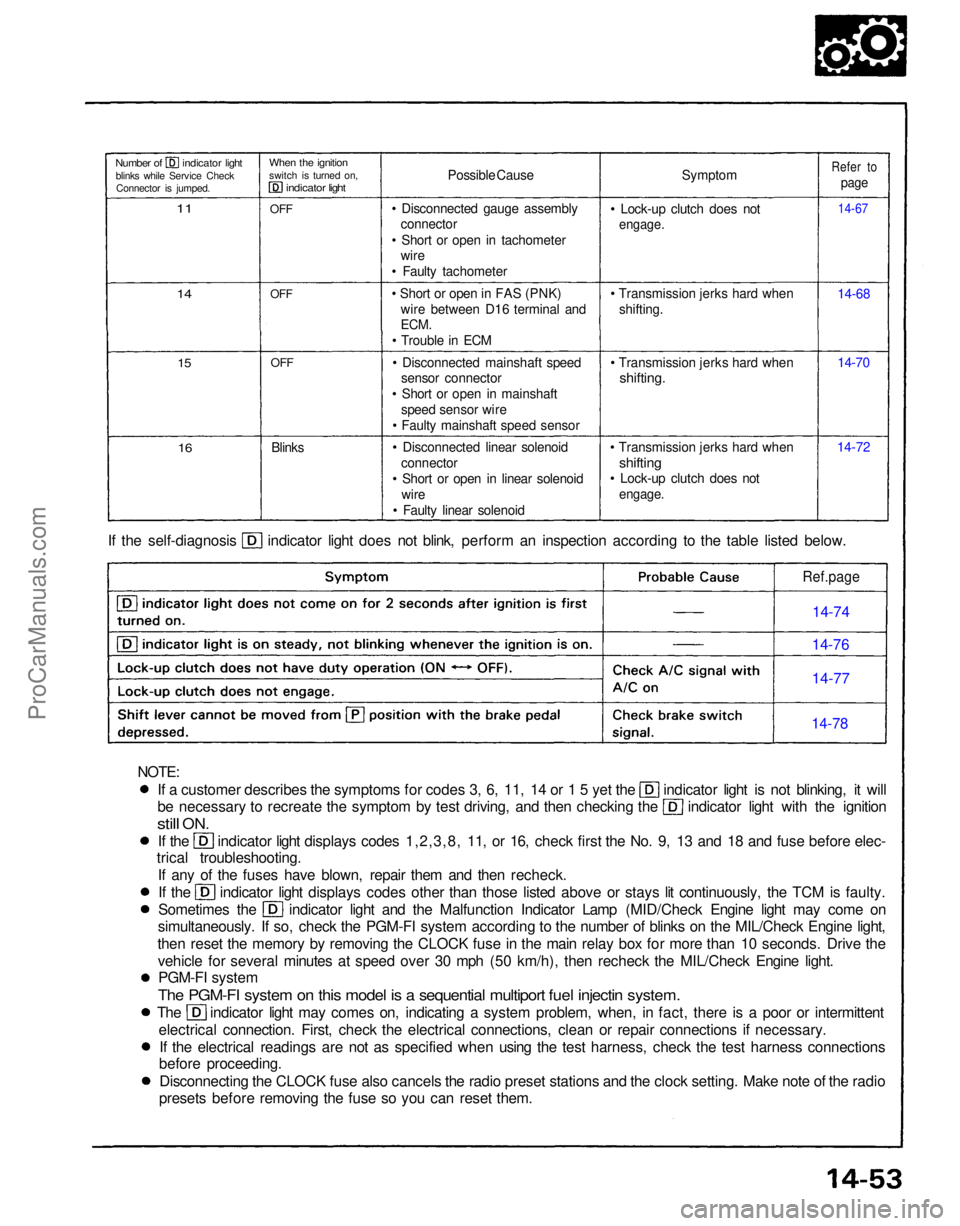

Number of indicator light

blinks while Service Check

Connector is jumped.

When the ignition

switch is turned on,

indicator light

1

Blinks

Possible Cause

Symptom

Lock-up clutch does not

engage.

Lock-up clutch does not

disengage.

Unstable idle speed.

Refer to

page

14-54

14-55

14-56

14-57

14-58

14-60

14-62

14-63

14-64

14-66

Lock-up clutch does not

engage.

Lock-up clutch does not

engage.

Fails to shift (stuck in 1 st or 4th

gears).

Fails to shift other than 2nd

4th gears.

Lock-up clutch does not

engage.

Lock-up clutch engages and

disengages alternately. Fails to shift other than 2nd

4th gears.

Lock-up clutch does not

engage.

Lock-up clutch does not

engage.

Lock-up clutch does not

engage.

Lock-up clutch does not

engage.

Disconnected lock-up control

solenoid valve A connector Short or open in lock-up control

solenoid valve A wire

Faulty lock-up control solenoid

valve A

Disconnected lock-up control

solenoid valve B connector Short or open in lock-up control

solenoid valve B wire

Faulty lock-up control solenoid

valve B

Disconnected throttle position(TP) sensor connector

Short or open in TP sensor wire

Faulty TP sensor

Disconnected vehicle speed

sensor (VSS) connector

Short or open in VSS wire

Faulty VSS

Short in A/T gear position

switch wire

Faulty A/T gear position switch

Disconnected A/T gear position

switch connector

Open in A/T gear position

switch wire Faulty A/T gear position switch

Disconnected shift control

solenoid valve A connector Short or open in shift control

solenoid valve A wire

Faulty shift control solenoid

valve A

Disconnected shift control

solenoid valve B connector

Short or open in shift control

solenoid valve B wire

Faulty shift control solenoid

valve B

Disconnected countershaft

speed sensor connector

Short or open in countershaft

speed sensor wire Faulty countershaft speed sen-

sor

Disconnected engine coolant

temperature (ECT) sensor

connectorShort or open in ECT sensor

wire Faulty ECT sensor

Blinks

10

9

Blinks

Blinks

8

7

Blinks

6

OFF

Blinks

5

4

Blinks

3

Blinks or OFF Blinks

2

Fails to shift (between 1 st

4th,

2nd

4th or 2nd

3rd

gears only).

Fails to shift (stuck in 4th gear)ProCarManuals.com

Page 1211 of 1640

If a customer describes the symptoms for codes 3, 6, 11, 14 or 1 5 yet the indicator light is not blinking, it will

be necessary to recreate the symptom by test driving, and then checking the indicator light with the ignition

still

ON.

If the indicator light displays codes 1,2,3,8, 11, or 16, check first the No. 9, 13 and 18 and fuse before elec-

trical troubleshooting.

If any of the fuses have blown, repair them and then recheck. If the indicator light displays codes other than those listed above or stays lit continuously, the TCM is faulty.

Sometimes the indicator light and the Malfunction Indicator Lamp (MID/Check Engine light may come on

simultaneously. If so, check the PGM-FI system according to the number of blinks on the MIL/Check Engine light,

then reset the memory by removing the CLOCK fuse in the main relay box for more than 10 seconds. Drive the vehicle for several minutes at speed over 30 mph (50 km/h), then recheck the MIL/Check Engine light.PGM-FI system

The PGM-FI system on this model is a sequential multiport fuel injectin system.

The indicator light may comes on, indicating a system problem, when, in fact, there is a poor or intermittent

electrical connection. First, check the electrical connections, clean or repair connections if necessary.If the electrical readings are not as specified when using the test harness, check the test harness connections

before proceeding.

Disconnecting the CLOCK fuse also cancels the radio preset stations and the clock setting. Make note of the radio

presets before removing the fuse so you can reset them. If the self-diagnosis indicator light does not blink, perform an inspection according to the table listed below.

Symptom

• Lock-up clutch does not

engage.

• Transmission jerks hard when shifting.

• Transmission jerks hard when

shifting.

• Transmission jerks hard when

shifting

• Lock-up clutch does not

engage.

14-7214-70 14-68

14-67

Refer to

page

Possible Cause

• Disconnected gauge assembly connector

• Short or open in tachometer wire

• Faulty tachometer

• Short or open in FAS (PNK) wire between D16 terminal and

ECM.

• Trouble in ECM

• Disconnected mainshaft speed sensor connector

• Short or open in mainshaft speed sensor wire

• Faulty mainshaft speed sensor

• Disconnected linear solenoid connector

• Short or open in linear solenoid wire

• Faulty linear solenoid

Blinks

OFF

OFF

OFF

When the ignition

switch is turned on,

indicator light

Number of indicator light

blinks while Service CheckConnector is jumped.

11

14

15

16

Ref.page

14-74

14-76

14-77

14-78

NOTE:ProCarManuals.com

Page 1221 of 1640

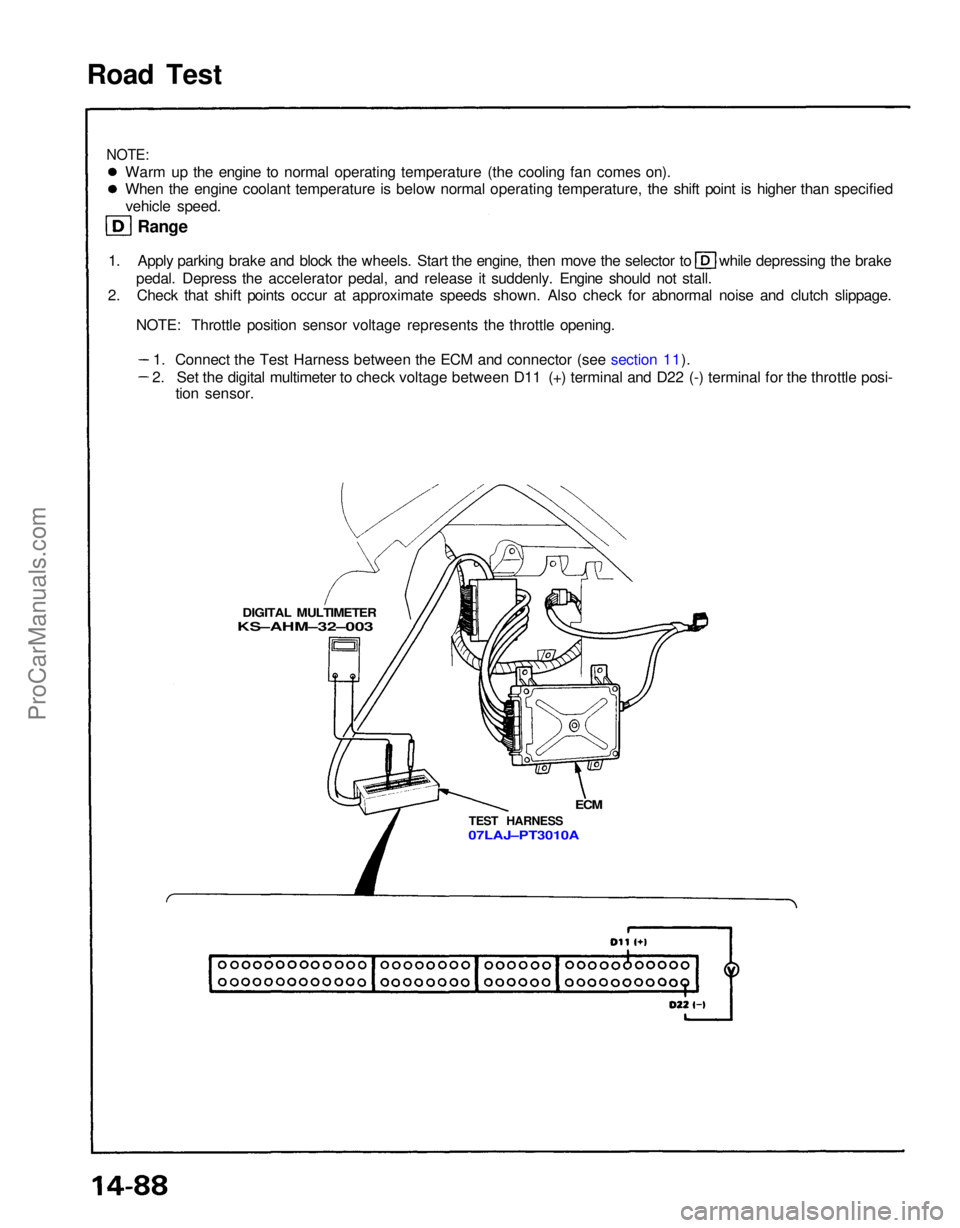

Road Test

NOTE:

Warm up the engine to normal operating temperature (the cooling fan comes on).

When the engine coolant temperature is below normal operating temperature, the shift point is higher than specifiedvehicle speed.

Range 1. Apply parking brake and block the wheels. Start the engine, then move the selector to while depressing the brake

pedal. Depress the accelerator pedal, and release it suddenly. Engine should not stall.

2. Check that shift points occur at approximate speeds shown. Also check for abnormal noise and clutch slippage.

NOTE: Throttle position sensor voltage represents the throttle opening.

DIGITAL MULTIMETER

KS–AHM–32–003

ECM

TEST HARNESS

07LAJ–PT3010A

1. Connect the Test Harness between the ECM and connector (see section 11).

2. Set the digital multimeter to check voltage between D11 (+) terminal and D22 (-) terminal for the throttle posi- tion sensor.ProCarManuals.com

Page 1222 of 1640

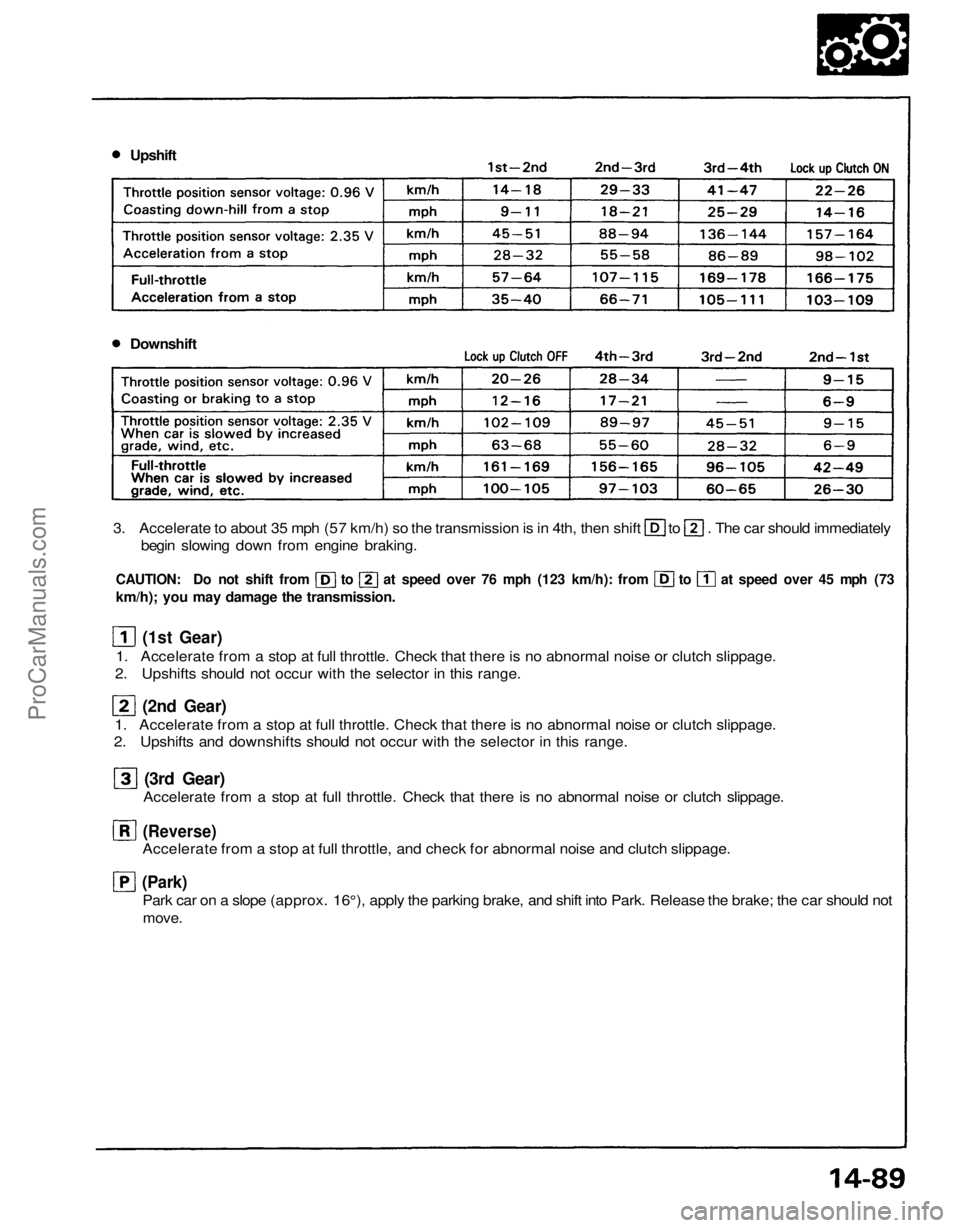

Upshift

Downshift

3. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th, then shift to . The car should immediately

begin slowing down from engine braking.

CAUTION: Do not shift from to at speed over 76 mph (123 km/h): from to at speed over 45 mph (73

km/h); you may damage the transmission.

(1st Gear)

1. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

2. Upshifts should not occur with the selector in this range.

(2nd Gear)

1. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

2. Upshifts and downshifts should not occur with the selector in this range.

(3rd Gear)

Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

(Reverse)

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

(Park)

Park car on a slope (approx. 16°), apply the parking brake, and shift into Park. Release the brake; the car should not

move.ProCarManuals.com

Page 1223 of 1640

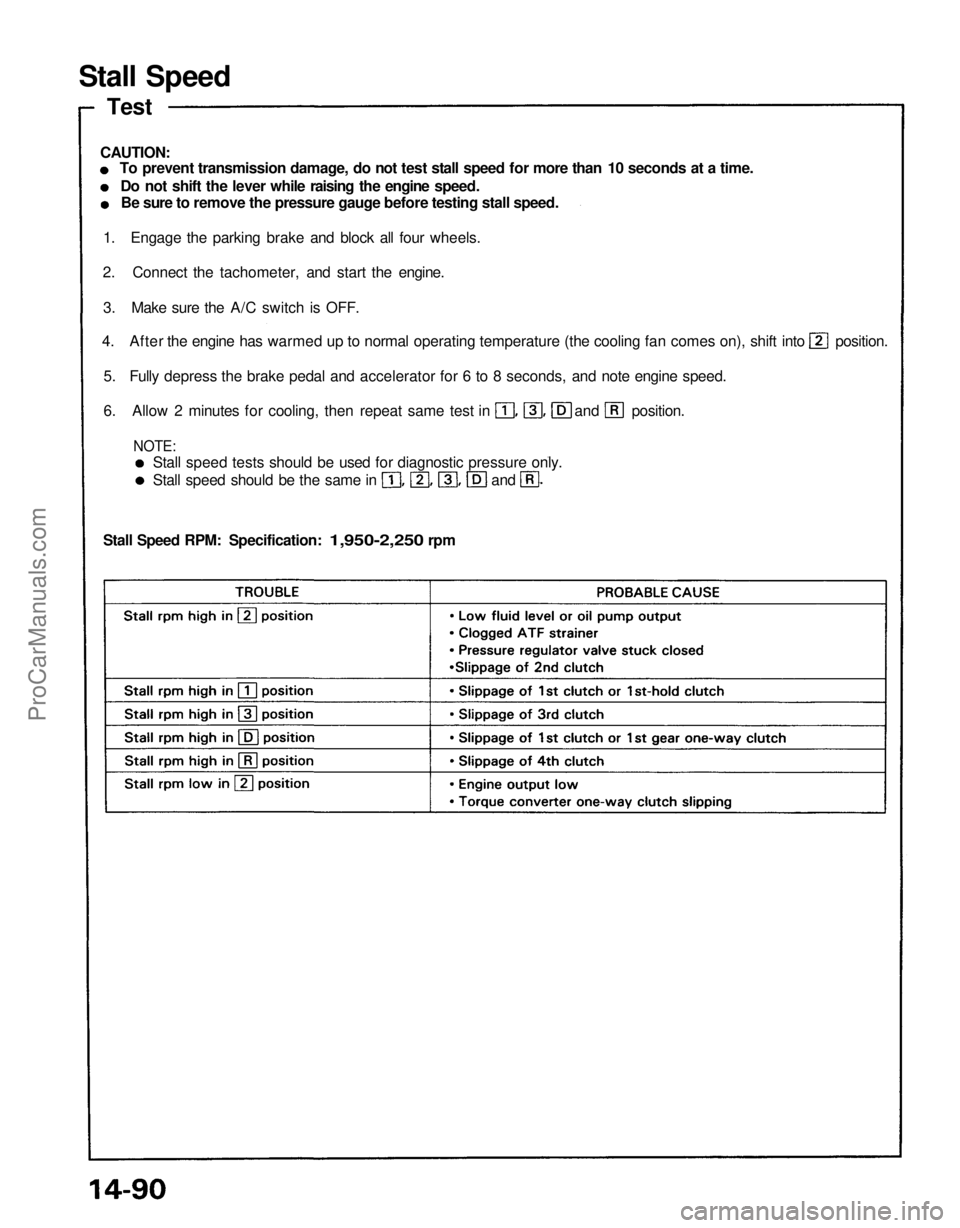

Stall Speed

Test

CAUTION:

To prevent transmission damage, do not test stall speed for more than 10 seconds at a time.

Do not shift the lever while raising the engine speed.

Be sure to remove the pressure gauge before testing stall speed.

1. Engage the parking brake and block all four wheels.

2. Connect the tachometer, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the cooling fan comes on), shift into position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed.

6. Allow 2 minutes for cooling, then repeat same test in and position.

NOTE:

Stall speed tests should be used for diagnostic pressure only.

Stall speed should be the same in and

Stall Speed RPM: Specification:

1,950-2,250

rpmProCarManuals.com

Page 1224 of 1640

Fluid Level

Checking/Changing

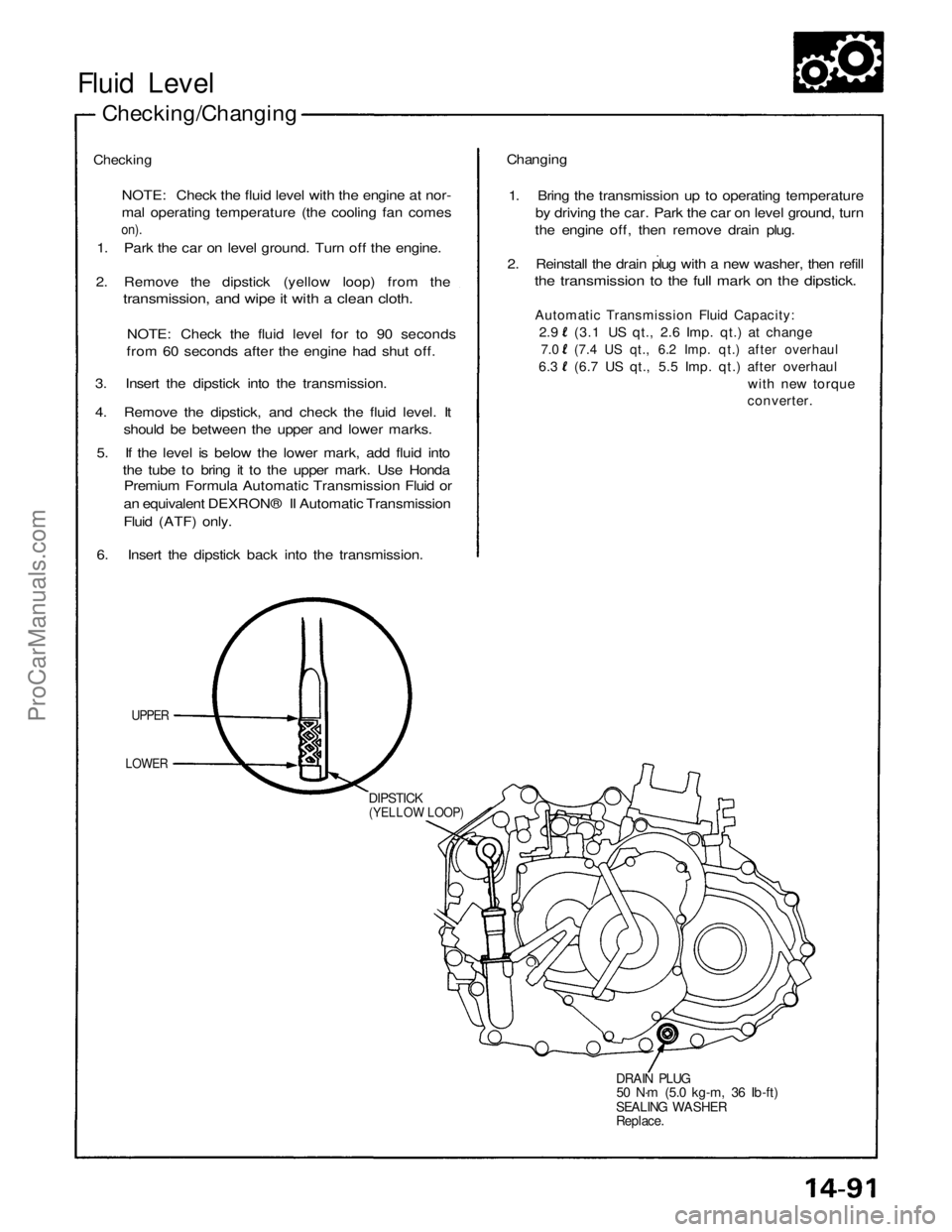

Checking

NOTE: Check the fluid level with the engine at nor-

mal operating temperature (the cooling fan comes

on).

1. Park the car on level ground. Turn off the engine.

2. Remove the dipstick (yellow loop) from the

transmission, and wipe it with a clean cloth.

NOTE: Check the fluid level for to 90 seconds

from 60 seconds after the engine had shut off.

3. Insert the dipstick into the transmission.

4. Remove the dipstick, and check the fluid level. It

should be between the upper and lower marks.

5. If the level is below the lower mark, add fluid into

the tube to bring it to the upper mark. Use Honda

Premium Formula Automatic Transmission Fluid or

an equivalent DEXRON® II Automatic Transmission

Fluid (ATF) only.

6. Insert the dipstick back into the transmission.

UPPER

LOWER

DIPSTICK

(YELLOW LOOP)

DRAIN PLUG

50 N·m (5.0 kg-m, 36 Ib-ft)

SEALING WASHER

Replace.

Changing

1. Bring the transmission up to operating temperature

by driving the car. Park the car on level ground, turn

the engine off, then remove drain plug.

2. Reinstall the drain plug with a new washer, then refill

the transmission to the full mark on the dipstick.

Automatic Transmission Fluid Capacity:

2.9 (3.1 US qt., 2.6 Imp. qt.) at change

7.0 (7.4 US qt., 6.2 Imp. qt.) after overhaul

6.3 (6.7 US qt., 5.5 Imp. qt.) after overhaul

with new torque

converter.ProCarManuals.com

Page 1225 of 1640

Pressure Testing

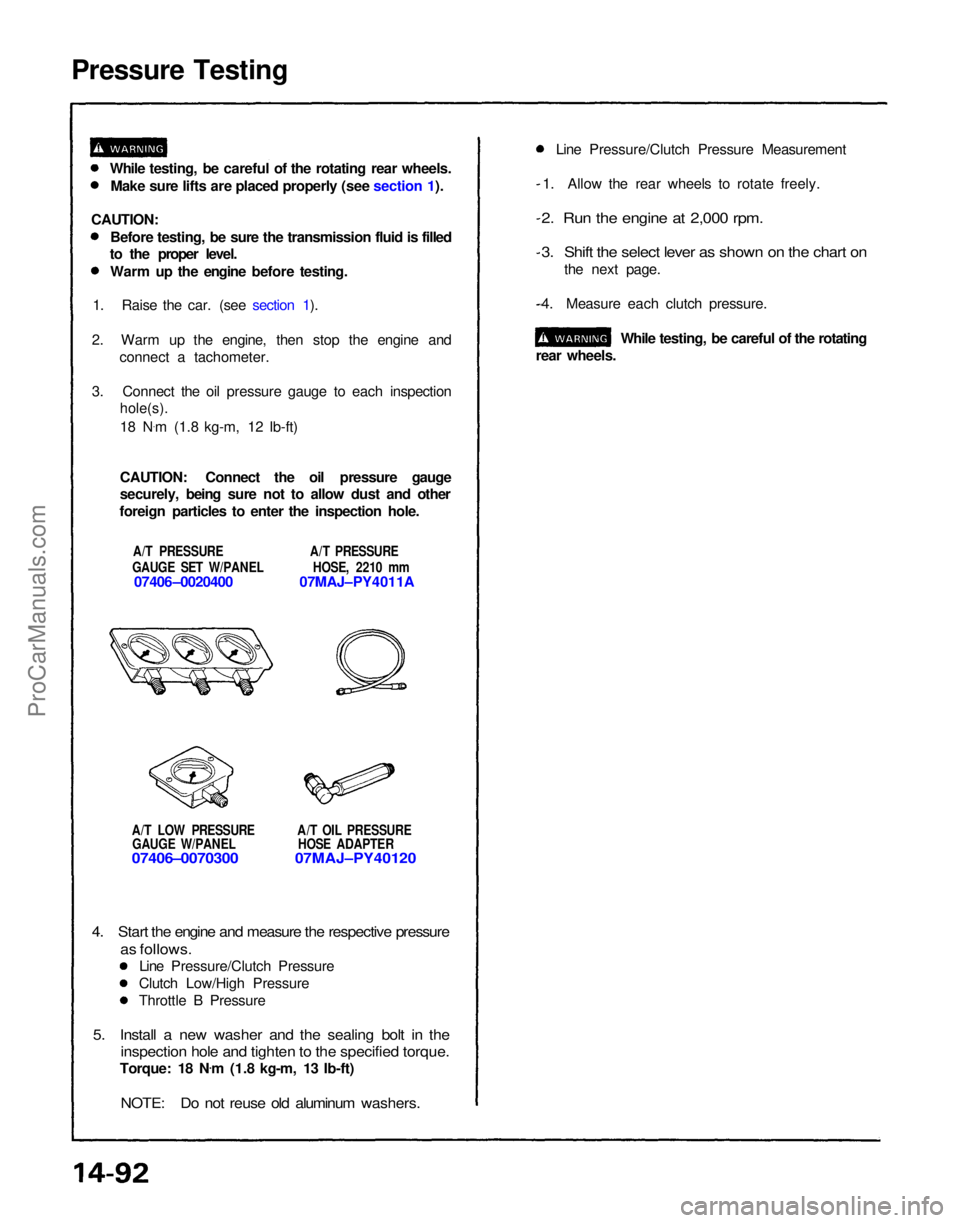

A/T LOW PRESSURE A/T OIL PRESSUREGAUGE W/PANEL HOSE ADAPTER

07406–0070300 07MAJ–PY40120

1. Allow the rear wheels to rotate freely.

2. Run the engine at 2,000 rpm.

3. Shift the select lever as shown on the chart on

the next page.

4. Measure each clutch pressure.

While testing, be careful of the rotating

rear wheels.

4. Start the engine and measure the respective pressure

as follows.

Line Pressure/Clutch Pressure

Clutch Low/High Pressure

Throttle B Pressure

5. Install a new washer and the sealing bolt in the

inspection hole and tighten to the specified torque.

Torque: 18 N .

m (1.8 kg-m, 13 Ib-ft)

NOTE: Do not reuse old aluminum washers.

While testing, be careful of the rotating rear wheels.

Make sure lifts are placed properly (see section 1).

CAUTION: Before testing, be sure the transmission fluid is filled

to the proper level.

Warm up the engine before testing.

1. Raise the car. (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer.

3. Connect the oil pressure gauge to each inspection

hole(s).

18 N .

m (1.8 kg-m, 12 Ib-ft)

CAUTION: Connect the oil pressure gauge

securely, being sure not to allow dust and other

foreign particles to enter the inspection hole.

A/T PRESSURE A/T PRESSURE

GAUGE SET W/PANEL HOSE, 2210 mm

07406–0020400 07MAJ–PY4011A Line Pressure/Clutch Pressure MeasurementProCarManuals.com