engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1227 of 1640

Pressure Testing

(cont'd)

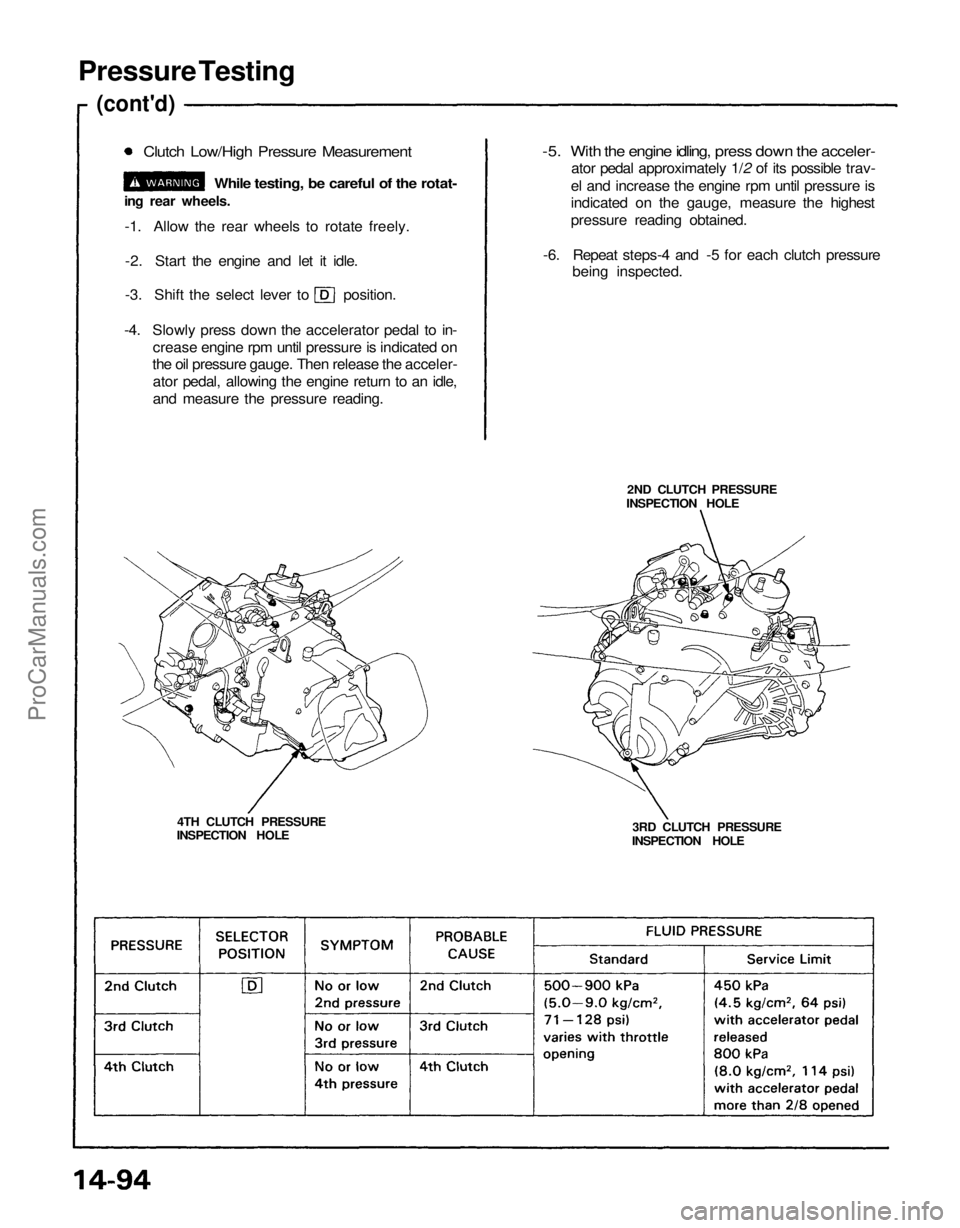

Clutch Low/High Pressure Measurement

While testing, be careful of the rotat-

ing rear wheels.

-1. Allow the rear wheels to rotate freely.

-2. Start the engine and let it idle.

-3. Shift the select lever to position.

-4. Slowly press down the accelerator pedal to in-

crease engine rpm until pressure is indicated on

the oil pressure gauge. Then release the acceler-

ator pedal, allowing the engine return to an idle,

and measure the pressure reading.

-5. With the engine idling, press down the acceler-

ator pedal approximately 1/2 of its possible trav-

el and increase the engine rpm until pressure is

indicated on the gauge, measure the highest

pressure reading obtained.

-6. Repeat steps-4 and -5 for each clutch pressure

being inspected.

2ND CLUTCH PRESSURE

INSPECTION HOLE

3RD CLUTCH PRESSURE

INSPECTION HOLE

4TH CLUTCH PRESSURE

INSPECTION HOLEProCarManuals.com

Page 1228 of 1640

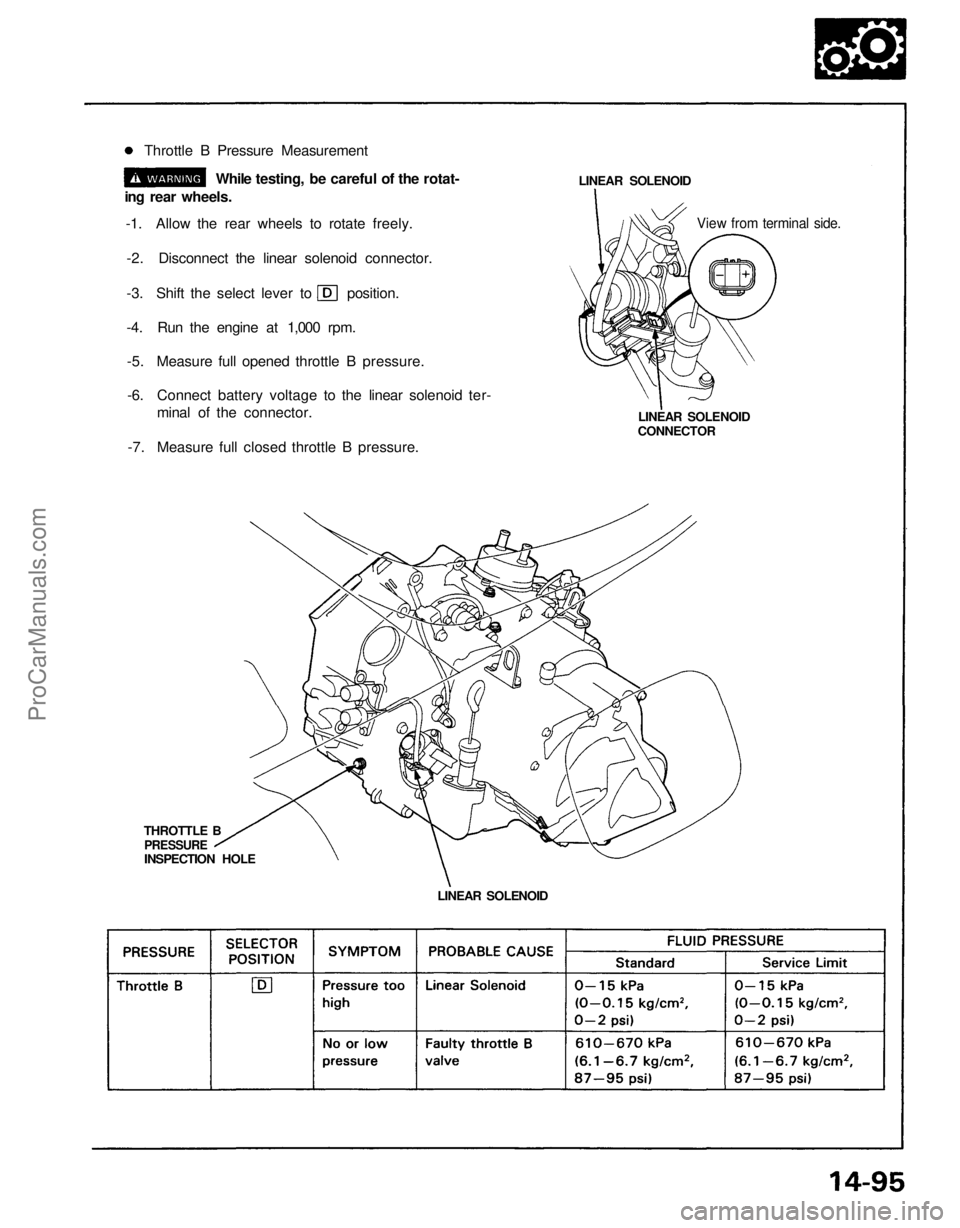

LINEAR SOLENOID

THROTTLE B

INSPECTION HOLE

LINEAR SOLENOID

CONNECTOR

View from terminal side.

LINEAR SOLENOID

Throttle B Pressure Measurement

While testing, be careful of the rotat-

ing rear wheels.

-1. Allow the rear wheels to rotate freely.

-2. Disconnect the linear solenoid connector.

-3. Shift the select lever to position.

-4. Run the engine at 1,000 rpm.

-5. Measure full opened throttle B pressure.

-6. Connect battery voltage to the linear solenoid ter-

minal of the connector.

-7. Measure full closed throttle B pressure.

PRESSUREProCarManuals.com

Page 1231 of 1640

Transmission

Removal (cont'd)

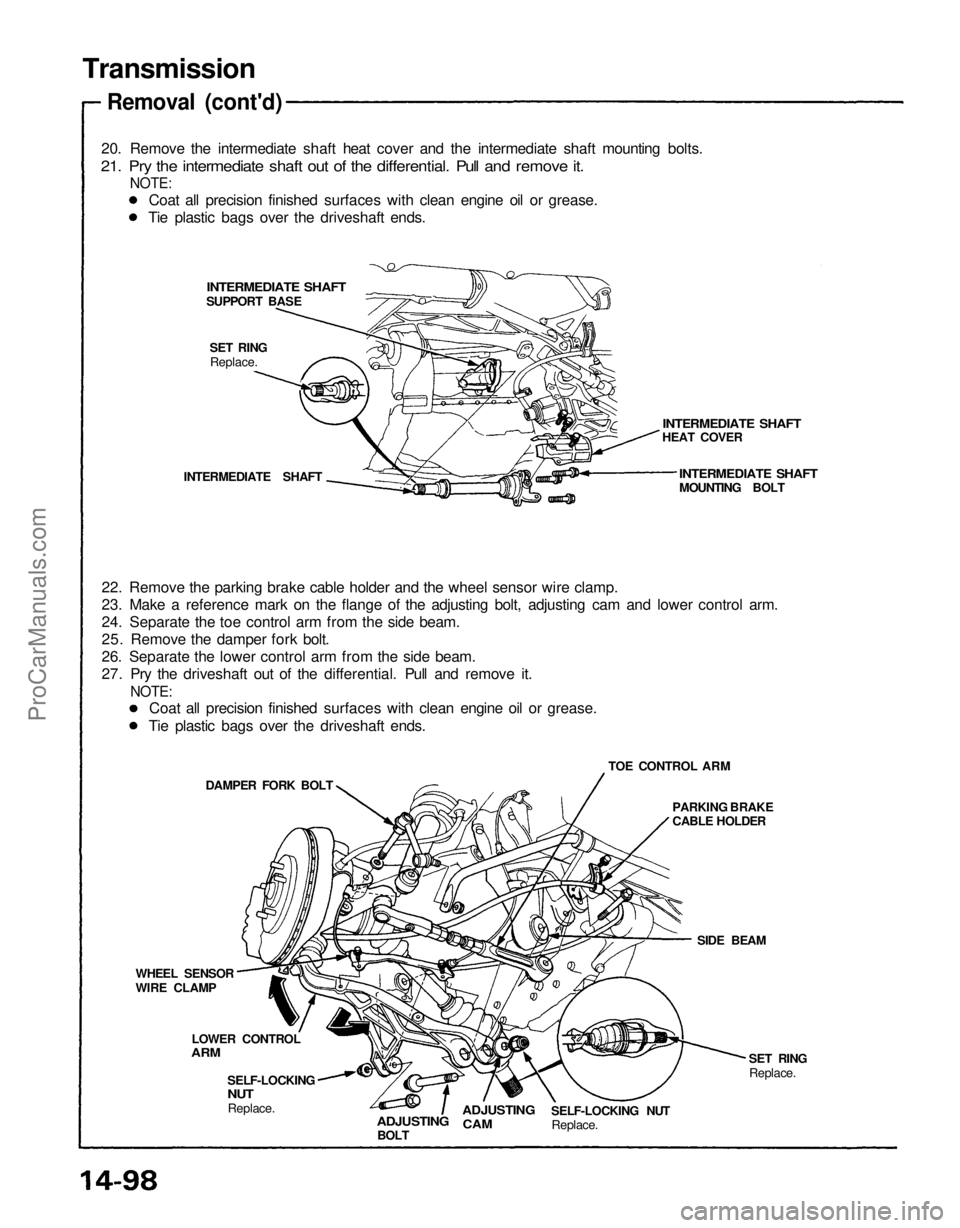

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

INTERMEDIATE SHAFT

INTERMEDIATE SHAFT

HEAT COVER

INTERMEDIATE SHAFT

MOUNTING BOLT

SET RING

Replace.

INTERMEDIATE SHAFT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Make a reference mark on the flange of the adjusting bolt, adjusting cam and lower control arm.

24. Separate the toe control arm from the side beam.

25. Remove the damper fork bolt.

26. Separate the lower control arm from the side beam.

27. Pry the driveshaft out of the differential. Pull and remove it.

NOTE:

TOE CONTROL ARM

DAMPER FORK BOLT

PARKING BRAKE

CABLE HOLDER

SIDE BEAM

SET RING

Replace.

SELF-LOCKING NUT

Replace.

ADJUSTING

CAM

ADJUSTING

BOLT

SELF-LOCKING

NUT

Replace.

LOWER CONTROL

ARM

WHEEL SENSOR

WIRE CLAMP

SUPPORT BASE

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.ProCarManuals.com

Page 1232 of 1640

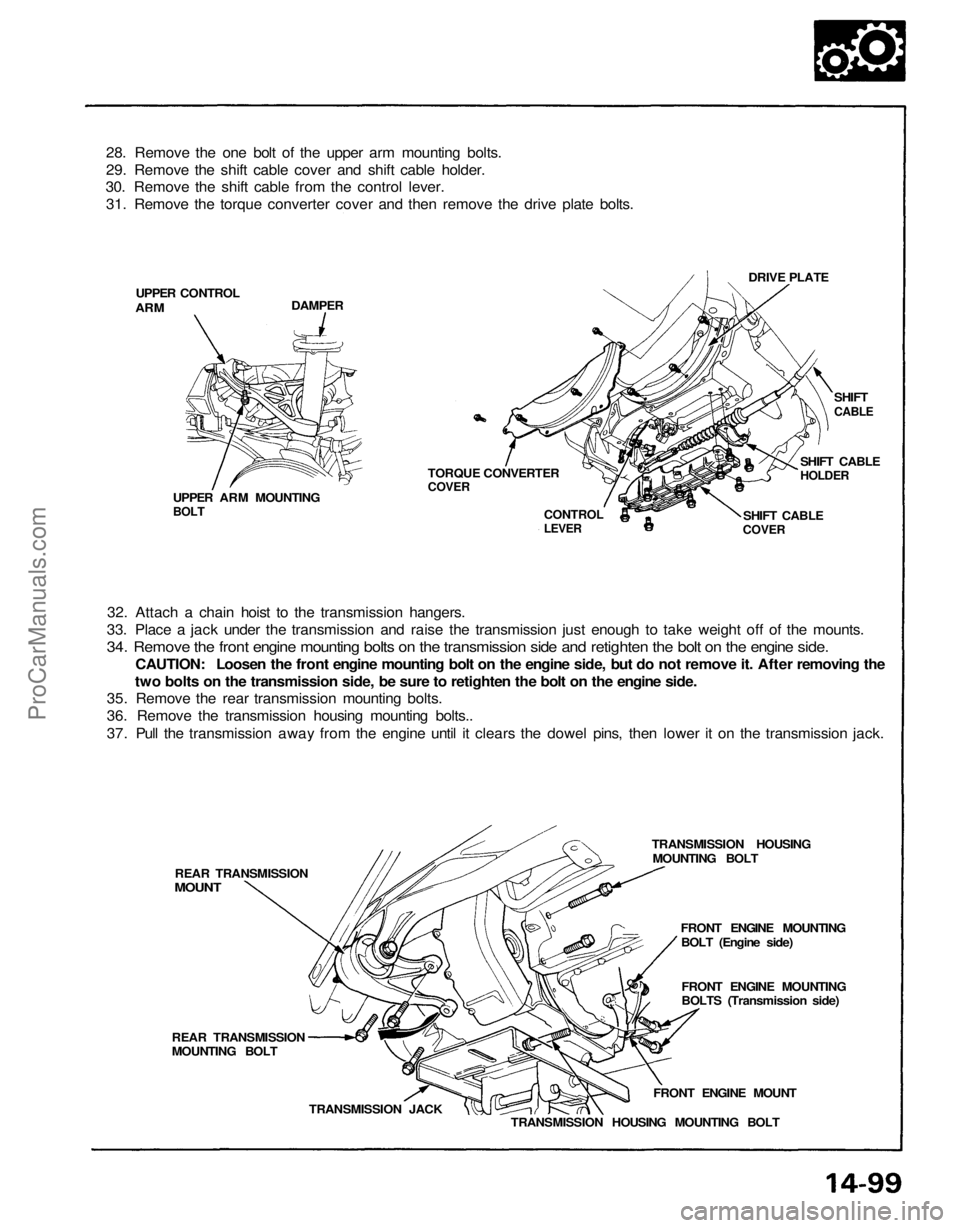

28. Remove the one bolt of the upper arm mounting bolts.

29. Remove the shift cable cover and shift cable holder.

30. Remove the shift cable from the control lever.

31. Remove the torque converter cover and then remove the drive plate bolts.

DRIVE PLATE

DAMPER

UPPER CONTROL

ARM

SHIFT

CABLE

SHIFT CABLE

HOLDER

SHIFT CABLE

COVER

CONTROL

LEVER

TORQUE CONVERTER

COVER

UPPER ARM MOUNTING

BOLT

32. Attach a chain hoist to the transmission hangers.

33. Place a jack under the transmission and raise the transmission just enough to take weight off of the mounts.34. Remove the front engine mounting bolts on the transmission side and retighten the bolt on the engine side.

CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the

two bolts on the transmission side, be sure to retighten the bolt on the engine side.

35. Remove the rear transmission mounting bolts.

36. Remove the transmission housing mounting bolts..

37. Pull the transmission away from the engine until it clears the dowel pins, then lower it on the transmission jack.

TRANSMISSION HOUSINGMOUNTING BOLT

FRONT ENGINE MOUNTINGBOLT (Engine side)

FRONT ENGINE MOUNTING

BOLTS (Transmission side)

FRONT ENGINE MOUNT

TRANSMISSION HOUSING MOUNTING BOLT

TRANSMISSION JACK

REAR TRANSMISSION

MOUNTING BOLT REAR TRANSMISSION

MOUNTProCarManuals.com

Page 1286 of 1640

Transmission

Installation

1. Place the transmission on the transmission jack, and raise to the engine level.

2. Check that the 14 mm and 10 mm dowel pins are installed in the torque converter housing.

3. Install the 3 transmission housing mounting bolts.

4. Install the 3 rear transmission mounting bolts.

5. Loosen the front engine mounting bolt and install the 2 front engine mounting bolts to transmission side, then

tighten the 3 bolts specified torque.

TRANSMISSION HOUSINGMOUNTING BOLT

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

DOWEL PIN

14 x 20 mm

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N .

m

(6.0 kg-m, 43 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12x1.25 mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

O-RING

Replace.

DOWEL PIN

10 x 20 mm

TORQUE CONVERTER REAR TRANSMISSION

MOUNTING BOLT

10 x

1.25

mm

60 N·m

(6.0 kg-m, 43 Ib-ft)

TRANSMISSION JACK

7. Attach the torque converter to the drive plate with 8 bolts to 12 N.m (1.2 kg-m, 9 Ib-ft). Rotate the crankshaft as necessary to tighten bolts to 1/2 of specified torque, then final torque, in a crisscross pattern. Check for free rotation after tighteningthe last bolt.

8. Install the torque converter cover. 9. Install the shift cable, shift cable holder and shift cable cover.

10. Install the upper control arm mounting bolt.

6x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

6 x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

CONTROL LEVER

UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

6 x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

(cont'd)

6 x 1.0 mm

8 N

.

m (0.8 kg-m, 6 Ib-ft)

Install in this

direction.

LOCK PIN

CONTROL LEVER

PIN

Corrosion resistant bolt/nut

Corrosion resistant bolt/nut

6. Remove the transmission jack.ProCarManuals.com

Page 1289 of 1640

Transmission

Installation (cont'd)

27. Install the 3 transmission mounting bolts, and the 2 transmission housing mounting bolts.

28. Install the starter motor and tighten the starter motor mounting bolts.

29. Install the ATF cooler.

30. Connect the transmission ground cable, starter motor cable, solenoid valve wire connectors and vehicle

speed sensor (VSS) wire connectors.

31. Install the control box and connect the control box connectors.

32. Install the air cleaner housing.

33. Install the strut bar.

TORQUE: 39 N .

m (3.9 kg-m, 28 Ib-ft)

Corrosion resistant bolt/nut 34. Refill the transmission with ATF.

35. Connect the battery positive (+) and negative (-) ca- ble to the battery.

36. Inspect the rear camber (see section 18).

37. Start the engine. Set the parking brake, and shift the transmission through all gears three times. Check forproper shift cable adjustment.

38. Check the ignition timing (see section 23).

39. Let the engine reach normal operating temperature (the cooling fan comeson) with the transmission in or position, then turn it off and check the

fluid level.

40. Road test as described on page 14-88.

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

CONTROL BOX

8x1.25 mm

18 N .

m

(1.8 kg-m,

13 Ib-ft)

TRANSMISSION MOUNTING BOLT

10 x 1.25mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

STARTER MOTOR

MOUNTING BOLT

12 x 1.25mm

75 N .

m

(7.5 kg-m,

54 Ib-ft)ProCarManuals.com

Page 1290 of 1640

Shift Cable

Adjustment

1. Start the engine. Shift to reverse to see if the reverse gear engages. If not, refer to Trouble-

shooting on pages 14-84 thru 14-87.

2. Stop the engine. 3. Raise the car (see section 1). 4. Shift the selector lever to position.

5. Remove the shift cable cover.

6. Remove the control lever pin and lock pin from the control lever.

CONTROL LEVER PIN

CONTROL

LEVER

SHIFT CABLE COVER

6 x 1.0 mm

8 N .

m (0.8 kg-m, 6 Ib-ft)

LOCK PIN Install in this

direction.

7. Shift the control lever to position.

SHIFT CONTROL LEVER 12. Install the shift cable cover.

13. Start the engine and check the shift lever in all gears. If any gear does not work properly, refer to

Troubleshooting on pages 14-84 thru 14-87. If you feel the control lever pin binding as you rein-

stall it, the cable is still out of adjustment and must

be readjusted.

Install the lock pin as shown in step 6.

10. Tighten the locknut.

11. Install the control lever pin and lock pin.

NOTE:

LOCKNUT

LOCKNUT

NOTE: Left-hand

threads

ADJUST NUT

9. If not perfectly aligned, loosen the locknut on the shift

cable and adjust as required. Cable Cable Exact

Too Short Too Long Alignment

SHIFT CABLE END

CONTROL LEVER

8. Check that the hole in the control lever is perfectly

aligned with the hole in the shift cable.ProCarManuals.com

Page 1298 of 1640

Inspection

Steering Wheel Rotational Play

1. Place the front wheels in a straight ahead position and measure the distance the steering wheel can be

turned without moving the front wheels.

2. If the

play

exceeds

the

service

limit,

check

all

steer- ing components.

Service Limit: 5 mm (0.2 in) maximum

Steering Effort Check (Manual Steering Only)

Operation Standard

Turn the steering wheel with a spring scale. Read the

measurement when the front wheels or steering wheel

start to move.Power Assist Check With Car

Parked (Electrical Power Steering

Only)

1. Raise the front wheels off the ground (see sec-

tion 1).

2. Turn the steering wheel with a spring scale and check its reading.

3. If the reading exceeds the service limit, adjust the steering gearbox as shown on the next page.

Service Limit: 20 N (2 kg, 4 Ibs) maximum Condition

Without power assist (engine off)

With power assist (engine running) Stationary Swing

operation load

120 N (12 kg, 26

Ibs)

maximum

42 N

(4.2

kg, 9.3

Ibs) maximumProCarManuals.com

Page 1324 of 1640

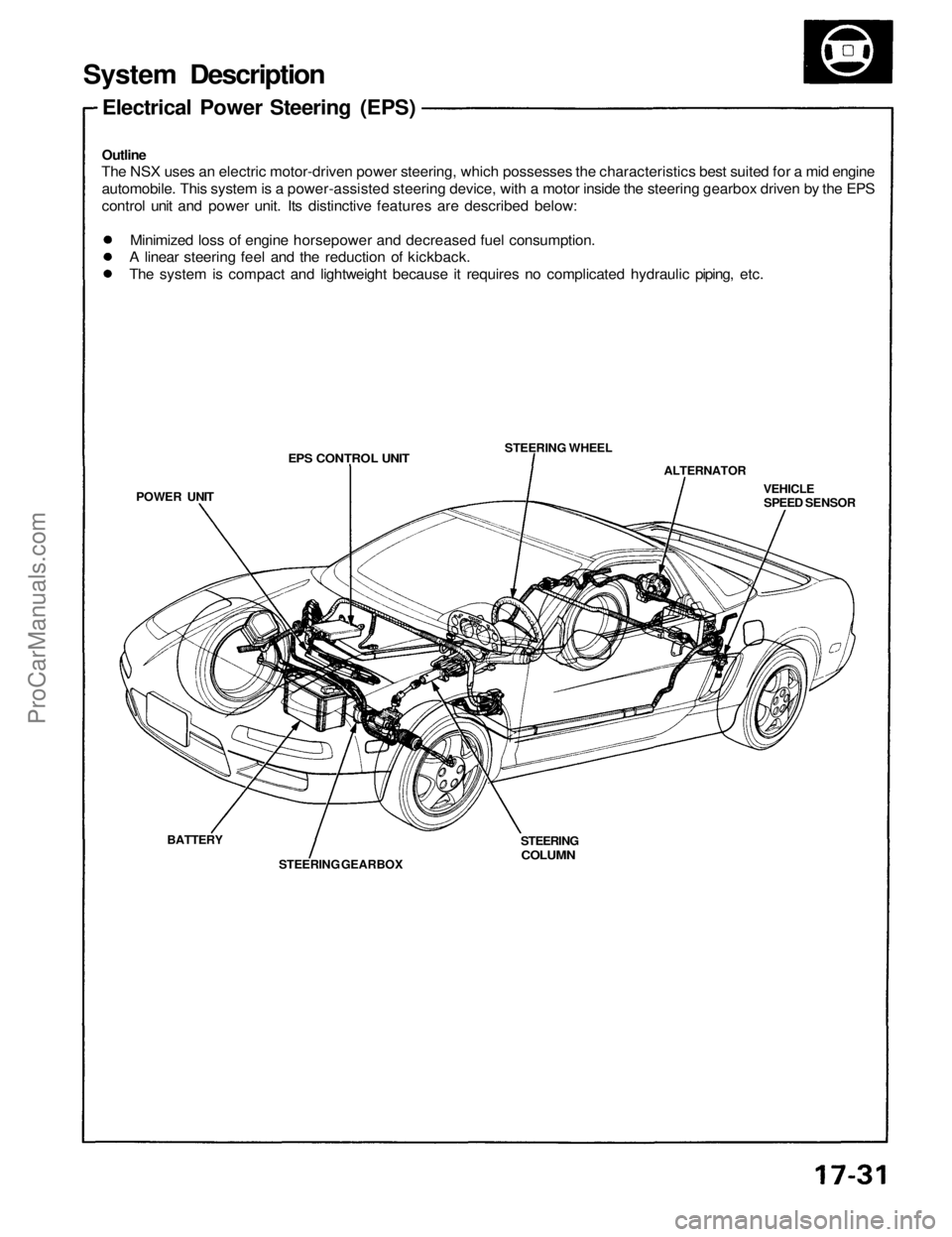

System Description

Electrical Power Steering (EPS)

Outline

The NSX uses an electric motor-driven power steering, which possesses the characteristics best suited for a mid engine

automobile. This system is a power-assisted steering device, with a motor inside the steering gearbox driven by the EPS

control unit and power unit. Its distinctive features are described below:

ALTERNATOR

VEHICLE

SPEED SENSOR

STEERING WHEEL

EPS CONTROL UNIT

POWER UNIT

BATTERY

STEERING GEARBOX

STEERING

COLUMN

Minimized loss of engine horsepower and decreased fuel consumption.

A linear steering feel and the reduction of kickback.

The system is compact and lightweight because it requires no complicated hydraulic piping, etc.ProCarManuals.com

Page 1329 of 1640

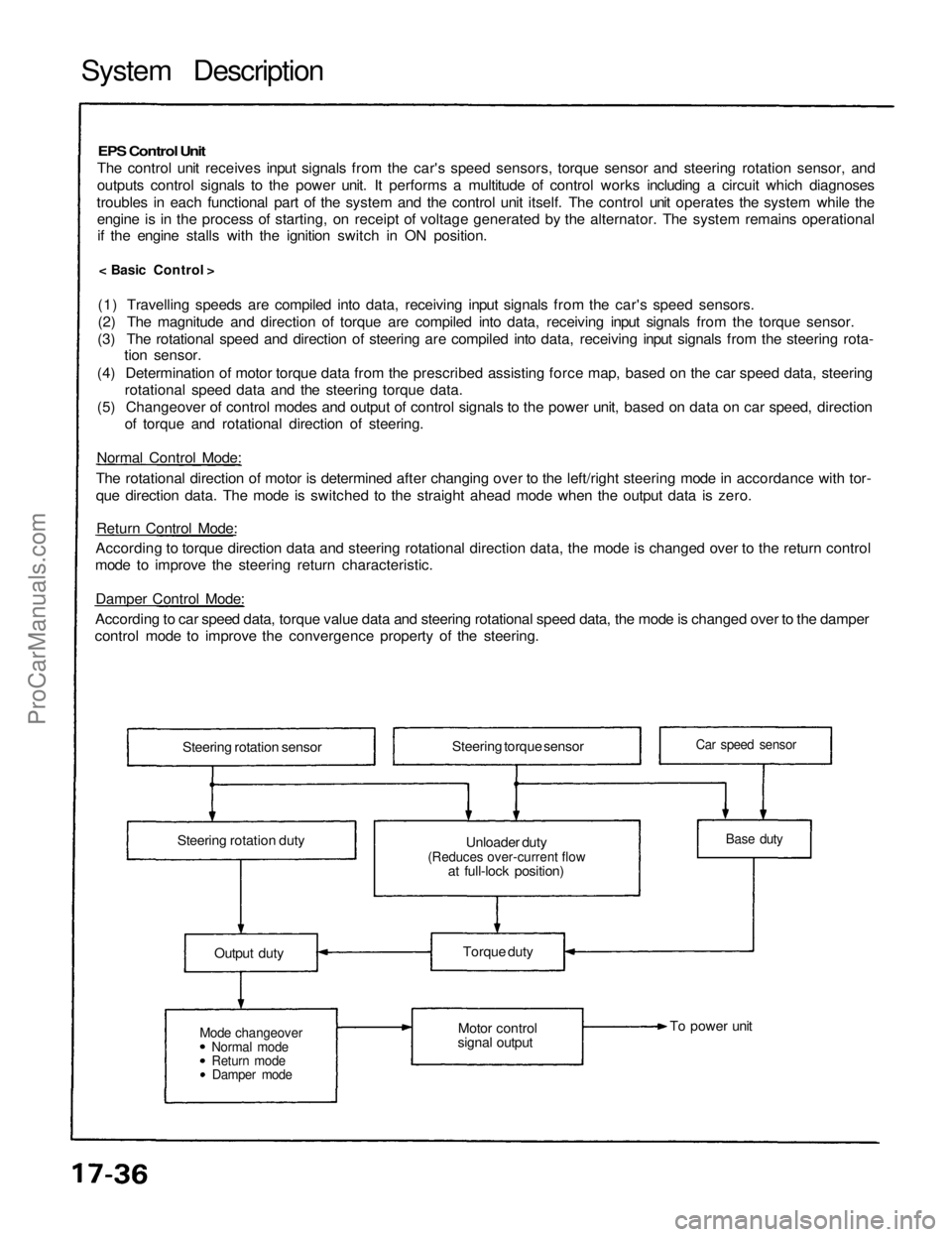

System Description

EPS Control Unit

The control unit receives input signals from the car's speed sensors, torque sensor and steering rotation sensor, and

outputs control signals to the power unit. It performs a multitude of control works including a circuit which diagnoses

troubles in each functional part of the system and the control unit itself. The control unit operates the system while the engine is in the process of starting, on receipt of voltage generated by the alternator. The system remains operationalif the engine stalls with the ignition switch in ON position.

< Basic Control >

(1) Travelling speeds are compiled into data, receiving input signals from the car's speed sensors.

(2) The magnitude and direction of torque are compiled into data, receiving input signals from the torque sensor.

(3) The rotational speed and direction of steering are compiled into data, receiving input signals from the steering rota- tion sensor.

(4) Determination of motor torque data from the prescribed assisting force map, based on the car speed data, steering rotational speed data and the steering torque data.

(5) Changeover of control modes and output of control signals to the power unit, based on data on car speed, direction of torque and rotational direction of steering.

Normal Control Mode:

The rotational direction of motor is determined after changing over to the left/right steering mode in accordance with tor-

que direction data. The mode is switched to the straight ahead mode when the output data is zero.

Return Control Mode:

According to torque direction data and steering rotational direction data, the mode is changed over to the return control

mode to improve the steering return characteristic.

Damper Control Mode:

According to car speed data, torque value data and steering rotational speed data, the mode is changed over to the damper

control mode to improve the convergence property of the steering.

Steering rotation sensor

Steering rotation duty Steering torque sensor

Unloader duty

(Reduces over-current flow

at full-lock position)

Output duty

Mode changeover

Normal mode

Return mode

Damper mode

Torque duty

Motor control

signal output To power unit

Base duty

Car speed sensorProCarManuals.com