engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1170 of 1640

Description

Clutches (cont'd)

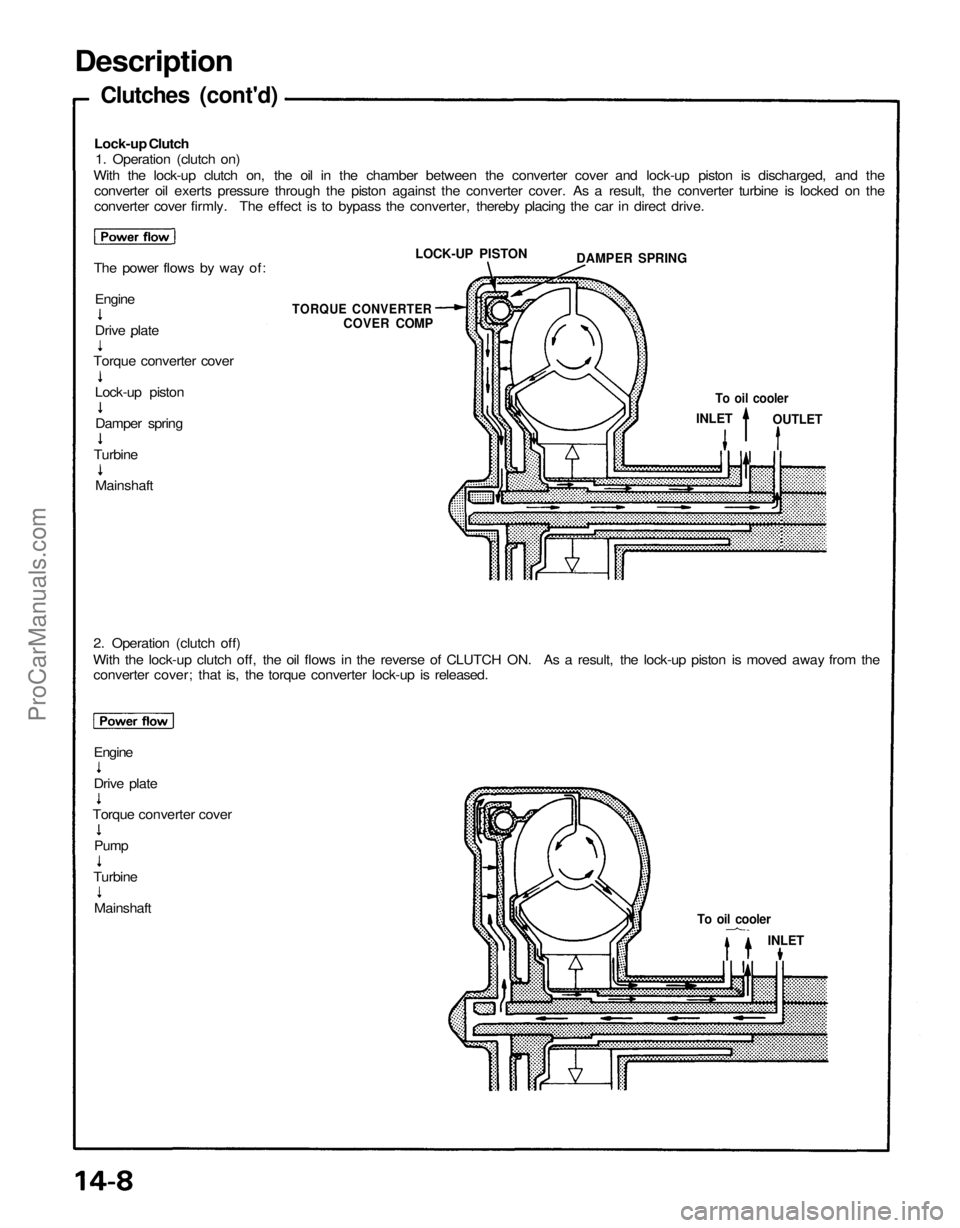

Lock-up Clutch

1. Operation (clutch on)

With the lock-up clutch on, the oil in the chamber between the converter cover and lock-up piston is discharged, and the

converter oil exerts pressure through the piston against the converter cover. As a result, the converter turbine is locked on the

converter cover firmly. The effect is to bypass the converter, thereby placing the car in direct drive.

The power flows by way of:

2. Operation (clutch off)

With the lock-up clutch off, the oil flows in the reverse of CLUTCH ON. As a result, the lock-up piston is moved away from the

converter cover; that is, the torque converter lock-up is released.

Engine

To oil cooler

INLET

To oil cooler

INLET

OUTLET

TORQUE CONVERTER

COVER COMP

LOCK-UP PISTON

DAMPER SPRING

Engine

Drive plate

Torque converter cover

Lock-up piston

Damper spring

Turbine

Mainshaft

Drive plate

Torque converter cover

Pump

Turbine

MainshaftProCarManuals.com

Page 1172 of 1640

Description

Power Flow (cont'd)

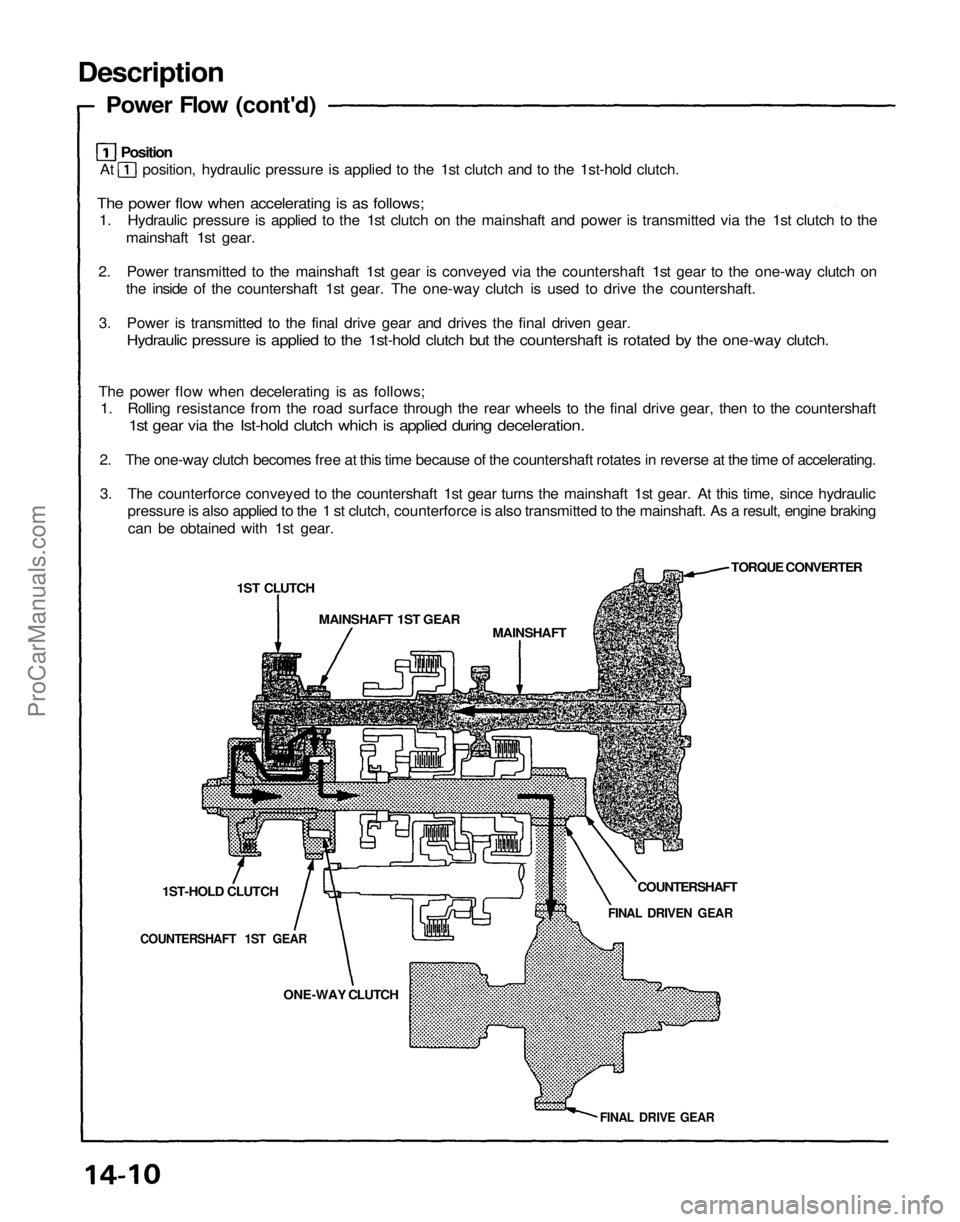

Position

At position, hydraulic pressure is applied to the 1st clutch and to the 1st-hold clutch.

The power flow when accelerating is as follows;

1. Hydraulic pressure is applied to the 1st clutch on the mainshaft and power is transmitted via the 1st clutch to the

mainshaft 1st gear.

2. Power transmitted to the mainshaft 1st gear is conveyed via the countershaft 1st gear to the one-way clutch on

the inside of the countershaft 1st gear. The one-way clutch is used to drive the countershaft.

3. Power is transmitted to the final drive gear and drives the final driven gear.

Hydraulic pressure is applied to the 1st-hold clutch but the countershaft is rotated by the one-way clutch.

The power flow when decelerating is as follows;

1. Rolling resistance from the road surface through the rear wheels to the final drive gear, then to the countershaft

1st gear via the Ist-hold clutch which is applied during deceleration.

2. The one-way clutch becomes free at this time because of the countershaft rotates in reverse at the time of accelerating.

3. The counterforce conveyed to the countershaft 1st gear turns the mainshaft 1st gear. At this time, since hydraulic

pressure is also applied to the 1 st clutch, counterforce is also transmitted to the mainshaft. As a result, engine braking

can be obtained with 1st gear.

1ST CLUTCH

MAINSHAFT 1ST GEAR

MAINSHAFT

TORQUE CONVERTER

COUNTERSHAFT

FINAL DRIVEN GEAR

1ST-HOLD CLUTCH

COUNTERSHAFT 1ST GEAR

ONE-WAY CLUTCH

FINAL DRIVE GEARProCarManuals.com

Page 1175 of 1640

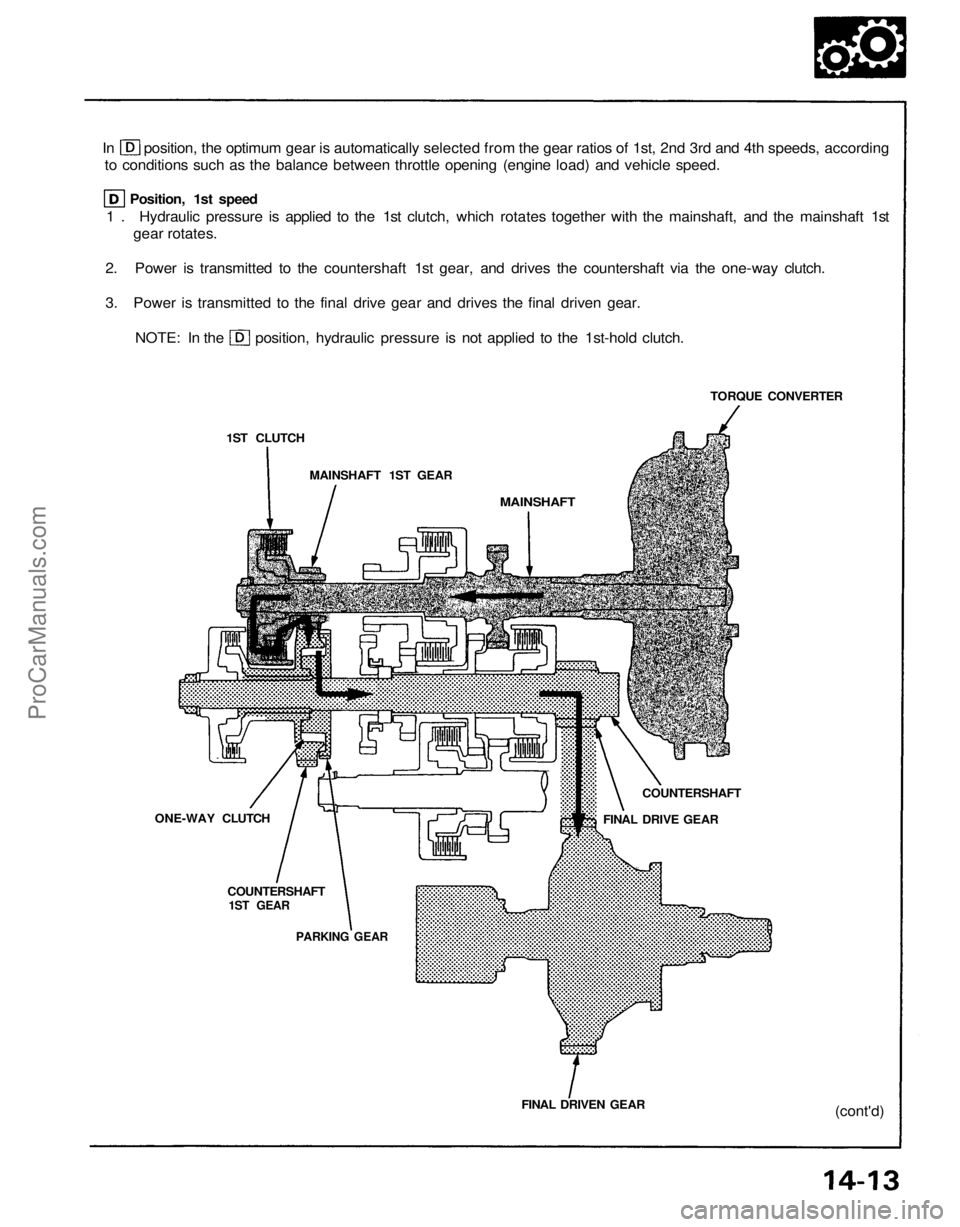

In position, the optimum gear is automatically selected from the gear ratios of 1st, 2nd 3rd and 4th speeds, according

to conditions such as the balance between throttle opening (engine load) and vehicle speed.

1ST CLUTCHMAINSHAFT 1ST GEAR

MAINSHAFT

TORQUE CONVERTER

COUNTERSHAFT

FINAL DRIVE GEAR

(cont'd)

FINAL DRIVEN GEAR

PARKING GEAR

COUNTERSHAFT

1ST GEAR

ONE-WAY CLUTCH

Position, 1st speed

1 . Hydraulic pressure is applied to the 1st clutch, which rotates together with the mainshaft, and the mainshaft 1st gear rotates.

2. Power is transmitted to the countershaft 1st gear, and drives the countershaft via the one-way clutch.

3. Power is transmitted to the final drive gear and drives the final driven gear. NOTE: In the position, hydraulic pressure is not applied to the 1st-hold clutch.ProCarManuals.com

Page 1177 of 1640

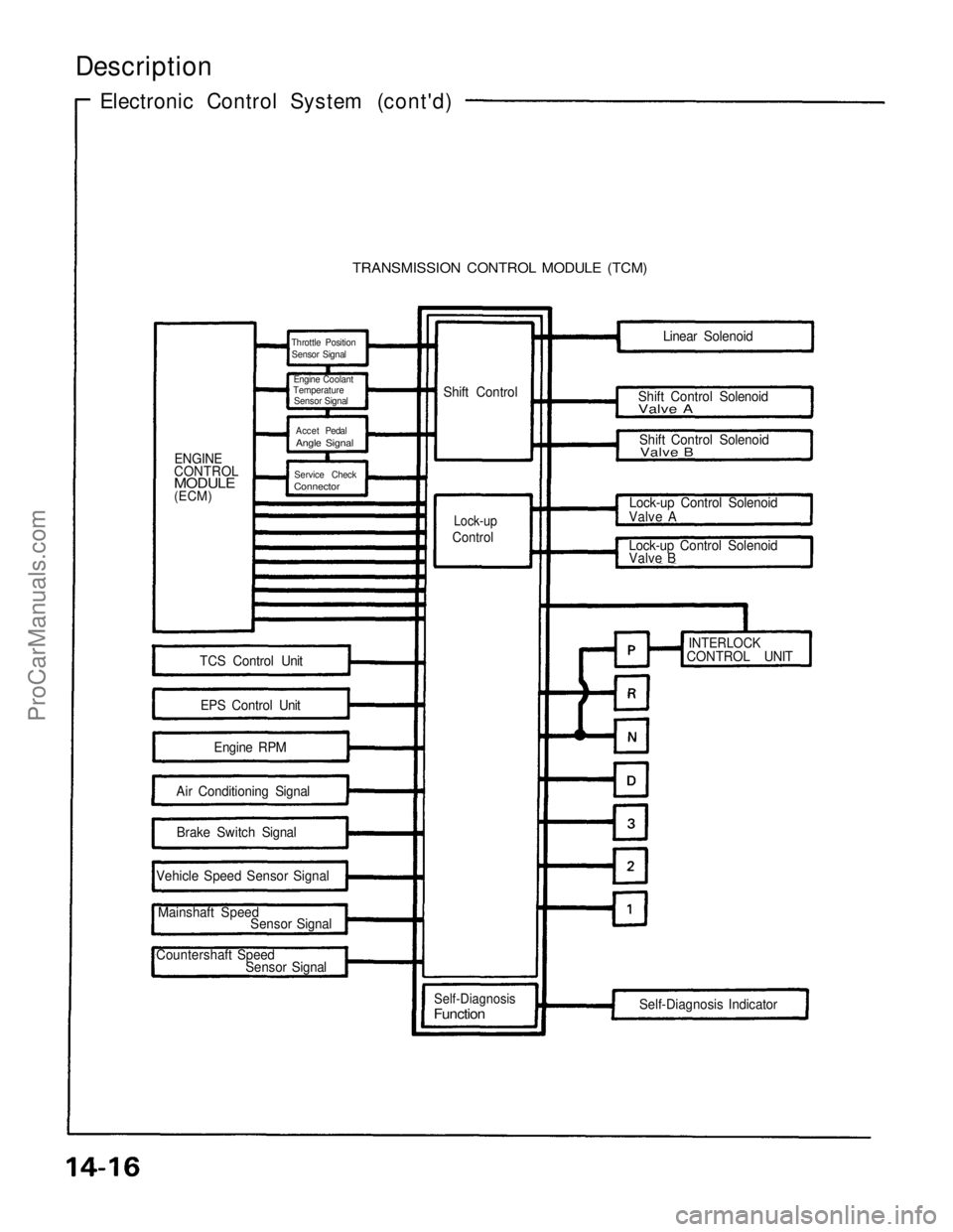

Electronic Control System

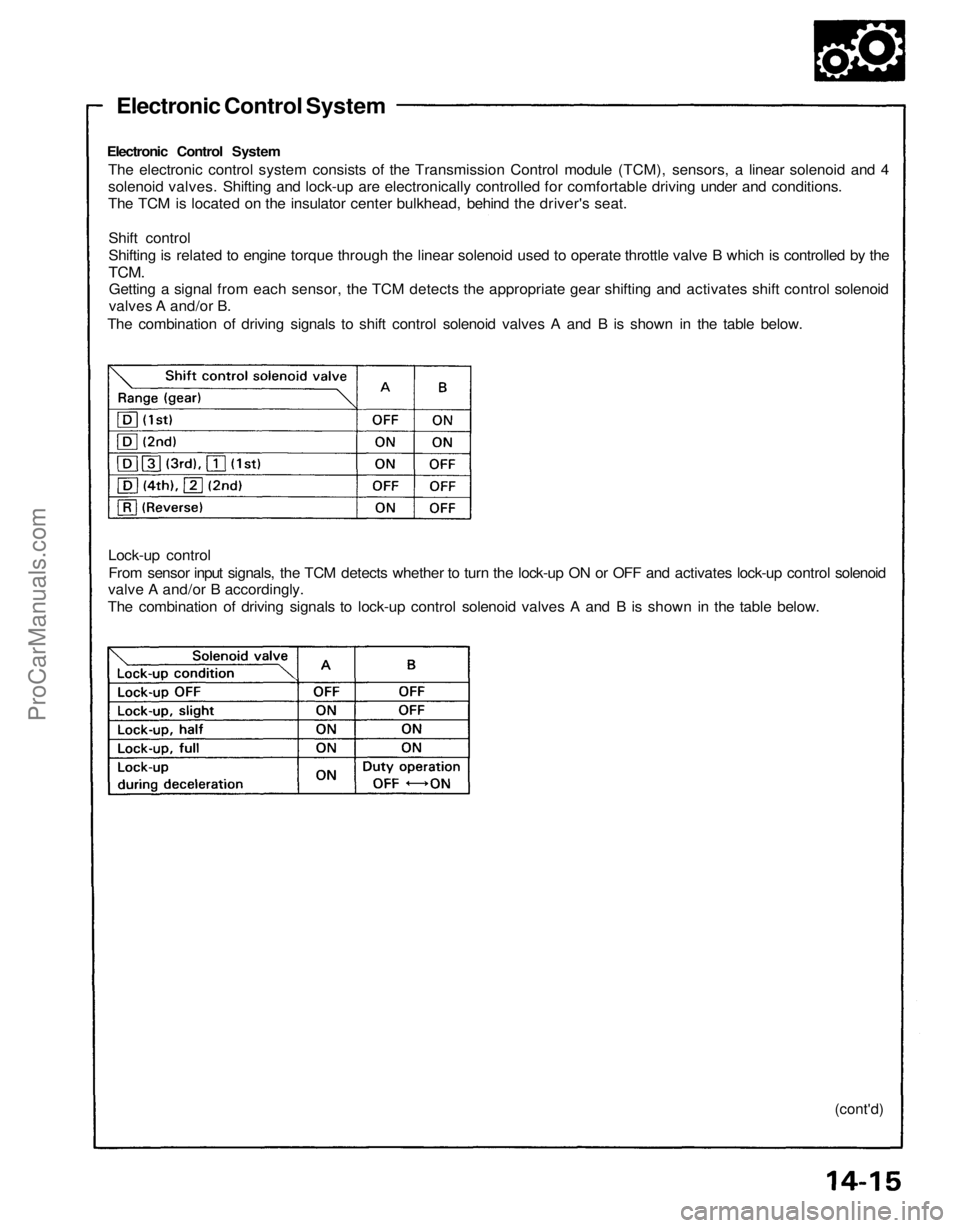

Electronic Control System

The electronic control system consists of the Transmission Control module (TCM), sensors, a linear solenoid and 4

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under and conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Shift control

Shifting is related to engine torque through the linear solenoid used to operate throttle valve B which is controlled by the

TCM.

Getting a signal from each sensor, the TCM detects the appropriate gear shifting and activates shift control solenoid

valves A and/or B.

The combination of driving signals to shift control solenoid valves A and B is shown in the table below.

Lock-up control

From sensor input signals, the TCM detects whether to turn the lock-up ON or OFF and activates lock-up control solenoid

valve A and/or B accordingly.

The combination of driving signals to lock-up control solenoid valves A and B is shown in the table below.

(cont'd)ProCarManuals.com

Page 1178 of 1640

Description

Electronic Control System (cont'd)

TRANSMISSION CONTROL MODULE (TCM)

ENGINE

CONTROL

MODULE

(ECM) Shift Control

Lock-up

Control

TCS Control Unit

EPS Control Unit Engine RPM

Air Conditioning Signal Brake Switch Signal

Vehicle Speed Sensor Signal

Mainshaft Speed Sensor Signal

Countershaft Speed Sensor Signal

Self-Diagnosis

Function

Self-Diagnosis Indicator

INTERLOCK

CONTROL UNIT

Lock-up Control Solenoid

Valve B

Lock-up Control Solenoid

Valve A Shift Control Solenoid

Valve B

Shift Control Solenoid

Valve A

Linear Solenoid

Throttle Position

Sensor Signal

Engine Coolant

Temperature

Sensor Signal

Accet Pedal

Angle Signal

Service Check

Connector

ProCarManuals.com

Page 1179 of 1640

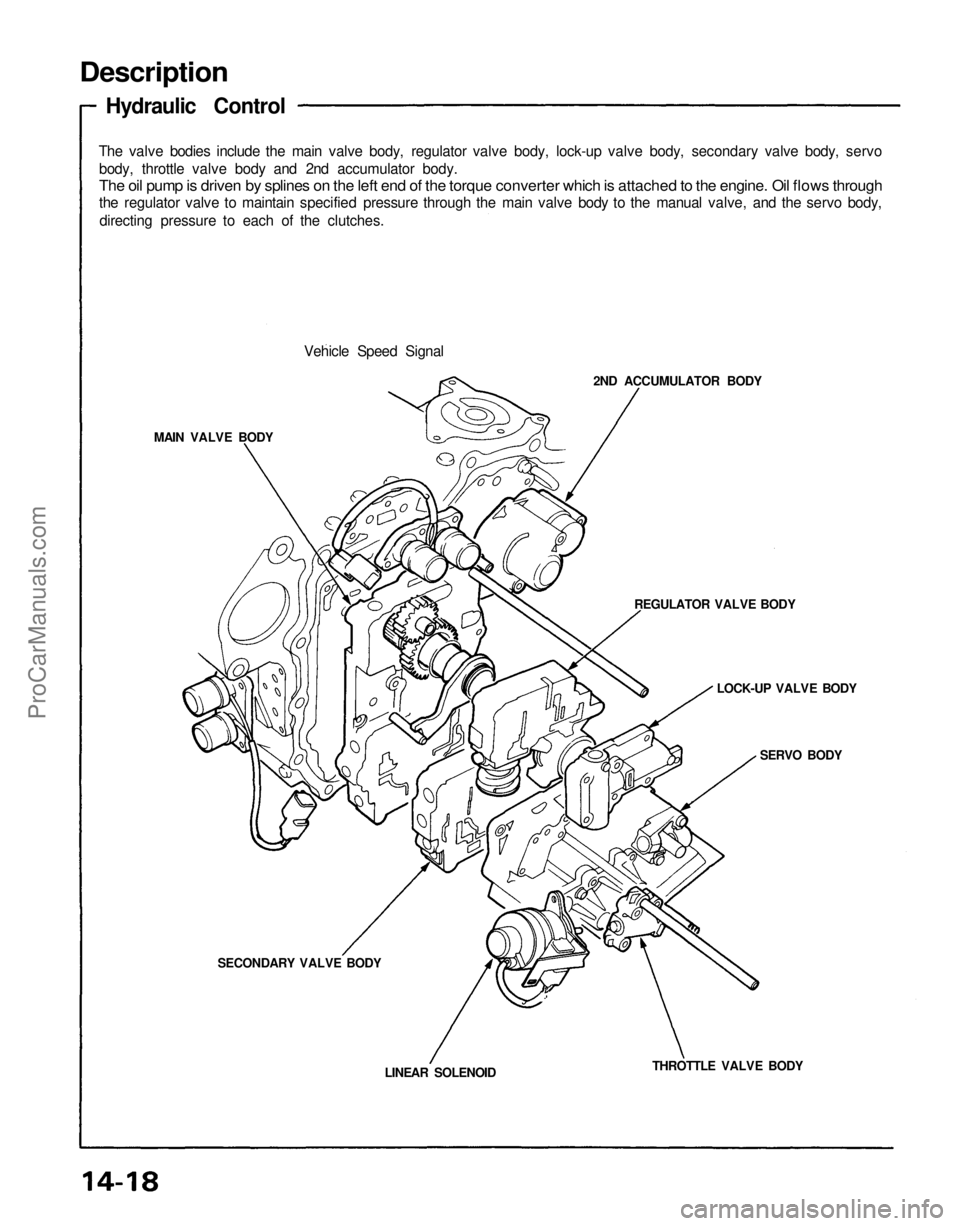

Description

Hydraulic Control

The valve bodies include the main valve body, regulator valve body, lock-up valve body, secondary valve body, servo

body, throttle valve body and 2nd accumulator body.

The oil pump is driven by splines on the left end of the torque converter which is attached to the engine. Oil flows through

the regulator valve to maintain specified pressure through the main valve body to the manual valve, and the servo body,

directing pressure to each of the clutches.

Vehicle Speed Signal

2ND ACCUMULATOR BODY

REGULATOR VALVE BODY

LOCK-UP VALVE BODY

SERVO BODY

THROTTLE VALVE BODY

LINEAR SOLENOID

SECONDARY VALVE BODY

MAIN VALVE BODYProCarManuals.com

Page 1182 of 1640

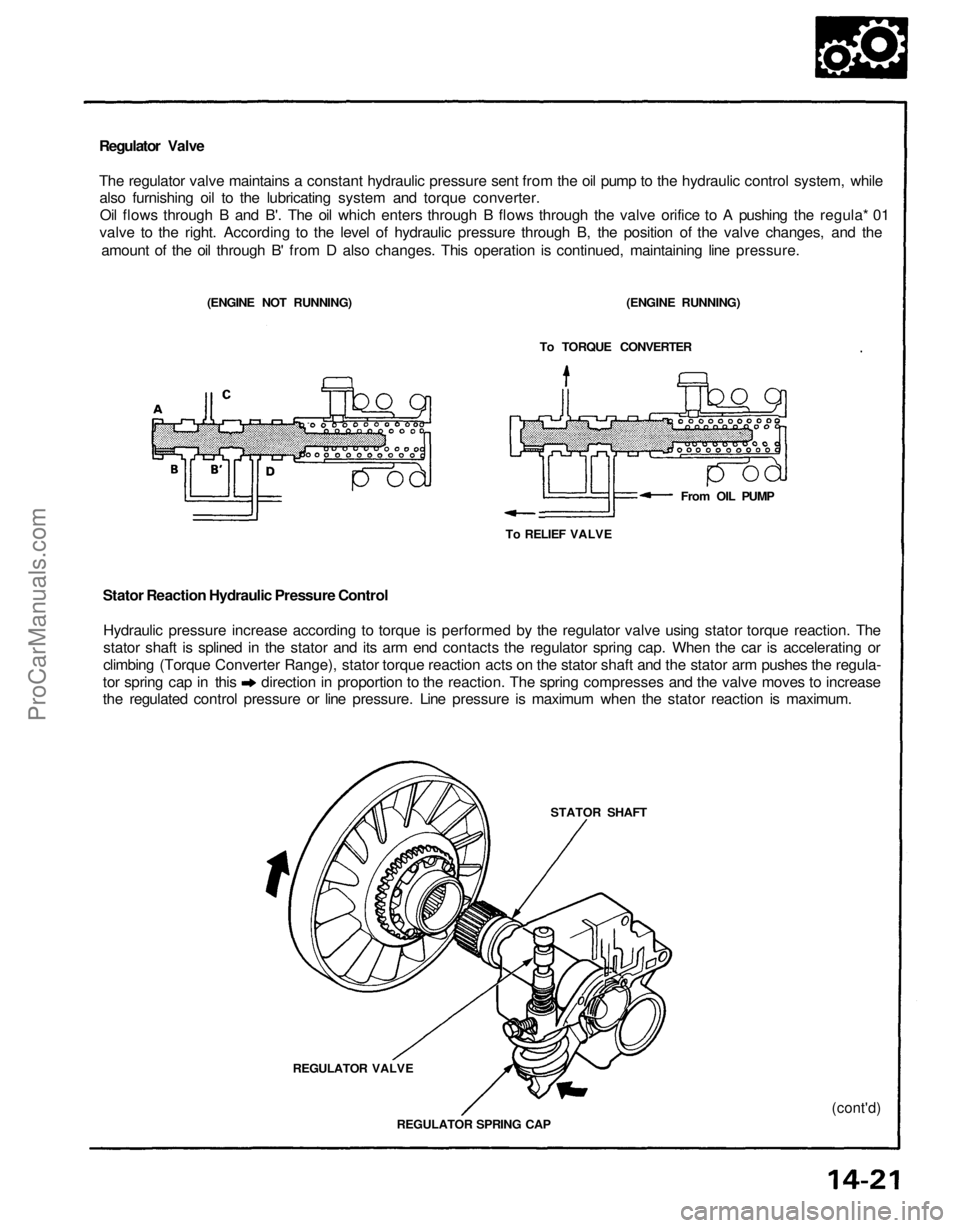

Regulator Valve

The regulator valve maintains a constant hydraulic pressure sent from the oil pump to the hydraulic control system, while

also furnishing oil to the lubricating system and torque converter.

Oil flows through B and B'. The oil which enters through B flows through the valve orifice to A pushing the regula* 01

valve to the right. According to the level of hydraulic pressure through B, the position of the valve changes, and the

amount of the oil through B' from D also changes. This operation is continued, maintaining line pressure.

(ENGINE NOT RUNNING) (ENGINE RUNNING)

To TORQUE CONVERTER

Stator Reaction Hydraulic Pressure Control

Hydraulic pressure increase according to torque is performed by the regulator valve using stator torque reaction. The

stator shaft is splined in the stator and its arm end contacts the regulator spring cap. When the car is accelerating or

climbing (Torque Converter Range), stator torque reaction acts on the stator shaft and the stator arm pushes the regula-

tor spring cap in this direction in proportion to the reaction. The spring compresses and the valve moves to increase

the regulated control pressure or line pressure. Line pressure is maximum when the stator reaction is maximum.

To RELIEF VALVE

From OIL PUMP

STATOR SHAFT

(cont'd)

REGULATOR SPRING CAP

REGULATOR VALVEProCarManuals.com

Page 1184 of 1640

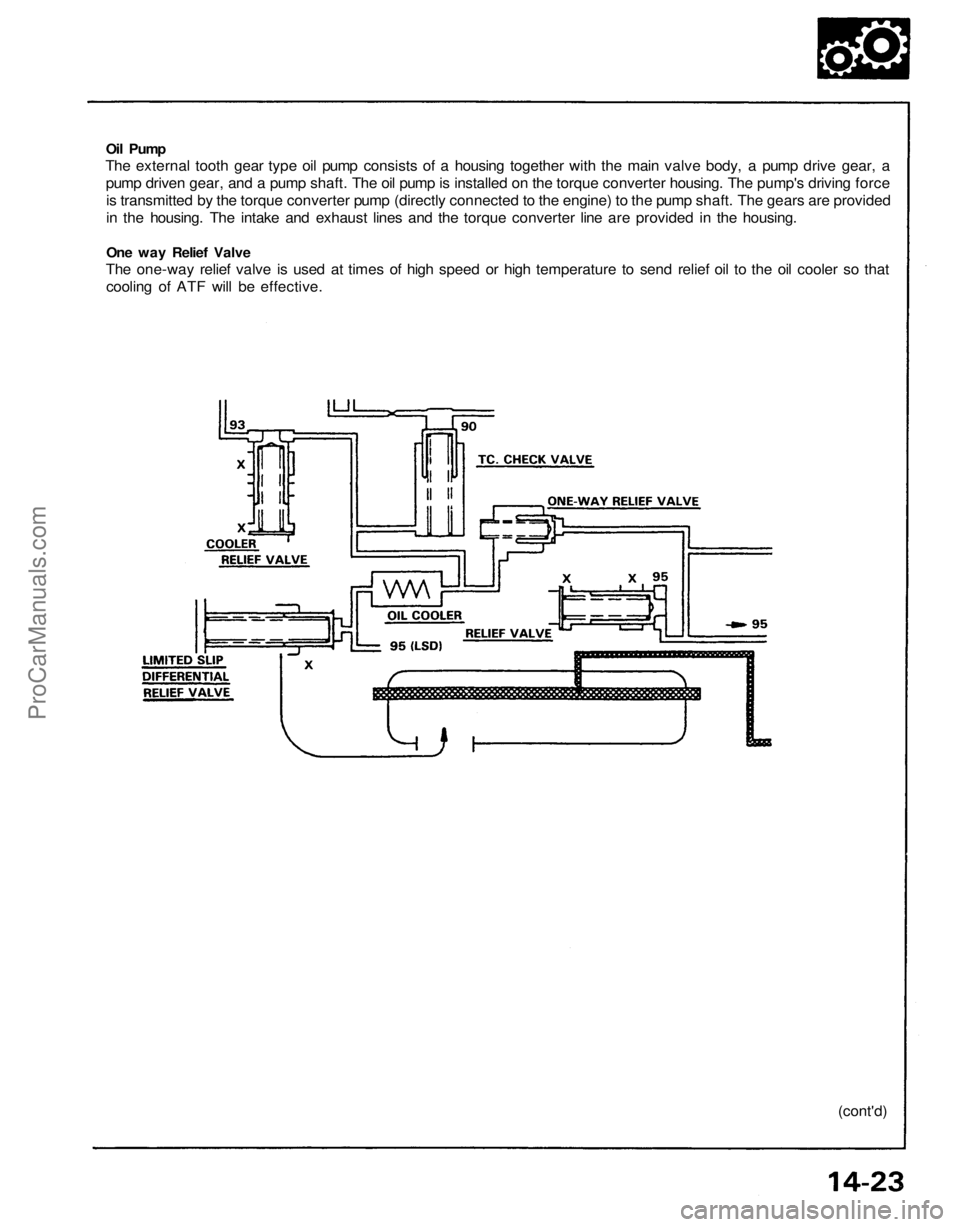

Oil Pump

The external tooth gear type oil pump consists of a housing together with the main valve body, a pump drive gear, a

pump driven gear, and a pump shaft. The oil pump is installed on the torque converter housing. The pump's driving force

is transmitted by the torque converter pump (directly connected to the engine) to the pump shaft. The gears are provided

in the housing. The intake and exhaust lines and the torque converter line are provided in the housing.

One way Relief Valve

The one-way relief valve is used at times of high speed or high temperature to send relief oil to the oil cooler so that

cooling of ATF will be effective.

(cont'd)ProCarManuals.com

Page 1190 of 1640

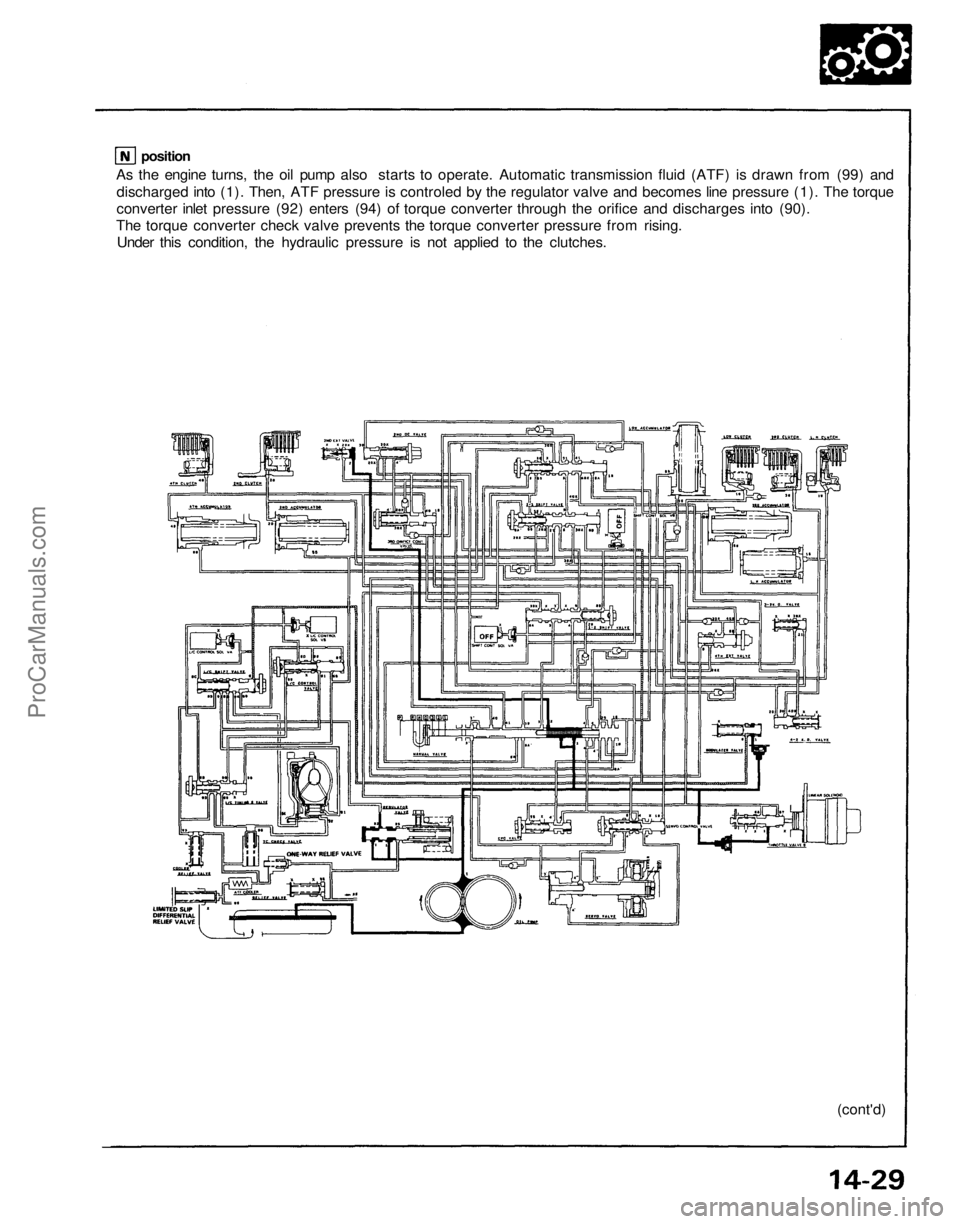

As the engine turns, the oil pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and

discharged into (1). Then, ATF pressure is controled by the regulator valve and becomes line pressure (1). The torque

converter inlet pressure (92) enters (94) of torque converter through the orifice and discharges into (90).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches.

(cont'd)

positionProCarManuals.com

Page 1194 of 1640

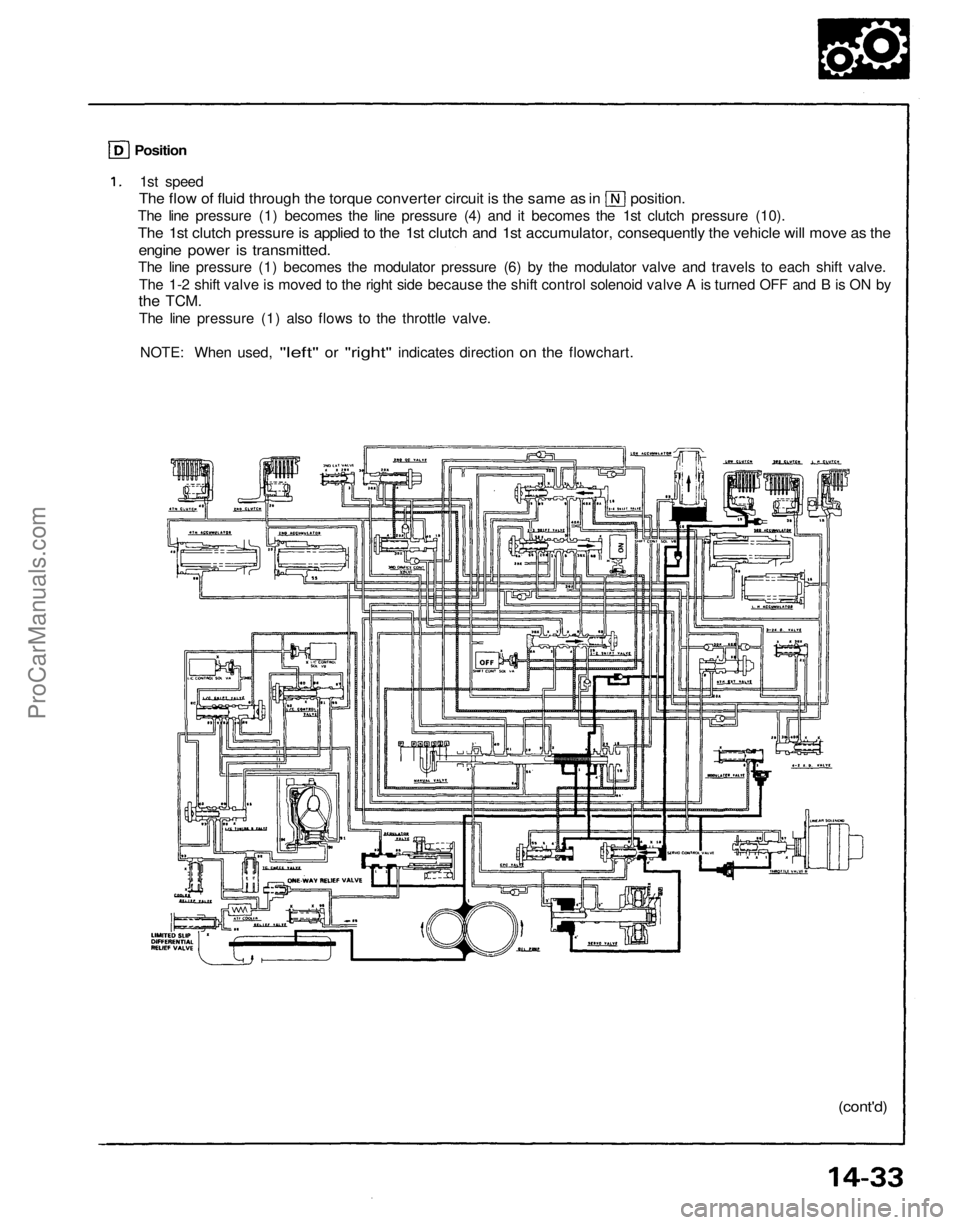

1st speed

The flow of fluid through the torque converter circuit is the same as in position.

The line pressure (1) becomes the line pressure (4) and it becomes the 1st clutch pressure (10).

The 1st clutch pressure is applied to the 1st clutch and 1st accumulator, consequently the vehicle will move as the

engine power is transmitted.

The line pressure (1) becomes the modulator pressure (6) by the modulator valve and travels to each shift valve.

The 1-2 shift valve is moved to the right side because the shift control solenoid valve A is turned OFF and B is ON by

the

TCM.

The line pressure (1) also flows to the throttle valve.

NOTE: When used,

"left"

or

"right"

indicates direction

on the

flowchart.

(cont'd)

PositionProCarManuals.com